Insulating safe battery module

A battery module, insulation safety technology, applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of uneven heat accumulation, prone to wrong connection, battery overcharging, etc., and achieve simple and convenient wiring operation, improve The effect of ensuring safety and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Best practice:

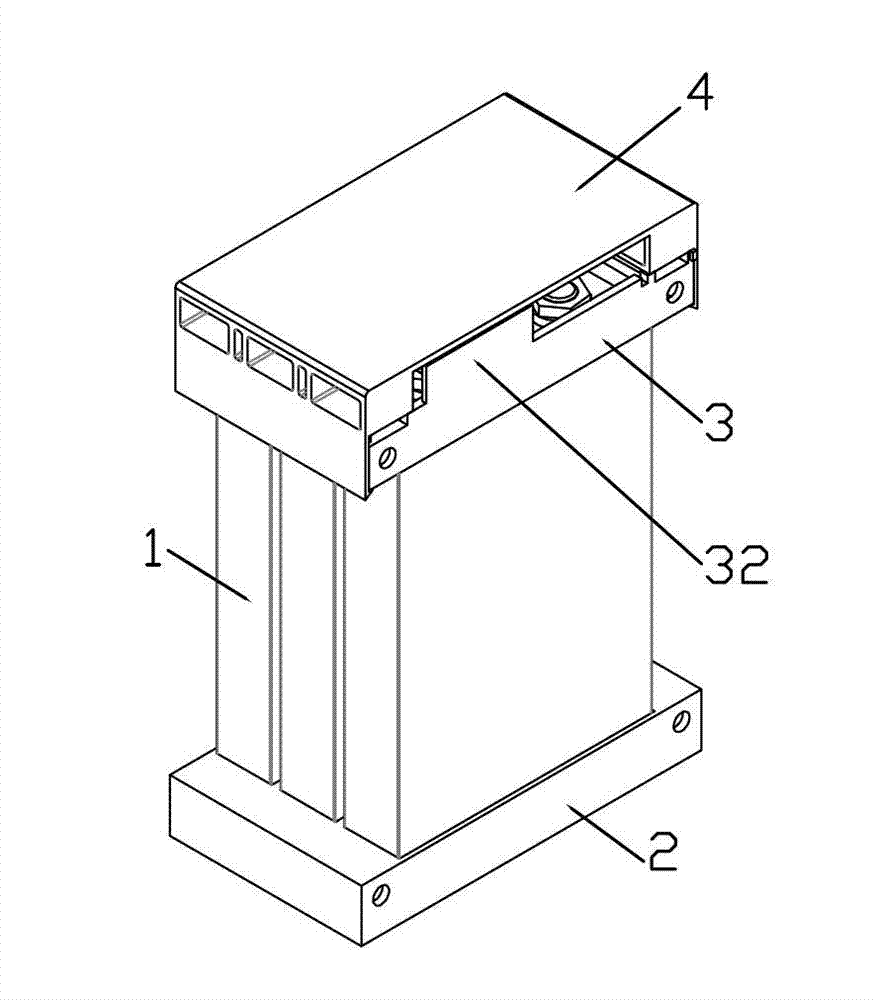

[0043] Refer to attached figure 1 The insulated safety battery module includes three single cells 1 , an insulating base 2 and an insulating top cover, and the insulating top cover includes an insulating frame 3 and an insulating cover plate 4 . The specific structures of the insulating base 2 and the insulating top cover will be described in detail below one by one.

