Patents

Literature

40results about How to "Realize fully automatic cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

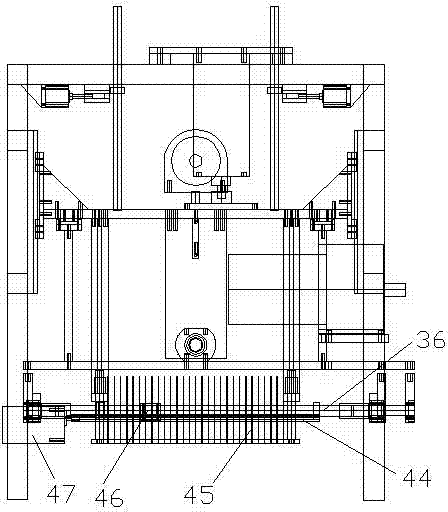

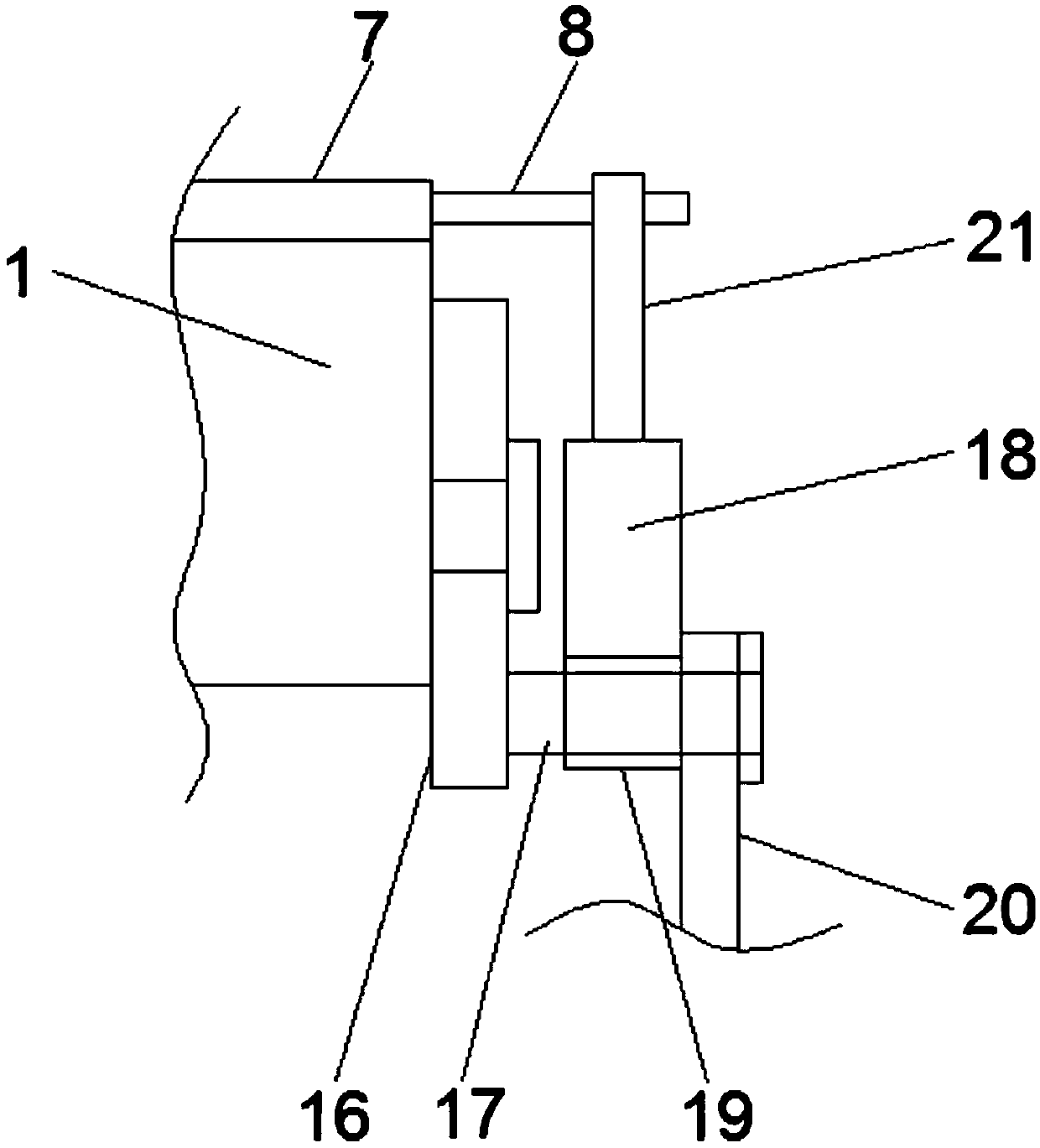

Outer clamp type bevelling machine

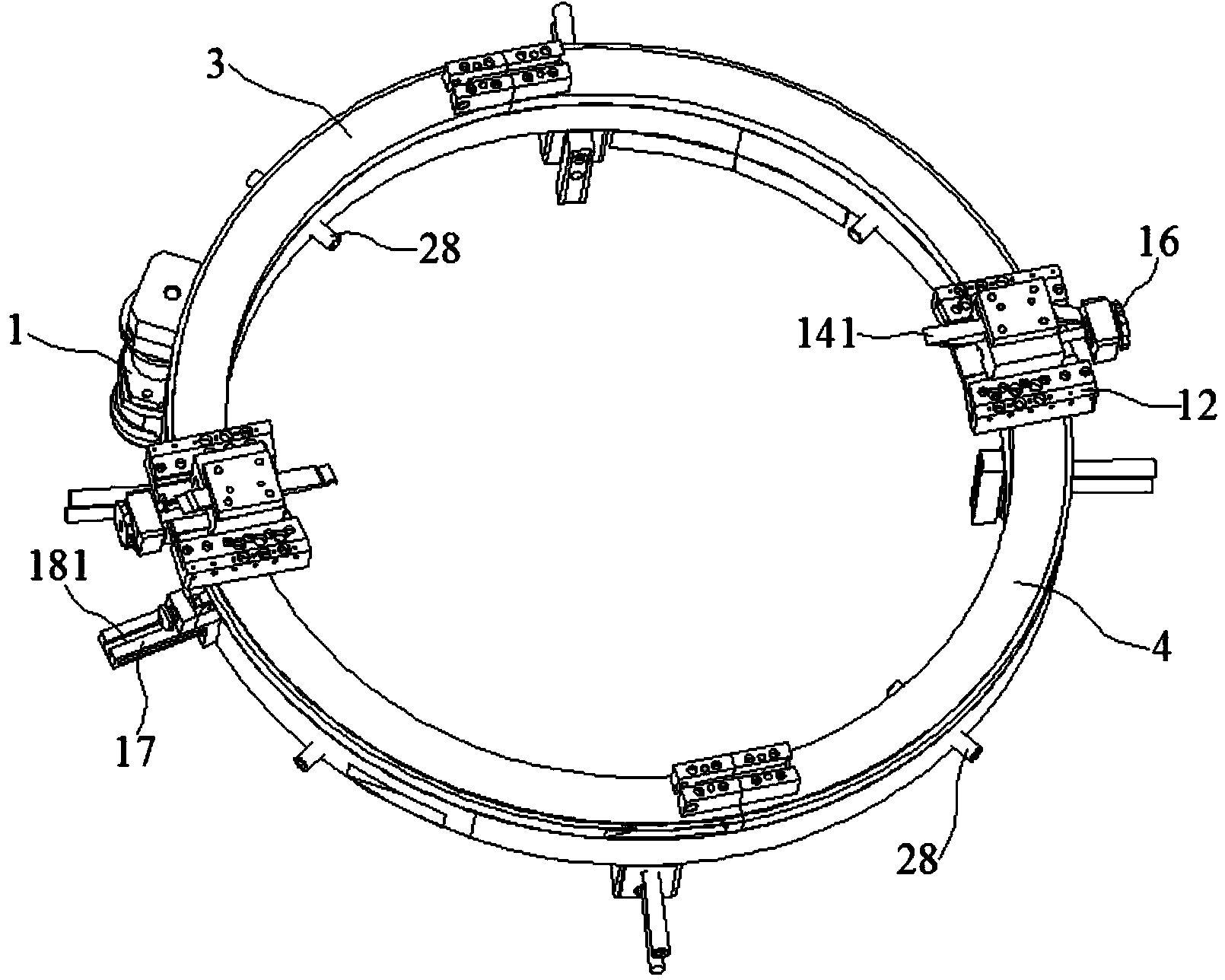

