Vertical feeding device

A feeding device and vertical technology, applied in the field of vertical feeding devices, can solve the problems of inability to process raw materials and automatically feed them, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

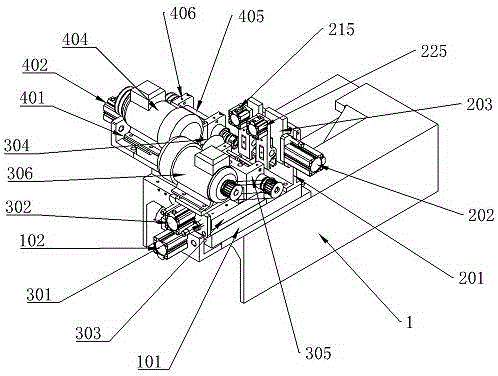

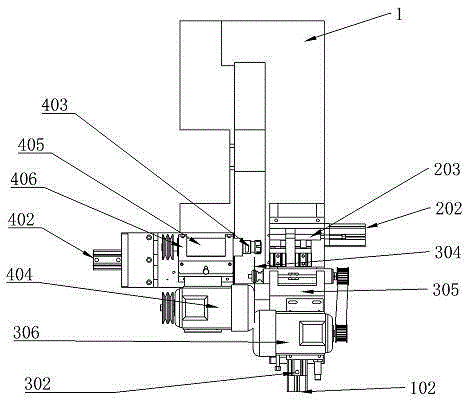

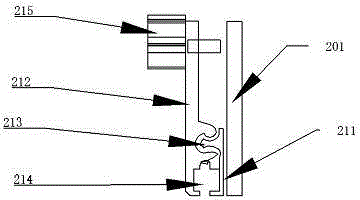

[0017] Such as Figure 1 to Figure 4 As shown, the vertical feeding device of the present invention includes a support 1, on which a feeding mechanism for feeding is arranged, and the feeding mechanism can deliver raw materials to the jaws of the clamps to be processed, The feeding mechanism includes a carriage one 101 and a cylinder one 102, the piston rod of the cylinder one 102 is fixedly connected with the carriage one 101, and the movement of the piston rod of the cylinder one 102 can drive the carriage one 101 to move back and forth to achieve continuous The purpose of feeding: the feeding mechanism for automatically pinching raw materials and the cutting mechanism for cutting raw materials are set on the carriage-101. cutting. As a further improvement measure of the present invention, a processing mechanism is set on one side of the feeding mechanism. According to the positional relationship between the vertical feeding device and the clamp, the processing mechanism ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com