Patents

Literature

91results about How to "Reach fixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

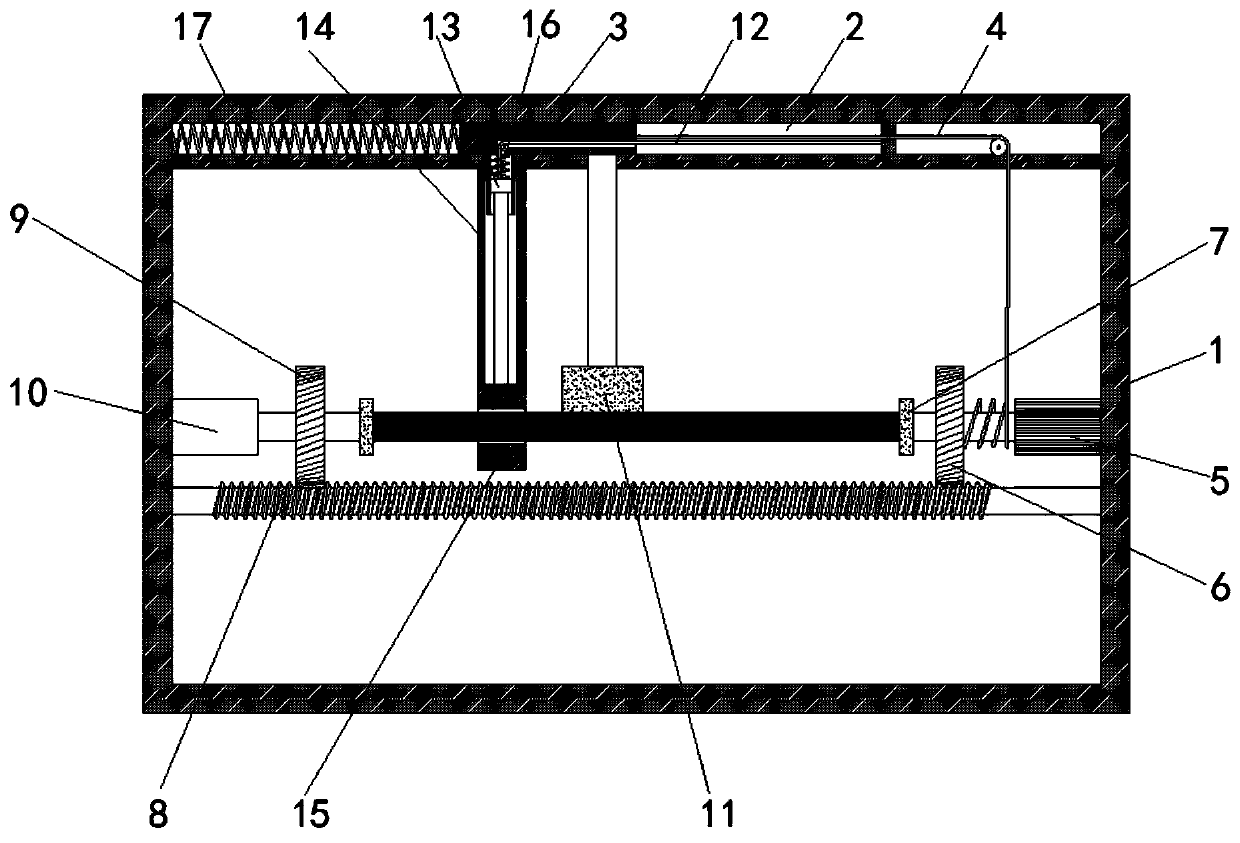

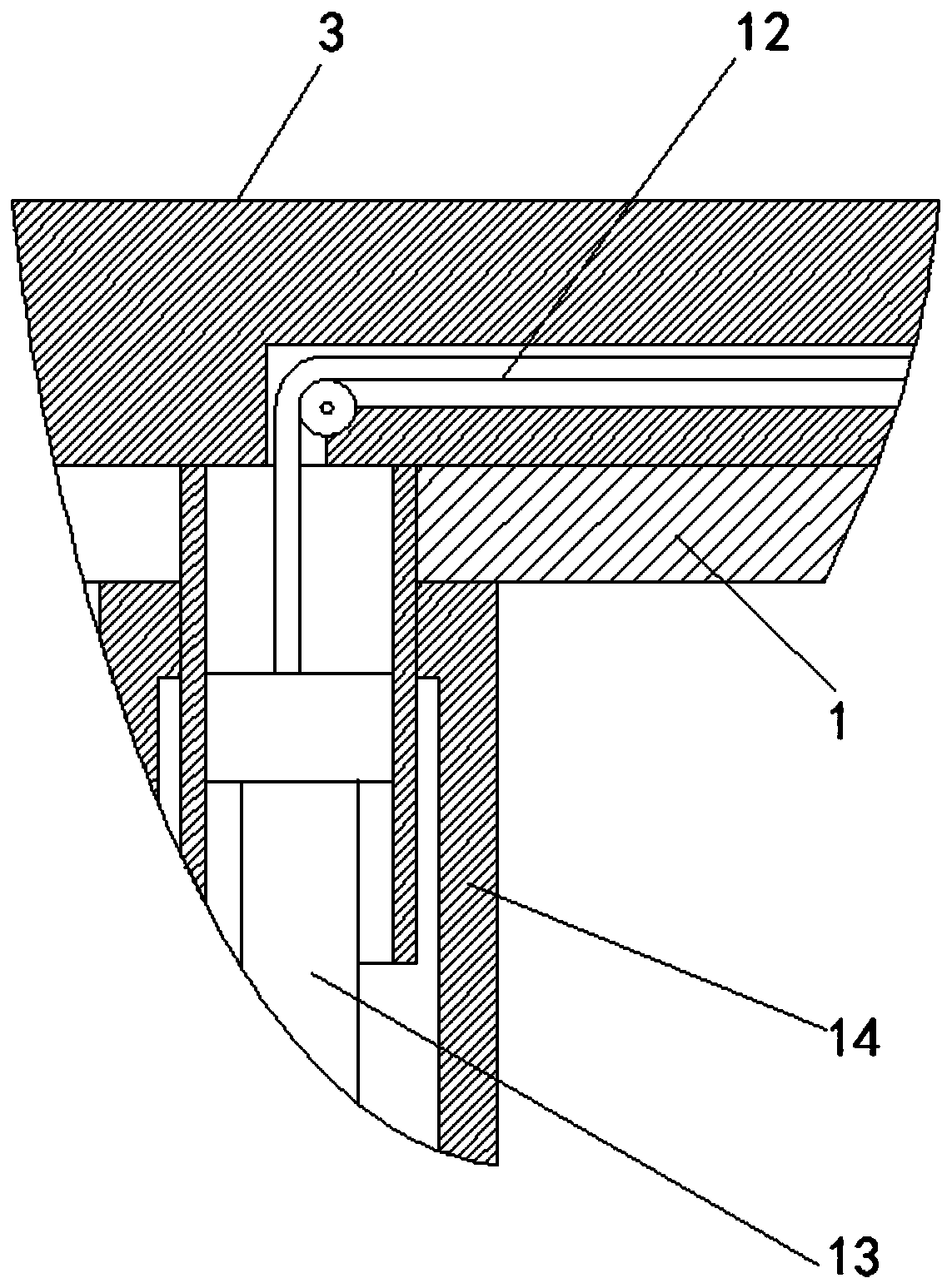

Surgical instrument placement box

InactiveCN108553174AReduce vibrationExtended service lifeSurgical furnitureSurgical instrumentArchitectural engineering

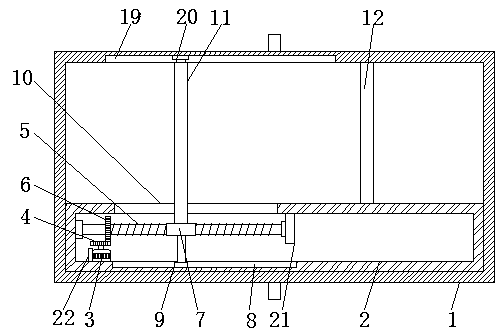

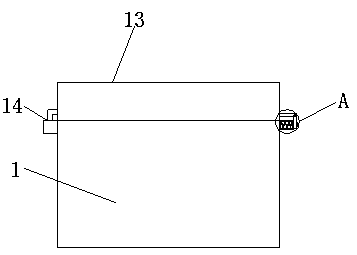

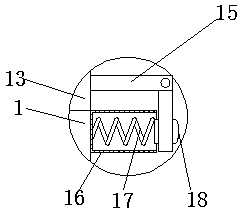

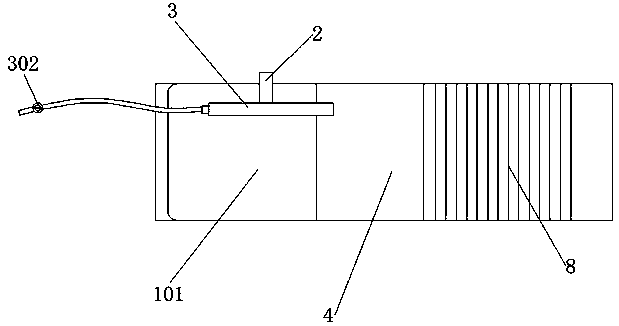

The invention discloses a surgical instrument placement box. The placement boxcomprises a box body, the bottom of the inner cavity of the box body is fixedly connected with a tank body,a motor is fixedly connected with the left side of the bottom of the innercavity of the tank body, a first gear is fixedly connected with the output end of the motor, the top of the left side of the inner cavity ofthe tank box is movably connected with a threaded rod through a bearing, and the surface of the left side of the threaded rod is sleeved with a second gear. According to the placement box, the effectof driving the threaded rod to rotate is achievedthrough the arrangement of the first gear and the second gear, the effect of driving a threaded sleeve to move left and right is achieved through the arrangement of the threaded rod, the effect of balancing and supporting when the threaded sleeve movesleft and right is achieved through the arrangement of a first sliding groove and a first sliding block, the effects of opening and closing the box body and preventing dust from falling tomedical instrumentsin the inner cavity of the boxbody are achieved through the arrangement of a box cover, and the effect of closing and locking the boxbody and thebox cover is achieved through the arrangement of a lock catch,a locking block, a spring and a telescopic block.

Owner:王永琴

Municipal road manhole with protection device

InactiveCN110725337APlay a buffer roleEasy to replaceArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

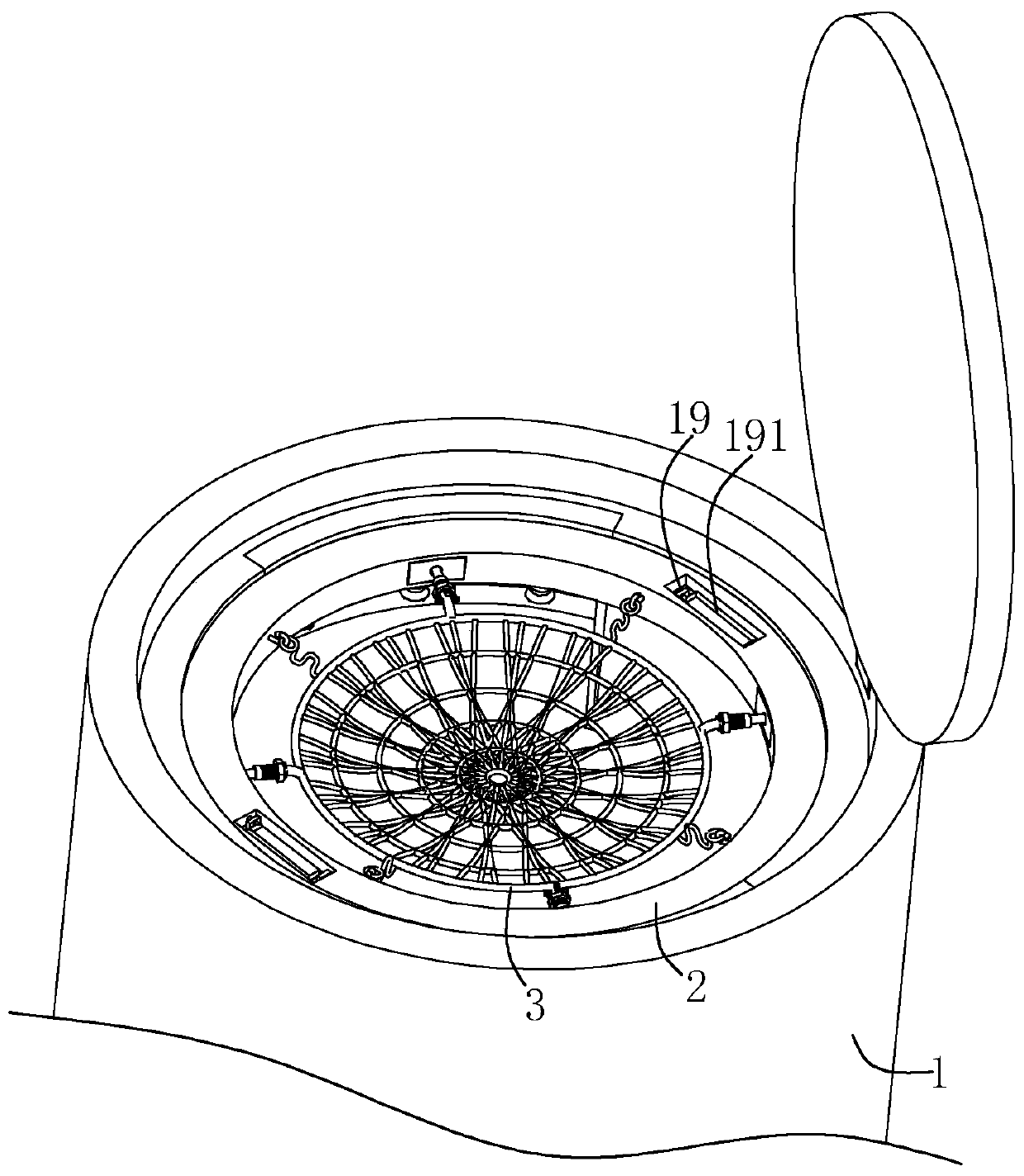

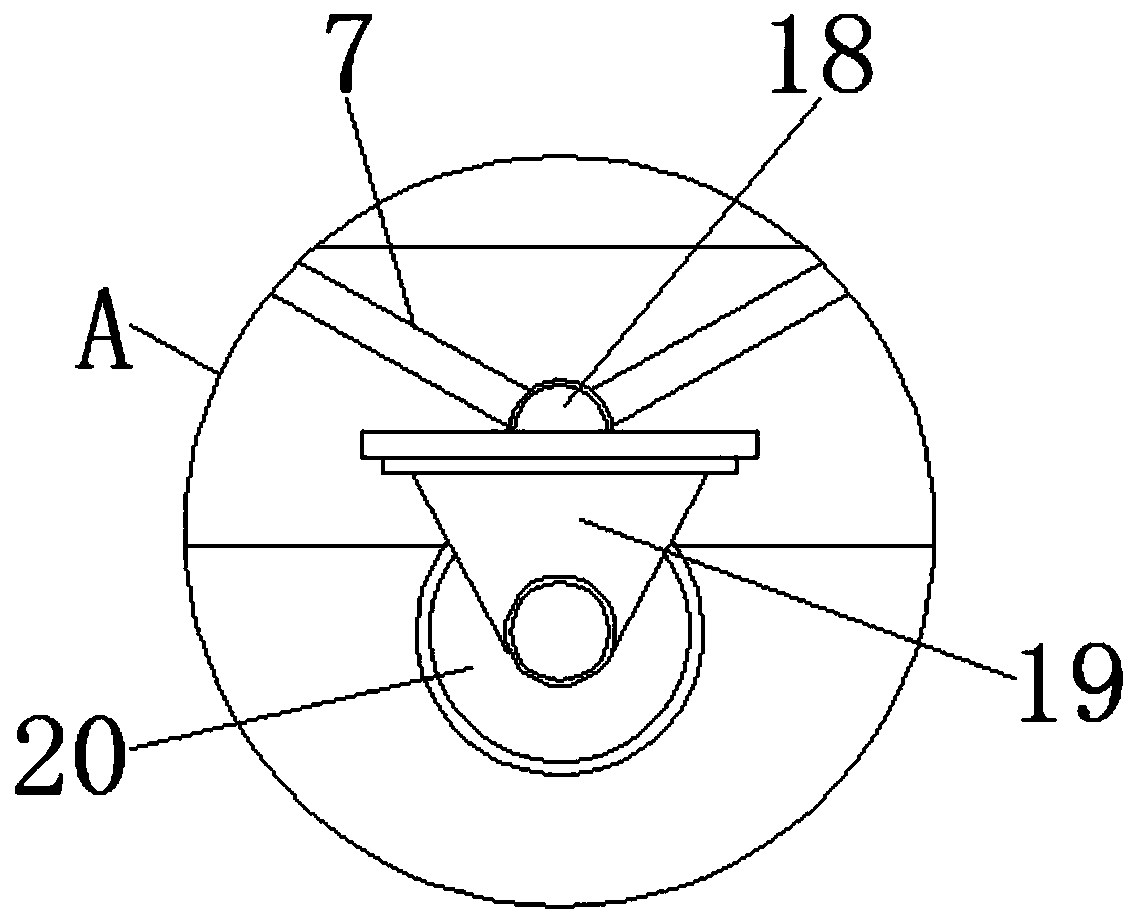

The invention relates to a municipal road manhole with a protection device. The municipal road manhole comprises a manhole body. The protection device is arranged at the position, close to a manhole mouth, of the manhole body. The protection device comprises an installation ring, an anti-falling net and buffer assemblies. The anti-falling net is arranged on the inner ring of the installation ring.The buffer assemblies are used for connecting the anti-falling net to the installation ring. Multiple installation grooves where the buffer assemblies are installed are formed in the inner ring of the installation ring in the circumferential direction. Each buffer assembly comprises a sliding block, a pull rope, a limiting ring and a first elastic piece. Each sliding block is installed in the corresponding installation groove in a sliding manner. One end of each pull rope is fixed to the corresponding sliding block, and the other end of each pull rope extends out of the corresponding installation groove. Each limiting ring is connected to a groove opening of the corresponding installation groove in a sleeving manner. Each first elastic piece is connected to the corresponding pull rope ina sleeving manner. One end of each first elastic piece is connected and fixed to the corresponding sliding block, and the other end of each first elastic piece is fixed to the corresponding limiting ring. Connection ropes corresponding to the pull ropes are arranged at the edge position of the anti-falling net. The connection ropes and the pull ropes are detachably connected through connection assemblies. The installation ring is detachably installed on the manhole body through an installation assembly. The municipal road manhole has the effect that the anti-falling net is not likely to fracture.

Owner:惠州市第一建筑工程有限公司

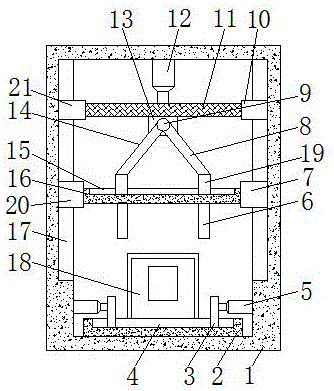

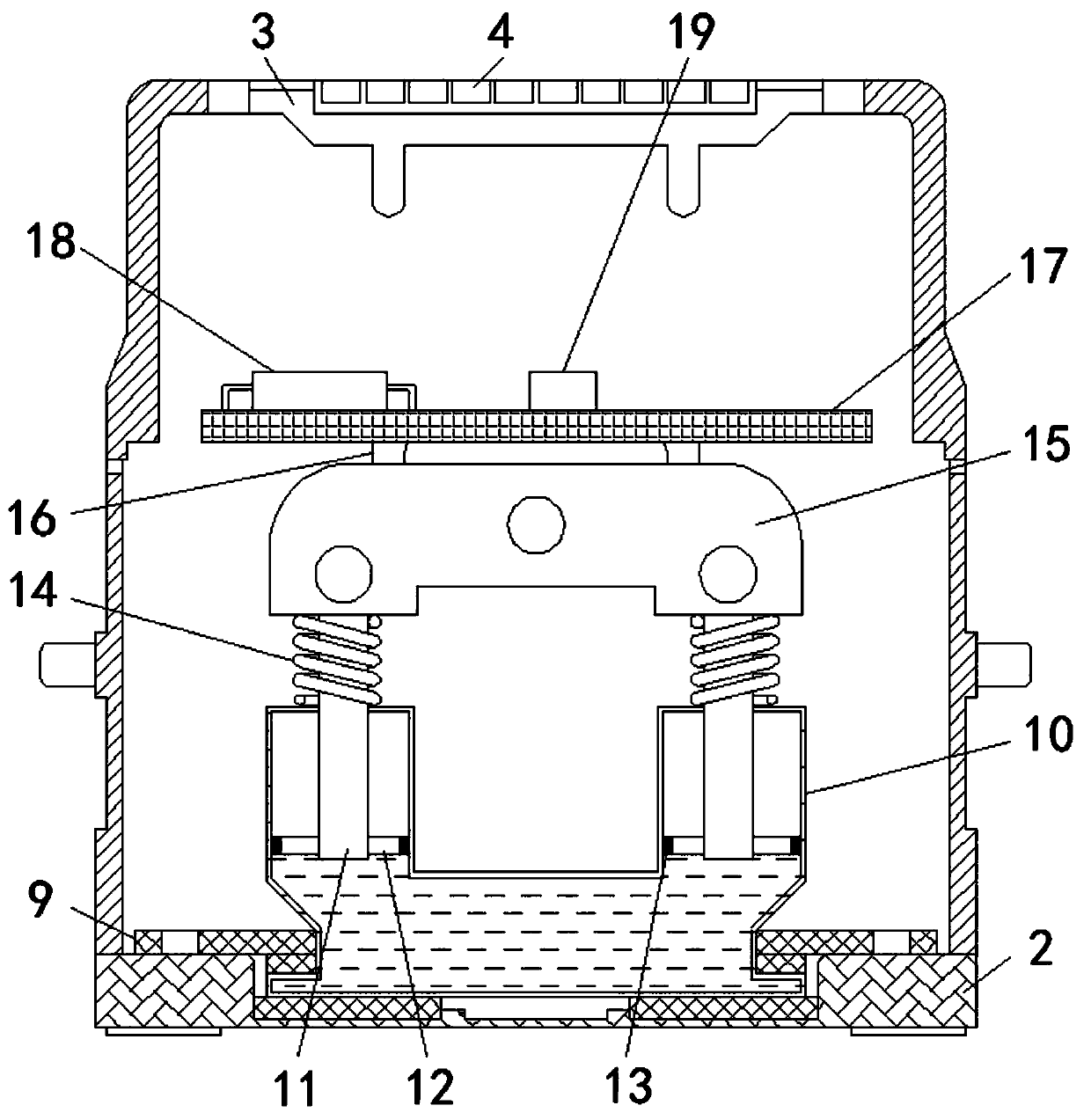

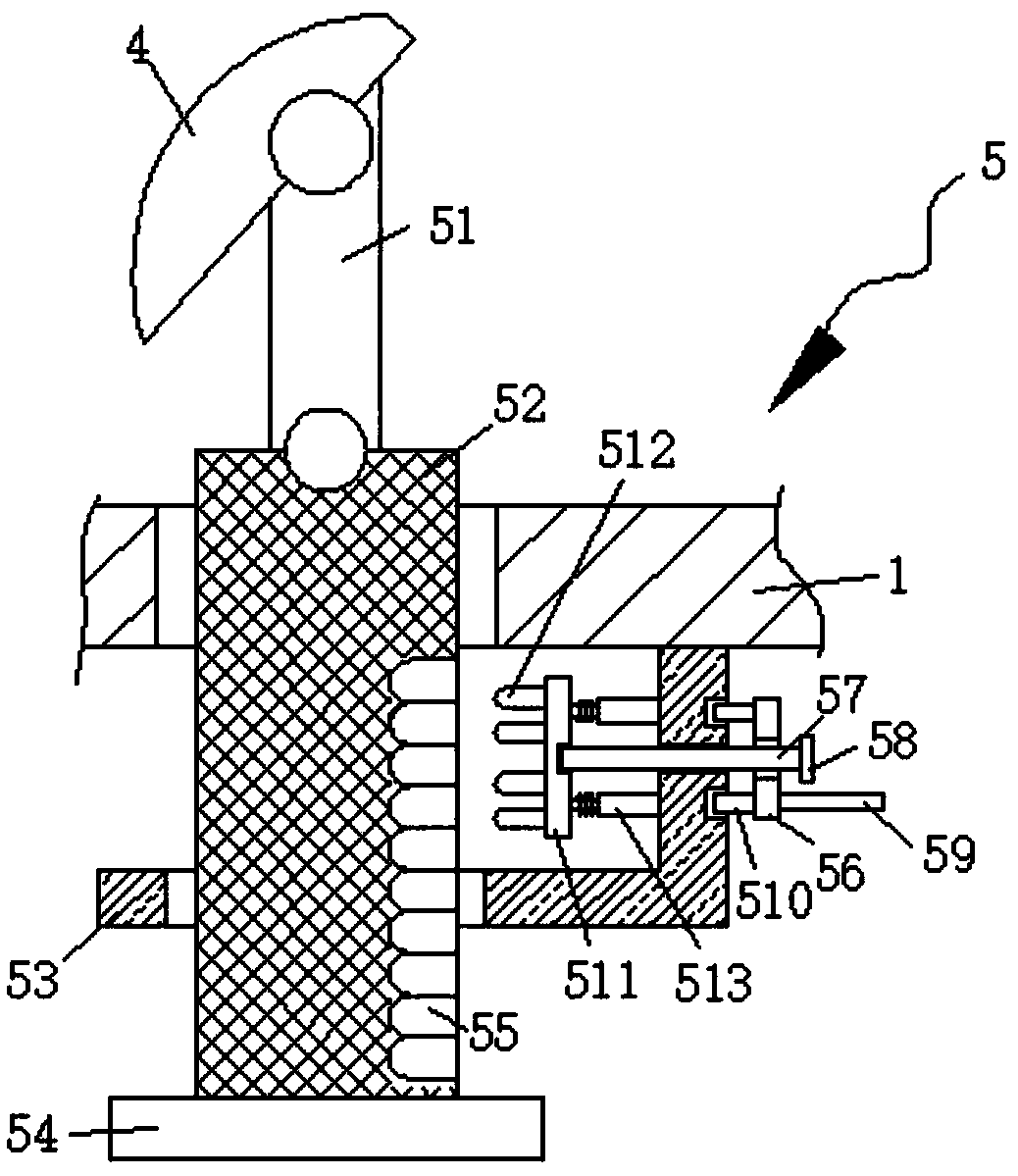

Watt hour meter with fixing function

PendingCN106291020ATo achieve the effect of left and right clamping and fixingTo achieve the effect of clamping and fixing up and downTime integral measurementFixed-functionEngineering

The invention discloses a watt hour meter with a fixing function. The watt hour meter with the fixing function comprises a box. The bottom of an inner cavity of the box is fixedly connected with a base. A watt hour meter body is arranged on the upper surface of the base. The bottom of one side face of the inner wall of the box is fixedly connected with a first electric telescopic rod. One end of the first electric telescopic rod is fixedly connected with a sliding rod. The bottom end of the sliding rod is connected to the interior of a first sliding groove formed in the upper surface of the base in a sliding mode. The top of the inner cavity of the box is fixedly connected with a second electric telescopic rod. Through the arrangement of the second electric telescopic rod, a supporting rod, a fixing block, a hinge pin, a first connecting rod, a second connecting rod, a squeezing board and clamping blocks, the effect of clamping and fixing the watt hour meter body in the vertical direction is achieved, so that the watt hour meter body is fixed in all directions, better fixation of the watt hour meter body is achieved, the problem that as a watt hour meter body cannot be fixed, the watt hour meter body tilts or shakes is solved, and the watt hour meter body is prevented from being damaged.

