Patents

Literature

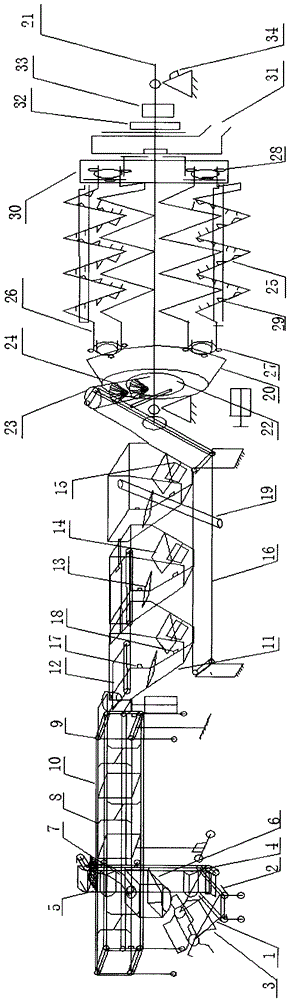

63results about How to "Achieve automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

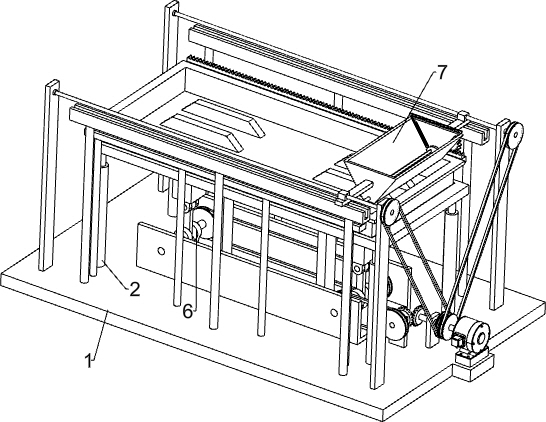

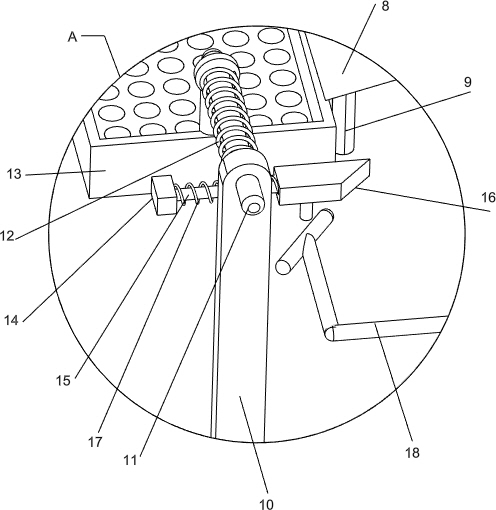

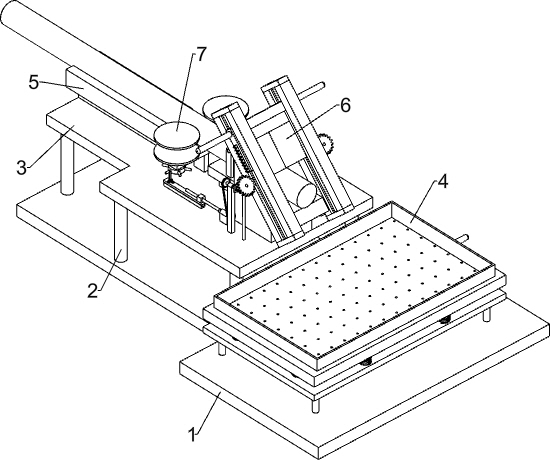

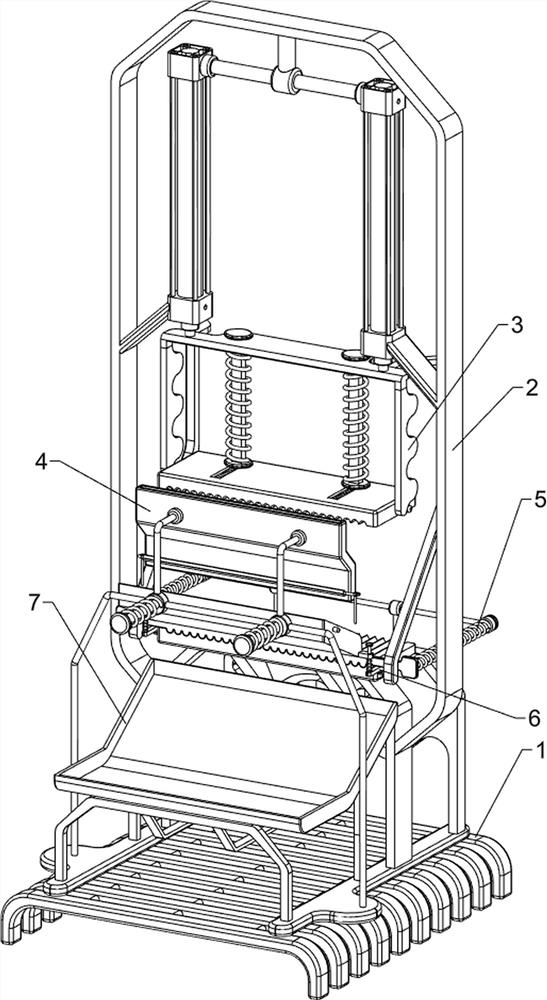

Forestry log auxiliary cutting device

ActiveCN111791309AAchieve automatic feedingEasy to cutFeeding devicesClimate change adaptationForest industryAgricultural engineering

The invention relates to a cutting device, in particular to a forestry log auxiliary cutting device. The forestry log auxiliary cutting device achieves the technical purposes of automatic dischargingand convenient cutting. According to the technical scheme, the forestry log auxiliary cutting device comprises a base the top side edge of which is provided with a collecting box; a workbench which isarranged in the middle of the top of the base; a cutting device which is arranged at the position, close to the workbench, of the top of the base, and is located over the collecting box; and a movingdevice which is used for driving the cutting device to reciprocate and is arranged on the workbench. The cutting device achieves the effects of automatic discharging and convenient cutting.

