Patents

Literature

231results about "Discharging equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

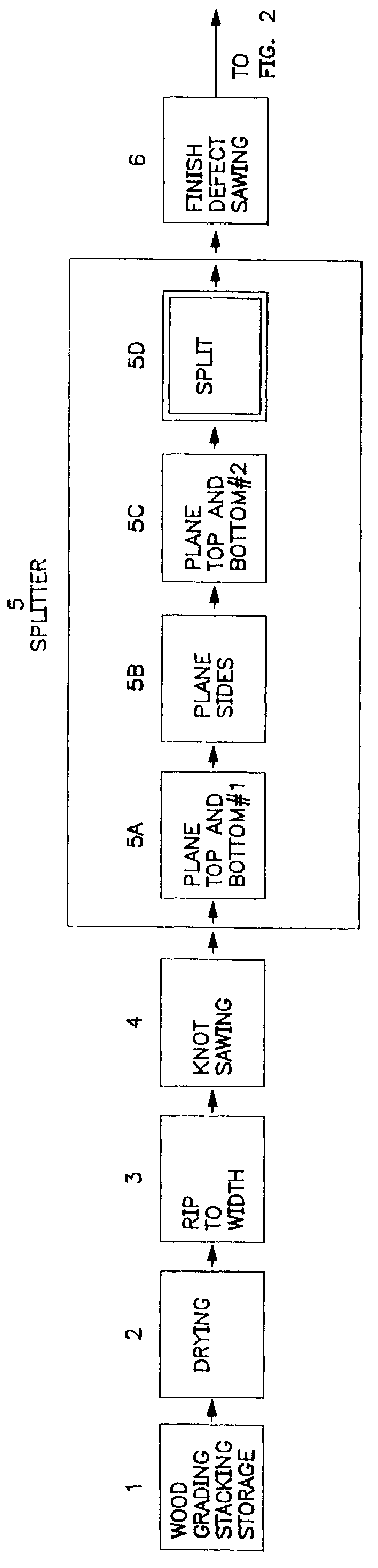

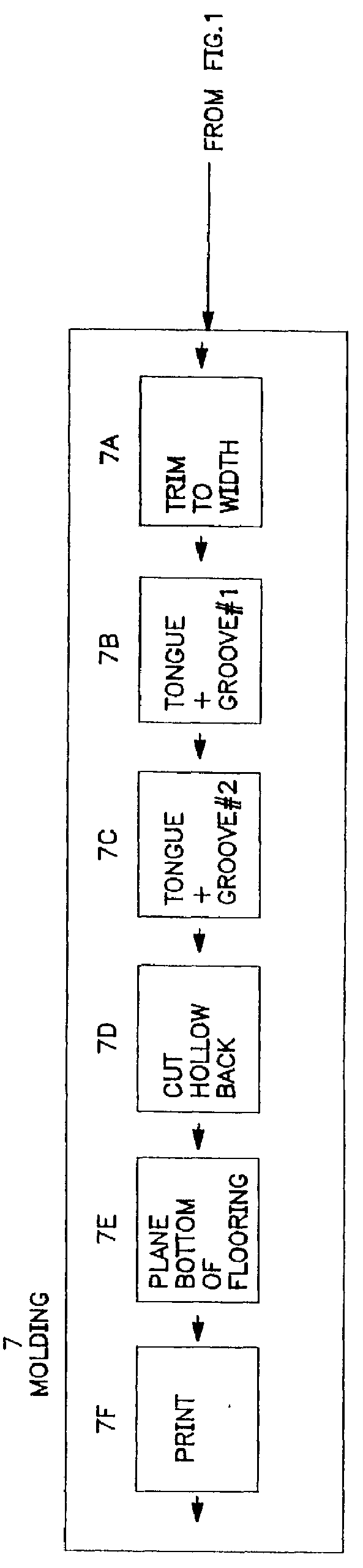

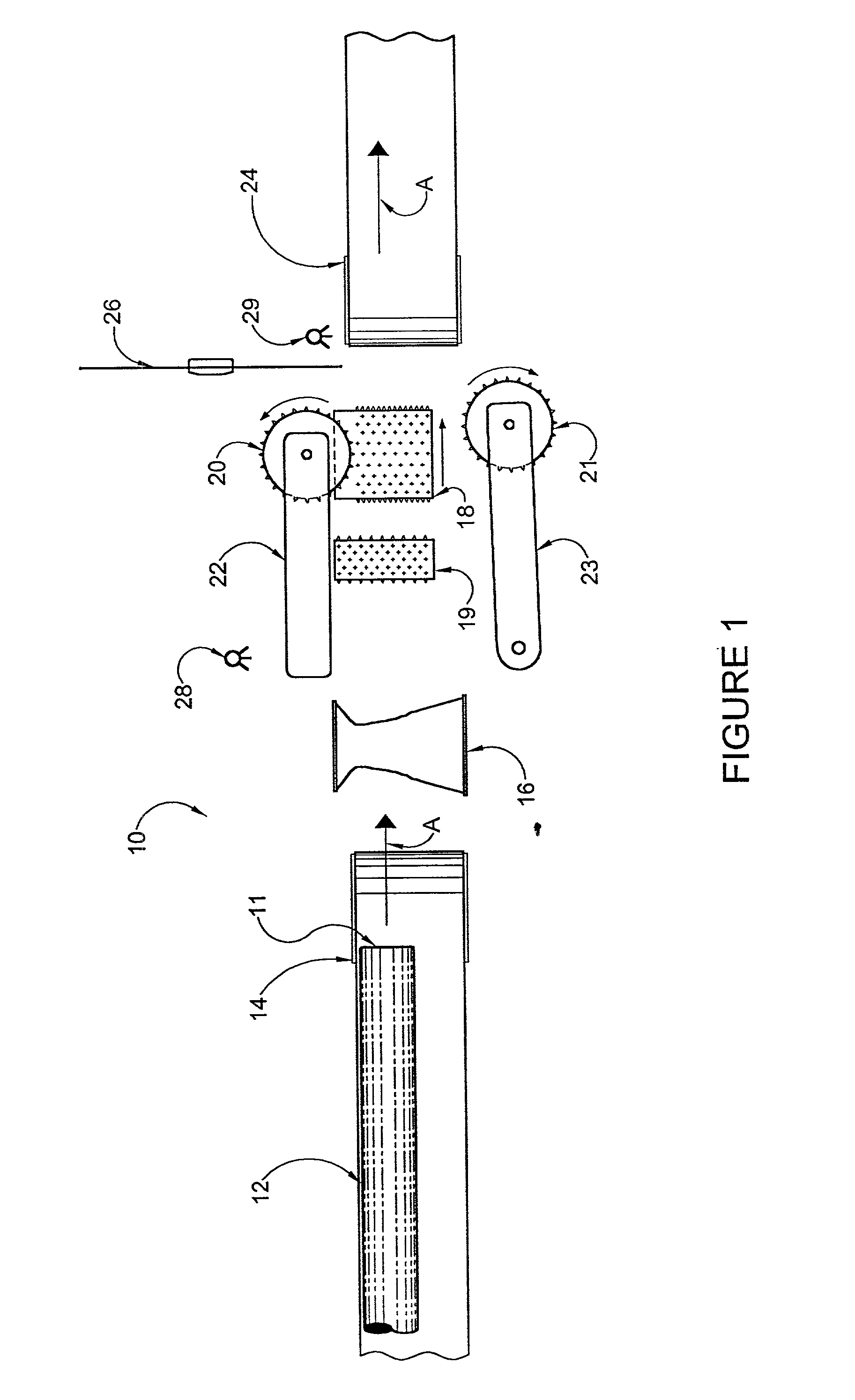

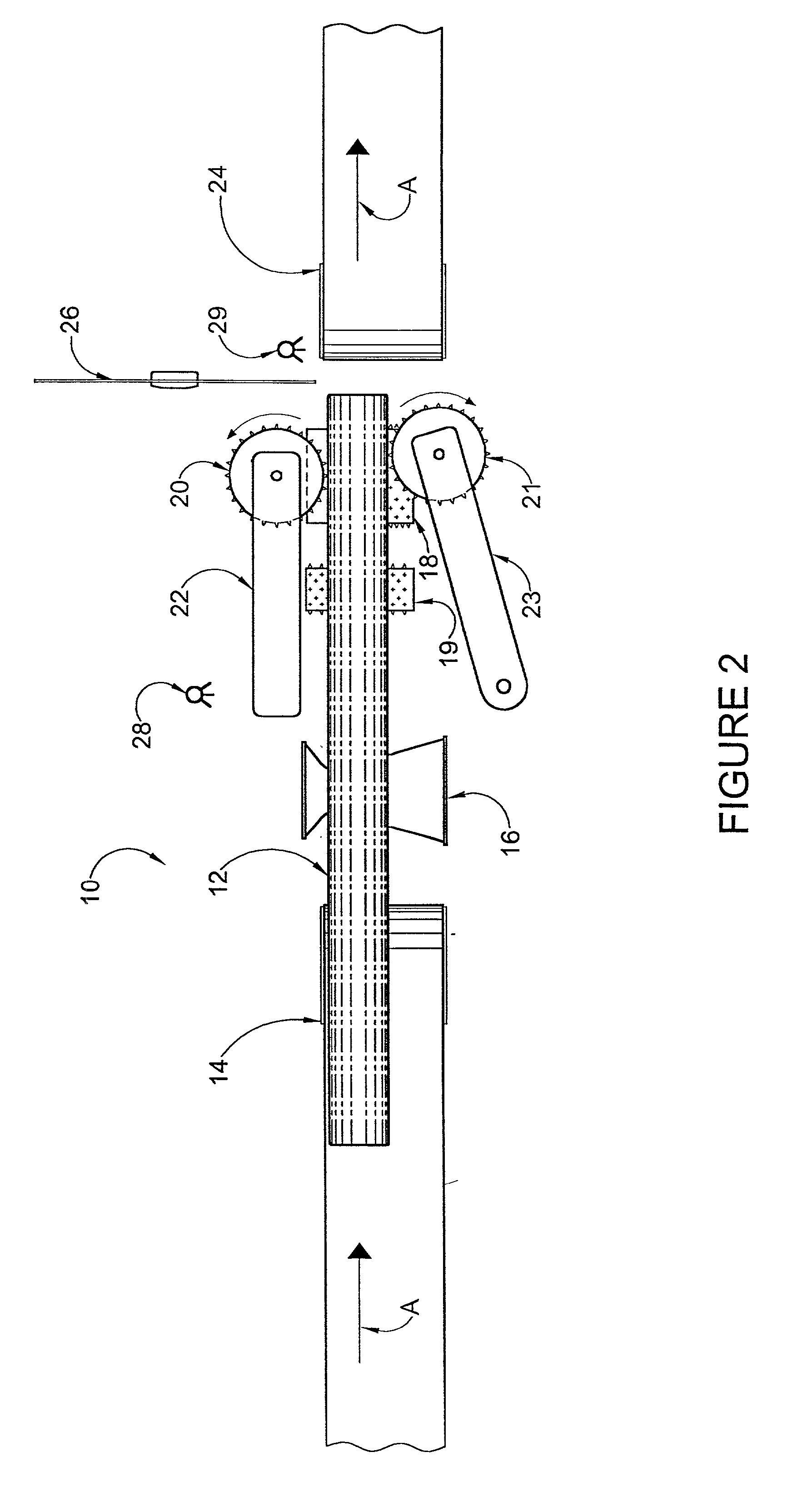

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

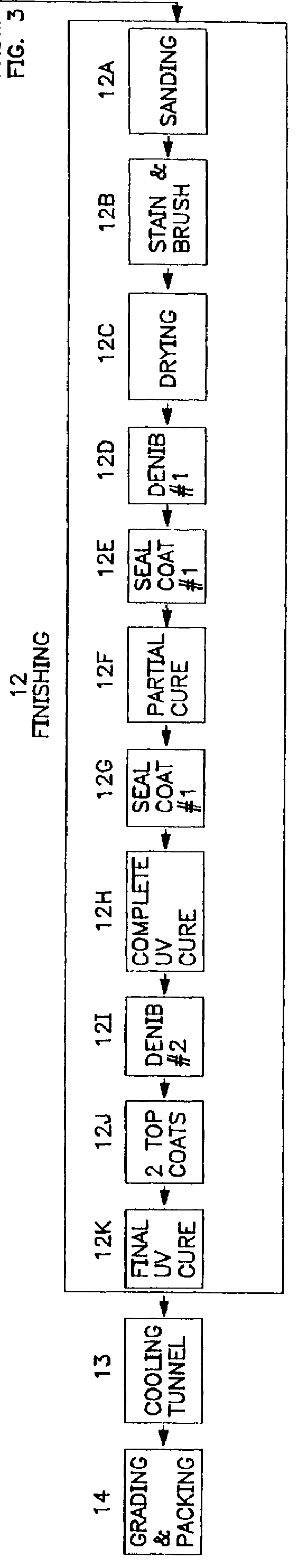

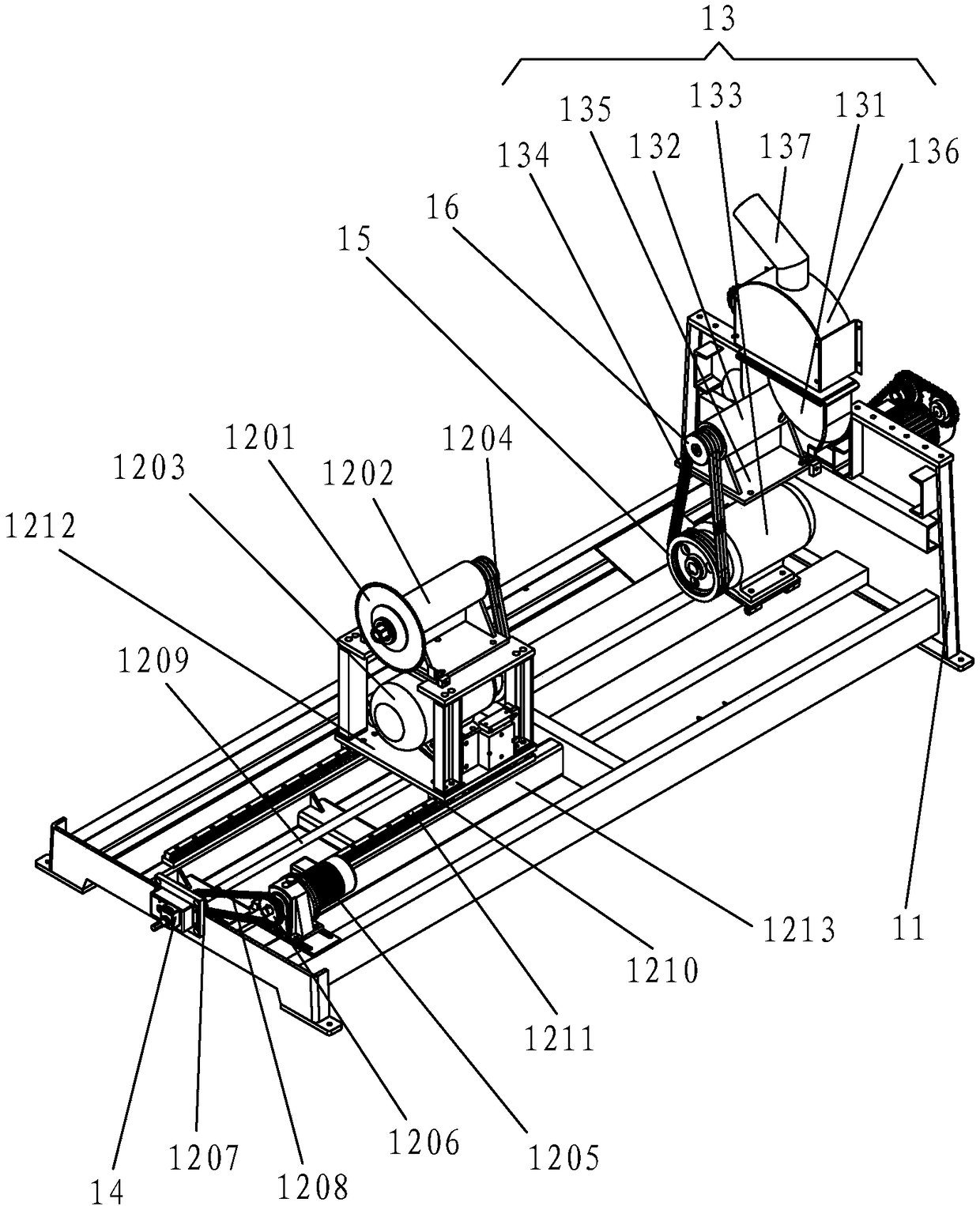

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

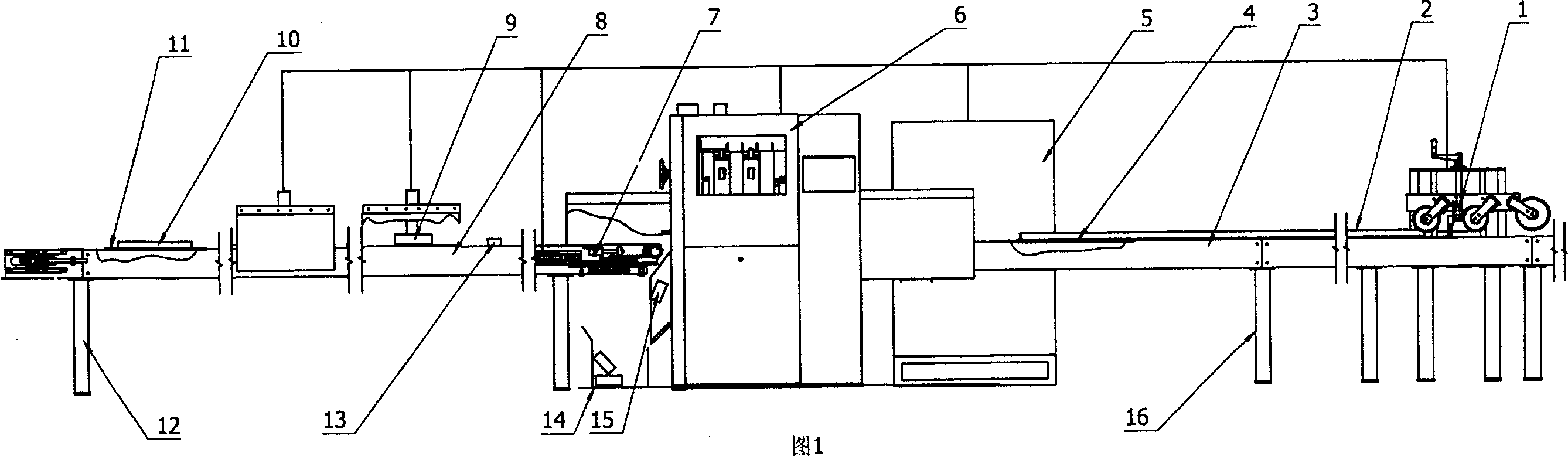

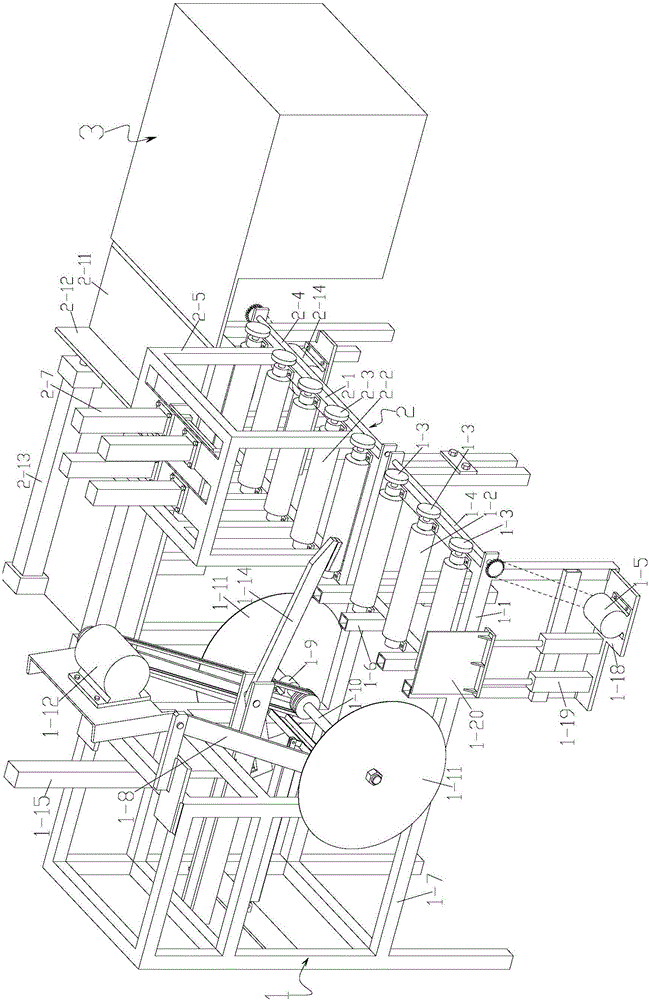

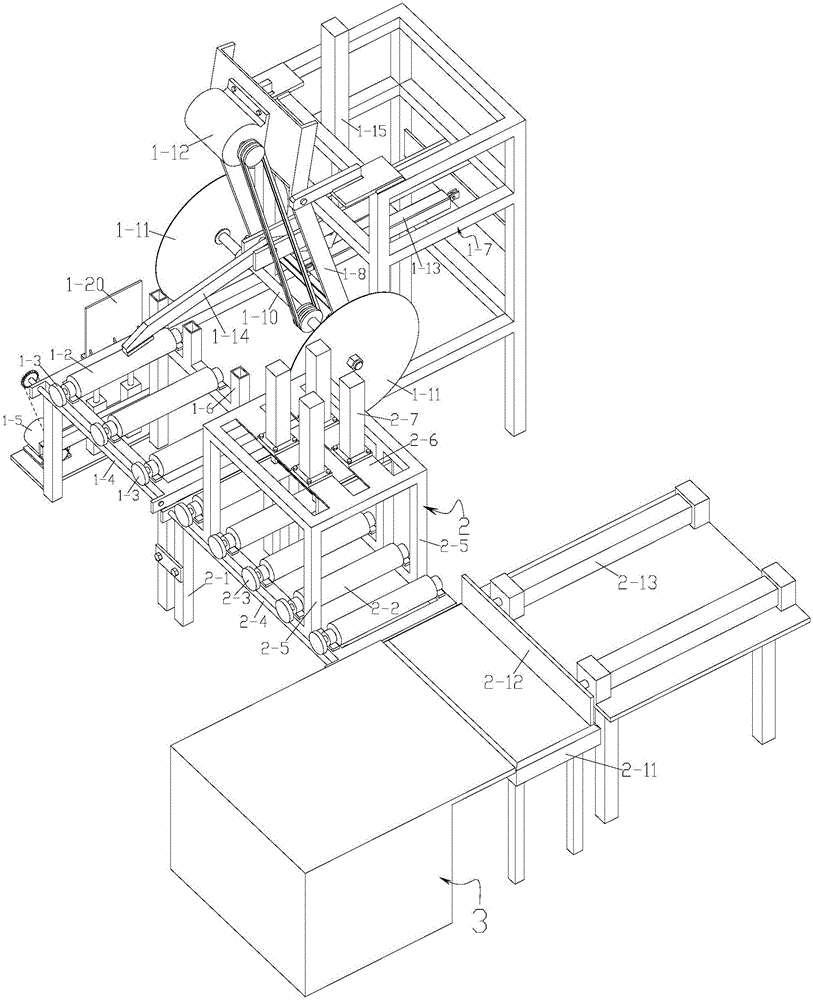

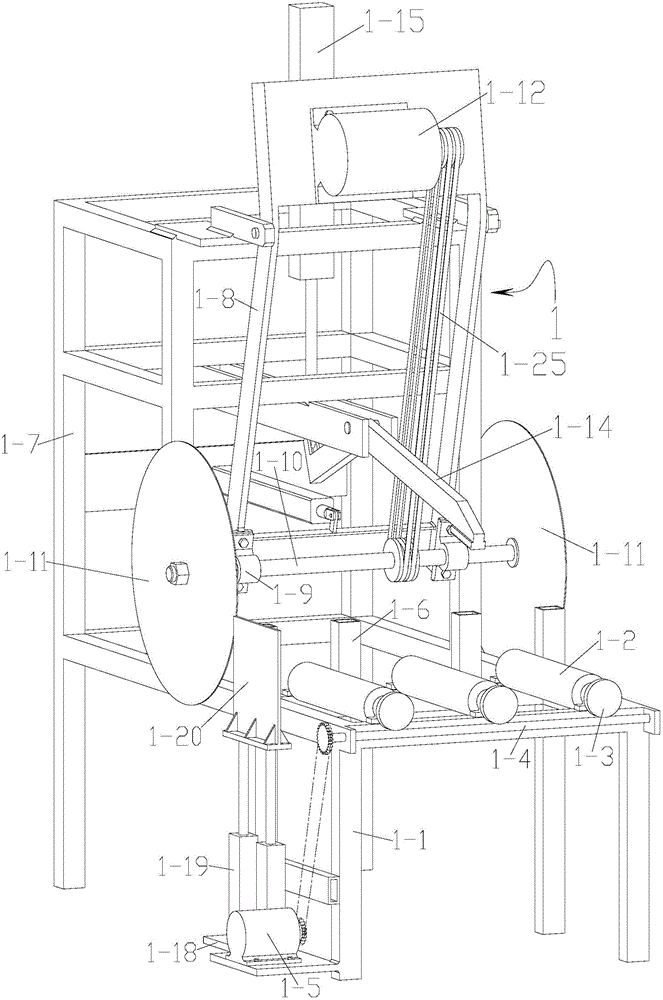

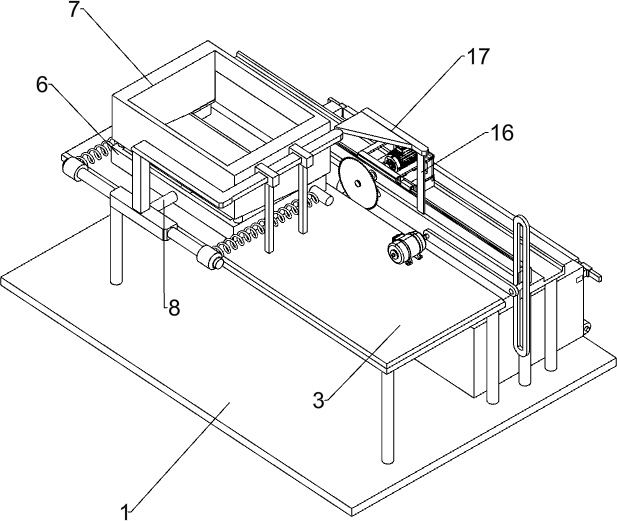

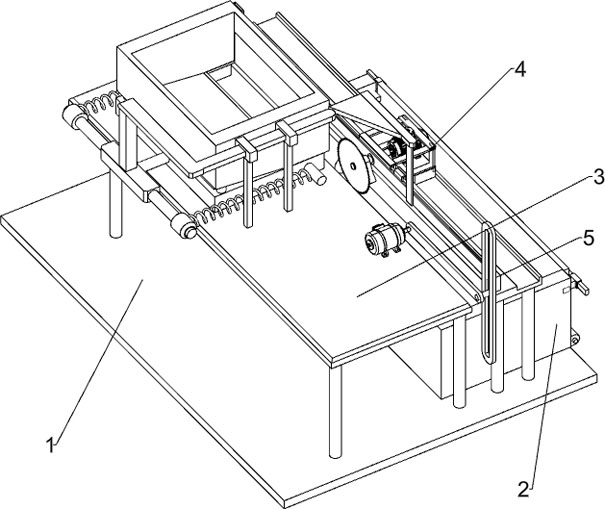

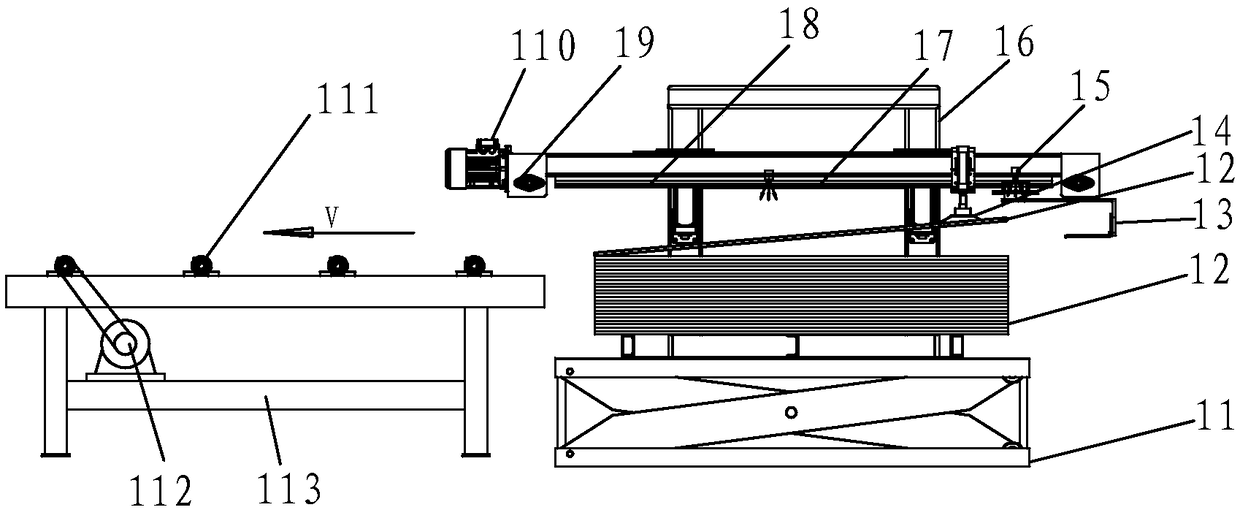

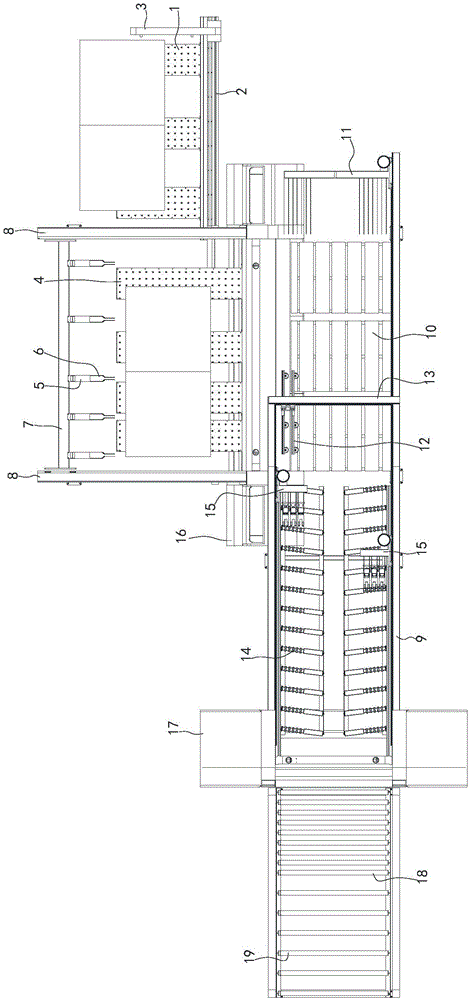

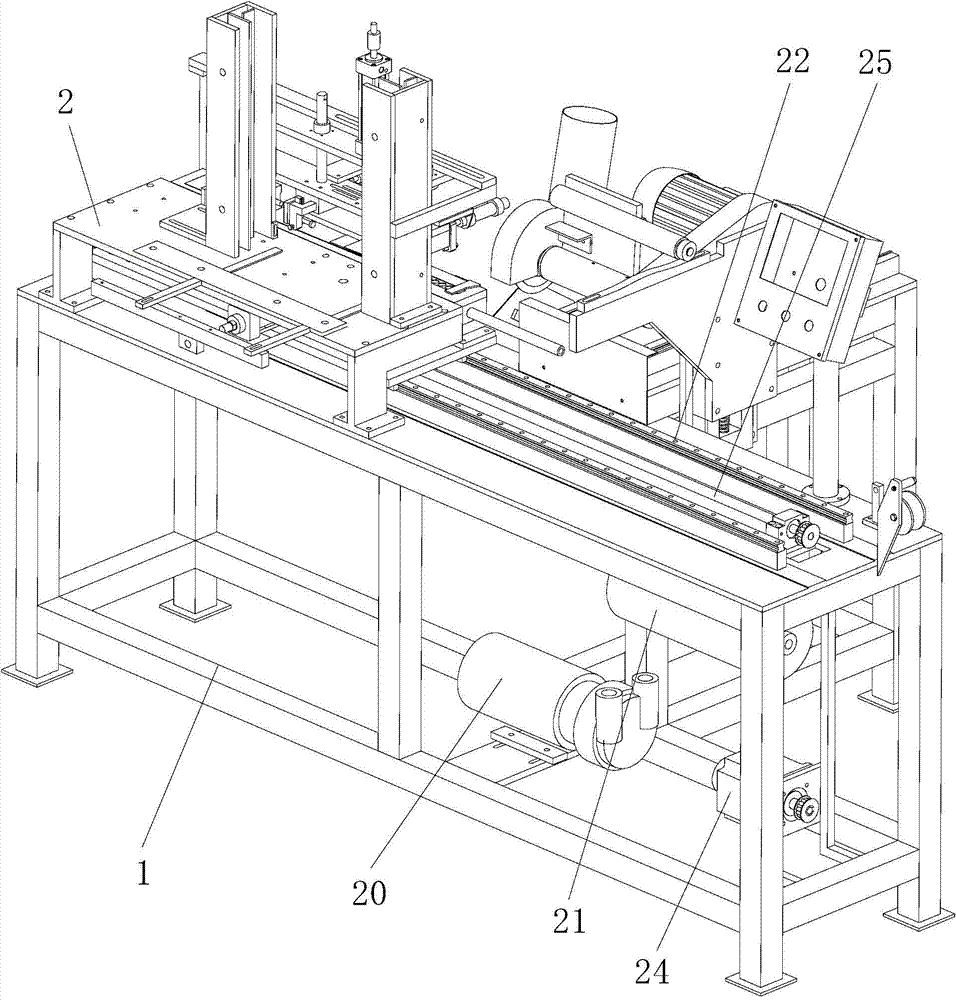

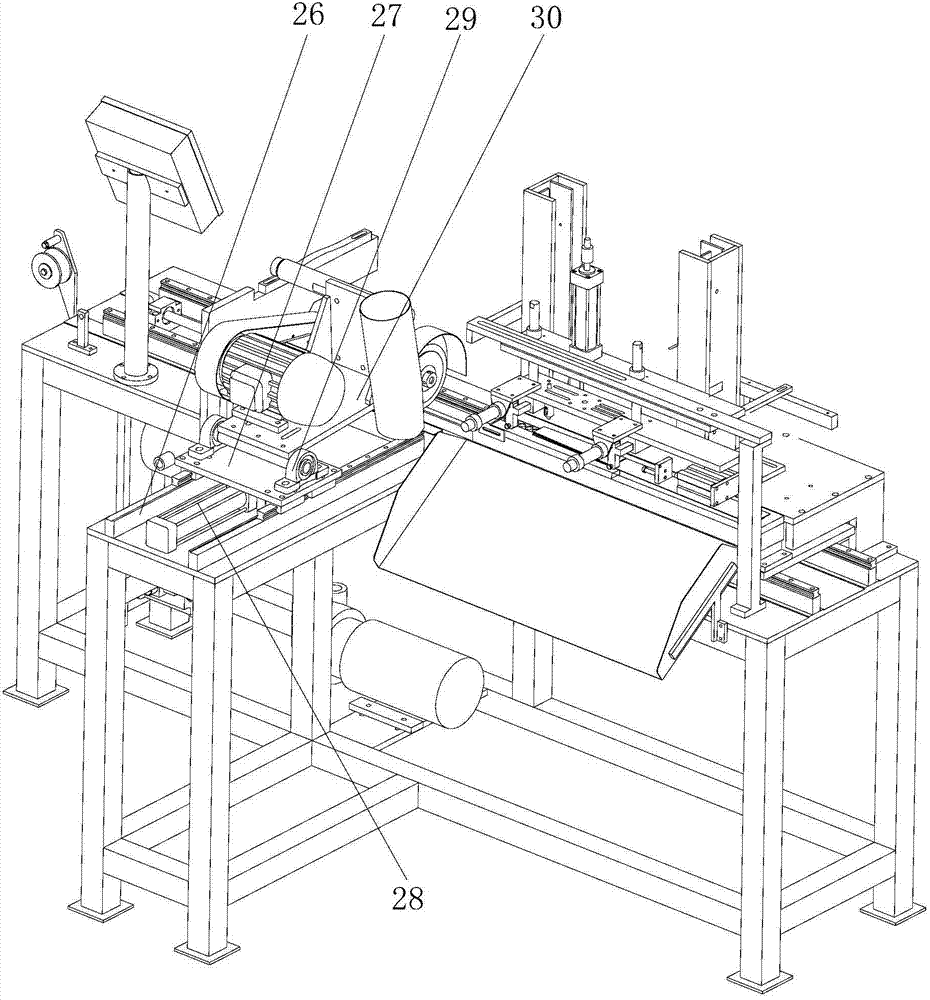

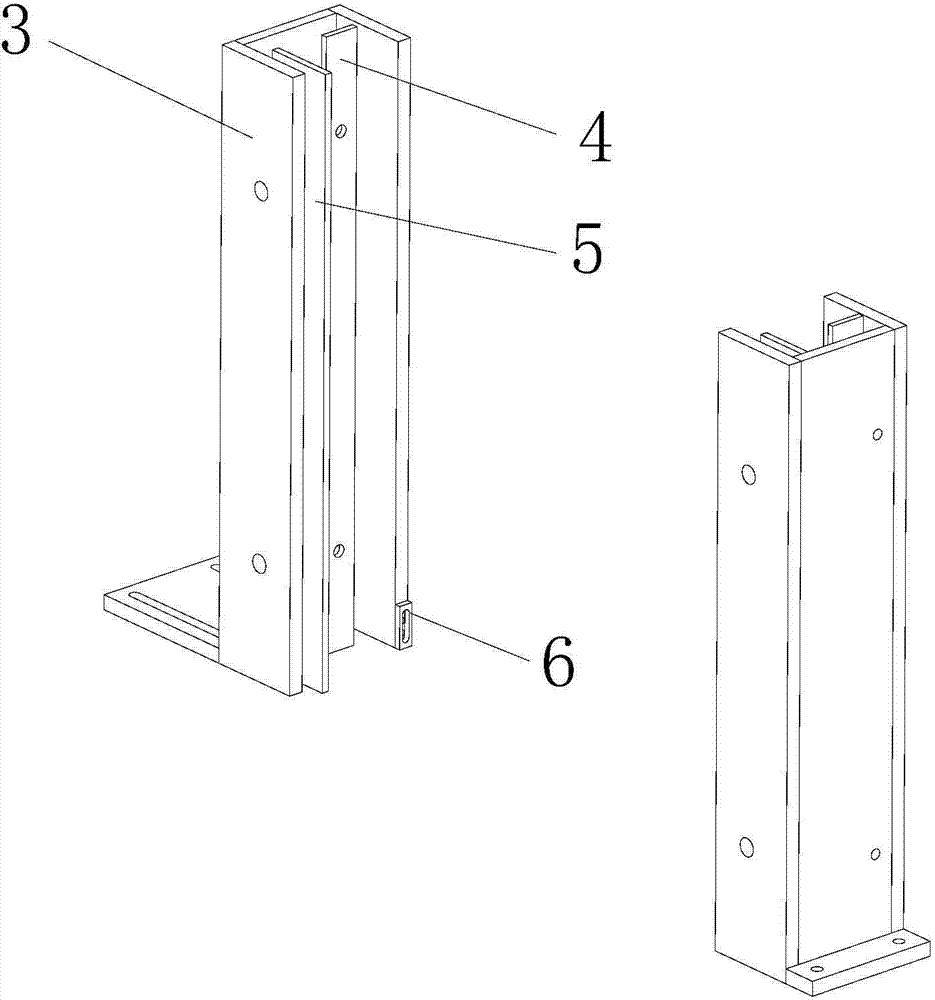

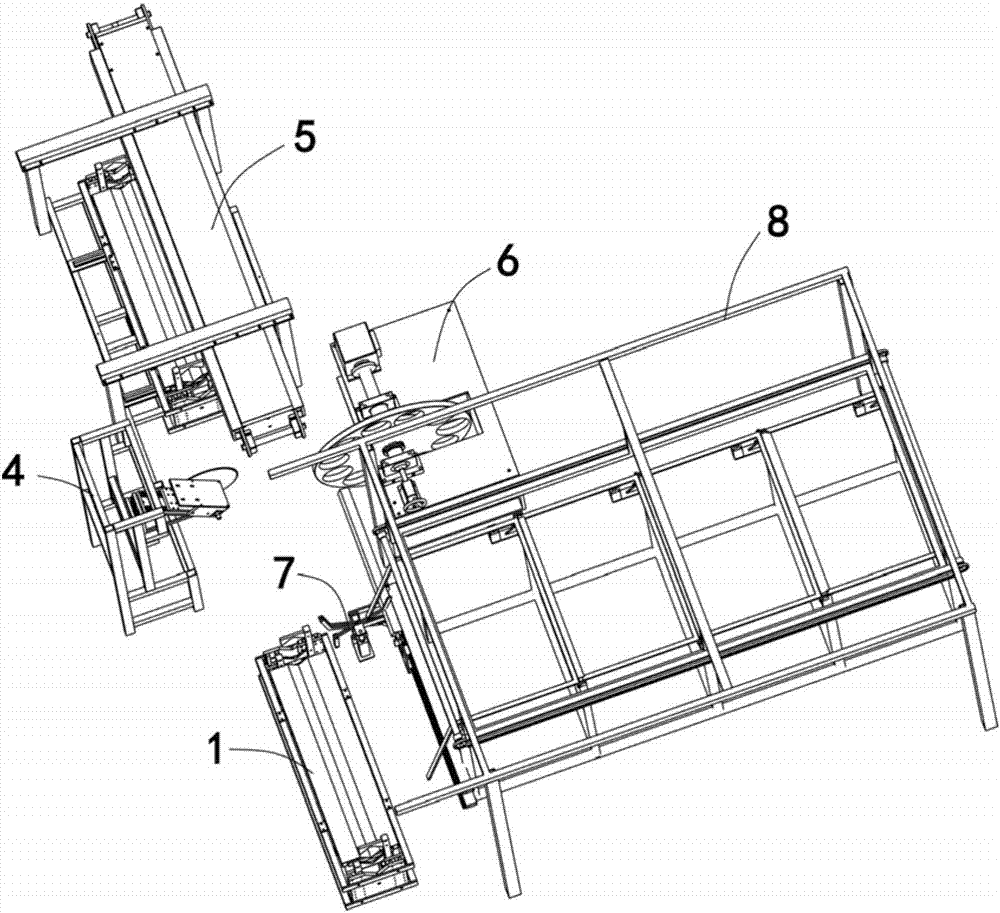

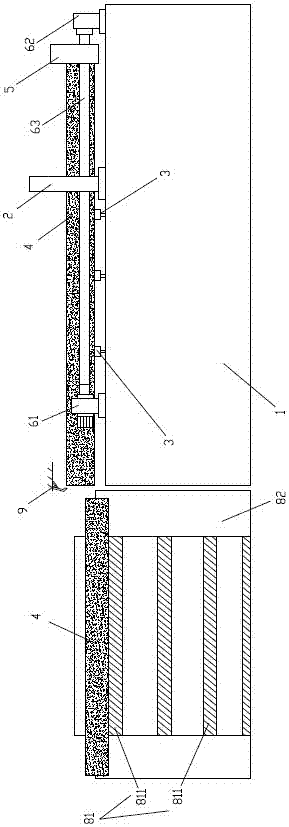

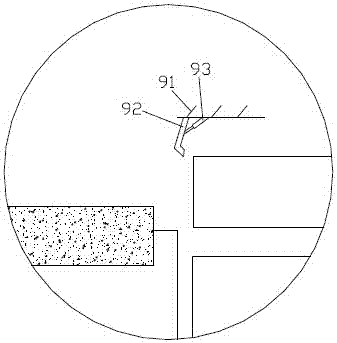

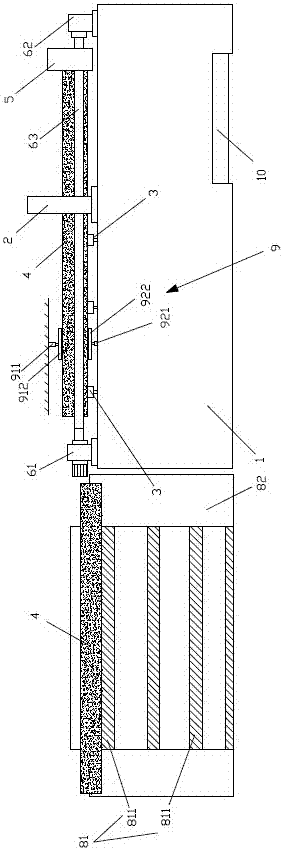

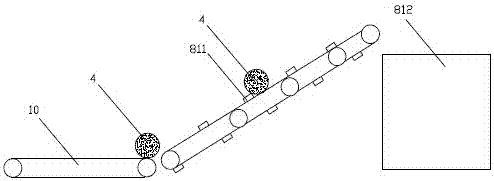

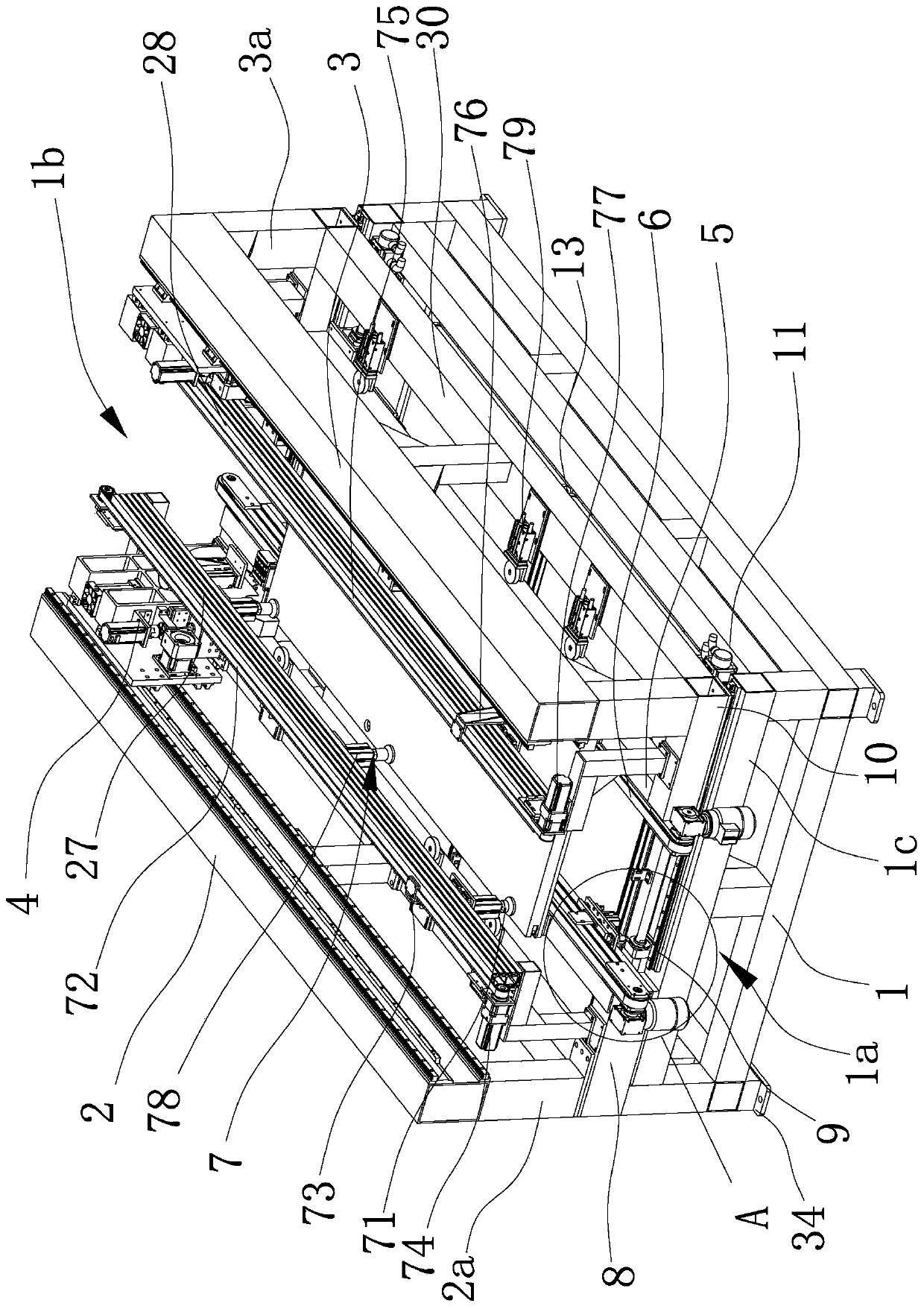

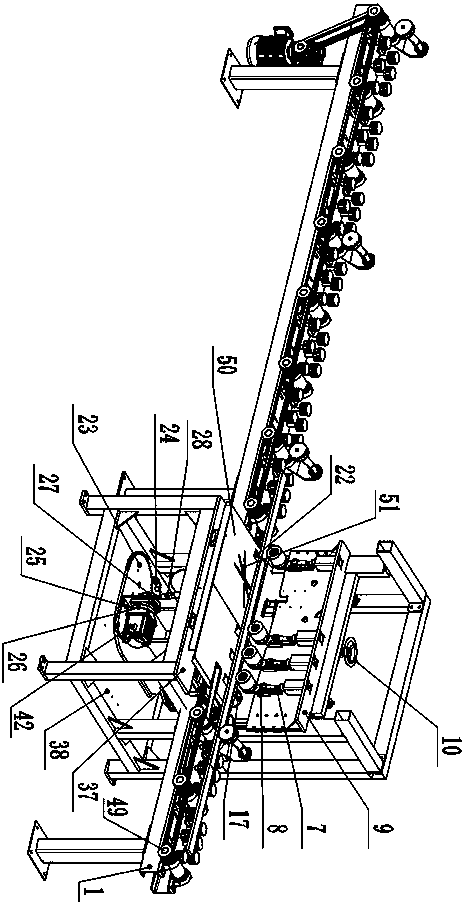

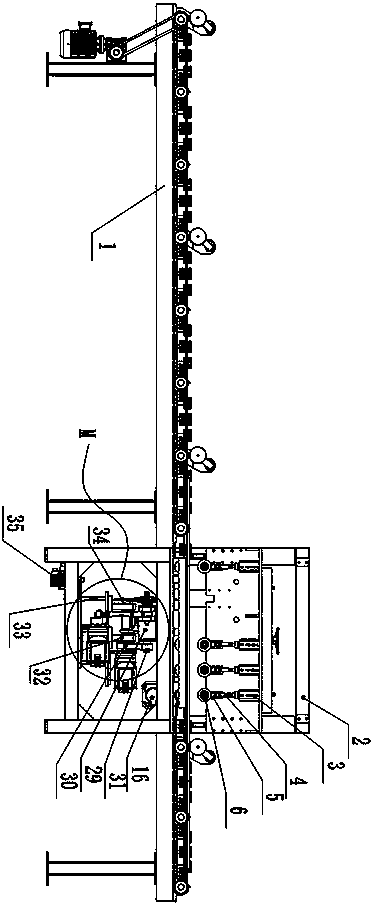

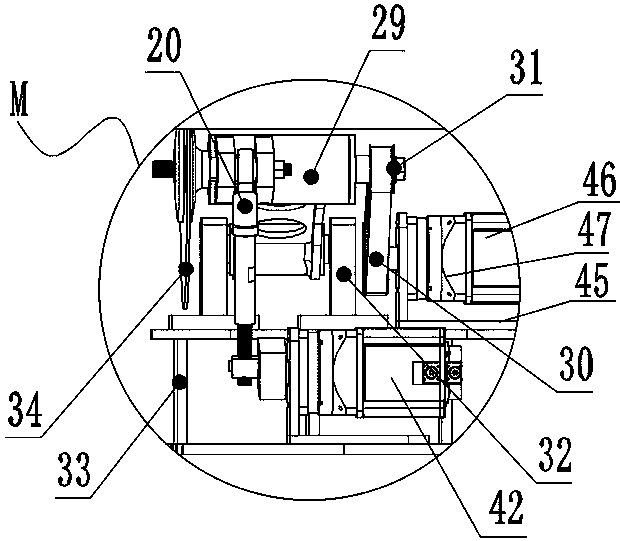