Owner:无锡市海升电子科技有限公司

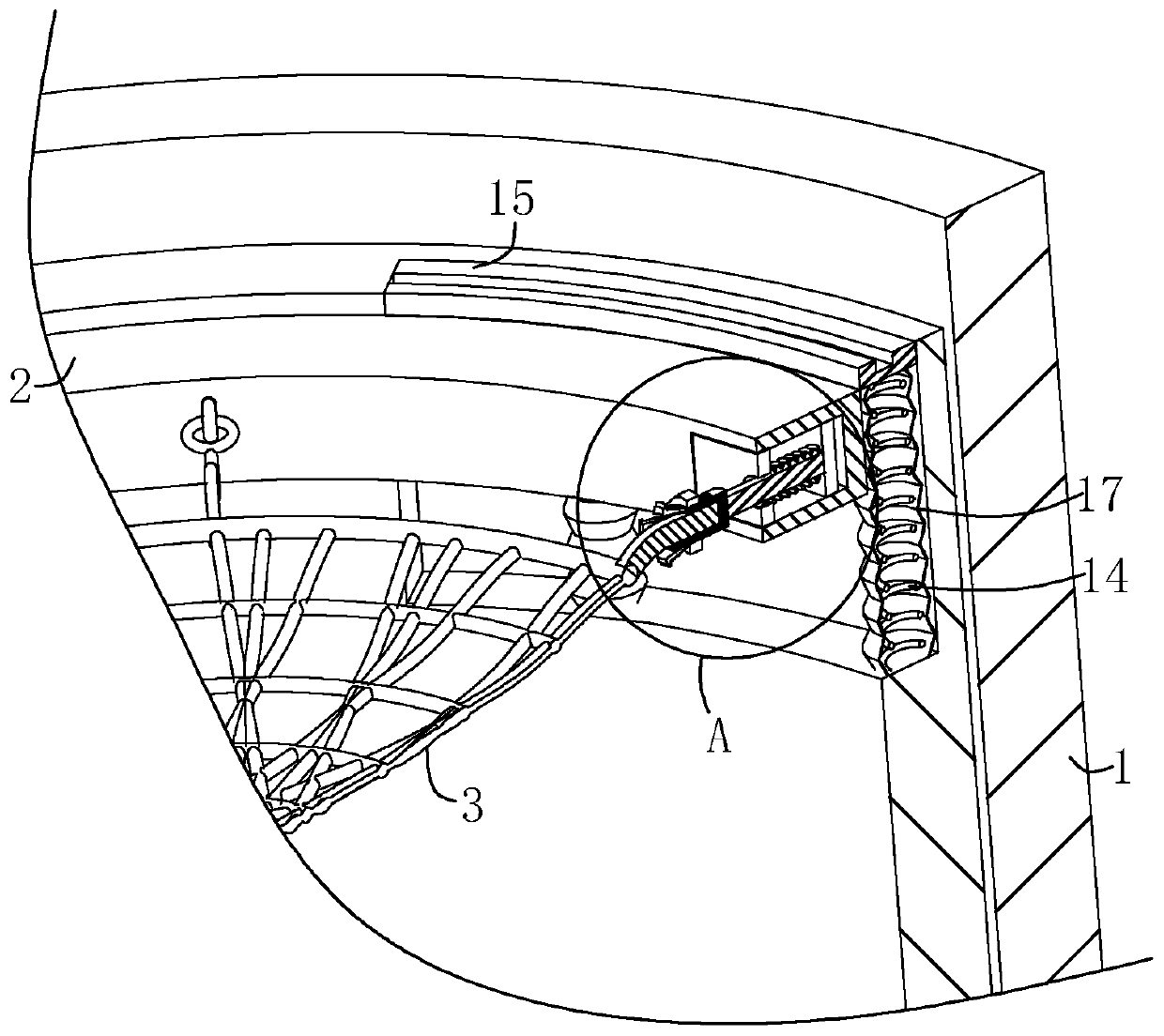

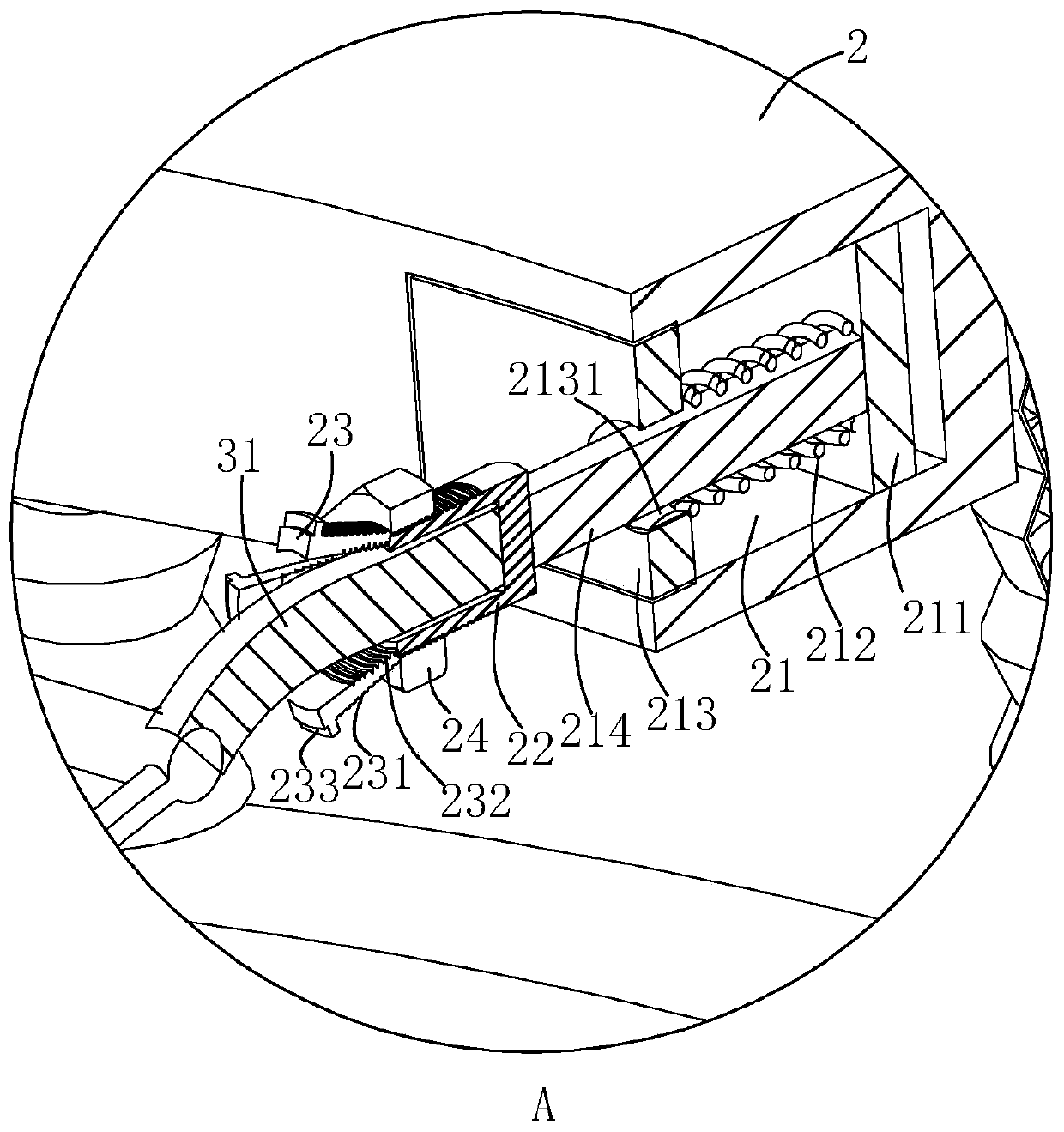

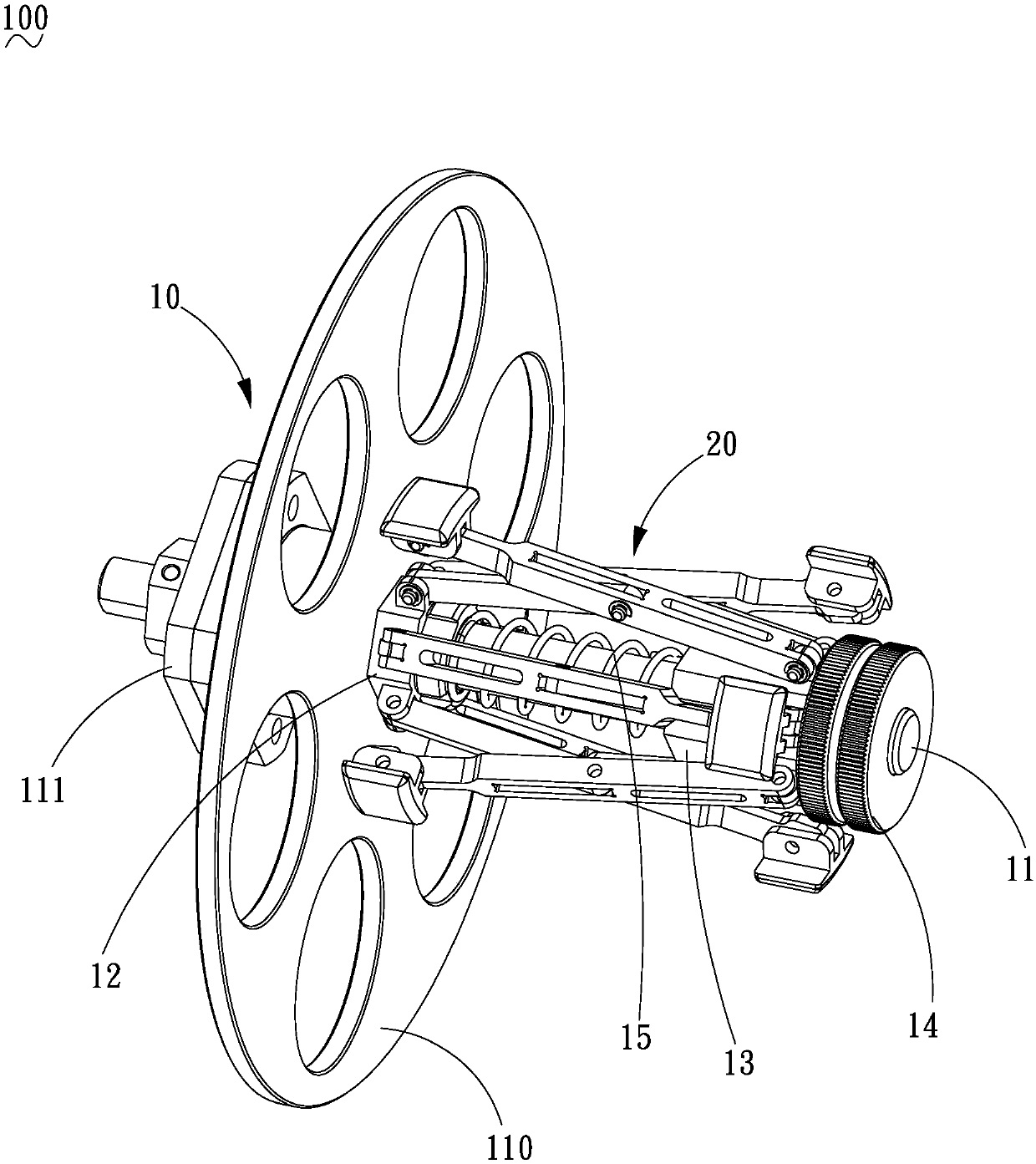

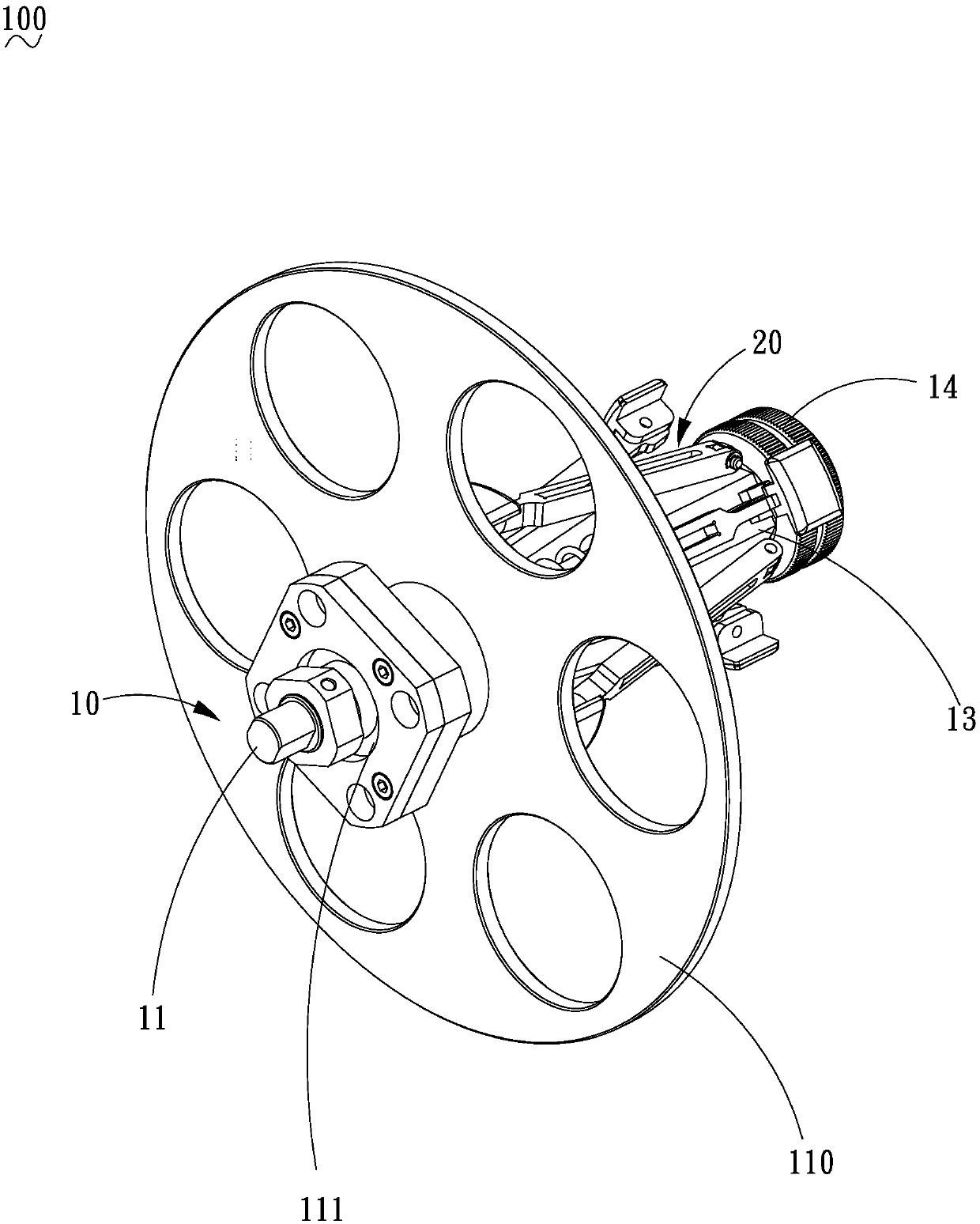

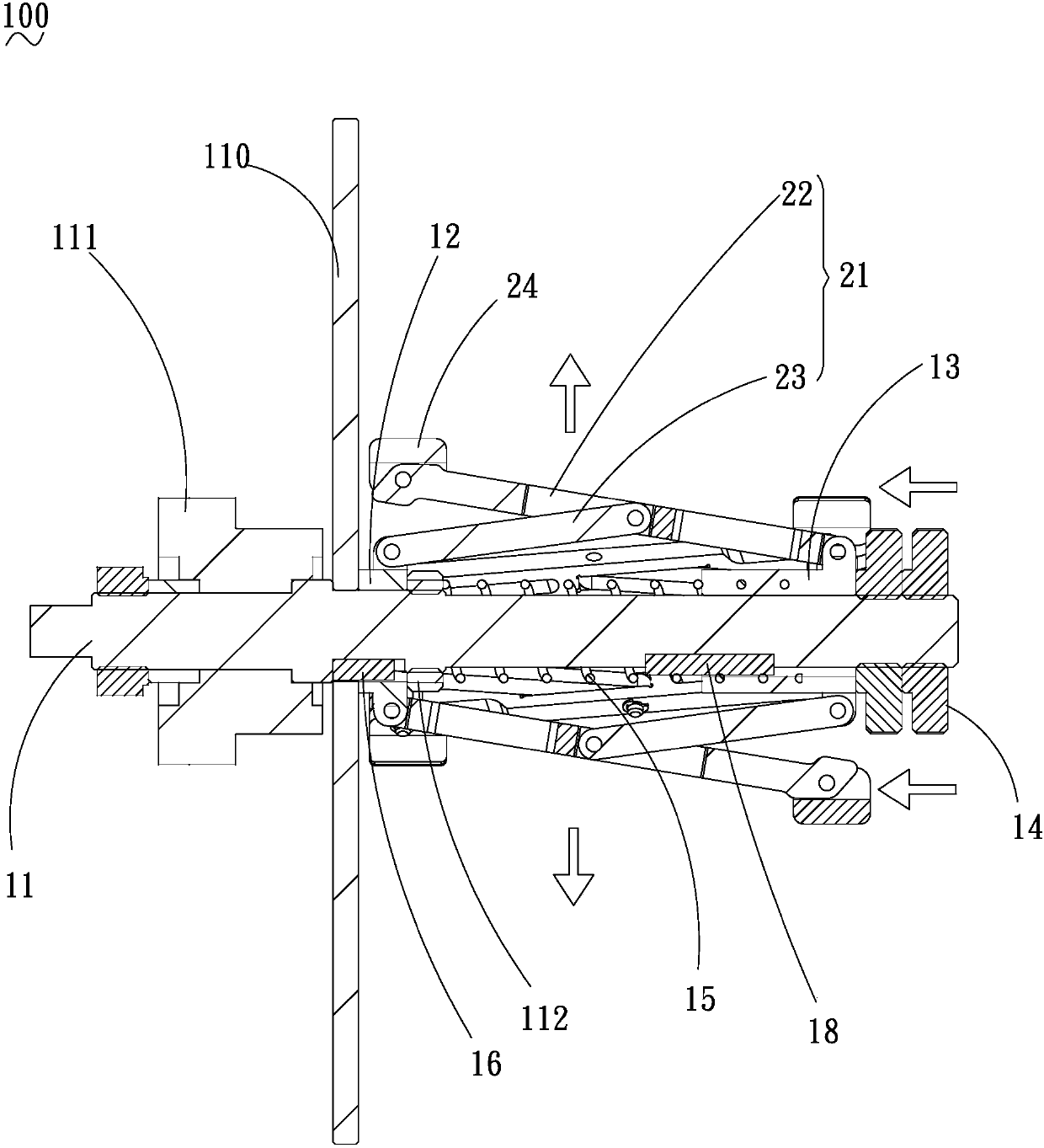

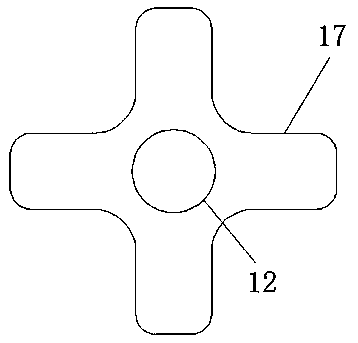

Universal auxiliary material quick clamping device

The invention relates to a universal auxiliary material quick clamping device which comprises an axis assembly and an expanding and tightening assembly connected with the axis assembly; the axis assembly comprises a main shaft, a fixed hinge seat connected with one end of the main shaft in a sleeving manner, and a sliding hinge seat connected with the other end of the main shaft in the sleeving manner; the expanding and tightening assembly comprises a plurality of expanding and tightening pieces hinged between the fixed hinge seat and the sliding hinge seat; the expanding and tightening piecessurrounds the main shaft; the expanding and tightening pieces are arranged in the positive direction and / or the reverse direction of the axial direction of the main shaft; and the expanding and tightening pieces comprise supporting rods and connecting rods hinged with the supporting rods. According to the universal auxiliary material quick clamping device, an expanding and tightening structure isadopted, so that the opening amplitude of the supporting rods can be adjusted rapidly and simply and conveniently, rapid clamping and simple clamping are realized, and the universality is achieved.

Owner:GUANGDONG EVERWIN PRECISION TECH

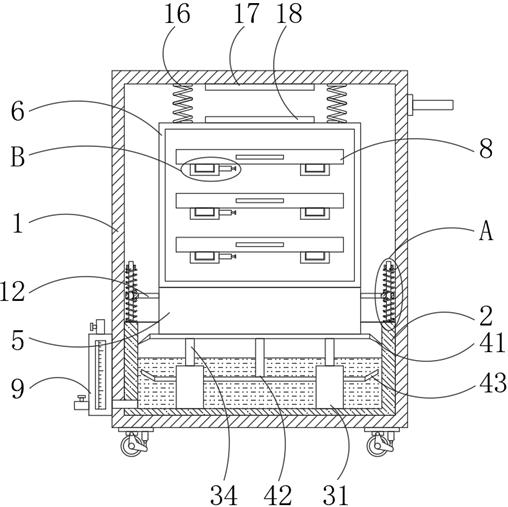

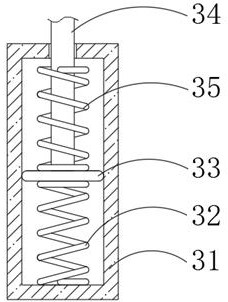

A power management device based on power line communication technology

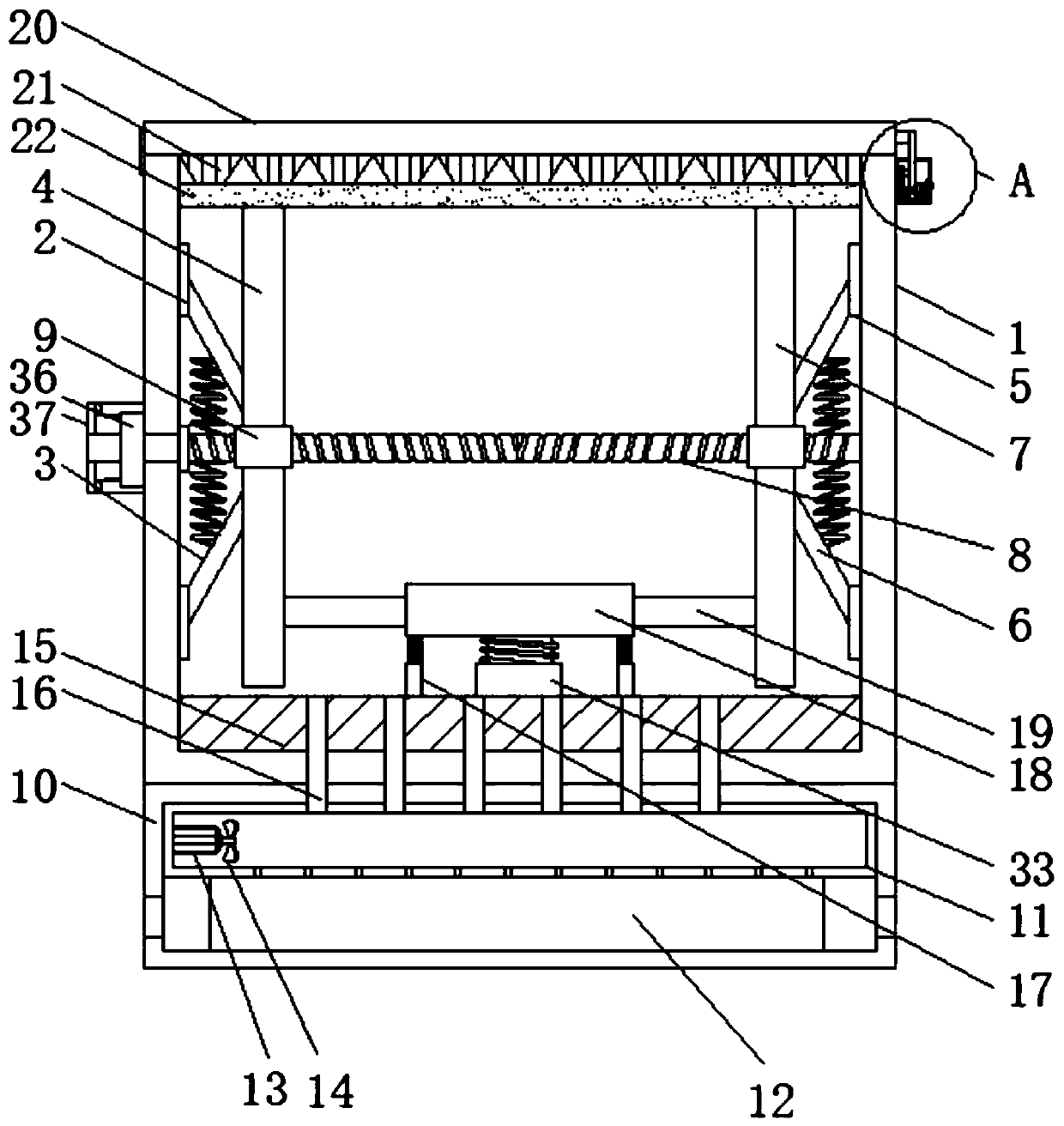

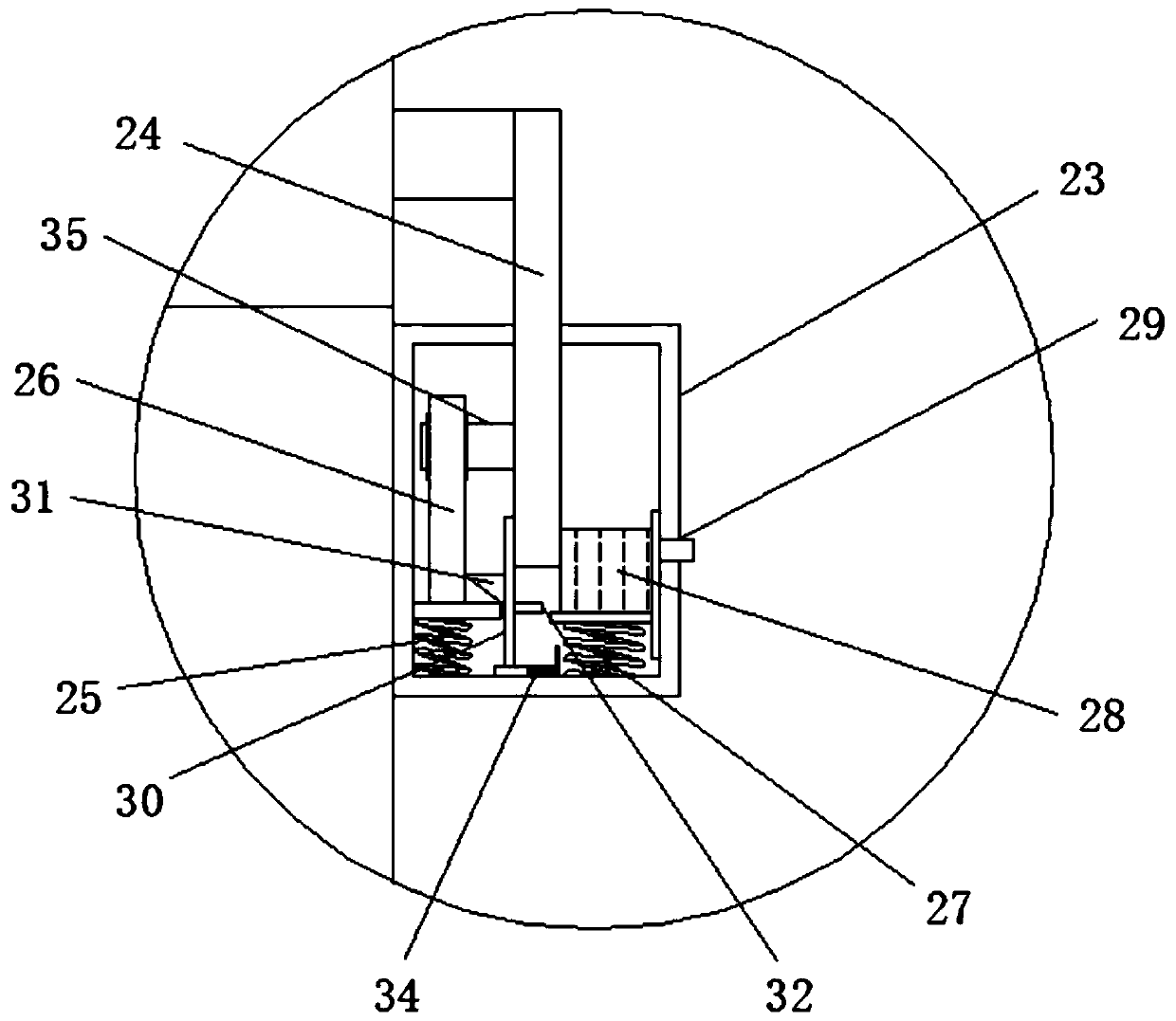

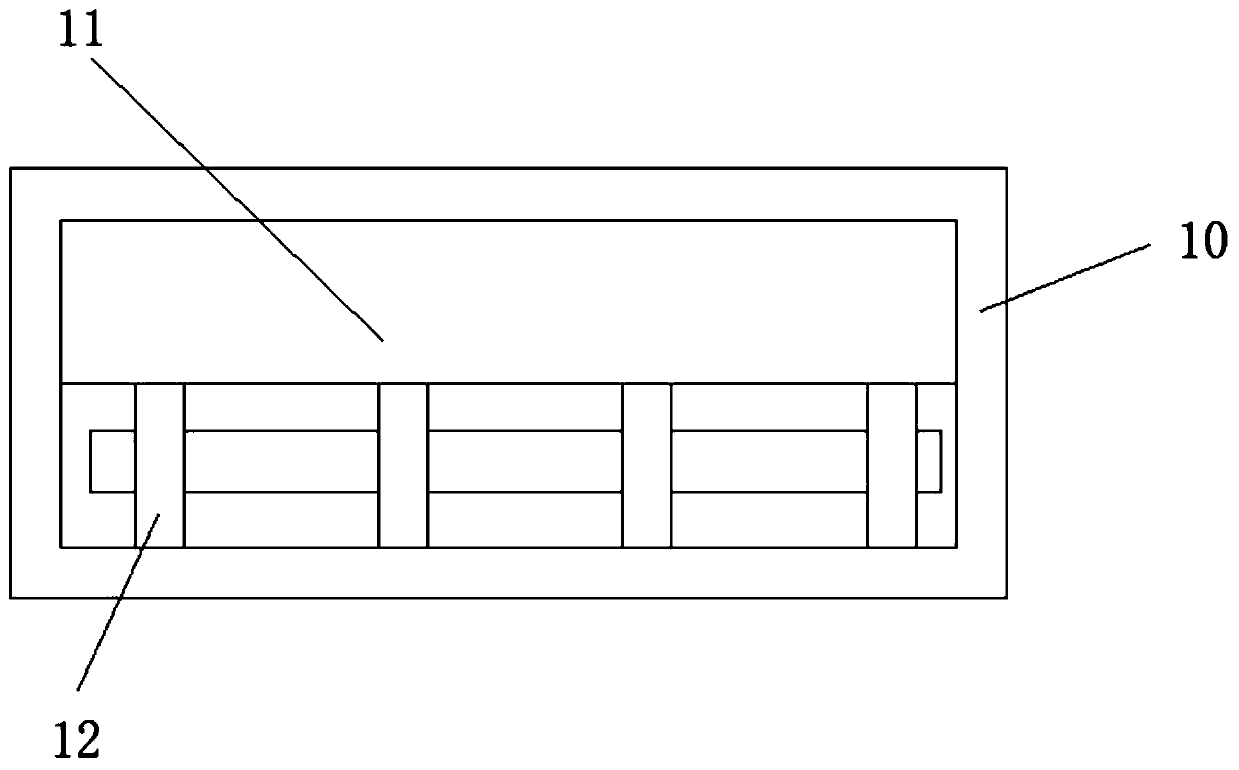

InactiveCN109066322AAct as a shock absorberActs as a secondary shock absorberSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsMaster controllerEngineering

