Gear extrusion forming equipment for metal powder metallurgy

A technology of pressing equipment and metal powder, which is applied in the field of gear pressing equipment for metal powder metallurgy, and can solve problems such as metal inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

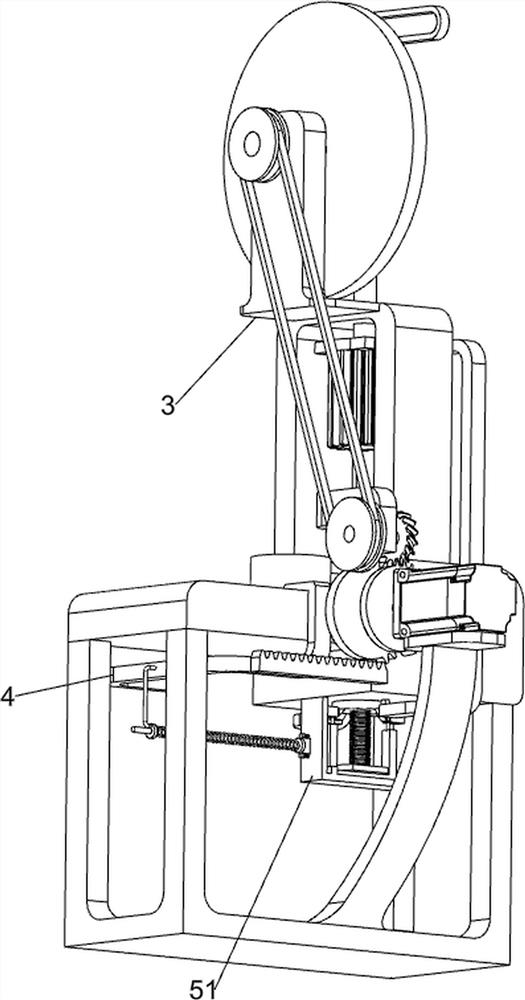

[0028] A gear pressing equipment for metal powder metallurgy, such as figure 1 As shown, it includes a support frame 1, a mold plate 2, a forming mechanism 3, a material spreading mechanism 4 and a material ejection mechanism 5. The upper left side of the support frame 1 is provided with a mold plate 2, and the mold plate 2 is provided with a forming mechanism 3. The plate 2 is provided with a spreading mechanism 4 , and the mold plate 2 is provided with a material ejecting mechanism 5 .

[0029] When the user needs to press the metal powder, this equipment can be used. First, the metal powder that needs to be pressed is placed in the spreading mechanism 4, and the metal powder is moved to the mold plate 2 through the spreading mechanism 4. Mechanism 3 extrudes the metal powder, then lifts the formed metal powder upwards through the ejector mechanism 5 , and pushes the formed metal powder through the spreading mechanism 4 .

