Continuous automatic processing production line for wood of furniture manufacturing

A technology for automatic processing and furniture manufacturing. It is used in manufacturing tools, wood processing appliances, unloading equipment, etc. It can solve the problems of wood swinging from side to side, affecting cutting accuracy, and uneven cutting surface of wood, so as to improve cutting accuracy and reduce danger. performance, improve production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

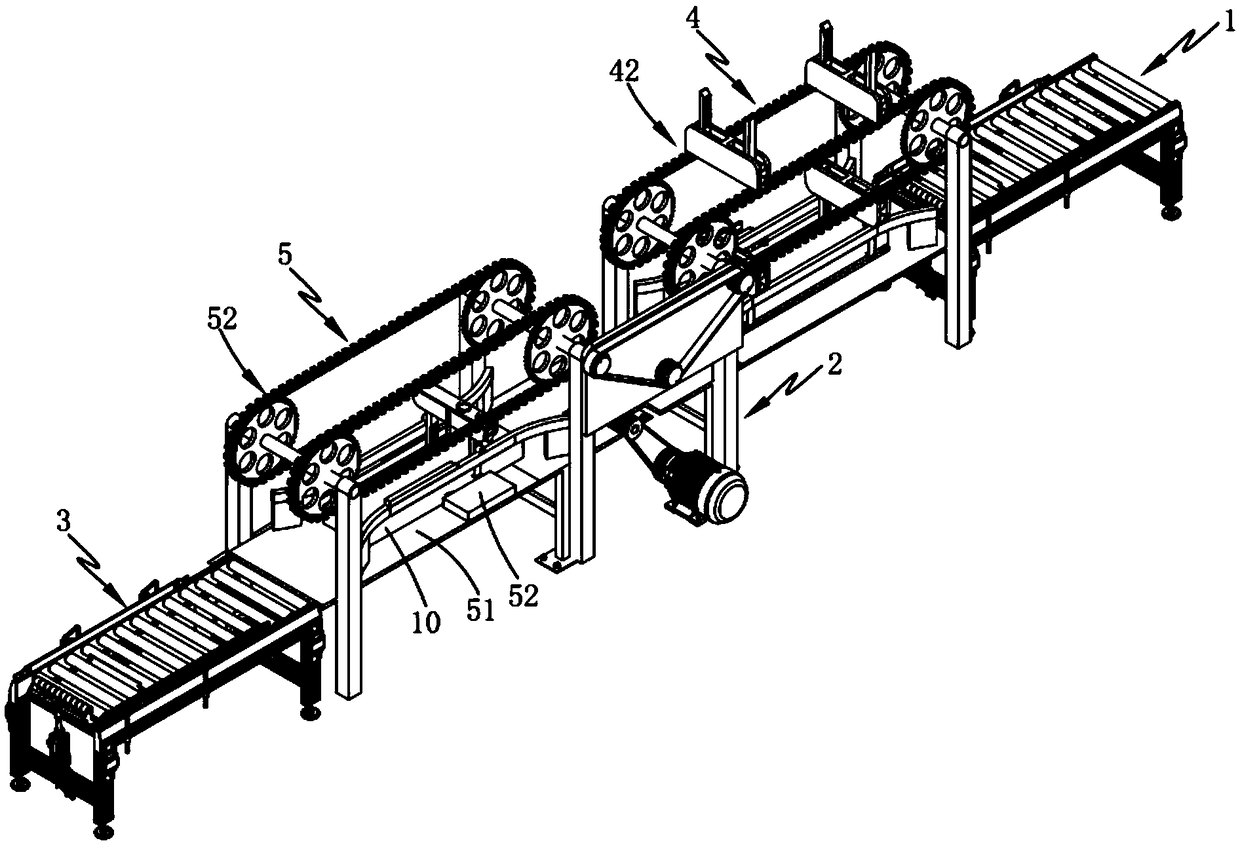

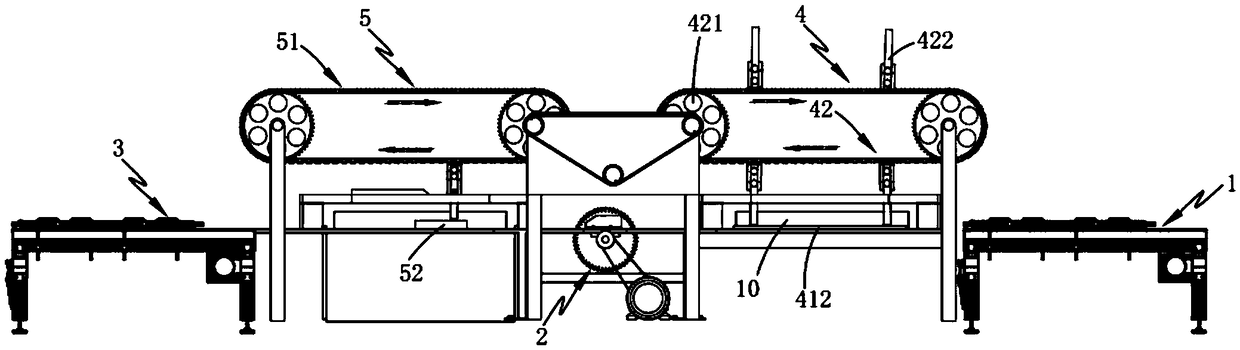

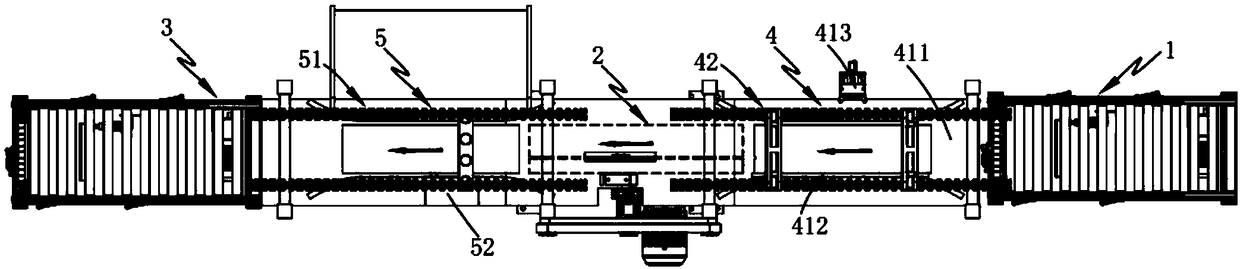

[0072] like figure 1 , 2 As shown in and 3, a continuous automatic processing line of wood for furniture manufacturing includes a feeding device 1, a cutting device 2 arranged behind the feeding device 1 and an output device 3 arranged behind the cutting device 2, Also includes:

[0073] Clamping feeding device 4, described clamping feeding device 4 is arranged between described feeding device 1 and cutting device 2, and this clamping feeding device 4 comprises wooden block positioning mechanism 41 and is arranged on this woode...

Embodiment 2

[0120] Figure 21 It is a structural schematic diagram of Embodiment 2 of a wood continuous automatic processing production line for furniture manufacturing of the present invention; as Figure 21 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment 1 is that: the feeding device 1 is provided with a feeding control mechanism 11 at one end close to the clamping feeding device 4, and the feeding control mechanism 11 intermittently controls the feeding device 1 Blocks 10 fed to clamp feeder 4.

[0121] It should be noted that the feed control mechanism 11 includes a control cylinder 111 arranged on the bracket of the clamping feeding device 4 and a stopper 112 which is rotatably arranged at both ends on the output end of the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com