The invention relates to the technical field of power management equipment, and discloses a power management device based on power line communication technology, comprising a housing, wherein a bottomcover is fixedly installed on the bottom of the housing. According to the power management device based on the power line communication technology, a hydraulic cartridge fixedly mounted through the interior of the enclosure, and through the pressure bar inside the hydraulic tank, A switch board is fixedly mounted on the top of the pressing block, when the main controller or other components on the switchboard are subjected to external vibration or impulse, the vibration force is transferred to the pressing block through the connected block, and the spring fixedly installed at the bottom of the pressing block plays the role of damping vibration of the pressing block, The hydraulic oil inside the hydraulic box is compressed by the pressure block through the position limiting block during the vibration process, and the hydraulic oil plays a shock absorbing role, thereby improving the shock absorbing effect of the device. The pressure bar is arranged inside the hydraulic box and is provided with a finite position block and a sealing rubber.

Owner:安徽国锦电力工程有限公司

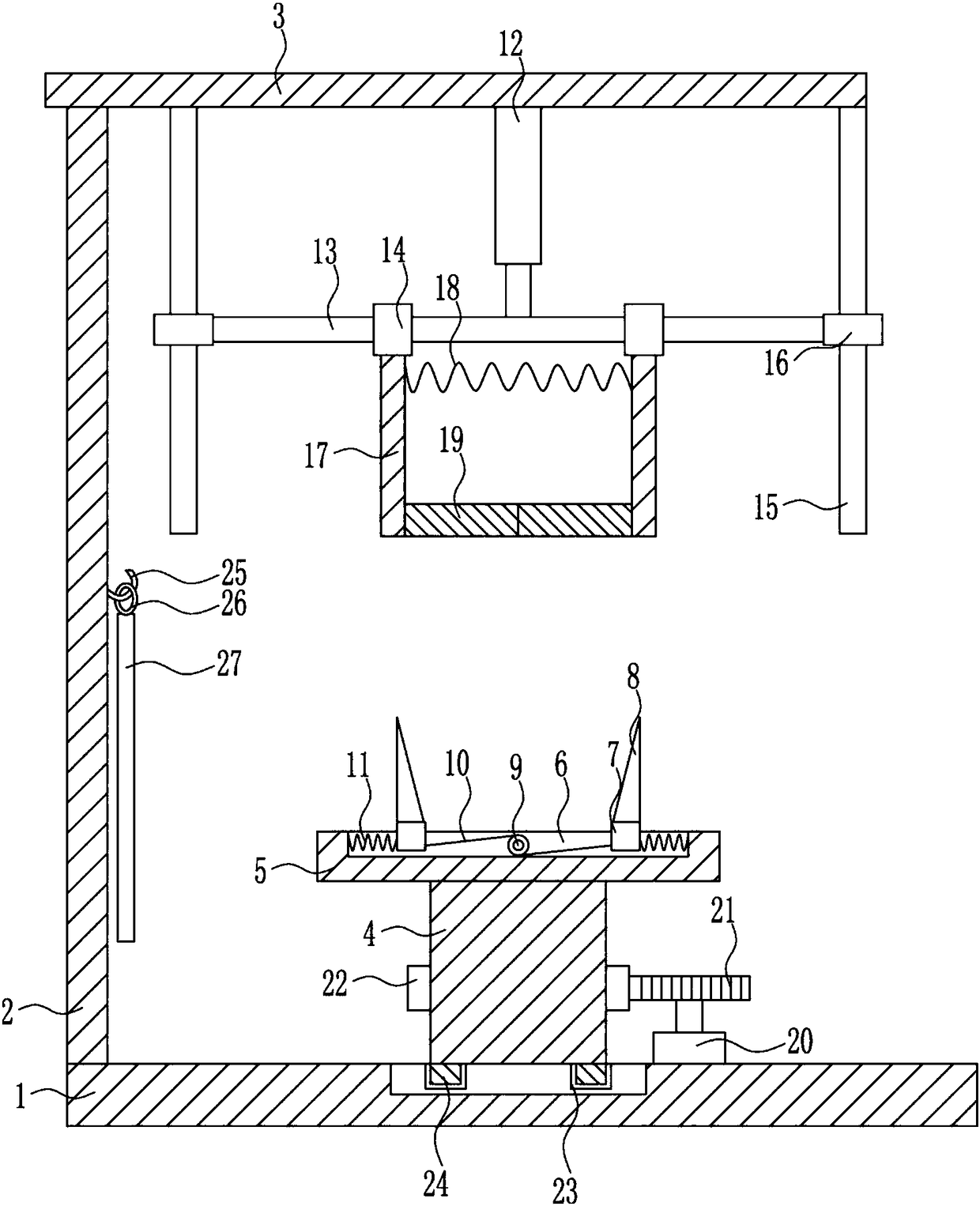

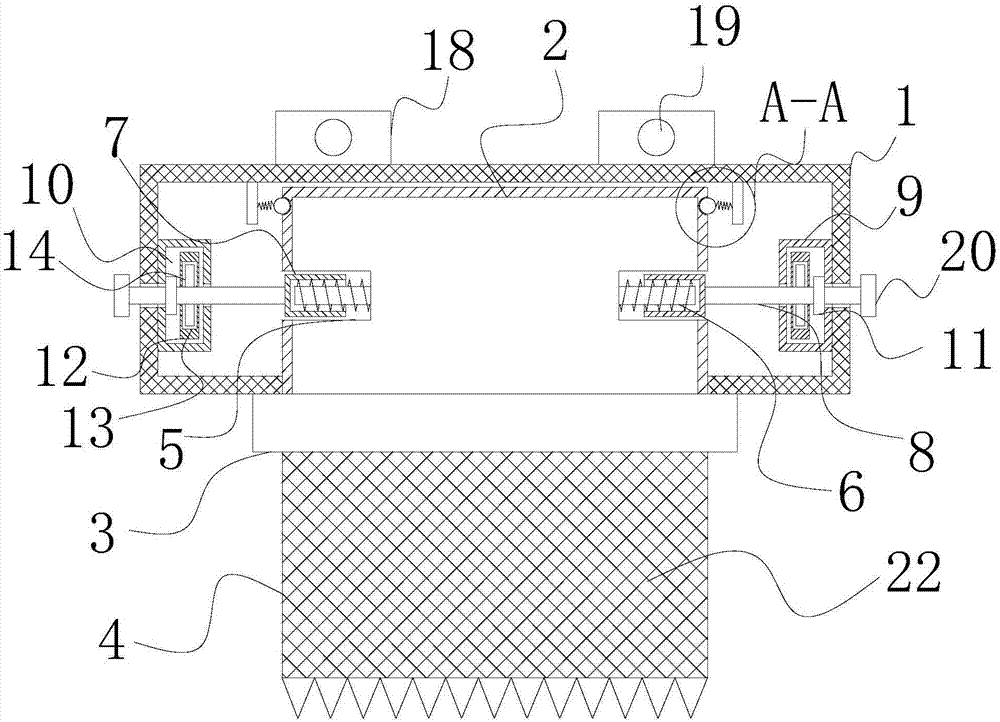

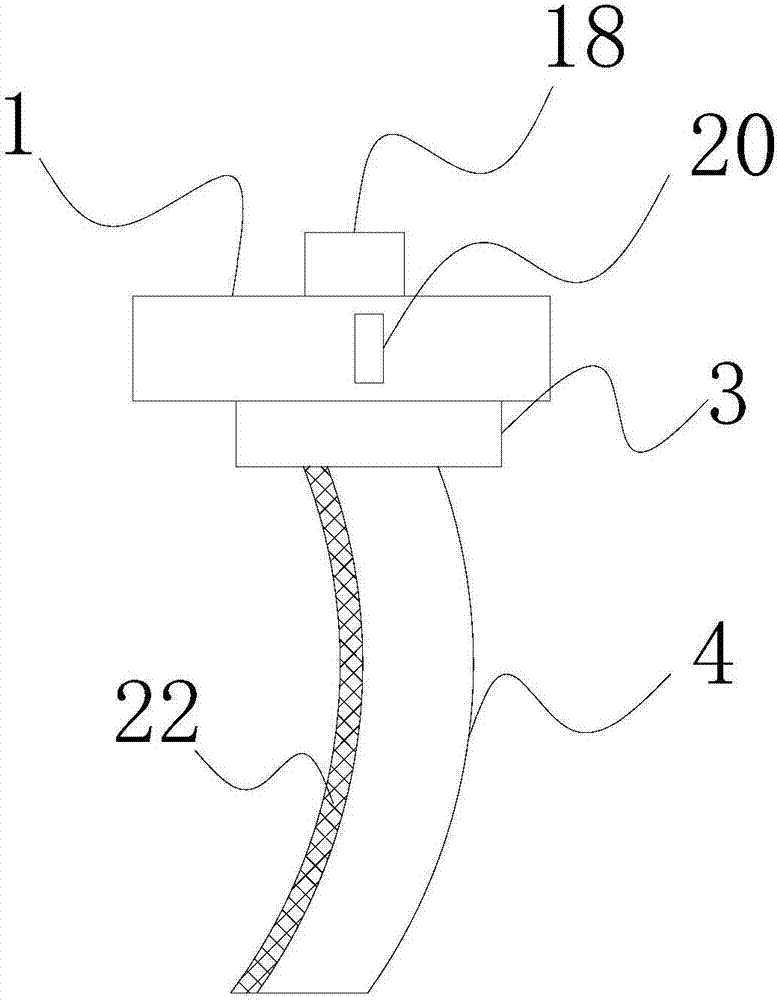

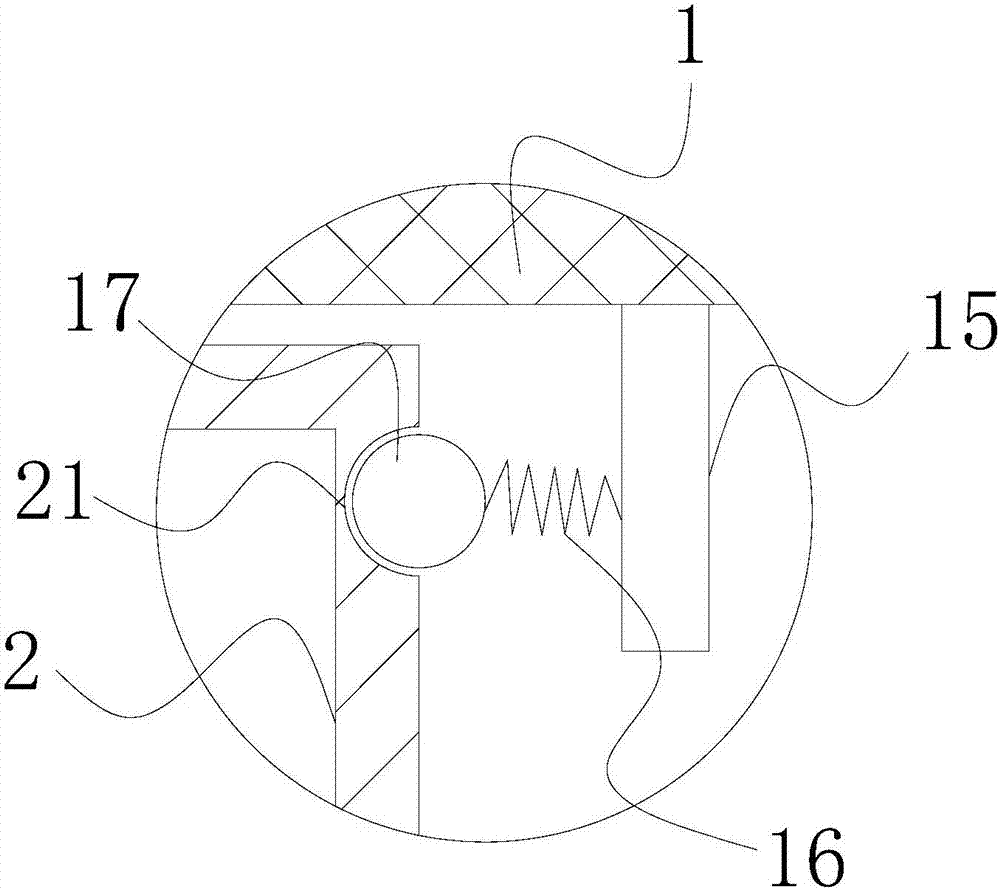

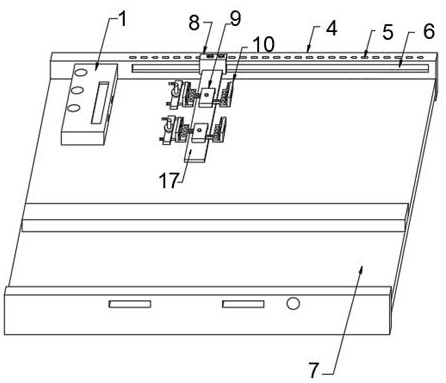

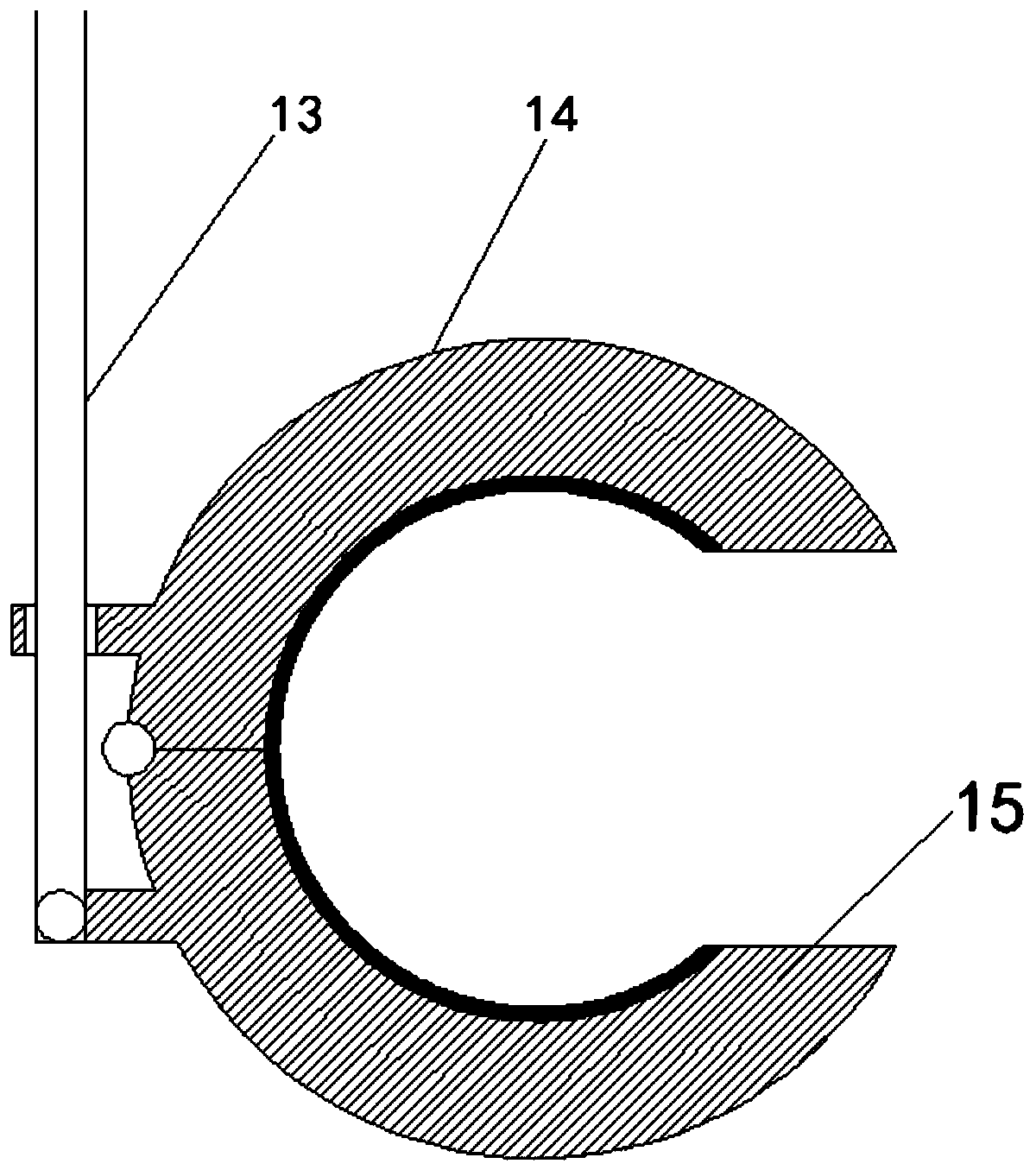

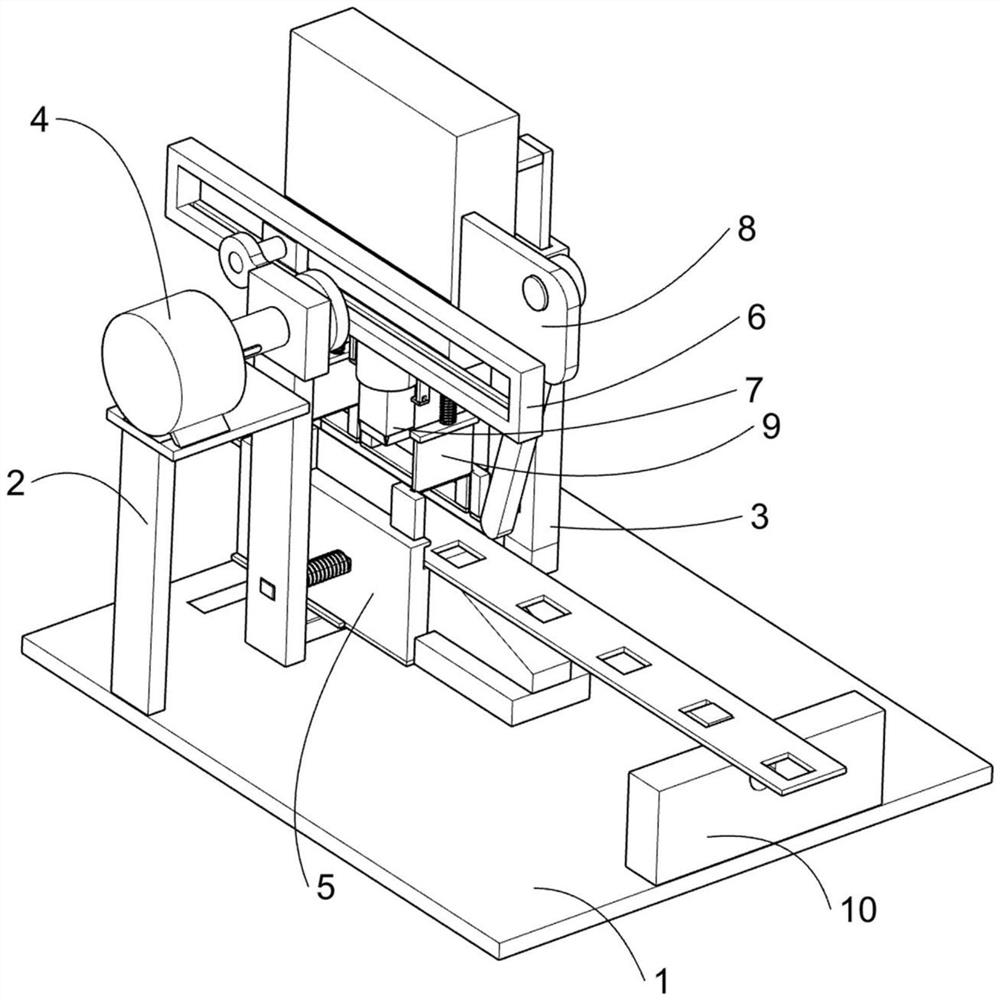

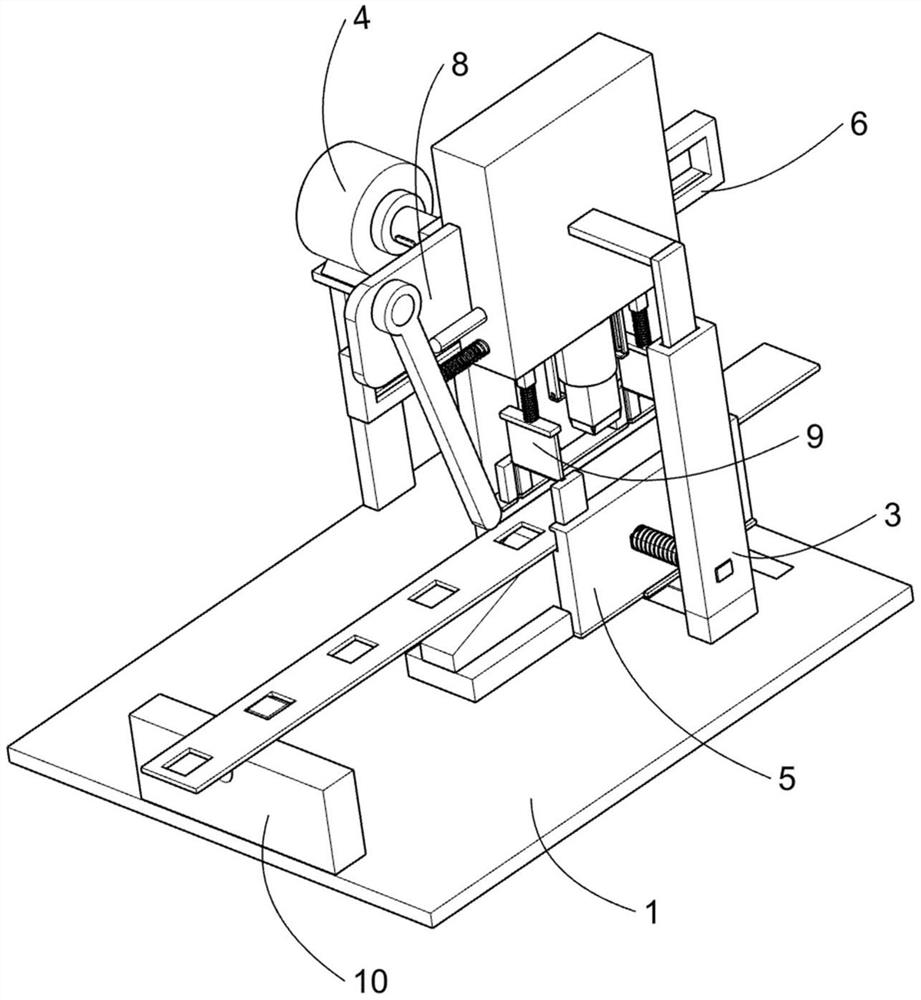

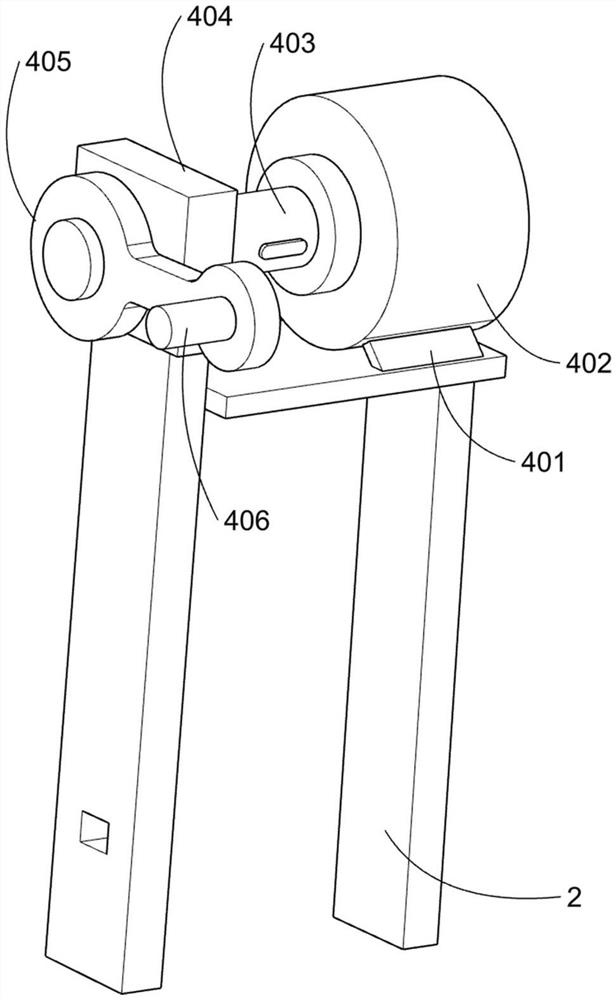

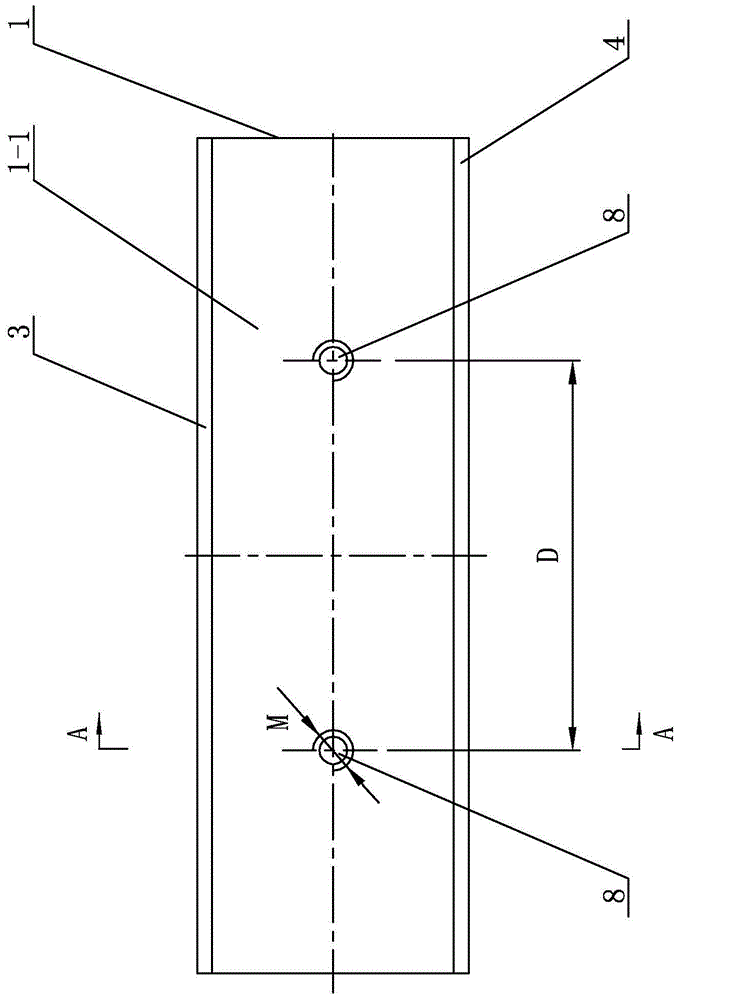

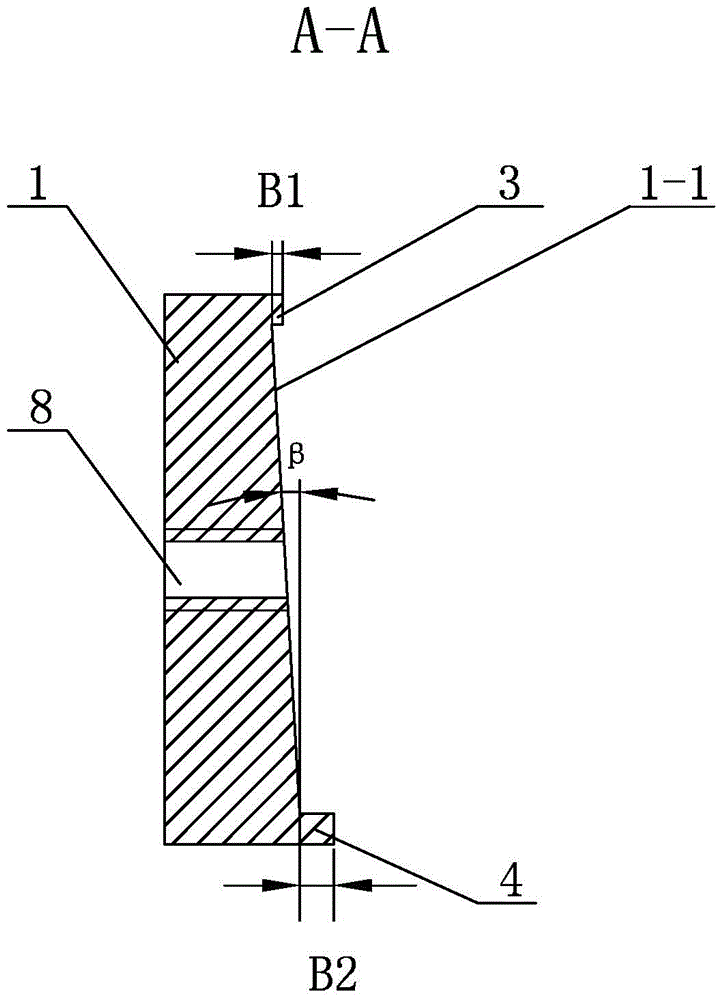

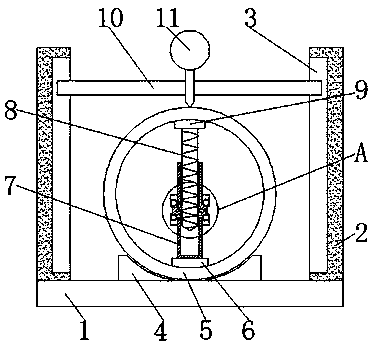

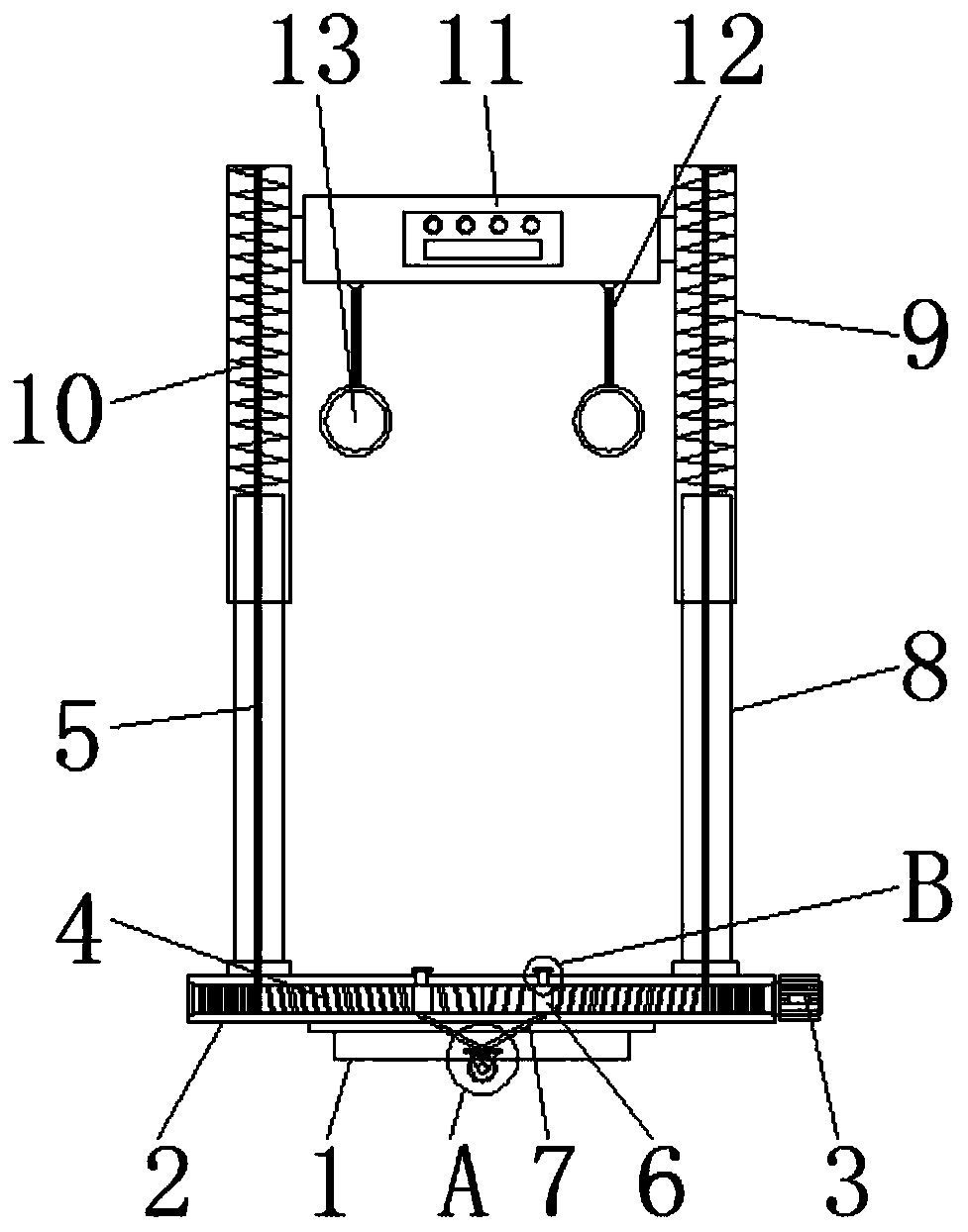

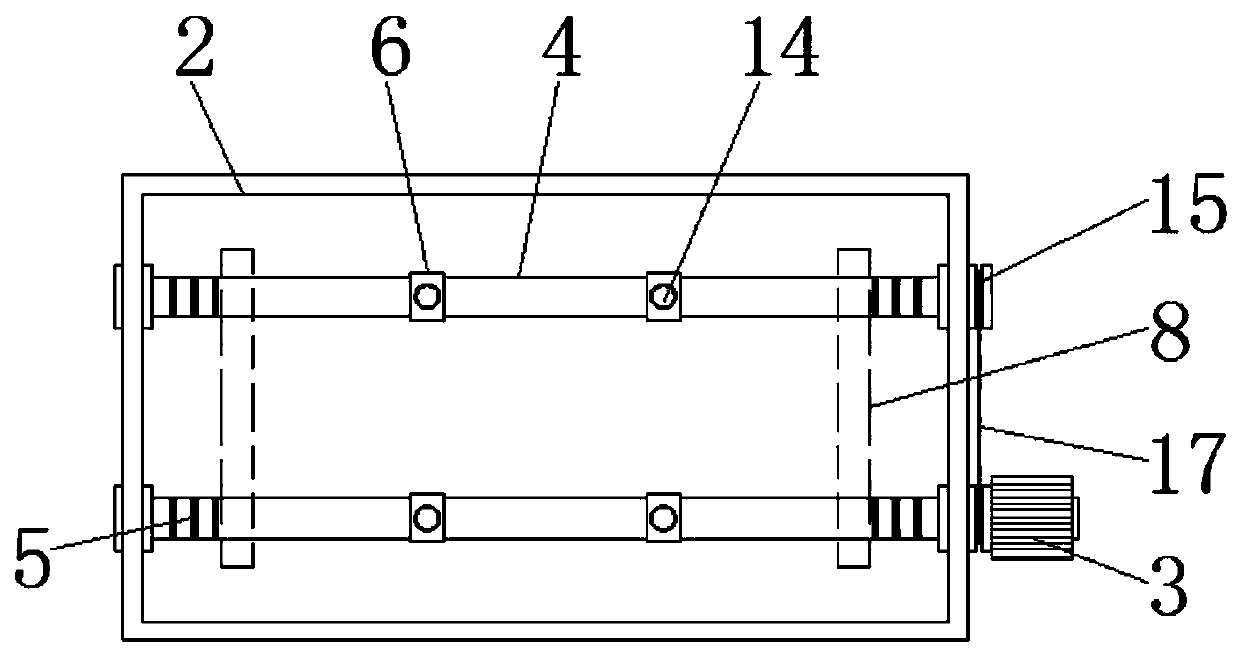

Inner diameter detecting device of circular pipe

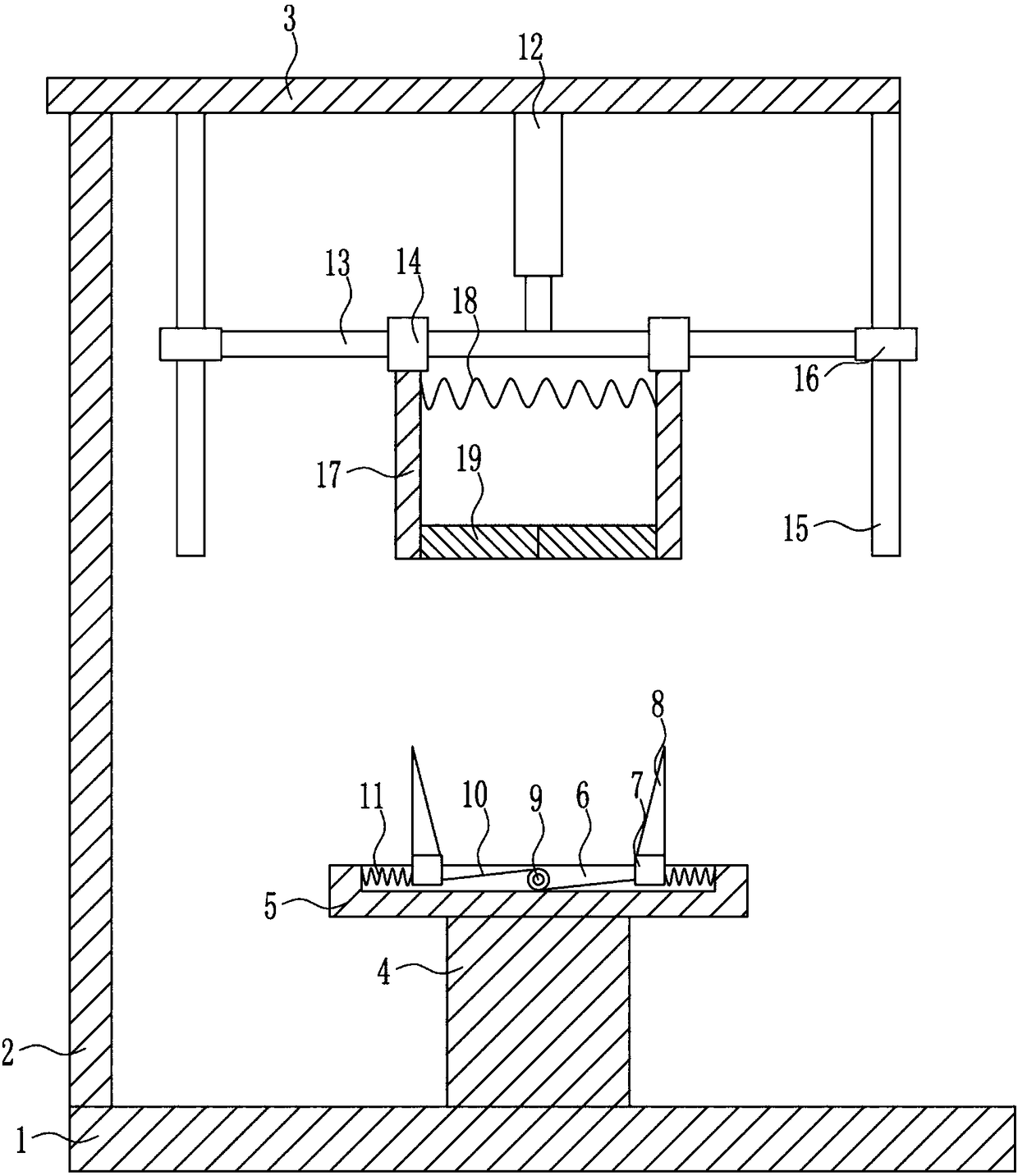

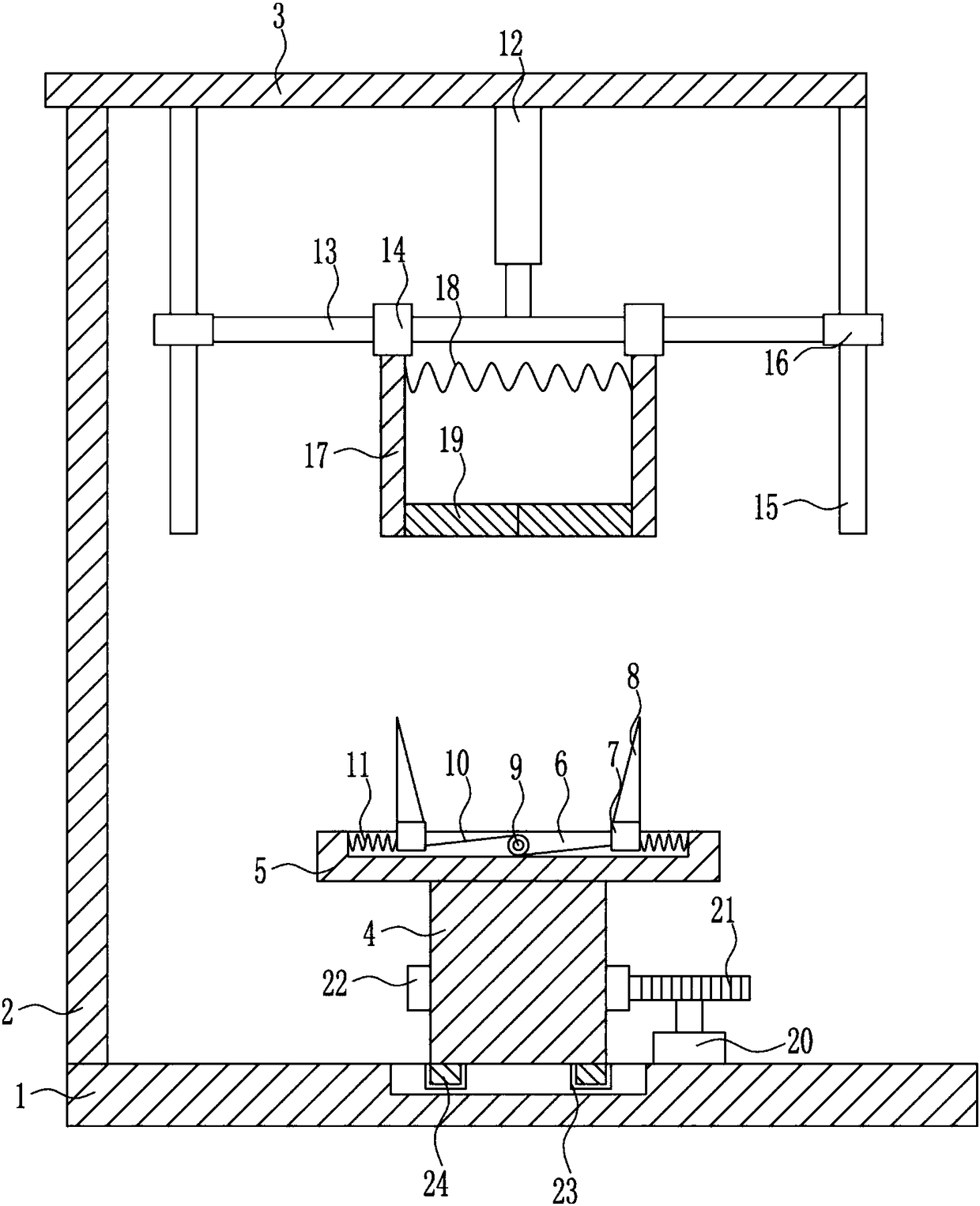

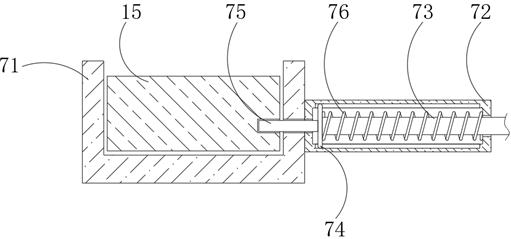

ActiveCN108548471AReach fixedIntuitive measurement of inner diameterMechanical diameter measurementsEngineering

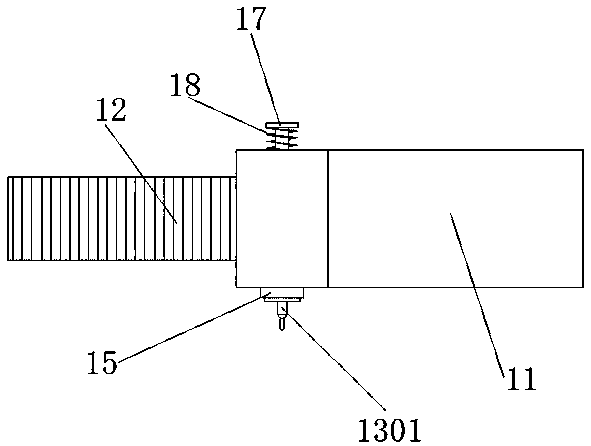

