Automatic paying-off device for power wiring operation

A technology of power wiring and pay-off device, applied in cable installation device, cable installation, electrical components and other directions, can solve the problems of error affecting construction quality, low work efficiency, scattered coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

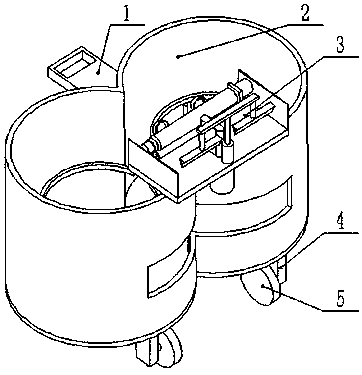

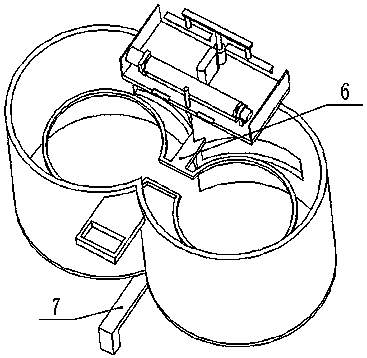

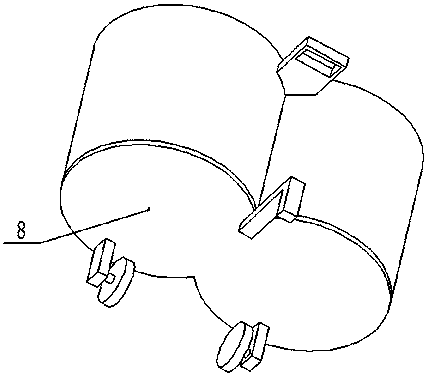

[0017] The present invention is realized through the following technical proposals: an automatic pay-off device for power wiring, including a hand-held support 1, a storage box 2, a cutting device 3, a wheel support 4, wheels 5, a guide ring 6 in the box, legs 7 and a chassis 8. The hand-held support 1 is fixed on the rear end of the storage box 2. The user can hold the hand-held support 1 and drag the device forward to reduce the burden. The storage box 2 is fixed on the chassis 8, and its front end has two square holes , the coil can be put into the storage box 2 from the square hole, and the cutting device 3 is fixed in front of the storage box 2, which is located at the top center of the storage box 2, and is used to flatten the wire and cut it into a required length. Two of the wheel brackets 4 are installed on the left and right sides of the bottom of the chassis 8, two of the wheels 5 are respectively fixed on the wheel brackets 4, and the guide ring 6 in the box is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com