Owner:湖南森海碳汇开发有限责任公司

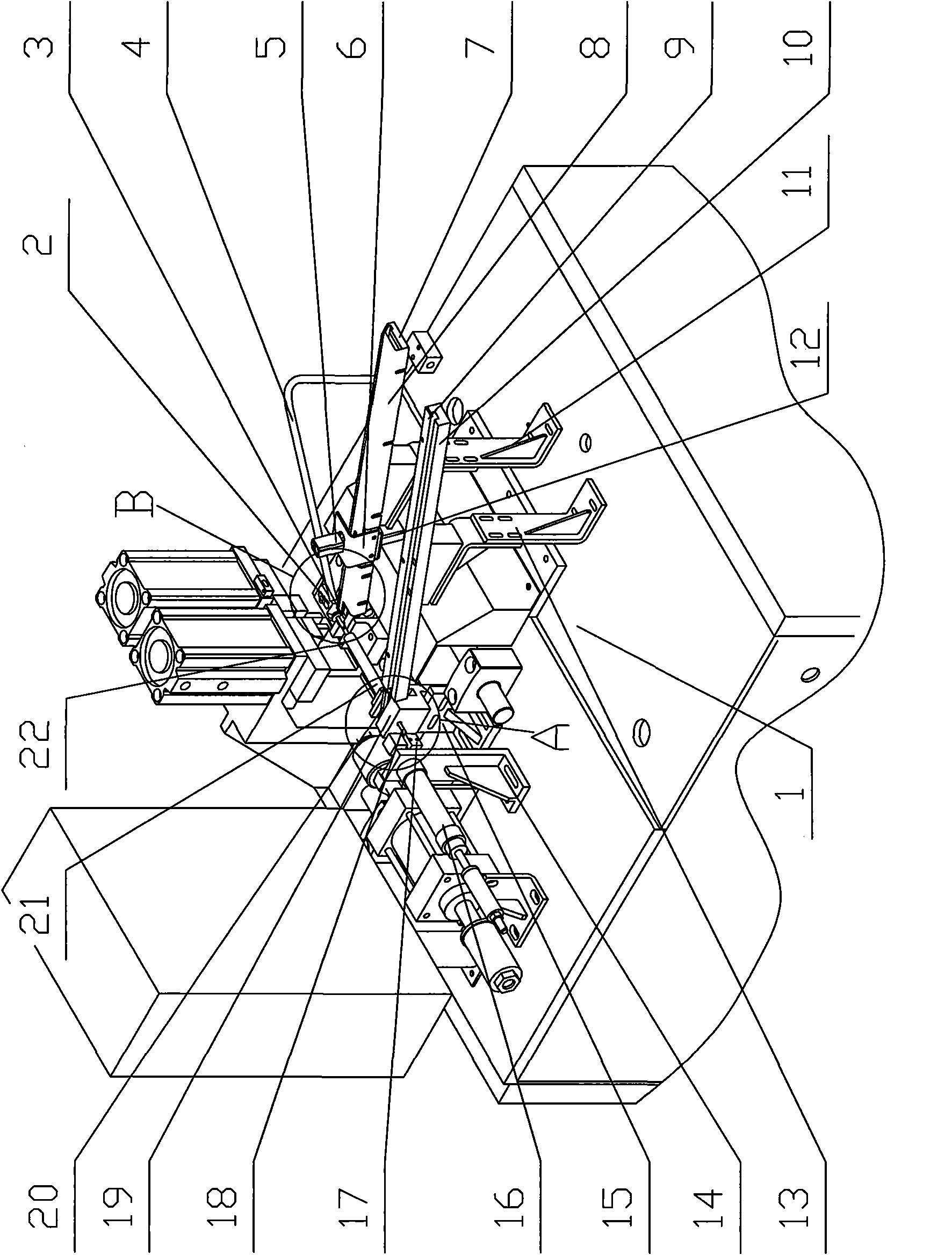

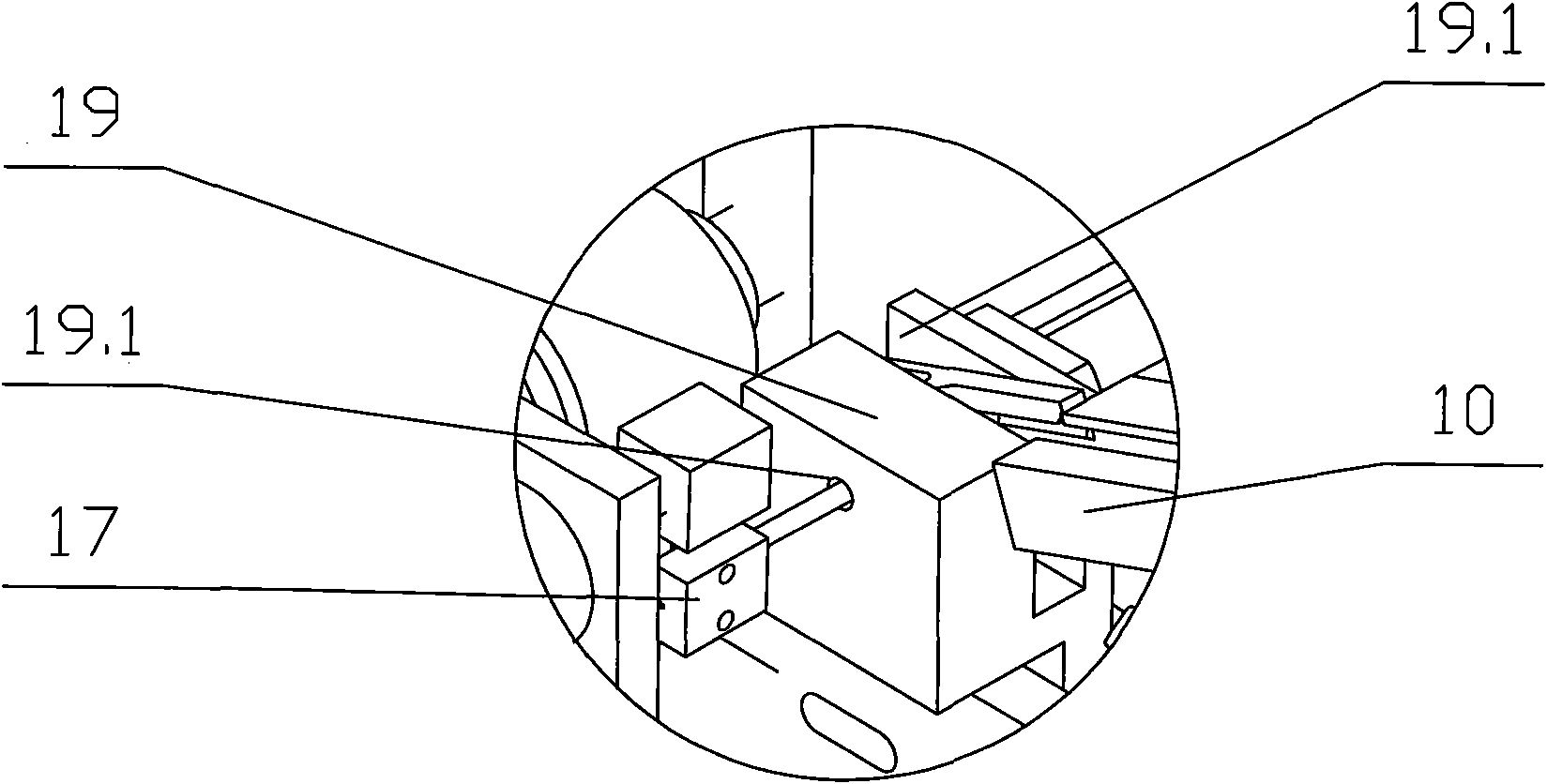

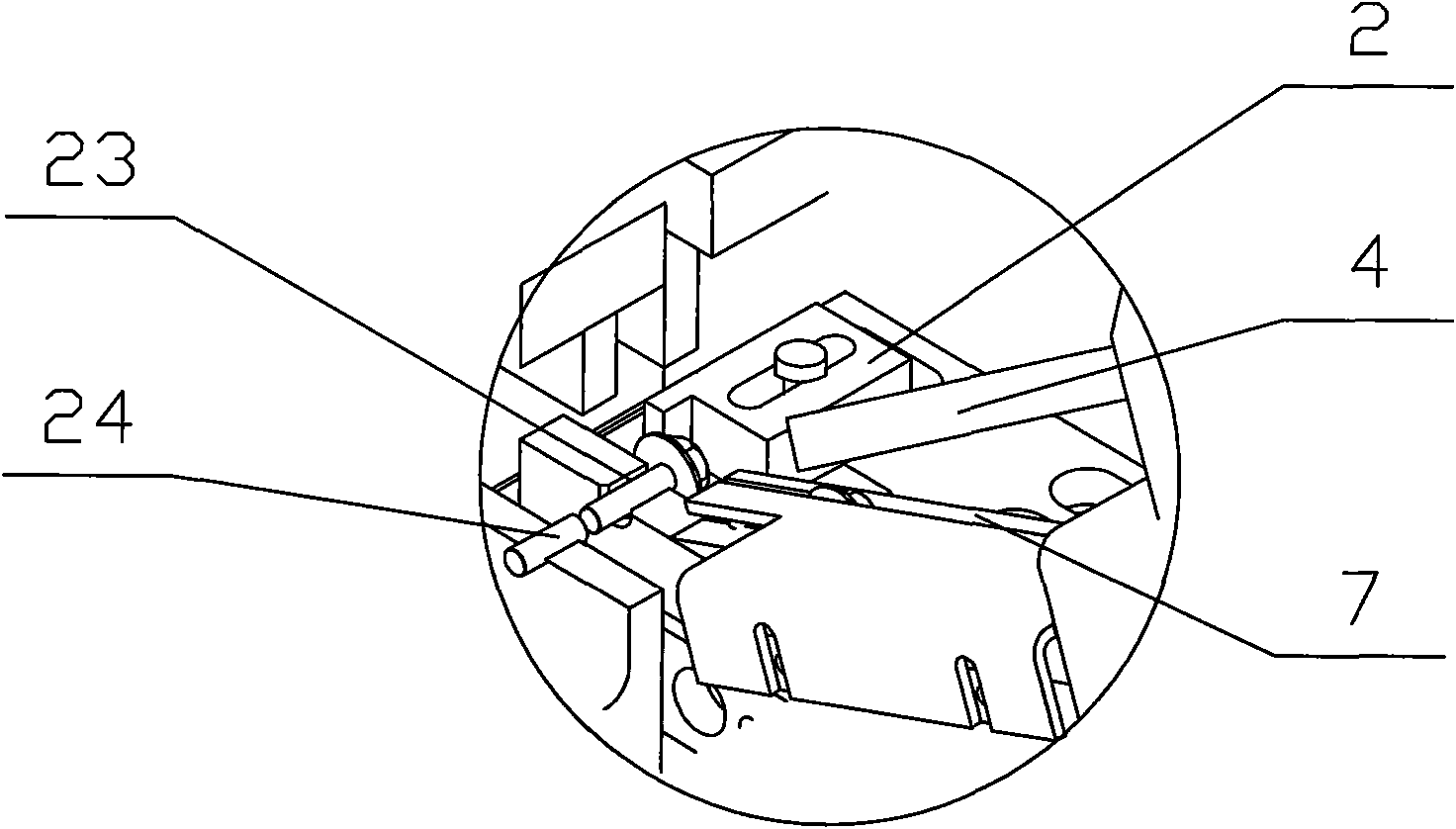

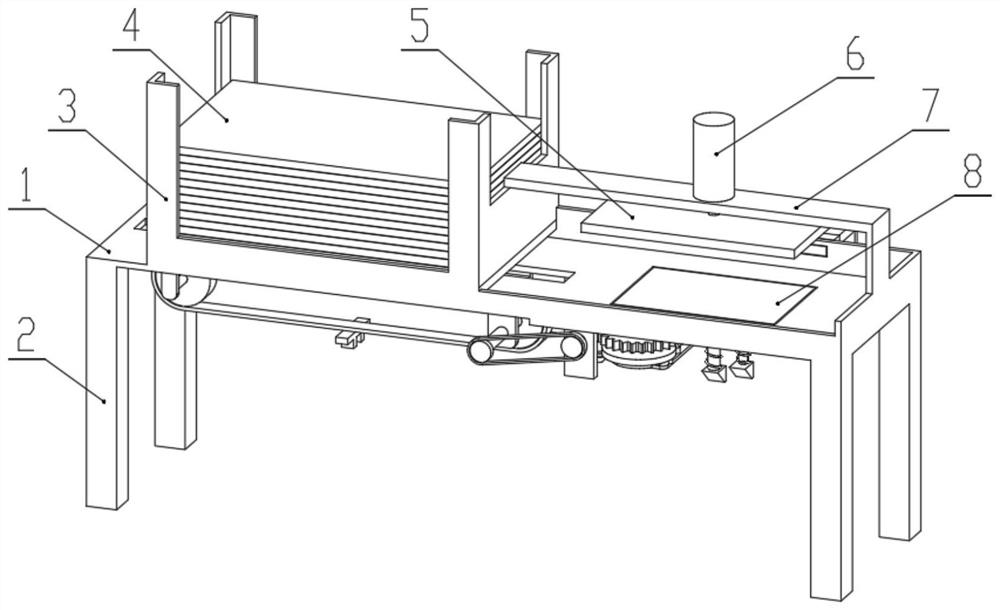

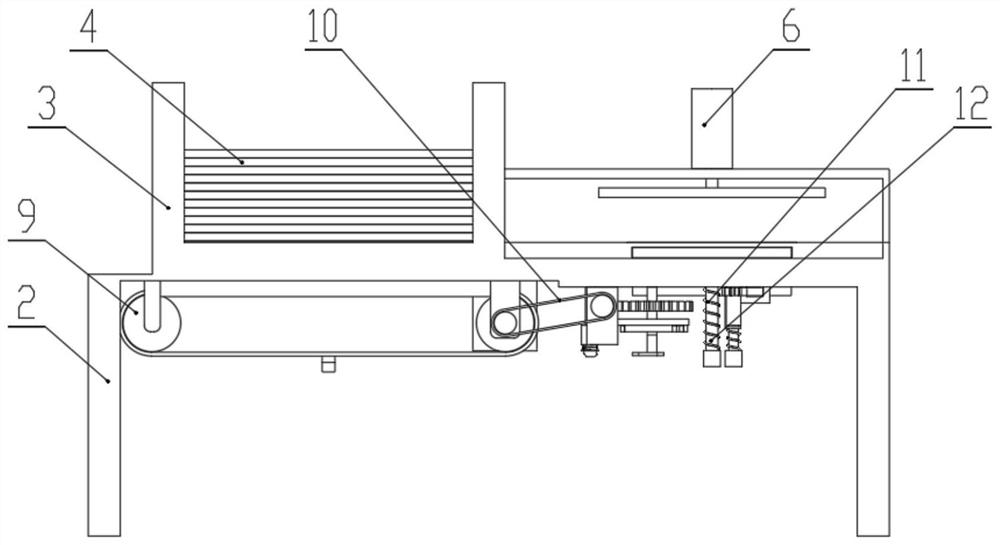

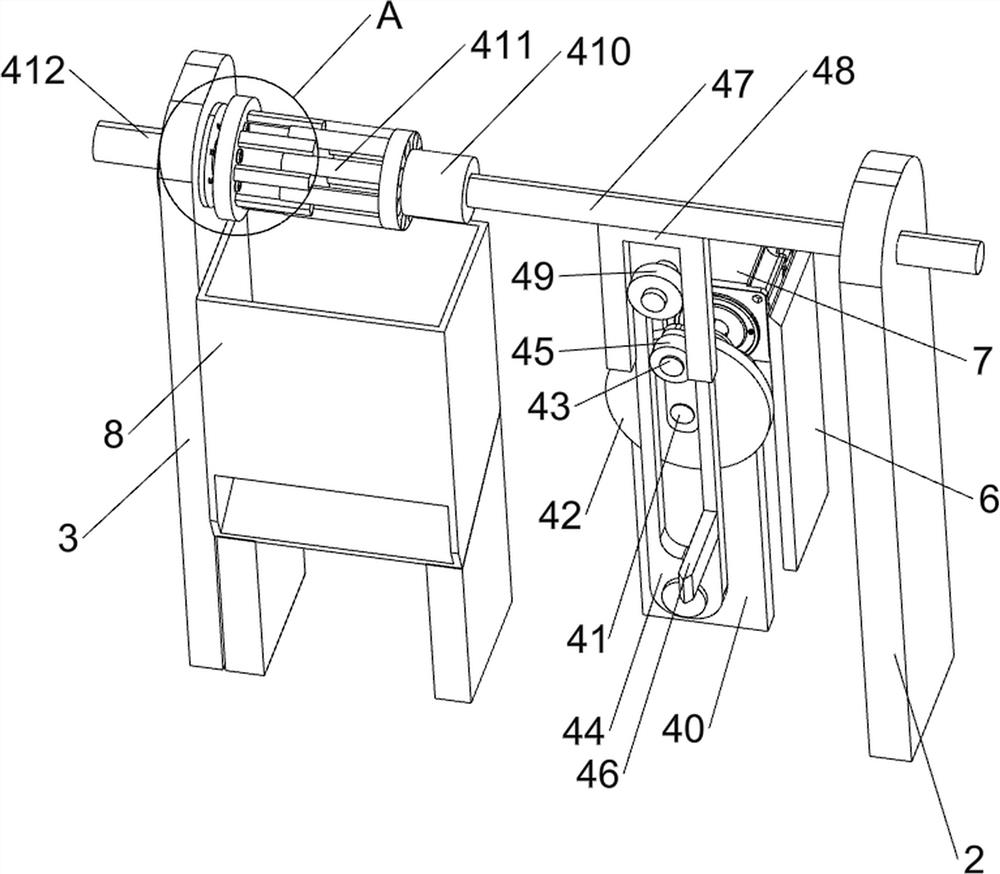

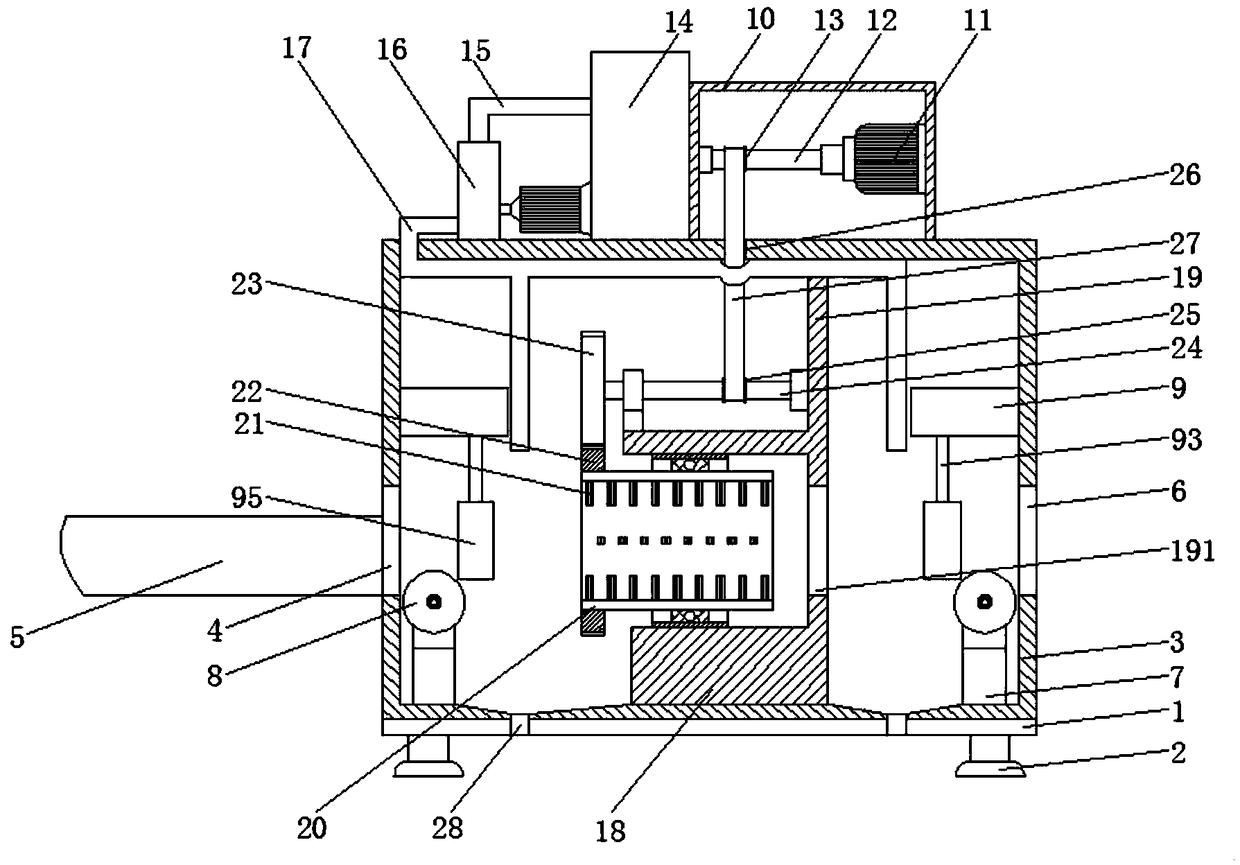

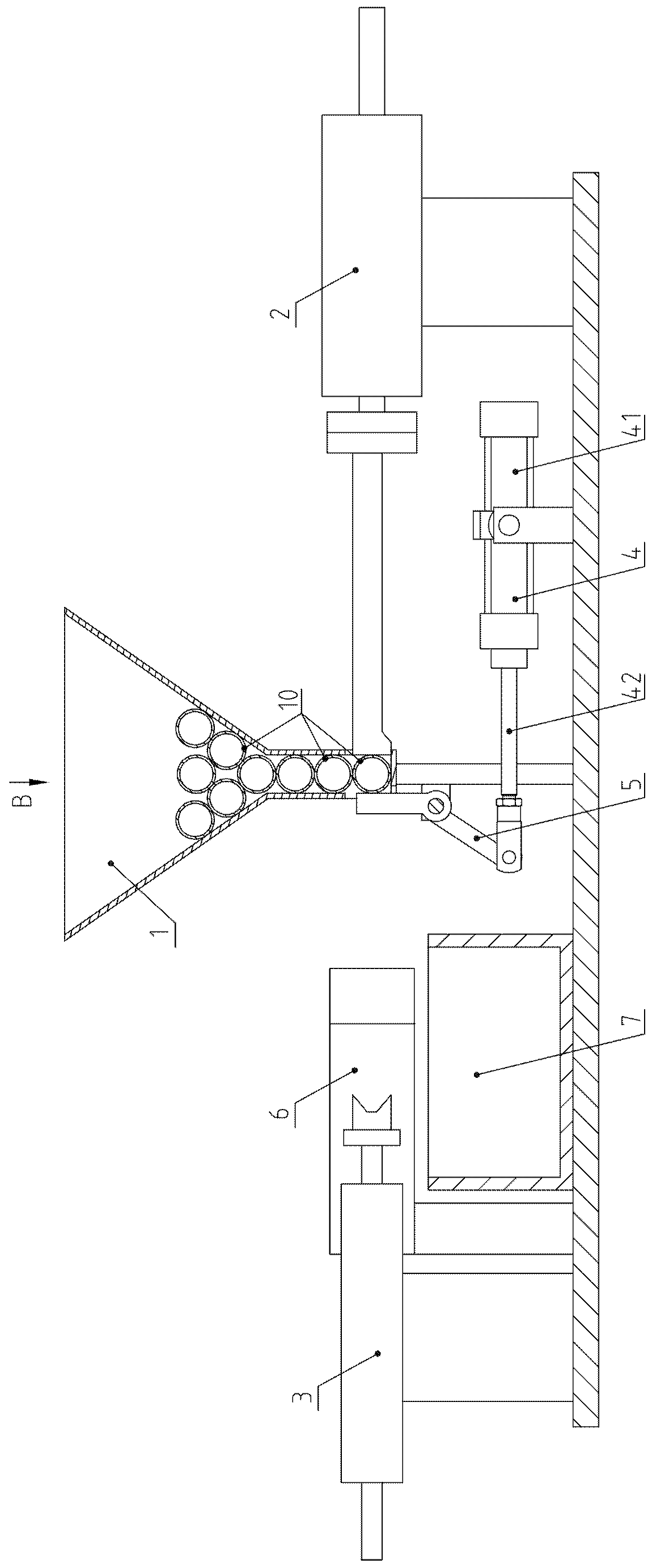

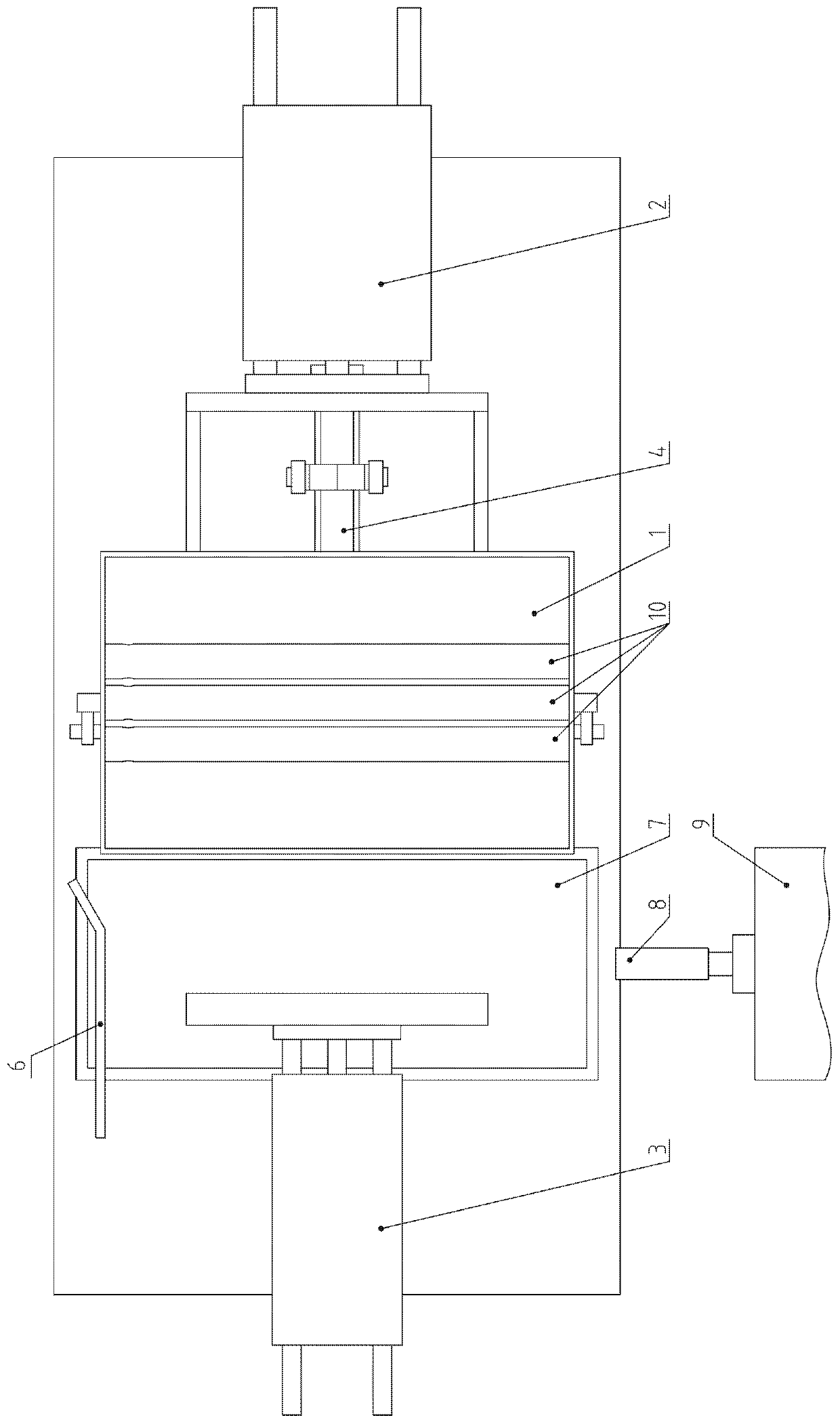

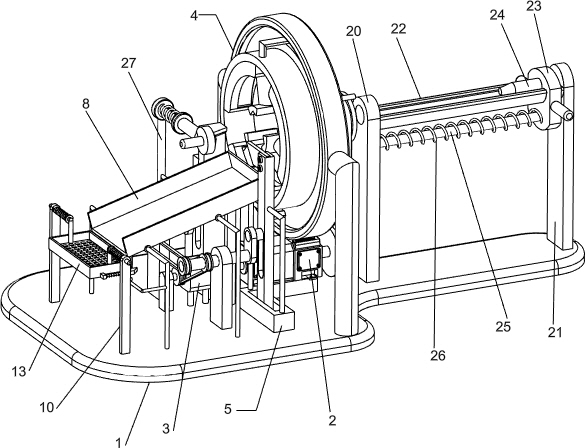

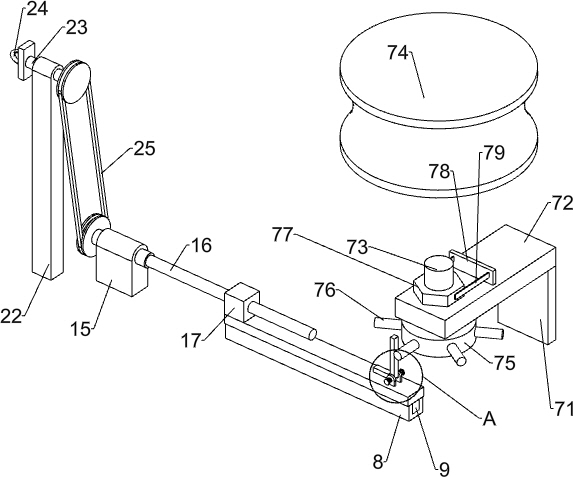

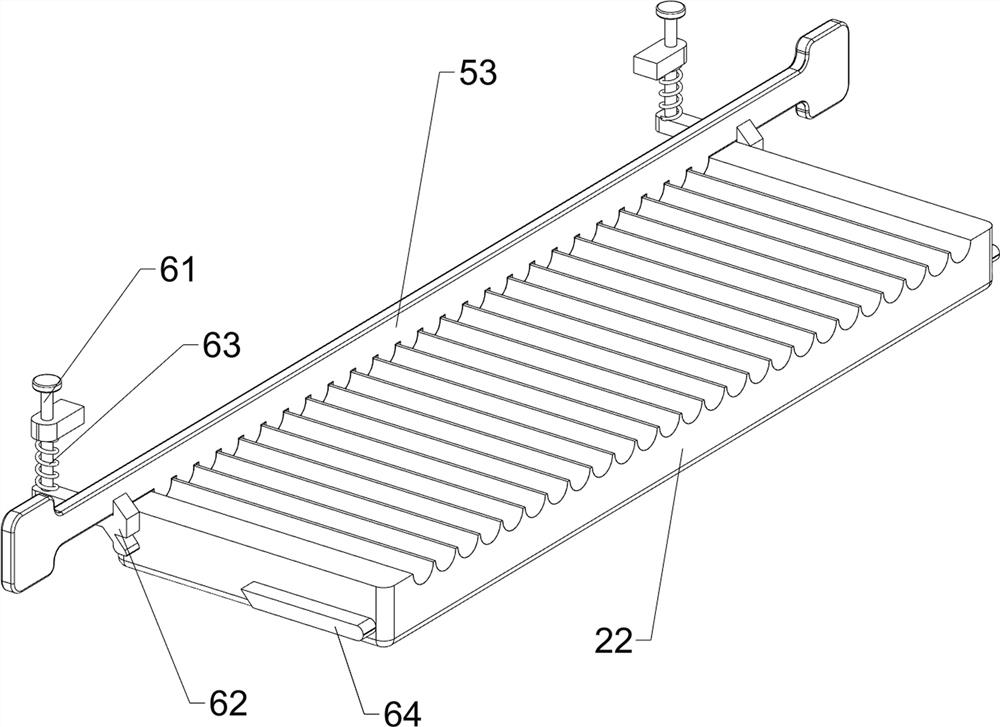

Full-automatic screw welder

InactiveCN101596644AOperational securityEnsure safetyResistance welding apparatusEngineeringOperation safety

The invention discloses a full-automatic screw welder. The welder comprises a left workbench (22) and a right workbench (3) which are arranged on a frame (1), and also comprises a left feed guide rail (10), a charging cylinder (16), a distribution block (19), a guide tube (21) and a right feed guide rail (7); wherein the left feed guide rail (10) is obliquely fixed on a left support (13); the charging cylinder (16) and the distribution block (19) are fixed on the frame (1); a charging ram (18) is connected with the charging cylinder (16); the right feed guide rail (7) is obliquely fixed on a right support (11); the right feed guide rail (7) is also provided with a fixed support (6); the fixed support (6) is provided with an upper distribution cylinder (5); the fixed support (6) is provided with a lower distribution cylinder (12). The full-automatic screw welder has automatic feeding, safe operation, high working efficiency, low labor cost for processing and high automatic degree.

Owner:NINGBO XINZHOU RESISTANCE WELDER

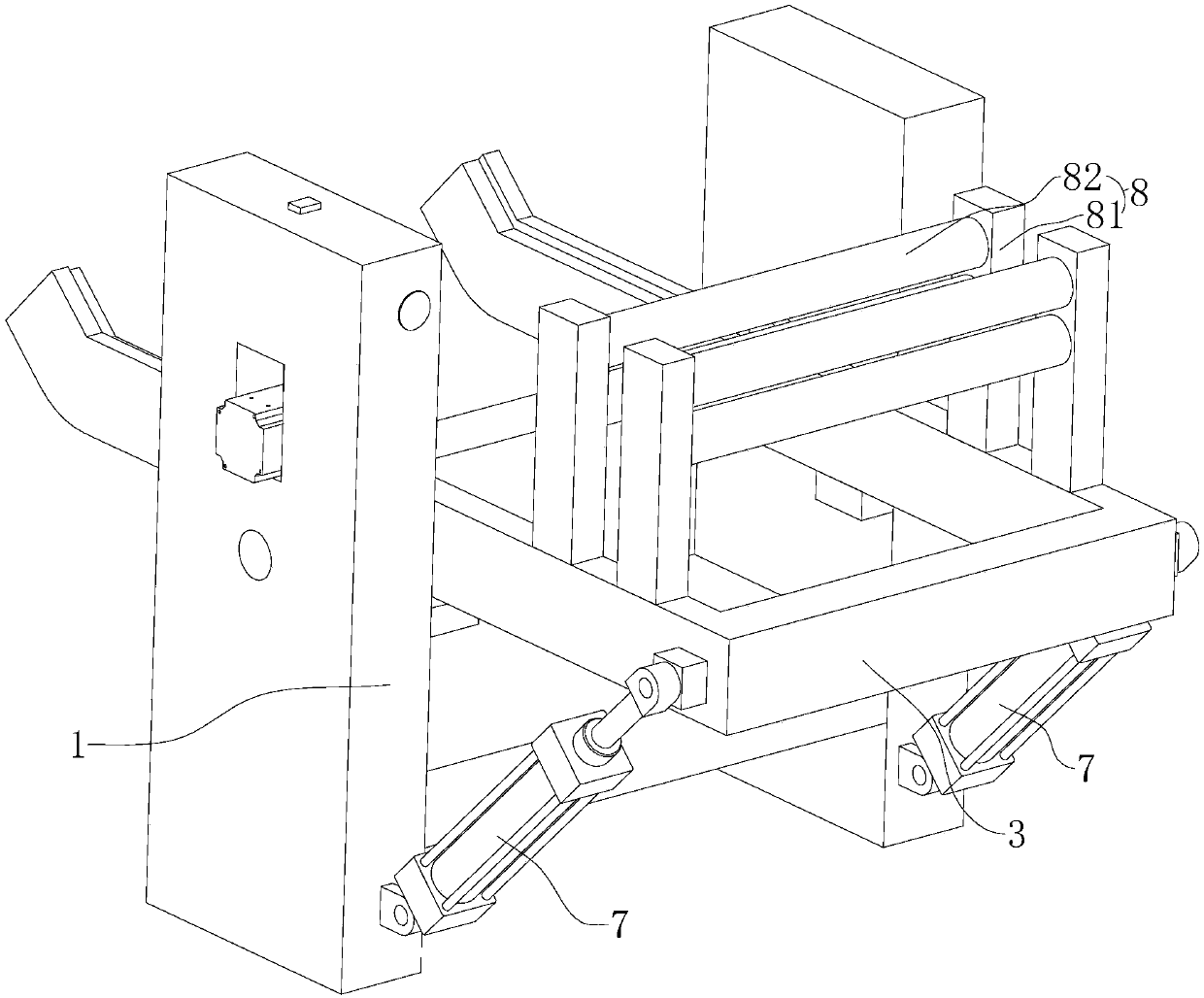

Automobile stamping mechanism capable of automatically demolding and feeding

PendingCN112620514AAvoid being inAvoid accidental injuryMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention discloses an automobile stamping mechanism capable of automatically demolding and feeding. The automobile stamping mechanism capable of automatically demolding and feeding comprises a supporting plate, wherein supporting legs are fixedly arranged at the four corners of the lower surface of the supporting plate correspondingly; a material frame is fixedly connected onto the supporting plate; a stamping part is placed in the material frame; a mounting plate is mounted on the supporting plate; an air cylinder is mounted on the upper surface of the mounting plate; the lower end of the air cylinder penetrates through the lower surface of the mounting plate so as to be connected with a stamping plate; a die groove is formed in the lower part of the stamping plate and is formed in the upper surface of the supporting plate; and the upper end of a limiting supporting piece is arranged in the die groove. The automobile stamping mechanism capable of automatically demolding and feeding has the functions of automatic feeding and automatic demolding and discharging, limbs of workers can be prevented from being located below a stamping structure, then the working efficiency can be improved, and the workers can be prevented from being accidentally injured.

Owner:黄浩然

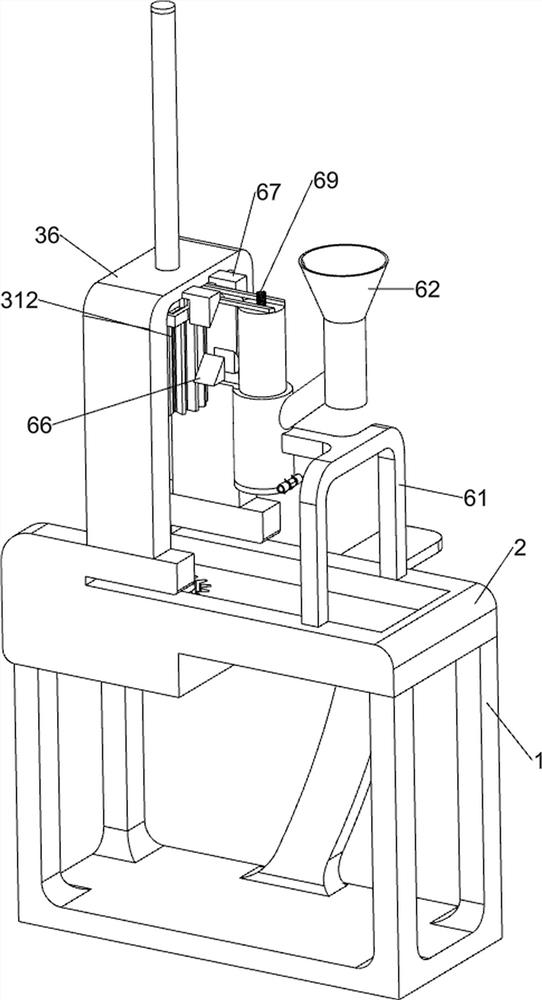

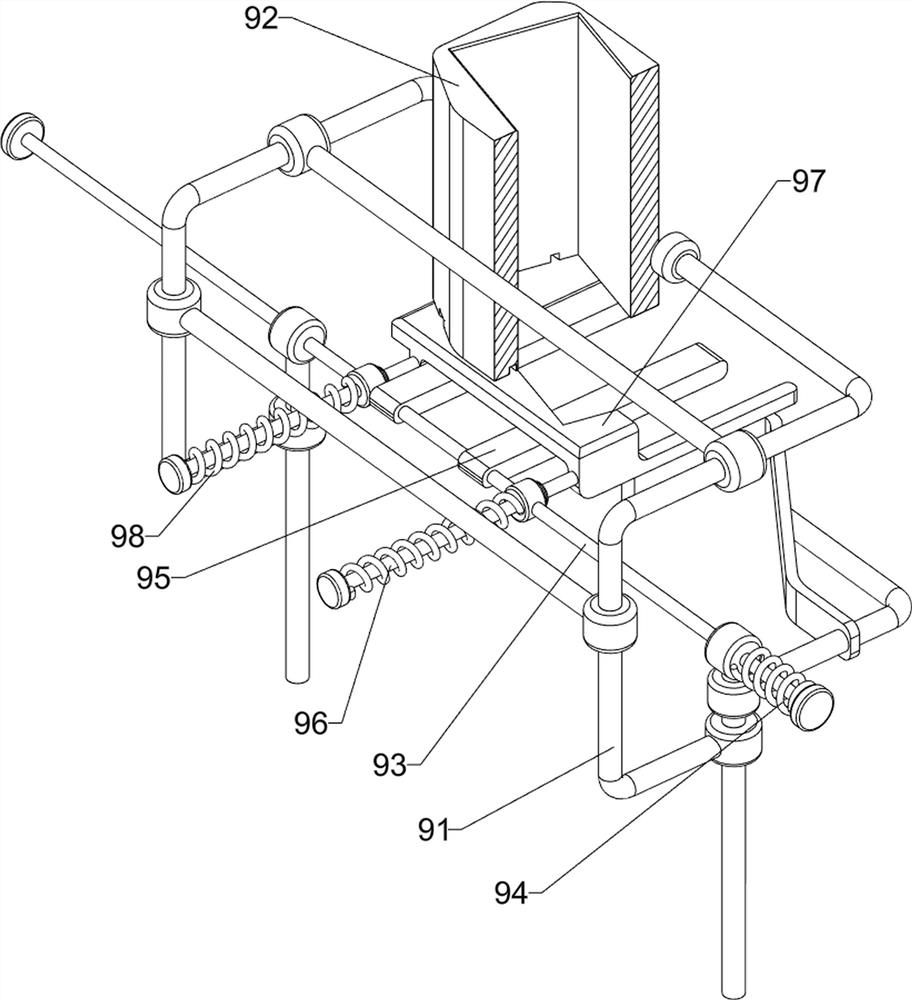

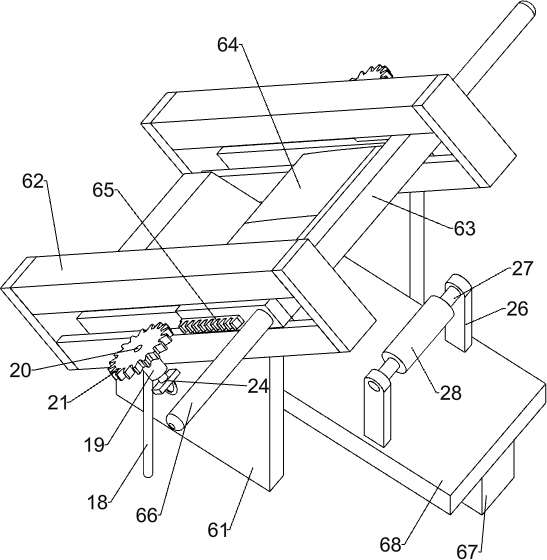

Gear extrusion forming equipment for metal powder metallurgy

PendingCN112387970AAchieve automatic feedingRealize the effect of automatic feedingMolding machineMetal powder

The invention relates to extrusion forming equipment, in particular to gear extrusion forming equipment for metal powder metallurgy. The invention provides the gear extrusion forming equipment for metal powder metallurgy capable of automatically carrying out discharging, and capable of ejecting out metal powder formed through extrusion. The gear extrusion forming equipment for metal powder metallurgy comprises a supporting frame, a die plate, a forming mechanism, a material spreading mechanism and a material ejection mechanism; the supporting frame is used for allowing the whole equipment to be arranged; and the die plate is arranged at the upper portion of the supporting frame; and the forming mechanism is arranged on the die plate, the material spreading mechanism is arranged on the dieplate, and the material ejection mechanism is arranged on the die plate. The gear extrusion forming equipment for metal powder metallurgy achieves the effects that automatic discharging can be achieved, and the metal powder formed through extrusion can be ejected out, the metal powder needing to be subjected to extrusion forming is placed in a discharging pipe, a pressing column moves up and down,the metal powder in the discharging pipe is extruded downwards, and therefore the automatic discharging effect can be achieved.

Owner:韦熙斌

Automatic iron sheet stamping equipment

InactiveCN112404214AAchieve automatic feedingRealize blankingMetal-working feeding devicesPositioning devicesElectric machineStructural engineering

The invention relates to automatic stamping equipment, in particular to automatic iron sheet stamping equipment. According to the automatic iron sheet stamping equipment, iron sheets can be automatically blanked, pushed and stamped, and people can conveniently collect the stamped iron sheets. The automatic iron sheet stamping equipment comprises a bottom plate, a table, a material pressing mechanism and a material pushing mechanism, wherein a double-shaft motor is arranged on one side of the top of the bottom plate, the table is arranged on the side, away from the double-shaft motor, of the top of the bottom plate, the material pressing mechanism is arranged on the side, close to the double-shaft motor, of the top of the bottom plate, parts of the material pressing mechanism are connectedto an output shaft of the double-shaft motor, and the material pushing mechanism is installed on the table. Under the cooperation of the double-shaft motor, the material pressing mechanism, the material pushing mechanism, the blanking mechanism, the discharging mechanism and a clamping mechanism, the effects of blanking the iron sheets, automatically pushing the iron sheets, carrying out stampingon the iron sheets and facilitating collection of the iron sheets subjected to stamping by people can be achieved.

