Full automatic stirring machine

A mixer, fully automatic technology, applied in mixing plants, clay preparation devices, mixing operation control devices, etc., can solve the problems of low manual efficiency, environmental pollution, low mixing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

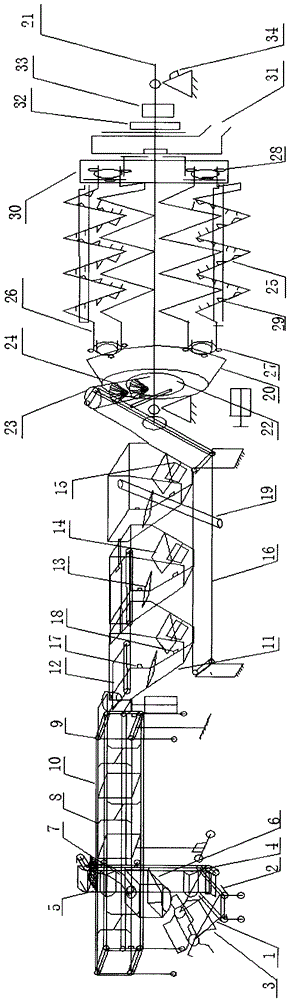

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0033] The invention provides a fully automatic mixer, the working principle of which is to drive the S-shaped feeding conveyor belt and the horizontal conveyor belt of the feeding mechanism through the upper and lower limit switches in the material box to realize the automation of feeding, and use the stopper of the material bin to The mixing board and several mixing pipes are used to prevent the raw materials from scattering during the mixing process, so as to achieve the purpose of automatic feeding, ensuring environmental quality, reducing production cost input, improving production efficiency and ensuring the health of the staff.

[0034] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com