Perforating device suitable for aluminum alloy plates in different shapes

An aluminum alloy plate and punching device technology, applied in the field of aluminum alloy plate processing, can solve the problems of hand injury and uneven opening, and achieve the effect of uniform punching and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

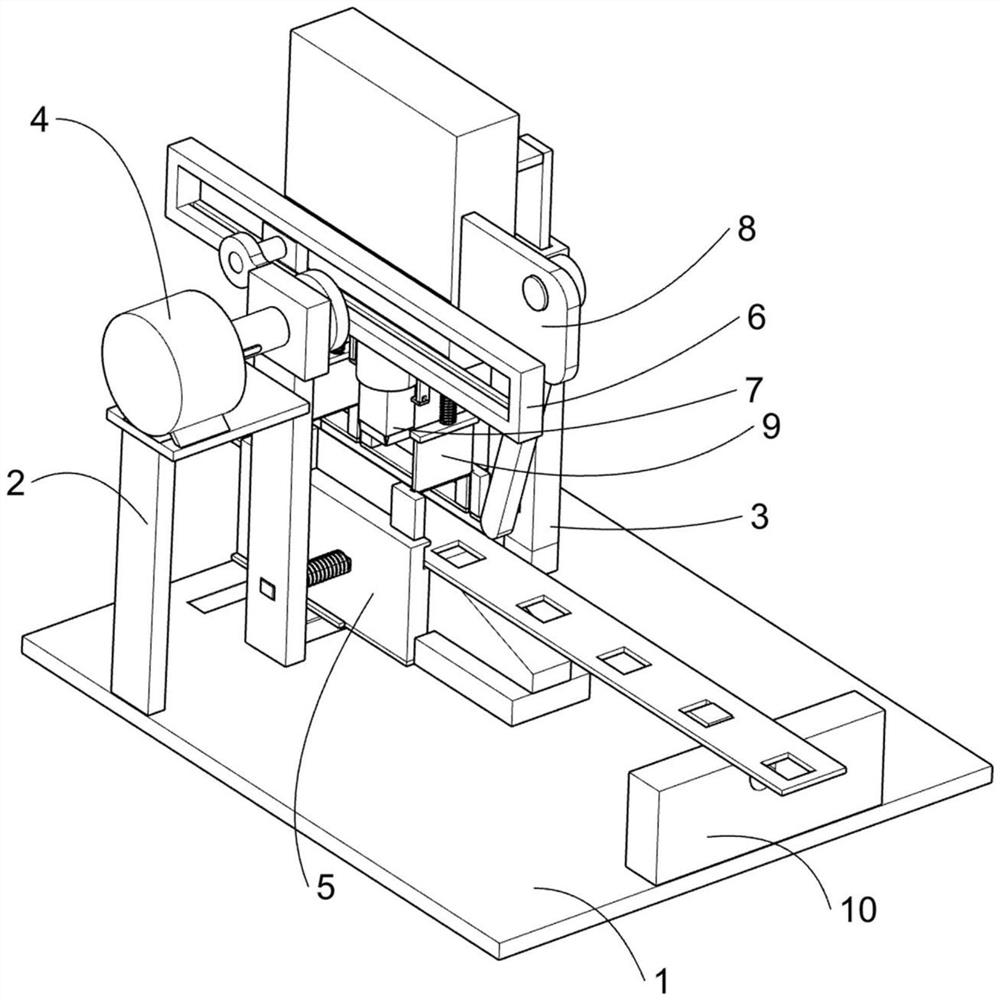

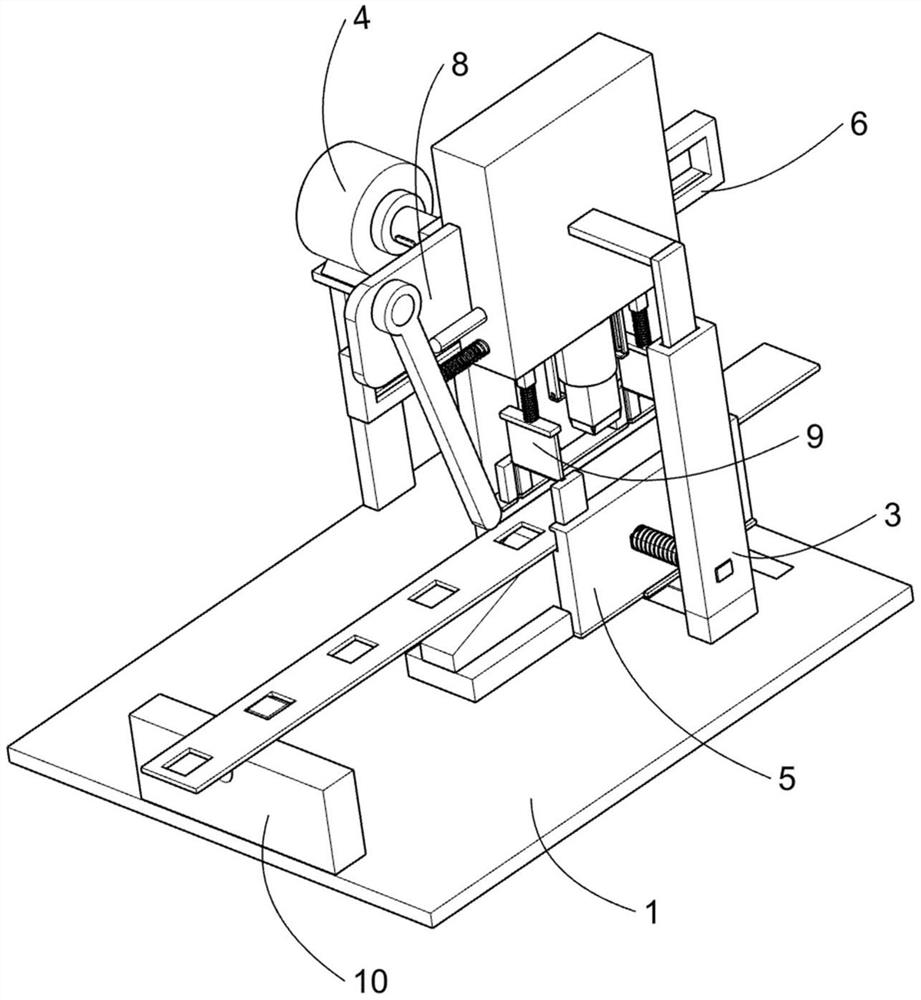

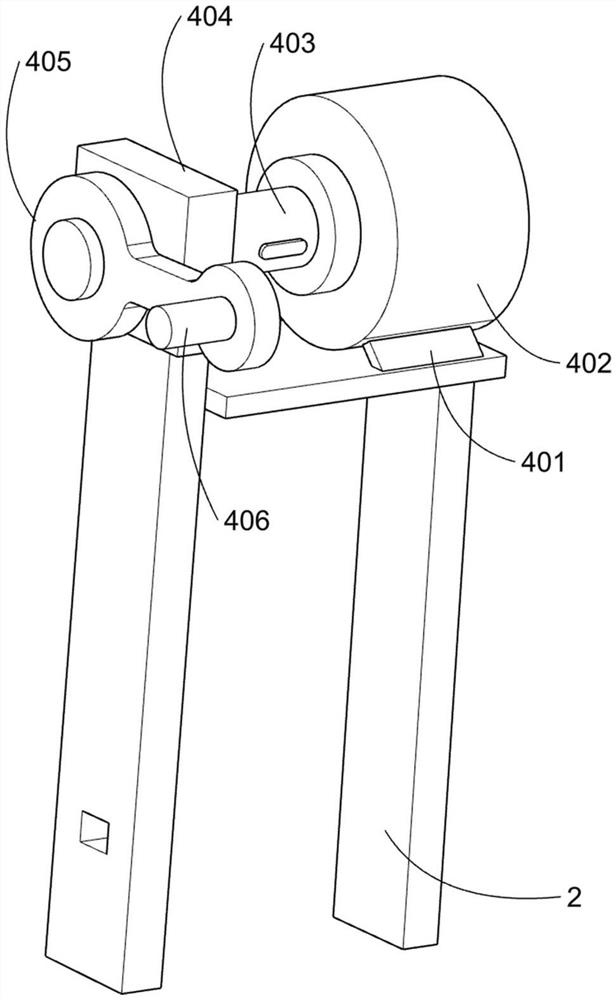

[0029] A punching device suitable for aluminum alloy plates of different shapes, such as Figure 1-11 As shown, it includes a base 1, an installation connecting frame 2, a guide frame 3, a power lifting mechanism 4, a plate bidirectional clamping mechanism 5, a sliding mechanism 6 and a plate stamping mechanism 7, and the upper surface of the base 1 is fixedly installed with an installation connecting frame 2 , the upper surface of the base 1 is also fixed with a guide frame 3, the guide frame 3 is located on the side where the connecting frame 2 is installed, and the end of the connecting frame 2 far away from the base 1 is equipped with a power lifting mechanism 4, and the power lifting mechanism 4 pairs aluminum alloy plates Drilling is carried out to provide power, and the bottom of the guide frame 3 and the installation connection frame 2 is provided with a plate bidirectional clamping mechanism 5. The plate bidirectional clamping mechanism 5 can initially clamp the alumin...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 1-11As shown, the plate bidirectional clamping mechanism 5 includes a fixed block 501, a clamping plate 502, a sliding rod 503, a first return spring 504 and a support frame 505, the fixed block 501 is fixedly installed on the upper surface of the base 1, and the upper surface of the fixed block 501 It can support the aluminum alloy plate and is located between the installation connecting frame 2 and the guide frame 3. The two clamping plates 502 are slidably connected to the base 1 and arranged symmetrically. One side of the two clamping plates 502 is fixedly connected with a sliding rod 503 , the sliding rods 503 are slidably arranged on the bottom of the installation connecting frame 2 and the guide frame 3 respectively, the first return spring 504 is covered on the two sliding rods 503, the sliding rod 503, the first return spring 504, the installation connecting frame 2 and the guide The frame 3 cooperates to clamp the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com