Forestry log auxiliary cutting device

A technology for cutting devices and logs, which is applied in the direction of clamping devices, feeding devices, circular saws, etc., and can solve the problems of low efficiency, time-consuming and labor-intensive cutting process, and inability to automatically feed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

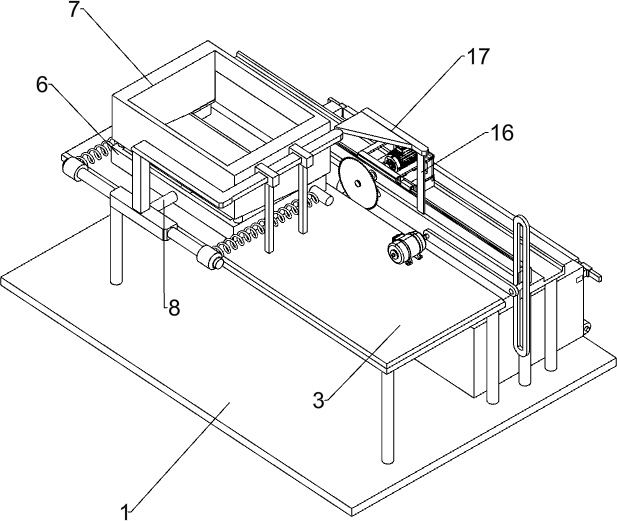

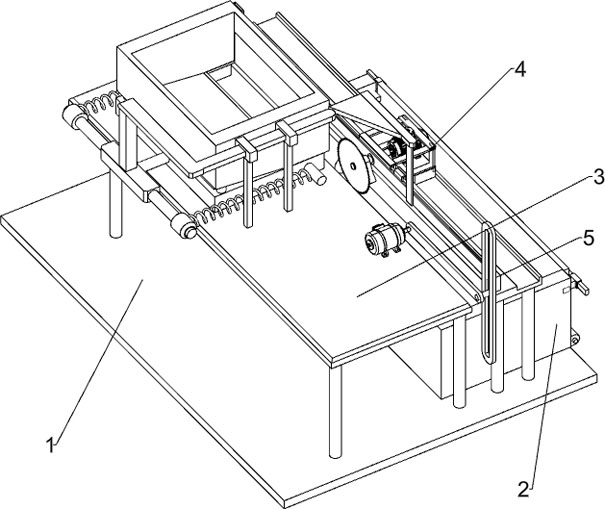

[0024] Such as Figure 1-3 As shown, a forestry log auxiliary cutting device includes a base 1, a collection box 2, a workbench 3, a cutting device 4 and a moving device 5, the rear side of the top of the base 1 is provided with a collection box 2, and the middle part of the top of the base 1 is provided with a The workbench 3 is provided with a cutting device 4 on the rear side of the top of the base 1. The cutting device 4 is located directly above the collection box 2. The workbench 3 is provided with a moving device 5 that drives the cutting device 4 to reciprocate.

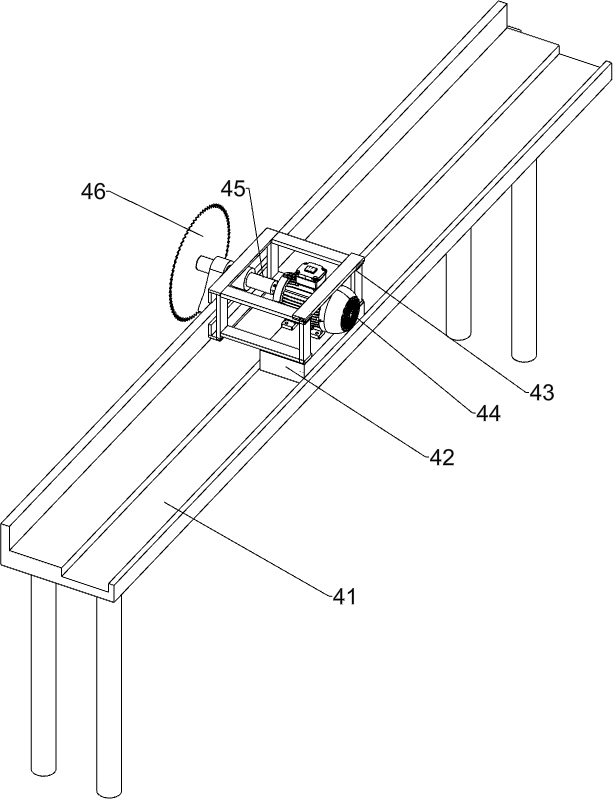

[0025] Cutting device 4 comprises slide rail 41, slide block 42, mounting frame 43, servomotor 44, rotating shaft 45 and circular saw 46, and base 1 top rear side is provided with slide rail 41, and slide rail 41 is provided with sliding type. Block 42, slide block 42 is provided with mounting frame 43, is provided with servomotor 44 in the mounting frame 43, and the output shaft of servomotor 44 is connected...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 4-6 As shown, it also includes N-shaped frame 6, blanking frame 7, sliding rod 8, push plate 9, baffle plate 10, fixed frame 11, fixed block 12, elastic member 13, guide sleeve 14, special-shaped connecting rod 15, connecting Rod 16 and wedge block 17, N-shaped frame 6 is arranged on the left side of the top of the workbench 3, the top of the N-shaped frame 6 is provided with a blanking frame 7, the middle part of the N-shaped frame 6 is slidingly provided with a sliding rod 8, and the rear end of the sliding rod 8 A push plate 9 is provided, the top of the push plate 9 is provided with a baffle 10, the baffle 10 cooperates with the discharge port of the blanking frame 7, the front end of the sliding rod 8 is provided with a fixed frame 11, and the rear part of the left and right side walls of the N-shaped frame 6 is symmetrical A fixed block 12 is provided, and an elastic member 13 is arranged between the fixed block 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com