Power transmission and distribution connector and power transmission and distribution connecting device

A connector, power transmission and distribution technology, which is applied to the parts, connections, coupling devices, etc. of the connection device, can solve the problems of inconvenient wiring position sealing protection, affecting the stage lighting effect, inconvenient wiring, etc., and achieves convenient wiring operation, Ease of sealing protection, reducing the effect of species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

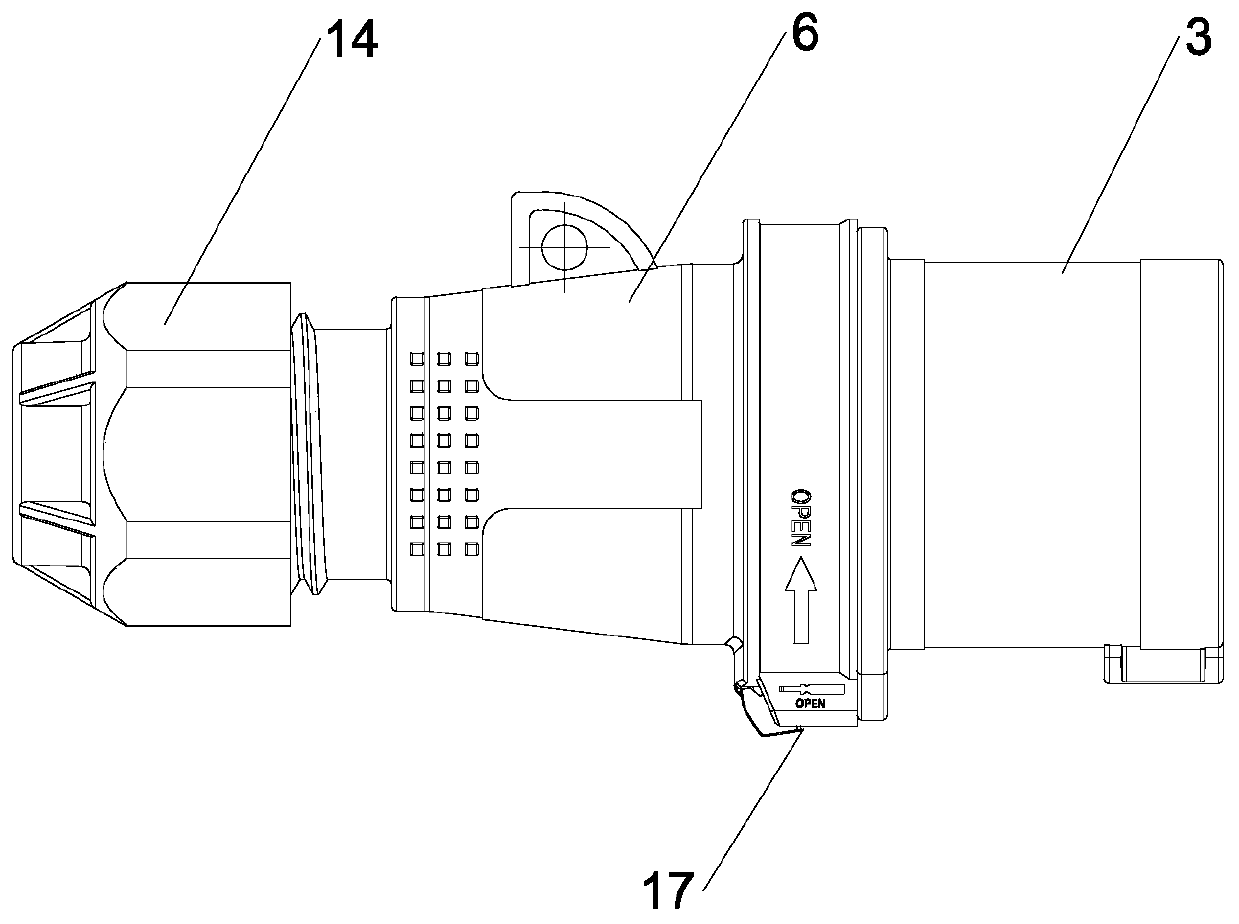

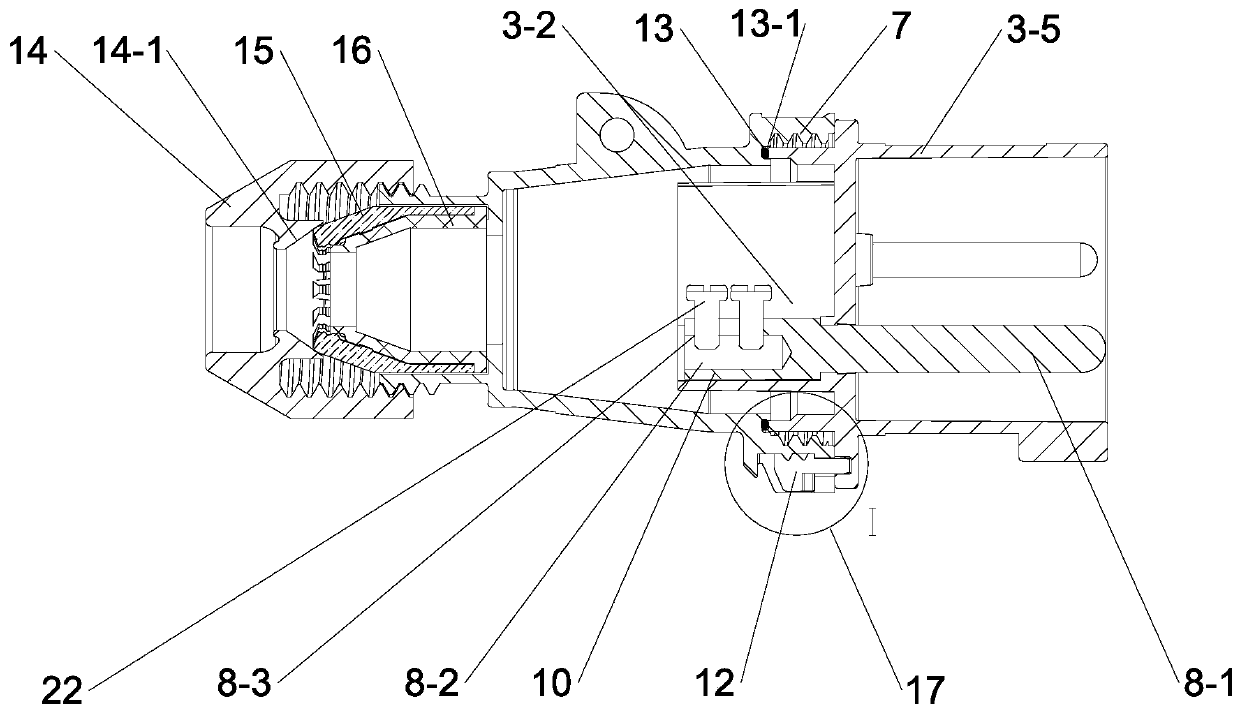

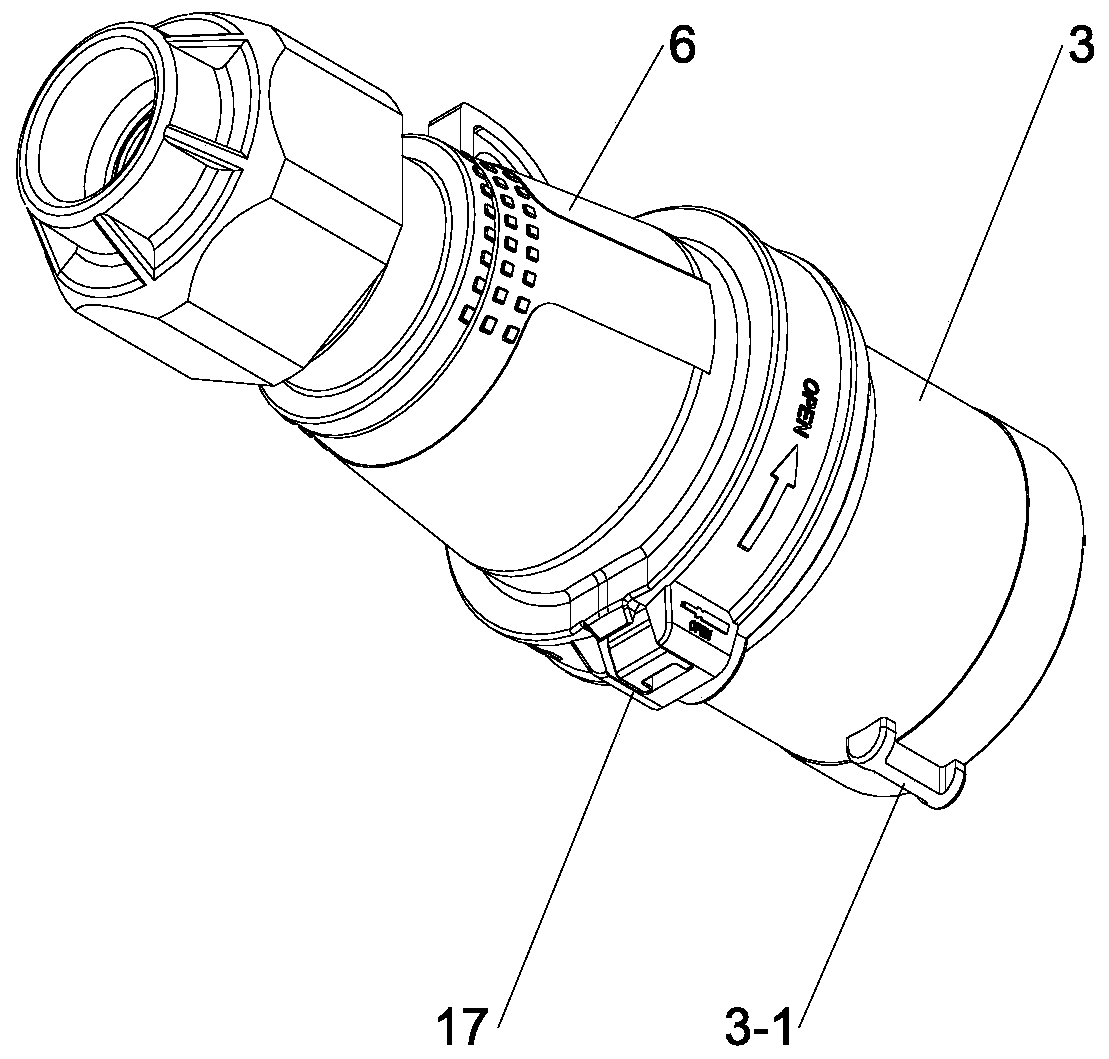

[0041] see Figure 1-Figure 6 , the power transmission and distribution connector of this embodiment includes a main body and connection terminals arranged in the main body, the main body includes a front connecting body and a rear connecting body 6, wherein the connecting terminals are arranged in the front connecting body; The connection body and the rear connection body 6 are connected together through the connection structure 7, and the connecting terminal is provided with a wiring part connected to the power