The invention relates to a detecting device, in particular to an inner diameter detecting device of a circular pipe so that a pipe can be fixed and detection can be realized accurately. The inner diameter detecting device is composed of a bottom plate, a left bracket, a top plate, a support base, a fixed plate, a first sliding block, a limit rod, an electric reel, a pulling wire, a first spring, an electric push rod, and a first guide rod and the like. The left bracket is arranged at the left side of the top of the bottom plate; the top plate is arranged on the top of the left bracket; the electric push rod is arranged in the middle of the bottom of the top plate; the first guide rod is connected to the bottom of the electric push rod; and two first guide sleeves arranged at the first guide rod. According to the invention, the circular pipe is clamped firmly by an arc clamp rod and the inner diameter of the pipe is measured by the limit rod. Therefore, the inner diameter can be measured visually and the measuring result is accurate; the pipe can be fixed; and the detection accuracy is high.

Owner:温州瑞智门窗有限公司

Automobile fender

InactiveCN106926905AEasy to disassembleStable disassemblySuperstructure subunitsEngineeringService efficiency

The invention discloses an automobile fender, which comprises an installation frame, wherein a first fixed block is arranged in an inner cavity of the installation frame; the bottom of the first fixed block penetrates through the installation frame, extends to the outside of the installation frame and is fixedly connected with a connection plate; one side, far away from the first fixed block, of the connection plate is fixedly connected with a fender body; first grooves are formed in the left side and the right side, in the installation frame, of the first fixed block; and an inner cavity of each first groove is fixedly connected with a threaded rod. Through an adjusting rod, the effect of driving a thread bushing to rotate is achieved; through the thread bushing, the effect of fixing the first fixed block in fit with the threaded rods is achieved, and meanwhile, the effect of facilitating disassembly is achieved; through a fixed shaft, the effects of supporting the adjusting rod, ensuring stable rotation of the adjusting rod and preventing deflection of the adjusting rod are achieved; and meanwhile, the problem that the fender is troublesome in disassembly when damaged and the service efficiency is reduced is solved.