Owner:赵勇

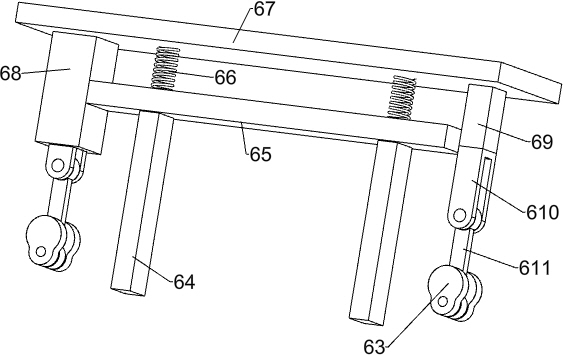

Cement board manufacturing device

InactiveCN111775274AAchieve automatic feedingSave human effortFeeding arrangmentsConstruction engineeringCement board

The invention belongs to the field of building construction, and particularly relates to a cement board manufacturing device. The cement board manufacturing device can realize automatic feeding and save manpower. According to the technical scheme, the cement board manufacturing device comprises a base, first supporting columns, first elastic pieces, a discharging plate, a vibration mechanism and amovable discharging mechanism, wherein supporting cylinders are evenly arranged at the top of the base, the four supporting cylinders are distributed at four corners, the first supporting columns arearranged in the supporting cylinders in a sliding mode, the first elastic pieces are arranged between the first supporting columns and the supporting cylinders, the first elastic pieces are located in the supporting cylinders, the discharging plate is arranged on the first supporting columns, the base is provided with the vibration mechanism for striking the discharging plate, the movable discharging mechanism is arranged on the base, and the discharging mechanism is located above the discharging plate. According to the cement board manufacturing device, the effects of automatic feeding and labor saving are achieved.

Owner:陈悦锋

Energy-saving and environment-friendly industrial sewage treatment equipment

ActiveCN113213675AAchieve automatic feedingFilter up toSpecific water treatment objectivesTreatment involving filtrationSewage treatmentEnvironmental protection

The invention relates to treatment equipment, in particular to energy-saving and environment-friendly industrial sewage treatment equipment. The technical problem is to provide the energy-saving and environment-friendly industrial sewage treatment equipment capable of automatically discharging and filtering impurities. According to the technical scheme, the energy-saving and environment-friendly industrial sewage treatment equipment comprises a base, a conveying mechanism and a discharging mechanism; the conveying mechanism is arranged on the top of the base, and the discharging mechanism is arranged on the conveying mechanism. According to the equipment, the effects of automatic discharging and impurity filtering can be achieved; by starting a servo motor, when an output shaft of the servo motor drives a sliding sleeve to move rightwards, the sliding sleeve can drive a first sliding rod to move rightwards, the first sliding rod does not block an outlet of a liquid medicine tank any more, liquid medicine can flow into a collecting frame, and the effect of automatic discharging is achieved.

Owner:金山环保集团有限公司

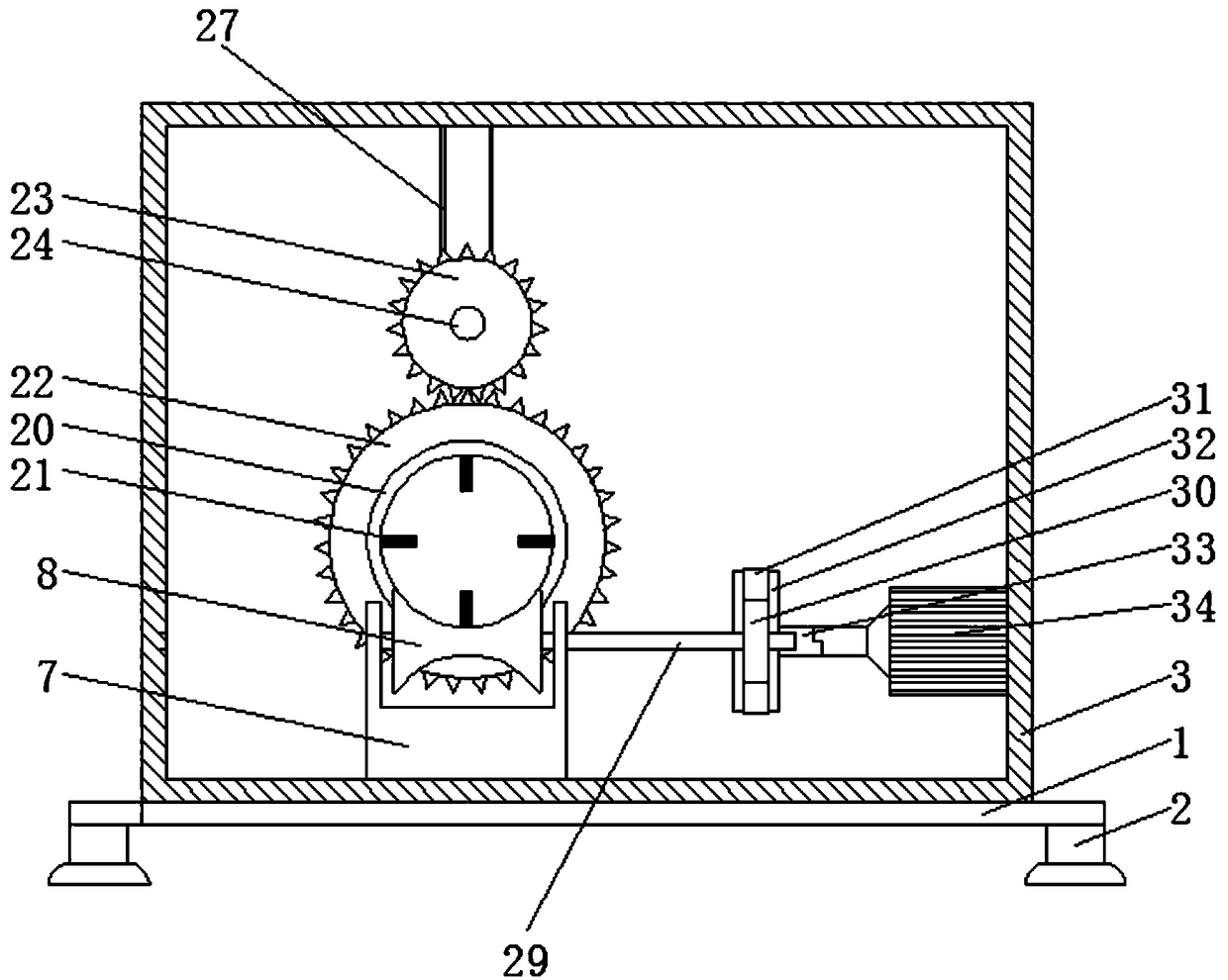

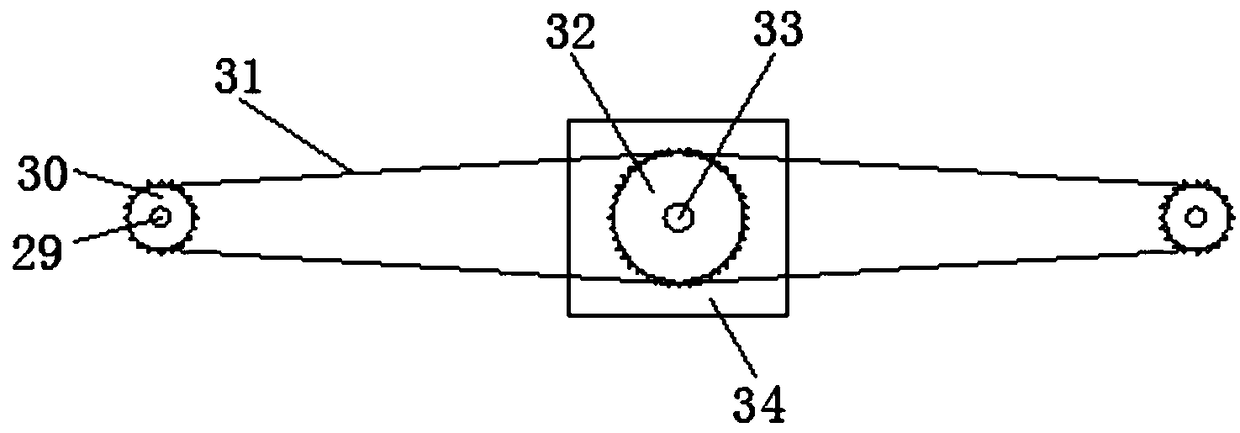

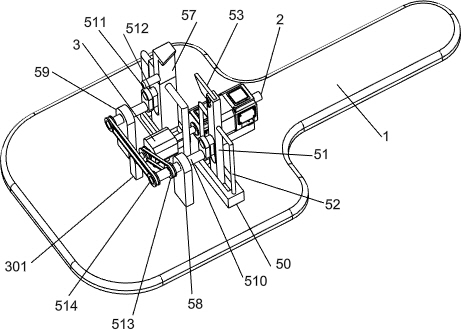

Automatic pecan shell opening equipment

PendingCN112089060AAchieve automatic feedingReached can be automatically unloadingHuskingHullingAgricultural engineeringStructural engineering