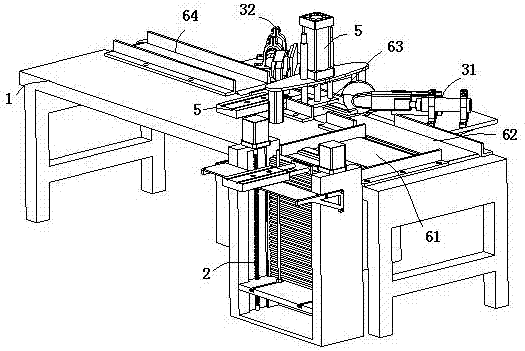

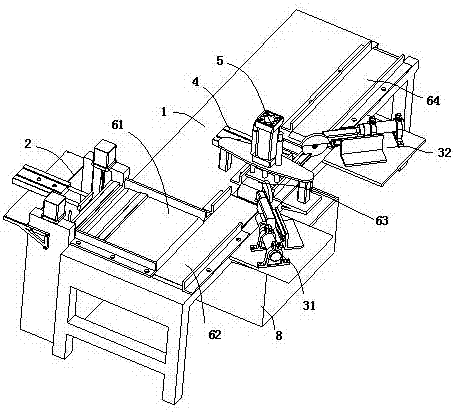

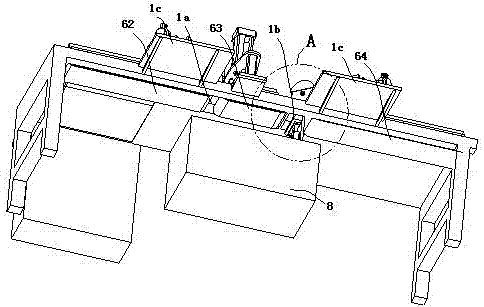

Wood thin-board machining process and wood thin-board automatic machining equipment

ActiveCN105818216AEasy to pushEasy to processFeeding devicesGripping devicesMachining processEngineering

A wood thin-board machining process comprises the following steps: A) clamping a log; B) cutting both ends of the log; C) conveying the cut log; D) machining the cut log. Wood thin-board automatic machining equipment comprises a log clamping and cutting device, a log conveying device and a wood thin-board machining device; a base I disposed on the log clamping and cutting device and a base II disposed on the log conveying device are matched with each other by position, and linked together; a material receiving platform disposed on the log conveying device and a base III disposed on the wood thin-board machining device are matched with each other by position, and linked together. The equipment disclosed by the invention achieves an ingenious and reasonable structure design. The process and equipment disclosed by the invention can greatly improve the efficiency of machining logs into wood thin-board, and are worth popularizing and applying.

