Ring-pull can shell cleaning device

A cleaning device and cans technology, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult to clean and clean cans sewage, etc., and achieves the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

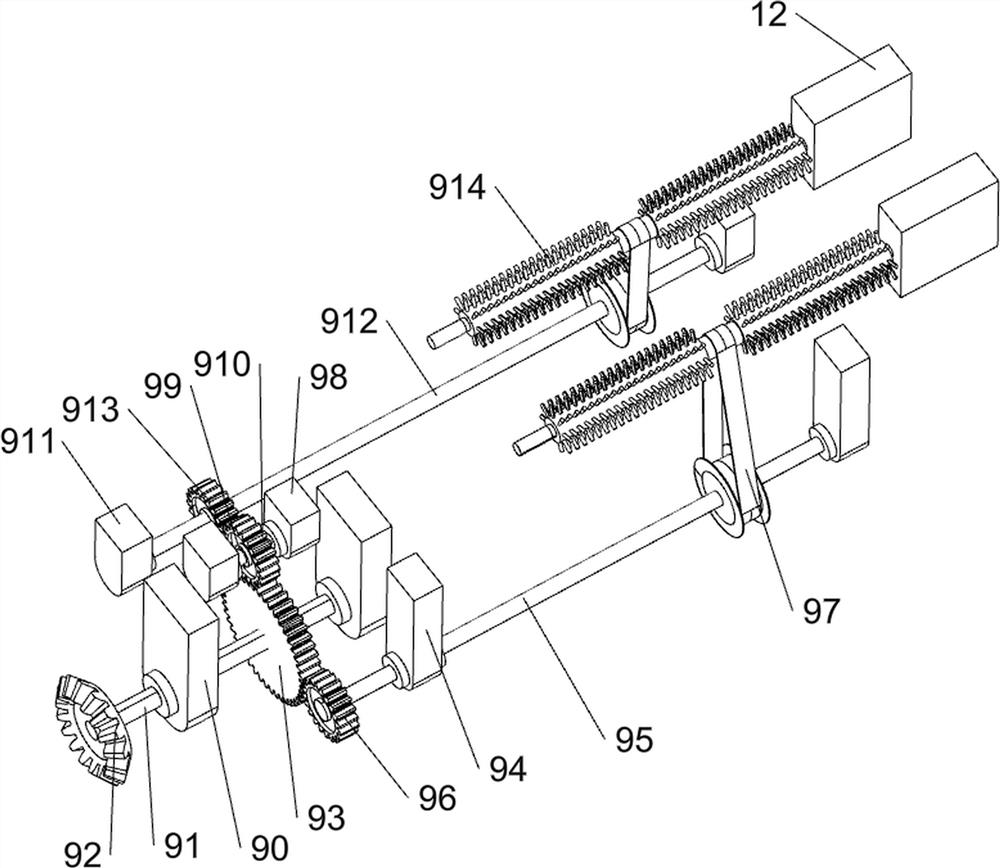

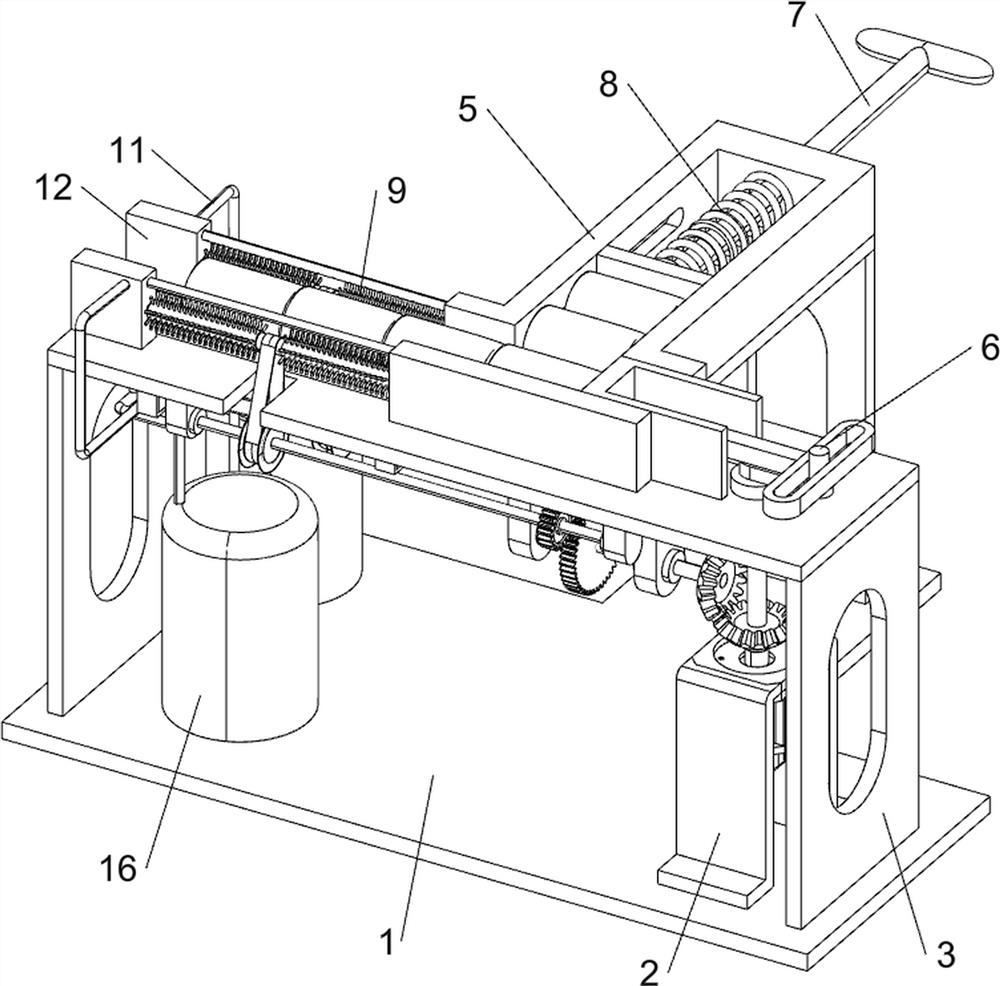

[0022] A kind of pop can shell cleaning device, such as figure 1 Shown, include base 1, motor seat 2, working platform 3, servo motor 4, waiting box 5, feeding mechanism 6, telescoping rod 7, return force spring 8, cleaning mechanism 9, cleaning bucket 10, water spray pipe 11 and Mounting base 12, base 1 top right side is provided with motor base 2, base 1 top is provided with work platform 3, and motor base 2 upper side is provided with servo motor 4, and the output shaft of servo motor 4 passes through motor base 2, and work platform 3 The rear side of the top is provided with a waiting box 5, and the right side of the top of the working platform 3 is provided with a feeding mechanism 6. The feeding mechanism 6 is connected with the output shaft of the servo motor 4, and the middle of the waiting box 5 is slidingly connected with a telescopic rod 7. 7 and the rear part of the inner wall of the material box 5 are connected with a return spring 8, and the return spring 8 is sl...

Embodiment 2

[0025] On the basis of Example 1, such as figure 2 and image 3 As shown, the feeding mechanism 6 includes a first rotating shaft 60, a first bevel gear 61, a rotating block 62, a push rod 63, a push plate 64, a baffle plate 65 and an annular guide rail 66, and the output shaft of the servo motor 4 is connected with the first rotating shaft 60, the first rotating shaft 60 passes through the working platform 3, the first bevel gear 61 is connected to the lower side of the first rotating shaft 60, the top of the first rotating shaft 60 is provided with a rotating block 62, and the middle part of the front side of the top of the working platform 3 is provided with a baffle 65, A push plate 64 is slidably connected between the baffle plate 65 rear portion and the front portion of the bin 5, the right portion of the push plate 64 is connected with a push rod 63, and the right portion of the push rod 63 is provided with an annular guide rail 66, and the annular guide rail 66 is con...