Owner:钟守云

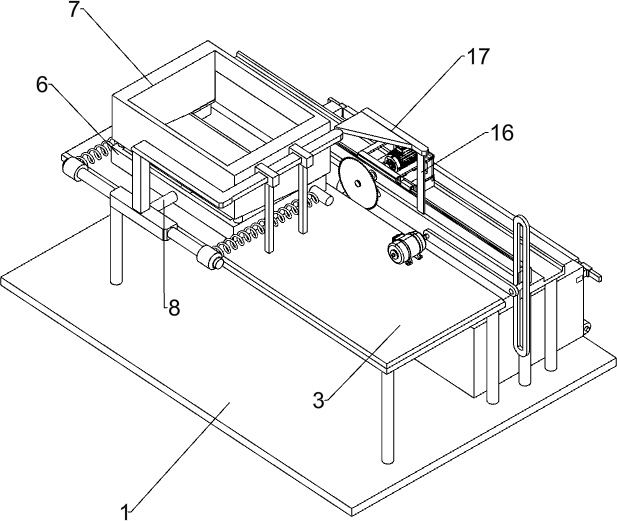

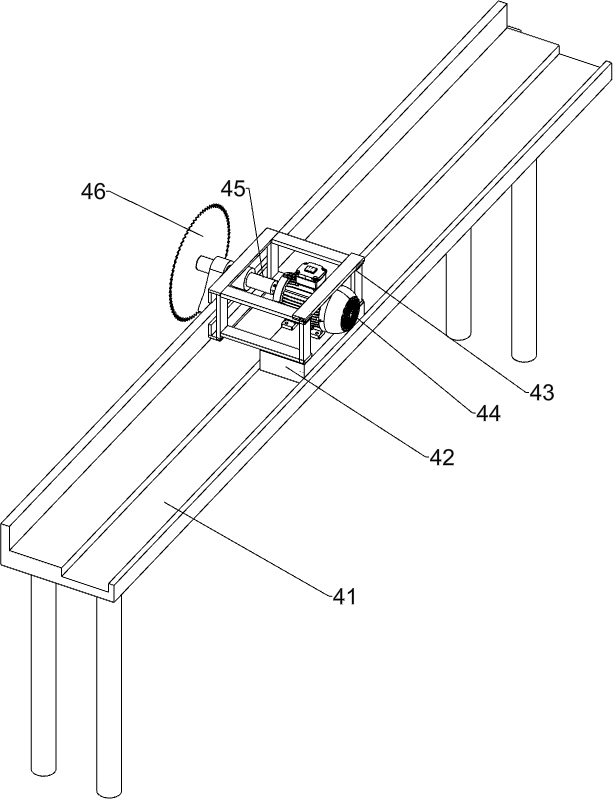

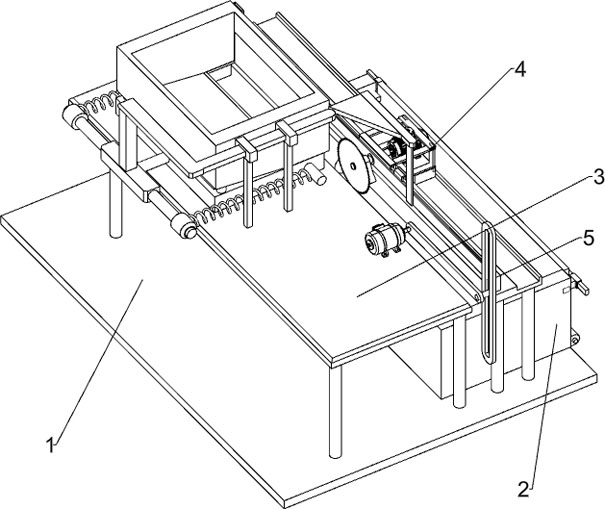

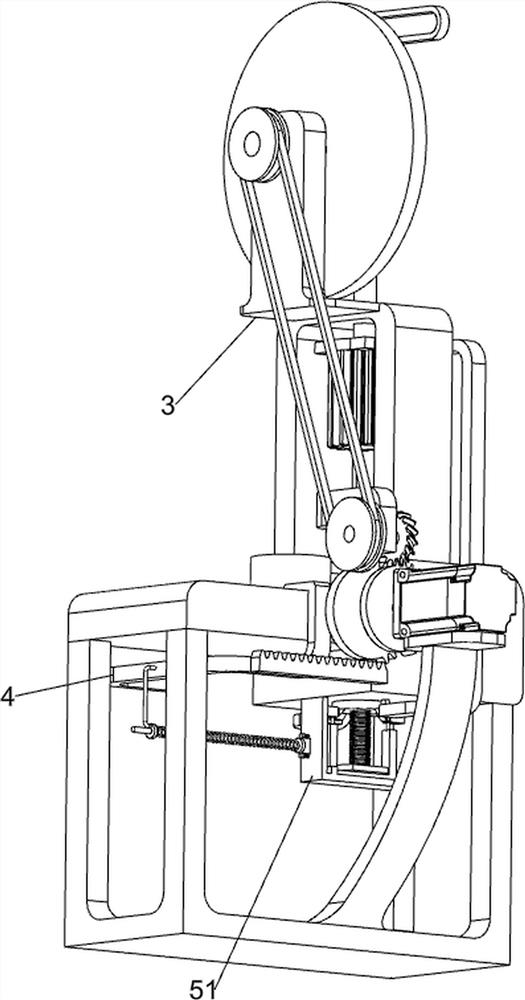

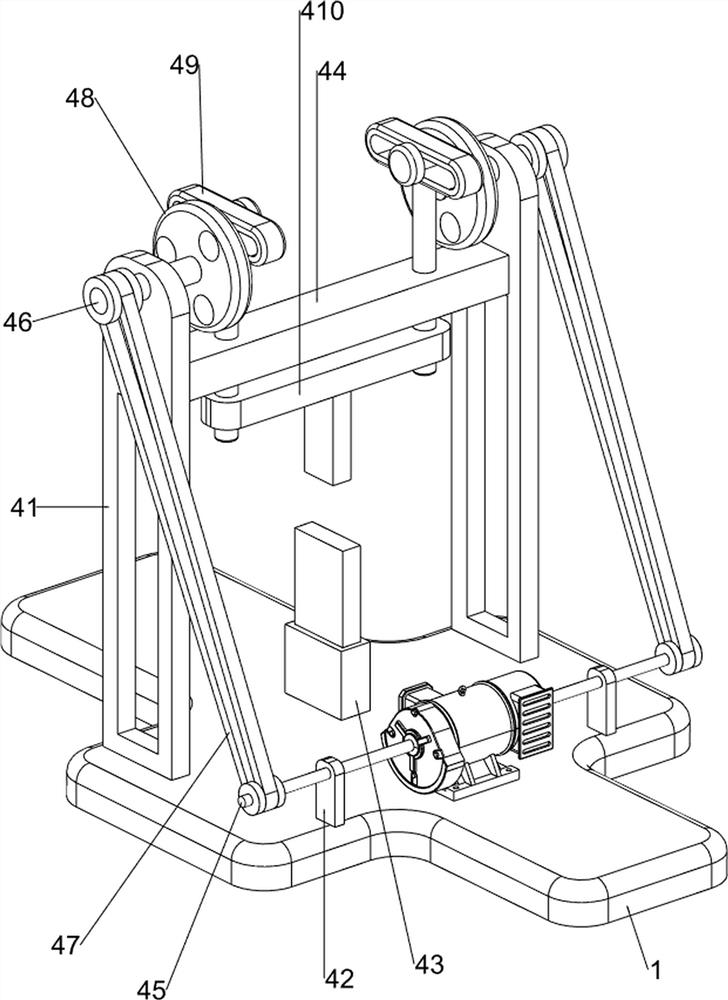

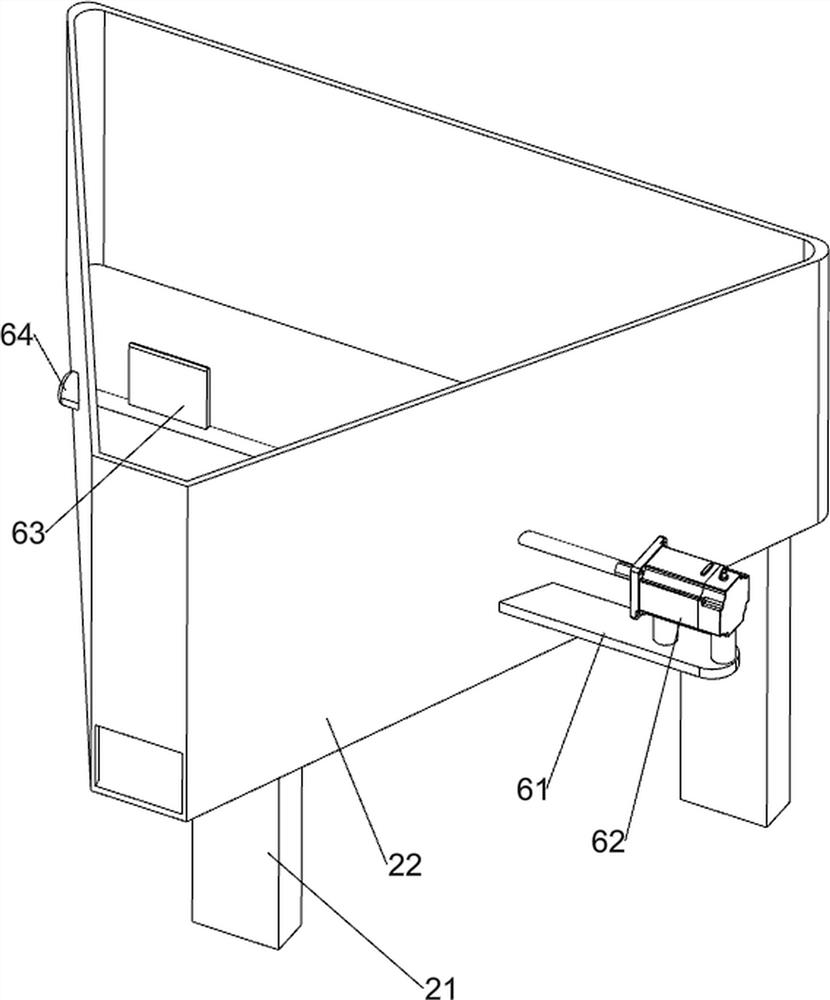

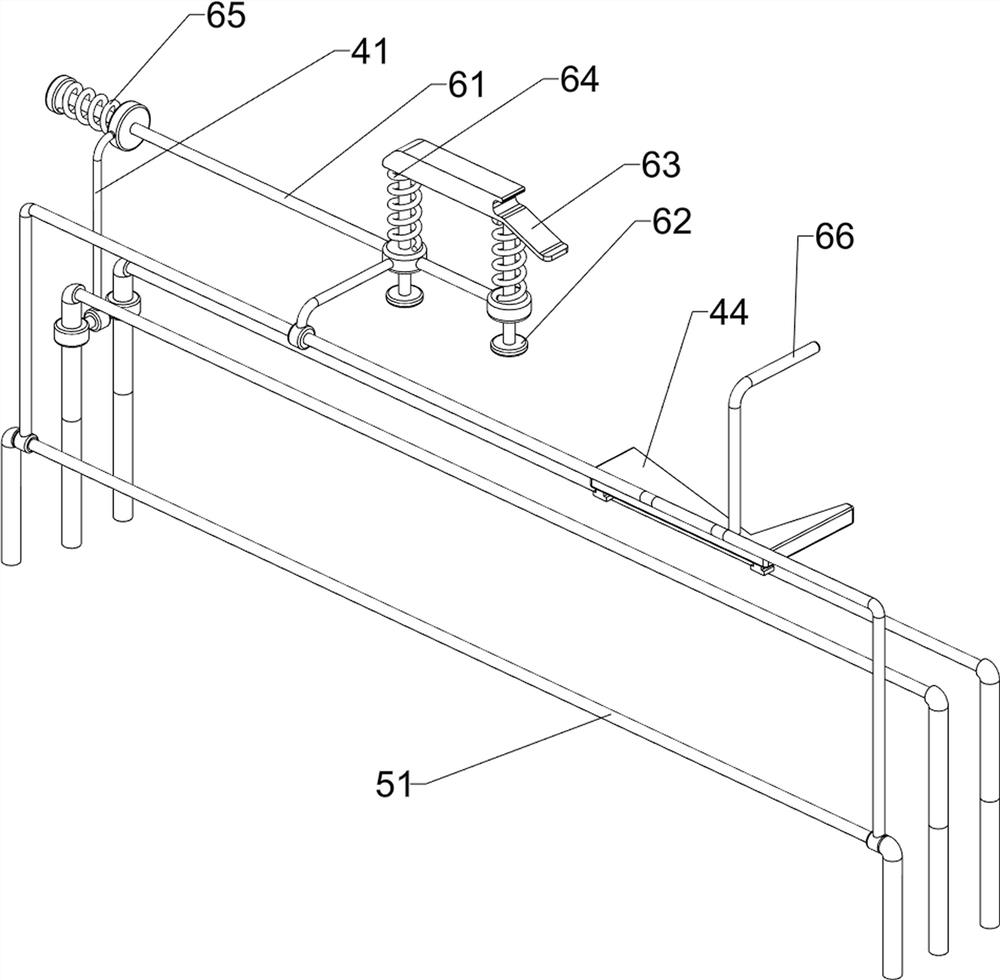

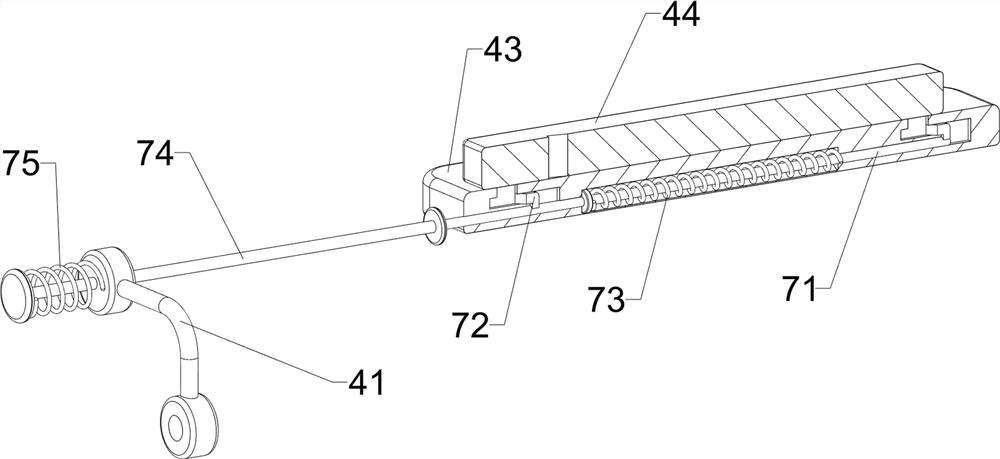

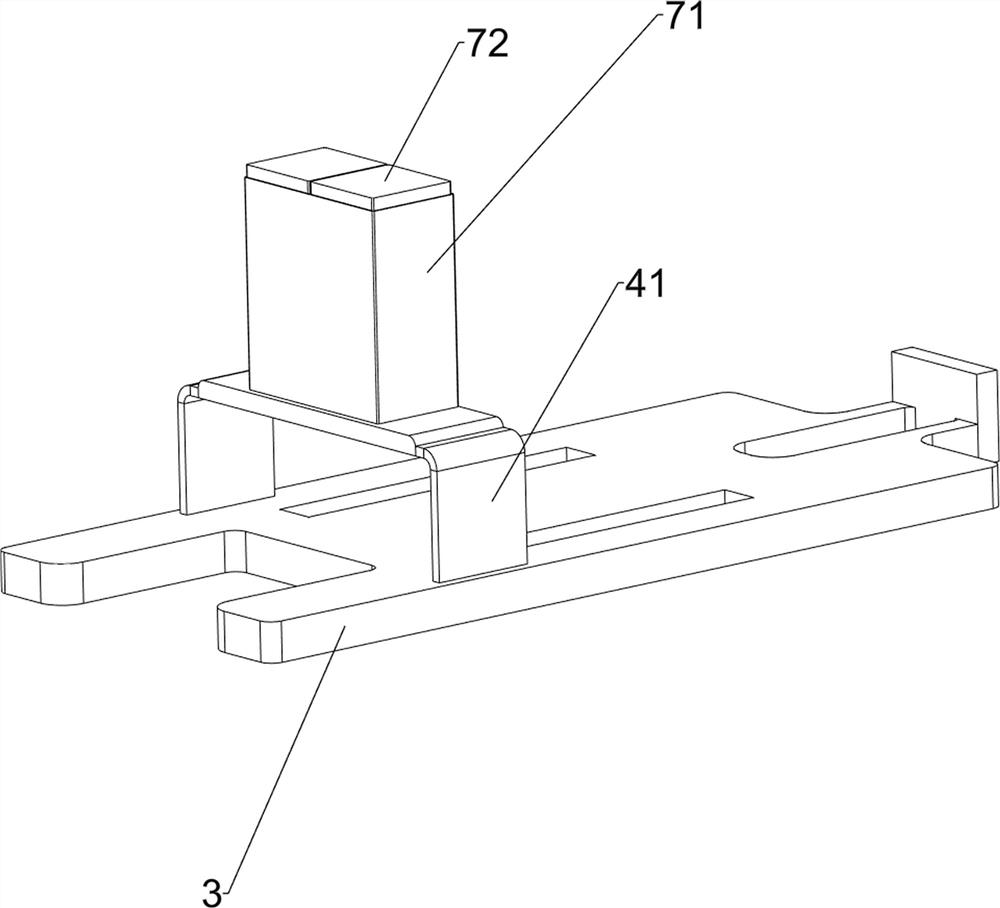

Wood corner cutting equipment for furniture

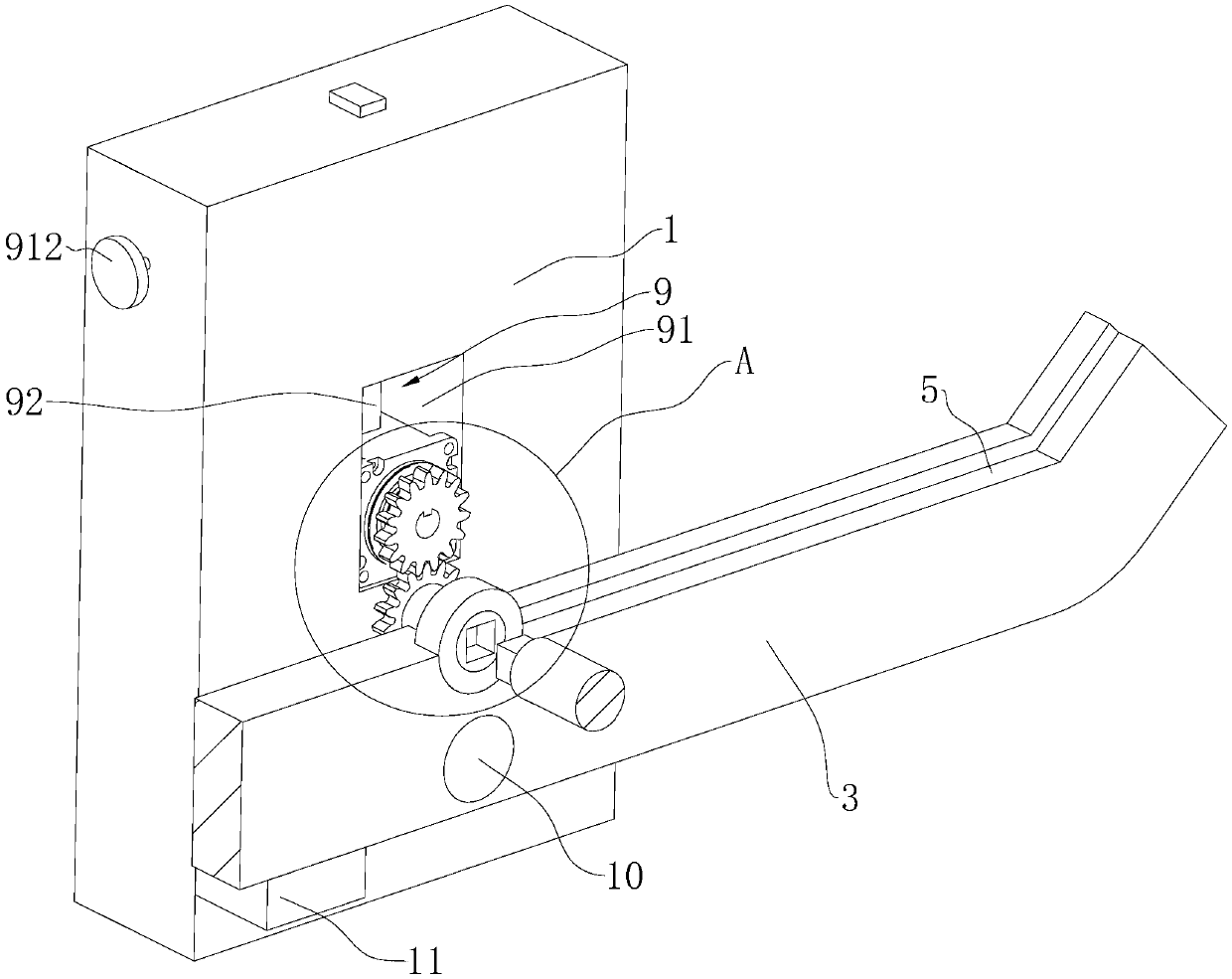

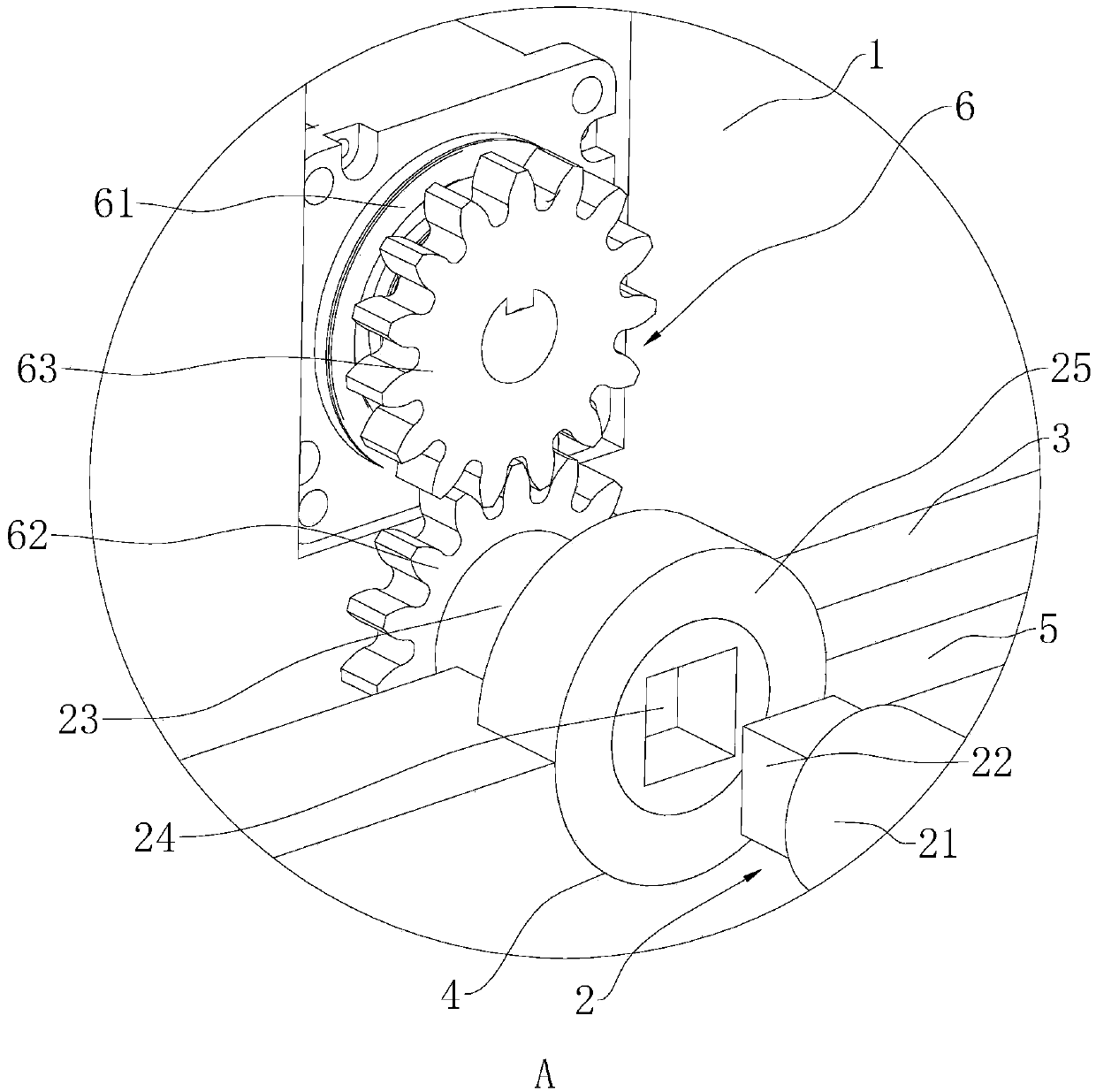

ActiveCN112621897AAchieve automatic feedingRealize the purpose of automatic feedingFeeding devicesGripping devicesElectric machineryAgricultural engineering

The invention relates to cutting equipment, in particular to wood corner cutting equipment for furniture. According to the wood corner cutting equipment for the furniture, automatic feeding is conducted before wood corner cutting, automatic clamping is conducted during wood corner cutting, and automatic pushing-out is conducted after wood corner cutting. The wood corner cutting equipment for the furniture comprises a base and a saw blade, and the saw blade is arranged on one side of the top of the base; a placing assembly, arranged at the top of the base; a motor, arranged on the placing assembly; and a pushing assembly, arranged on the side, close to the placing assembly, of the top of the base, wherein components of the pushing assembly are connected with components of the placing assembly. The effects of automatic feeding before wood corner cutting, automatic clamping during wood corner cutting and automatic pushing-out after wood corner cutting are achieved.

Owner:NANJING YUZHI INTELLIGENT TECH CO LTD

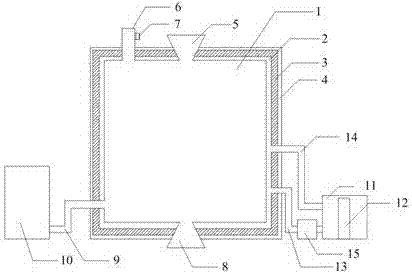

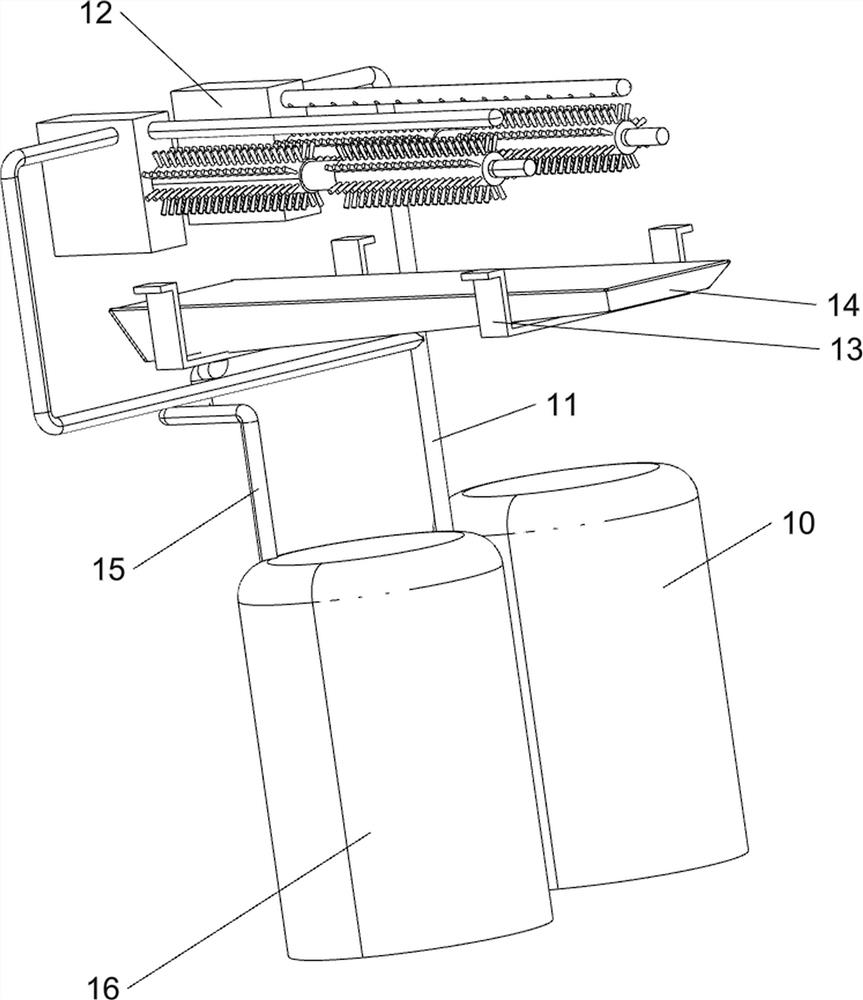

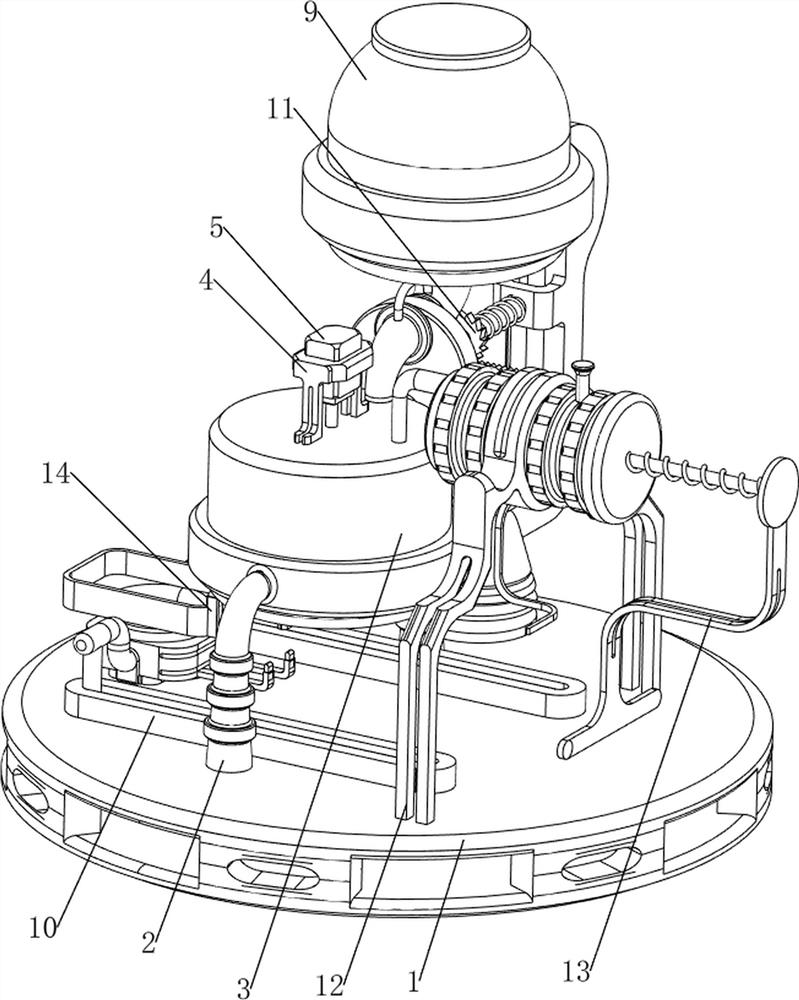

Automatic cleaning device for log production and processing

InactiveCN109277331AWash thoroughlyReach fixedCleaning using toolsCleaning using liquidsEngineeringWater pipe

The invention relates to the technical field of wood processing, and discloses an automatic cleaning device for log production and processing. The automatic cleaning device comprises a base. Base feetare fixedly mounted at the four corners of the bottom of the base. A shell is fixedly mounted at the top of the base. A feeding opening is formed in the left side of the shell. An automatic feeding device is fixedly mounted on the left side of the feeding opening. A discharging opening is formed in the right side of the shell. Supporting blocks are fixedly mounted on the left side and the right side of the inner bottom wall of the shell. Rolling wheels are movably mounted at the tops of the supporting blocks. Fixed shells are fixedly mounted on the inner walls of the left side and the right side of the shell. Two first rotating shafts are inserted in each shell in a penetrating manner, and a first gear is fixedly mounted on the outer side of each first rotating shaft. A rotating barrel drives brushes on the inner wall of the rotating barrel to annularly and continuously wash the log surface, two water outlets of a second water pipe wash the log two times, the function of log washing is achieved, and the effect that washing is achieved thoroughly is achieved.

Owner:湖州南浔双杨木业有限公司

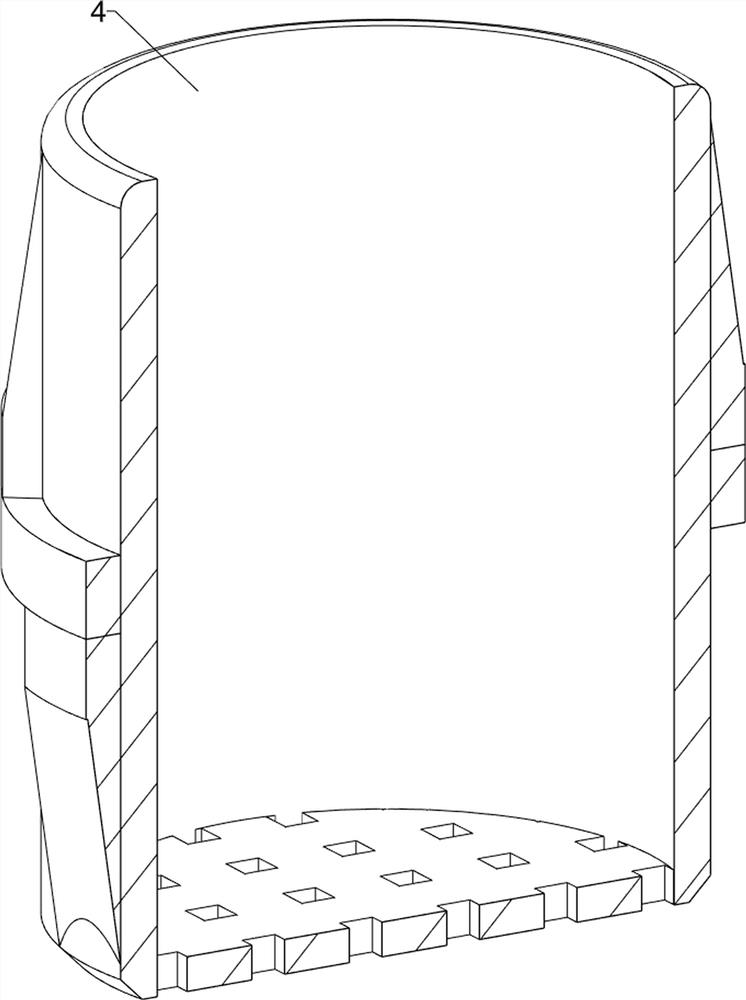

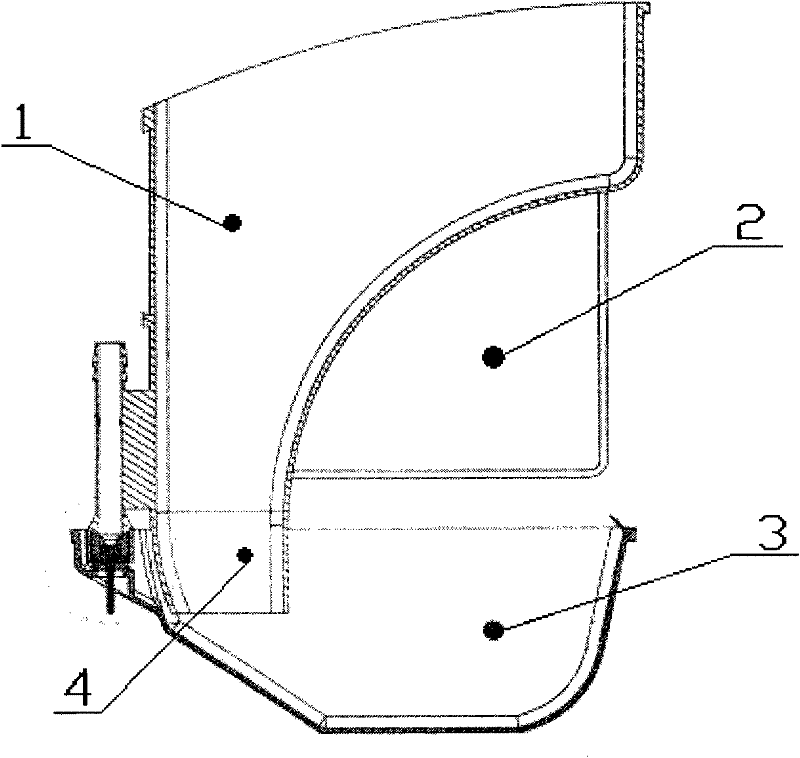

Grain dryer

InactiveCN108007101AReduce lossesReduce wasteDrying gas arrangementsDrying chambers/containersEngineeringHeat losses

The invention discloses a grain dryer. The grain dryer is characterized by comprising that the exterior of a drying bin is wrapped by a cavity; the exterior of the cavity is wrapped by a heat preserving layer; the exterior of the heat preserving layer is wrapped by a shell; a feeding port and an air outlet are formed in the upper portion the drying bin; the air outlet is installed on the left sideof the feeding port; the middle of the lower portion of the drying bin is provided with a discharging port; a hot air blower is connected to one side of the drying bin through a hot air channel; a water tank is connected to one side of a water heating layer through a conveying channel and a recycling channel; a water pump is installed on the conveying channel; a heater is installed in the water tank; and a valve is installed on the outer side of the air outlet. According to the grain dryer, on the premise that control over the water of dried grain is guaranteed, hot water is injected into thecavity to rise the temperature in the bin, and the hot air blower is used for accelerating flowing of air on the surface of grain under the condition that the temperature in the bin is not affected to increase the drying speed; the exterior of the drying bin is wrapped by the heat preserving layer so that the heat loss can be reduced; the controllable air outlet is installed in the upper portionthe drying bin, the size of the air outlet is controlled to adjust flowing of air in the drying bin, and a function of controlling the water of the grain is achieved.