Owner:ZHEJIANG DOLO IND

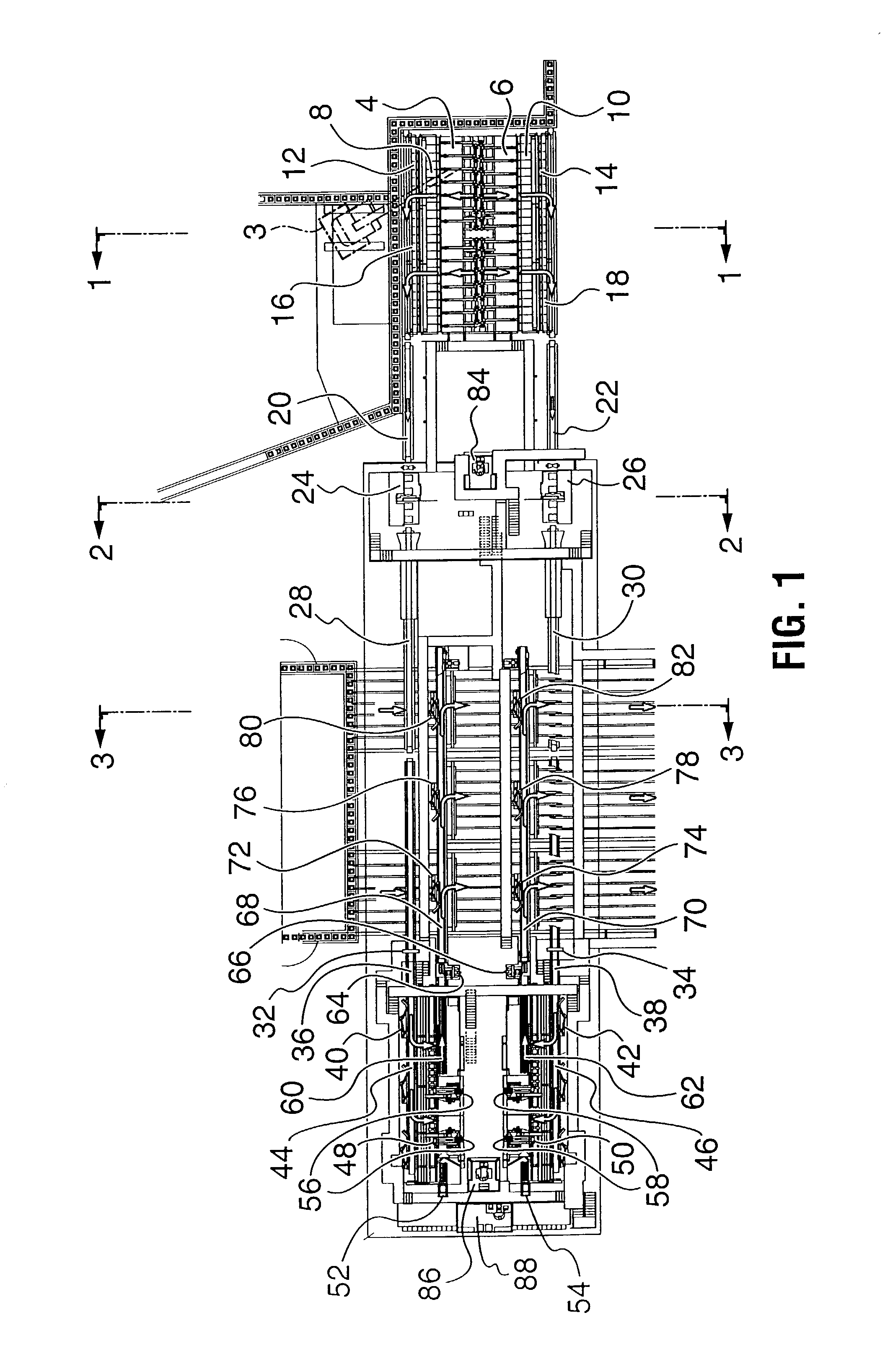

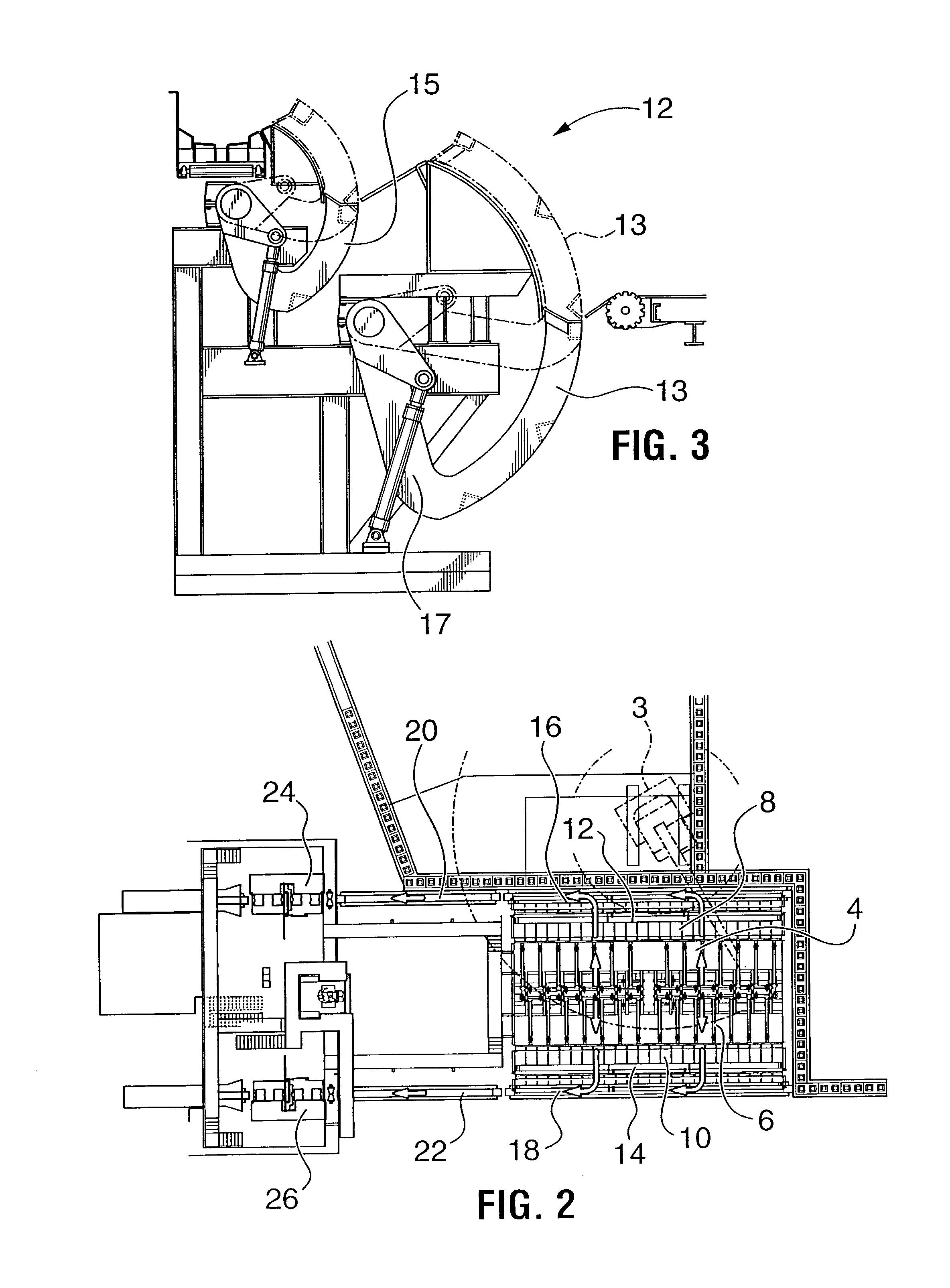

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS6539993B1Reduce stepsMinimize travelMulti-purpose machinesAdjusting equipmentComputer hardwareAlgorithm

Owner:WEYERHAEUSER CO

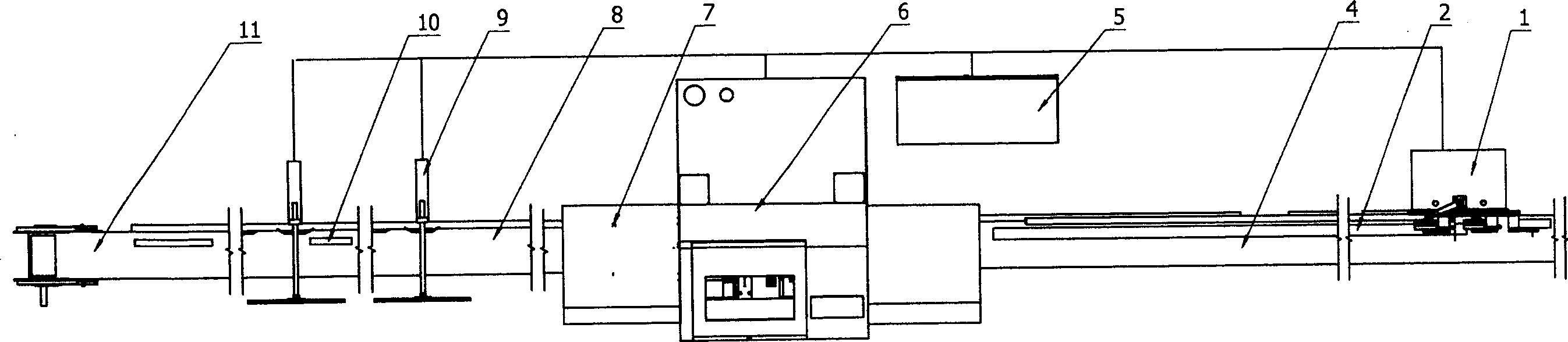

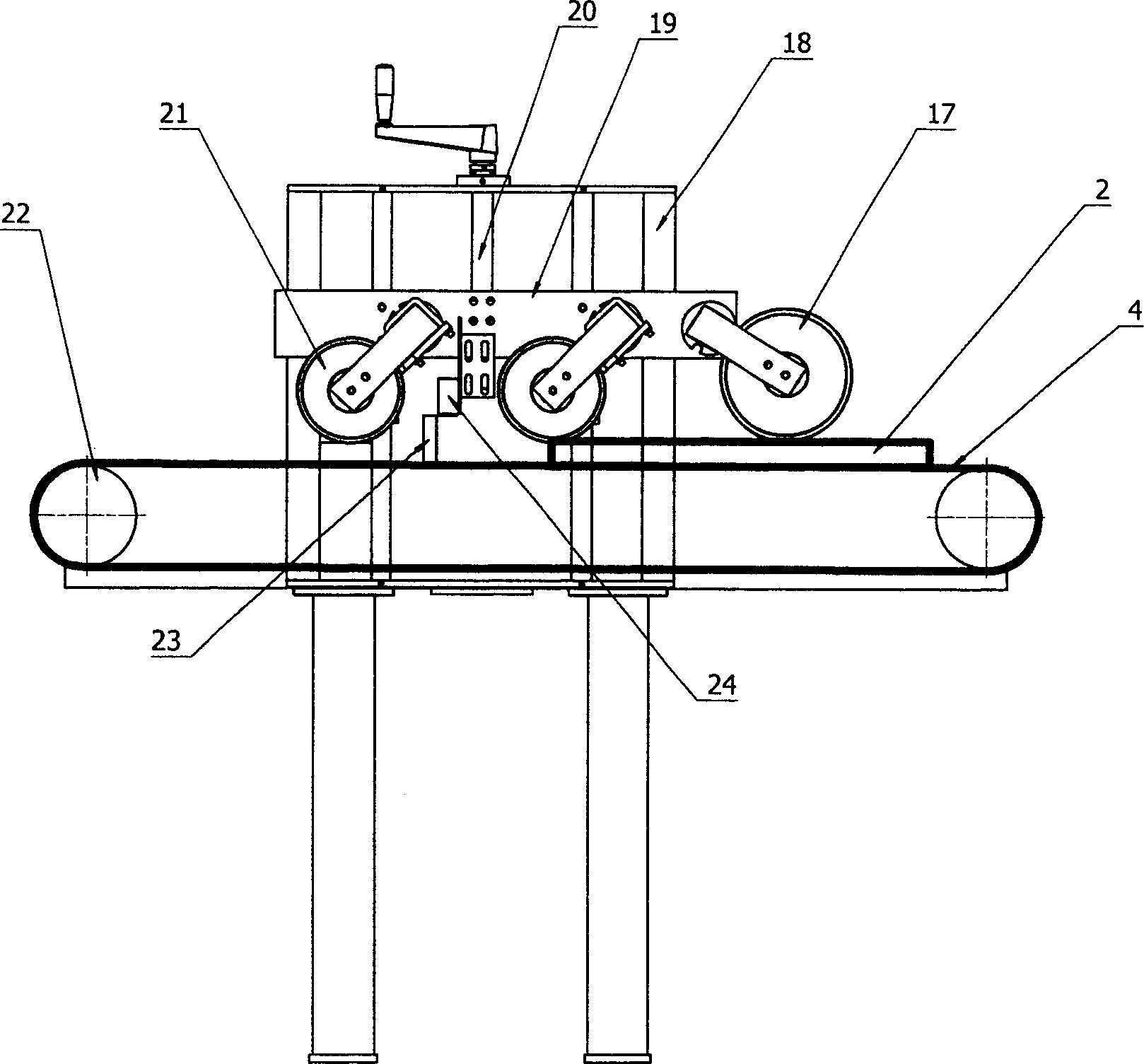

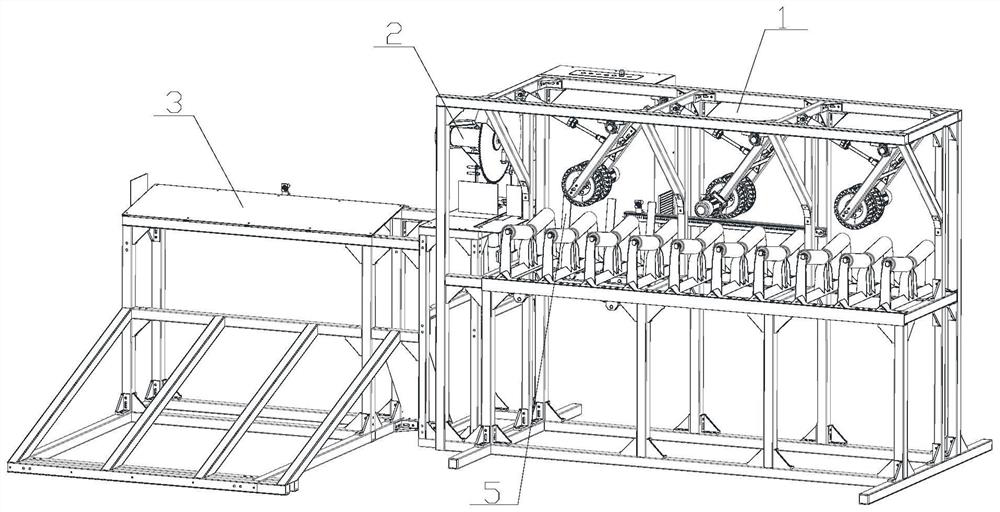

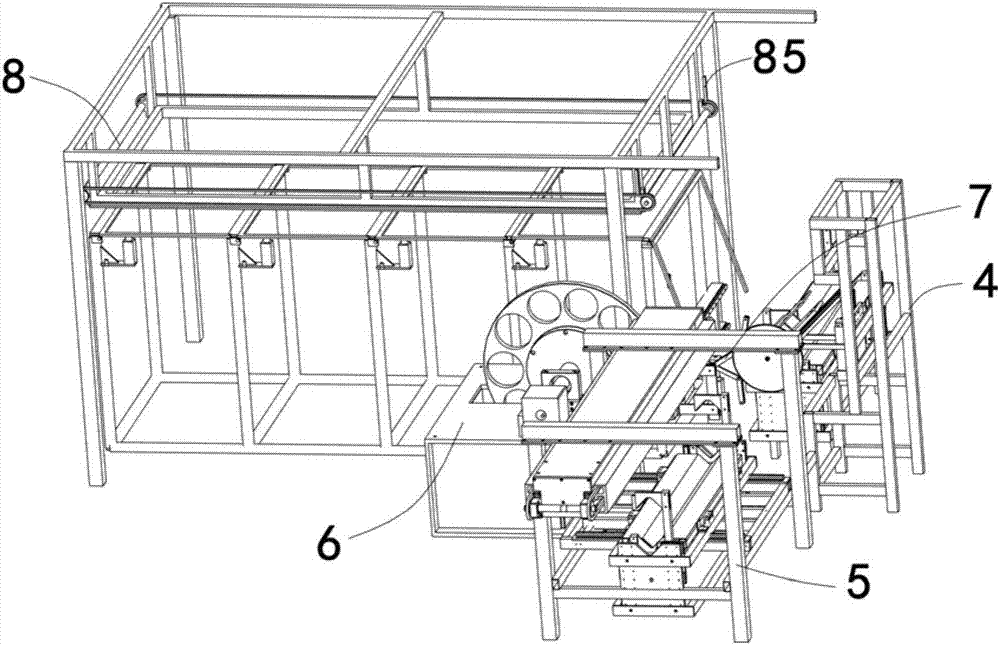

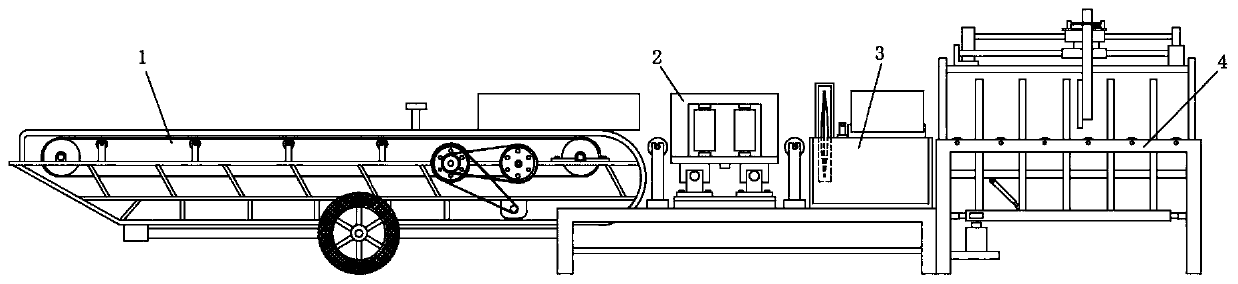

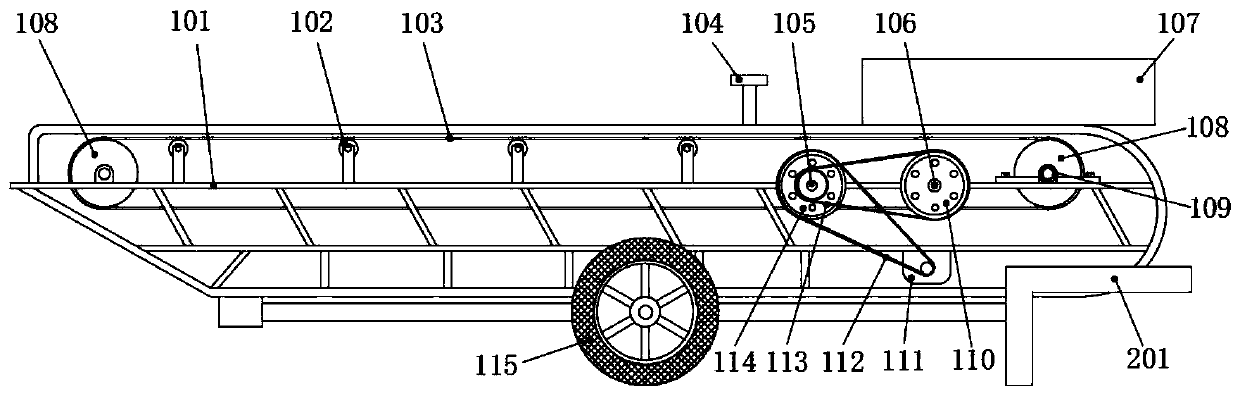

Intelligent wood floor cutting production line

ActiveCN105818217AConsistent finishNo chippingFeeding devicesCircular sawsProduction lineRejection rate

The invention relates to an intelligent wood floor cutting production line. The intelligent wood floor cutting production line comprises a feeding mechanism, a wood floor cutting machine and a discharging mechanism which are arranged in sequence. The intelligent wood floor cutting production line has the beneficial effects that the surface plate and the backing plate of a medium plate cut from a large plate are consistent in smooth finish, no cutting surface is damage, and the rejection rate is remarkably lowered; the loss is low, the outturn percentage is high, the width of a finished product is increased, and the size precision of wood floor cutting is high; the manpower is saved, the labor intensity is reduced, and the machining efficiency is improved; and the intelligent wood floor cutting production line is suitable for a wood floor cutting process, that is, the intelligent wood floor cutting production line can be used for cutting the large plate into the medium plate.

Owner:SHANDONG ZHONGXIN MACHINERY

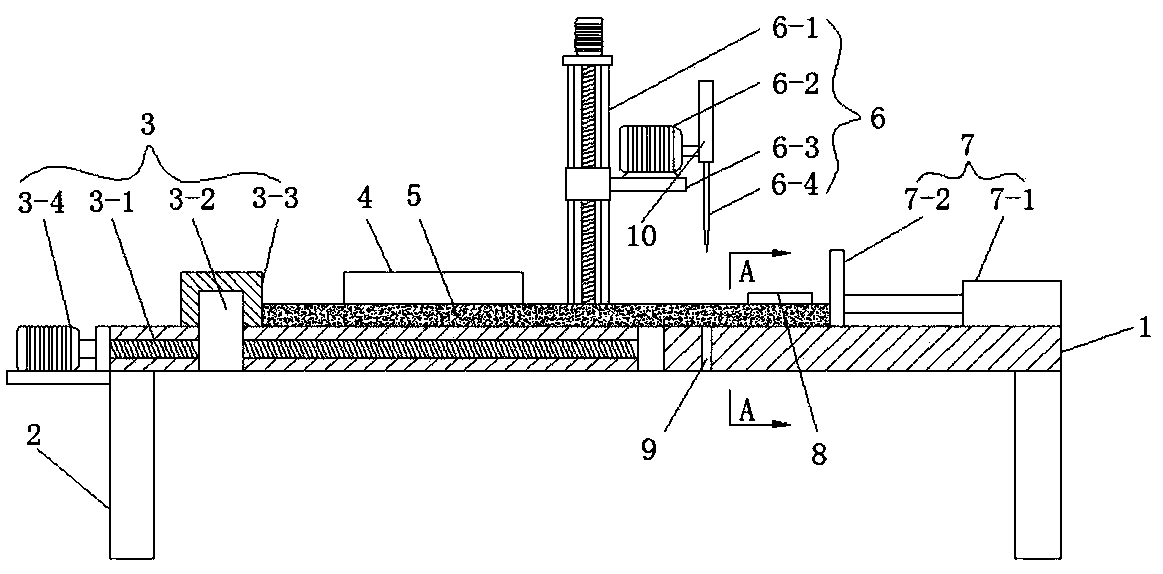

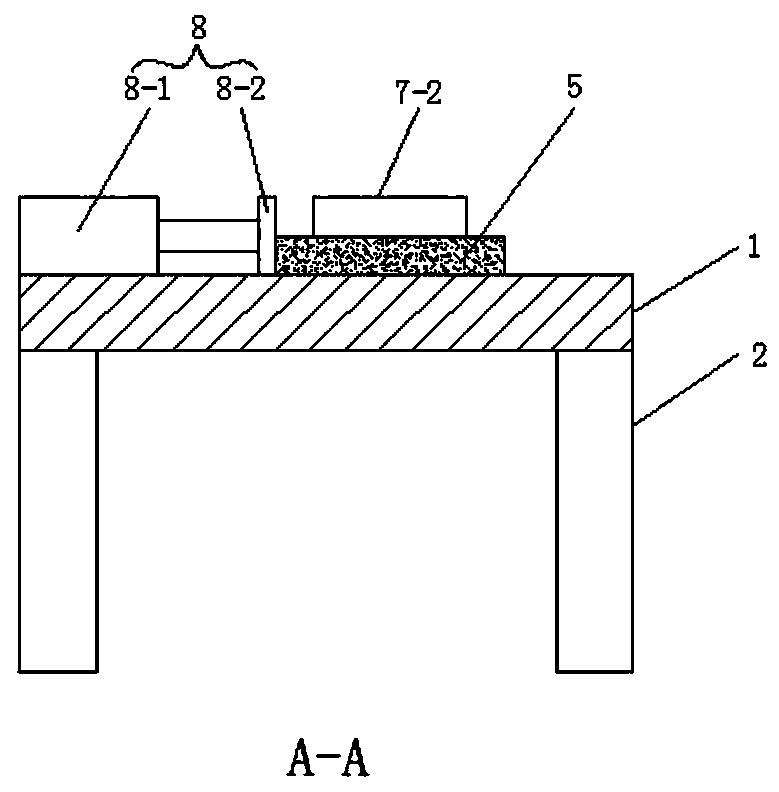

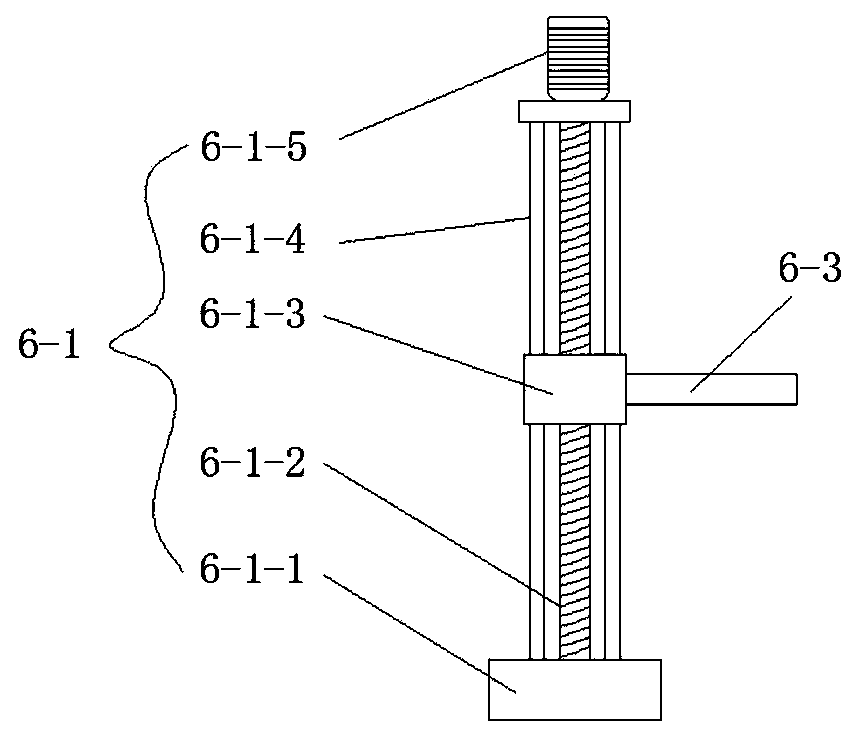

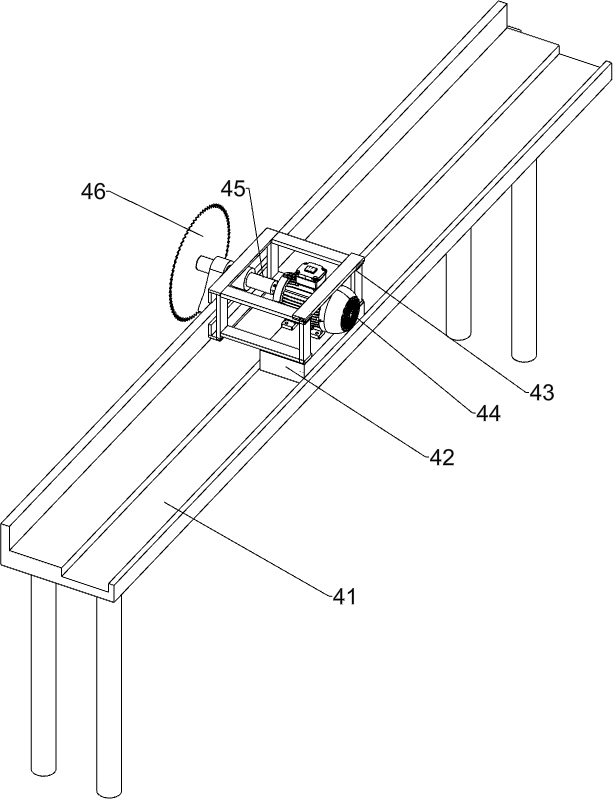

Adjustable wood board cutting processing device

InactiveCN107839021ASimple structureEasy to operateGuide fencesFeeding devicesConnection tableAgricultural engineering

The invention discloses an adjustable wood board cutting processing device and relates to the technical field of board processing equipment. The adjustable wood board cutting processing device comprises a workbench, the four corners of the lower end of the workbench are provided with supports correspondingly, a push mechanism, two side plates for positioning boards, a cutting mechanism and a limiting mechanism are sequentially arranged on the workbench from left to right, the push mechanism comprises a lead screw arranged inside the workbench, the lead screw is provided with a nut base, the nut base is sleeved with a push block which can slide on the workbench, the lead screw is connected with a stepping motor arranged on the outer side of the workbench, the cutting mechanism comprises a lifting mechanism arranged on the workbench, the lifting mechanism is connected with a supporting plate capable of moving on the lifting mechanism, the supporting plate is provided with a motor, the motor is connected with a saw blade, the limiting mechanism comprises an air cylinder arranged on the workbench, and a piston rod of the air cylinder is connected with a baffle. The adjustable wood board cutting processing device has the advantages of being simple in structure, convenient to operate and easy to adjust.

Owner:SICHUAN GUANTENG TECH CO LTD

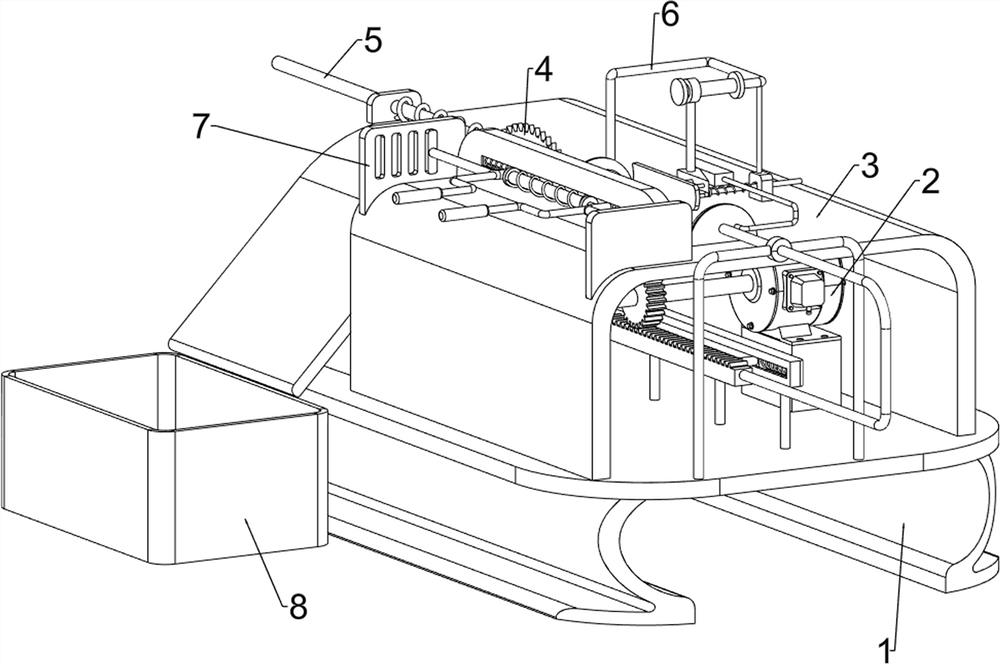

Automatic wood slicing device for building materials

ActiveCN112092099AAvoid unevennessSuit one's needsGuide fencesFeeding devicesAgricultural engineeringElectric machinery

The invention relates to a slicing device, in particular to an automatic wood slicing device for building materials. According to the automatic wood slicing device for the building materials, the efficiency can be improved, the thickness of cut wood blocks can be adjusted, and convenience is achieved. The automatic wood slicing device for building materials comprises a first working table, a second working table, an electric saw, a pushing mechanism and a pressing mechanism. A motor is arranged on the side wall of the upper part of the first working table; the second working table is arrangedon the first working table; the electric saw is rotatably arranged on the second working table; the pushing mechanism is arranged on the first working table; and the pressing mechanism is arranged onthe second working table. The pressing mechanism can stabilize the wood block and prevent the wood block from being unevenly cut due to instability during cutting. After the wood blocks are sliced bythe electric saw, the wood chips can be collected by a collecting box and are convenient to arrange; and a distance adjusting mechanism enables the wood block to be cut thick or thin according to needs, the needs of people can be met, and convenience is achieved.