Embodiment 3

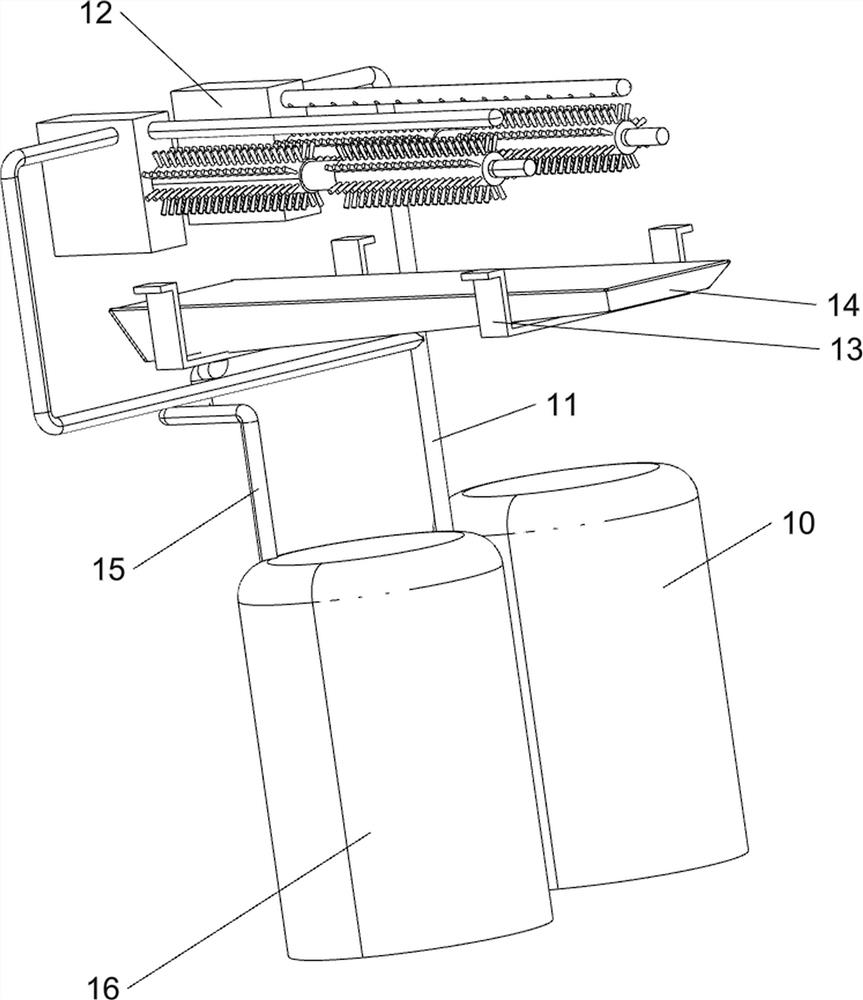

[0030] On the basis of Example 2, such as Figure 4 Shown, also include hanging plate 13, sewage collecting frame 14, sewage drain pipe 15 and sewage barrel 16, the left side of working platform 3 bottoms is evenly connected with hanging plate 13, the quantity of hanging plate 13 is 2, between hanging plate 13 Connected with a sewage collection frame 14, the sewage collection frame 14 is located below the brush 914, a sewage bucket 16 is arranged on the top front side of the right side of the base 1, and a sewage drainage pipe 15 is connected to the top of the sewage bucket 16, and the sewage drainage pipe 15 is connected to the sewage collection frame 14 Connected on the left.

[0031] When people need to collect and clean the sewage of the pop cans, under the cooperation of the cleaning bucket 10, the water spray pipe 11, the feeding mechanism 6 and the cleaning mechanism 9, the brush 914 cleans the shell of the pop can, and the water falls on the brush 914 to the brush. 91...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com