Energy-saving and environment-friendly industrial sewage treatment equipment

A technology for industrial sewage and treatment equipment, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of inability to filter impurities and automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

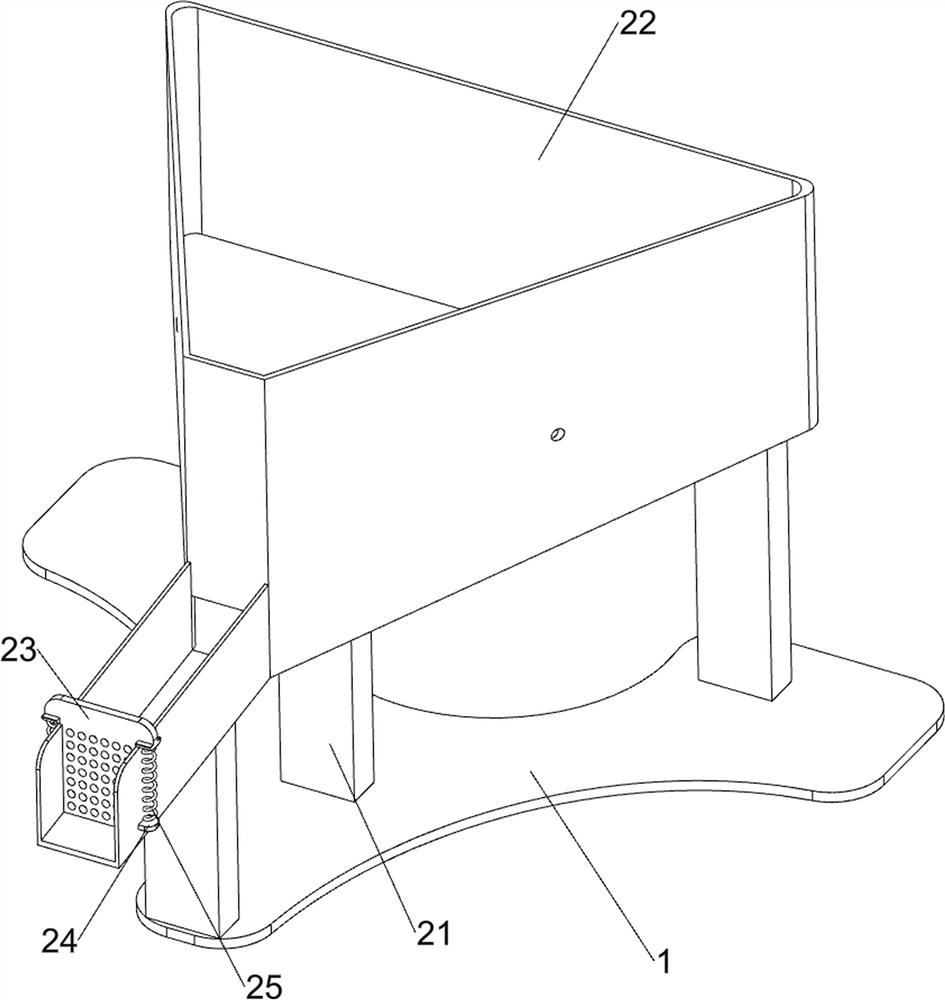

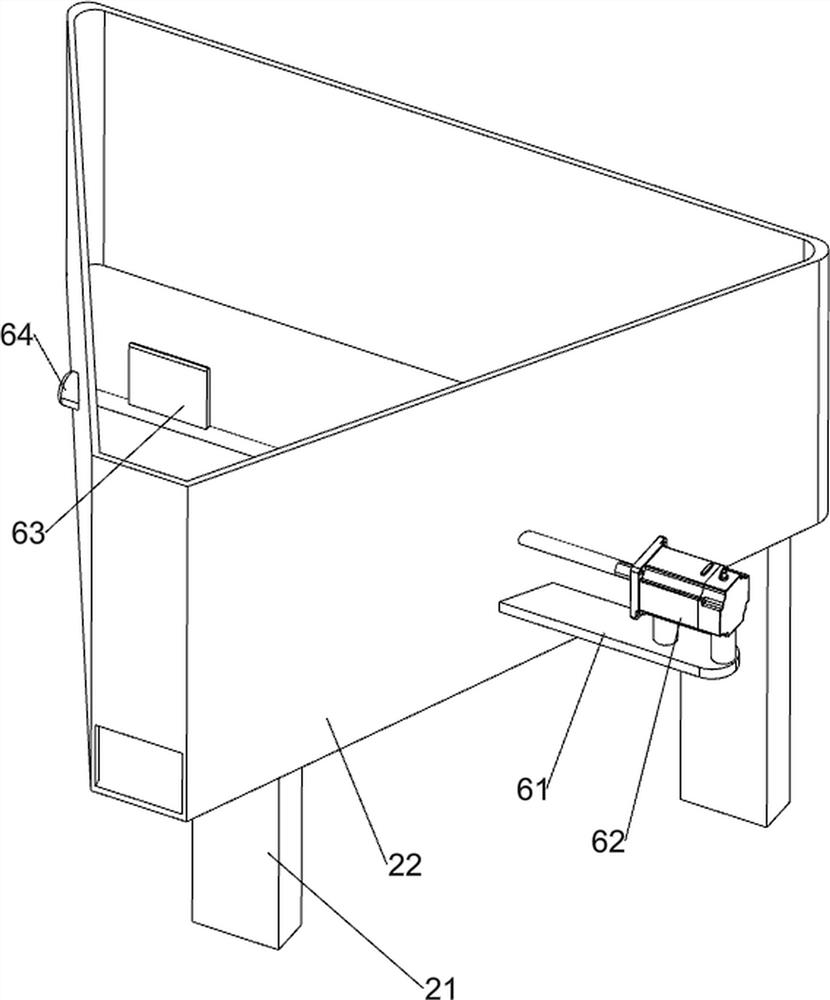

[0028] A kind of energy-saving and environment-friendly industrial sewage treatment equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1 , a transport mechanism 2 and a blanking mechanism 3 , the top of the base 1 is provided with a transport mechanism 2 , and the upper part of the transport mechanism 2 is provided with a blanking mechanism 3 .

[0029] Transport mechanism 2 includes support 21, collection frame 22, filter screen 23, adhesive block 24 and first spring 25, base 1 top is provided with four supports 21, is provided with collection frame 22 between support 21, and collection frame 22 front The side sliding type is provided with a filter screen 23, and the left and right sides of the front part of the collection frame 22 are provided with adhesive blocks 24, and a first spring 25 is arranged between the adhesive block 24 and the filter screen 23.

