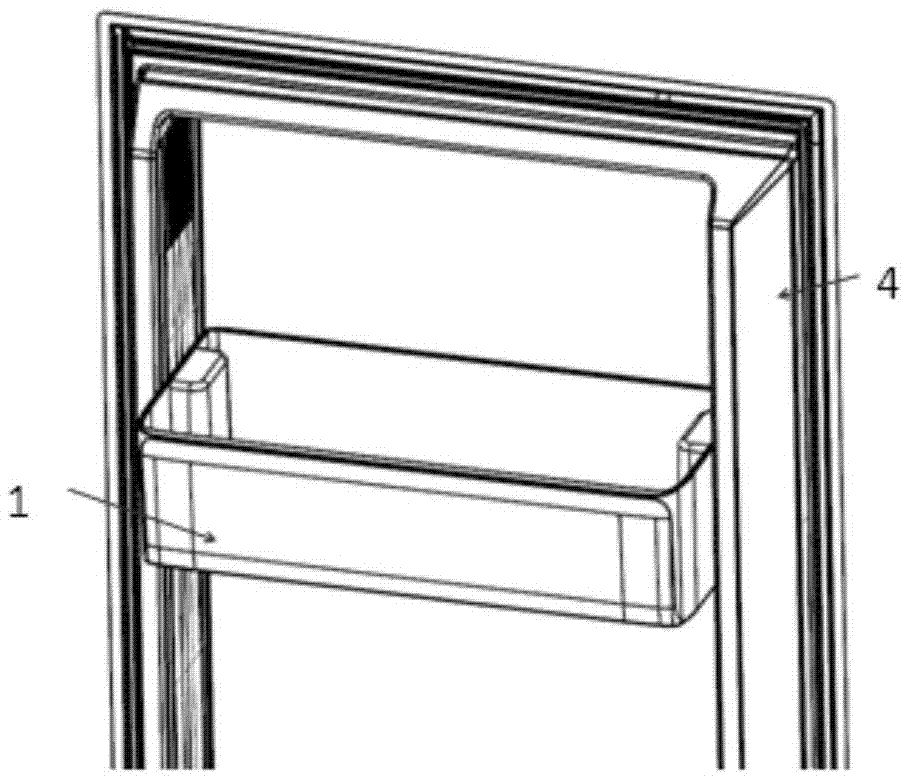

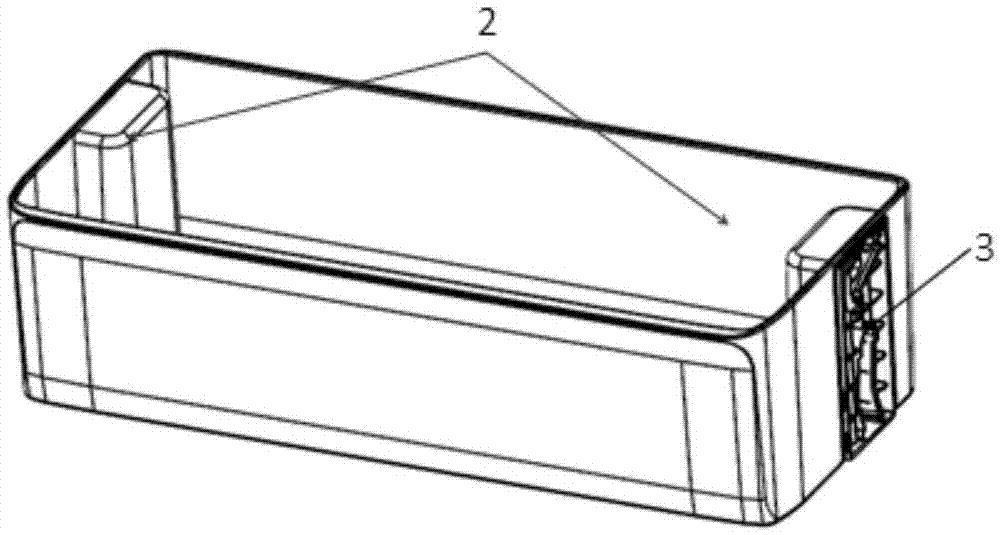

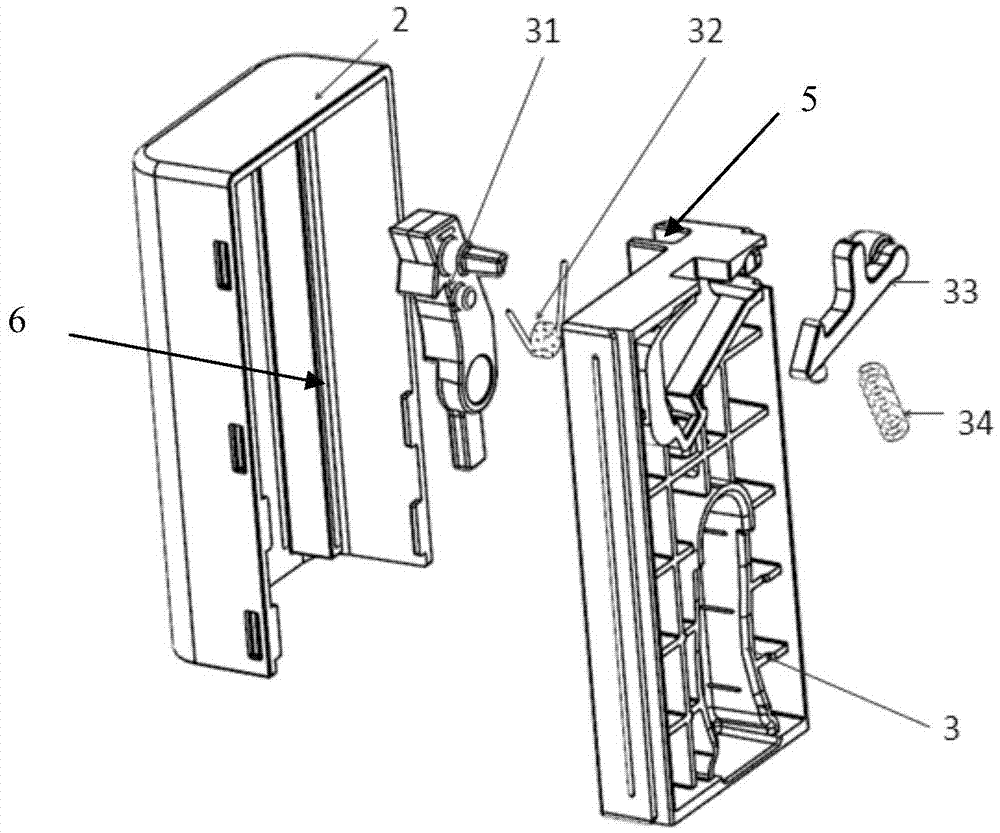

Bottle rack lifting mechanism and refrigerator containing same

A technology for bottle racks and refrigerator doors, which is applied in the field of lifting bottle rack mechanisms and refrigerator structure design. It can solve the problems of inconvenient operation, disengagement of the door liner, inconvenience of reinstallation, etc., and achieves convenient operation, high reliability and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the prior art, the height space of the bottle rack is mainly adjusted by adjusting the vertical position of the bottle rack. It mainly realizes the lifting movement and locking of the bottle rack through the deformation of the plastic connecting rod itself and the engagement of the guide groove. When the bottle rack is lowered, pull the connecting rod with both hands to disengage the hook on the connecting rod from the guide groove, and realize the downward movement of the bottle rack. This method requires manual operation by the user, which is inconvenient to use, and secondly, the connecting rod needs to be exposed for operation, which takes up space and is not beautiful. When it is raised to the highest position, it needs to be lowered in the opposite direction. Every time it is raised or lowered, the connecting rod needs to be moved once, which is inconvenient to operate. When the bottle rack rises to the highest position, it is easy to disengage from the door l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com