Owner:长兴达程科技有限公司

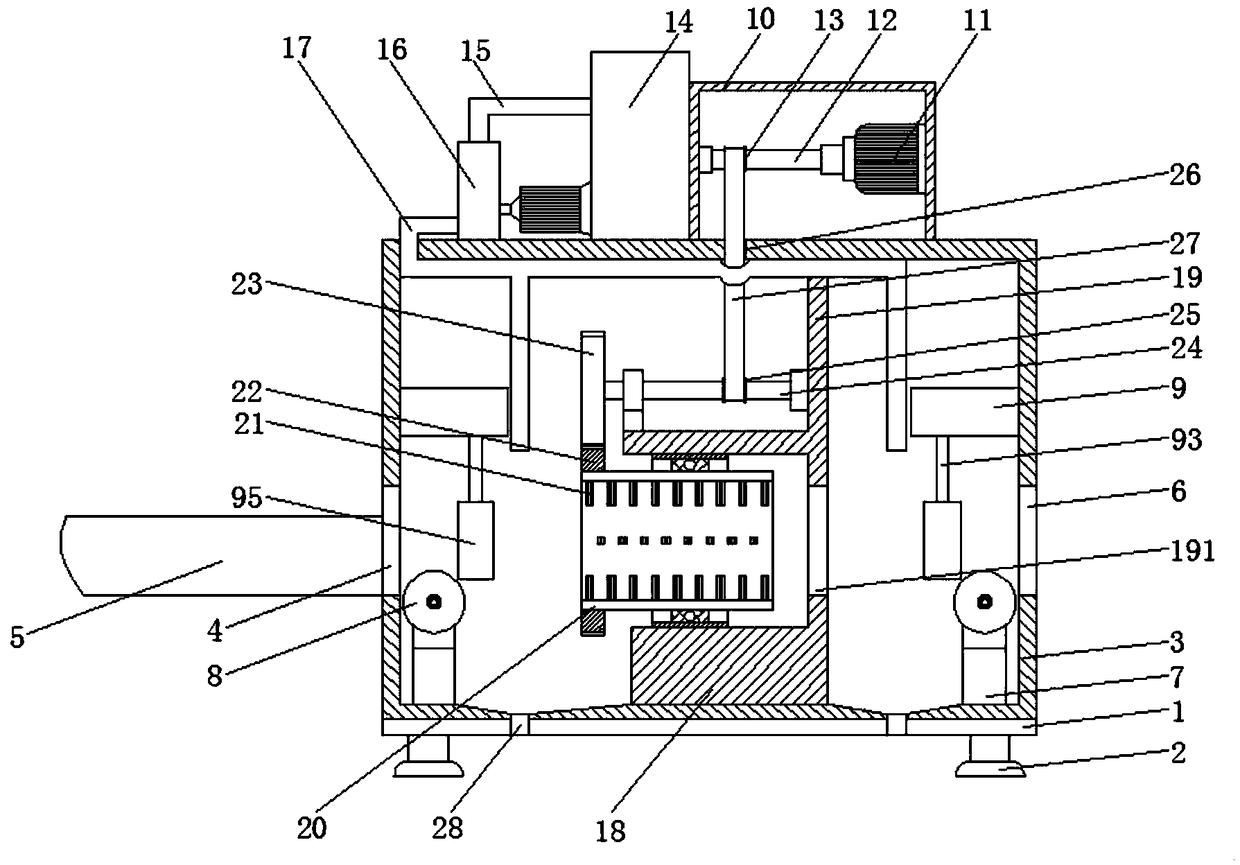

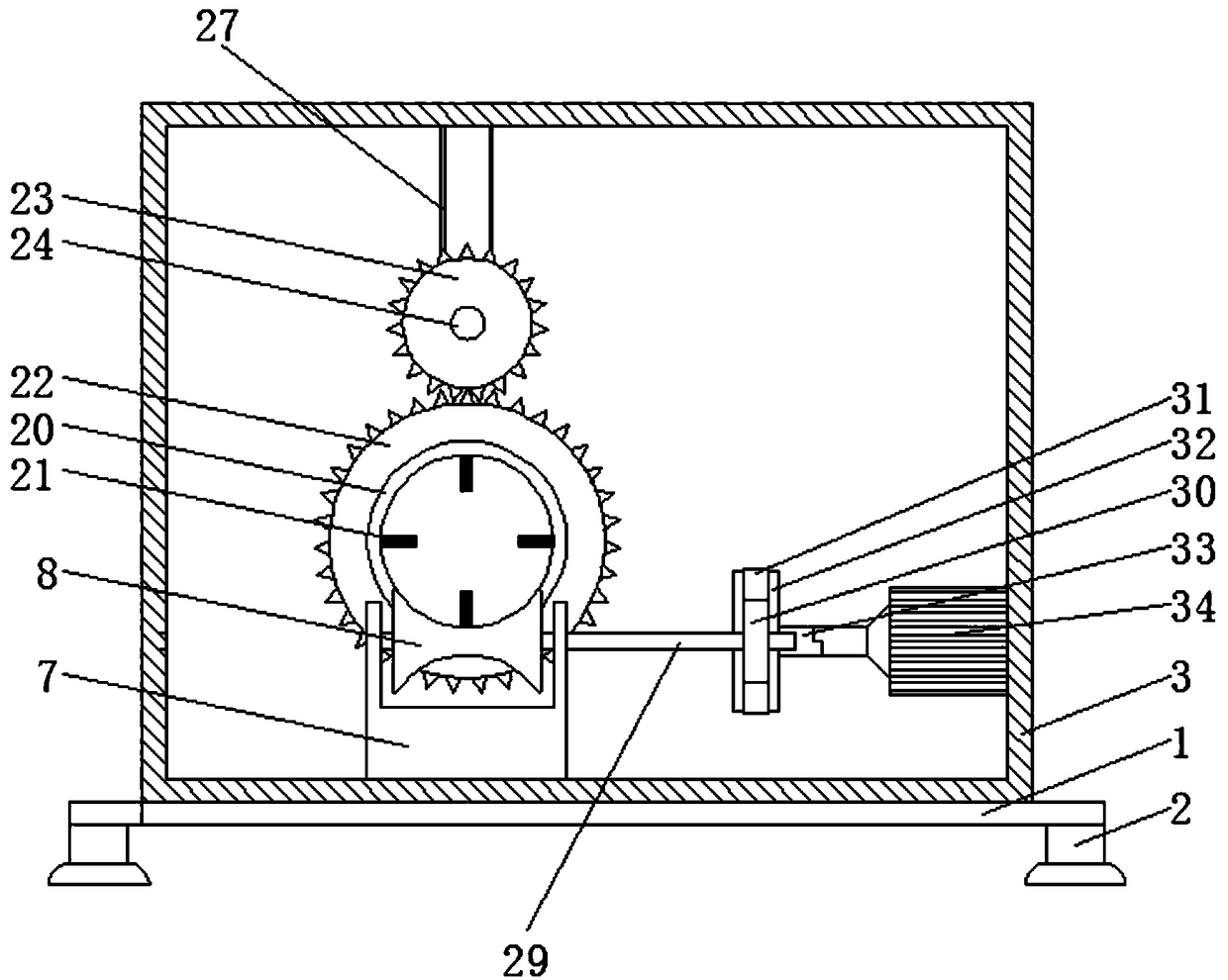

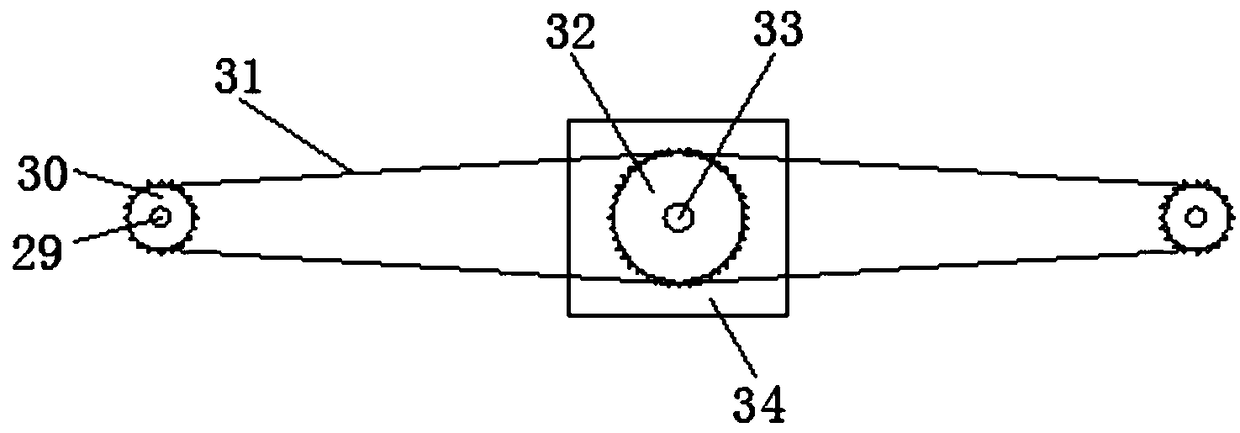

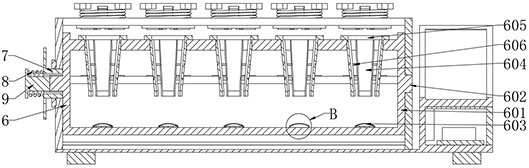

Automatic cleaning device for log production and processing

InactiveCN109277331AWash thoroughlyReach fixedCleaning using toolsCleaning using liquidsEngineeringWater pipe

The invention relates to the technical field of wood processing, and discloses an automatic cleaning device for log production and processing. The automatic cleaning device comprises a base. Base feetare fixedly mounted at the four corners of the bottom of the base. A shell is fixedly mounted at the top of the base. A feeding opening is formed in the left side of the shell. An automatic feeding device is fixedly mounted on the left side of the feeding opening. A discharging opening is formed in the right side of the shell. Supporting blocks are fixedly mounted on the left side and the right side of the inner bottom wall of the shell. Rolling wheels are movably mounted at the tops of the supporting blocks. Fixed shells are fixedly mounted on the inner walls of the left side and the right side of the shell. Two first rotating shafts are inserted in each shell in a penetrating manner, and a first gear is fixedly mounted on the outer side of each first rotating shaft. A rotating barrel drives brushes on the inner wall of the rotating barrel to annularly and continuously wash the log surface, two water outlets of a second water pipe wash the log two times, the function of log washing is achieved, and the effect that washing is achieved thoroughly is achieved.

Owner:湖州南浔双杨木业有限公司

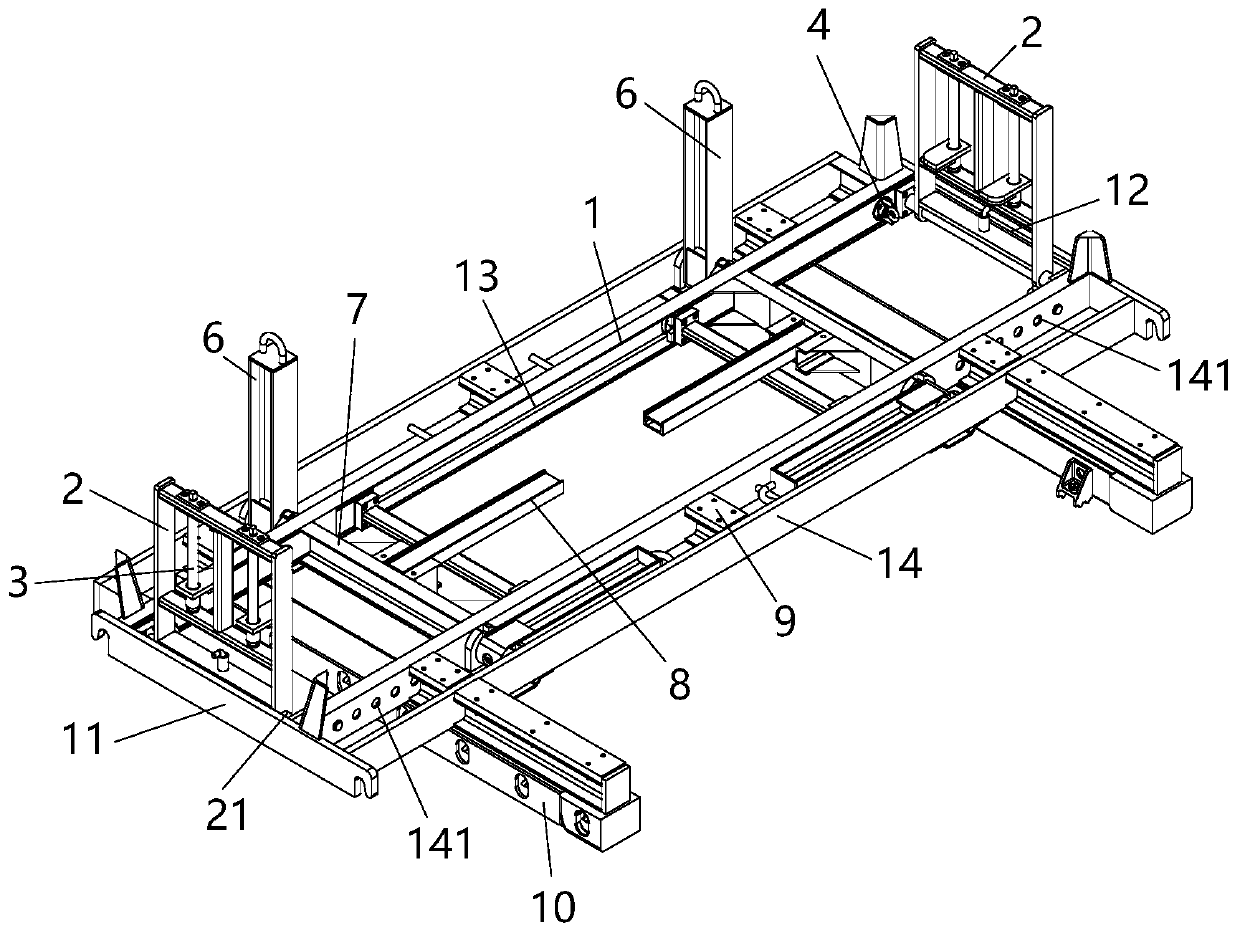

Plate flatcar transport frame and flatcar dual-purpose transport vehicle

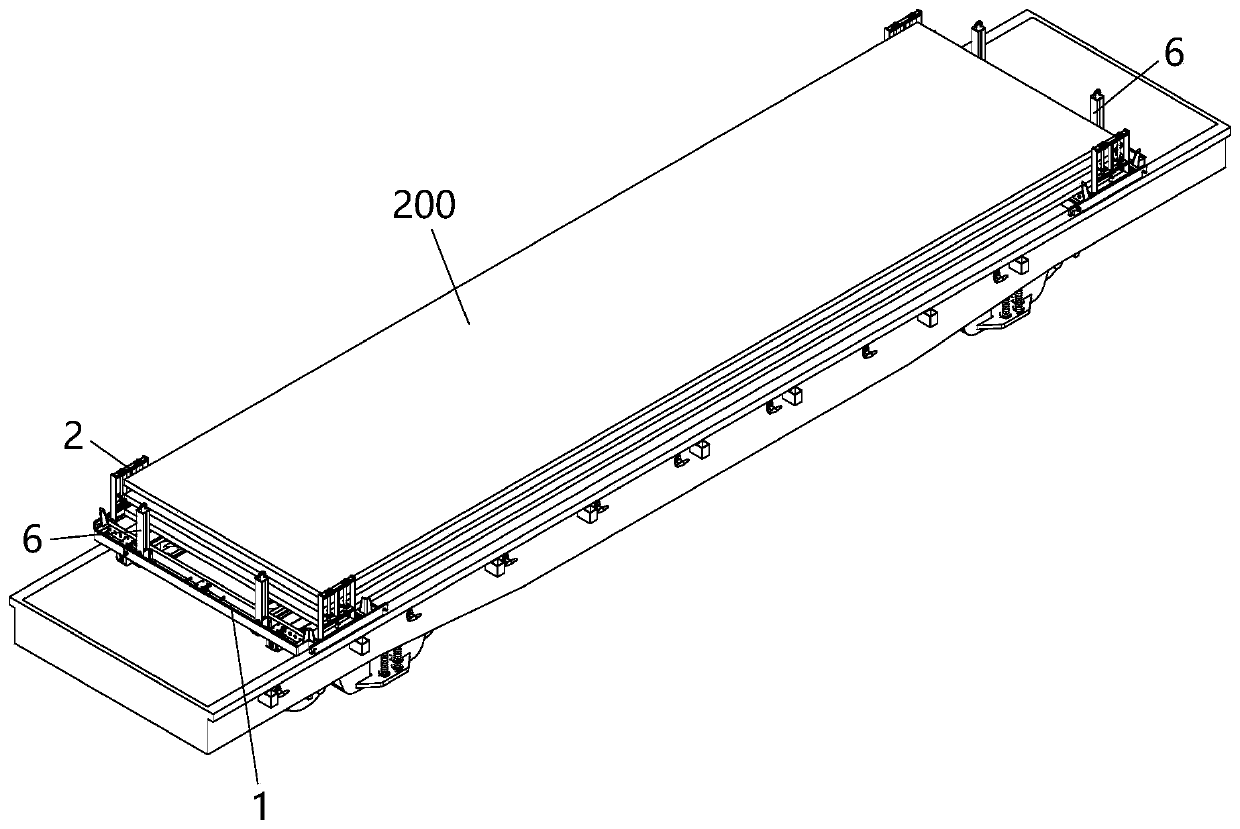

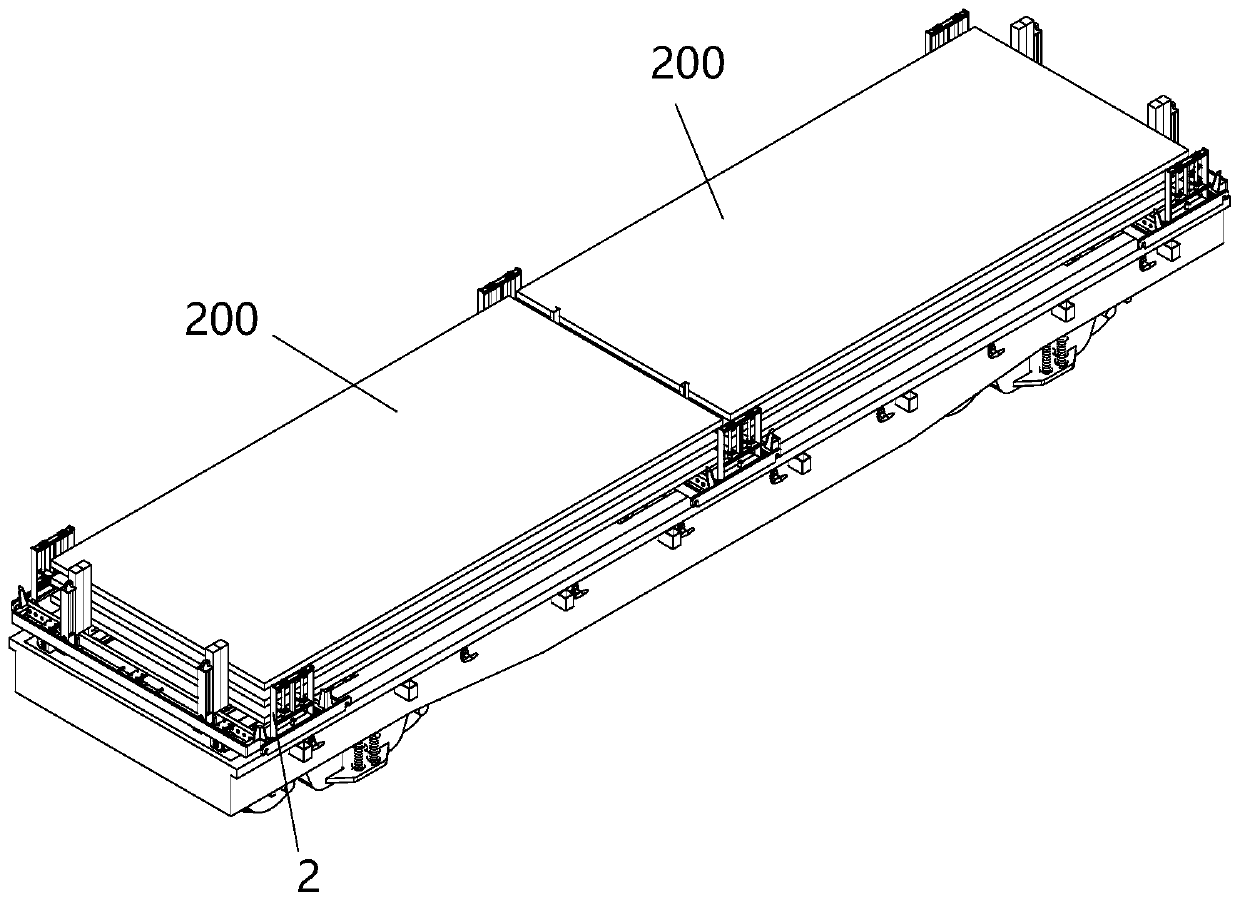

PendingCN111169502AAvoid shakingReach fixedWagons/vansCargo supporting/securing componentsCartChassis

The invention relates to the technical field of plate transport equipment, and discloses a plate flatcar transport frame and flatcar dual-purpose transport cart which comprises an underframe assembly,a flatcar assembly, a flatcar assembly and a flatcar assembly. And the pair of end overturning stop structures are arranged in the length direction of the underframe assembly in a spaced mode and used for preventing the to-be-transported plates from moving left and right in the width direction of the underframe assembly. The plate flatcar transportation frame has the advantages of being easy to operate, high in operation efficiency, capable of being repeatedly used and capable of saving operation cost.