Owner:泰州市乐律金属制品有限公司

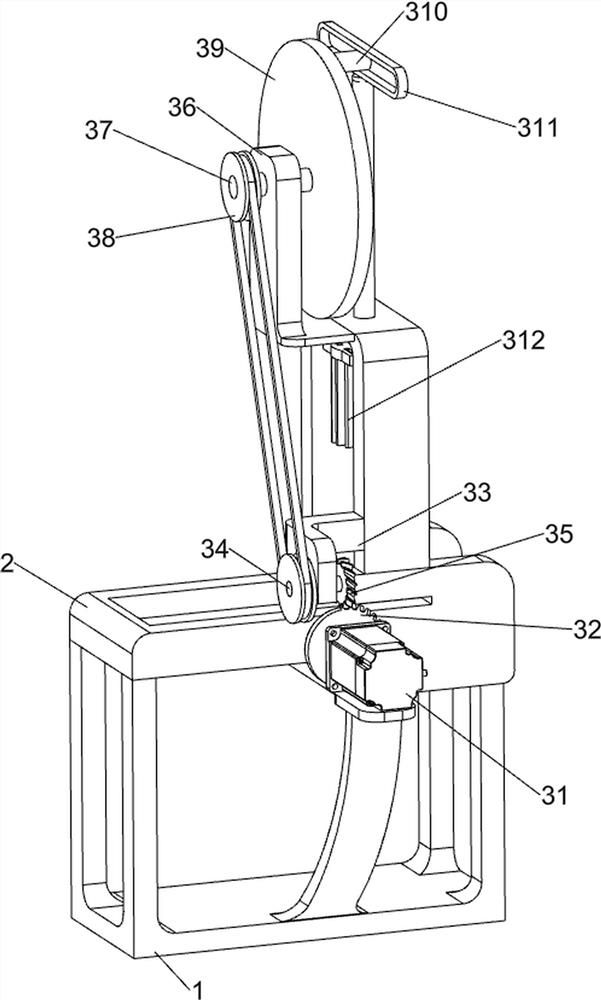

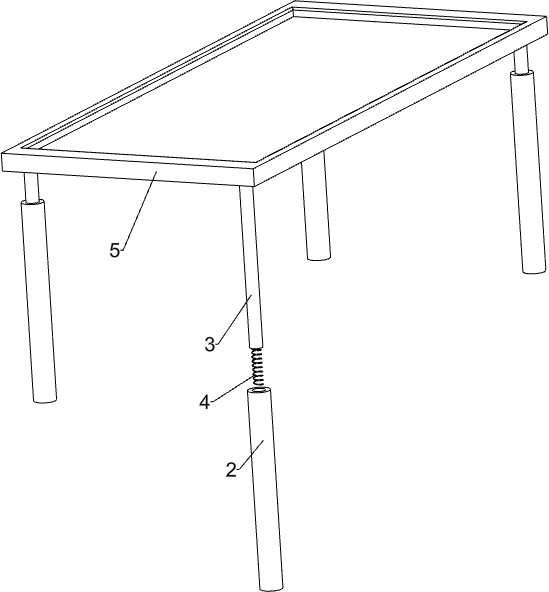

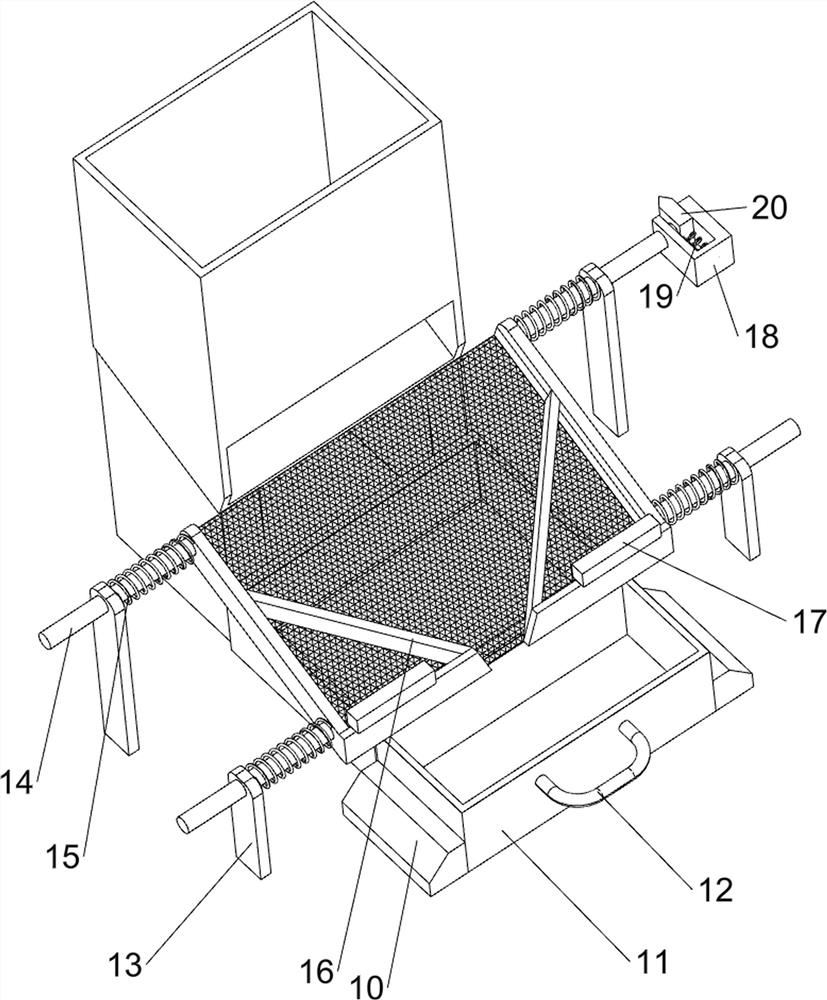

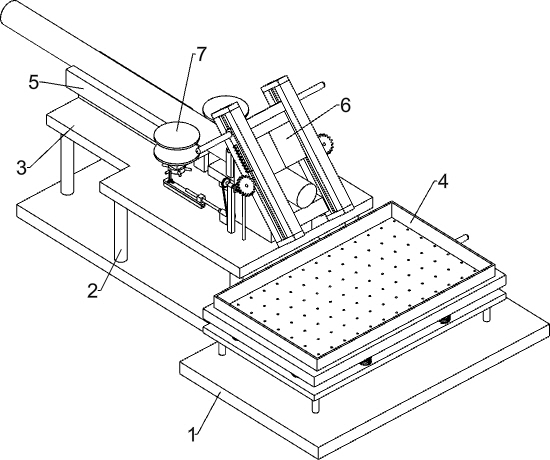

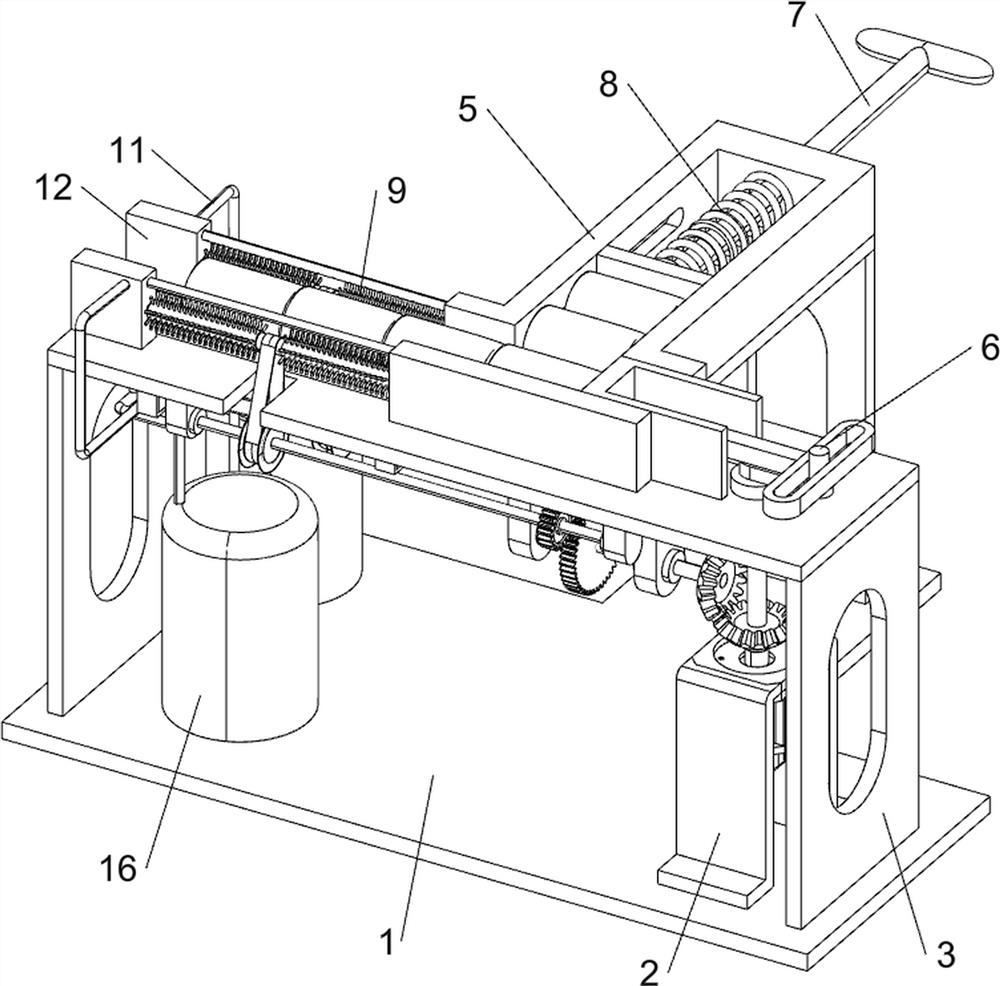

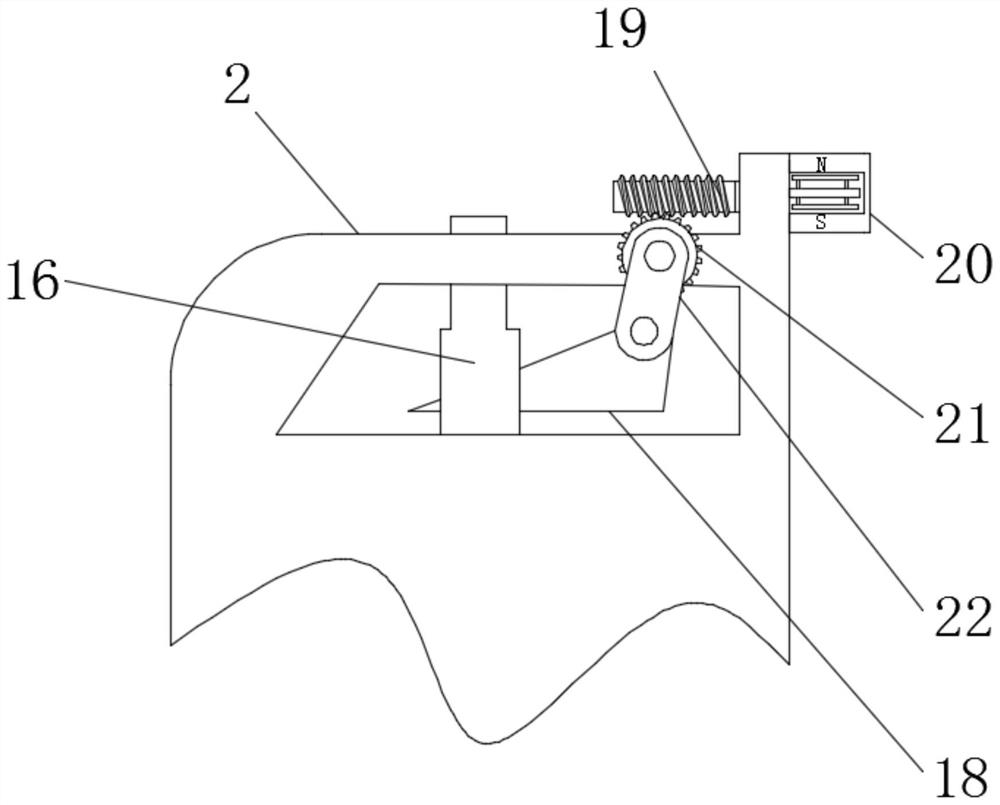

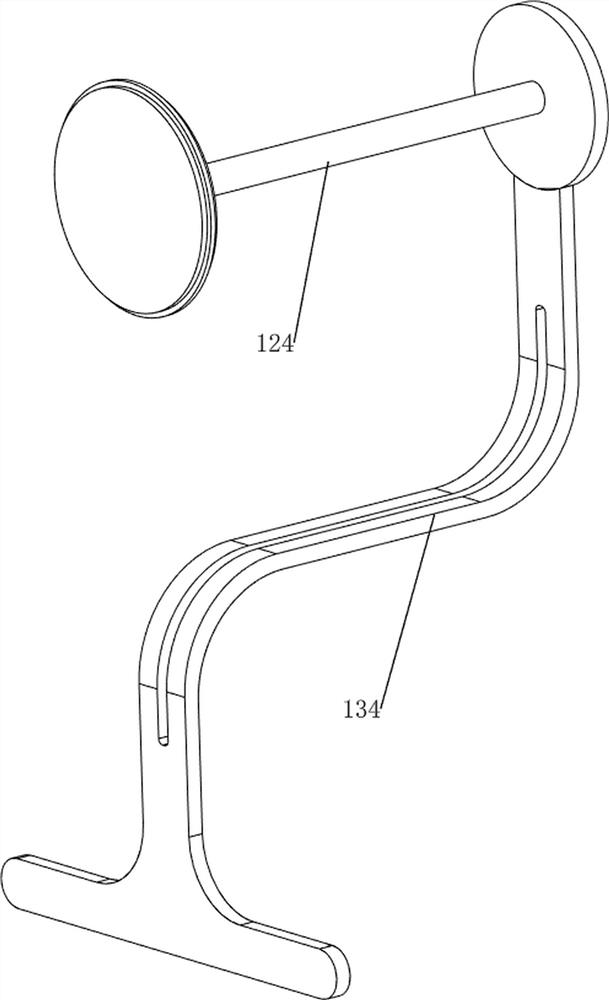

Radix astragali slicing device

ActiveCN111873006AAchieve automatic feedingUniform thicknessMetal working apparatusRadix Astragali seu HedysariEngineering

The invention relates to a slicing device, in particular to a radix astragali slicing device. The technical problem to be solved is to provide the radix astragali slicing device which is automatic infeeding and uniform in slicing thickness. According to the technical scheme, the radix astragali slicing device comprises a base, a workbench, a collecting screen, a cushion block, a slicing mechanismand a feeding mechanism; a first supporting column is arranged on one side of the base; the workbench is arranged on the first supporting column; the collecting screen is arranged on the side, away from the workbench, of the base; the cushion block is arranged on the side, away from the collecting screen, of the workbench; the slicing mechanism is arranged on the side, close to the collecting screen, of the workbench; and the feeding mechanism is arranged on the workbench, and the feeding mechanism is located between the slicing mechanism and the cushion block. The radix astragali slicing device achieves the effects of being automatic in feeding and uniform in slicing thickness.

Owner:王发云

Plastic square piece block mark branding equipment

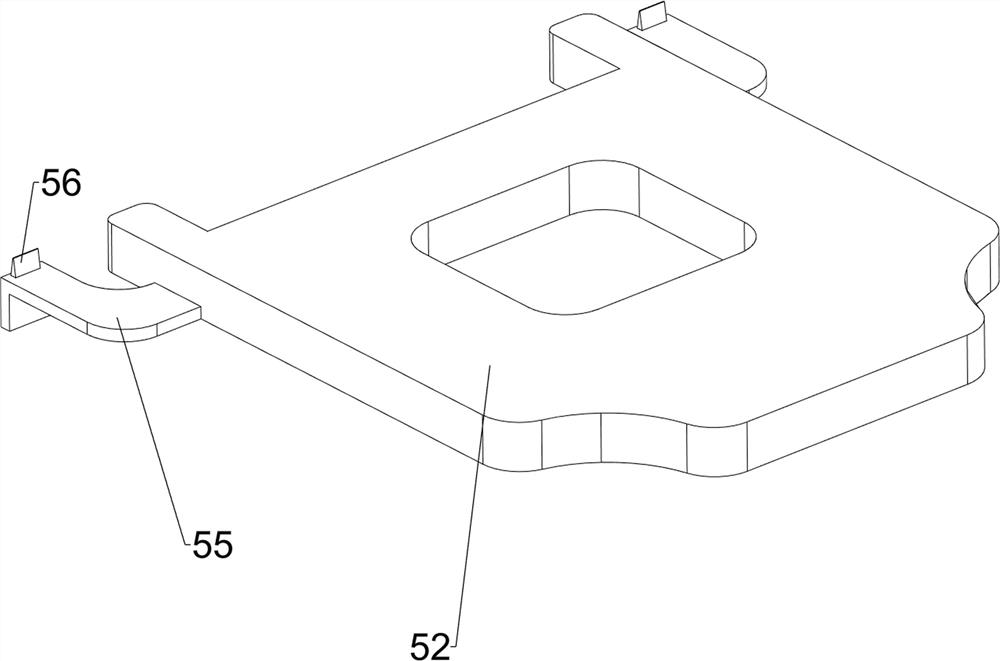

PendingCN112549515AAchieve automatic feedingAchieve the effect of automatic brandingDispersed particle filtrationWorkbenchIndustrial engineering

The invention relates to branding equipment, in particular to plastic square piece block mark branding equipment. The plastic square piece block mark branding equipment can achieve automatic feeding and automatic branding and is high in safety performance. The plastic square piece block mark branding equipment comprises a bottom plate, two supporting seats, a workbench and a branding mechanism, wherein the two supporting seats are arranged on the bottom plate, the workbench is arranged between the upper parts of the two supporting seats, and the branding mechanism is arranged on the workbench.Through cooperation of the feeding mechanism and the branding mechanism, the effects of automatic feeding and automatic branding are achieved, and the working efficiency is improved; through a material blocking mechanism, the plastic square piece block stuck to a high-temperature branding plate is not prone to moving upwards, and contact of workers with the high-temperature branding plate is reduced; and through a purification mechanism, toxic smoke generated during branding is purified and then discharged, and the safety of workers is guaranteed.

Owner:唐菁

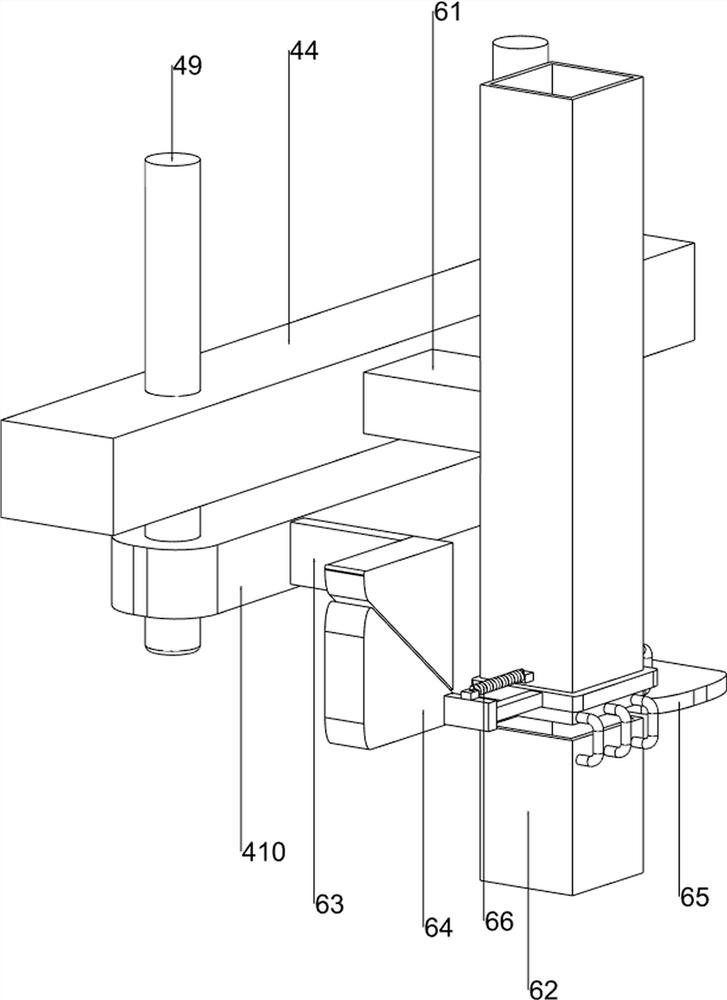

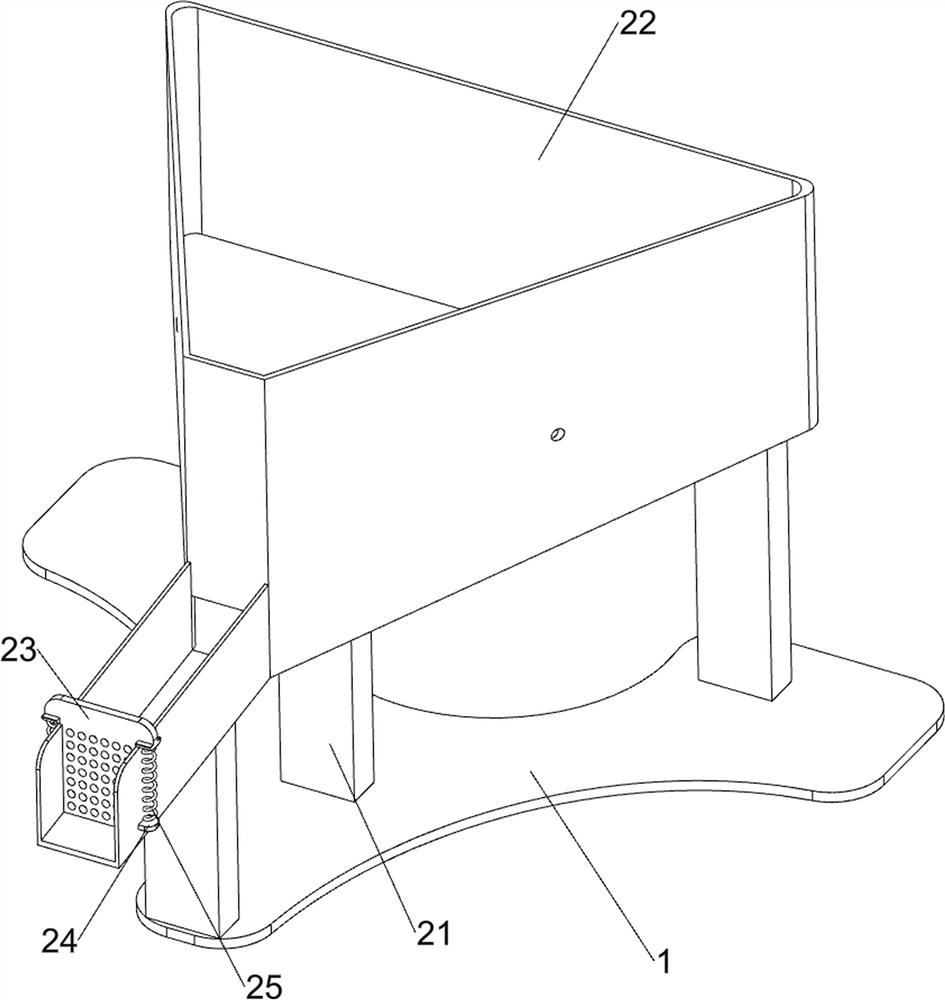

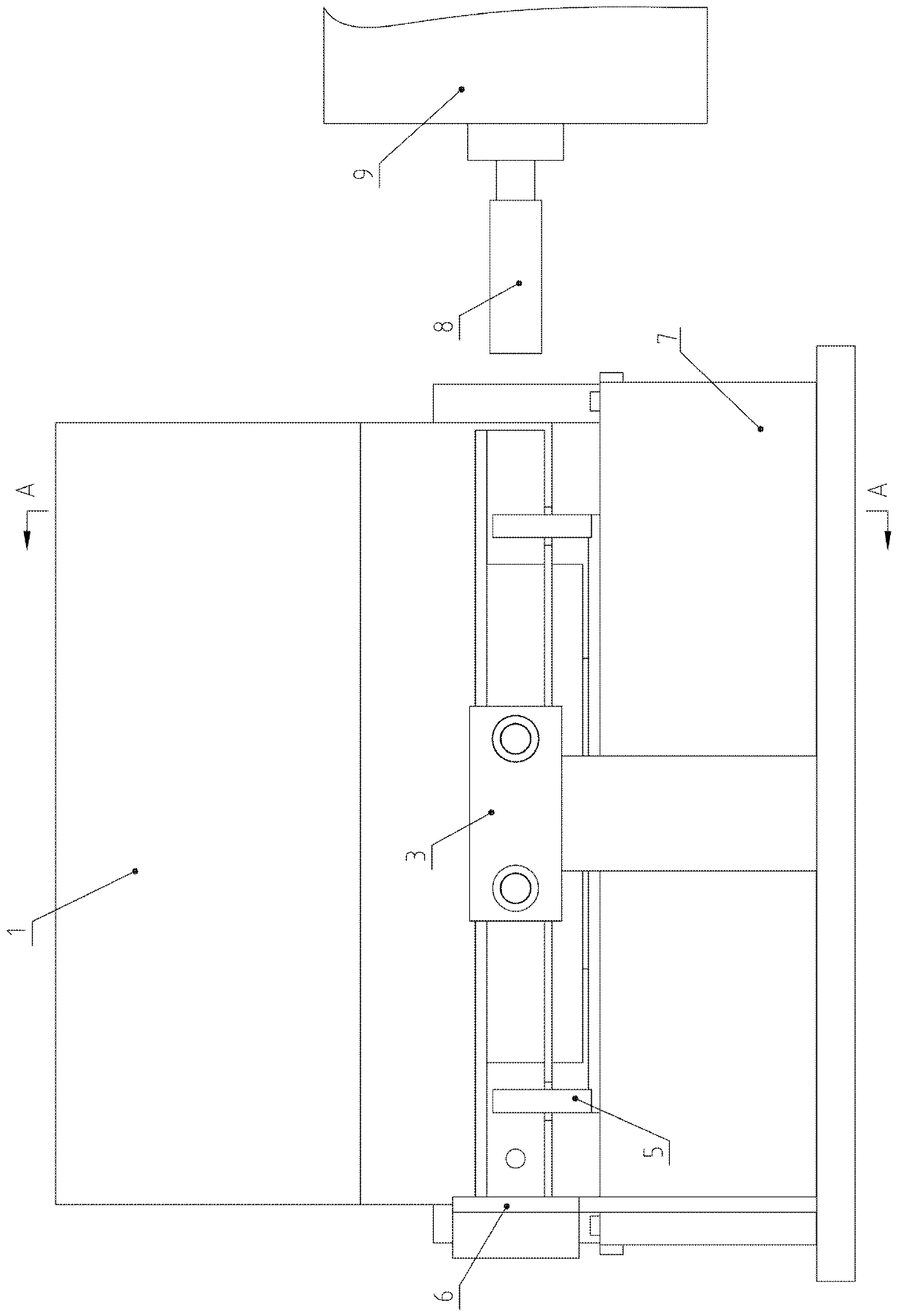

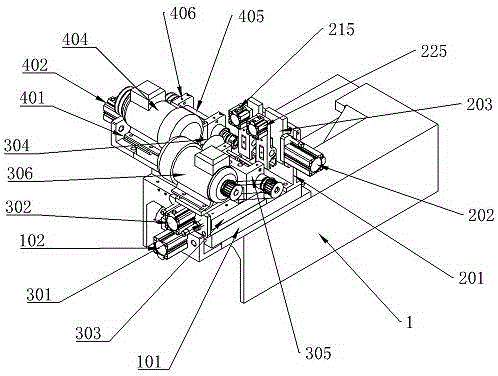

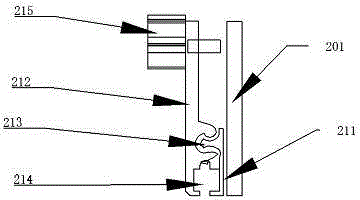

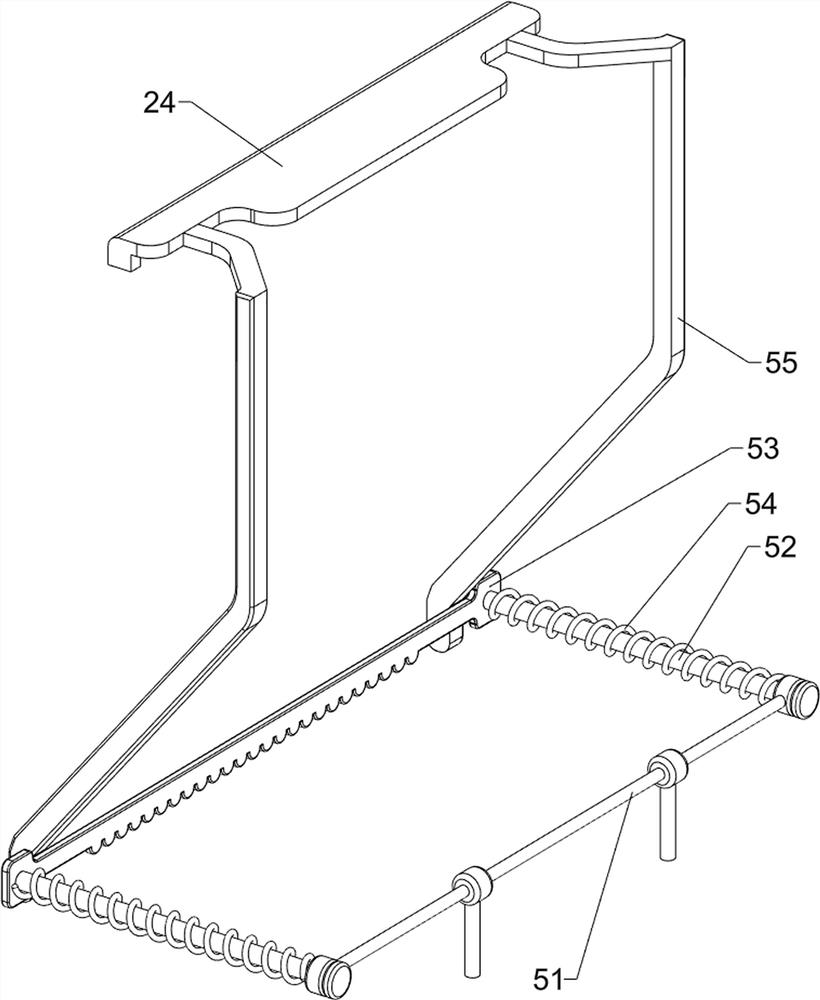

Automatic tapping equipment for one end of steel pipe for medical transfer bed

InactiveCN110076398AIncrease the level of automationImprove work efficiencyThread cutting feeding devicesThread cutting machinesHydraulic cylinderRejection rate

The invention belongs to the technical field of manufacturing equipment for medical equipment parts, and relates to automatic tapping equipment for one end of a steel pipe for a medical transfer bed.A V-shaped push claw is driven by a return hydraulic cylinder piston rod to do translation backwards, the V-shaped push claw stretches into a narrow and long channel, and the steel pipe on the lowestportion is pressed by the V-shaped push claw and a front push face together. A propelling hydraulic cylinder carries out forward propelling, the V-shaped push claw and the return hydraulic cylinder piston rod passively return from back to front, and an overflow valve achieves overflowing. A stop claw hydraulic cylinder piston rod is in a floating state, a stop claw is pushed by the steel pipe to avoid a steel pipe channel, and the stop claw hydraulic cylinder piston rod contracts into a stop claw hydraulic cylinder body. A horizontal tapping machine returns after achieving tapping. The propelling hydraulic cylinder returns, and the steel pipe falls down. Automatic feeding, clamping, tapping and material return are achieved, the automation level is increased, labor force is saved, the workefficiency and product quality are improved, and the rejection rate is reduced.

