Gift paper slitting machine

A technology of slitting machine and gift paper, applied in metal processing and other directions, can solve the problems of low processing efficiency, increase labor intensity of workers, poor safety, etc., and achieve the effect of improving processing efficiency, avoiding knife injury and reducing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

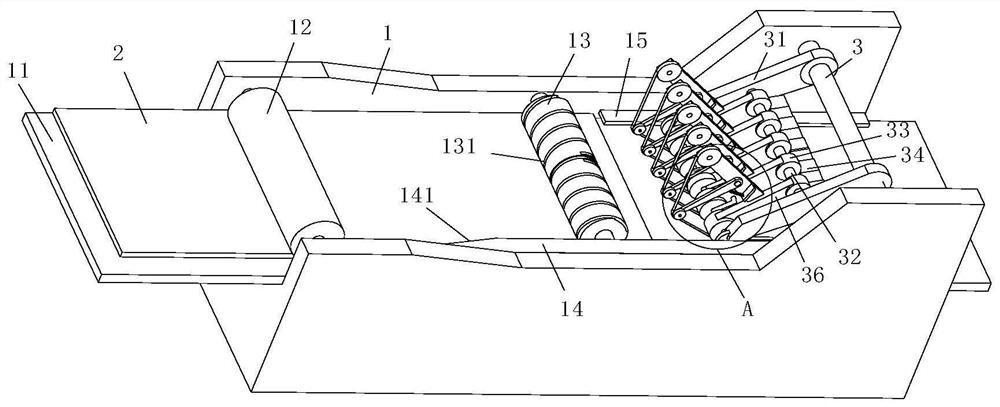

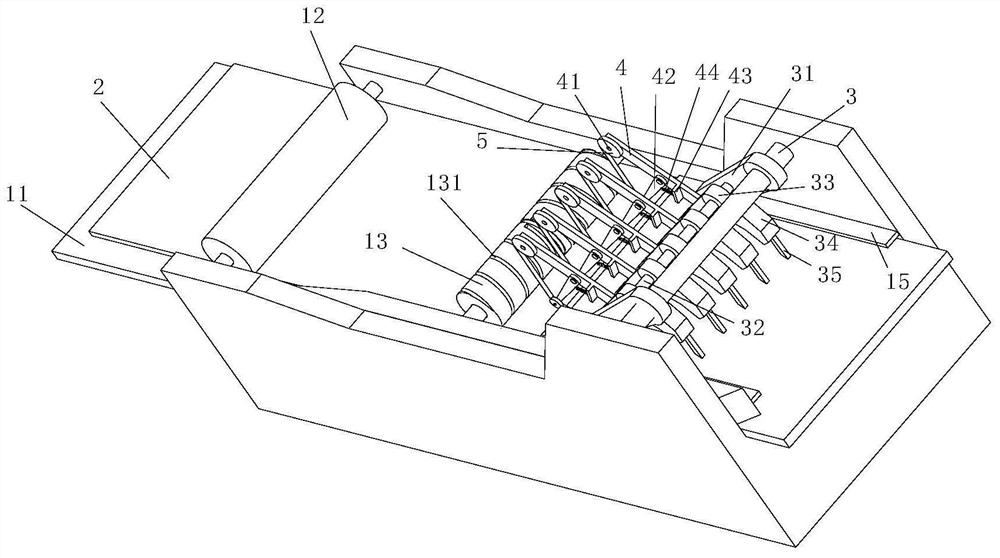

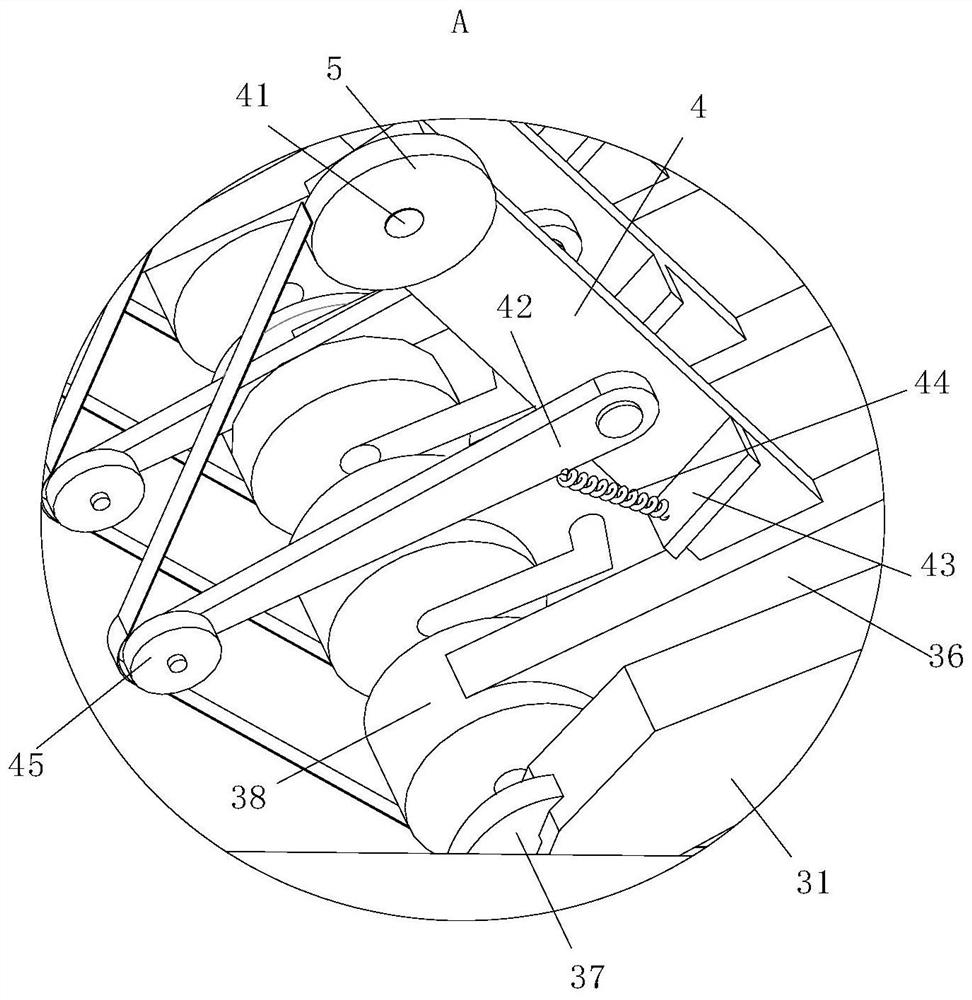

[0030] Such as Figure 1-5 Shown, a kind of gift paper cutting machine comprises frame 1, and described frame 1 upper end is provided with workbench 11, and the frame 1 of described workbench 11 front and rear sides is provided with retaining edge; 11 along the left and right directions are arranged in turn with conveying rollers 12 and cutting structure, one side of the frame 1 is provided with a drive motor connected to the transmission roller 12; The horizontal bar 3 is symmetrically arranged on the horizontal bar 3 with a fixed frame 31 extending obliquely to the lower left, and a sliding bar 32 is arranged between the middle parts of the fixed frame 31. The outer cover of the sliding bar 32 is equipped with a plurality of Sliding sleeve 33, the upper end of the sliding sleeve 33 is provided with a locking mechanism for fixing its position, the lower end of the sliding sleeve 33 is provided with a knife seat 34, and the lower end of the knife seat 34 is provided with a Sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com