Owner:蓝山县奔嘉木业有限公司

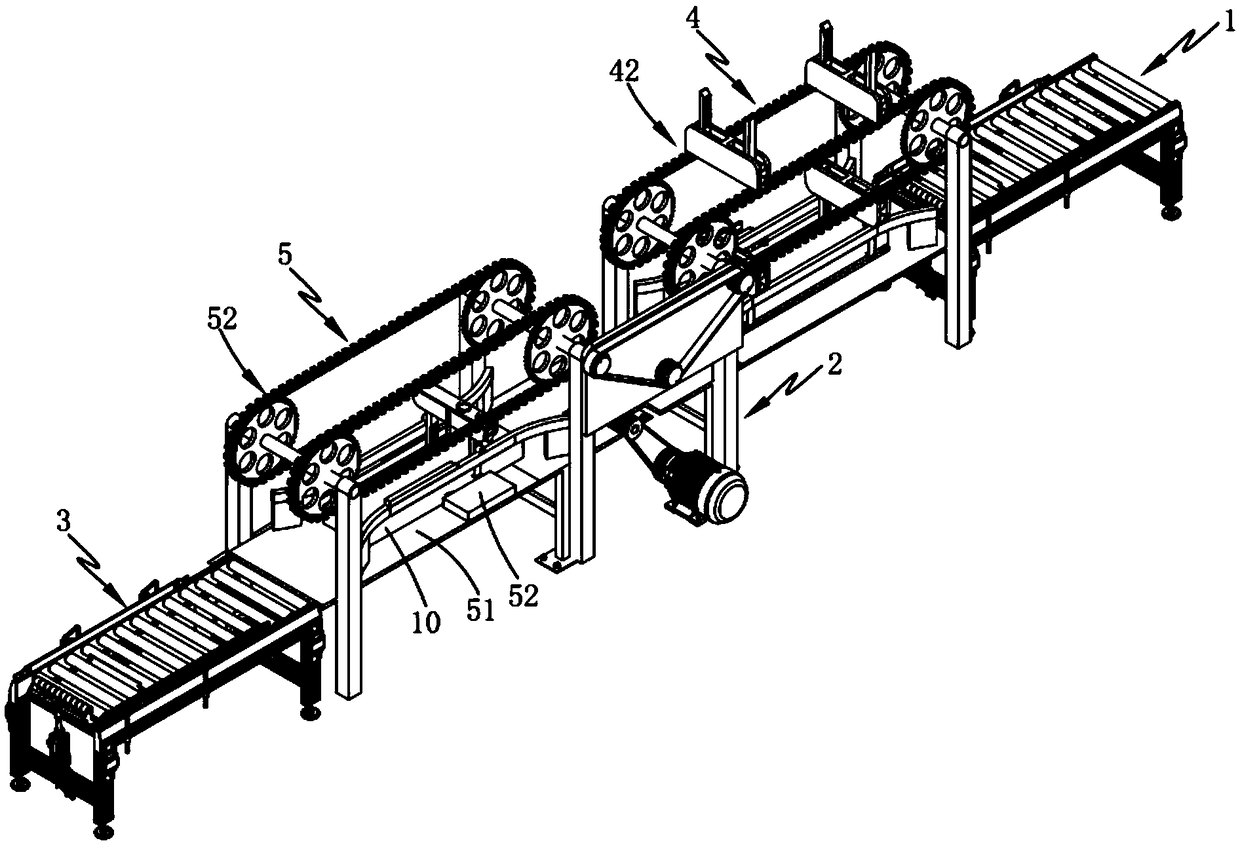

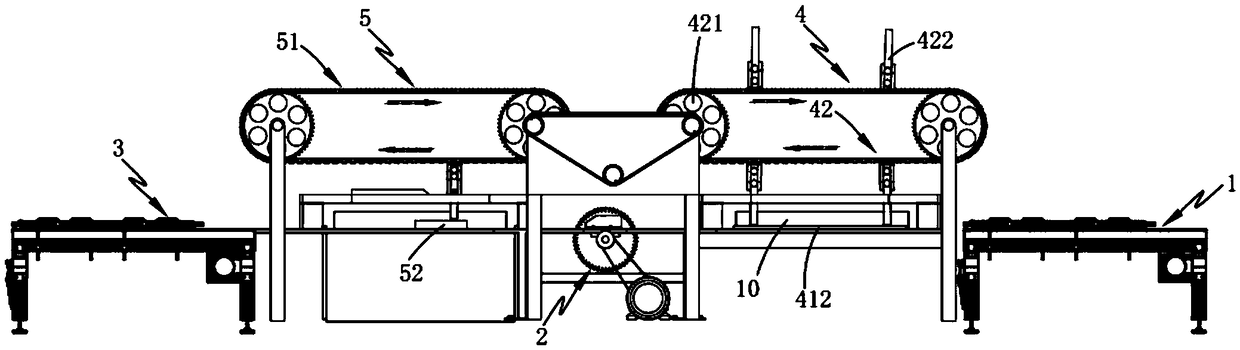

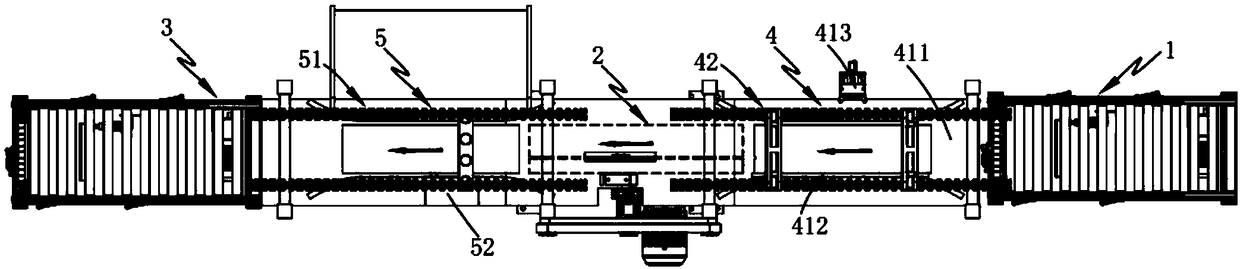

Continuous automatic processing production line for wood of furniture manufacturing

ActiveCN109291140ARealize fully automatic cuttingAchieve separationFeeding devicesGripping devicesProduction lineReciprocating motion

The invention provides a continuous automatic processing production line for wood of furniture manufacturing. The production line comprises a feeding device, a cutting device, an output device, a clamping and feeding device and a waste separating device, wherein the clamping and feeding device is arranged between the feeding device and the cutting device, and comprises a wooden block positioning mechanism and a clamping and transporting mechanism; and the waste separating device is arranged between the cutting device and the output device, and comprises a separating workbench, a clamping staggering mechanism and a separating mechanism. After the clamping and feeding device clamps wooden blocks in a mode of reciprocating motion, the stepwise feeding and cutting are carried out in the cutting device; after the cutting of the wooden blocks is completed, the clamping and feeding device is fitted with the waste separating device to carry out the staggering separation of finished products and waste, so that the full-automatic cutting and the waste separating of the wooden blocks are realized; and in this way, an original manual wooden block feeding and cutting method is replaced, so thatthe problem that the leftward and rightward swaying of the wood results in irregular wood cutting surfaces and the imprecise cutting in the prior art is solved.

Owner:佛山市顺德区博领家具有限公司

Automatic bamboo sawing equipment and bamboo sawing method capable of customizing cutting length

ActiveCN111906852AImprove work efficiencyReduce labor costsGuide fencesFeeding devicesStructural engineeringMechanical engineering

The invention discloses automatic bamboo sawing equipment and bamboo sawing method capable of customizing the cutting length. The automatic bamboo sawing equipment comprises a conveying mechanism, a bamboo sawing mechanism, a discharging mechanism, a custom length fixing mechanism and a push-out mechanism. The conveying mechanism is used for conveying to-be-cut raw bamboo to the bamboo sawing mechanism; the bamboo sawing mechanism is arranged at a discharge port of the conveying mechanism and used for cutting the raw bamboo; the discharging mechanism is arranged in the discharging direction ofthe bamboo sawing mechanism and used for collecting the cut bamboo with the fixed length sections; the custom length fixing mechanism comprises a first photoelectric sensor and a second photoelectricsensor, the first photoelectric sensor is slidably mounted on the discharging mechanism, and the second photoelectric sensor is slidably mounted on the conveying mechanism; and the push-out mechanismcomprises a first air cylinder and a push plate connected with the first air cylinder, the first air cylinder and the push plate are installed on the conveying mechanism, and the push plate is located in front of the second photoelectric sensor in the discharging direction. By means of the automatic bamboo sawing equipment and bamboo sawing method, customized length cutting and collecting of theraw bamboo and discharging of excess materials can be achieved.

Owner:SOUTH CHINA AGRI UNIV

Automatic bamboo pole sawing device

ActiveCN105599075AFully automatedOvercome the shortcomings of slow speed and low efficiencyFeeding devicesCane mechanical workingSolenoid valveHigh pressure

The invention relates to an automatic bamboo pole sawing device which is characterized in that a plurality of material cutting devices are arranged on a saw table in parallel; each material cutting device comprises a material cutting motor; the material cutting motor is connected with a saw blade through a material cutting conveyor belt; the material cutting devices are movably mounted on a material cutting frame; material cutting cylinders used for pushing the material cutting devices to move forwards or backwards are arranged behind the material cutting devices; material cutting solenoid valves are mounted on high-pressure air inlet pipes of the material cutting cylinders; the material cutting devices are positioned on a same straight line; the distance between the every two saw blades of the material cutting devices is equal to the length of a bamboo pole required to be cut down; the material cutting devices simultaneously move forwards, saw off the whole bamboo pole at a time and are mounted on the saw table through bolts; the distance between the every two material cutting devices can be adjusted according to the length of a bamboo segment to be sawed. The automatic bamboo pole sawing device provided by the invention realizes the effect through the controller that the bamboo pole is placed by a scraper plate conveyor on the saw table and is sawed off by the material cutting devices at a time, overcomes the defects that the artificial bamboo pole sawing speed is low, and the efficiency is low and realizes the automation of bamboo pole sawing-off.

Owner:湖南贝旺农林科技有限公司

Strip cutting machine suitable for regular plate

ActiveCN104441065AImprove cutting accuracyImprove cutting efficiencyGripping devicesClamping devicesEngineeringMechanical engineering

The invention discloses a strip cutting machine suitable for a regular plate. The strip cutting machine comprises a bracket, a worktable, a cutting mechanism, a receiving box and a conveying belt, wherein a plurality of material-falling holes are formed in one side of the worktable; a cutting groove is formed between the any two adjacent material-falling holes; the width of each material-falling hole is greater than the distance between the material-falling hole and the cutting groove; the length of the cutting groove is greater than that of the material-falling hole; positioning parts are arranged at the two ends of the worktable; a positioning baffle is arranged above the material-falling holes close to the end part of the worktable; the distance between the positioning baffle and the worktable is greater than the thickness of a wood plate to be cut; the distance between the positioning baffle and a cutter close to the positioning baffle is equal to the width of a cut wood strip; the cutting mechanism comprises a plurality of cutters arranged in the cutting grooves; the conveying belt is arranged below the material-falling holes; the receiving box is arranged below the discharging end of the conveying belt. According to the strip cutting machine, one wood plate can be regularly cut into a plurality of wood strips in one time and the cut wood strips can be quickly collected.

Owner:广西北港不锈钢有限公司

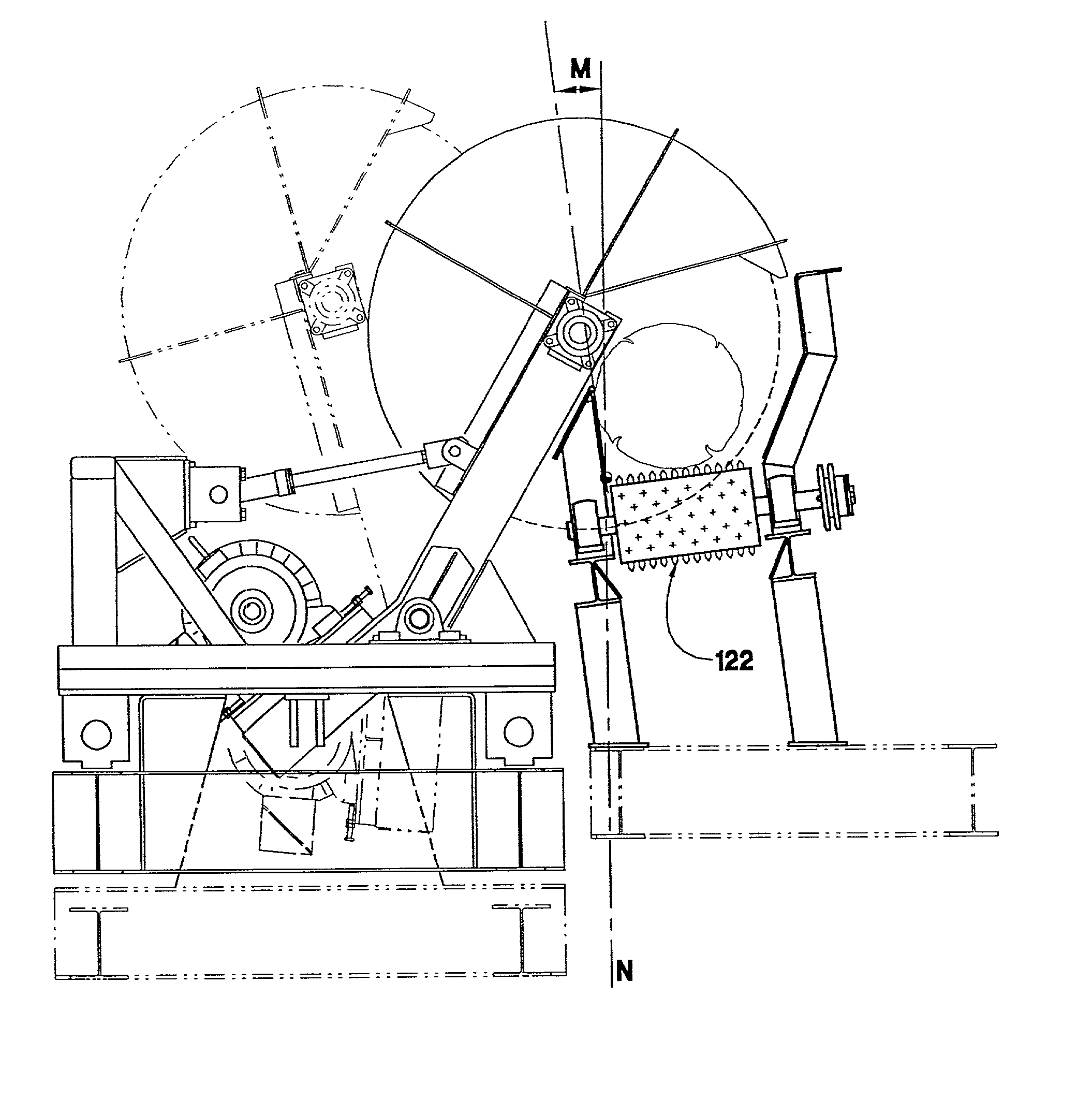

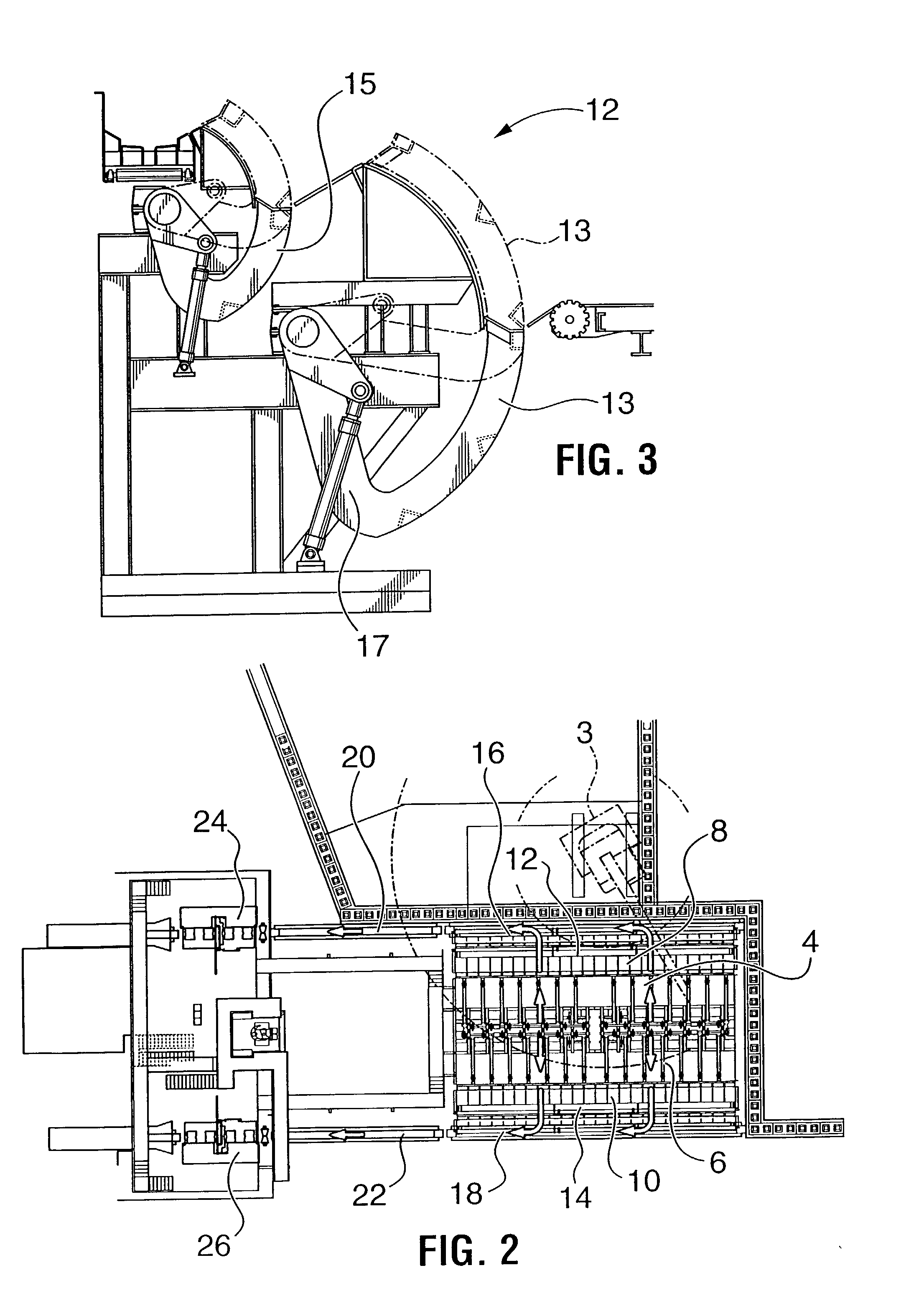

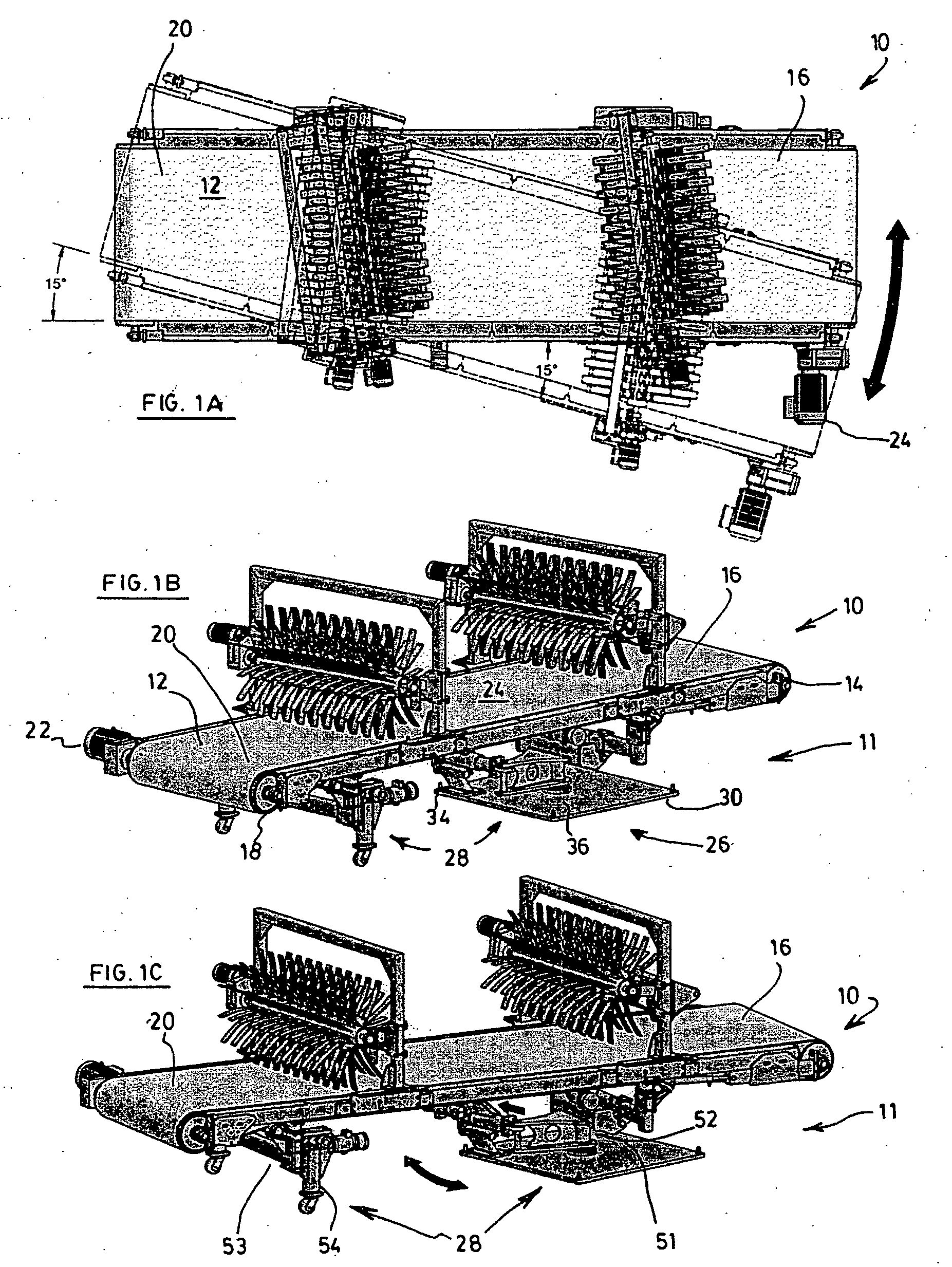

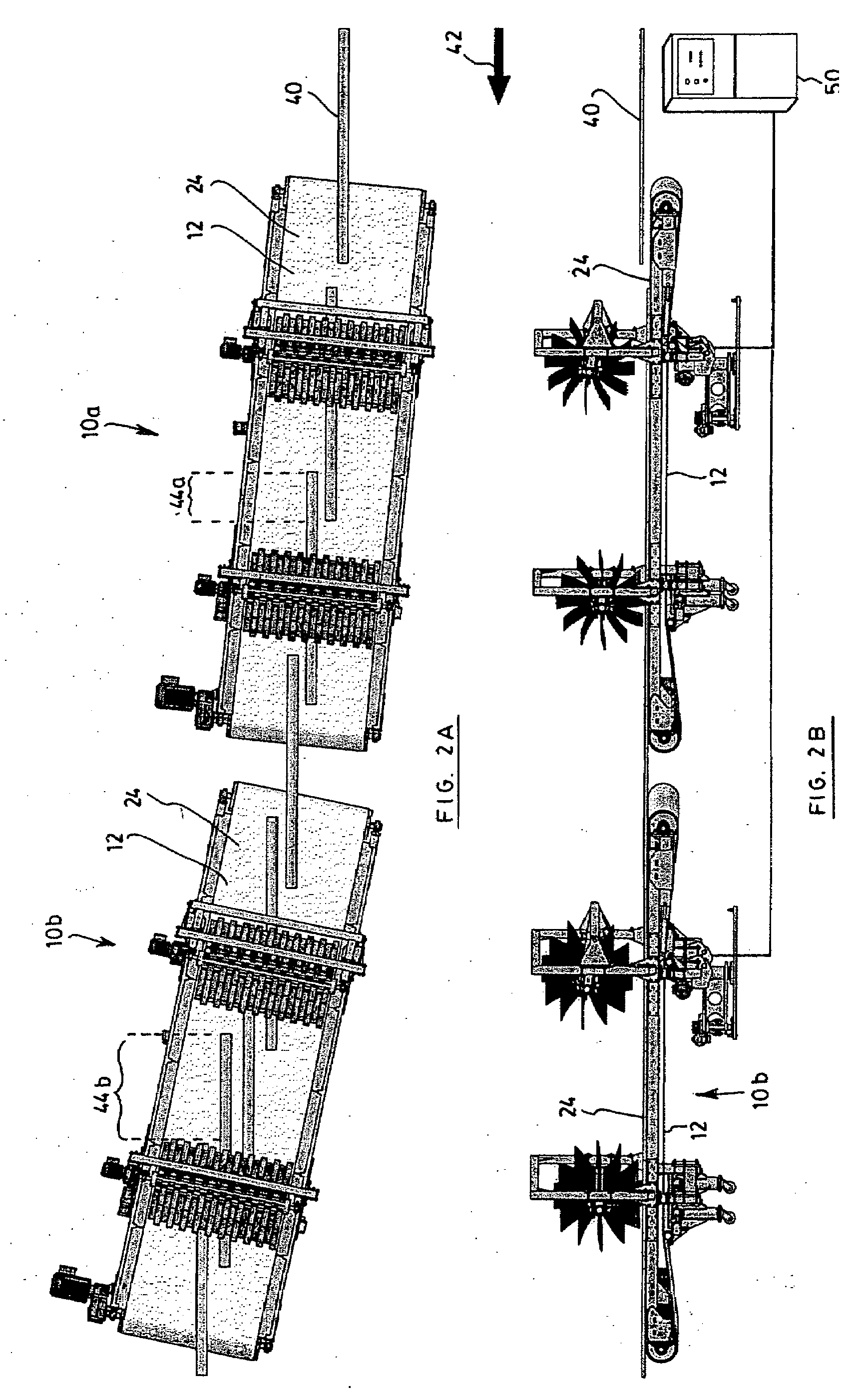

Method and apparatus for bucksawing logs

Previous methods of bucksawing logs slow the throughput of a sawmill in that the conveyor line is stopped while a given log is bucksawed to length. The present invention provides a method for bucksawing a log which improves the throughput speed. The present invention provides a method and apparatus for bucksawing a log comprising the steps of a) advancing the log endwise along a tilted infeed conveyor; b) positioning the log on a tilted feed roll above the level of an outfeed conveyor while advancing the log; c) measuring the advance of the log while on the tilted feed roll; d) stopping the log at the desired length; e) sawing the log to produce a forward log segment; f) moving the forward log segment onto a tilted outfeed conveyor while advancing the remaining log segments. The present invention further provides a method and apparatus for bucksawing a log comprising utilizing a second multi-positional cut-off saw in the bucksawing station. The present invention further provides a method for bucksawing a log comprising utilizing a shifting gap in the conveyor system associated with the second multi-positional cut-off saw in the bucksawing station. The present invention further provides a method and apparatus for bucksawing a log comprising utilizing two multi-positional cut-off saws in the bucksawing station for indefinite length cuts.

Owner:MURRAY ROBERT JAMES

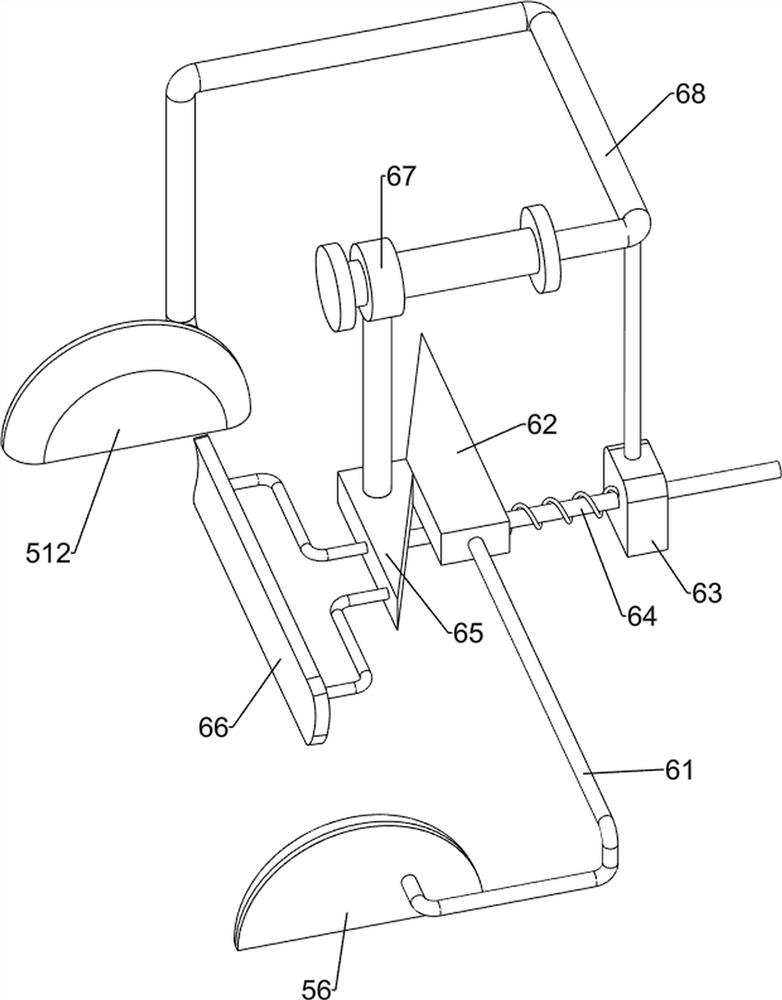

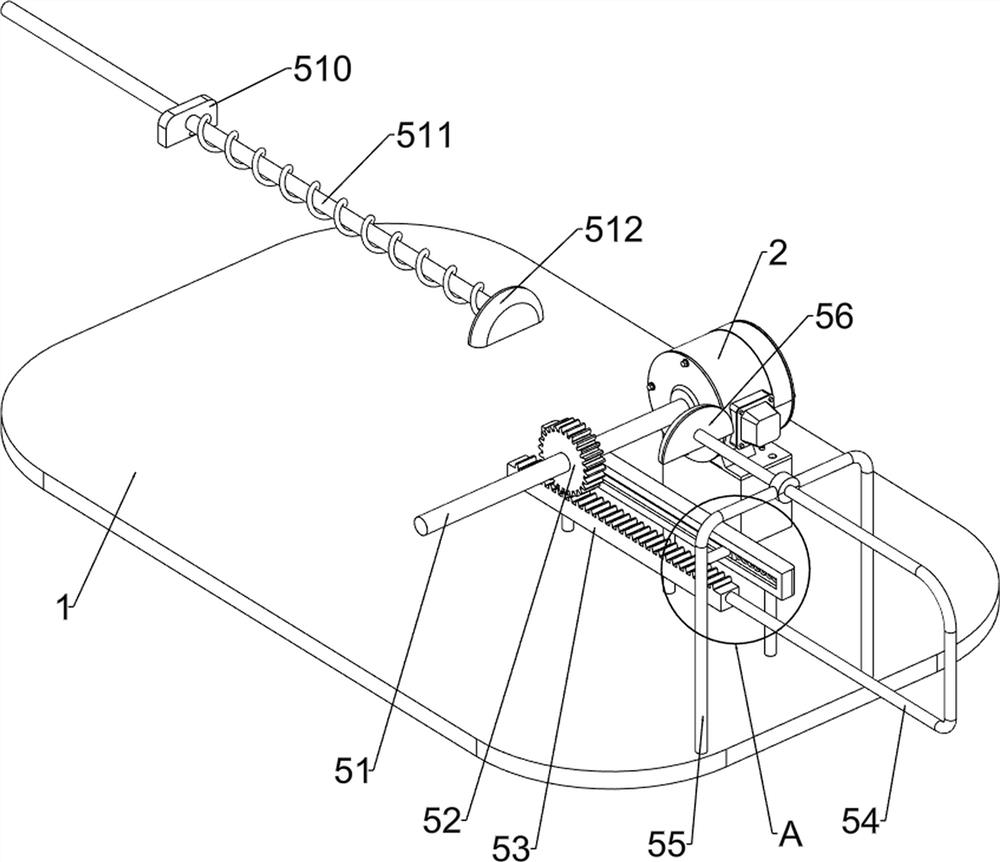

Forestry log auxiliary cutting device

ActiveCN111791309AAchieve automatic feedingEasy to cutFeeding devicesClimate change adaptationForest industryAgricultural engineering

The invention relates to a cutting device, in particular to a forestry log auxiliary cutting device. The forestry log auxiliary cutting device achieves the technical purposes of automatic dischargingand convenient cutting. According to the technical scheme, the forestry log auxiliary cutting device comprises a base the top side edge of which is provided with a collecting box; a workbench which isarranged in the middle of the top of the base; a cutting device which is arranged at the position, close to the workbench, of the top of the base, and is located over the collecting box; and a movingdevice which is used for driving the cutting device to reciprocate and is arranged on the workbench. The cutting device achieves the effects of automatic discharging and convenient cutting.