Owner:杜宗英

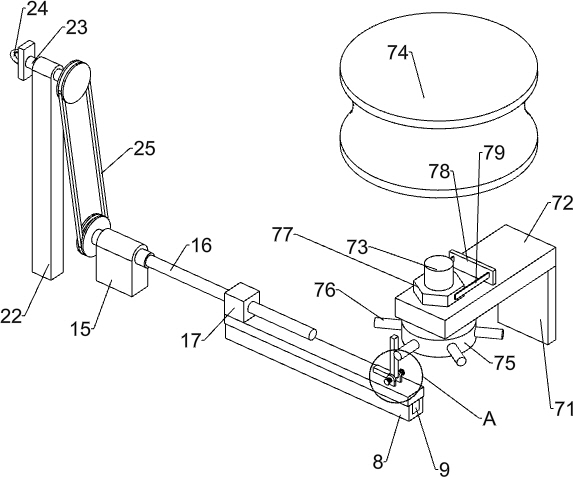

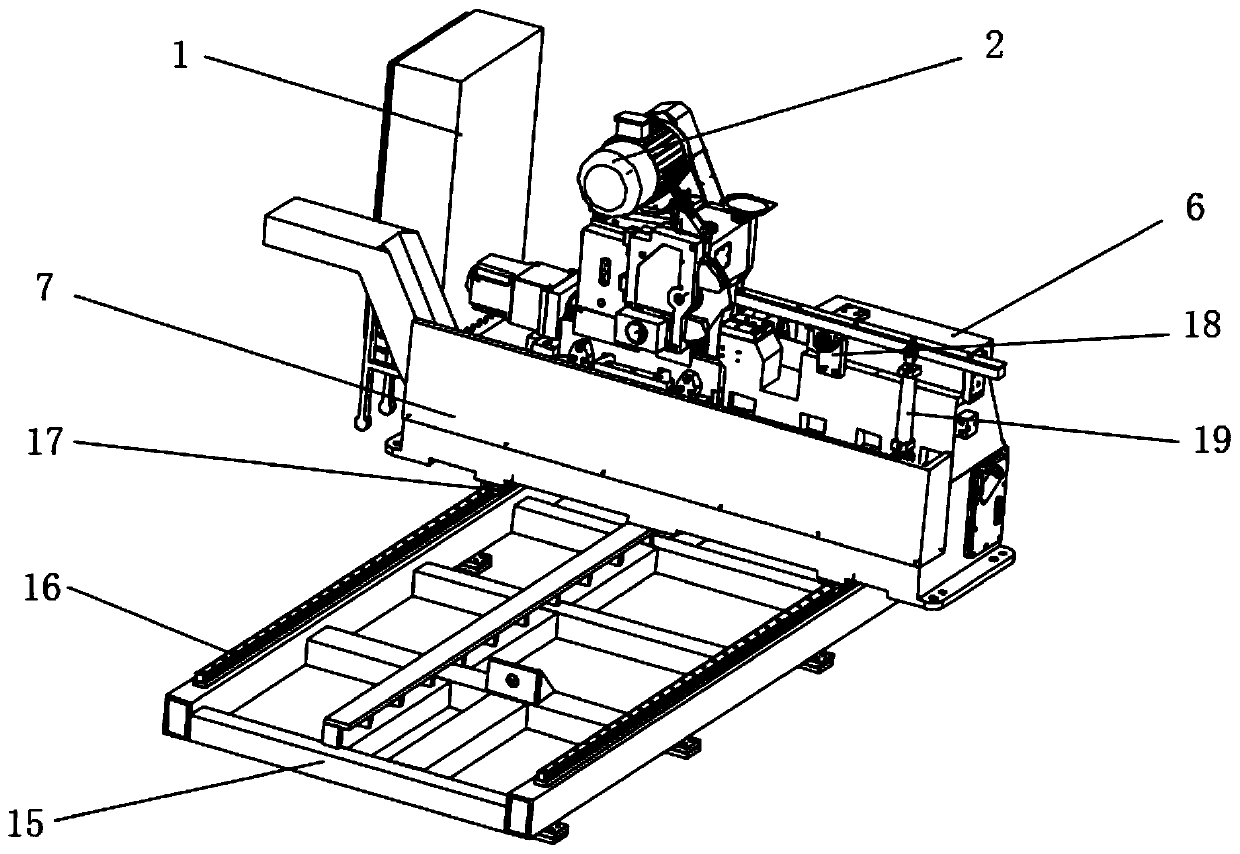

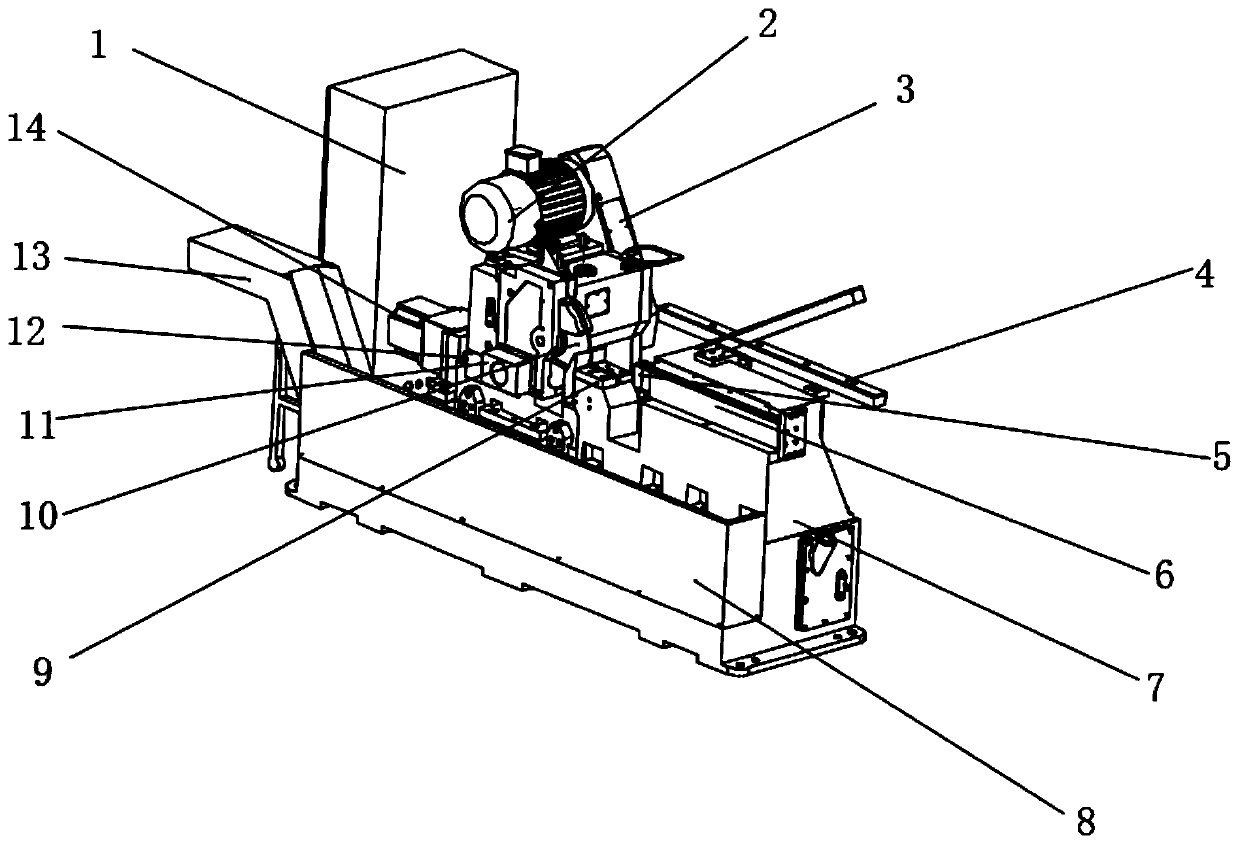

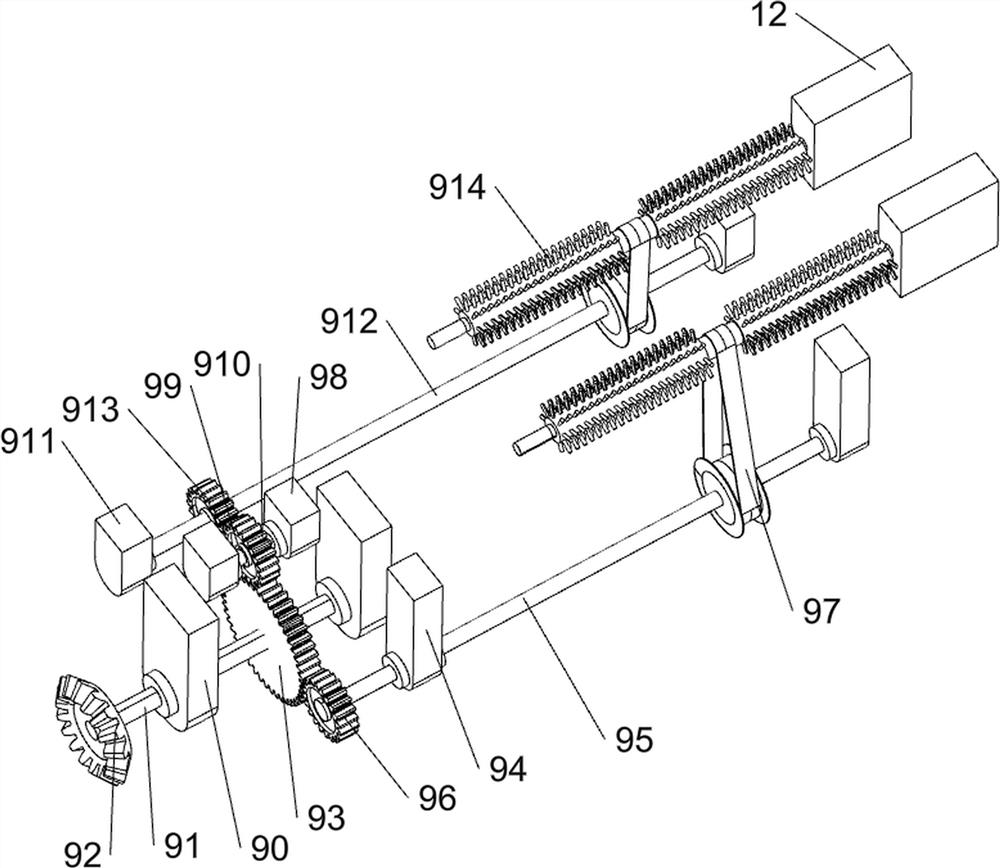

Linked-integrated cutting machine

PendingCN110238688ARealize continuous operationImprove work efficiencyLarge fixed membersMetal working apparatusEngineeringMachine tool

The invention discloses a linked-integrated cutting machine. The linked-integrated cutting machine comprises an electric box, a motor, a transmission belt, a loading plate, a pneumatic rod, a location cylinder, a rack, a fence, a workbench, a cutting wheel, a cutting frame, a slide rail, a chip removal pipeline, a linkage frame, a moving guide rail, a slide block, a loading frame and a loading cylinder. According to the linked-integrated cutting machine, five groups of machine tools can be arranged on the linkage frame simultaneously, and one straight line is formed by five linked cutting machines; the linked-integrated cutting machine is composed of five same machine tools, the first machine tool is in a fixed state, and the second machine tool, the third machine tool, the fourth machine tool and the fifth machine tool are capable of moving forwards and backwards; the needed cutting length can be adjusted by adjusting the positions of racks of the machine tools on the moving guide rail, so that a material is cut into four sections with a specified length; then the material is conveyed onto the workbench along the loading plate through the working of the loading cylinder, and discharged through a discharge port after being cut, so that automatic loading and automatic unloading can be realized, the continuous working is realized, and the working efficiency is greatly increased.

Owner:浙江沪缙机床有限公司

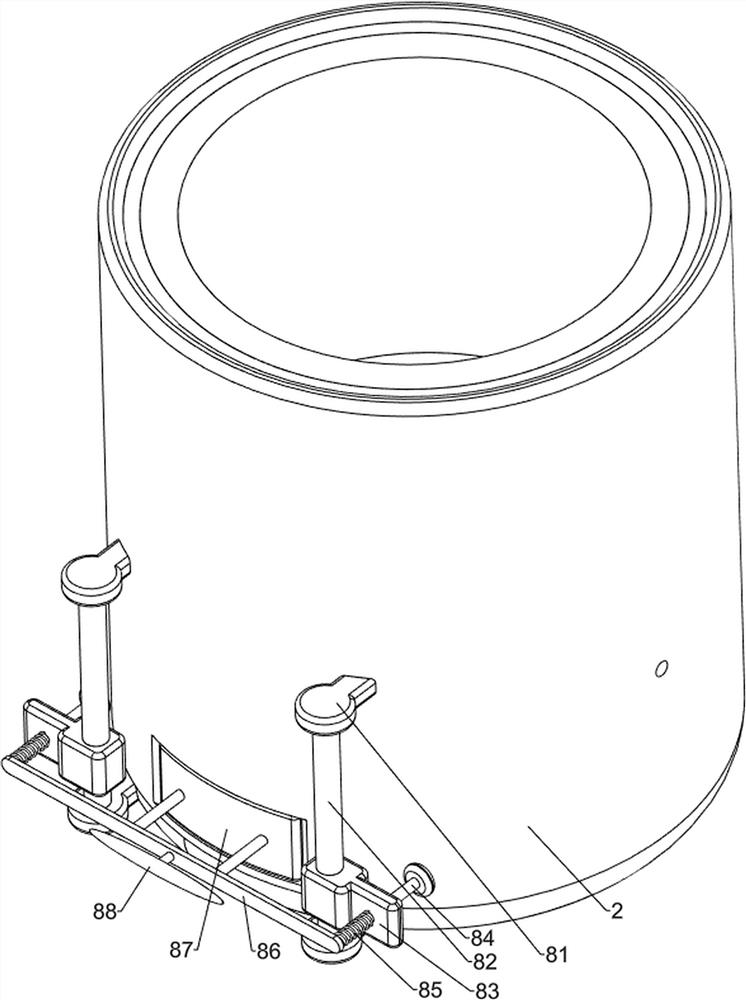

Ring-pull can shell cleaning device

InactiveCN112893365ARealize automatic feedingAutomated cleaningHollow article cleaningElectric machinerySewage

The invention relates to a cleaning device, in particular to a ring-pull can shell cleaning device. According to the ring-pull can shell cleaning device, automatic feeding of ring-pull cans can be achieved, the ring-pull can shells can be automatically cleaned, and sewage can be conveniently collected. The ring-pull can shell cleaning device comprises a base and a motor base, wherein the motor base is arranged on the right side of the top of the base; a working platform which is arranged at the top of the base; a servo motor which is arranged on the upper side of the motor base; a material waiting box which is arranged on the rear side of the top of the working platform; a feeding mechanism which is arranged on the side, close to the servo motor, of the top of the working platform; a cleaning mechanism, wherein the left side of the top of the working platform is connected with a part of the cleaning mechanism; and a cleaning water bucket which is arranged on the side, far away from the motor base, of the base. By matching the servo motor, the feeding mechanism, the cleaning mechanism and a sewage collecting frame, ring-pull cans can be automatically fed, shells of the ring-pull cans can be automatically cleaned, and sewage generated after cleaning is conveniently collected.

Owner:马军义

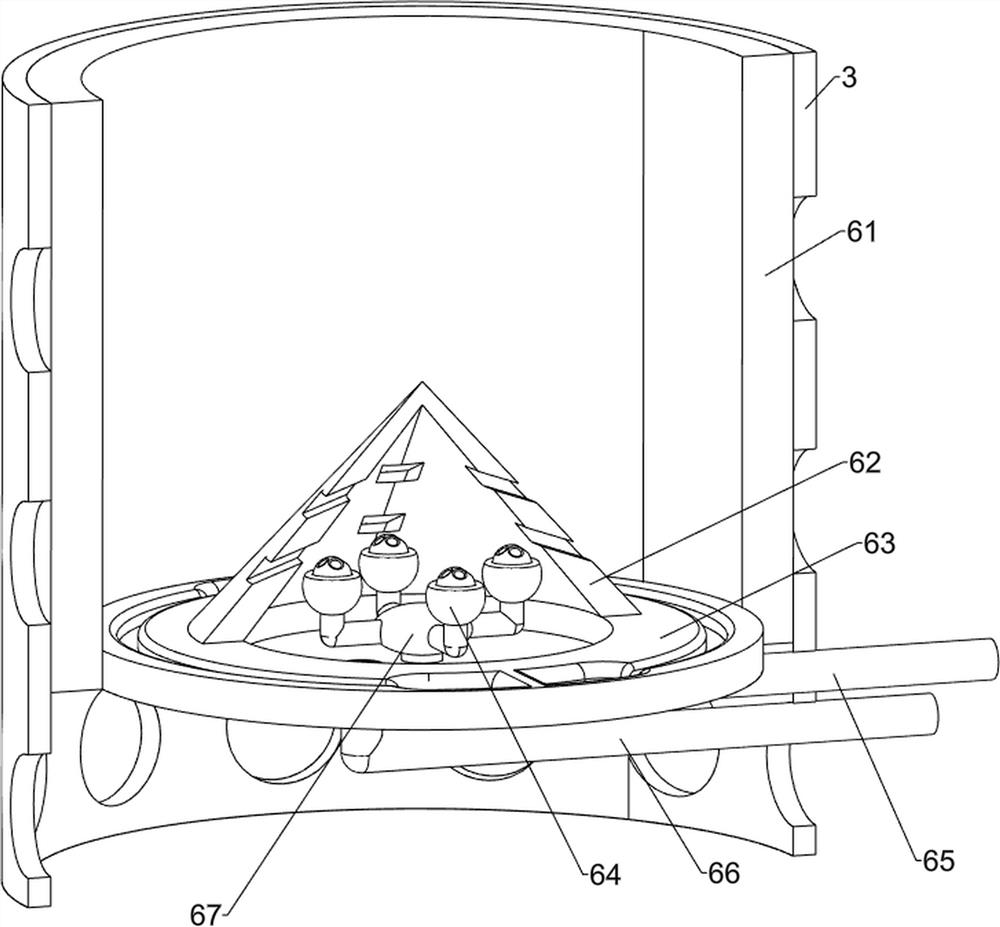

Traditional Chinese medicine ointment preparation equipment for department of pediatrics

ActiveCN113694794AEasy to addReduce wasteRotary stirring mixersMixer accessoriesMedicinal herbsDrug ointment

The invention discloses traditional Chinese medicine ointment preparation equipment for the department of pediatrics. The technical problem of the invention is to provide the traditional Chinese medicine ointment preparation equipment for pediatrics, which is simple in operation and can realize crushing of medicinal materials, convenient addition of liquid medicine, automatic stirring to prepare ointment and automatic vertical shaking of a charging tank. According to the technical scheme, the traditional Chinese medicine ointment preparation equipment for the pediatric department comprises a base, wherein a supporting frame is connected to one side of the upper portion of the base; a motor which is mounted in the middle of the upper part of the supporting frame; a placing assembly which is arranged on one side of the upper part of the supporting frame; a charging tank which is arranged on the placing assembly; a driving assembly which is arranged on one side of the upper portion of the supporting frame; and a plurality of cutter blocks which are arranged on the driving assembly. The paediatric traditional Chinese medicine ointment preparation equipment disclosed by the invention has the advantages of automatically receiving and stirring to prepare ointment, conveniently adding liquid medicine, automatically shaking the charging tank, reducing the waste of medicinal materials and ensuring the rotation of the cutter blocks.