Owner:BEIJING RUI LI HENG YI LOGISTICS TECH PLC

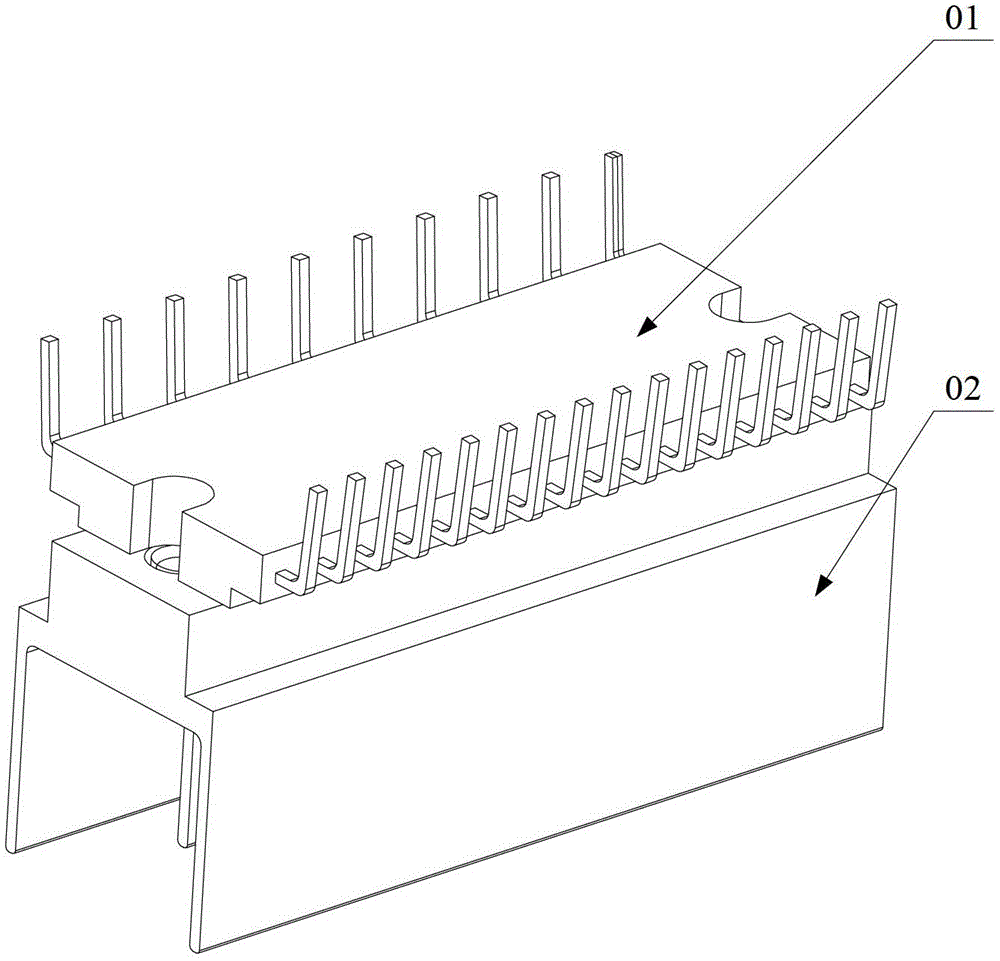

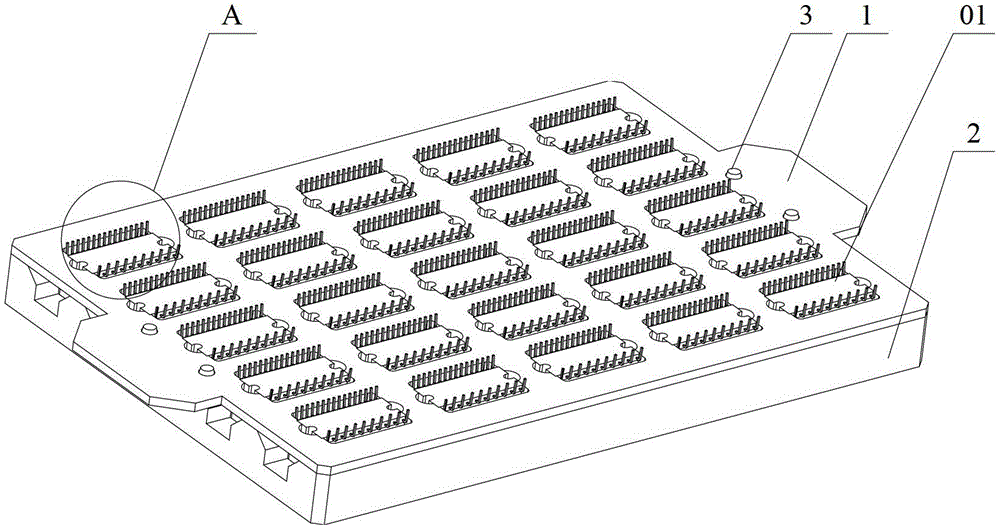

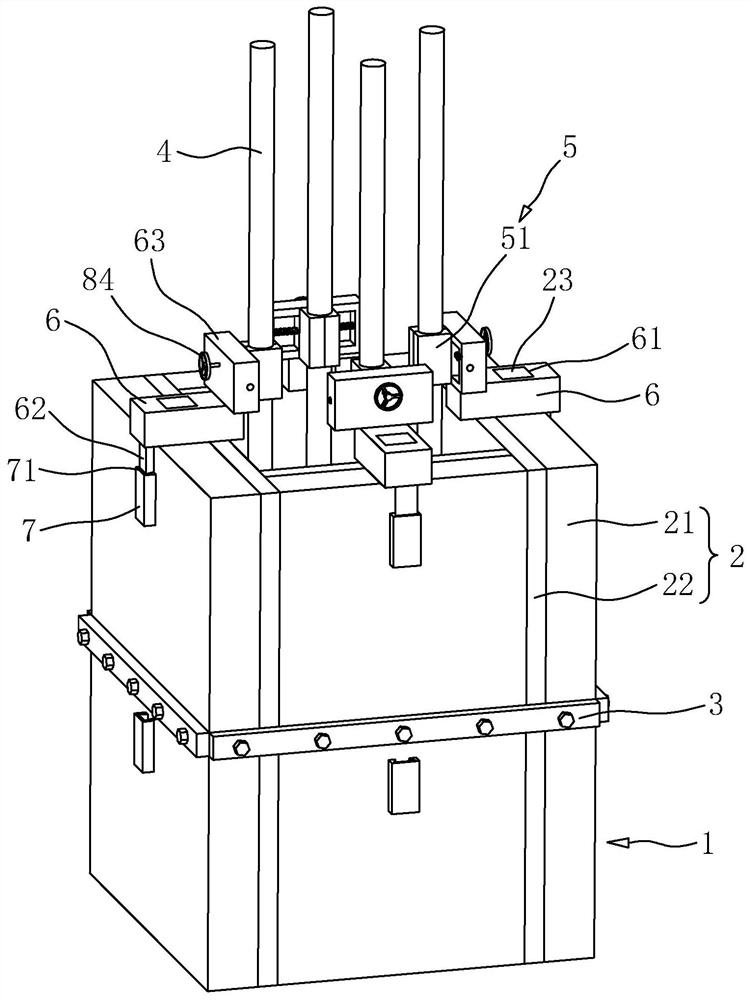

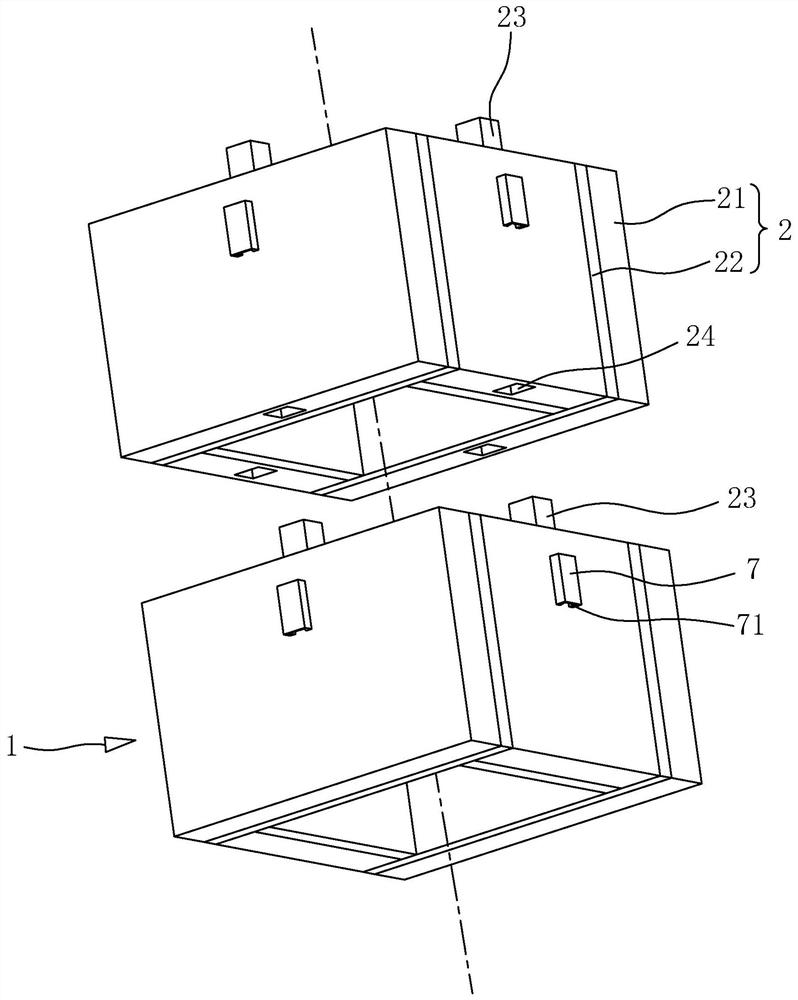

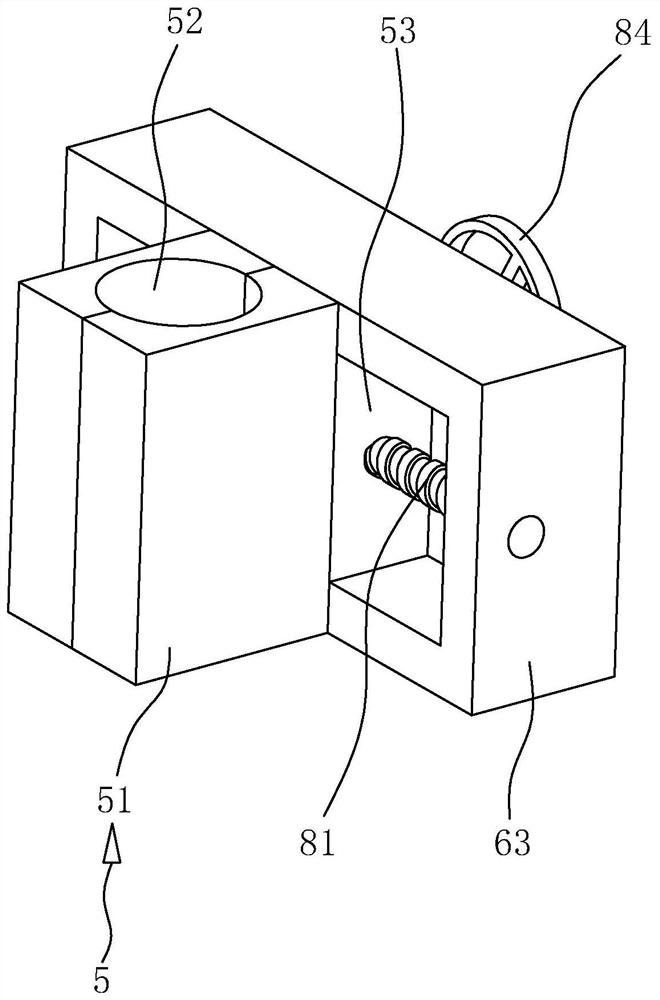

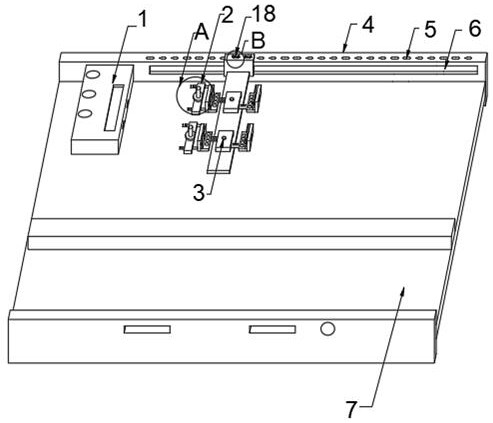

an assembly device

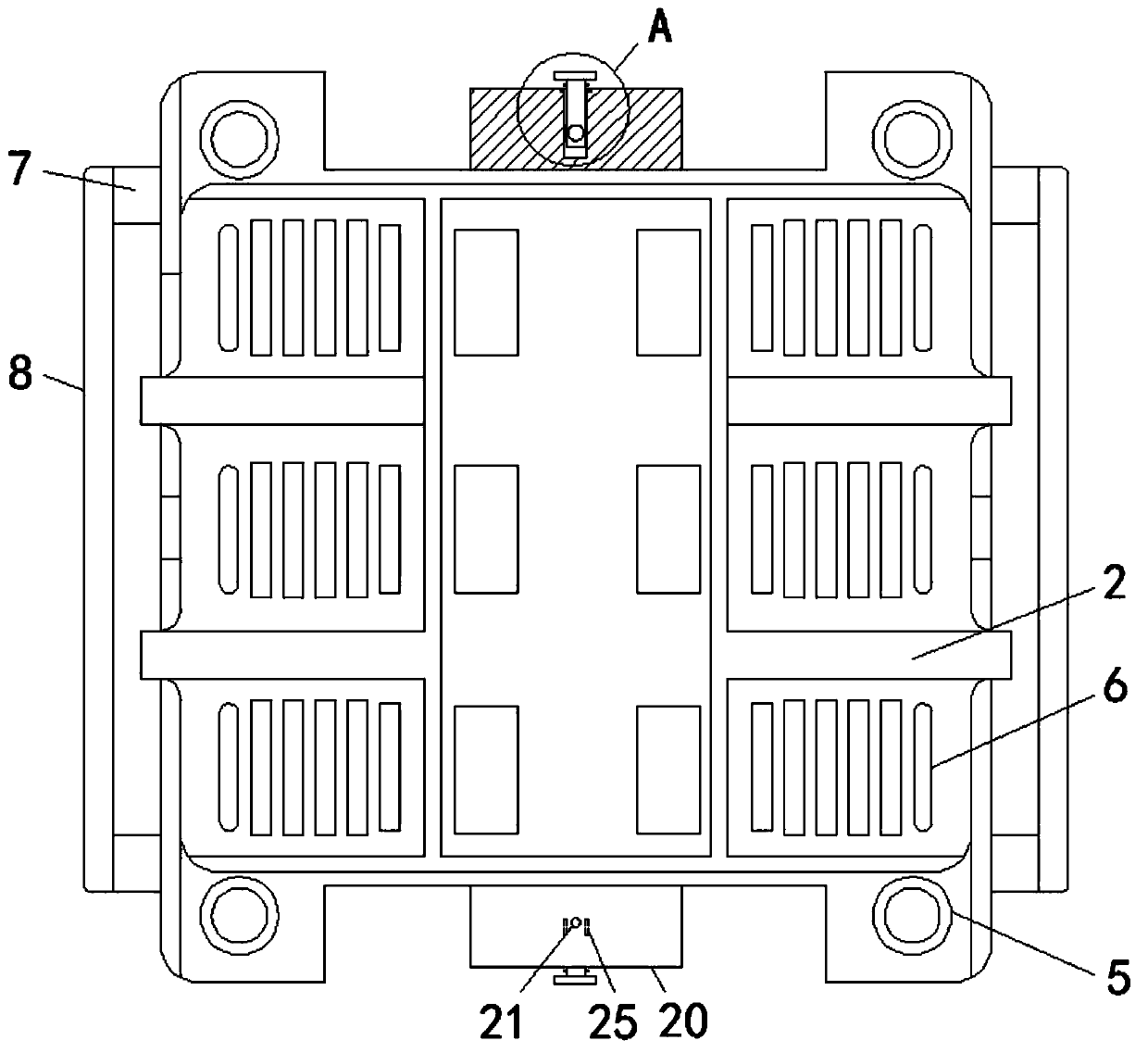

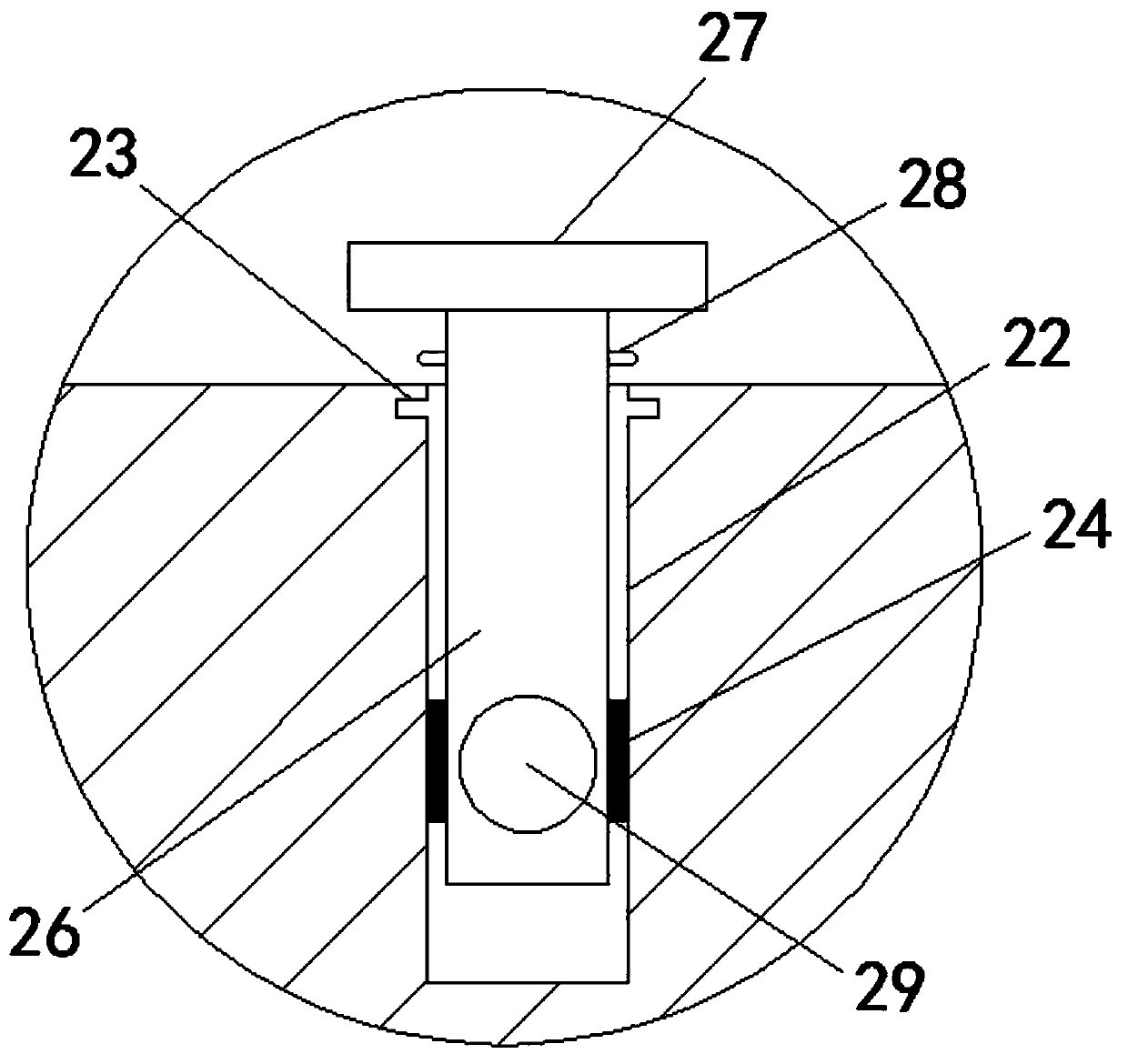

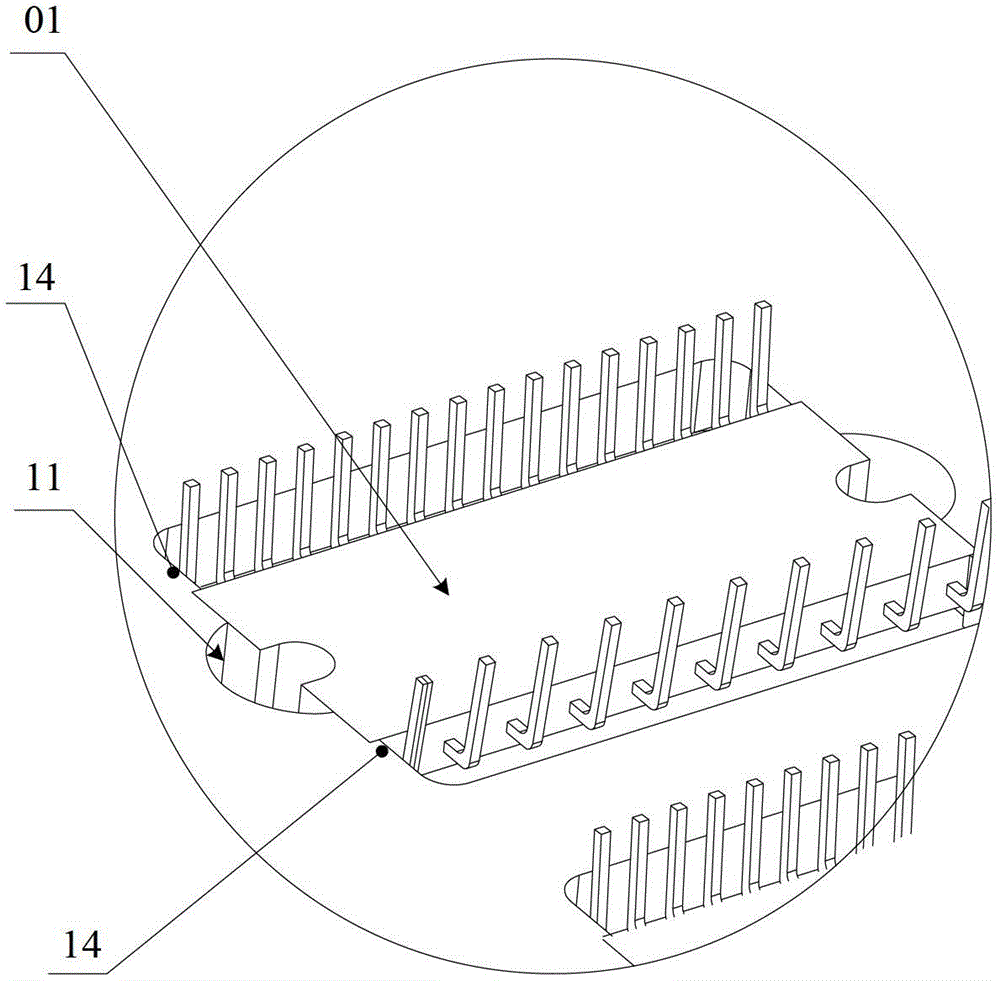

The invention discloses an assembling device for assembling IPM (intelligent power module) modules and heat dissipaters. The assembling device comprises a lower template and an upper template, wherein the lower template is provided with lower cavities for fixing the heat dissipaters; the upper template is detachably connected with the lower template and is provided with upper through holes which correspond to the lower cavities of the lower template and is used for fixing the IPM modules. According to the assembling device provided by the invention, the lower template with the lower cavities for fixing the heat dissipaters are matched with the upper template with the upper through holes for fixing the IPM modules, so that the lower cavities are matched with the upper through holes, and the heat dissipaters arranged in the lower cavities are aligned with the IPM modules arranged in the upper through holes in a matched manner; furthermore, screws are tightened to the heat dissipaters and the IPM modules through the upper through holes, so that fixing of the heat dissipaters and the IPM modules are implemented; the fixing operation for the heat dissipaters and the IPM modules are facilitated, and the accuracy of mutual connection of the heat dissipaters and the IPM modules are effectively improved; therefore the quality of a finished product obtained by connecting the IPM modules with the heat dissipaters through the screws are increased, and the working efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

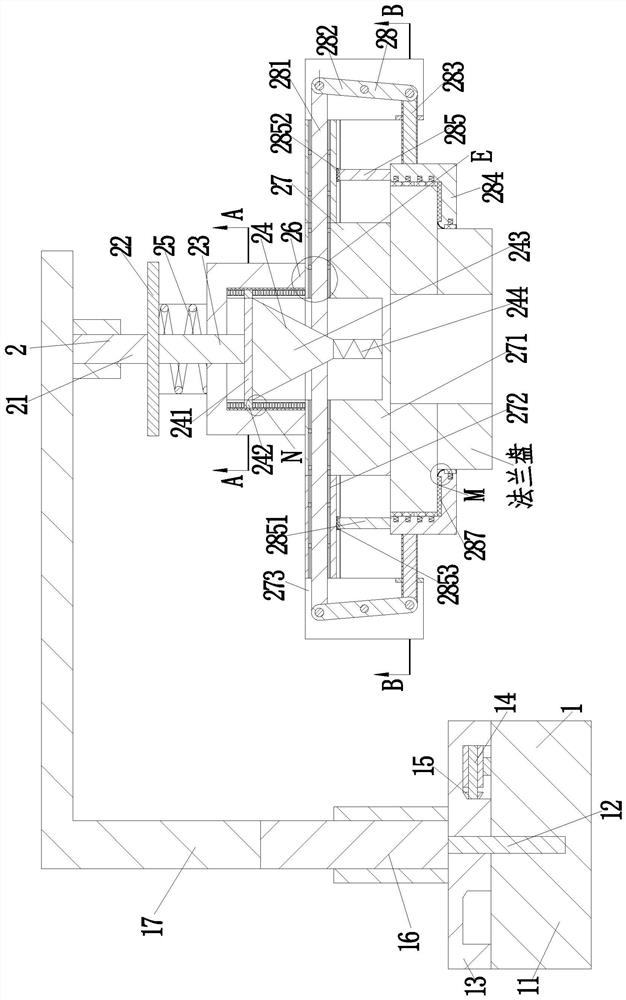

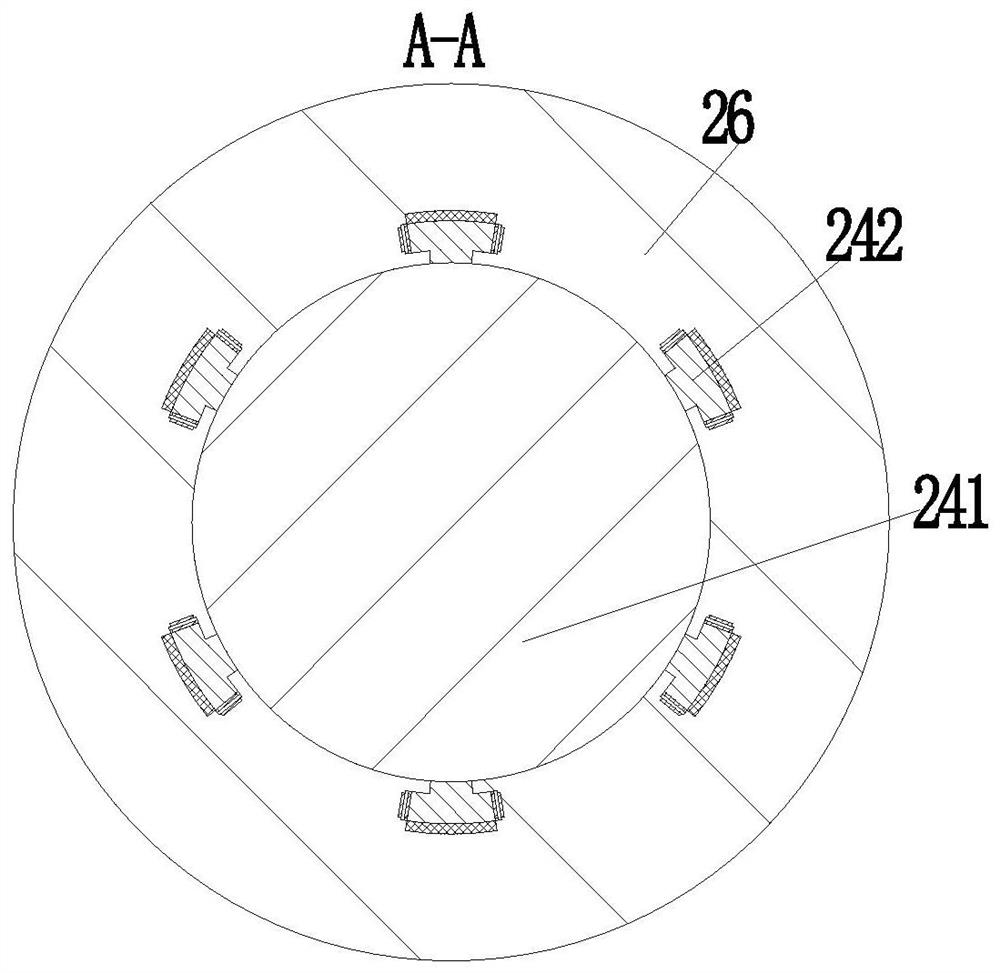

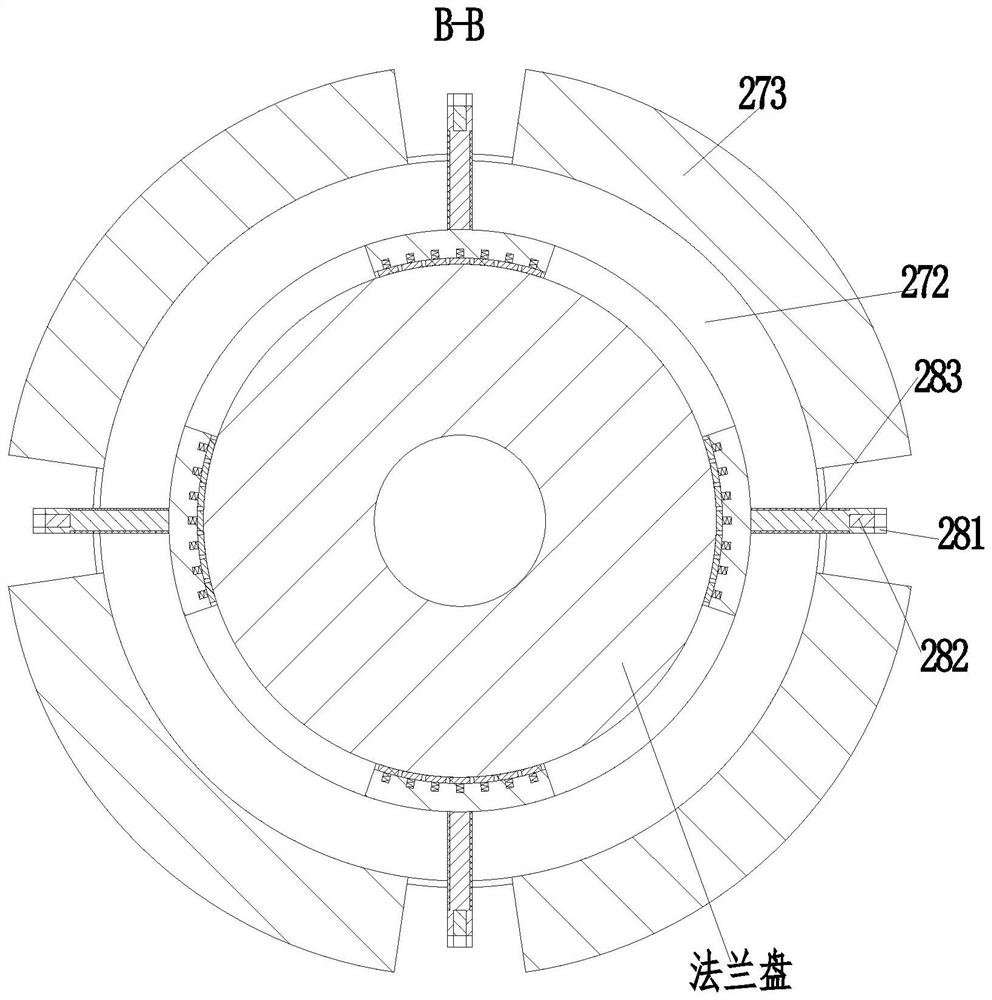

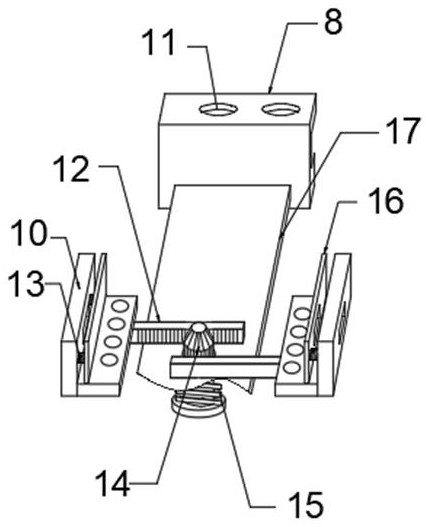

Clamping jaw mechanism of mechanical arm

InactiveCN111730628AImprove efficiencyReach fixedGripping headsConveyor partsPhysicsElectric machinery

The invention relates to a clamping jaw mechanism of a mechanical arm. The clamping jaw mechanism of the mechanical arm comprises a fixing device and a clamping jaw device; the clamping jaw device isinstalled at the lower end of the fixing device; the fixing device comprises a fixing plate, a rotating column, a rotating plate, a motor, a bevel gear, a first telescopic support and an inverted-L-shaped plate; the clamping jaw device comprises a second telescopic support, a supporting plate, a push column, a circular truncated cone frame, a cylindrical spring, a positioning column, a disc frameand a clamping frame; and the clamping frame comprises a long sliding rod, a rotating rod, a control rod, an arc-shaped block, a guide frame, a small ball and a thick rubber plate. According to the clamping jaw mechanism of the mechanical arm, the clamping jaw device is positioned through the fixing device, meanwhile, horizontal displacement of the clamping jaw device is controlled, flange platesof different sizes are clamped and fixed through the clamping jaw device, the clamping jaw device can be controlled to clamp the flange plates only through the second telescopic support, and thereforethe use efficiency of equipment is improved.

