Mining multifunctional self-stirring grouting device and control method thereof

A self-stirring grouting and multi-functional technology, which is applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as grouting work cannot be carried out normally, fire extinguishing powder is easy to stick into blocks, pumps and pipelines are blocked, etc. , to achieve the effect of reducing labor intensity, reasonably controlling the amount of powder ingredients, and eliminating pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

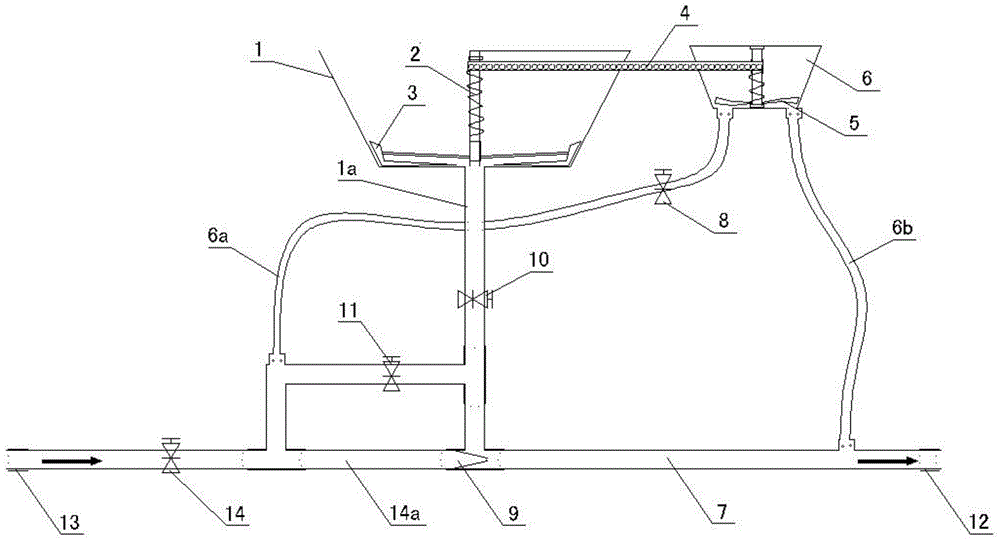

[0016] see figure 1 , the structural form of the mine-used multifunctional self-stirring grouting device in this embodiment is:

[0017] An ejector 9 is provided, the nozzle side of the ejector 9 is connected to the main liquid supply valve 14 through the liquid supply pipe 14a, the inlet of the main liquid supply valve 14 is the inlet 13 of the downhole high-pressure source, and the outlet of the ejector 9 passes through The slurry discharge pipe 7 is connected to the slurry outlet 12, and the lower material pipe 1a is connected between the suction port of the ejector 9 and the powder outlet of the lower material box 1, and the spiral screw is vertically arranged in the lower material box 1. A stirring knife 2, a fan blade stirring knife 3 is arranged at the lower end of the spiral stirring knife 2;

[0018] A liquid supply tank 6 is set, the liquid inlet at the bottom of the liquid supply tank 6 communicates with the liquid supply pipe 14a through the liquid inlet pipe 6a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com