Multifunctional test bar

A test rod, multi-functional technology, applied in the direction of TV, closed-circuit television system, electrical components, etc., can solve the problems of difficult test wiring, location in the corner, time-consuming and labor-intensive, etc., to achieve convenient image acquisition, convenient wiring operation, exquisite design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

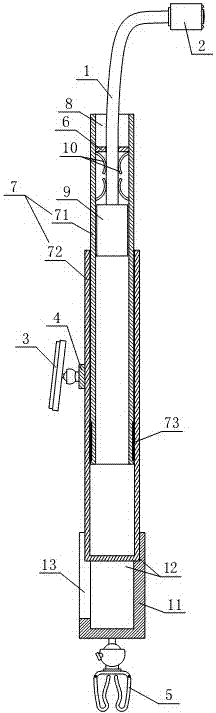

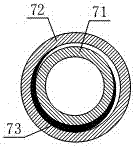

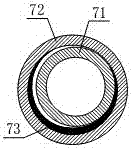

[0033] Referring to the accompanying drawings, the multifunctional test rod of the present invention includes a hollow rod body 7 with adjustable length. The top end of the rod body 7 is connected with a universal positioning hose 1, and the universal positioning hose 1 is slidably mounted in the top inner cavity of the rod body 7. , the inner cavity of the top end of the rod body 7 is provided with a hose clamping and positioning mechanism, and the extended end of the universal positioning hose 1 is equipped with a camera box 2, and a camera is installed on the camera box 2, and the test rod also includes a wireless connection with the camera. The display screen device 3 connected by communication, the display screen device 3 is hand-held or detachably mounted on the rod body 7 through the holder 4 . A spring wire clip 5 is installed on the bottom of the rod body 7, and a current detection line and a voltage detection line are drawn from the spring wire clip 5. Wherein, for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com