Owner:JIANGMEN YINXING ROBOTICS LTD

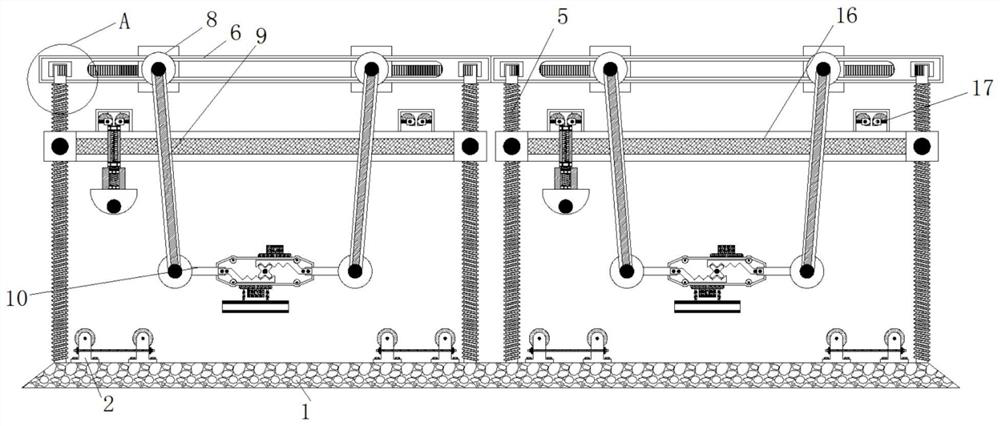

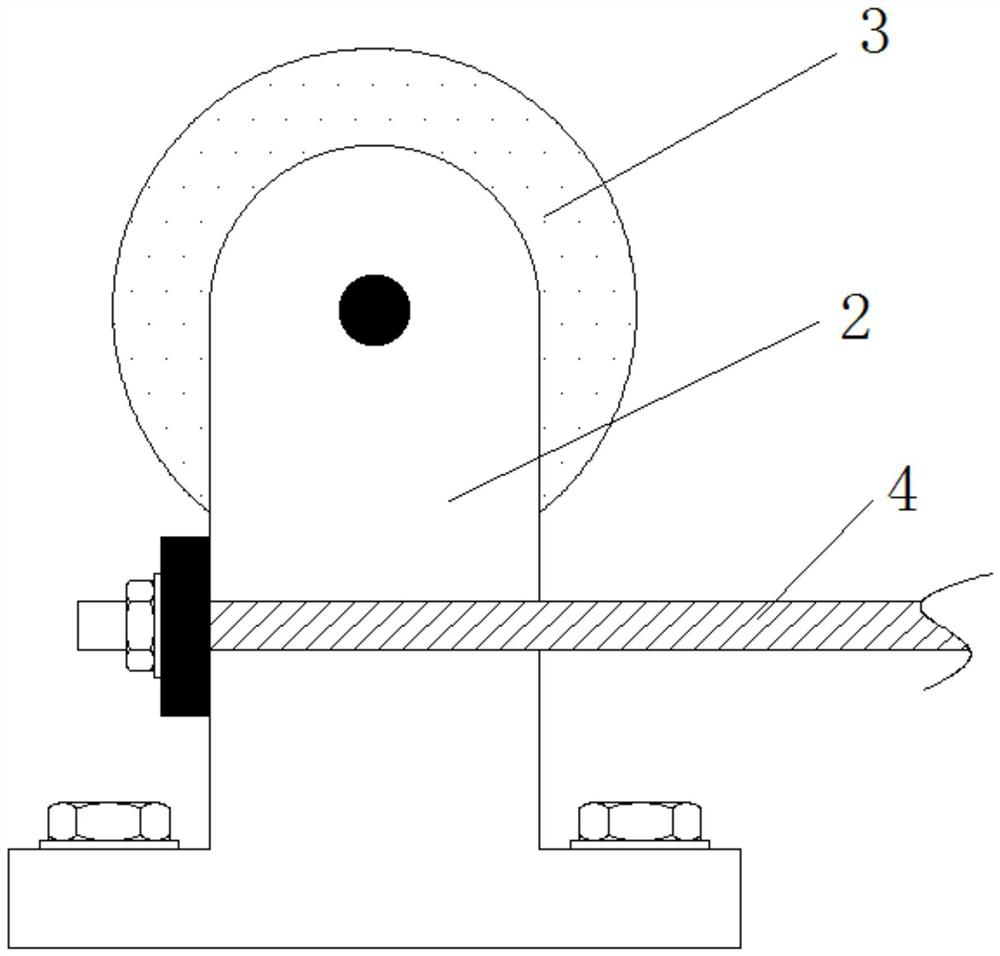

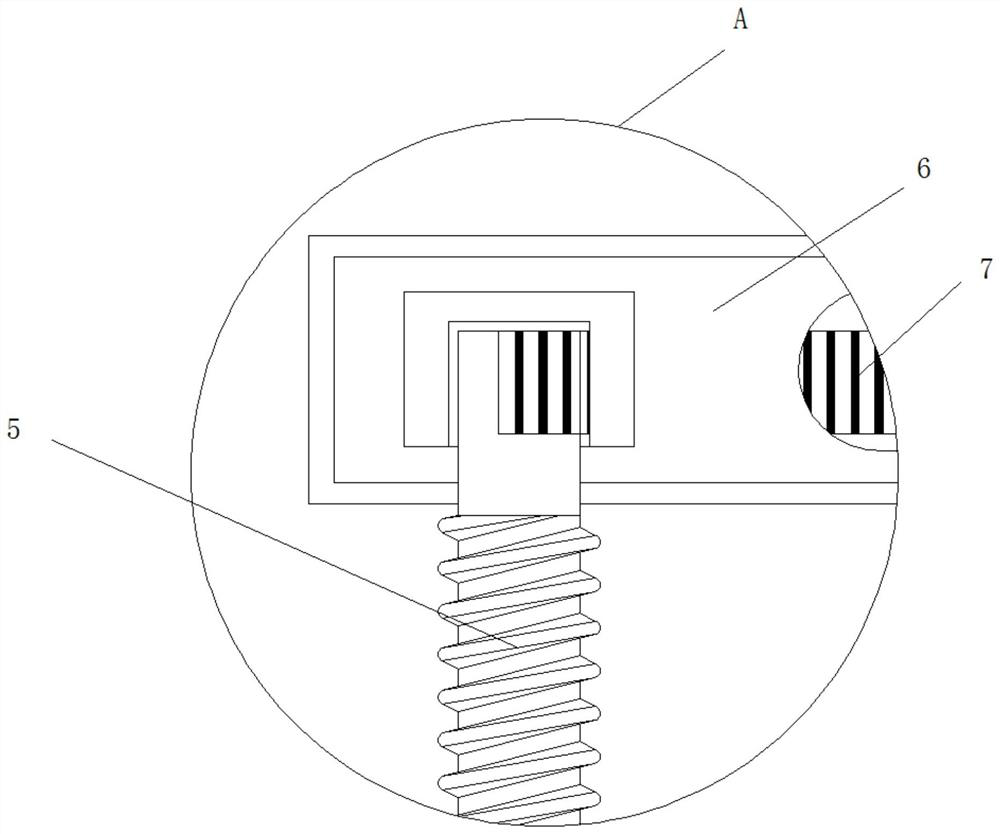

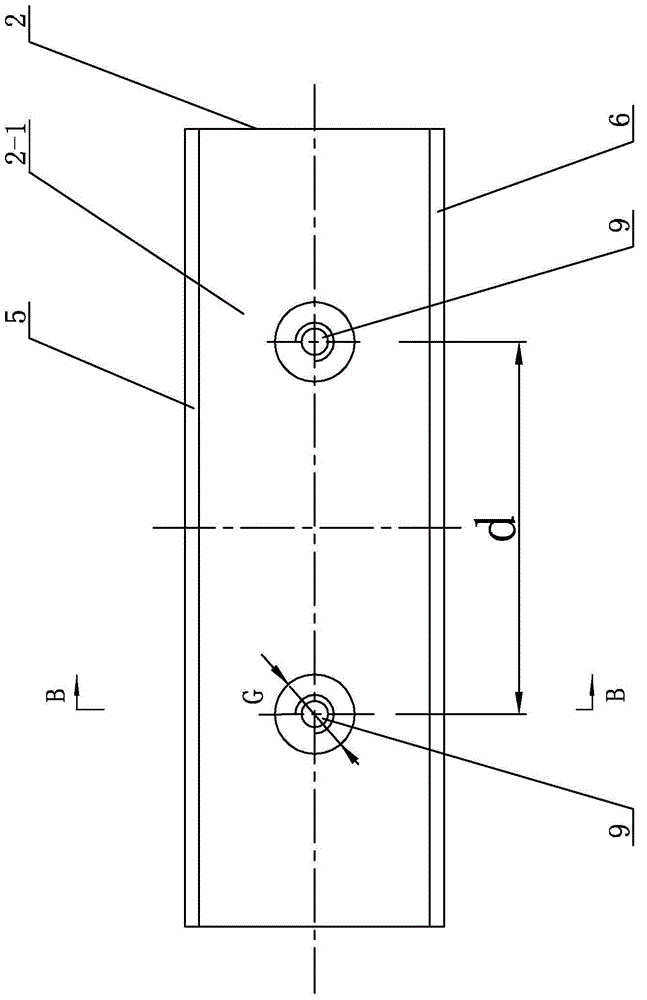

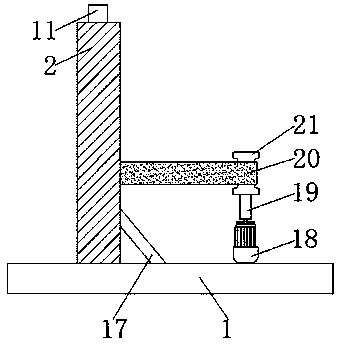

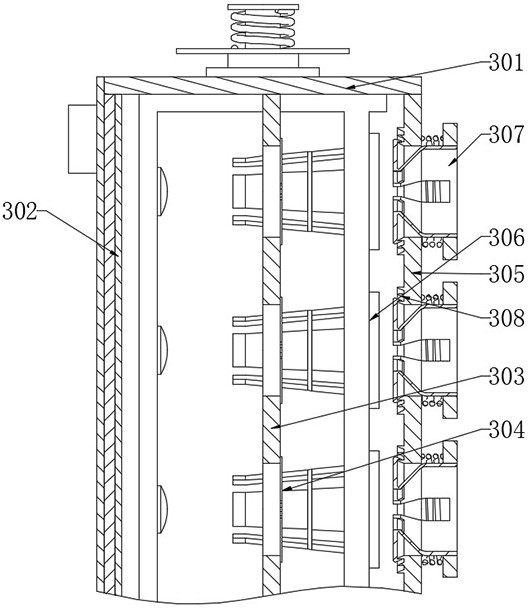

Formwork device of mirror-surface bare concrete beam column and construction method of formwork device

The invention relates to the field of concrete pouring, in particular to a formwork device of a mirror-surface bare concrete beam column and a construction method of the formwork device. The formwork device of the mirror-surface bare concrete beam column comprises formwork assemblies, each formwork assembly is in a square shell shape, a square inner cavity is formed in each formwork assembly, the multiple sets of formwork assemblies are sequentially connected in the vertical direction, the inner cavities of the multiple sets of formwork assemblies communicate with each other, a plurality of reinforcing rods are arranged in the formwork assemblies, the reinforcing rods are vertically arranged, plurality of sets of auxiliary assemblies used for keeping the reinforcing rods in the vertical state are arranged in the formwork assemblies, and the auxiliary assemblies correspond to the reinforcing rods in a one-to-one mode. The construction method of the formwork device applying the mirror-surface bare concrete beam column comprises the steps of formwork assembly installing, rod inserting, auxiliary assembly installing, reinforcing rod positioning, pouring, auxiliary assembly dismantling, formwork assembly accumulating, reinstalling, circulating and dismantling. The formwork device of the mirror-surface bare concrete beam column has the effect of improving the stability of the mirror-surface bare concrete beam column.

Owner:浙江信宇建设集团有限公司

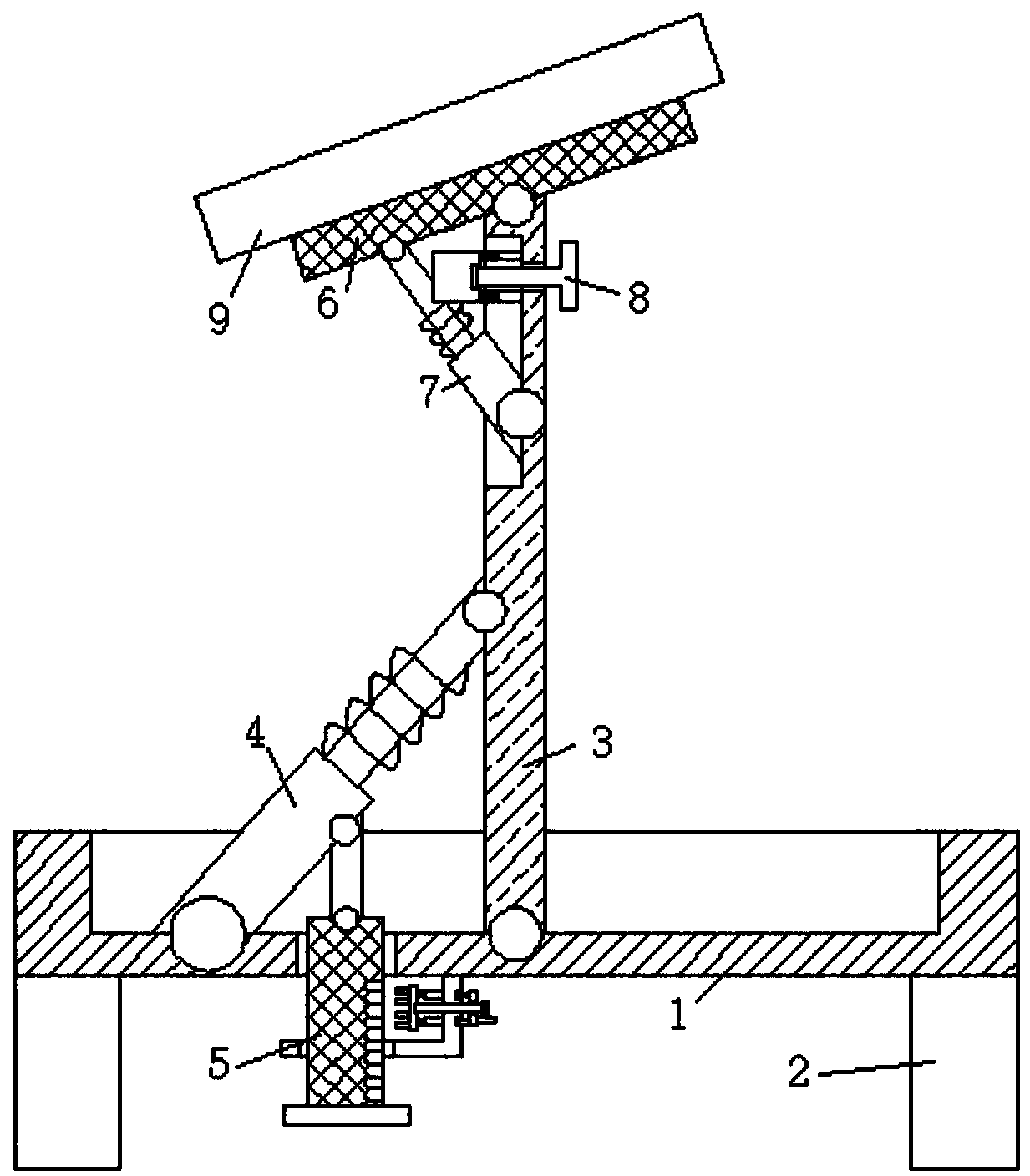

Foldable device for solar panel

InactiveCN109412510AAchieve rotationAchieve the effect of shrinkingPhotovoltaic supportsSolar heating energyClamp connectionMechanical engineering

The invention discloses a foldable device for a solar panel. A limiting device comprises a hinge rod; one end of the hinge rod is hinged onto the side wall of a first electric expansion rod; furthermore, the other end of the hinge rod is hinged onto the upper end face of a movable column; the movable column is movably inserted in a base; furthermore, the lower end of the movable column movably passes through an L-shaped plate; a screw moves, so that a resistance plate is contacted with a second electric expansion rod; a clamping groove continuously moves, so that the resistance plate drives asteel rope to move; therefore, a clamping rod rotates, so that the current position of the second electric expansion rod is in clamped connection; the effect of changing the angle is achieved; and thus, the device has the contractile effect, and also has the effect of adjusting the angle of the solar panel.

Owner:安徽兆拓新能源科技有限公司

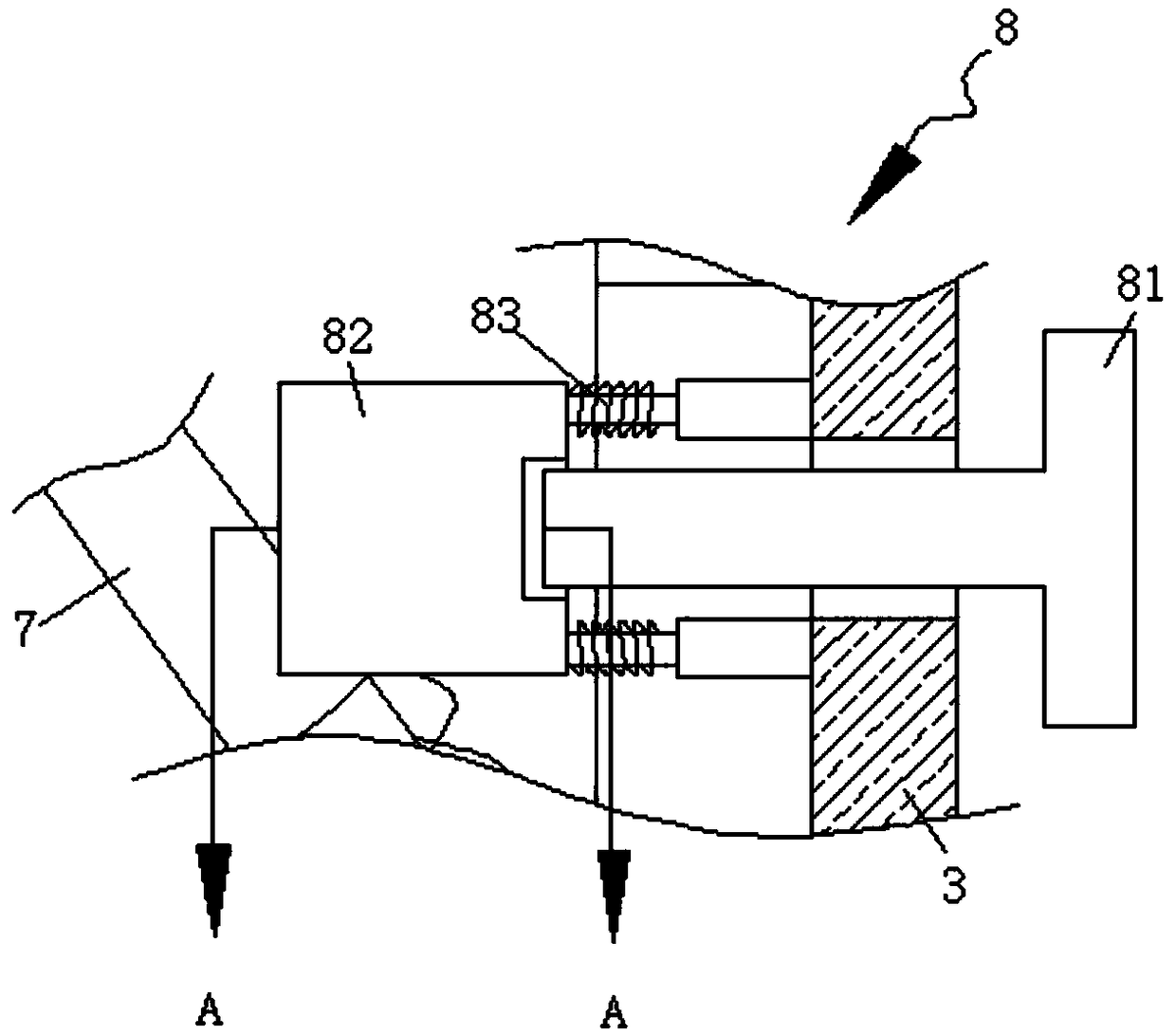

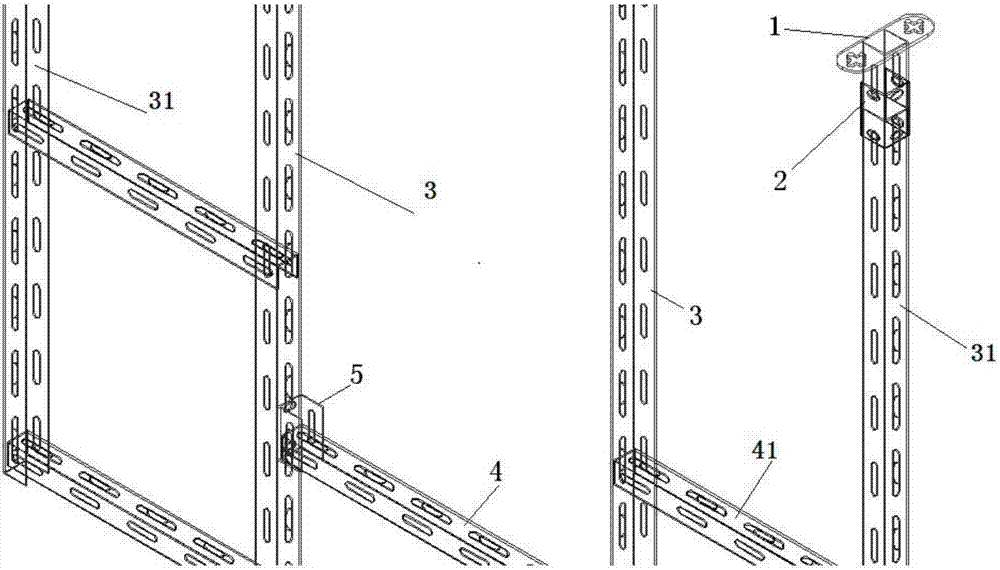

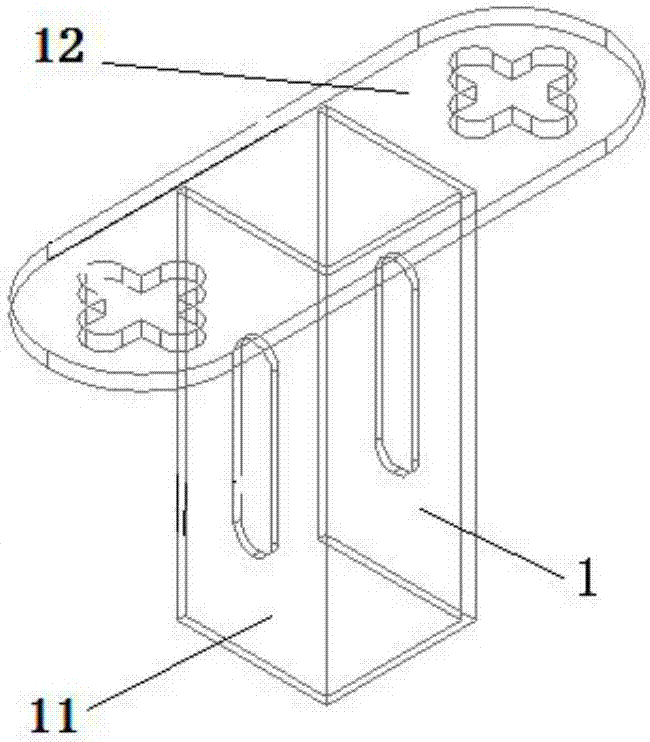

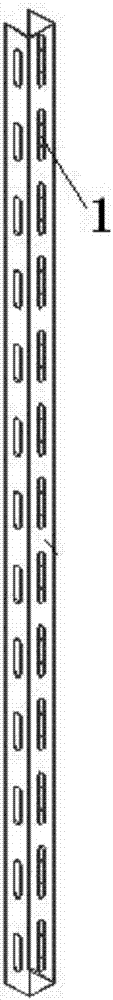

Mechanical and electrical installation comprehensive support

PendingCN106958694ATo achieve the purpose of comprehensive arrangementReach fixedPipe supportsLine tubingEngineering

The invention discloses a mechanical and electrical installation comprehensive support which comprises a plurality of support units formed by hanging brackets 1 and hanging brackets 2, wherein each of the hanging brackets 1 and the hanging brackets 2 is a piece of channel steel provided with a plurality of layers of elliptic bolt holes; each of the hanging brackets 1 is connected with one end of a corresponding cross arm 1; the other end of each of the cross arms 1 is connected with the corresponding hanging bracket 2; one end of each of the hanging brackets 1 and one end of the corresponding hanging bracket 2 are connected with a hanging bracket base through a hanging bracket connector; a hanging bracket reverse connector 1 is connected to the outer side surface of the bottom wall of each of the hanging brackets 1 or each of the hanging brackets 2; each of the hanging bracket reverse connectors 1 is connected with one end of a cross arm 2; the other end of each of the cross arms 2 is connected with a hanging bracket reverse connector 2; each of the hanging bracket reverse connectors 2 is connected with the outer side surface of the bottom wall of the corresponding hanging bracket 1 or hanging bracket 2 of the other support unit. According to the mechanical and electrical installation comprehensive support provided by the invention, a limited space is layered, so as to achieve the purpose of integrally arranging various pipelines in an electromechanical engineering; therefore the mechanical and electrical installation comprehensive support is simple and practical, convenient and fast to assemble, and high in universality and interchangeability.

Owner:CHINA RAILWAY CONSTR GROUP

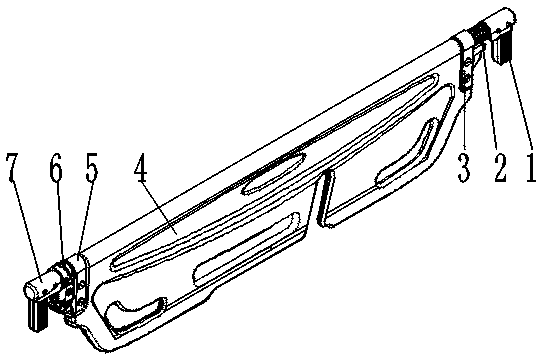

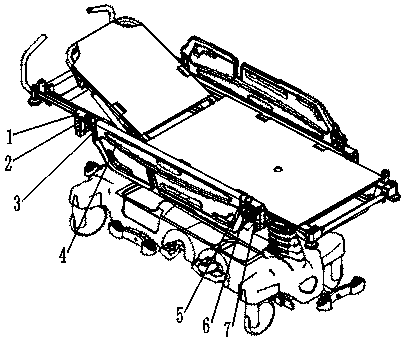

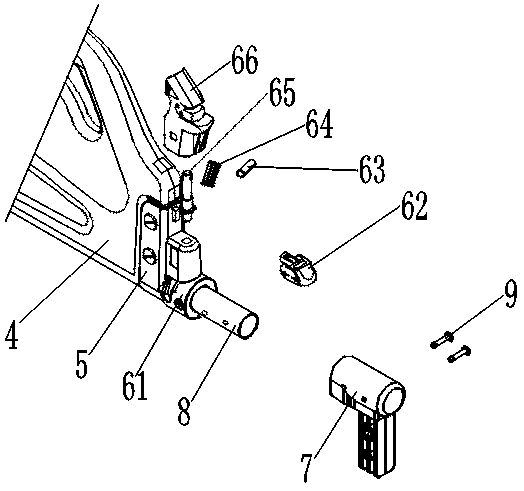

Rotatingly locking and automatically reset medical stretch rail unlocking device

The invention discloses a rotatingly locking and automatically reset medical stretch rail unlocking device. The rotatingly locking and automatically reset medical stretch rail unlocking device comprises a rail body, first rail fixing units, second rail fixing units, first rail support units, second rail support units, rail rotating shafts, support rotary pressure springs and a rail locking module;both ends of the rail body are hinged onto the rail rotating shafts through the first rail fixing units and the second rail fixing units, and both ends of the rail rotating shafts are fixed on both sides of a stretcher through the first rail support units and the second rail support units; the support rotary pressure springs are mounted between the second rail fixing units and the second rail support units; the rail locking module is mounted between the first rail fixing units and the first rail support units and composed of a first rail locking unit, a second rail locking unit, a rotary limiting unit, a retaining pin, a compressed spring and a hollow pin. The rotatingly locking and automatically reset medical stretch rail unlocking device is complex in structure but simple in operation and meanwhile achieves a function of avoiding maloperation of patients or other non-medical personnel.

Owner:HEBEI PUKANG MEDICAL INSTR

Hardware expansion unit structure based on computer modularization

ActiveCN113391683AReach fixedRealize the clamping effectDigital processing power distributionComputer moduleModularity

The invention discloses a hardware expansion unit structure based on computer modularization, the modular hardware expansion unit structure based on the computer comprises a mainboard and partition plates fixedly connected with two sides of the mainboard, the partition plates are used for being fixed on a computer box body, one of the partition plates is provided with a sliding groove, through holes are formed in the upper surface of the partition plate in an equidistant array mode; a connector which is fixedly connected to one end of the main board; and a limiting device which comprises a sliding block and a supporting plate, the sliding block is arranged in a channel steel shape and is slidably connected between the sliding groove and the upper surface of the partition plate, the two rack plates connected to the lead screw in a meshed mode are far away from each other, and the baffles fixed to one ends of the rack plates are also far away from each other; a unit plate needing to be expanded is placed between the two clamping plates, the two rack plates and the baffle are close to each other by reversely rotating the lead screw, and the effect of clamping the unit plate needing to be expanded is achieved.

Owner:东营职业学院

Special climbing device for military training

The invention discloses a special climbing device for military training, which comprises a bottom plate, a support rod, a spray head, a support frame, an avoidance hole, an adjusting plate, a push plate, a ladder seat, a guide sleeve, a sliding rod, an adjusting seat, a rack plate, a rotating shaft, a first gear, a gear sleeve, a second gear, a baffle plate and a spring. The special climbing device for military training is simple to operate and powerful in function. Firstly, the difficulty of climbing training can be conveniently adjusted by a training instructor through a sliding type adjusting design, the climbing training requirements of different degrees are met, the practicability of military training is expanded, secondly, the climbing difficulty of training personnel can be increased through the matching effect of the rainy day simulation mechanism, and finally, the special climbing device for military training is beneficial to the popularization and application of military training.

Owner:郭礼

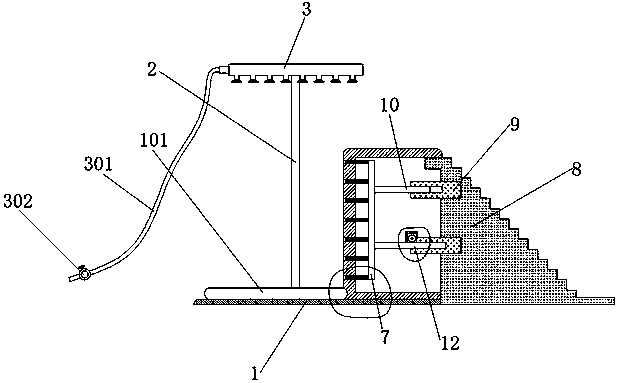

Adjustable household floor lamp

InactiveCN109595489AEasy to useImprove applicabilityLighting support devicesElectric circuit arrangementsEngineeringLED lamp

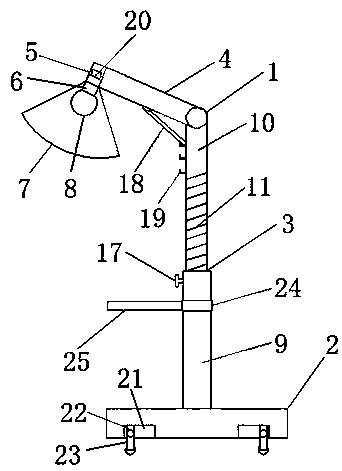

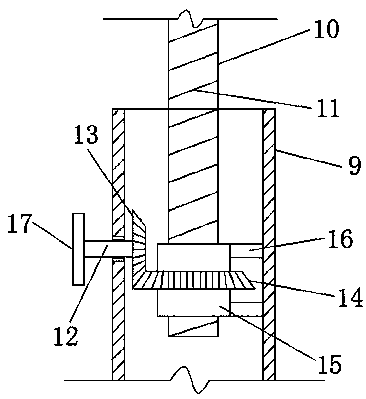

The invention discloses an adjustable household floor lamp which comprises a lamp body. A base is mounted at the bottom of the lamp body. A support rod is vertically mounted at the upper center of thebase upwards. A connection rod is mounted at the top end of the support rod in a hinged mode through a hinge column. A lampshade mounting seat is fixedly mounted at the other end of the connection rod. A lampshade is mounted on the lampshade mounting seat. An LED lamp holder is connected to the part, inside the lampshade, of the lampshade mounting seat. An LED bulb is mounted on the LED lamp holder. A telescopic adjustment mechanism is arranged in the support rod. An angle adjustment mechanism is arranged between the support rod and the connection rod. According to the adjustable household floor lamp disclosed by the invention, the telescopic adjusting mechanism is arranged in the support rod to adjust the height of the support rod, and the angle adjustment mechanism is arranged to adjustthe angle between the connection rod and the support rod, so that the applicability of the floor lamp is improved, and the floor lamp is more convenient to use; a rotatable storage plate is arrangedon a lower support rod body, sundries can be placed on the storage plate, thereby achieving a storage function of the floor lamp.