Owner:湖南森海碳汇开发有限责任公司

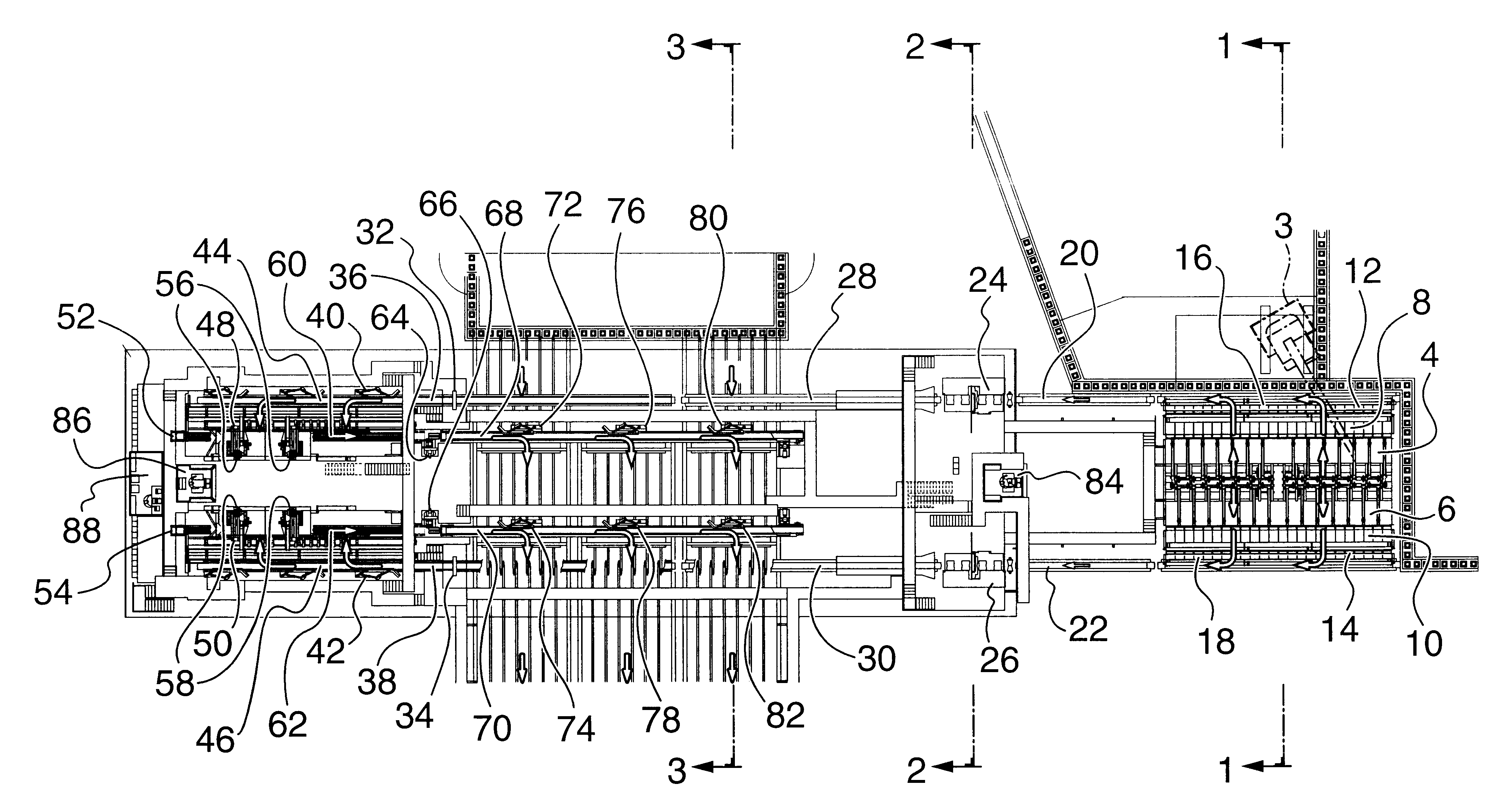

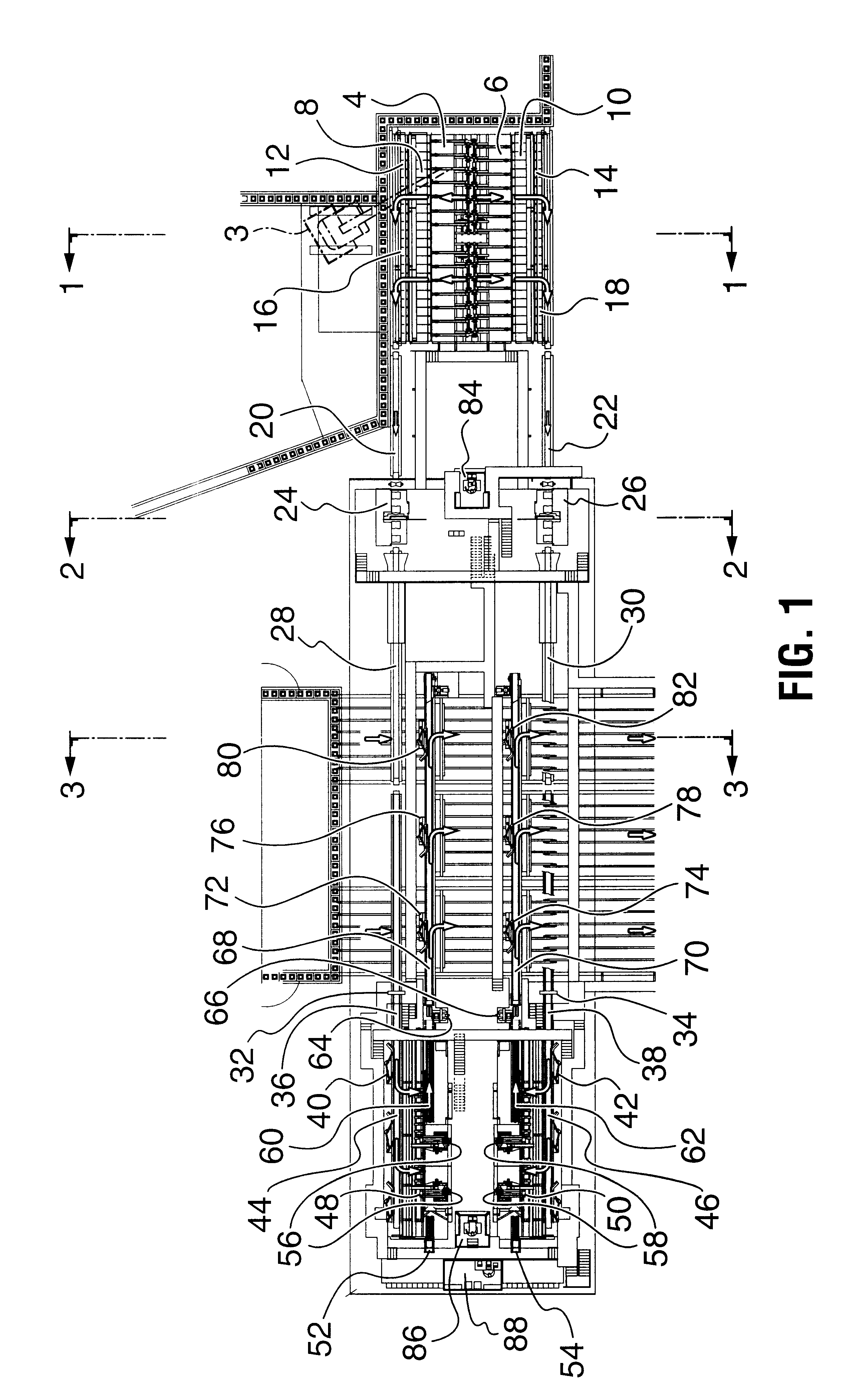

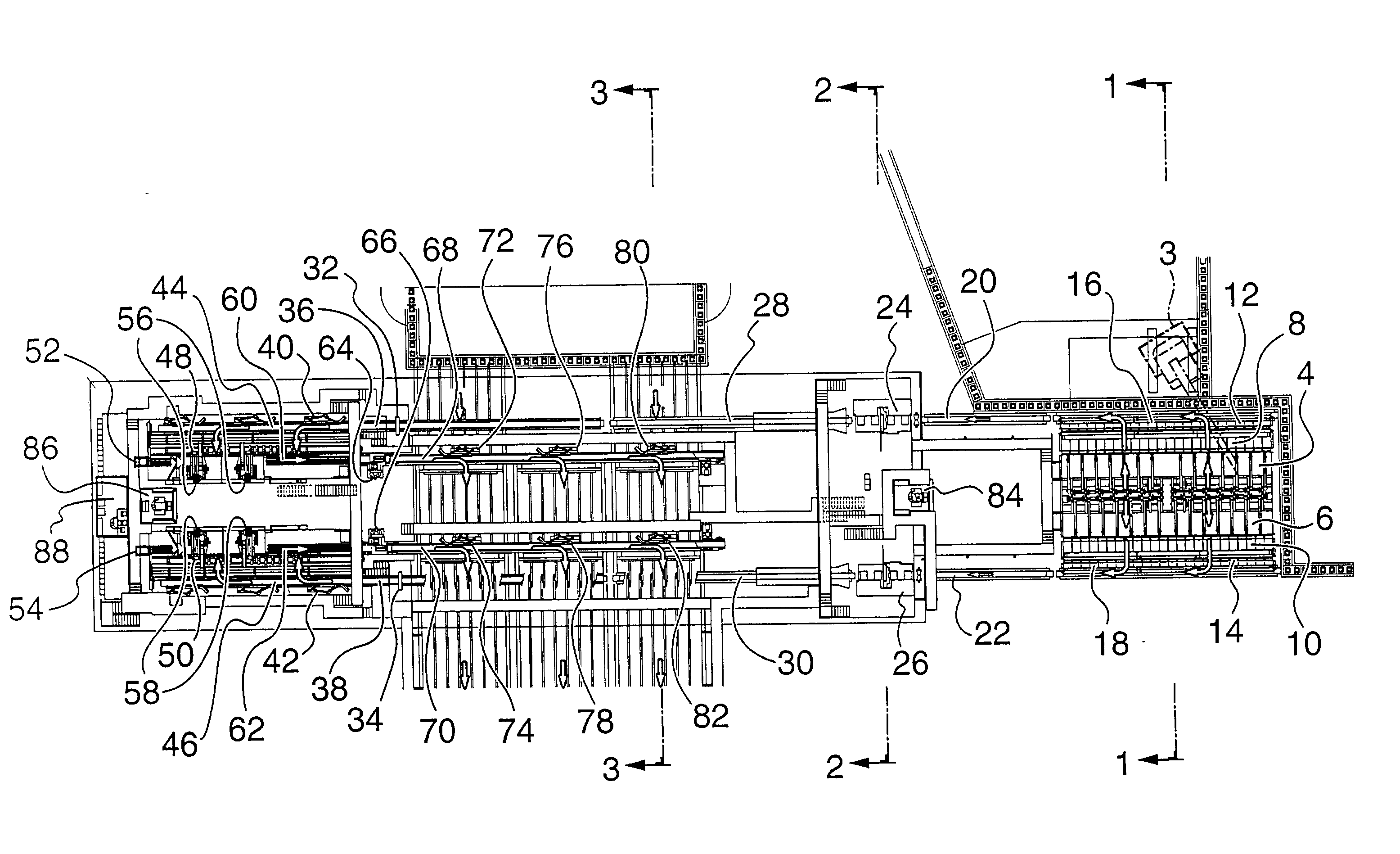

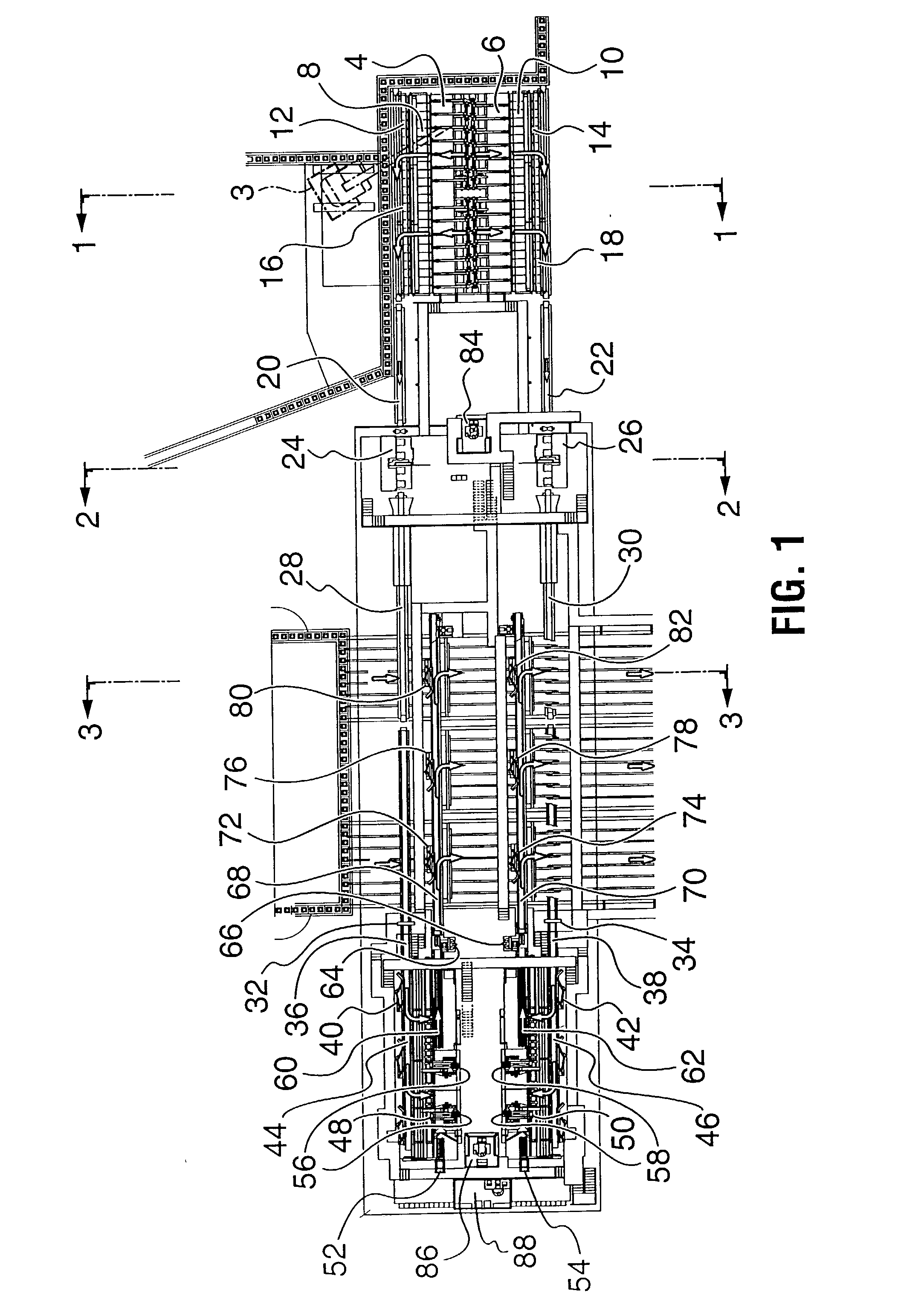

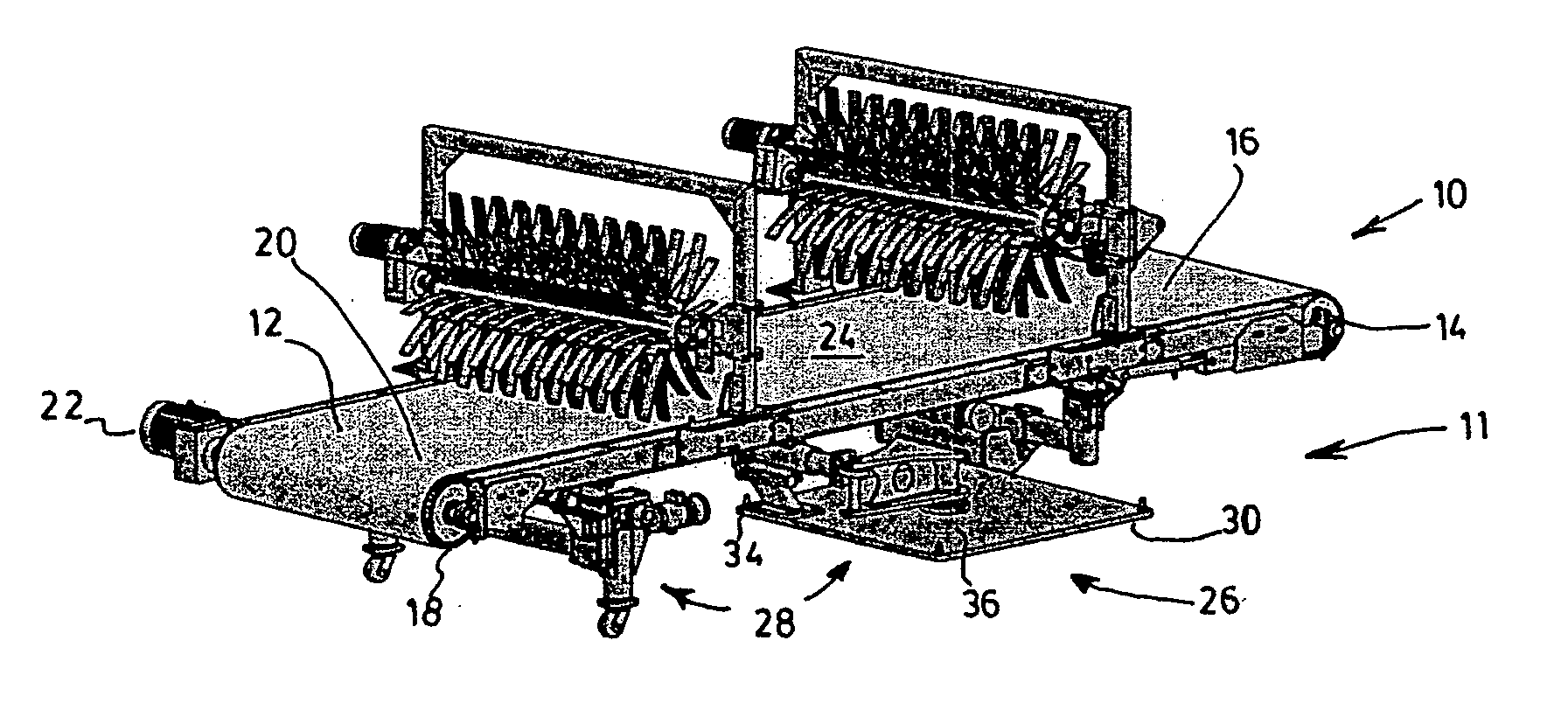

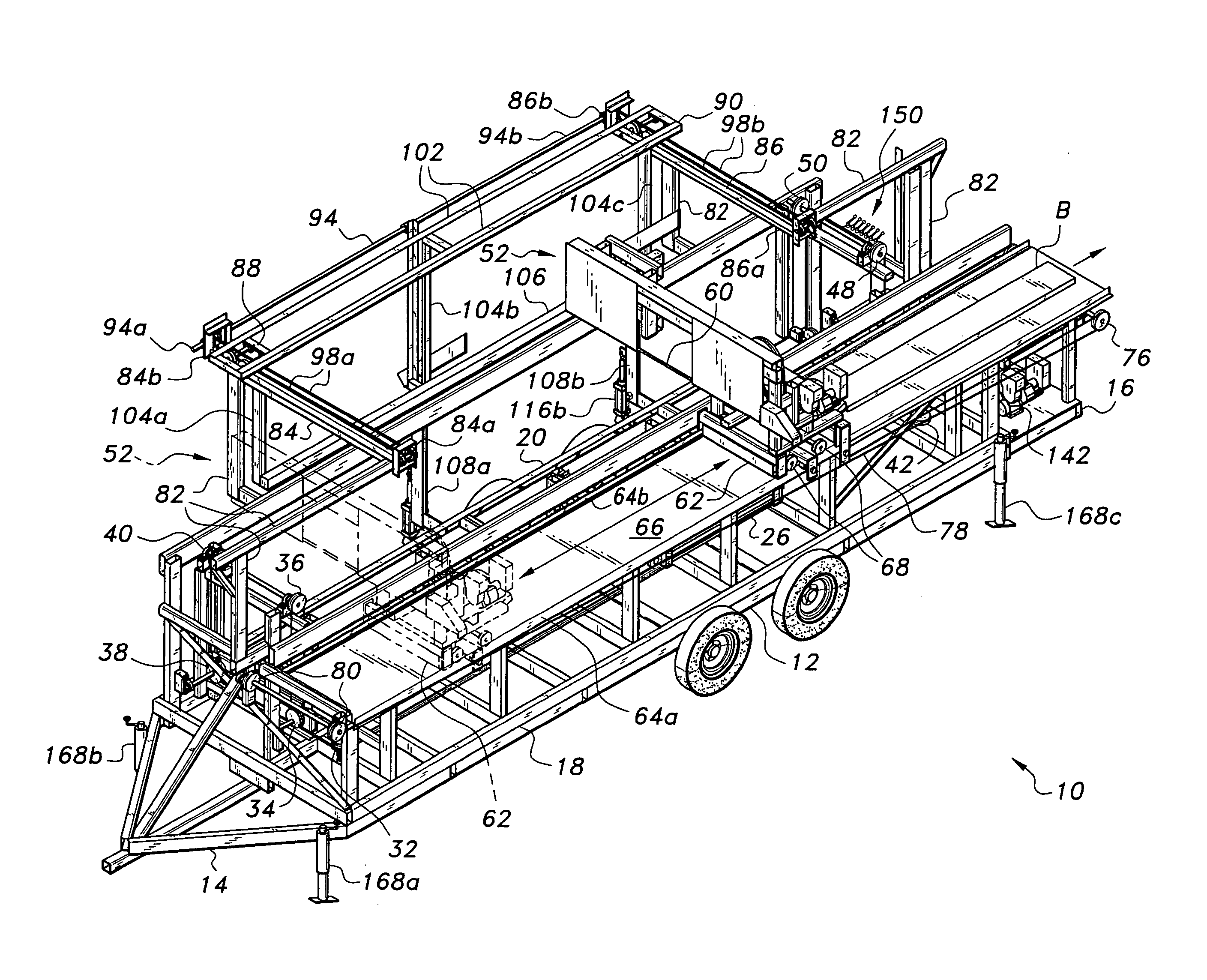

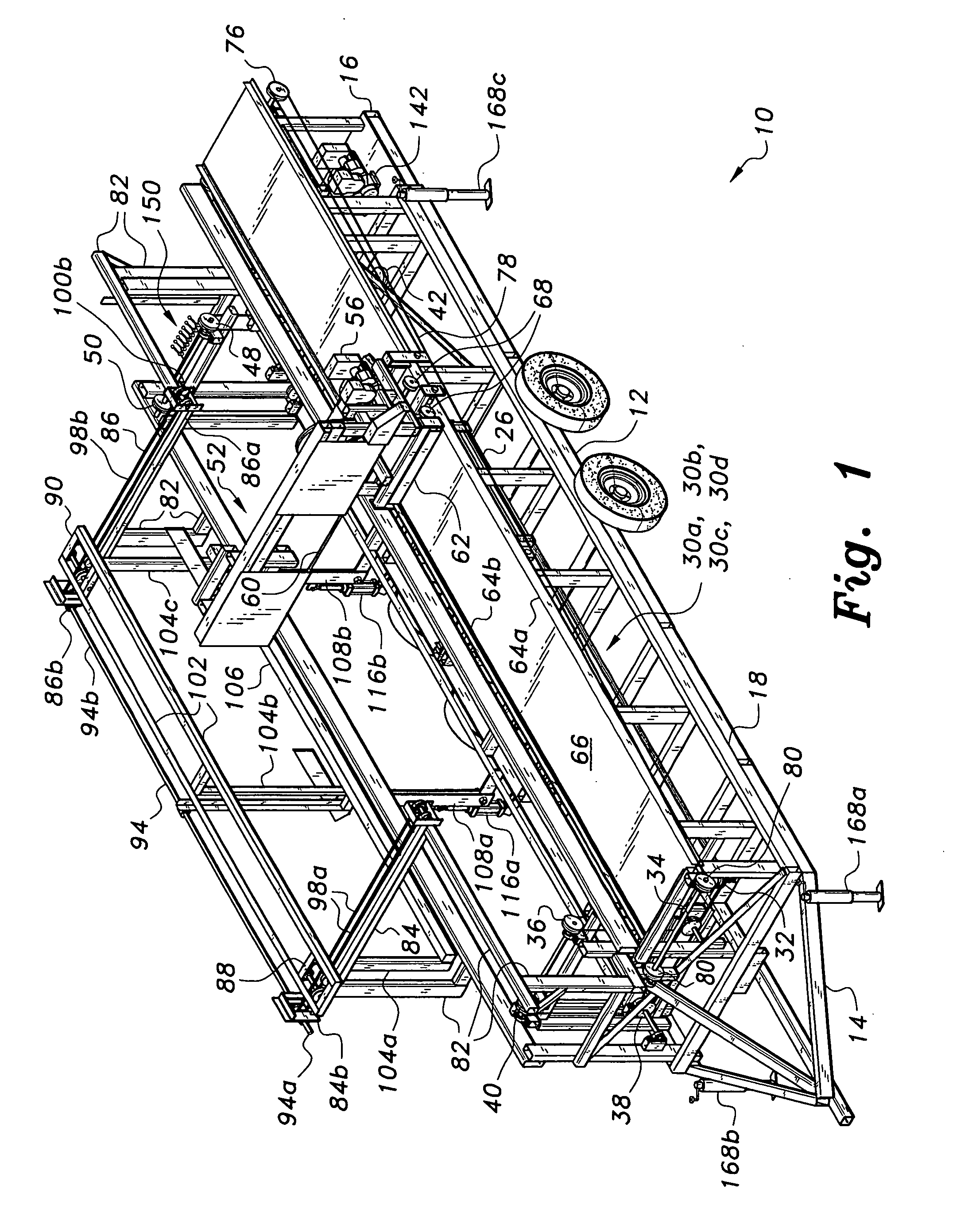

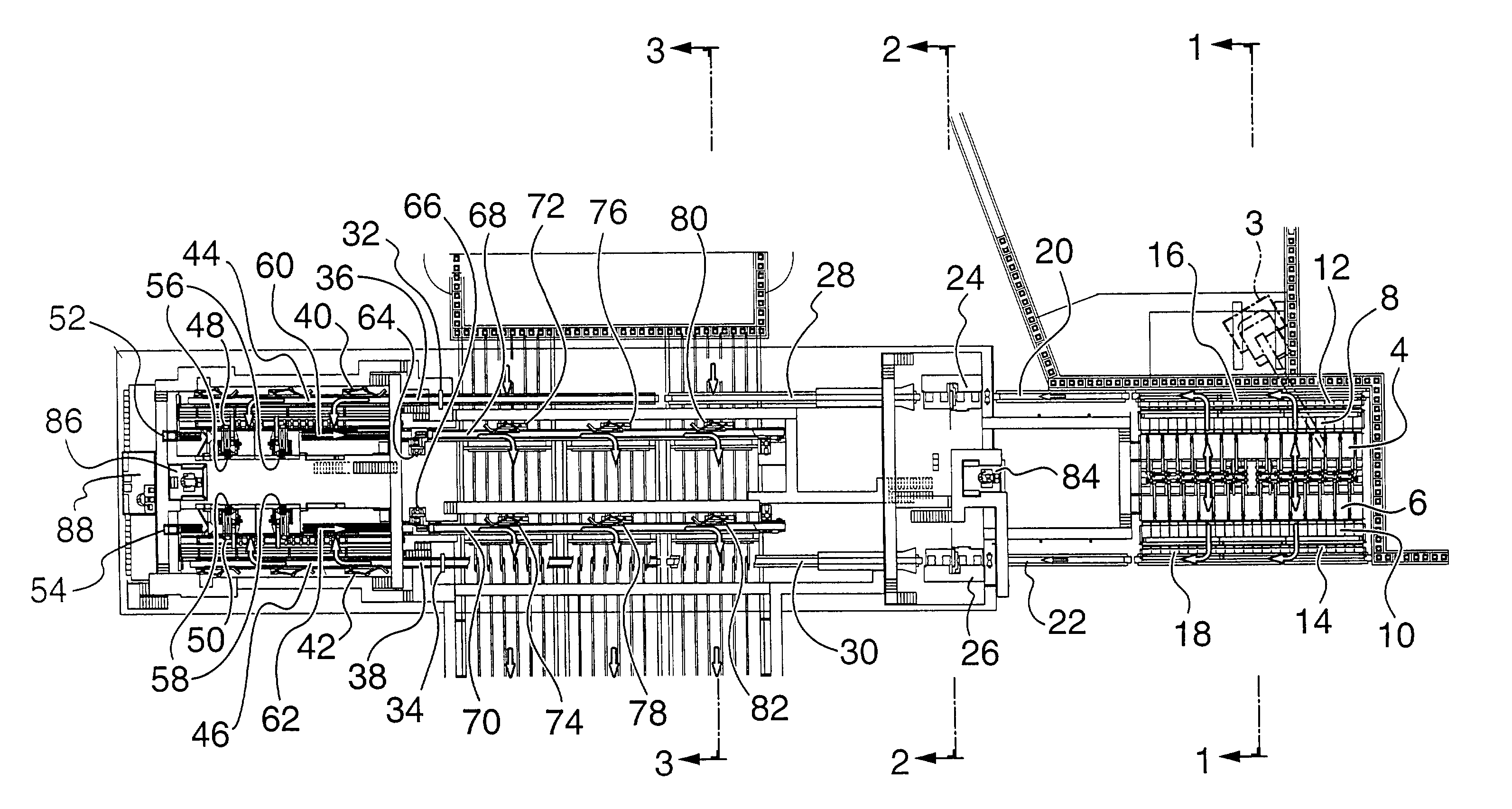

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029519A1Reduce stepsMinimize travelAdjusting equipmentFeeding apparatusFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

