Full-automatic double-end cutting photo frame corner cutting machine

A fully automatic, angle-cutting machine technology, applied in the direction of clamping angle iron, sawing components, sawing equipment, etc., can solve the problems of unsealed corners, affecting the beauty of the photo frame, affecting the cutting accuracy, etc., to save human resources, The effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

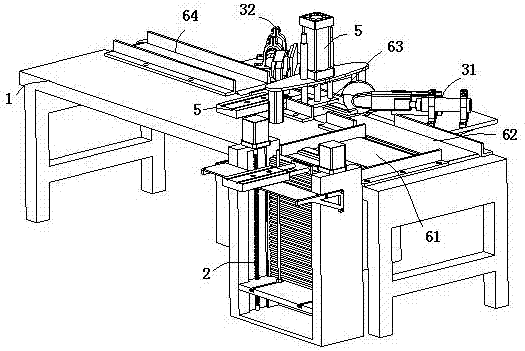

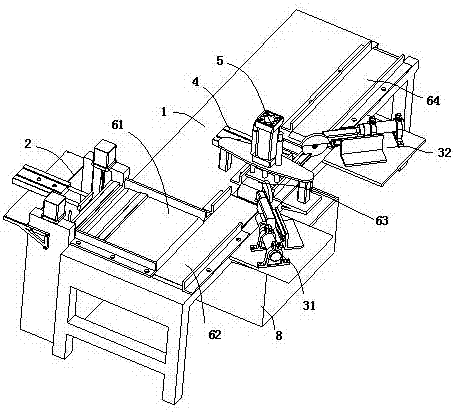

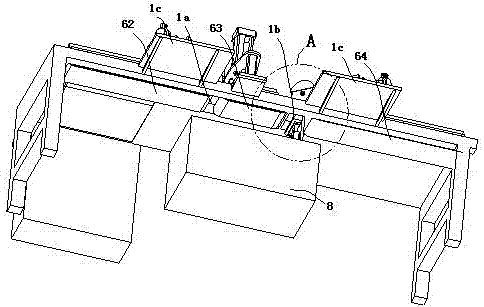

[0026] Below in conjunction with accompanying drawing and embodiment of specification, specific embodiment of the present invention is described in further detail: According to Figure 1 to Figure 9 A kind of full-automatic double-head cutting photo frame angle cutting machine shown includes a workbench 1, which is provided with a conveying device, and the starting end of the conveying device is provided with a feeding device 2, and the workbench 1 There is also a cutting device on the top, and the cutting device includes a first cutting device 31 and a second cutting device 32, and the first cutting device 31 and the second cutting device 32 are arranged perpendicular to each other and form an angle of forty-five degrees with the conveying device Setting, the first clamp 4 and the second clamp 5 set up vertically are arranged between the first cutting device 31 and the second cutting device 32 on the workbench 1, and the first clamp 4 and the second clamp 5 are set up vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com