Owner:珠海横琴新区辉腾电子科技有限公司

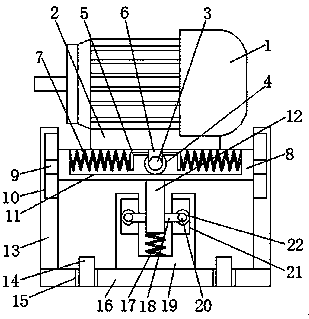

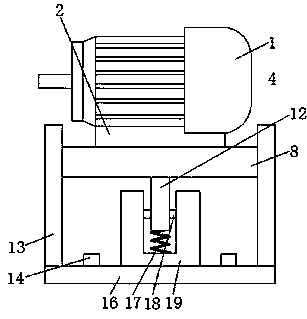

Damping and noise reduction motor

InactiveCN109756060ATo achieve the mobile effectReduce vibrationSupports/enclosures/casingsEngineeringWheel and axle

The invention provides a damping and noise reduction motor, and relates to the field of motors. The damping and noise reduction motor includes a motor body, a motor body seat is fixedly connected to the bottom of the motor body, a supporting plate is connected to the lower surface of the motor body seat in an overlapped mode, and a buffer groove is formed in the upper surface of the supporting plate. A bracket is fixedly connected the lower surface of the motor body seat and located in the buffer groove, a wheel shaft is fixedly connected to the end, away from the motor body seat, of the bracket, a connecting plate is fixedly connected to the left side of the bracket, a side plate is connected to the left side of the supporting plate in an overlapped mode, and a bottom plate is fixedly connected to the bottom of the side plate. The damping and noise reduction motor achieves the effect that the motor body moves when the motor body vibrates by the cooperation between the bracket, the wheel shaft and a roller, and the effect of buffering the vibration force of the motor body by a compression spring is achieved by the movement of the connecting plate; and a fixing rod is arranged inside a fixing hole, the bottom plate can be fixed, and the motor is fixed.

Owner:扬州市龙腾焦化设备有限公司

Movable baking device for biscuit and pastry production

InactiveCN112544641AReach shock absorptionArrival bufferBaking ovenVibration suppression adjustmentsEngineeringMechanical engineering

The invention discloses a movable baking device for biscuit and pastry production. The movable baking device comprises a shell, a water tank is fixedly installed at the bottom of an inner cavity of the shell, damping assemblies are fixedly installed at the four corners of the bottom of the inner cavity of the water tank, and buffer assemblies are fixedly installed at the tops of the damping assemblies. Fourth springs are pushed through a box body, the fourth springs deform after being extruded, and impact is further buffered through recoil force generated after the fourth springs deform; and meanwhile, the box body drives fixing rods to move, the fixing rods drive sliding sleeves to move, the sliding sleeves extrude second springs, impact force is further buffered through the second springs, and when the box body is bumped, the box body drives first supporting rods to move, the first supporting rods drive first sliding blocks to move, the first sliding blocks extrude first springs, andthe impact force on the box body after bumping is buffered through the reverse thrust generated after the first springs are extruded, so that the damping purpose is achieved.

Owner:刘子锐

Surface polishing equipment for metal bar based on worm wheel and worm

ActiveCN111496614AAchieve the effect of automatic polishing sideReach fixedEdge grinding machinesGrinding carriagesPolishingElectric machinery

The invention relates to the technical field of metal bar polishing and discloses surface polishing equipment for a metal bar based on a worm wheel and a worm. The equipment comprises a rack, whereina chute is formed in the top of the rack; a slide block is slidably connected in the chute; a transmission rope is fixedly connected to the right side of the slide block; the bottom of the transmission rope is fixedly connected to a motor; the left side of the motor is fixedly connected to a driving worm; the left side, on the left side of the driving worm wheel, is fixedly connected to a polishing sheet; the worm is engaged to the bottom of the driving worm wheel; and the left side of the slide block is fixedly connected to a reset spring. According to the surface polishing equipment for themetal bar based on the worm wheel and a worm, the motor rotates to tighten up the transmission rope and the transmission rope drives the slide block to move rightward, a pull rope is relaxed, a pressure spring pushes a push rod to descend, the push rod descends to push a lower claw to ascend, and then, by matching the upper and lower claws in use, effects of fixing the metal bar and polishing thebottom surface and the top surface are achieved.

Owner:青岛张氏力拓精密机械有限公司

Concrete quality detection device

ActiveCN113092236AReduce scratchesReduce the possibility of damageMaterial strength using tensile/compressive forcesTotal factory controlStructural engineeringWorkbench

The invention relates to a concrete quality detection device which comprises a device body, a splash-proof frame, a workbench, an air cylinder, a mounting plate and a pressure sensor, the splash-proof frame is fixedly connected to the top of the workbench, the workbench is fixedly mounted in the splash-proof frame, and the pressure sensor is fixedly mounted at the top of the workbench. A guide rail is fixedly connected to the inner side wall of the splash-proof frame, a first storage rail and a second storage rail are fixedly connected to the two ends of the guide rail correspondingly, and the first storage rail and the second storage rail are located on the two sides of the workbench correspondingly; a first winding roller is rotatably connected to the inner side wall of the first storage rail, a second winding roller is arranged in the second storage rail, a protective film is fixedly connected between the first winding roller and the second winding roller, and the protective film covers the upper surface of the pressure sensor; and a fixing assembly used for fixing the second winding roller is further arranged in the workbench. The protective film covers the upper surface of the pressure sensor, so that the possibility that the surface of the pressure sensor is scratched or damaged is reduced.

Owner:安徽泓建工程项目管理有限公司

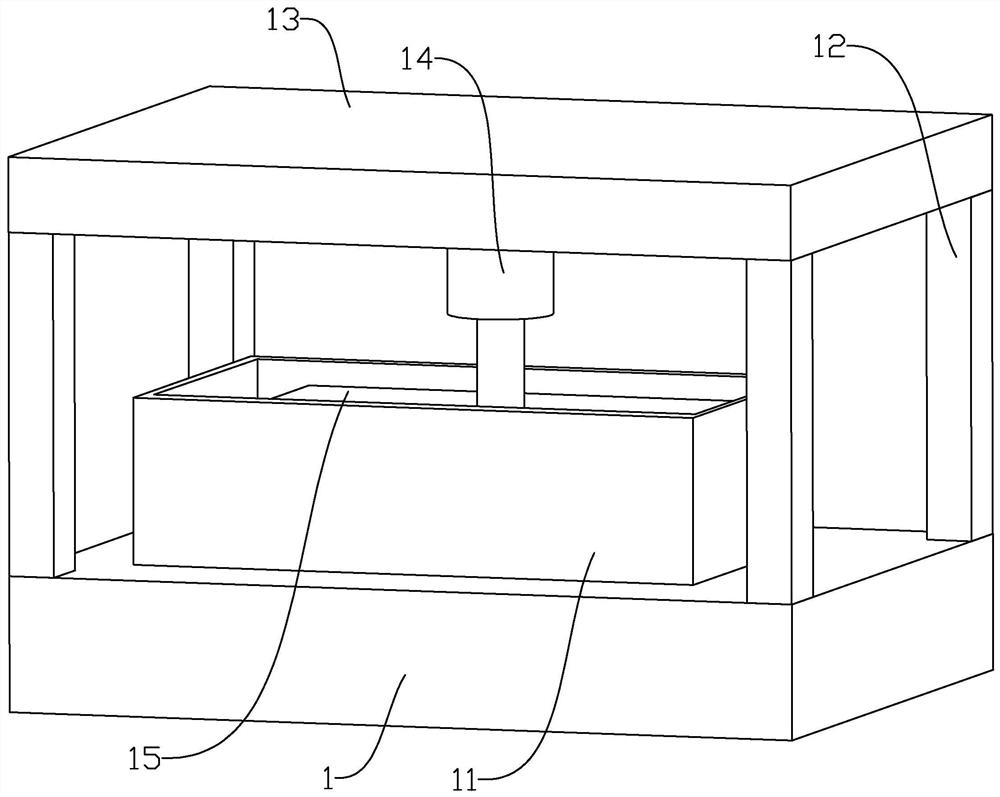

Intelligent manufacturing bending equipment for hardware mechanical production and machining

InactiveCN112718981AReach fixedAvoid wastingMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention relates to the technical field of hardware machinery production, and discloses intelligent manufacturing bending equipment for hardware machinery production and machining. The intelligent manufacturing bending equipment for hardware machinery production and machining comprises an equipment main body; a fixed plate is fixedly mounted at the bottom of the equipment main body; rolling wheels are rotatably connected to the top of the fixed plate; a balance bracket is fixedly connected to the front surface of the fixed plate; and a rotating screw rod is rotationally connected to the interior of the equipment main body. Hardware is pressed and sucked through a pressing plate, so that the effects of fixing hardware parts and avoiding waste are achieved; a screw is rotated to drive a lifting plate to descend to the bending position, a bending ball abuts against the hardware, a pressing frame at the top of a lower baffle is driven to deform, the pressing ball gets close to the edge of the pressing frame while the interior of the pressing frame senses a pressure, and a telescopic spring is driven to do synchronous motion to generate a reserved moving space, so that the bending ball is prevented from directly descending to bend; and therefore, the effect of adjusting the bending angle is achieved.

Owner:杭州蒙托机械科技有限公司

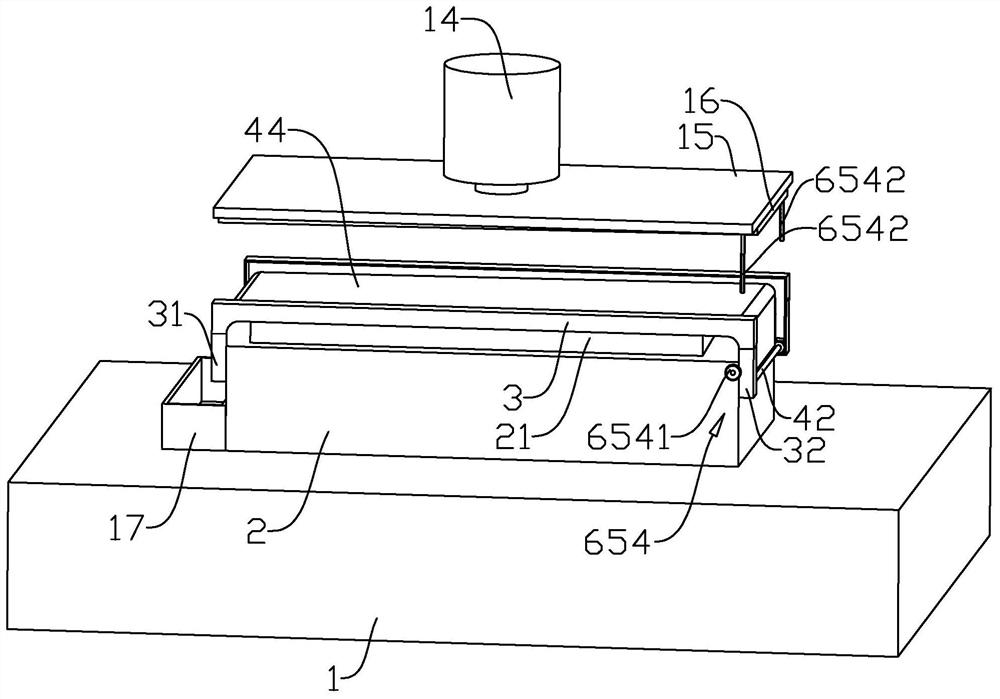

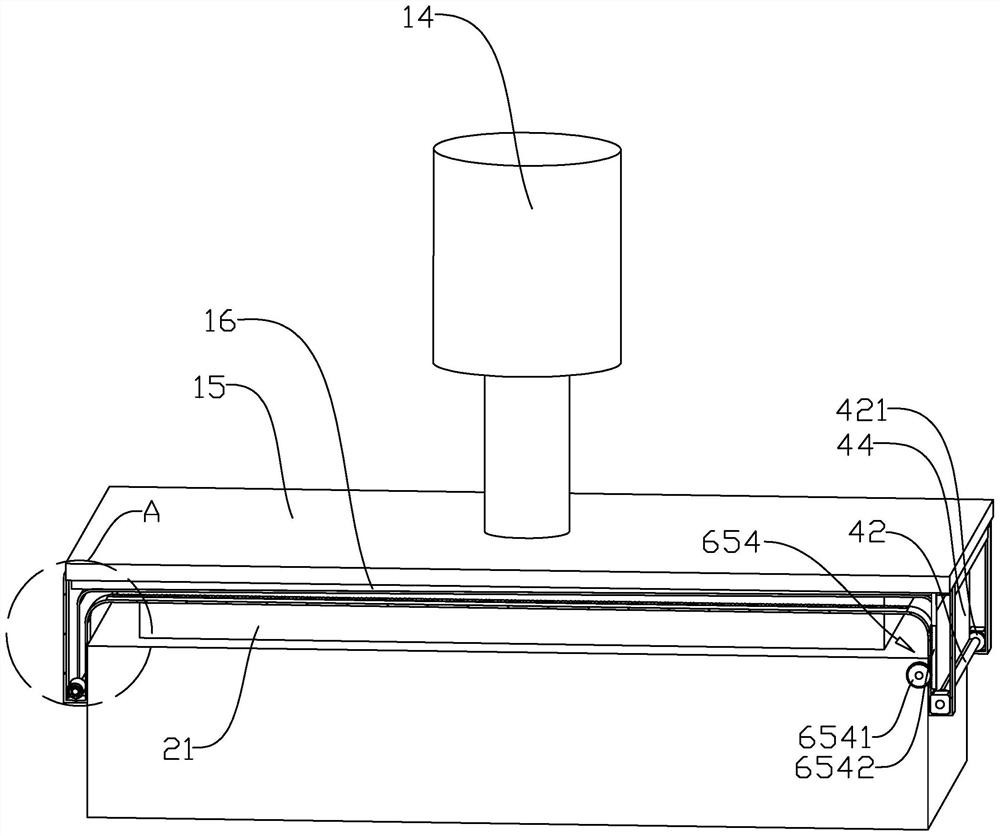

Perforating device suitable for aluminum alloy plates in different shapes

ActiveCN112517739AEvenly punchedHigh speedMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention relates to the field of aluminum alloy plate machining, in particular to a perforating device suitable for aluminum alloy plates in different shapes. The perforating device comprises a base, a mounting connecting frame, a guide frame, a power lifting mechanism, a plate bidirectional clamping mechanism and the like; the mounting connecting frame is fixedly installed on one side of thebase, and the guide frame is fixedly installed on one side of the base, and located on one side of the mounting connecting frame; and the power lifting mechanism is installed at the end, away from the base, of the mounting connecting frame. According to the perforating device, through cooperation of the power lifting mechanism and a plate intermittent pushing mechanism, the aluminum alloy platescan be punched, and the function of uniform and quick punching is achieved.

Owner:凯米特新材料科技有限公司

Special fixture for milling inclined planes of symmetric V-shaped parts with holes

InactiveCN106141724ASimple structureEasy to operatePositioning apparatusMetal-working holdersEngineeringProcessing cost

The invention discloses a special fixture for milling inclined planes of symmetric V-shaped parts with holes, relates to the special fixture for milling the inclined planes and aims at solving the problems that high processing cost, difficulty in clamping and aligning and inaccuracy in locating are caused due to the fact that no special fixture is used for milling the inclined planes of the symmetric V-shaped parts with holes. A first fixture body and a second fixture body are rectangular respectively; one end face of the first fixture body is a first inclined plane; both a first stopping edge and a second stopping edge are located on the first inclined plane; the first stopping edge is fixedly connected to the upper part of the first inclined plane; the second stopping edge is fixedly connected to the lower part of the first inclined plane; two through holes are formed in the first inclined plane; one end face of the second fixture body is a second inclined plane; both a third stopping edge and a fourth stopping edge are located on the second inclined plane; the third stopping edge is fixedly connected to the upper part of the second inclined plane; the fourth stopping edge is fixedly connected to the lower part of the second inclined plane; two counter bores are processed in the second inclined plane; and the diameters of two screws are identical with the apertures of the two counter bores. The special fixture disclosed by the invention is used for processing the symmetric V-shaped parts with holes.

Owner:HARBIN JIANCHENG GRP

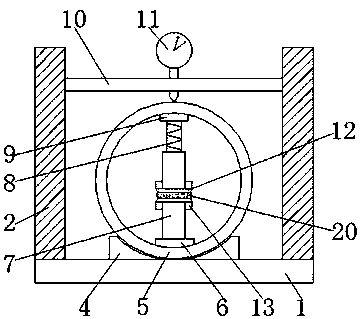

After-forging shaping device for bearing ring assembly

The invention relates to the technical field of bearing ring production, and discloses an after-forging shaping device for a bearing ring assembly. The after-forging shaping device comprises a base; supporting frames are fixedly connected to the two ends of the front side of the upper surface of the base, sliding grooves are formed in the opposite faces of the two supporting frames, and the two sliding grooves are slidably connected with the two ends of a cross rod correspondingly; and a dial indicator is fixedly connected to the middle of the cross rod, a measuring rod of the dial indicator penetrates through the cross rod and extends to the lower portion of the cross rod. According to the after-forging shaping device for the bearing ring assembly, shaping of a bearing ring is measured through the sliding grooves, the cross rod and the dial indicator; by arranging a fixing seat, the bearing ring is placed more stably; through a driving wheel, a driven wheel, a movable rod and a jacking head, the bearing ring is expanded and shaped to reach the standard size; and through a fixing block, a pipe sleeve and a fixing ring, the moving direction of the movable rod is further fixed, and using is more convenient.

Owner:HEFEI YUANDA BEARING FORGING

Outdoor equipment protection mechanism with damp-proof and reinforcing functions

InactiveCN110944481AImprove efficiencyFixedCasings/cabinets/drawers detailsDrying gas arrangementsDamp proofingEngineering

The invention provides an outdoor equipment protection mechanism with damp-proof and reinforcing functions. The mechanism comprises a watchcase . First sliding blocks are slidably connected to the topand the bottom of the left side of an inner wall of the watchcase. The right sides of the two first sliding blocks are rotationally connected with first supporting rods. The right sides of the two first supporting rods are rotationally connected with a first clamping plate. Second sliding blocks are slidably connected to the top and the bottom of the right side of the inner wall of the watchcase,second supporting rods are rotatably connected to the right sides of the two second sliding blocks, second clamping plates are rotatably connected to the right sides of the two second supporting rods, and a threaded rod is rotatably connected to the right side of the inner wall of the watchcase. The first clamping plate, the second clamping plates and a threaded rod are used in cooperation, andthe distance between the two clamping plates is controlled through the threaded rod and the threaded block, so that equipment is fixed.

Owner:扬州国润新能源科技有限公司

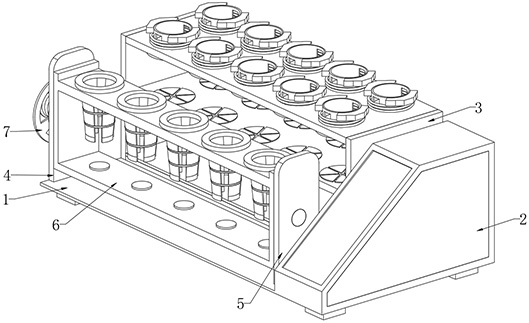

Biological kit device with indication function

InactiveCN112547160AEasy to operateAchieve a fixed effectTest tube stands/holdersKit deviceTube placement

The invention discloses a biological kit device with an indication function, and belongs to the field of biology, the biological kit device with the indication function comprises a chassis, one side of the top of the chassis is fixedly connected with a control mechanism, and the front end of the top of the chassis is provided with an experiment test tube placing mechanism; a second fixing plate isrotatably connected to the side, close to the control mechanism, of the experiment test tube placing mechanism, the second fixing plate is fixedly connected to the top of the chassis, and a first fixing plate is arranged on the side, away from the control mechanism, of the experiment test tube placing mechanism and fixedly connected to the top of the chassis; a pressing plate shaft is fixedly connected to the side, away from the control mechanism, of the experiment test tube placing mechanism, and a rotating handle is in transmission connection to the side, away from the control mechanism, ofthe experiment test tube placing mechanism. The inclination angle of a prevention frame can be adjusted, an adaptive culture solution can be conveniently extracted, and test tubes with different diameters can be clamped, so that centrifugal tubes can be centrifugally placed.

Owner:李晓露

Construction site personnel health detection door

ActiveCN110731754AReach fixedEasy to useDiagnostic recording/measuringSensorsArchitectural engineeringElectric machinery

The invention discloses a construction site personnel health detection door. The detection door comprises a base, a motor, a detection main body, a hanging rope and a detection lantern ring, a fixed bottom plate is fixedly mounted above the base, a motor is mounted outside the top end of the right side of the fixed bottom plate, the top end of the motor is connected to rotating discs, and the topend of each rotating disc is connected to a lead screw arranged in the fixed bottom plate, a fixed rod connected to the top end of a rotating sleeve passes through a limiting sliding groove in the surface of the fixed bottom plate and is connected to a movable plate, bristles are connected to the lower portion of the movable plate, and the rotating discs are connected t through a belt. According to the construction site personnel health detection door, the lead screw can drive an upper cylinder body and a lower cylinder body to extending and retracting at the same time in the rotating process,movable rolling wheels can be well driven to extend and retract in the extending and retracting process, and the effects of fixing the whole detection door and conveniently moving the whole detectiondoor are achieved.

Owner:深圳中物智建科技有限公司

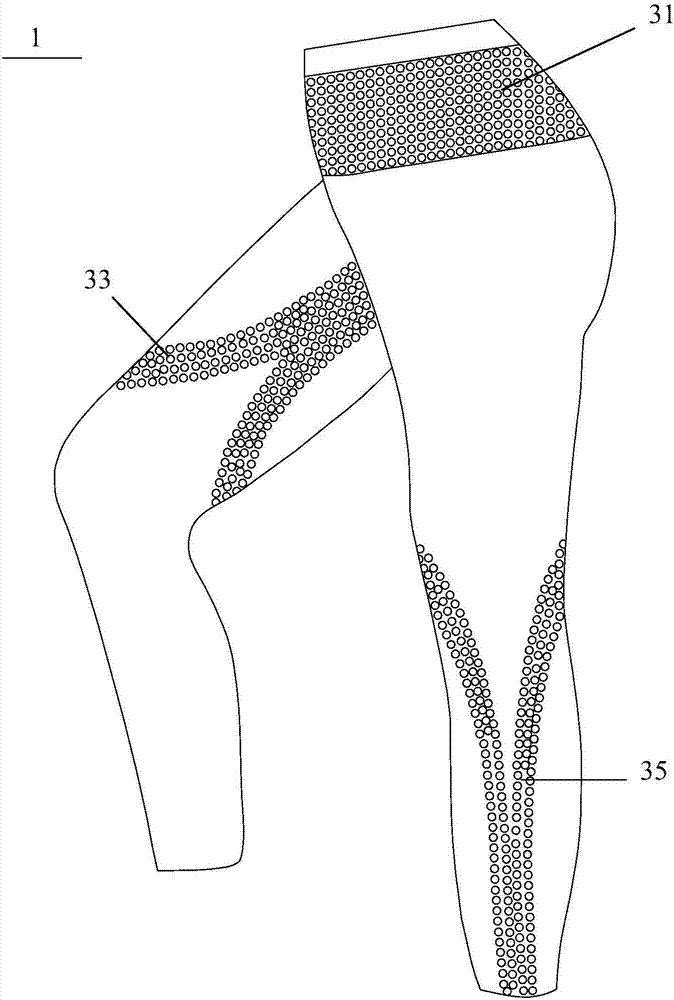

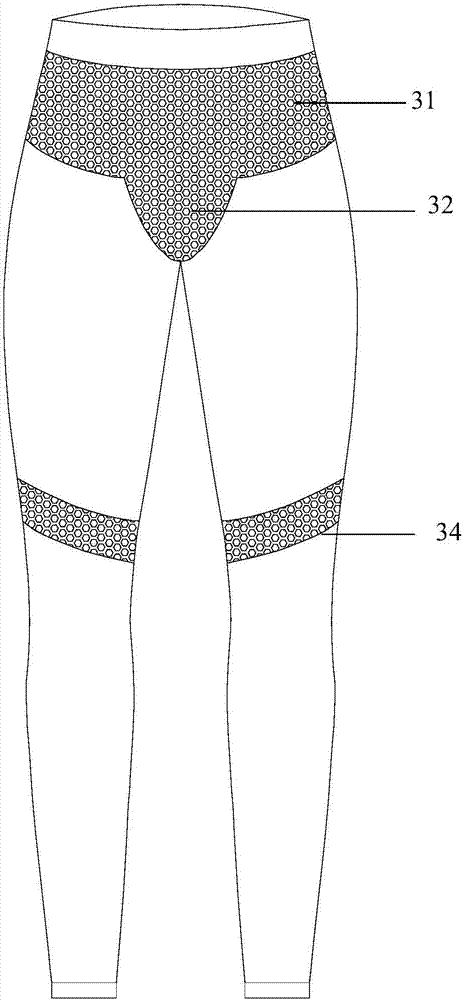

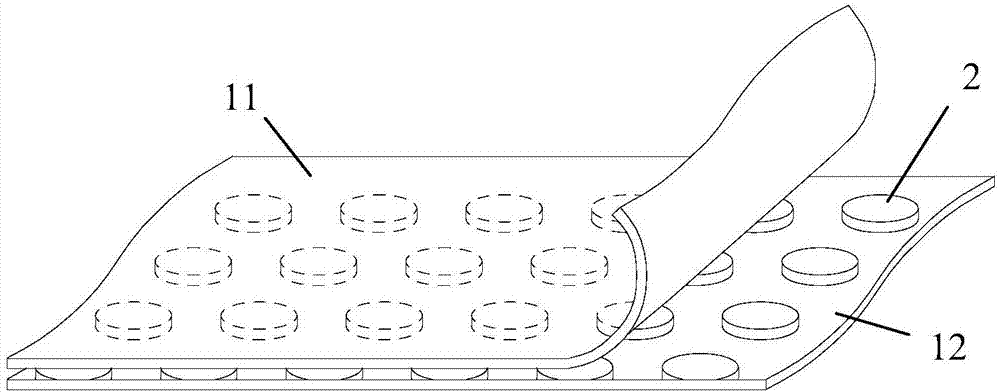

Trousers

The invention discloses a pair of trousers, which comprises an integrated trouser body (1) which is composed of at least two layers of fabrics, namely an inner fabric and an outer fabric, wherein the outer fabric (11) and the inner fabric (12), which are adjacent, are bonded by virtue of point adhesives (2); and the point adhesives, in correspondence to force exerting parts of a body, are arranged on a crotch part (21), a front rise part (32), thigh parts (33), knees (34) and calf parts (35), so that the body is fixed. According the trousers provided by the invention, the inner fabric and the outer fabric are in trace-less bonding by virtue of the point adhesives on some parts (such as force exerting points of the crotch part, the front rise, parts round the knees, the calf parts and the thigh parts) of the human body, so that high-elasticity fabric is saved, cost is reduced and dead weight of the trousers can be reduced; through bonding of the point adhesives, special parts of the body can be fixed in one aspect, so that the body is better covered to prevent muscle vibration in motions, and upward circulation of blood is accelerated in the other aspect, so that fatigue is relieved.

Owner:SHANGHAI YONGZI FASHION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com