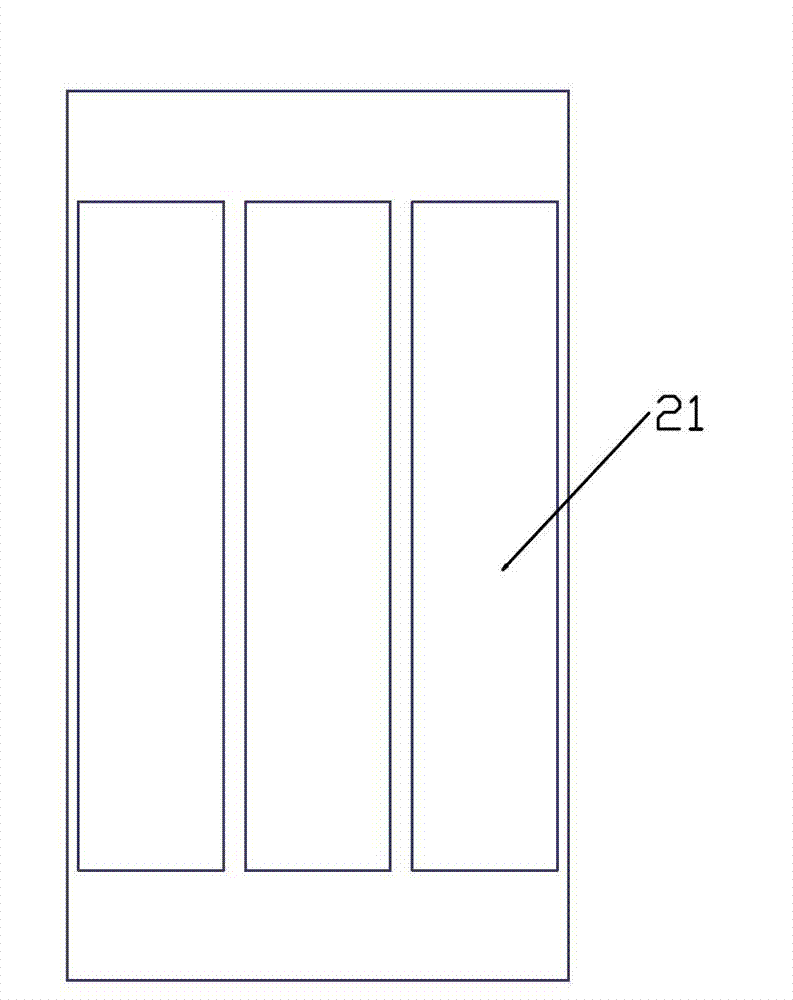

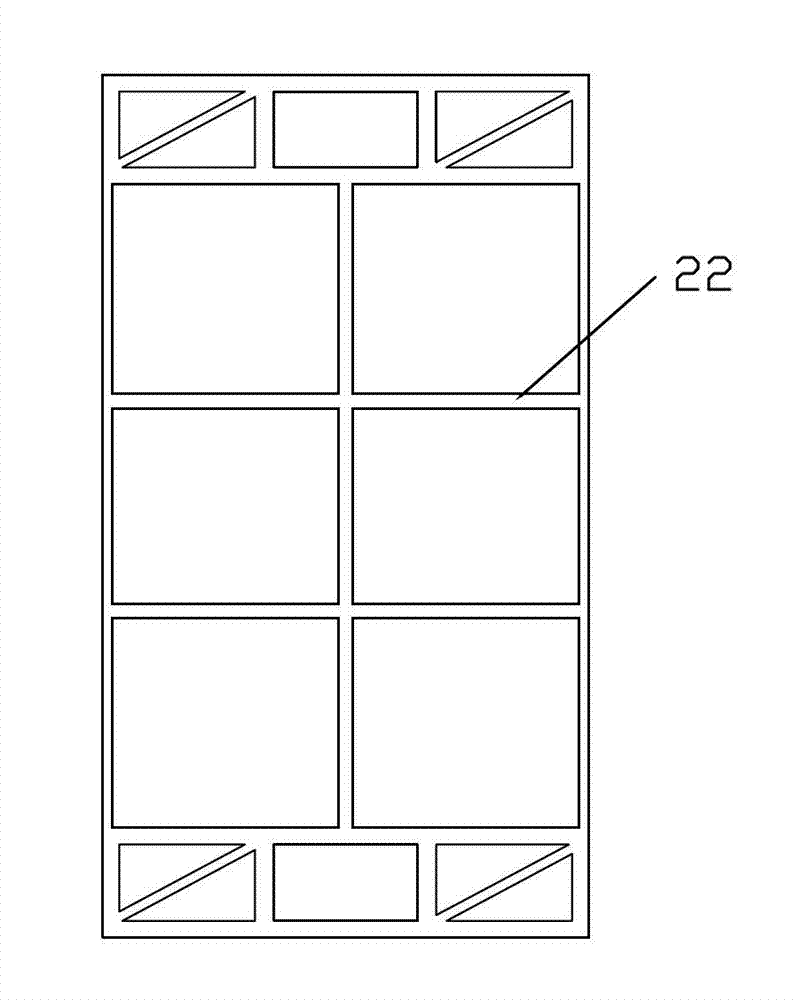

[0044] in the attached figure 1 on the basis of referring to the attached figure 2 And attached image 3 , there are three side-by-side grooves 21 on the insulating base 2 (see attached figure 2 ), the length and width of the slot are the same as those of the single battery (see the attachment for the specific structure of the single battery Figure 4 ), the groove 21 plays a role in positioning the single battery 1, and the lower part of the insulating base 2 is provided with reinforcing ribs 22 in different directions (see image 3 ), while reducing weight, it has high strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com