[0030] The blanking mechanism 3 includes a support frame 31, a limit block 32, a firs...

Embodiment 2

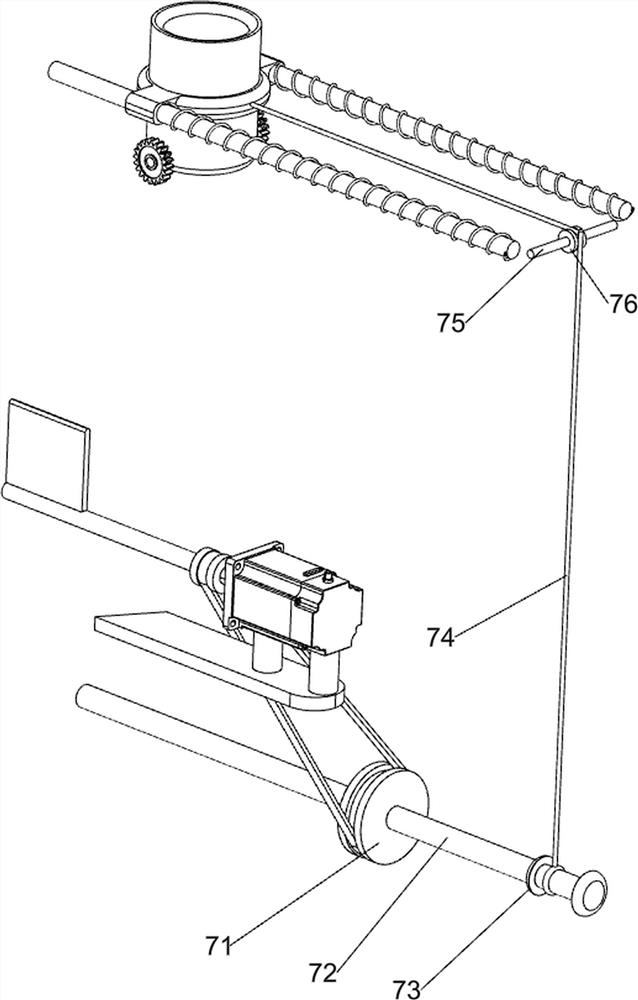

[0033] On the basis of Example 1, such as Figure 4 , Figure 6 , Figure 7 and Figure 8 As shown, the filter assembly 4 is also included, and the filter assembly 4 includes a support rod 41, a connecting block 42, a rack 43, a guide rod 44, a second spring 45, a sliding sleeve 46, a filter frame 47, a first rotating shaft 48, a screen Net 49, gear 410 and torsion spring 411, base 1 top is left and right symmetrically provided with support bar 41, and support bar 41 upper inner side and collecting frame 22 upper part outer sides are symmetrically provided with connection block 42, and support bar 41 tops are all provided with two racks 43, guide rods 44 are symmetrically arranged between the support rods 41, and the guide rods 44 are slidably connected with the first slide bar 33 on the front side, and the left and right symmetrical sliding types between the guide rods 44 are provided with sliding sleeves 46, and the sliding sleeves 46 are connected to the support A second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com