Owner:湖南金寿制药有限公司

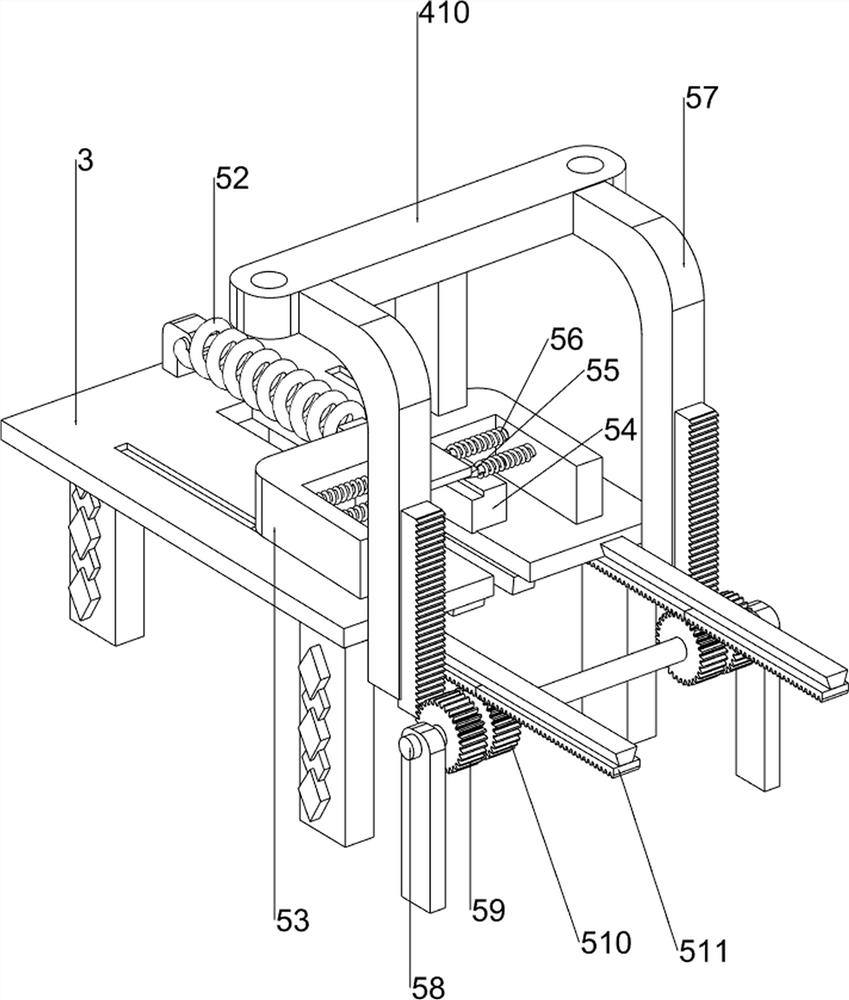

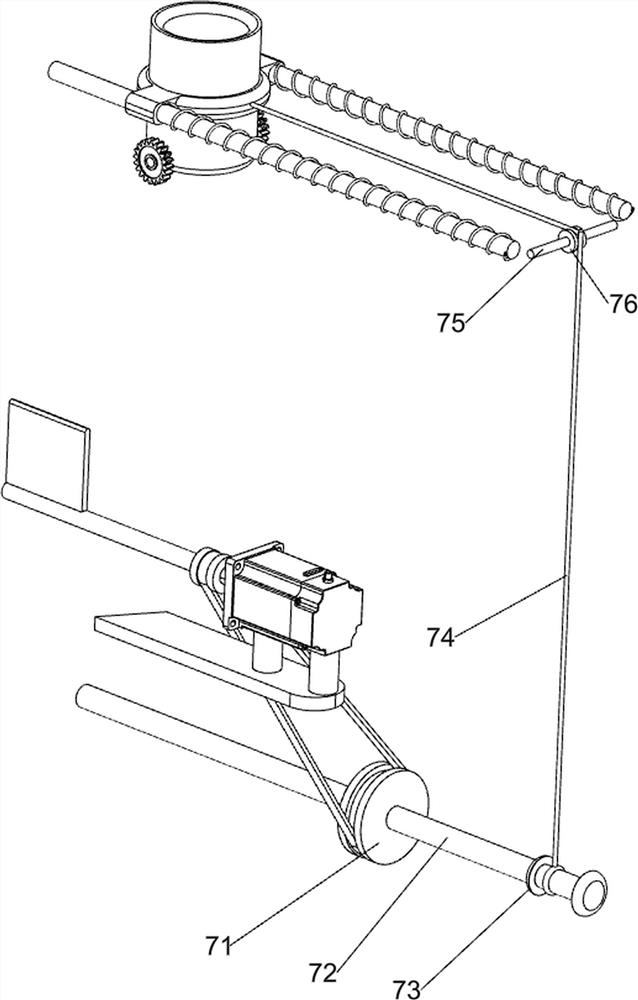

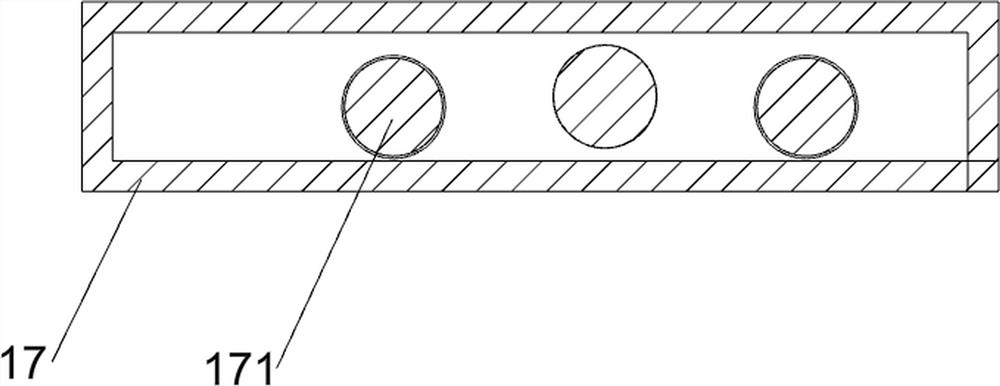

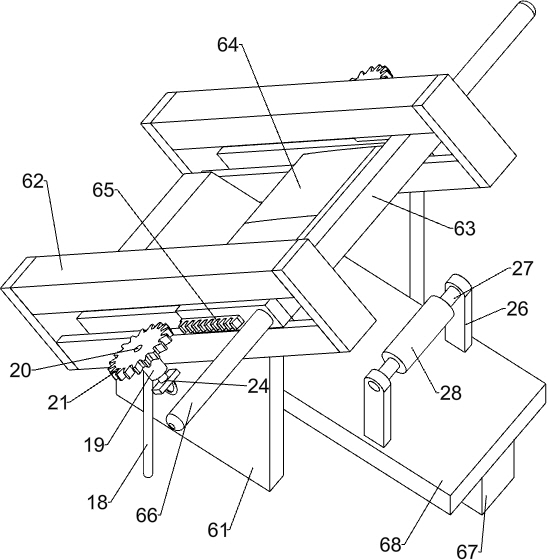

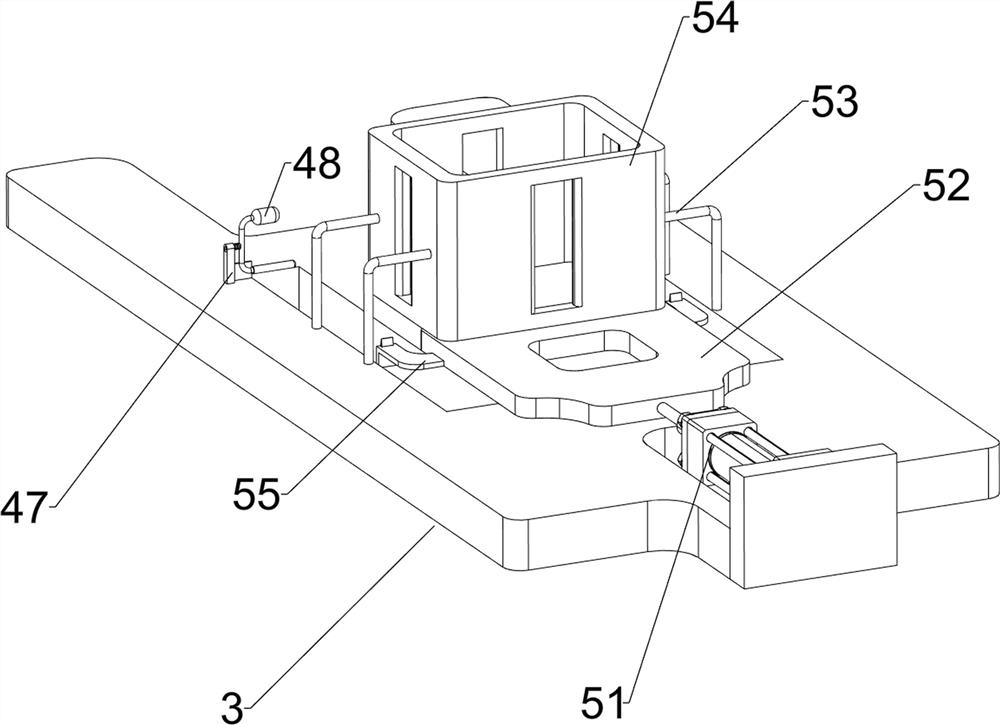

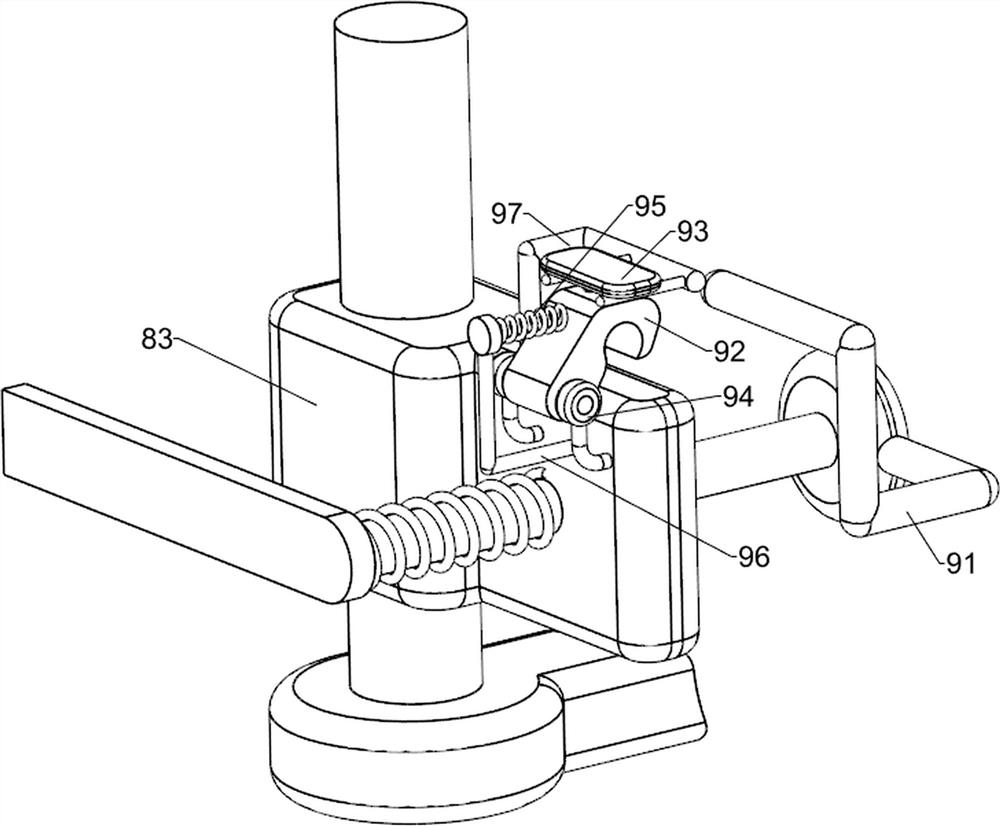

Manufacturing equipment for conical blanks of wooden building blocks

ActiveCN112388746AAchieve automatic feedingAchieve the effect of automatic feedingSievingSolid waste managementElectric machineryStructural engineering

The invention relates to manufacturing equipment, in particular to manufacturing equipment for conical blanks of wooden building blocks. The technical aims of the manufacturing equipment is that the effects of automatic feeding and automatic wood chip screening can be achieved. The manufacturing equipment for the conical blanks of the wooden building blocks comprises a base, a double-shaft motor,a speed reducer and a fixing plate; the double-shaft motor is arranged in the middle of the upper portion of the base; the speed reducer is arranged on an output shaft on one side of the double-shaftmotor; and the fixing plate is arranged in the middle of the upper portion of the base, and the fixing plate is connected with the speed reducer. The effects of automatic feeding and automatic wood chip screening are achieved; and a screening frame is driven to move front and back through front-back movement of a second fixing rod, so that wood chips in the screening frame can fall off, and manufactured conical wood sticks are reserved.

Owner:山东卓辰科技服务有限公司

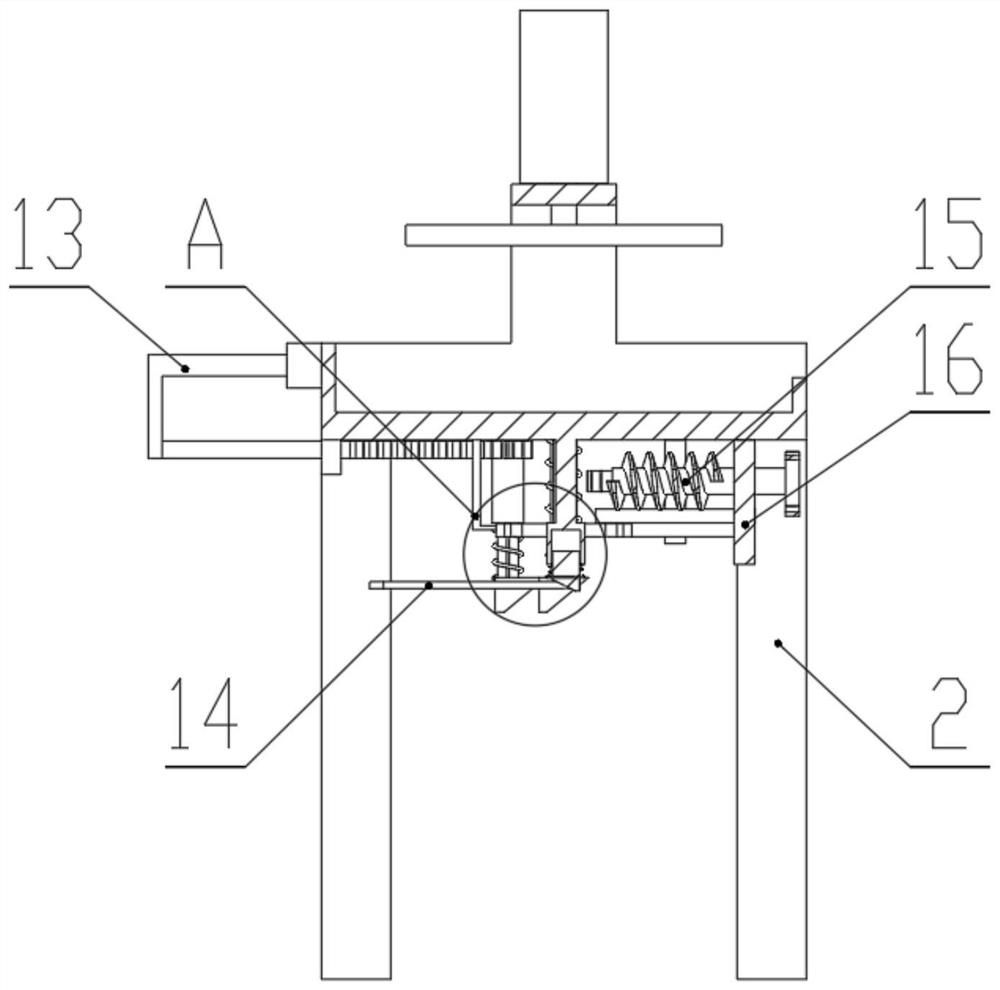

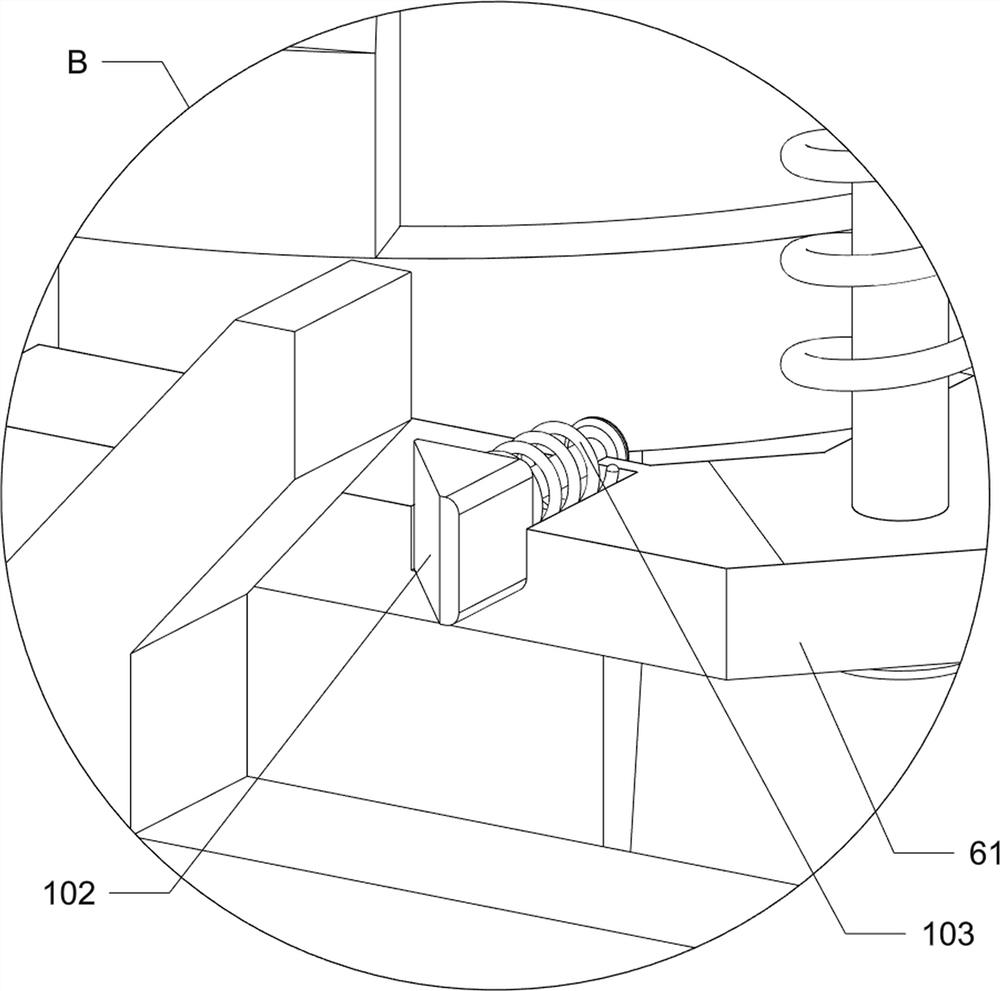

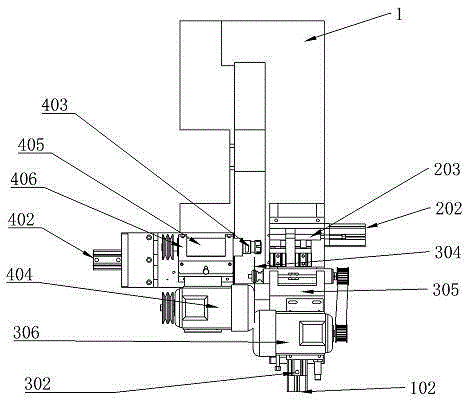

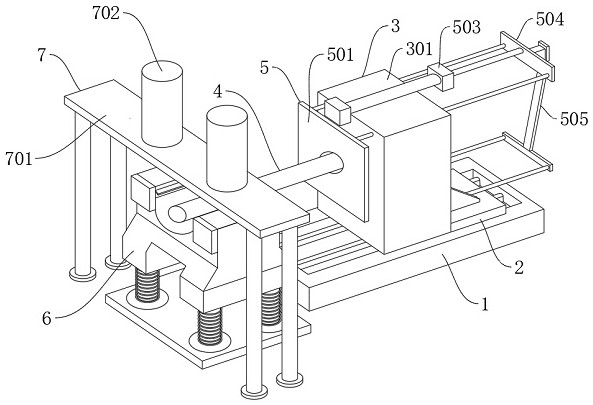

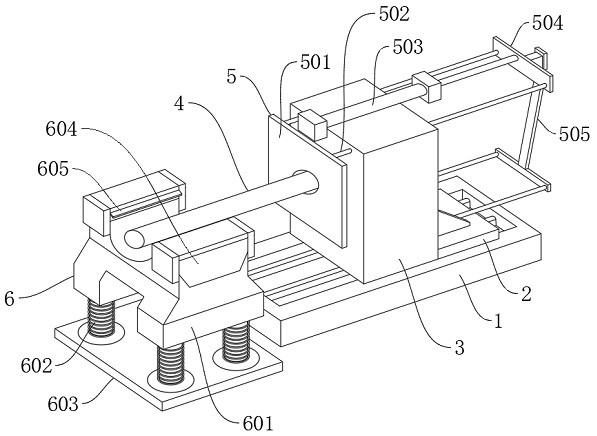

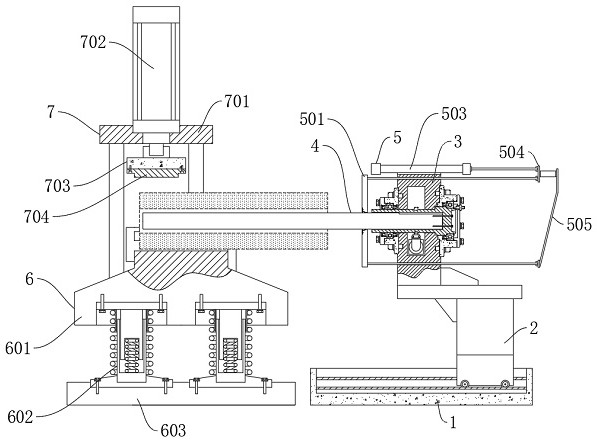

Vertical feeding device

ActiveCN104875064APrecise deliveryAchieve automatic feedingMetal working apparatusEngineeringMachining

The invention discloses a vertical feeding device, and belongs to the field of machining equipment. The vertical feeding device comprises a machine seat (1). A feeding mechanism for feeding is arranged on the machine seat (1). The feeding mechanism comprises a first drag plate (101) and a first air cylinder (102). A piston rod of the first air cylinder (102) is fixedly connected with the first drag plate (101), the first drag plate (101) is provided with a material inflow mechanism for automatically clamping raw materials and a cutting mechanism for cutting the raw materials, and a machining mechanism is arranged on one side of the feeding mechanism. The material inflow procedure, the machining procedure and the cutting procedure are automatically and synchronously conducted, production efficiency can be improved, and the placement accuracy of parts can be guaranteed.

Owner:浙江盛业科技有限公司

A device for slicing astragalus

ActiveCN111873006BAchieve automatic feedingUniform thicknessMetal working apparatusAnimal scienceMedicine

The invention relates to a slicing device, in particular to an astragalus slicing device. The technical problem to be solved is to provide an automatic feeding device for astragalus slicing with uniform slice thickness. The technical solution is: an astragalus slicing device, comprising: a base, a first support column is arranged on one side of the base; a workbench, a workbench is arranged on the first support column; Sieve; spacer, a spacer is provided on the side of the workbench away from the collection sieve; a slicing mechanism, a slicing mechanism is provided on the side of the workbench close to the collection sieve; a feeding mechanism, a feeding mechanism is provided on the workbench, and the feeding mechanism is located in the slicing mechanism between the pads. The invention achieves the effect of automatic feeding and uniform slice thickness.

Owner:岷县归芪堂药业有限公司

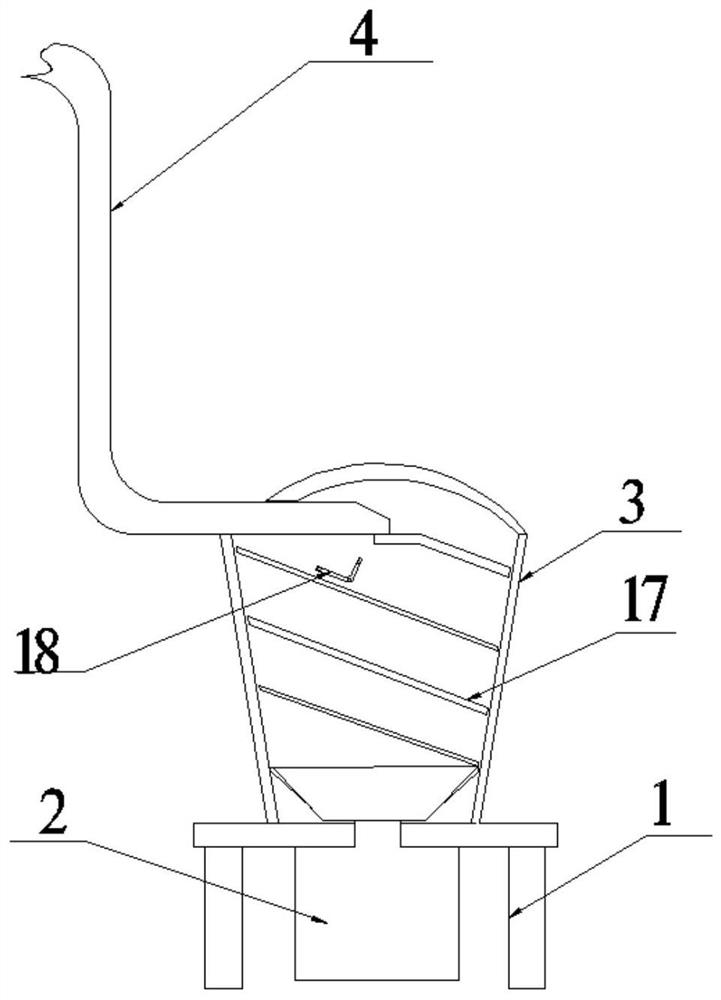

The structure of a new type of food box

InactiveCN102293163AReasonable structureSuperior feeding performanceAnimal feeding devicesEngineeringFunnel shape

A new type of food box structure, which is composed of a funnel, a baffle, a bottom bowl, and a fulcrum. The food box is composed of a funnel, a baffle, and a bottom bowl. The food box has a funnel, which is funnel-shaped. There is a rectangular feeding opening at the bottom, and the lower feeding opening of the hopper is installed vertically on the top of the bottom bowl close to the side of the bottom bowl. The mounting holes on the board are used to symmetrically install the baffle on both sides of the funnel, and a closed space with only one side open is formed between the baffle, the bottom bowl and the funnel.

