Clamping jaw mechanism of mechanical arm

A technology of mechanical arms and grippers, which is applied in the field of workpiece transportation, can solve the problems of increased processing costs, reduced service life of flanges, and low efficiency of gripper mechanisms, and achieves the effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

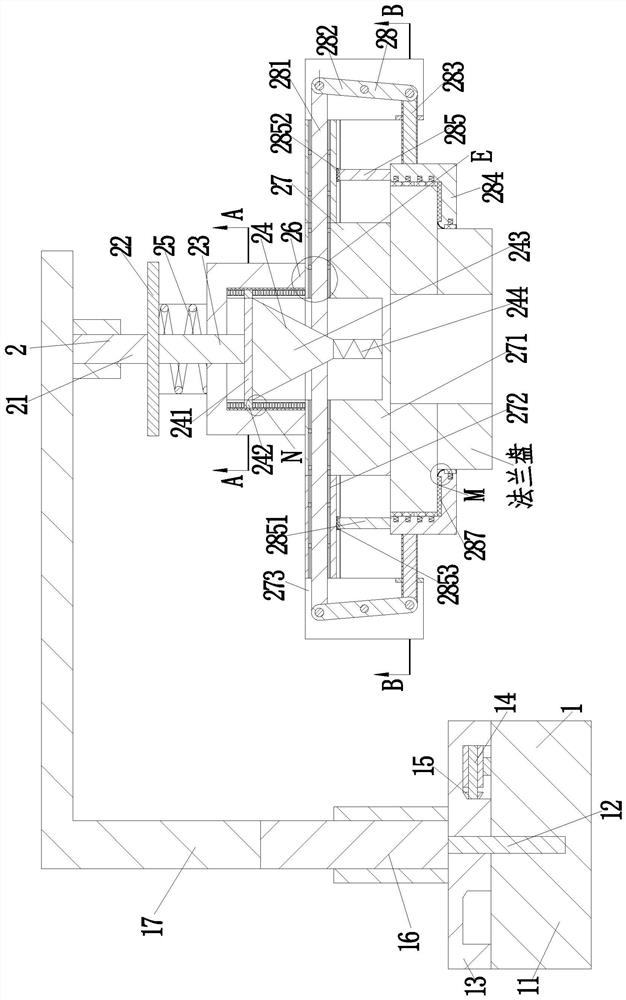

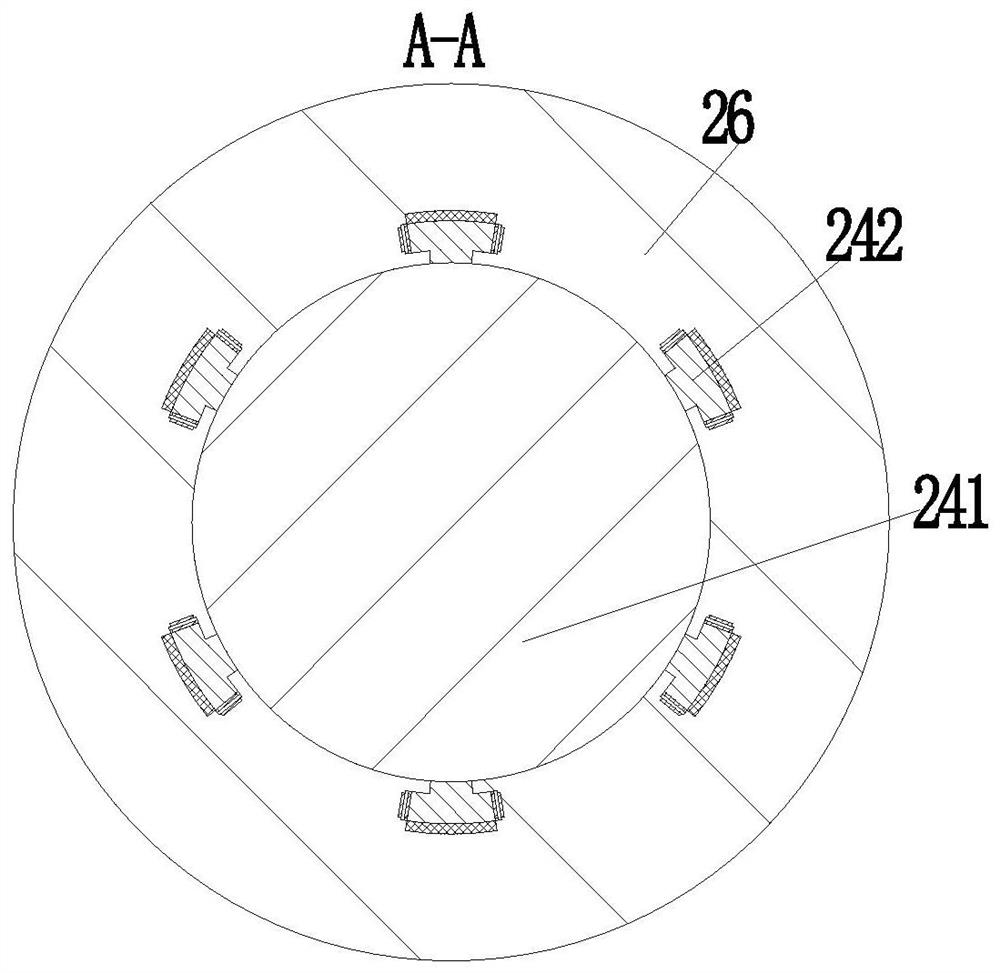

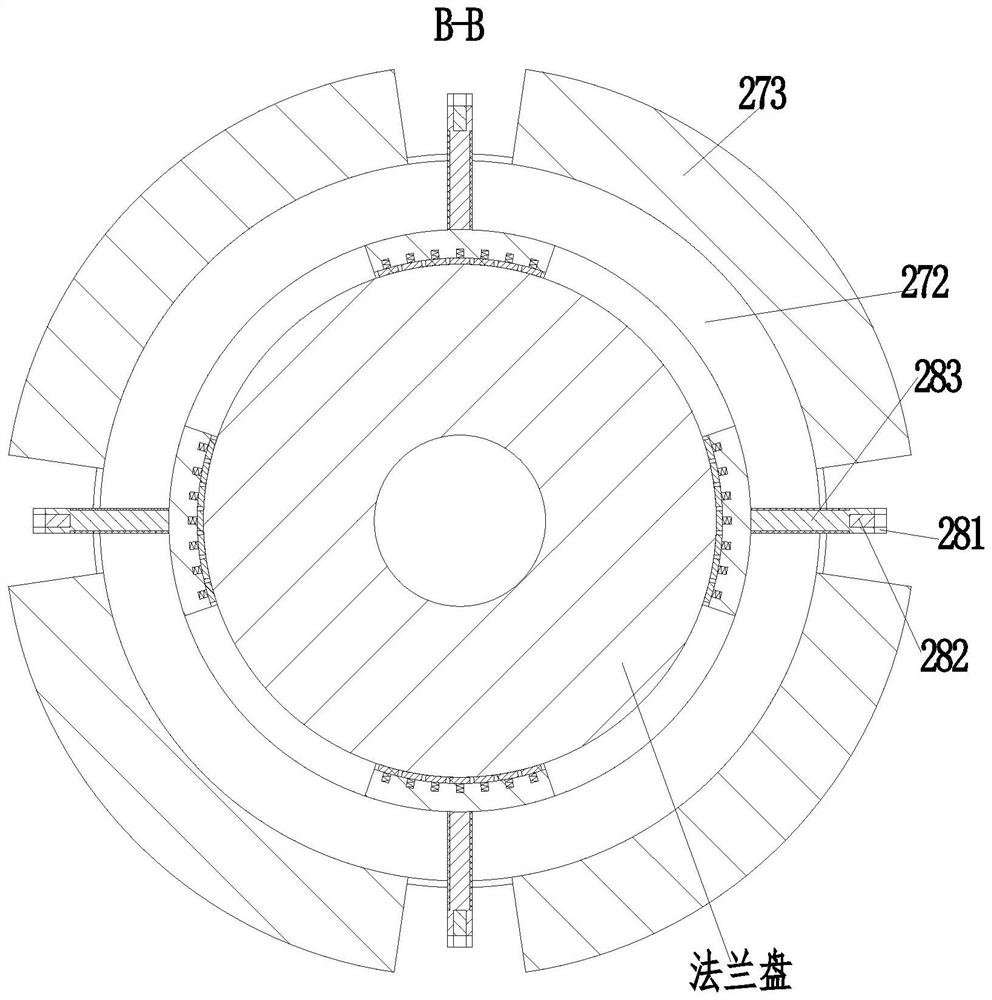

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0031] A gripper mechanism of a mechanical arm, comprising a fixing device 1 and a gripping device 2, the lower end of the fixing device 1 is equipped with a gripping device 2; wherein:

[0032] Described fixture 1 comprises fixed plate 11, rotating column 12, rotating plate 13, motor 14, bevel gear 15, telescopic support 16 and inverted L-shaped plate 17, fixed plate 11 upper end is fixedly installed with rotating column 12, rotates The column 12 is connected with a rotating plate 13 in a sliding fit, the upper end of the fixed plate 11 on the right side is fixed with a motor 14 through a motor 14 seat, the output shaft at the left end of the motor 14 is fixed with a bevel gear 15 through a coupling, and the rotating plate 13 The lower end is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com