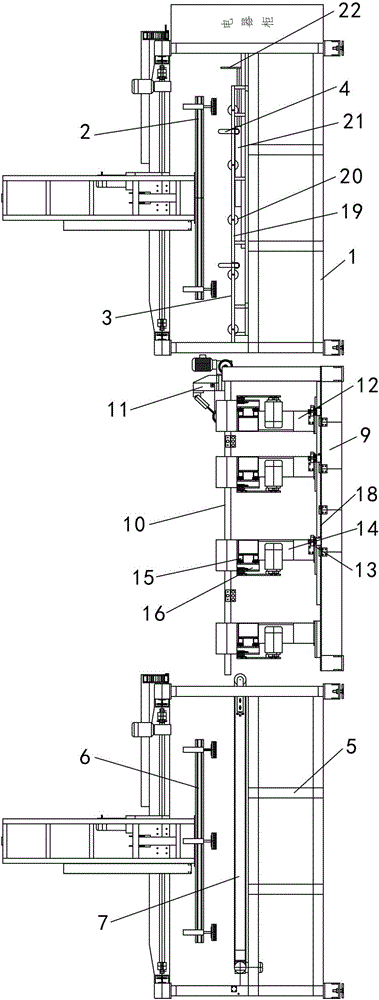

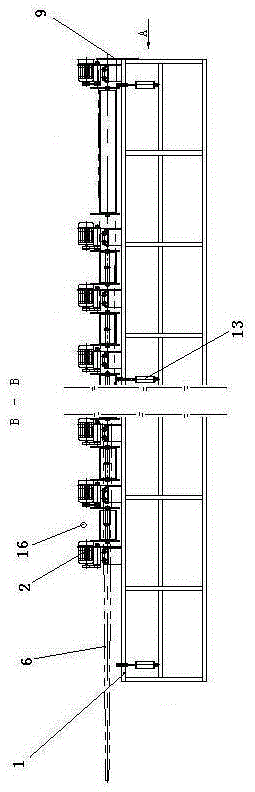

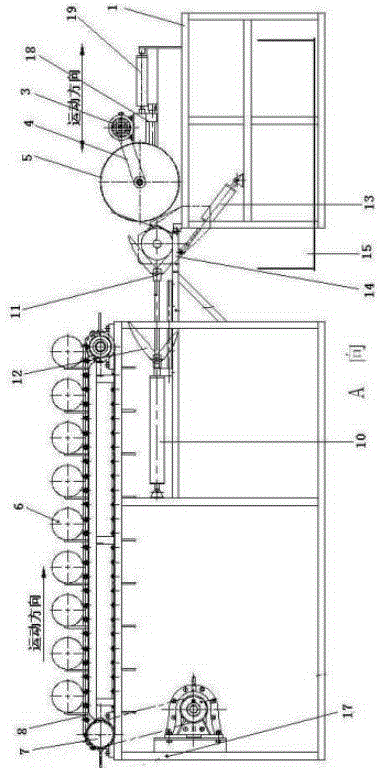

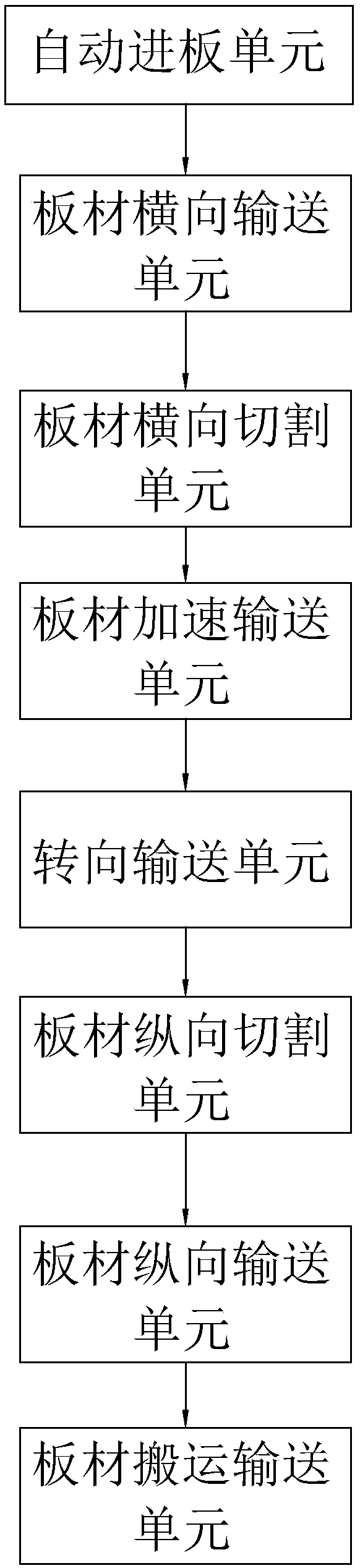

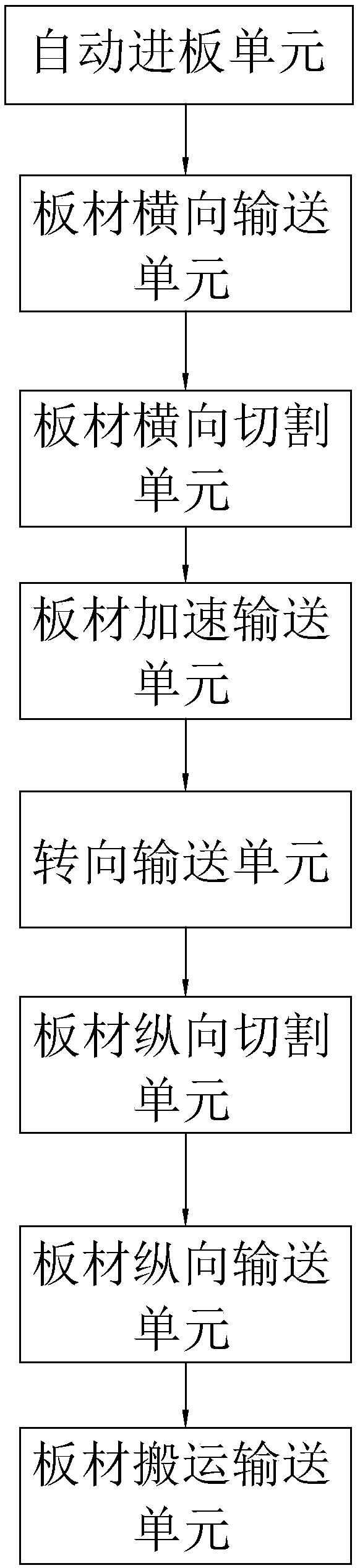

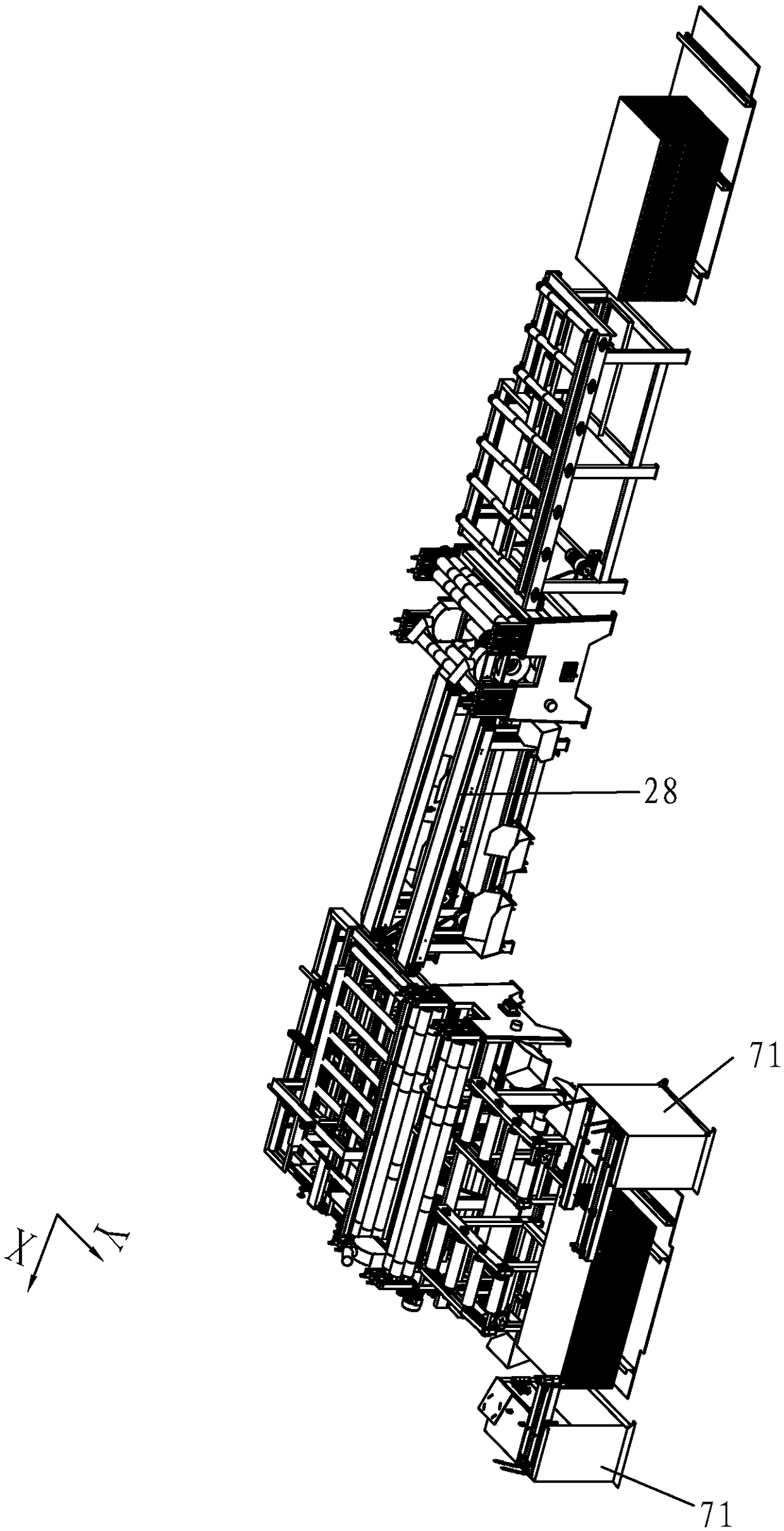

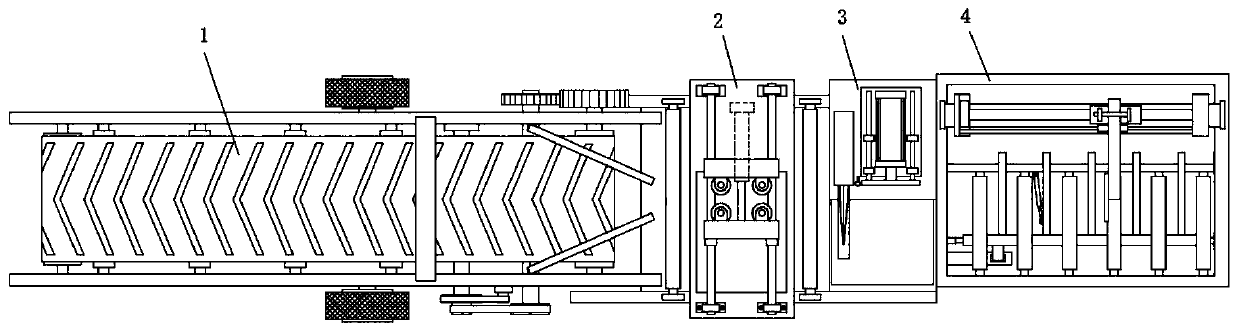

Board processing production line for highly automatically conveying boards

PendingCN109129724ACut Rate Improvement TuningImprove processing efficiencyFeeding devicesLoading equipmentProduction lineDischarge rate

The invention discloses a board processing production line for highly automatically conveying boards. The board processing production line comprises an automatic board feeding unit, a transverse boardcutting unit, a longitudinal board conveying unit and a board carrying and conveying unit; the automatic board feeding unit comprises a board feeding device with a feeding frame; the board carrying and conveying unit comprises positioning stack aligners and a carriage assembly; a transport frame is arranged on the carriage assembly; the feeding frame is connected with the transverse board conveying unit; the transport frame is connected with the longitudinal board conveying unit; and the two positioning stack aligners are arranged on two sides of the transport frame. Both board feeding beforecutting and board discharging after cutting are conducted automatically, safety is achieved, the automatic board feeding unit and the board conveying unit are located on the initial point and the stop point of the whole production line respectively, the board feeding rate and the board discharging rate are both improved, the cutting rate of the production line is improved and adjusted, and thus the processing efficiency of the whole production line is improved.

Owner:福建兴恒机械科技有限公司

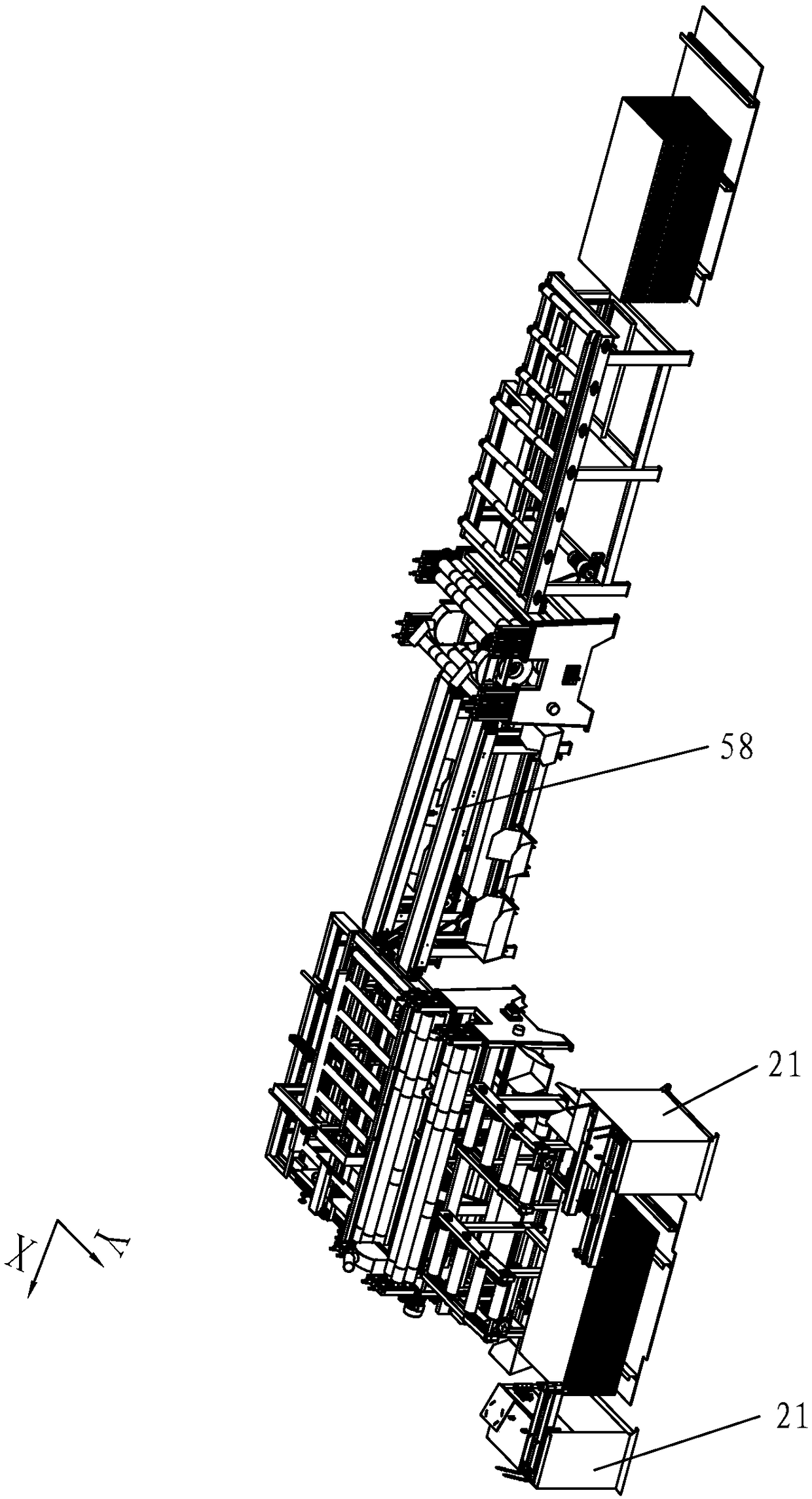

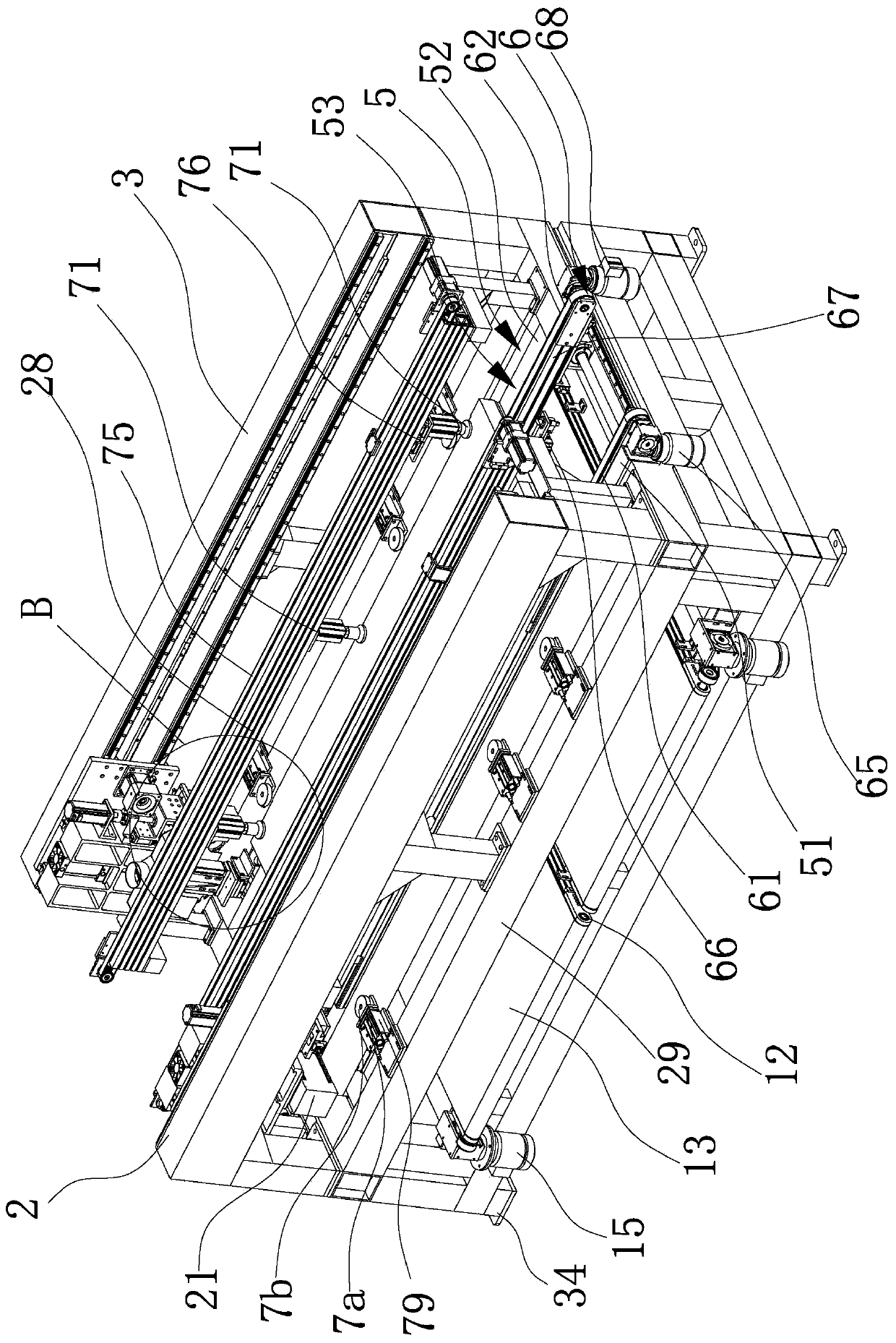

Longitudinal and transverse saw cutting device

ActiveCN106003253ARealize continuous automatic productionIncrease productivityFeeding devicesLoading equipmentEngineeringMachining

The invention provides a longitudinal and transverse saw cutting device comprising a transverse cutting mechanism and a longitudinal cutting mechanism. The feeding end of the transverse cutting mechanism communicates with a feeding mechanism; a plate material is supplied to the transverse cutting mechanism through the feeding mechanism; the transverse cutting mechanism performs transverse saw cutting treatment on the plate material; a conveying mechanism is arranged between the transverse cutting mechanism and the longitudinal cutting mechanism; the discharging end of the transverse cutting mechanism communicates with the feeding end of the longitudinal cutting mechanism through the conveying mechanism; the plate material subjected to the transverse saw cutting treatment of the transverse cutting mechanism enters the longitudinal cutting mechanism and is subjected to longitudinal saw cutting treatment through the longitudinal cutting mechanism; the feeding mechanism comprises a primary position material supporting platform and a secondary position material supporting platform; the primary position material supporting platform communicates with a feeding device which supplies the plate material to the primary position material supporting platform; the secondary position material supporting platform communicates with the primary position material supporting platform which transfers the plate material to the secondary position material supporting platform; and the primary position material supporting platform comprises a set of primary position supporting plates, and the secondary position material supporting platform comprises a set of secondary position supporting plates. The device adopts a door sleeve plate as a main machining object and is reasonable in structure, high in production efficiency and high in machining precision.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