Owner:李洪军

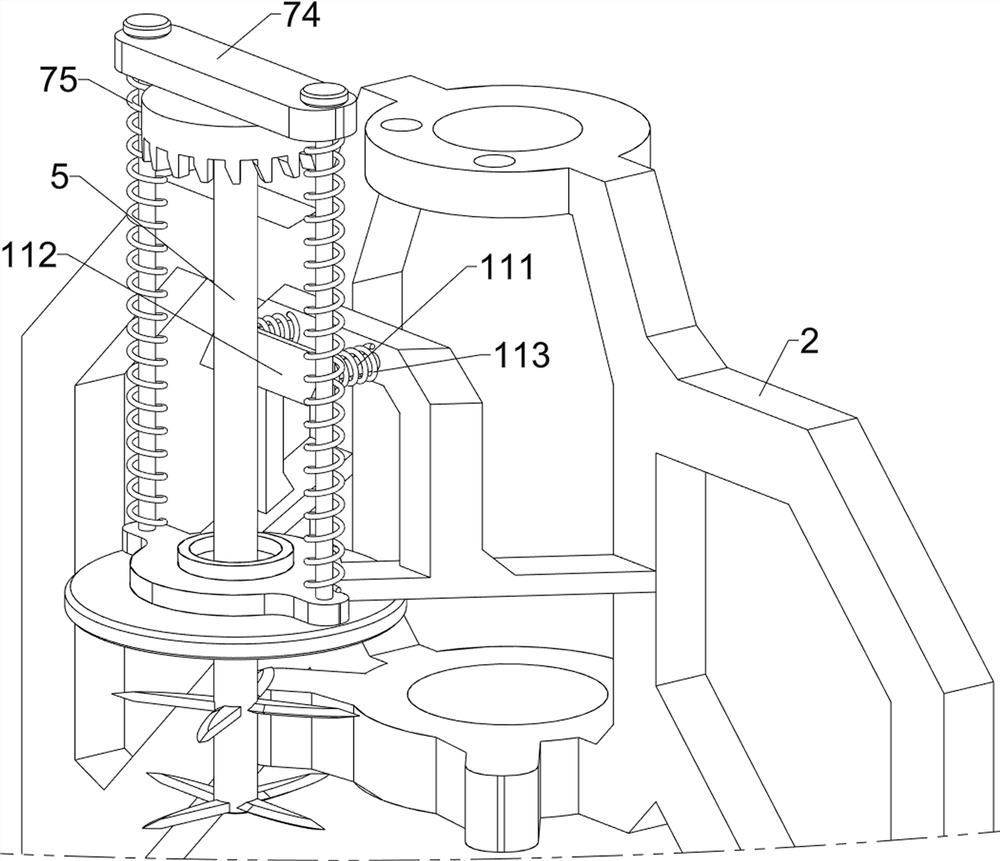

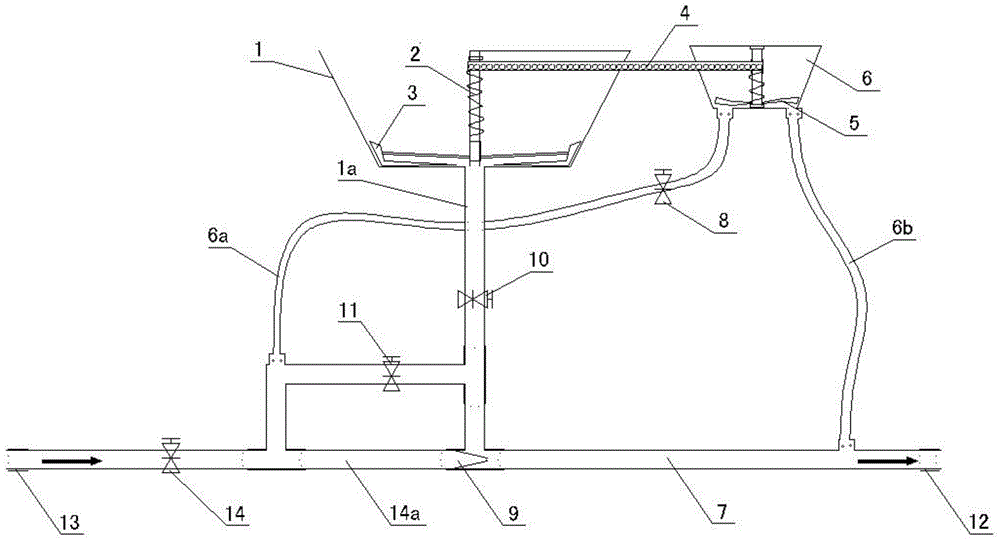

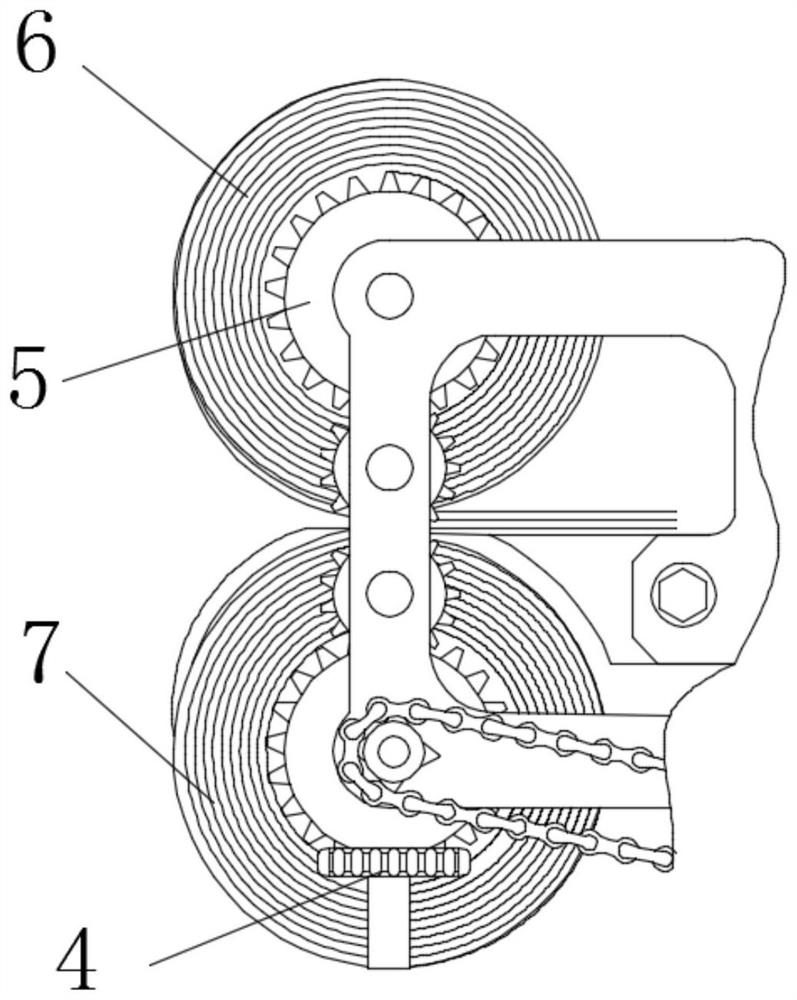

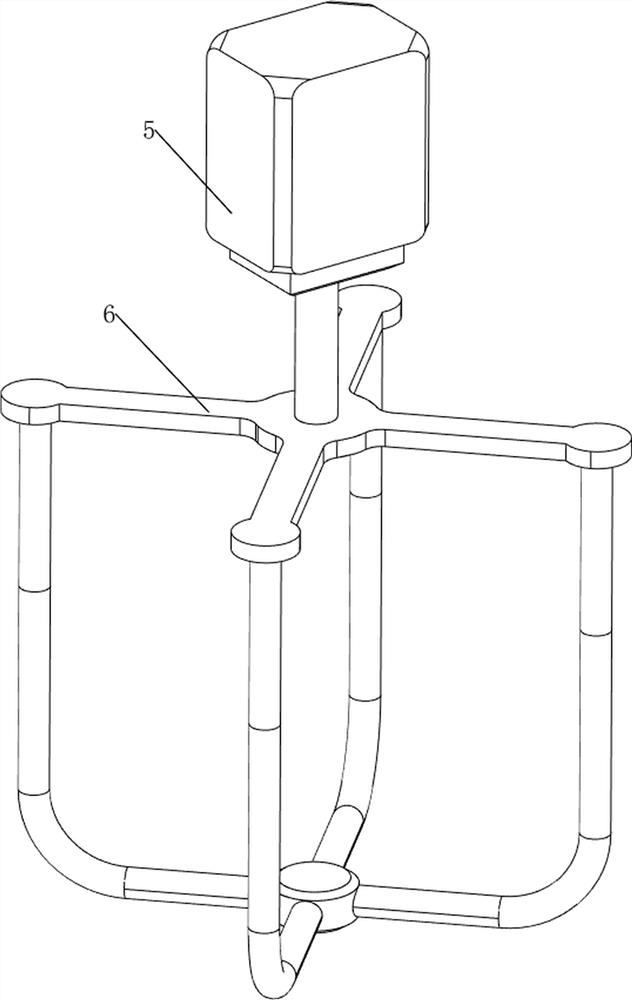

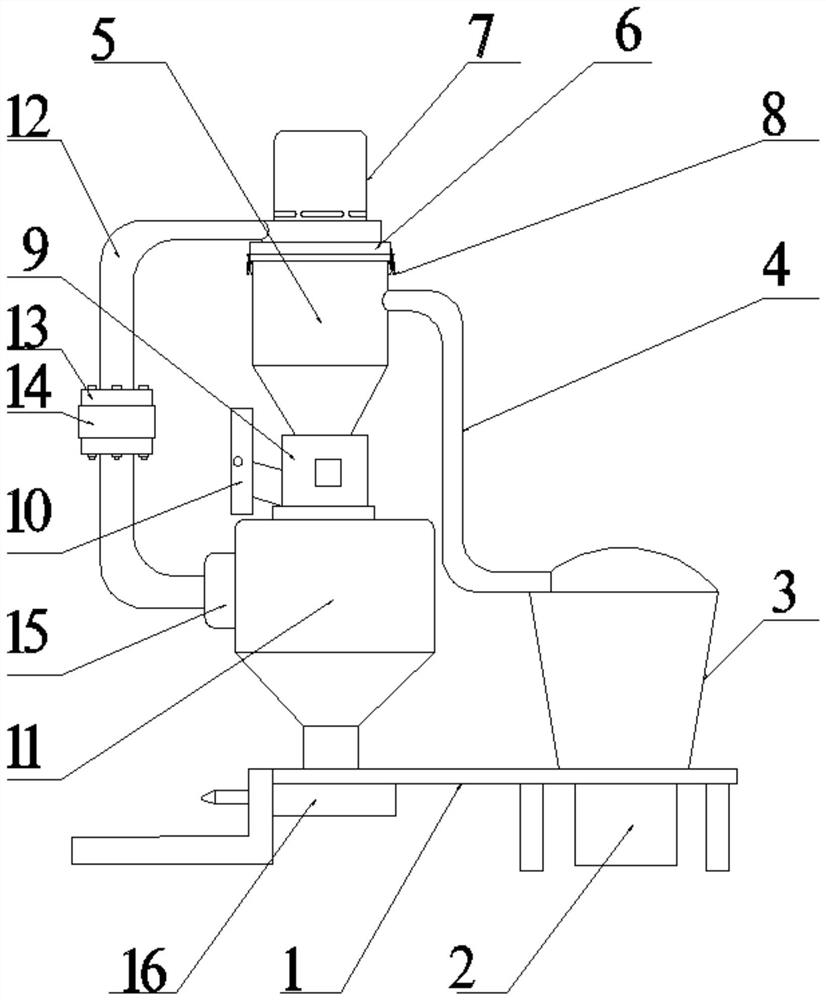

Mining multifunctional self-stirring grouting device and control method thereof

InactiveCN104373151AAchieve automatic feedingReasonable control of ingredientsDust removalFire preventionImpellerAccess port

The invention discloses a mining multifunctional self-stirring grouting device and a control method thereof. The mining multifunctional self-stirring grouting device is characterized by being provided with an ejector, wherein a nozzle side of the ejector is connected with a liquid supply main valve through a liquid supply pipe; an inlet of the liquid supply main valve is an underground high-pressure source access port; an outlet of the ejector is connected with a slurry outlet through a slurry discharge pipe; a suction inlet of the ejector is communicated with a powder outlet of a discharge box through a discharge pipe; a spiral stirring knife is vertically arranged in the discharge box; a blade stirring knife is arranged at the lower end of the spiral stirring knife; a liquid supply box is arranged; a liquid inlet in the bottom of the liquid supply box is communicated with the liquid supply pipe through a liquid inlet pipe; a liquid outlet in the bottom of the liquid supply box is communicated with the slurry discharge pipe; the liquid supply box is provided with an impeller and an impeller shaft rotating along with the impeller; a transmission chain is arranged between the impeller shaft and the spiral stirring knife; and the rotation of the spiral stirring knife is driven by the impeller through the transmission chain. The discharge quantity is controlled through the change of the liquid supply quantity, and the burdening is more uniform, so that the blockage phenomenon of viscous masses and pipelines is eliminated, and the slurry dissolution effect is effectively improved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

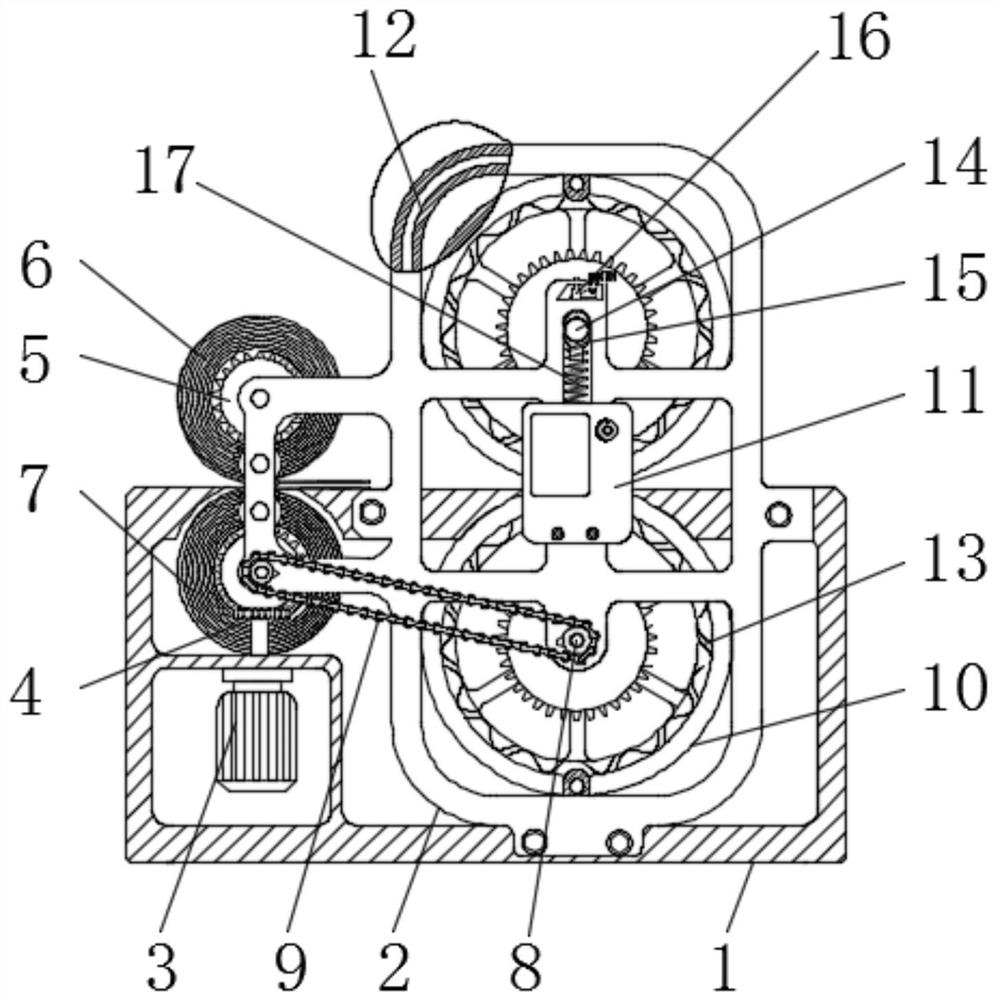

Thickness-adjustable automatic film coating mechanism for computer jet drawing

InactiveCN112123954AAchieve automatic feedingQuick filmLaminationLamination apparatusDrive wheelMotor drive

The invention relates to the technical field of computer jet drawing, and discloses a thickness-adjustable automatic film coating mechanism for computer jet drawing. The mechanism comprises a frame; afilm coating frame is fixedly connected to the front surface of the frame; a feed motor is fixedly connected to the interior of the frame; a driving wheel is rotatably connected to the top of the feed motor; synchronous wheel assemblies are rotatably connected to the left side of the film coating frame; an upper valve roller and a lower valve roller are rotatably connected between the synchronouswheel assemblies; a transmission chain wheel is fixedly connected to the front surface of each synchronous wheel assembly; and a transmission chain is in transmission connection to the outer side ofeach transmission chain wheel. According to the thickness-adjustable automatic film coating mechanism for computer jet drawing, the feed motor drives the driving wheel to rotate, the driving wheel drives the synchronous wheel assemblies to rotate, the synchronous wheel assemblies drive the upper valve roller and the lower valve roller to rotate in opposite directions, and then, the frame and othermechanisms are used in cooperation, so that the effects of automatic feeding and rapid film closing are achieved.

Owner:广州市美色喷画设计有限公司

Full automatic stirring machine

InactiveCN104647608AAvoid flyingQuality assuranceMixing operation control apparatusMixing operation plantEngineeringAutomation

The invention discloses a full automatic stirring machine which includes a material feeding mechanism, a conveying mechanism, a burdening mechanism and a stirring mechanism. The material feeding mechanism is connected to one end of the conveying mechanism. The other end of the conveying mechanism is connected to one end of the burdening mechanism. The other end of the burdening mechanism is connected to the stirring mechanism. By means of an S-shaped material feeding conveyor belt in the material feeding mechanism and a horizontal conveyor belt, automation of material feeding is achieved. By means of a baffle of a material bin and a plurality of stirring pipelines for stirring a raw material, the raw material is prevented from being flown-off during a stirring process. The full automatic stirring machine can achieve objects of carrying out automatic material feeding, ensuring environment quality, reducing production cost, improving production efficiency and ensuring body health of workers.

Owner:胥传祥

Conveying device of punching machine

ActiveCN109675959AReduce intensityAchieve automatic feedingMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention relates to a conveying device of a punching machine. The conveying device comprises a rack; the rack is rotationally connected with an unwinding roller which is to be connected with a gold plate reel in a sleeving manner; the unwinding roller is detachably connected relative to the rack; the rack is further provided with a driving mechanism and a flattening mechanism, wherein the driving mechanism is used for driving the unwinding roller to rotate spontaneously; and the flattening mechanism is positioned between the unwinding roller and the punching machine and is used for flattening the gold plate reel. The conveying device provided by the invention achieves the effects of realizing automatic conveying and saving labor.

Owner:杭州航民百泰首饰有限公司

Gas-switching ironmaking device

PendingCN112760440AAchieve automatic feedingTake advantage ofFluidised-bed furnacesCombustionThermal insulation

The invention relates to an ironmaking device, in particular to a gas-switching ironmaking device. The technical problem of the invention is to provide the gas-switching ironmaking device which can automatically switch gas to complete ironmaking, fully utilize discharged heat and autonomously control and maintain the opening of a closing door and a material blocking plate. The gas-switching ironmaking device comprises a base, a furnace body, a thermal insulation plate, a filter plate, a feeding mechanism and a combustion mechanism, and a feeding box is connected to the middle of one side of the upper portion of the base. The middle of one side of the upper part of the base is connected with the furnace body. The thermal insulation plate is connected in the furnace body. The filter plate is connected to the lower side in the furnace body and located on the lower side of the thermal insulation plate. The feeding mechanism is arranged in the feeding box. The combustion mechanism is arranged in the thermal insulation plate. A second motor is started to drive fan blades to rotate, hot gas in the furnace body is sucked in through a gas suction cover and conveyed to the raw material position of the feeding box through a conveying pipe, the effect of preheating raw materials is achieved, heat is more sufficiently utilized, and environment protection and energy conservation are achieved.

Owner:卢长丽

High-strength wear-resistant hydraulic oil cylinder block forging device and forging method thereof

InactiveCN113084062ARealize the collectionRealize automatic unloadingPower hammersCleaning using toolsGear wheelCylinder block

The invention relates to the technical field of post-machining equipment, in particular to a high-strength wear-resistant hydraulic oil cylinder block forging device and a forging method thereof. The high-strength wear-resistant hydraulic oil cylinder block forging device comprises a device base, a supporting plate is arranged at the top end of the device base, a rotating assembly is arranged at the top end of the supporting plate and comprises a shell, a connecting sleeve is arranged inside the shell in a sleeve mode, a limiting block is arranged at the right end of the connecting sleeve, the outer surface of the shell is sleeved with a bearing ring, the outer surface of the bearing ring is sleeved with a bearing sleeve, a first air cylinder is arranged at the position, close to the lower portion of the connecting sleeve, inside the shell, a transmission rod is arranged at the output top end of the first air cylinder, a gear ring is arranged on the outer surface of the connecting sleeve, and a guide rail is fixed to the inner wall of the shell. According to the high-strength wear-resistant hydraulic oil cylinder block forging device and the forging method thereof, forging is more uniform, a cylinder block finished product is high in strength and resistant to abrasion, the finished product is not prone to abrasion during discharging, meanwhile, a scrap collecting mechanism is arranged, and environmental pollution and resource waste are avoided.

Owner:南京金满园机械制造科技有限公司

Medicine dispensing and stirring device for oncology department

ActiveCN114259915AAchieve automatic feedingAutomatic cuttingRotary stirring mixersTransportation and packagingPharmacy medicineElectric machinery

The invention relates to a stirring device, in particular to a medicine dispensing and stirring device for the oncology department. According to the medicine dispensing and stirring device for the oncology department, automatic discharging can be achieved, and medicine can be automatically stirred. A medicine dispensing and stirring device for the oncology department comprises a supporting plate, a first supporting frame, a first fixing frame, a second supporting frame, a motor and a stirring rod, the first supporting frame is arranged on one side of the top of the supporting plate, the first fixing frame is arranged on the first supporting frame, the second supporting frame is arranged on the top of the first fixing frame, and the motor is arranged on the second supporting frame; a stirring rod is rotationally arranged in the first fixing frame, and the stirring rod is connected with an output shaft of the motor through a coupler. The effects of automatic discharging and automatic stirring of the medicine are achieved; and the output shaft of the motor rotates, so that the stirring rod rotates, and the effect of automatically stirring the medicine can be achieved.

Owner:南京善若网络科技有限公司

Traditional Chinese medicine pill forming equipment

PendingCN112891210ASimple and efficient operationAchieve automationPharmaceutical product form changeEngineeringTraditional medicine

The invention relates to forming equipment, in particular to traditional Chinese medicine pill forming equipment. The technical aim of the invention is to provide the traditional Chinese medicine pill forming equipment which is high in automation degree, rapid in forming and uniform in pill forming. The traditional Chinese medicine pill forming equipment comprises a base, a pressing assembly and a pill rolling assembly, wherein the pressing assembly is arranged in the middle of the base; and the pill rolling assembly is arranged in the middle of the pressing assembly. According to the invention, medicine strips are placed on the pressing assembly, a pressing plate moves downwards to be attached to a placing plate, the medicine strips are pressed into blocks, the pressing assembly is started, the medicine strips are made into pills through processing of the pill rolling assembly, the pills fall onto a discharging plate when being scraped off by a second baffle from back to front, and the second baffle helps to prevent the pills from rolling down to prevent waste; and therefore, the effects of simple operation and high efficiency are achieved.

Owner:皮海燕

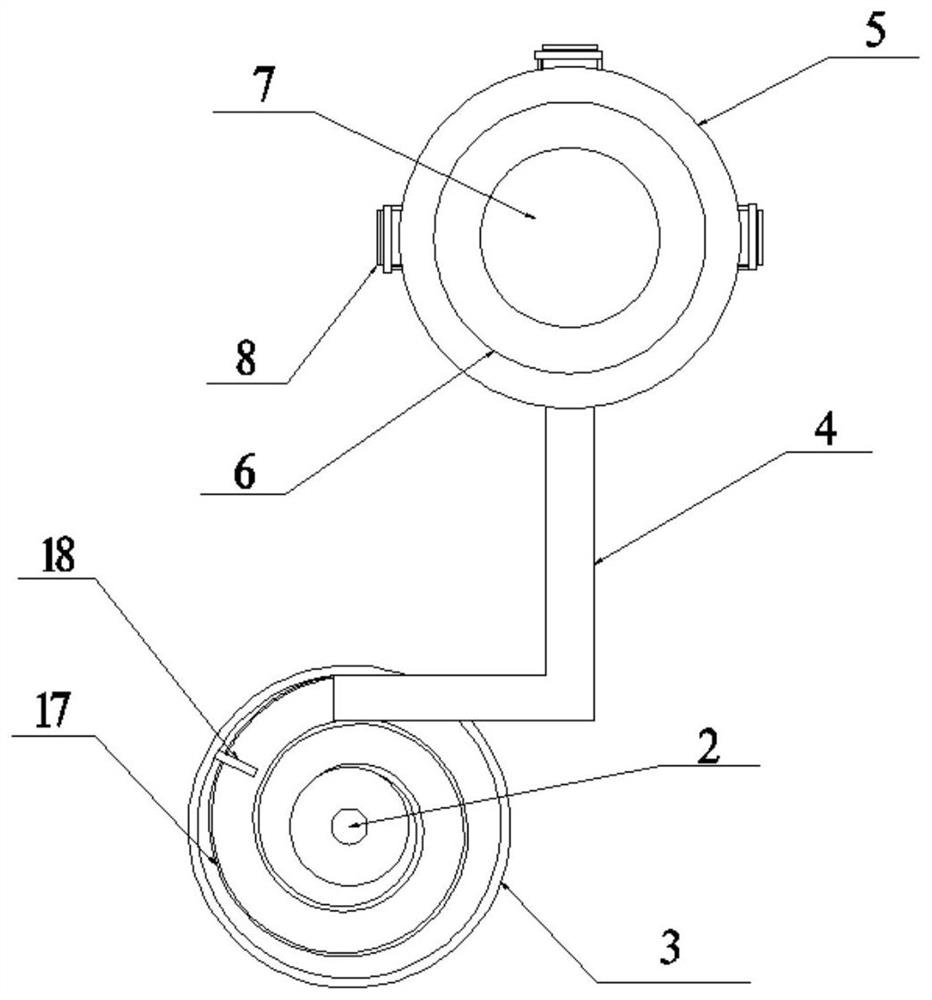

An innovative mechanism of automatic suction machine for environmental protection LED lamp plastic granule raw materials

ActiveCN111688061BAchieve automatic feedingLow powerDispersed particle filtrationTransportation and packagingAir filterAir pump

The invention relates to the technical field of granule drying, and discloses an innovative mechanism of an automatic suction machine for plastic granule raw materials of environment-friendly LED lamps, including a frame. The innovative mechanism of the environmental-friendly LED lamp plastic granule raw material automatic suction machine drives the feeding plate to rotate through the motor, and the feeding plate drives the granule material to rotate and climb. When the granule material reaches the position of the stop block, it contacts with it and exceeds the stop block. The granular material at the bottom is blocked and falls back into the feeding cylinder, and the remaining granular material is transported to the suction pipe, which absorbs the granular material. This action continues to move, so as to achieve automatic feeding, reduce power, and reduce noise. , the air is driven by the air pump to be discharged from the exhaust pipe, the powerful air is purified by the action of the air filter element, and continues to move forward, passing through the heat source, the air is heated, drives the wind wheel to rotate, the wind wheel drives the cam to rotate, the cam drives the filter plate to vibrate, and then passes through The buffer spring and other mechanisms are used together to achieve the effect of wind cycle utilization and fast drying speed.

Owner:海宁市天翼龙电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com