Manufacturing equipment for conical blanks of wooden building blocks

A conical and blank technology, applied in the field of wooden building block conical blank production equipment, can solve the problem of easy mixing of sawdust and cut conical building blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

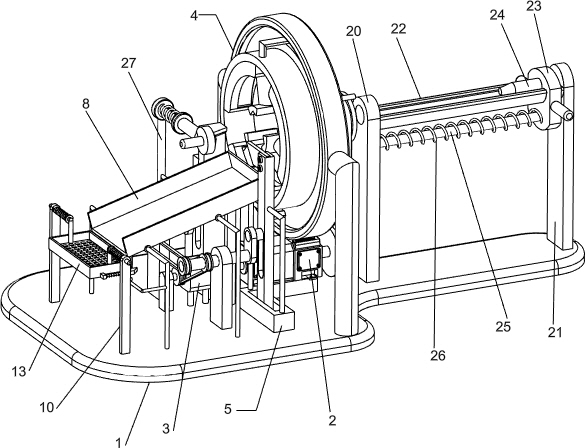

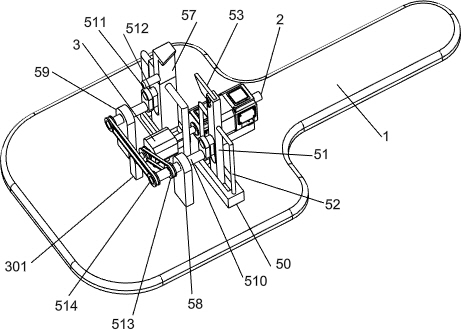

[0028] A kind of wooden building block conical blank production equipment, such as Figure 1-7As shown, it includes a base 1, a biaxial motor 2, a reducer 3, a fixed plate 301, a rotating mechanism 4 and a cutting mechanism 5, a biaxial motor 2 is provided in the middle of the upper part of the base 1, and a fixed plate 301 is provided in the middle of the upper part of the base 1. The right part of the fixed plate 301 is provided with a reducer 3, the reducer 3 is connected with the output shaft on the left side of the biaxial motor 2, the base 1 is provided with a rotating mechanism 4 in the middle of the upper part, and the rotating mechanism 4 is connected with the output shaft on the right side of the biaxial motor 2 , A cutting mechanism 5 is provided in the middle of the upper part of the base 1, and the cutting mechanism 5 is connected with the reducer 3.

[0029] When the user needs to make conical building blocks, this device can be used. First, the cylindrical woode...

Embodiment 2

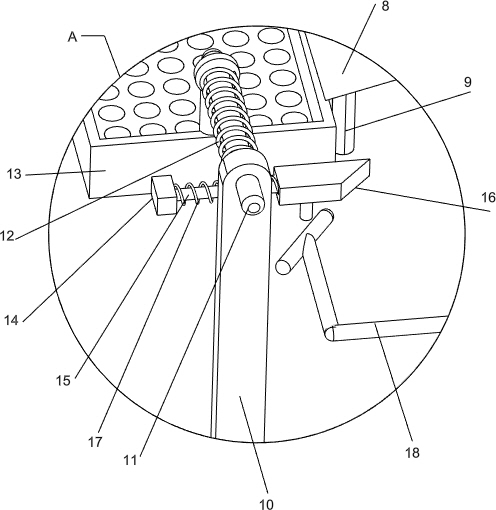

[0035] On the basis of Example 1, such as figure 1 and Figure 8-10 As shown, it also includes the fifth slide bar 6, the sixth slide bar 7, the collection frame 8, the second fixed bar 9, the first mounting plate 10, the seventh slide bar 11, the second spring 12, the screening frame 13, the installation Block 14, the first slide bar 15, wedge-shaped block 16, the 3rd spring 17 and stop bar 18, base 1 top left front and rear symmetrical formula is provided with the fifth slide bar 6, base 1 top left front and rear symmetrical formula is provided with the sixth Slider 7, the sixth slider 7 on the front and rear sides are respectively located on the left side of the fifth slider 6 on the front and rear sides, the fifth slider 6 and the sixth slider 7 on the front and rear sides are slidingly provided with a collection frame 8 The right part of the collection frame 8 is located between the first chute plate 51 and the second chute plate 55, the left side of the bottom of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com