Embodiment 2

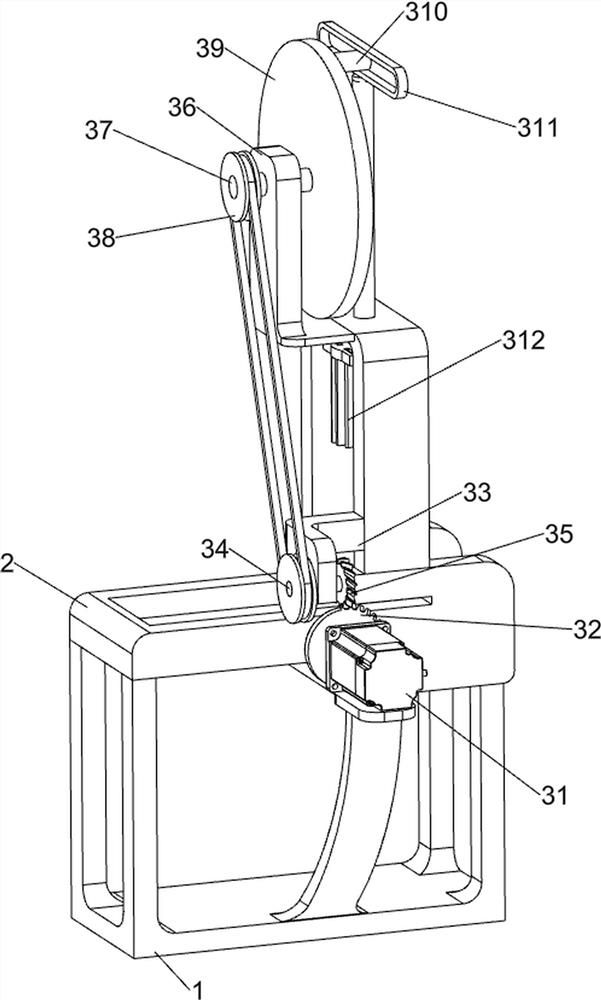

[0031] On the basis of Embodiment 1, as shown in Figure X, the forming mechanism 3 includes a servo motor 31, a missing helical gear 32, a bearing seat 33, a first rotating shaft 34, a full helical gear 35, a mounting frame 36, and a second rotating shaft 37. Pulley assembly 38, turntable 39, eccentric shaft 310, lifting slide rail 311 and pressing mold 312, servo motor 31 is provided on the upper part of support frame 1, and helical gear 32 is provided on the output shaft of servo motor 31, and mold plate 2 The upper right side is provided with a mounting frame 36, the mounting frame 36 is provided with a bearing seat 33, the bearing seat 33 is provided with a first rotating shaft 34, the first rotating shaft 34 is provided with a full helical gear 35, the full helical gear 35 and the missing helical gear 32 meshing, the upper side of the mounting bracket 36 is rotatably provided with a second rotating shaft 37, a pulley assembly 38 is connected between the second rotating sha...

Embodiment 3

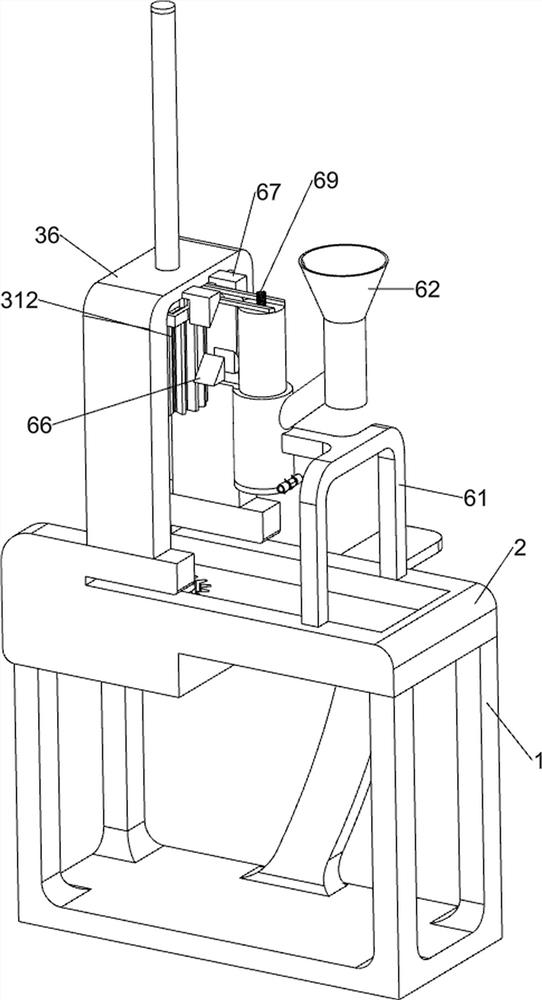

[0038] On the basis of Example 2, such as Figure 8 and Figure 9 As shown, it also includes a blanking mechanism 6, and the blanking mechanism 6 includes a connecting frame 61, a blanking tube 62, a lower pressure column 63, a material retaining plate 64, a torsion spring 65, a first wedge 66, a second wedge 67, sliding bar 68 and the seventh spring 69, mold plate 2 upper left side is provided with connecting frame 61, connecting frame 61 is provided with feeding pipe 62, and the upper feeding pipe 62 slide type is provided with down-pressing column 63, blanking The lower part of the pipe 62 is rotatably provided with a stopper 64, and a torsion spring 65 is connected between the stopper 64 and the feeding pipe 62. The upper side of the feeding pipe 62 is symmetrically provided with a first wedge-shaped block 66, and the lower side of the mounting frame 36 The second wedge-shaped block 67 is arranged symmetrically, and the sliding rod 68 is arranged symmetrically on the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com