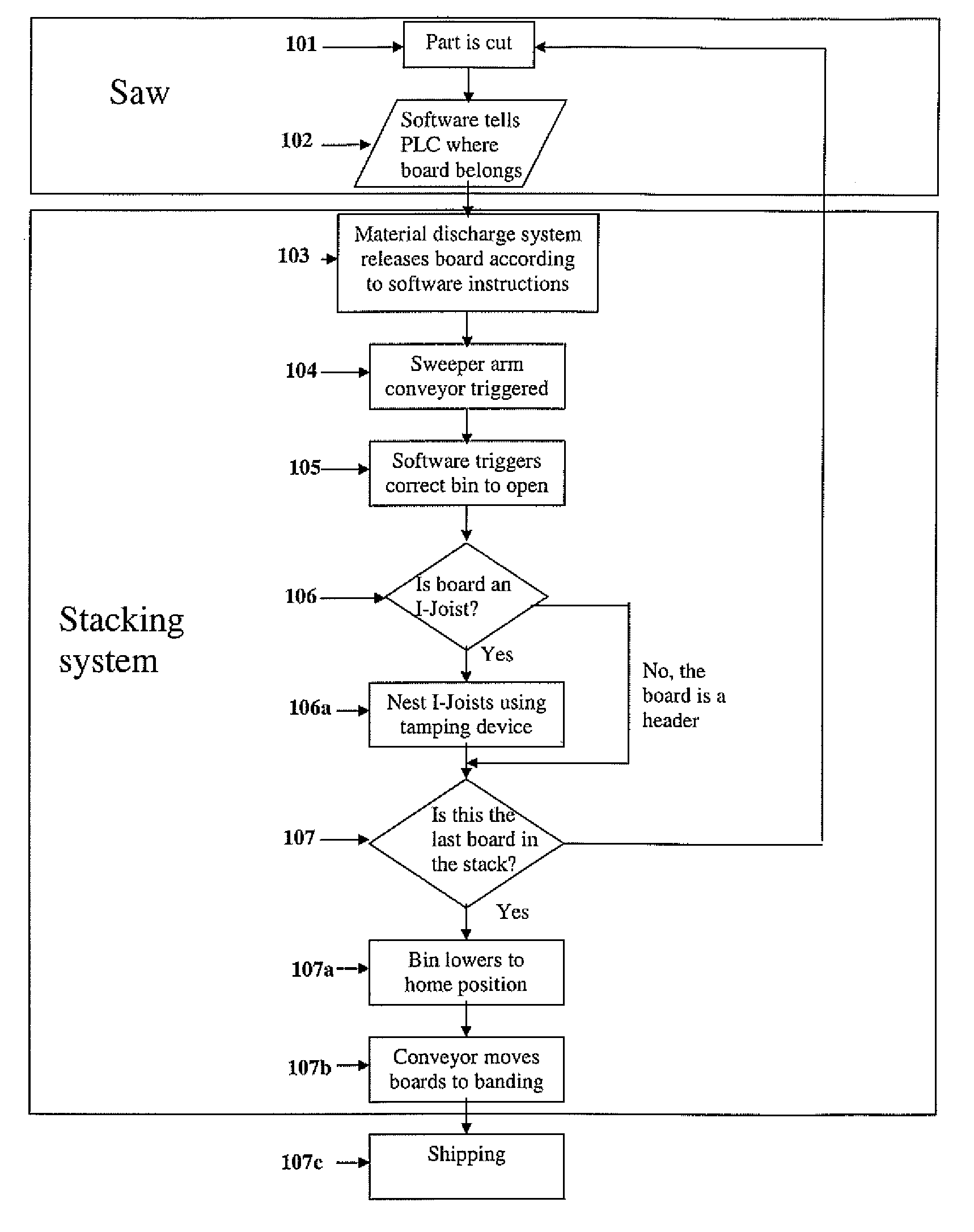

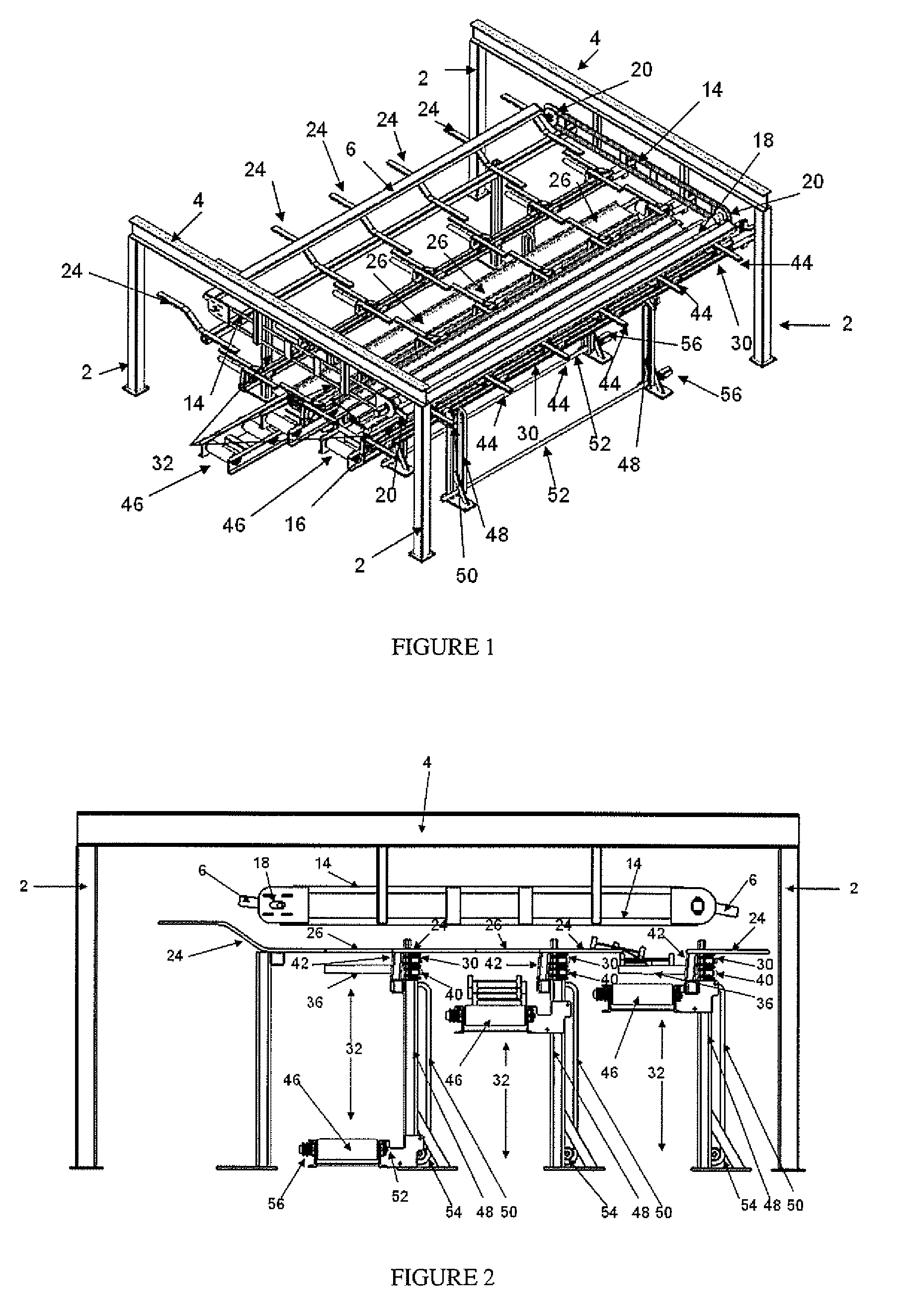

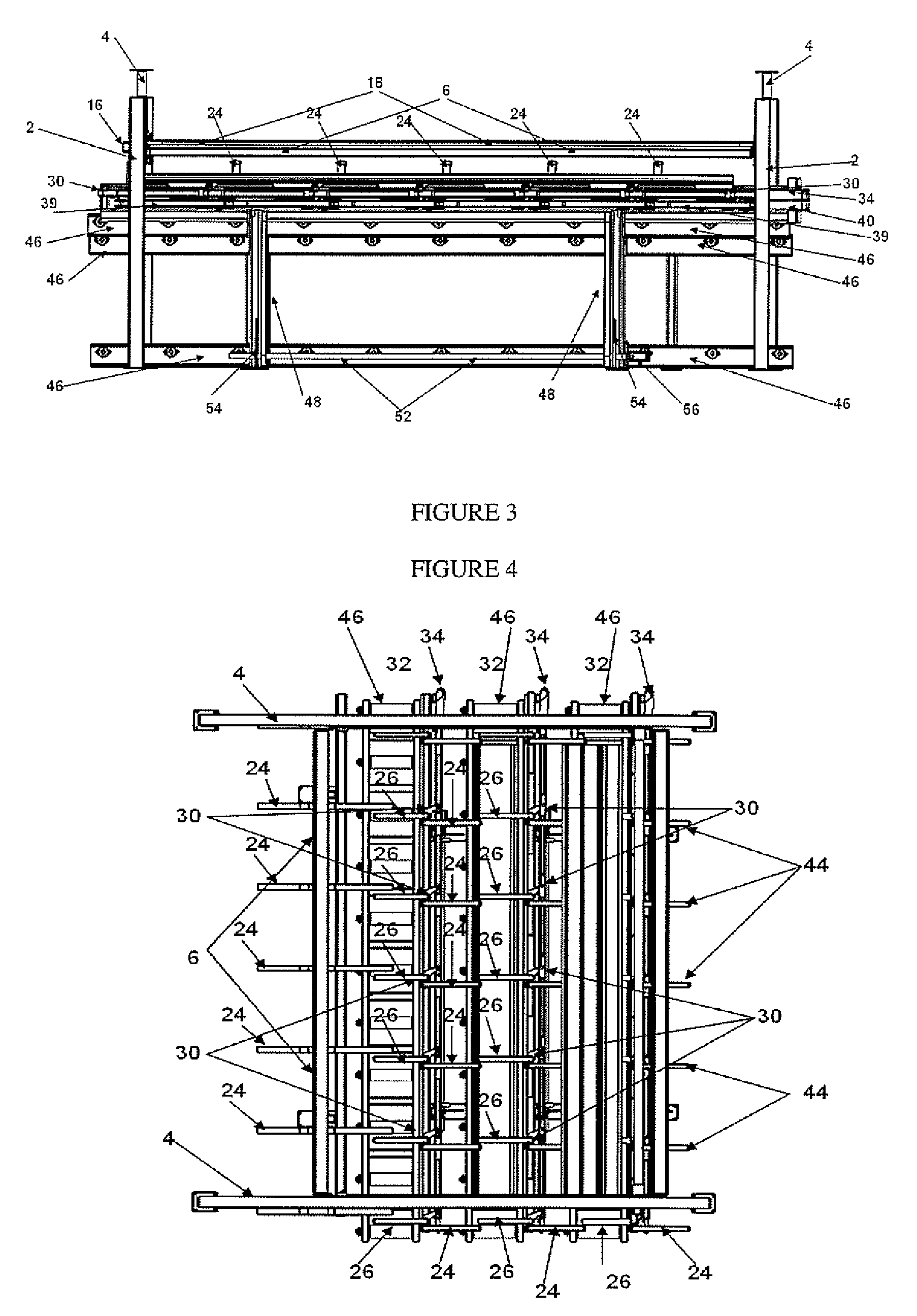

Method for sorting engineered wood products

Provided is a system for cutting and sorting of engineered wood products. Using appropriate software, a designer may model an entire house's structural frame. The dimensions and labeling for individual members of the structure are extracted from the model and captured by the software. The software may batch and optimize the products to be cut on the saw and develop sawing control instructions. The instructions are used by the saw to process the parts according to the house structure design. As the parts are processed by the saw, they are discharged and sent to an outfeed system that will stack the engineered wood products according to the parameters defined by the workstation operator. The system can handle the multiple lengths and widths of engineered wood parts from the saw and stack them in the order the software may specify.

Owner:WEYERHAEUSER NR CO

Guitar fingerboard cutting machine

ActiveCN104493925AQuality assuranceReduce scrap rateFeeding devicesWood mortising machinesEngineeringMachining

The invention relates to a guitar fingerboard cutting machine. The guitar fingerboard cutting machine comprises a frame, a blanking device, a pushing device, a setting device, a positioning device, a back-and-forth translation device, a cutting device and a left-and-right translation device; the blanking device for blanking fingerboards, the pushing device for pushing the fingerboards to the positioning device from the blanking device and the setting device for setting on the positioning device are all fixed on the frame; the positioning device is capable of translating front and back between the pushing device and the cutting device on the frame by virtue of the back-and-forth translation device; the cutting device is capable of translating front and back on the frame by virtue of the back-and-forth translation device. The guitar fingerboard cutting machine has the advantages of fully mechanized cutting function, guarantee of cutting quality, machining of grooves richer in shapes, and high machining efficiency, and belongs to the technical field of guitar machining equipment.

Owner:广东红棉乐器股份有限公司

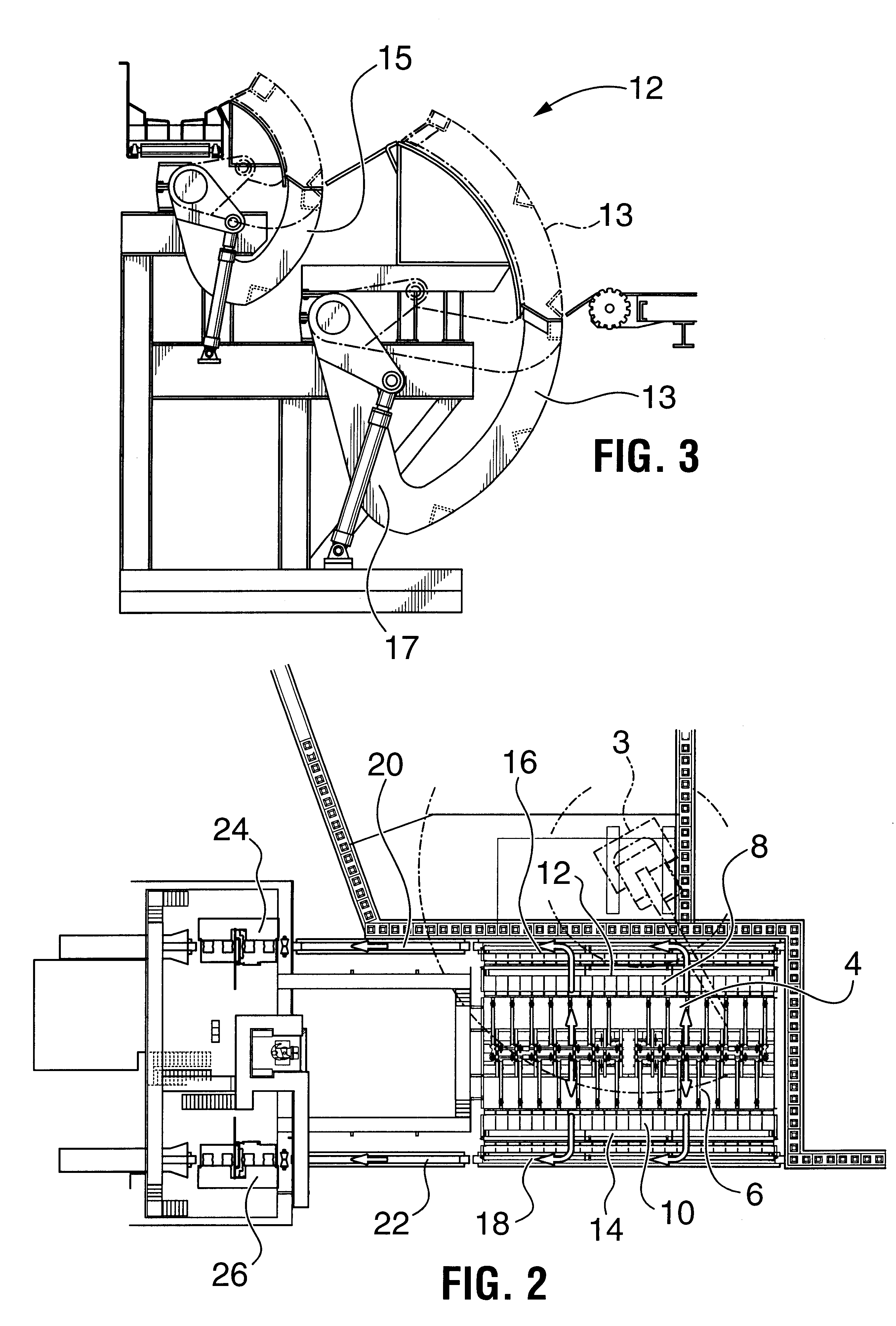

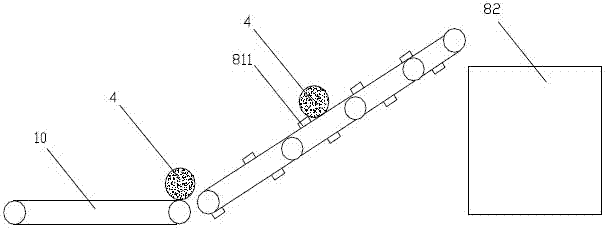

Adjustment system for a speed reduction belt assembly

An automated adjustment system is provided for positioning a speed reduction belt assembly to receive an elongated wood article exiting a processing machine. The speed reduction belt assembly has opposite first and second ends. The automated adjustment system includes a horizontal adjustment mechanism operable to adjust an angle of the speed reduction belt assembly in a horizontal plane. The automated adjustment system also includes a vertical adjustment mechanism operable to adjust the height of one of the first and second ends of the belt assembly relative to the other of the first and second ends of the belt assembly, thereby adjusting an inclination of the belt assembly. The automated adjustment system further includes a control unit in communication with the horizontal and vertical adjustment mechanisms for sending control signals thereto. The control signals determine the angle and inclination of the belt assembly.

Owner:LES PRODN GIBERGO

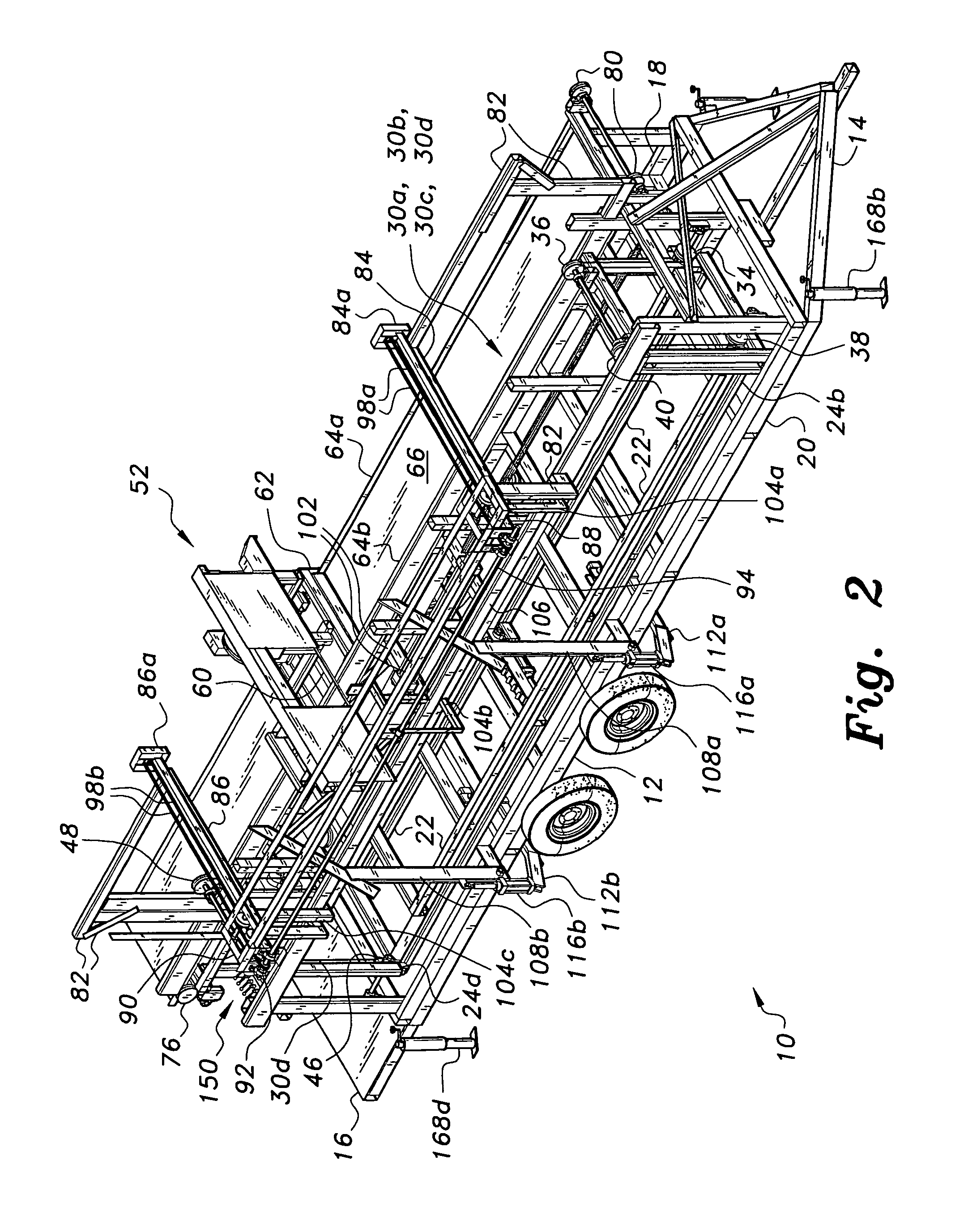

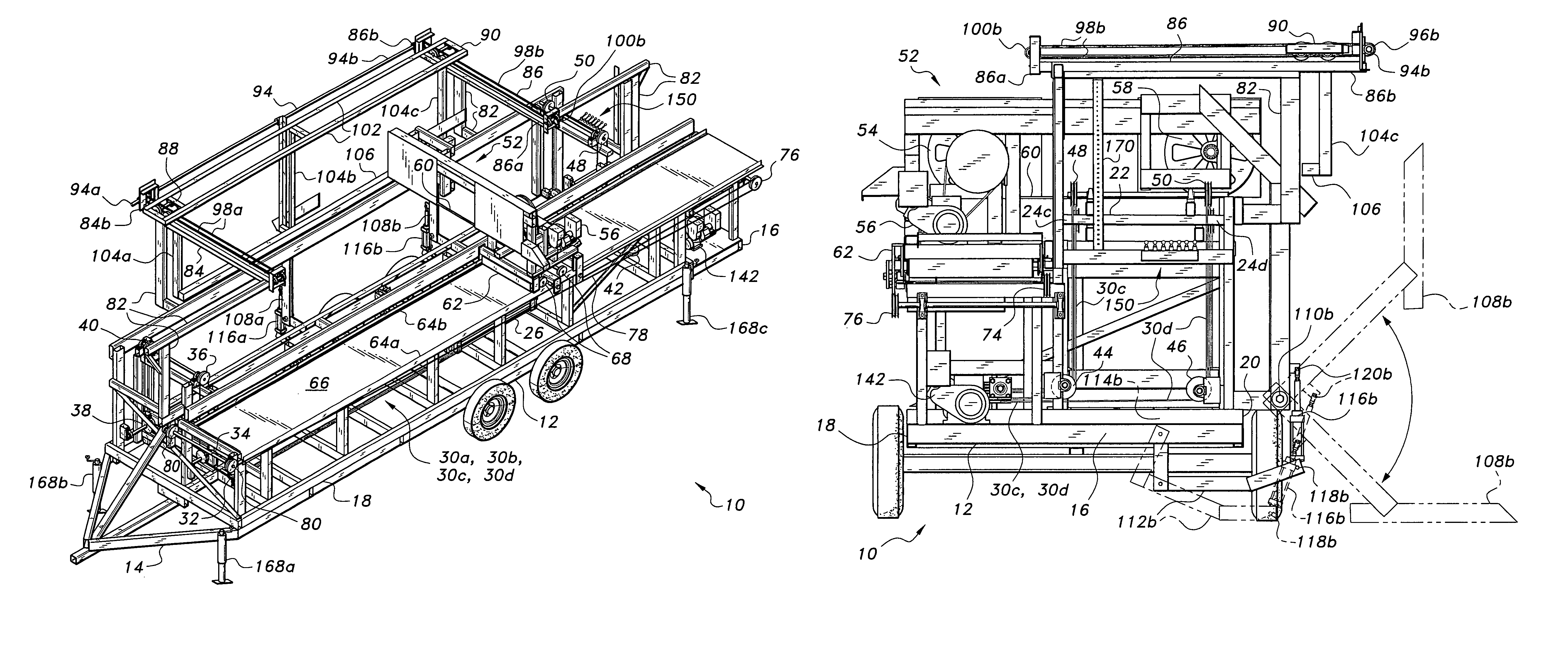

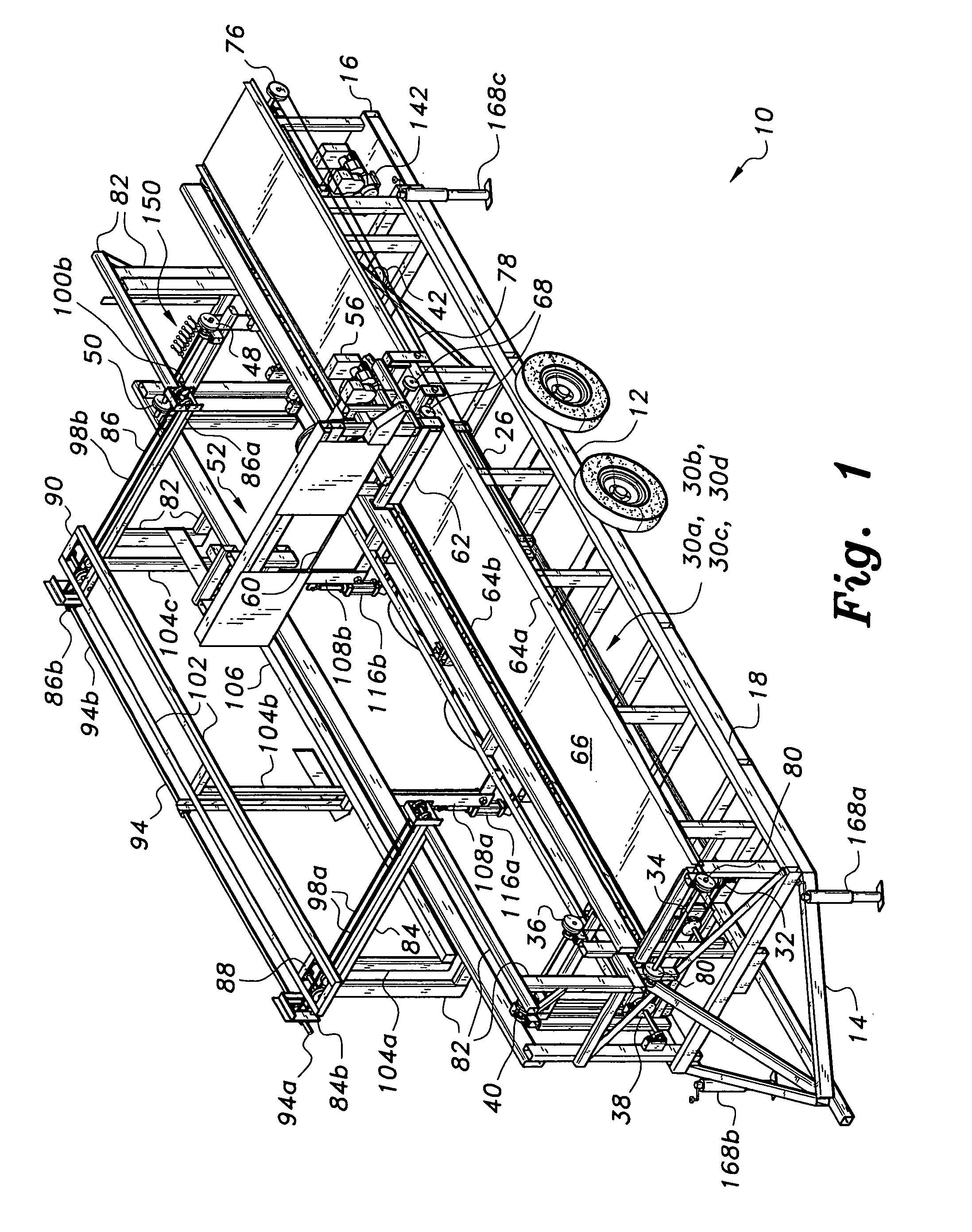

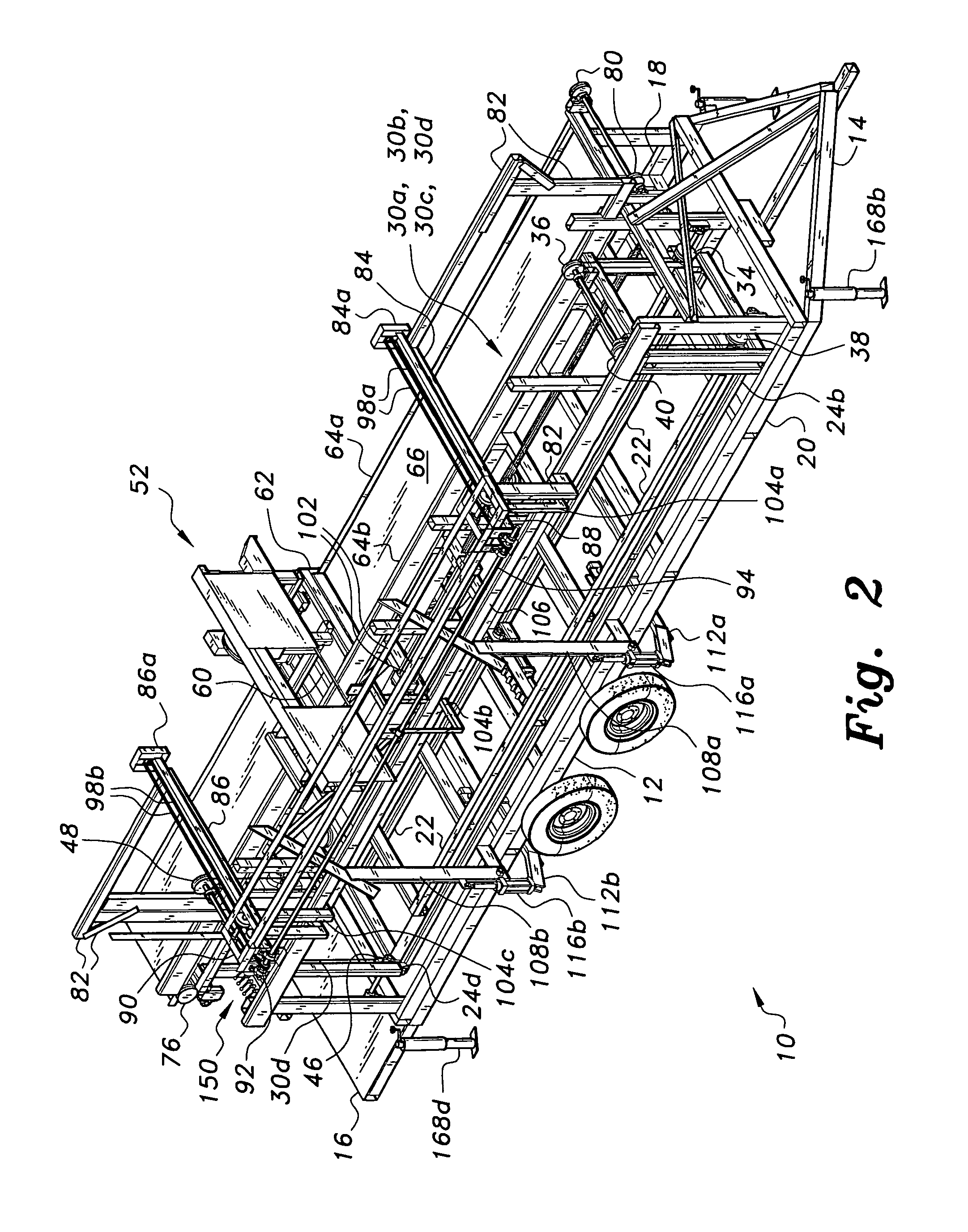

Portable sawmill

The portable sawmill is constructed on a frame having a series of mechanisms for loading and manipulating a log thereon and removing boards cut from the log. Powered tines load a log onto a vertically adjustable log deck, the deck including powered mechanisms for turning and securing the log in the desired orientation for cutting. Cuts are made by a horizontally traveling band saw. The saw has no vertical adjustment. Board thickness is determined by the height of the vertically adjustable log deck. Cut boards are removed by a board sweep that pushes the board laterally from the top of the log onto a tray. The saw travels along the tray to push the board longitudinally onto a suitable platform for transport. All of the above mechanisms are controlled hydraulically from a single operator station on the mill, thus freeing the operator from many manual tasks and increasing production.

Owner:BURTON LARRY C

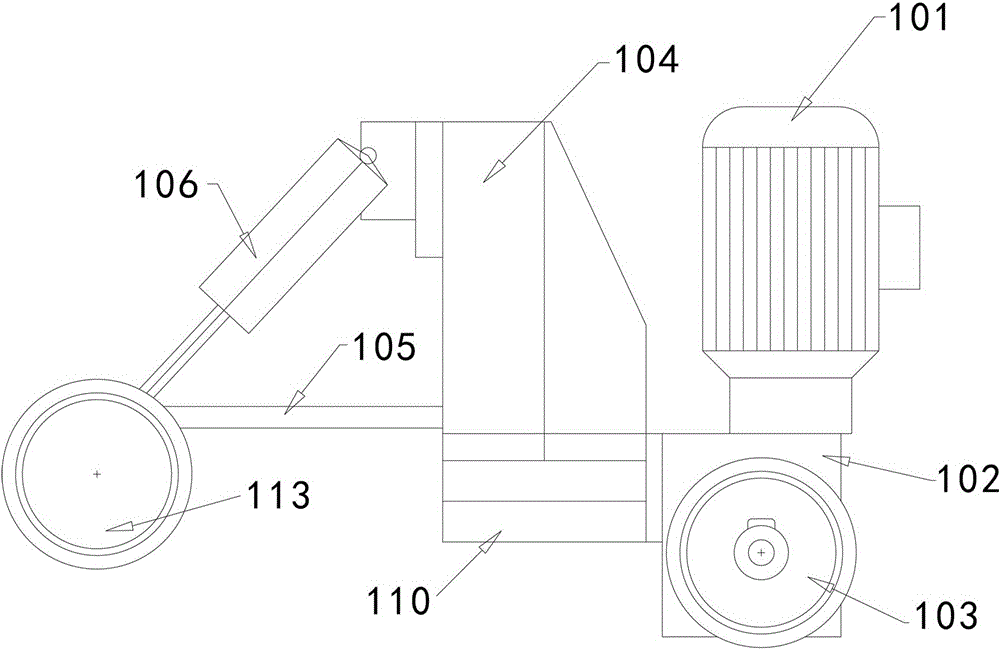

Bamboo strip splitting equipment and operating method thereof

PendingCN107972134ASimple structureCut structure is stableFeeding devicesMulti-purpose machinesEngineeringMaterial storage

The invention discloses bamboo strip splitting equipment. The bamboo strip splitting equipment comprises a feeding mechanism which is provided with a self-centering limiting structure, a cutting mechanism, a knife rest assembly with a knife disc, a sliding table mechanism which is used for transferring a cut material to the knife rest assembly, a sorting device provided with a plurality of material storage cabins, and a material moving mechanism which is used for conveying the cut material to the sorting device; the cutting mechanism and the material which is placed on the feeding mechanism are arranged at an inclined angle; the self-centering limiting structure is used for clamping the material to ensure that the central axis of the material is positioned in a horizontal position; a material ejecting device is arranged on the sliding table mechanism; and when the material is moved to the opposite position of the knife rest assembly, the material ejecting device can press the materialto move in the direction of the knife rest assembly. The invention also discloses an operating method of the bamboo strip splitting equipment. The bamboo strip splitting equipment is simple in structure; an integrated automatic splitting system is formed; a cutting structure is stable; the cutting precision is high; bamboo strips can be sorted automatically according to different specifications; the sorting size is accurate; the safety performance is high; and the production efficiency is high.