line at one end corresponding to the rear connection body 6, and the rear connection body is at an end far away from the front connection body. A power cord passing hole 6-5 is provided; when the front connecting body and the rear connecting body are not connected, the wiring part of the connecting terminal is exposed outside.

[0042] see Figure 1-Figure 6 , the power transmission and distribution connector in this embodiment is a plug, the front connecting body is a...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that in this embodiment, the power transmission and distribution connector is a socket, see Figure 7-Figure 11 , the connecting terminal in the front connecting body 4 of the socket is a jack terminal 9, and the jack terminal 9 includes a jack front part 9-1 and a jack terminal wiring part 21; There is a wiring hole 9-2 for accommodating the power cord, and the jack terminal wiring part 21 is also provided with a threaded hole 9-3 for locking the power cord on the wiring hole 9-2; the front connecting body 4 of the socket A jack terminal fixing frame 4-2 is arranged inside, and the jack terminal 9 is installed on the jack terminal fixing frame 4-2.

[0057] see Figure 8 and Figure 11 , the socket terminal fixing frame 4-2 includes a front mounting part 4-7 for accommodating the socket terminal 9 and a rear mounting part 4-3 for connecting a power line, wherein the rear mounting part 4- 3 extending backward...

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 or 2 is that in this embodiment, the connection structure is a flange connection structure, the rear end of the front connecting body is provided with a front flange flange 23, and the front There is a front through hole 23-1 on the flange flange, and a rear flange flange 24 is provided at the front end of the rear connecting body, and the rear flange flange 24 corresponds to the front through hole of the front flange flange 23-1 has a rear through hole 24-1, the front flange flange 23 and the rear flange flange 24 are fixedly connected by screws and nuts, specifically, the screws pass through the front through hole of the front flange flange 23 23-1 penetrates the rear through hole 24-1 of the rear flange flange 24, and then locks the nut, and then connects the front connecting body of the plug with the rear connecting body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com