Cement board manufacturing device

A technology for making devices and cement boards, which is applied to supply devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of cumbersome operation and low efficiency, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

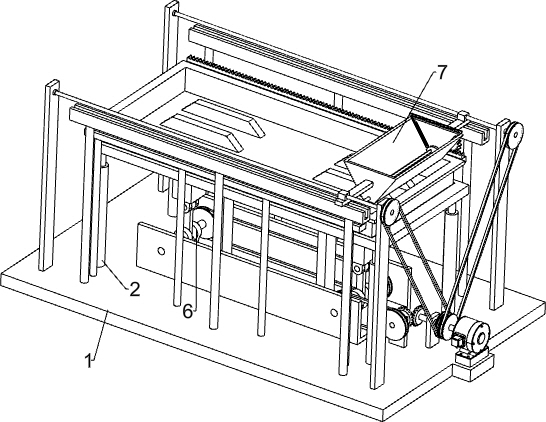

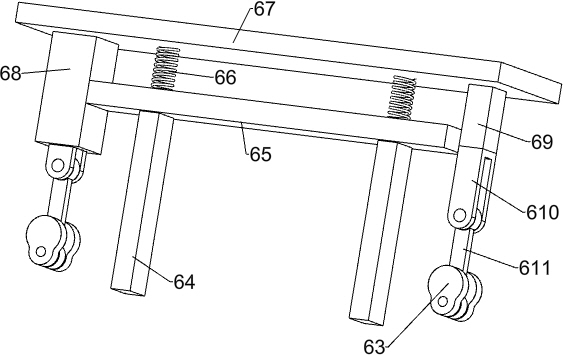

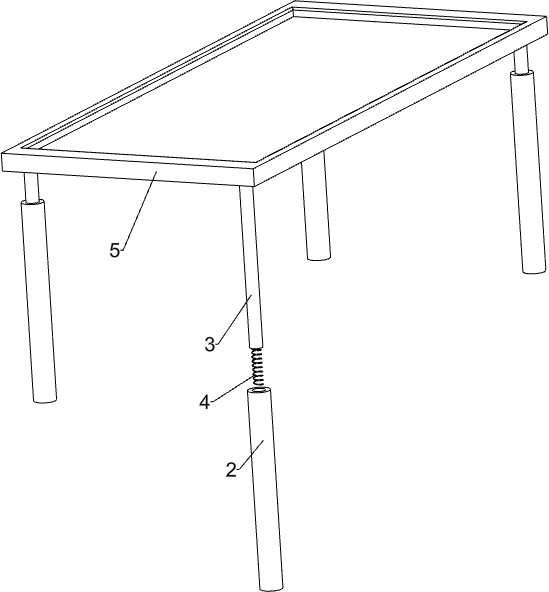

[0025] Such as Figure 1-5 As shown, a cement board production device includes a base 1, a support cylinder 2, a first support column 3, a first elastic member 4, a discharge plate 5, a vibration mechanism 6 and a mobile blanking mechanism 7, and the top of the base 1 is uniform A support cylinder 2 is provided, and four support cylinders 2 are arranged in a 4-corner distribution. The first support columns 3 are slidably arranged in the support cylinders 2, and the first support columns 3 and the inner bottom of the support cylinder 2 are provided with first Elastic part 4, the first elastic part 4 is located in the support cylinder 2, the first elastic part 4 is a compression spring, a discharge plate 5 is arranged between the tops of the four first support columns 3, and a pair of discharge plates are arranged on the base 1 5 hits the vibration mechanism 6, and the base 1 is provided with a mobile blanking mechanism 7, and the blanking mechanism is located above the discharg...

Embodiment 2

[0030] On the basis of Example 1, such as Figure 6-7 As shown, it also includes a third bearing seat 8, a screw rod 9, a nut 10 and a third belt transmission mechanism 11, the four corners of the top of the base 1 are provided with a third bearing seat 8, and between the two third bearing seats 8 on the front side Screw mandrels 9 are all arranged between the two third bearing blocks 8 on the rear side, nuts 10 are movably arranged on the two screw mandrels 9, the nuts 10 cooperate with the screw mandrels 9, and the nuts 10 are connected with the second slide block 73, The right ends of the screw mandrels 9 on the front and rear sides are connected to the second rotating shaft 617 through the third belt transmission mechanism 11 .

[0031] During the rotation of the second rotating shaft 617, the rotation of the second rotating shaft 617 will drive the screw mandrel 9 to rotate through the third belt transmission mechanism 11, so that the nut 10 moves on the screw mandrel 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com