Owner:童建勇

Wood transporting and cutting integrated mechanism

InactiveCN107127829AIncrease the number ofNo need for manual markingGuide fencesFeeding devicesEngineeringWorkbench

The invention discloses a wood transporting and cutting integrated mechanism. The wood transporting and cutting integrated mechanism comprises a workbench, a cutting device and a wood transporting device. The wood transporting device is close to the wood feeding start end of the workbench or the wood transporting device makes contact with the wood feeding start end of the workbench. The wood transporting device comprises a slope type conveying device and a horizontal conveying platform. The workbench is provided with wood supporting frames. The multiple wood supporting frames in the same row are distributed from the wood feeding start end of the workbench to the wood feeding stop end of the workbench in the length direction of the workbench at intervals. A fixed length baffle is arranged at the wood feeding stop end of the workbench, and a pushing mechanism is arranged between the horizontal conveying platform and the workbench. The pushing mechanism is used for pushing woods to the position abutting against the fixed length baffle. The wood transporting and cutting integrated mechanism has the beneficial effects that the length fixing working procedure is easy and convenient, the cutting defective percentage is low, tool abrasion is slight, the cutting speed is high, and the multiple woods can be cut at the same time.

Owner:薛忠来

Method and apparatus for singulating, debarking, scanning and automatically sawing and sorting logs into lengths

InactiveUS20030029518A1Reduce disadvantagesReduce stepsAutomatic control devicesPrecision positioning equipmentFiberEngineering

A log handling and cutting system which cuts logs into lengths, and allows for maximum use of fiber. The system includes equipment for singulating the logs, optimally removing the bark from the logs, scanning the true log image, cutting the logs to length, and sorting the cut logs arranged in a sequence of coupled operations. The logs are singulated using a dual quadrant singulation system to provide maximum singulation reliability, thereby allowing a single operator to attend to this process. Once singulated, the logs are fed automatically into a debarker where the diameter and volume are scanned and debarker-operating parameters are set for optimum bark removal. The log is then scanned, tree length, using a unique scanning system, which determines the true image of the log. This enables the determination by computer of the optimum bucking solution of the log as well as a proper sorting of the optimum random lengths. The saws are adjusted in response to the computer solution and the log is positioned by a positioner according to a computer generated reference datum. This results in the log being positioned for cutting to the optimum random lengths. A command signal is sent from the computer to the log sorting system, which tracks the position of the random lengths and allows them to be sorted to the appropriate sort storage bin.

Owner:WEYERHAEUSER CO

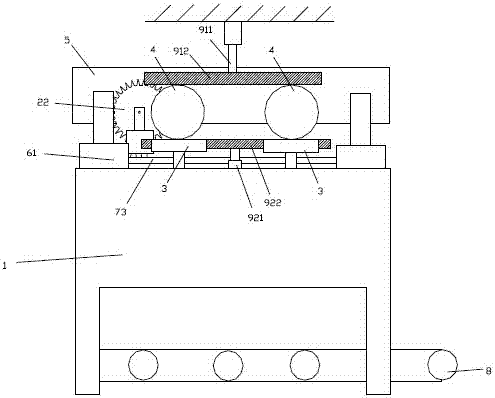

Machine tool for wood processing based on feeding, cutting and blanking production integration

InactiveCN107139268AAffect cutting accuracyAvoid damageFeeding devicesCircular sawsReciprocating motionWood machining

The invention discloses a machine tool for wood processing based on feeding, cutting and blanking production integration. The machine tool comprises a worktable, a cutting device, a wood transporting device and a wood clamping device. The wood transporting device comprises a ramp type conveying device and a horizontal conveying platform. The ramp type conveying device is arranged on the side face of the horizontal conveying platform and used for transporting wood onto the horizontal conveying platform. Partitioning plates are arranged on the conveying path of the ramp type conveying device at intervals. The horizontal conveying platform is used for transporting the wood onto the worktable. A set length baffle cutting device is arranged at the wood feeding terminating end in the worktable to be in slide fit with the worktable and can make reciprocating motion in the width direction of the worktable. The machine tool has the technical effects that the set length process is simple and convenient, the cutting defective rate is low, tool abrasion is less, the cutting speed is high, and multiple pieces of the wood can be cut simultaneously.

Owner:薛忠来

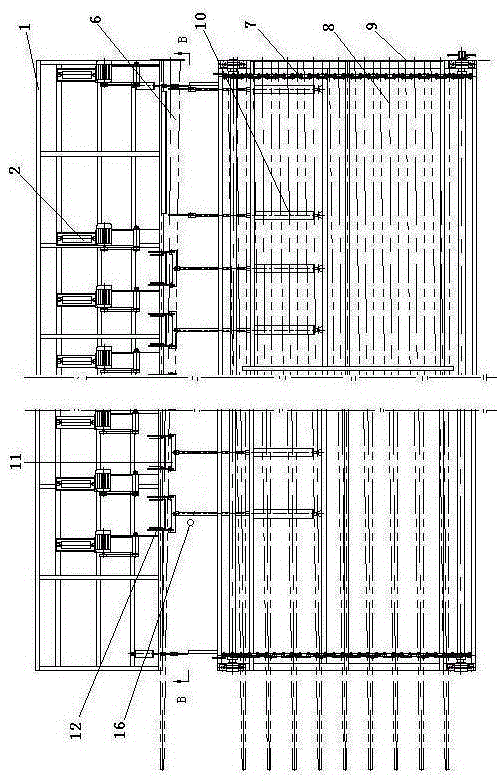

Plate production line capable of being adjusted to adapt to plate specifications

PendingCN109159212ASmall footprintReduce investmentFeeding devicesCircular sawsProduction lineEngineering

The invention discloses a plate production line capable of being adjusted to adapt to plate specifications. The plate production line comprises a plate transverse cutting unit, a plate longitudinal cutting unit and a plate acceleration conveying unit. The plate transverse cutting unit and the plate longitudinal cutting unit each comprise a sawing device, each sawing device comprises a main frame,a movable sawing mechanism and a fixed sawing mechanism, and the movable sawing mechanisms and the fixed sawing mechanisms are arranged at the left end and the right end of the main frame. The plate acceleration conveying unit comprises an acceleration fixed frame and an acceleration movable frame which are arranged in parallel, and a plate keeps unchanged during the machining process, and the movable sawing device moves in the longitudinal direction or the transverse direction relative to the plate so as to cut plates with different widths and lengths, the distance between the fixed frame andthe movable frame is adjusted by accelerating the movable frame to move relative to the acceleration fixed frame so as to meet the conveying requirements of plates with different specifications, andthe conveying edge distance of the plate accelerating conveying unit can adapt to plates with different specifications.

Owner:福建兴恒机械科技有限公司

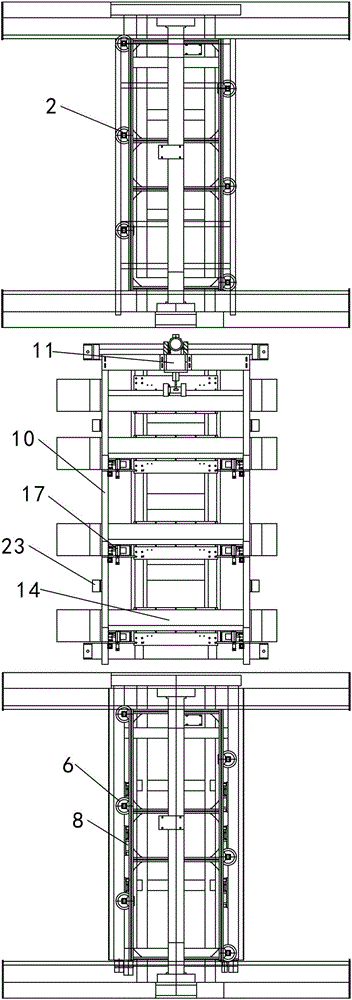

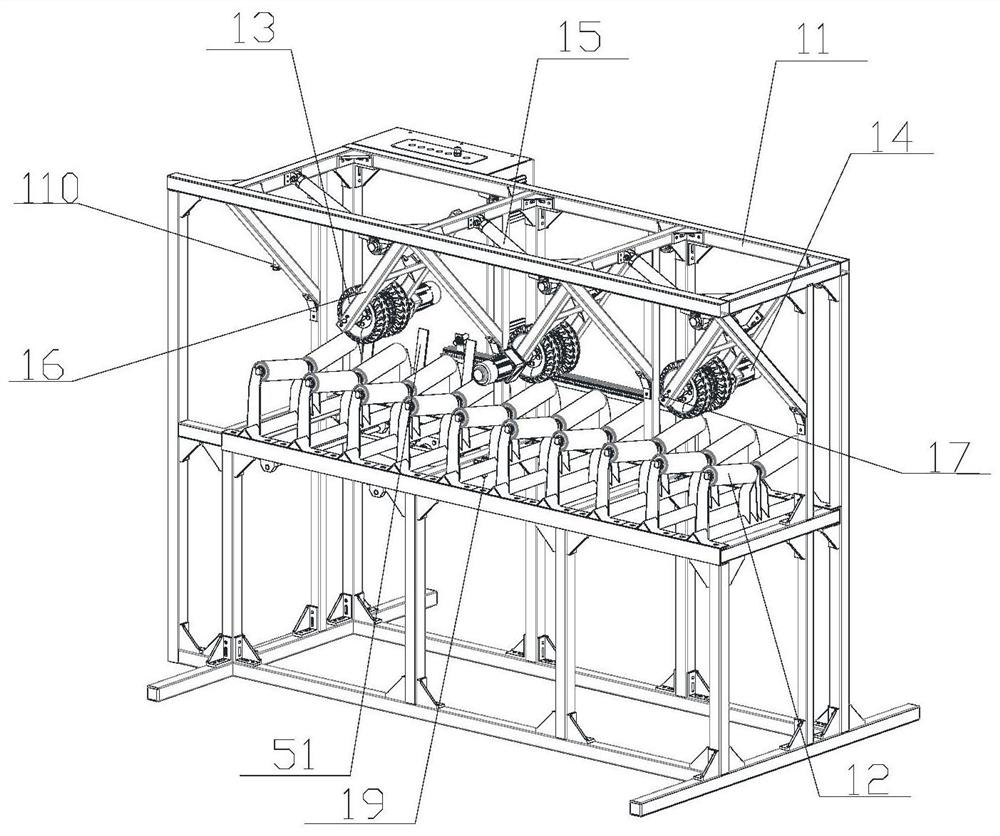

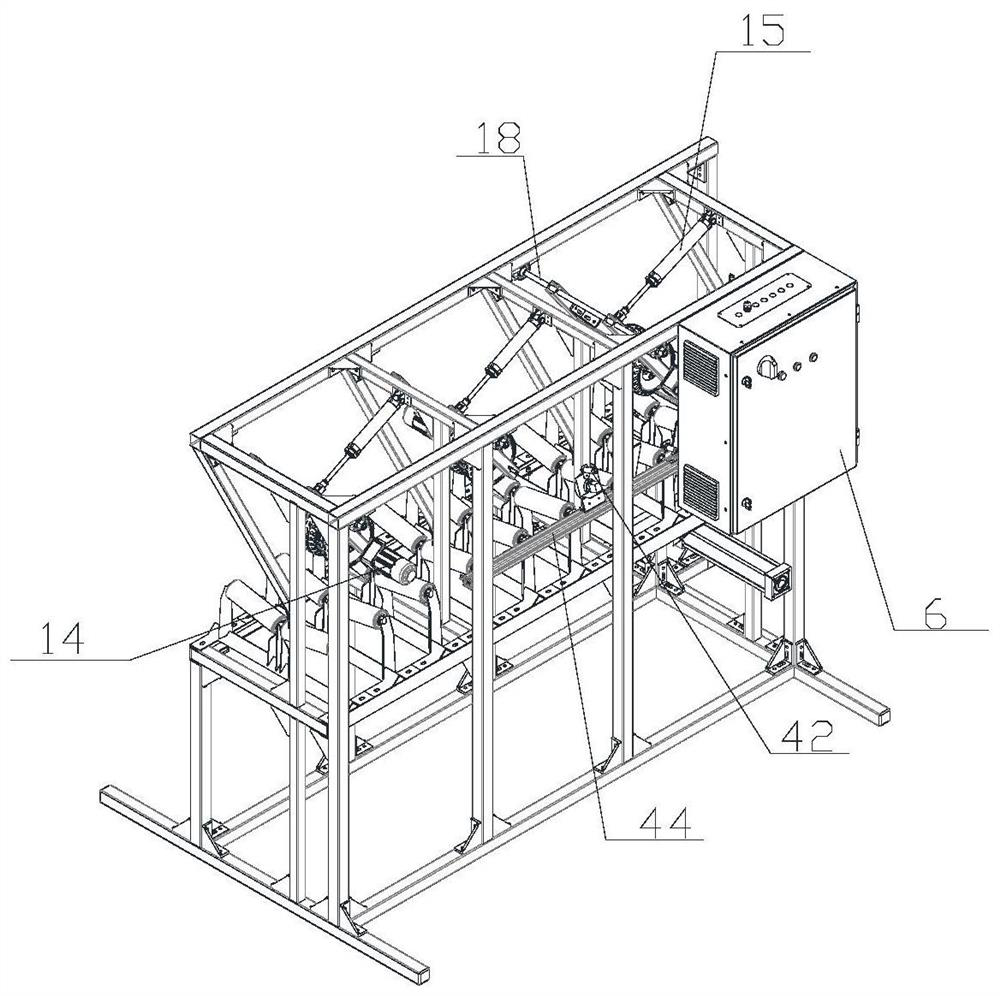

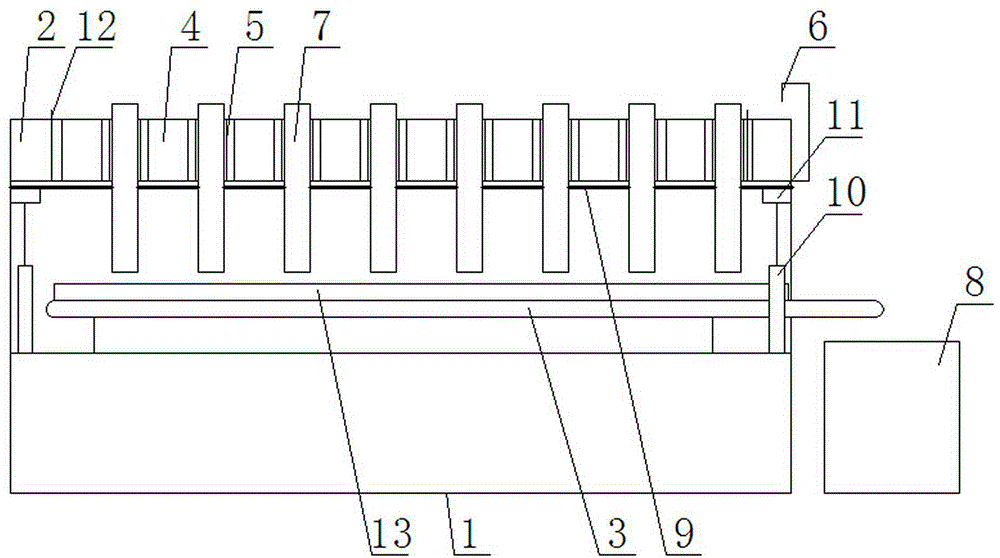

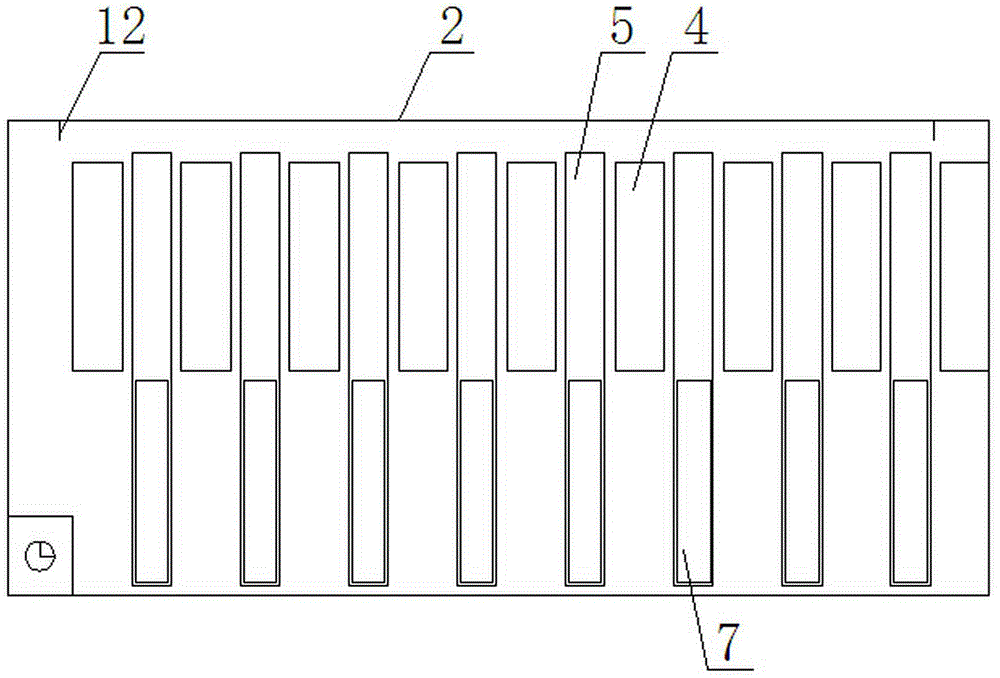

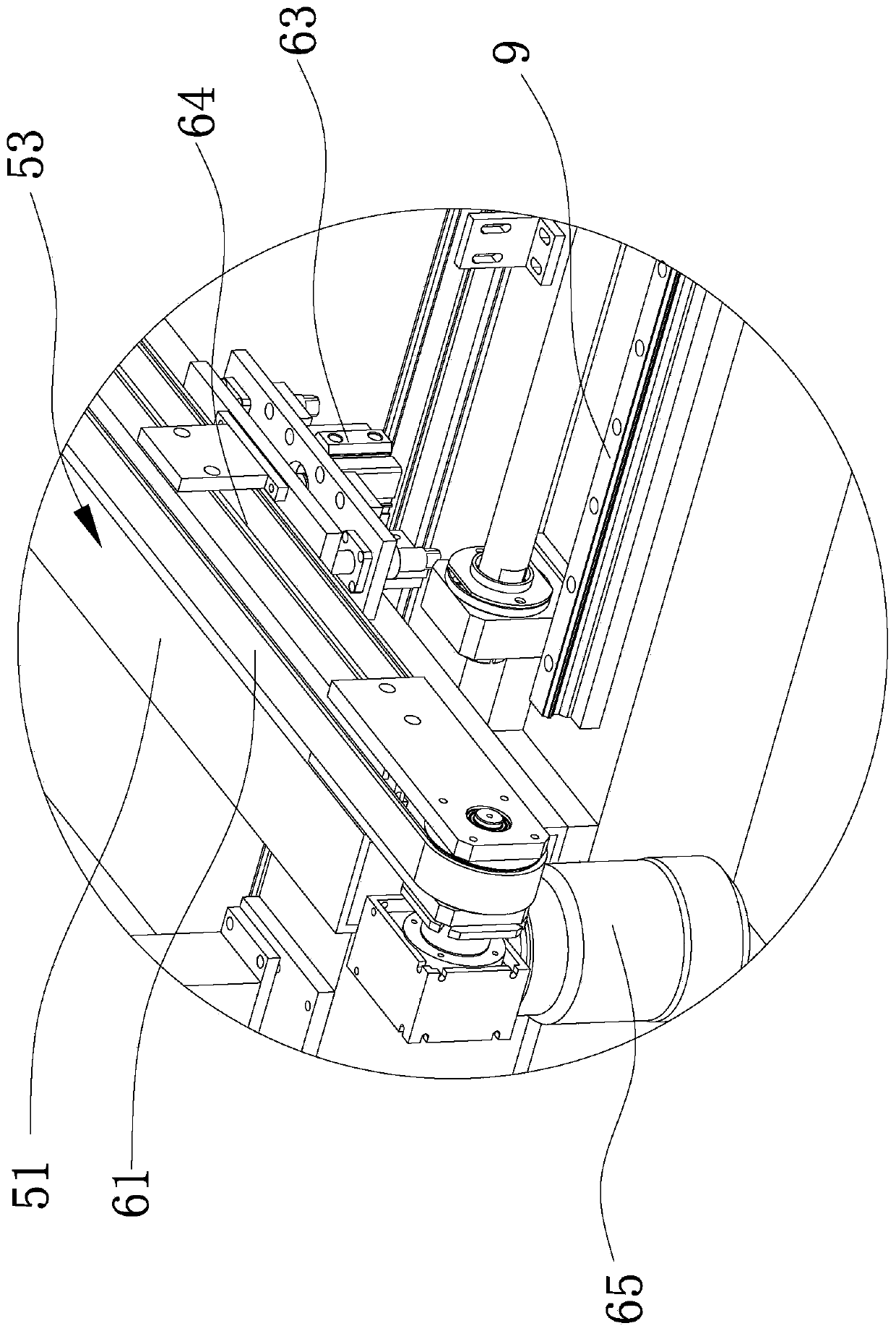

Double-end rip sawing device

PendingCN110696099AGuaranteed timelinessGuaranteed smoothnessFeeding devicesGripping devicesAutomatic controlReciprocating motion

The invention provides a double-end rip sawing device and belongs to the technical field of automatic mechanical equipment. The technical problems that in the prior art, automatic feeding and discharging of large plates are inconvenient, and the double-end rip sawing device is not suitable for plates needed by large door and window furniture and the other products are solved. The double-end rip sawing device comprises a rack, one end of the rack is an input end, and the other end of the rack is an output end. A fixed frame is fixedly arranged on one side of the rack, and a movable frame capable of moving in the width direction of the rack is arranged on the other side of the rack. Machining head assemblies with saw discs are arranged on the fixed frame and the movable frame, and the machining head assemblies can do reciprocating motion on the fixed frame or the movable frame in the length direction. According to the double-end rip sawing device, automatic conveying, positioning and machining are carried out after feeding is carried out, full-automatic control is achieved, and the timeliness and smoothness of feeding and discharging can be guaranteed; and the two sides of a door plate are machined and cut at the same time through the machining head assemblies on the fixed frame and the movable frame, and therefore the machining efficiency is greatly improved.

Owner:TAIZHOU EVOK MASCH CO LTD

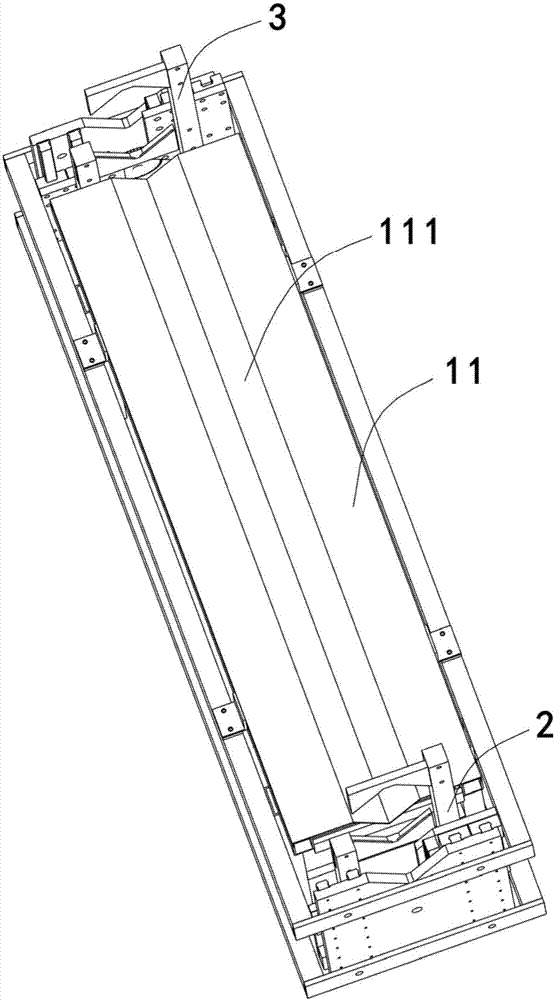

Automatic fixed-section material sawing machine

ActiveCN110053100AImprove labor efficiencyOvercome the shortcomings of slow speed and low efficiencyFeeding devicesCane mechanical workingEngineeringAutomatic processing

The invention discloses an automatic fixed-section material sawing machine which is particularly suitable for automatic processing operations of bamboo wood and can automatically process raw materialslike bamboo. The automatic fixed-section material sawing machine is provided with a feeding mechanism, a clamping mechanism, a sawing-off mechanism and a fixed-section discharging mechanism. The feeding mechanism comprises a conveying belt, and the conveying belt feeds the raw materials into the clamping mechanism. The clamping mechanism comprises a movable clamping base body and a fixed clampingbase body. The movable clamping base body and the fixed clamping base body are matched to clamp the materials and further feed the materials into the sawing-off mechanism. The sawing-off mechanism comprises a saw blade containing cavity. A saw blade is arranged in the saw blade containing cavity and can saw off the raw materials. The fixed-section discharging mechanism comprises a discharging support and a discharging rod. The discharging rod can discharge the sawed bamboo wood. By means of the automatic fixed-section material sawing machine, automatic feeding and discharging can be achievedquickly, labor intensity is low, labor efficiency is high, the lengths of the sawed materials can be adjusted, the desired material lengths can be sawed out, operation is easy, using is made convenient, and the defects that the manual material sawing speed is low and efficiency is also low at present are overcome.

Owner:桃江县湘农机械研制有限公司

Wood plate cutting equipment and implementation method thereof

InactiveCN110216740AImplement Angular HandlingNo wearFeeding devicesCircular sawsMulti materialPulp and paper industry

The invention provides wood plate cutting equipment. The wood plate cutting equipment comprises a material conveying frame and cutting equipment; the cutting equipment comprises a machine frame; the material conveying frame is arranged on the middle platform surface of the machine frame; the part positioned at the front end of the machine frame and on the material conveying frame is a wood plate material feeding end; and the part positioned at the back end of the machine frame is a wood plate material discharging end. The invention also provides an implementation method of the wood plate cutting equipment. The wood plate cutting equipment can perform multi-angle and rapid cutting on the wood plate material and can perform accurate cutting and blanking, and the precision can reach to + / - 1mm; furthermore, the wood plate cutting equipment is suitable for cutting various materials and is wide in application range; and the transmission efficiency is improved, the potential safety hazard iseliminated, no deviation in the process of transmitting the right-angle wood plate material is guaranteed, the right-angle wood plate material is not worn in the transmission process, the quality ofthe right-angle wood plate material is improved and the utilization rate of materials is increased.

Owner:高密市瑞力特数控设备有限公司

Portable sawmill

The portable sawmill is constructed on a frame having a series of mechanisms for loading and manipulating a log thereon and removing boards cut from the log. Powered tines load a log onto a vertically adjustable log deck, the deck including powered mechanisms for turning and securing the log in the desired orientation for cutting. Cuts are made by a horizontally traveling band saw. The saw has no vertical adjustment. Board thickness is determined by the height of the vertically adjustable log deck. Cut boards are removed by a board sweep that pushes the board laterally from the top of the log onto a tray. The saw travels along the tray to push the board longitudinally onto a suitable platform for transport. All of the above mechanisms are controlled hydraulically from a single operator station on the mill, thus freeing the operator from many manual tasks and increasing production.

Owner:BURTON LARRY C

Full-automatic double-end cutting photo frame corner cutting machine

InactiveCN106965253AReduce precisionRealize automatic corner cuttingGuide fencesFeeding devicesEngineeringWorkbench

The invention relates to the field of photo frame corner cutting machines, in particular to a full-automatic double-end cutting photo frame corner cutting machine. The full-automatic double-end cutting photo frame corner cutting machine comprises a workbench. A conveying device is arranged on the workbench. A feeding device is arranged at the initial end of the conveying device. A cutting device is further arranged on the workbench and comprises a first cutting device body and a second cutting device body. The first cutting device body and the second cutting device body are arranged perpendicularly and form a 45-degree angle with the conveying device. A first clamp arranged vertically and a second clamp arranged horizontally are arranged on the part, located between the first cutting device body and the second cutting device body, on the workbench. The first clamp and the second clamp can jointly jack and fix a photo frame onto the conveying device in the working state. Automatic corner cutting of the photo frame is achieved, manpower sources are saved, and the production efficiency and product quality are improved.

Owner:东莞市勤唯机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com