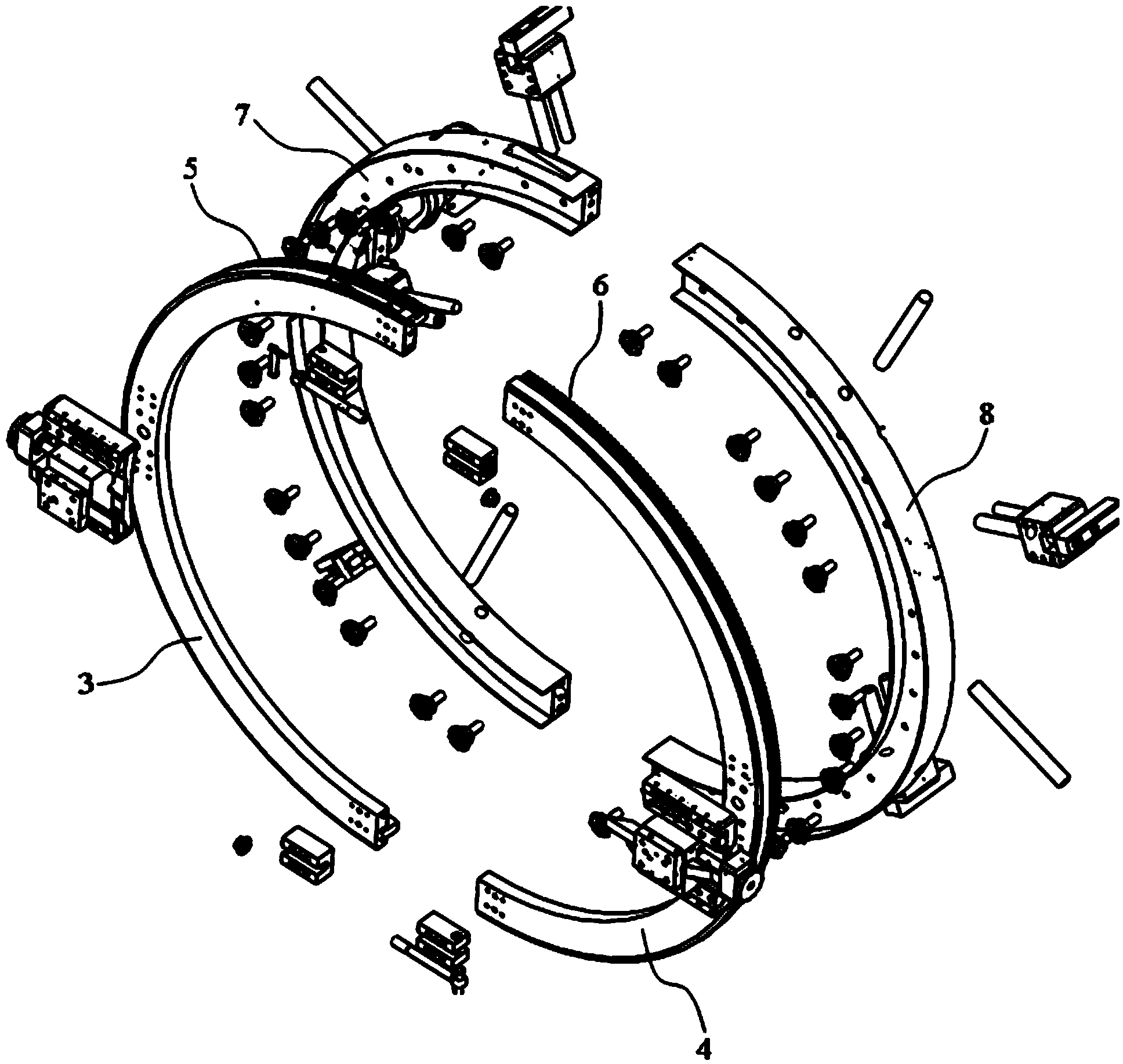

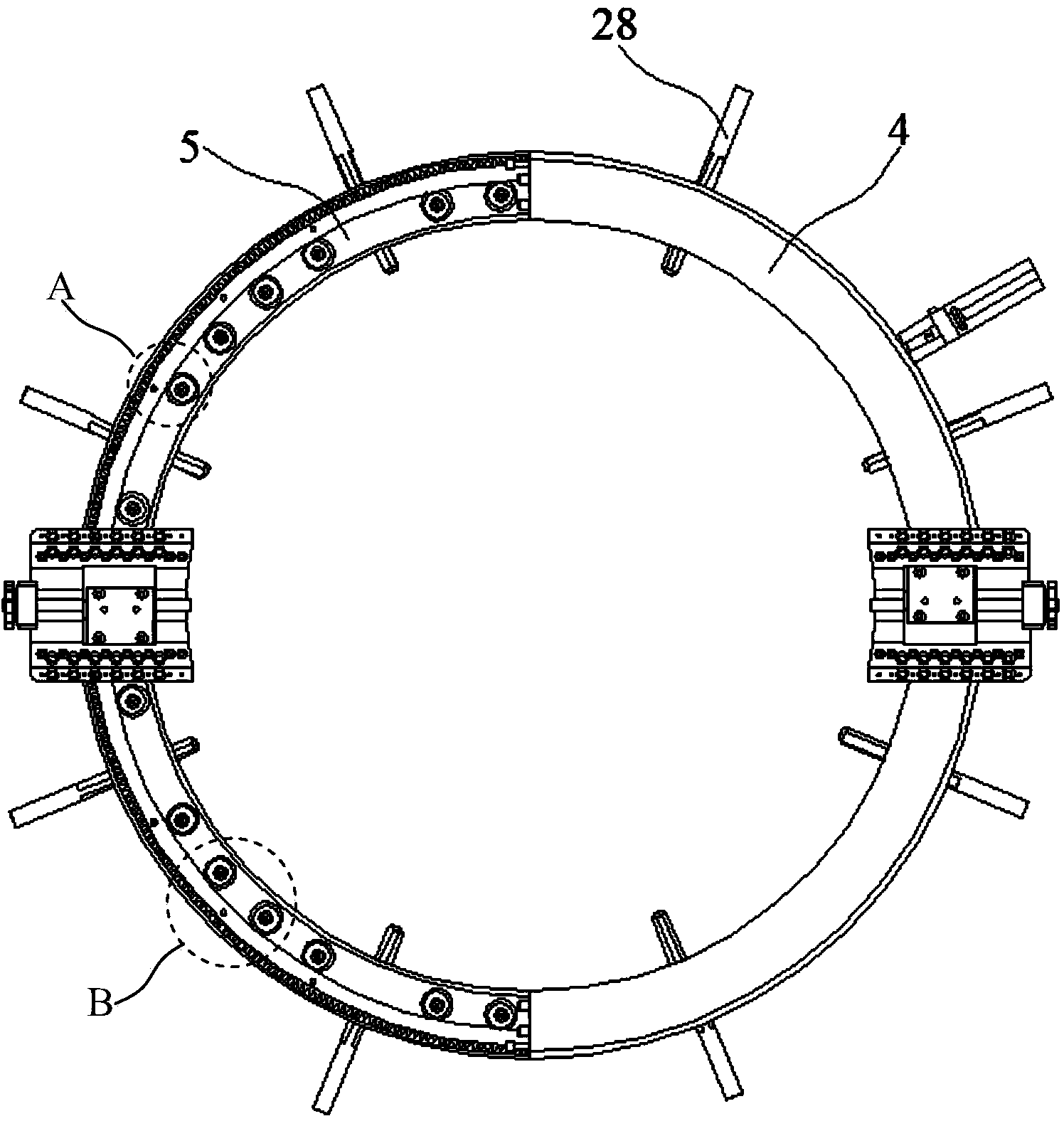

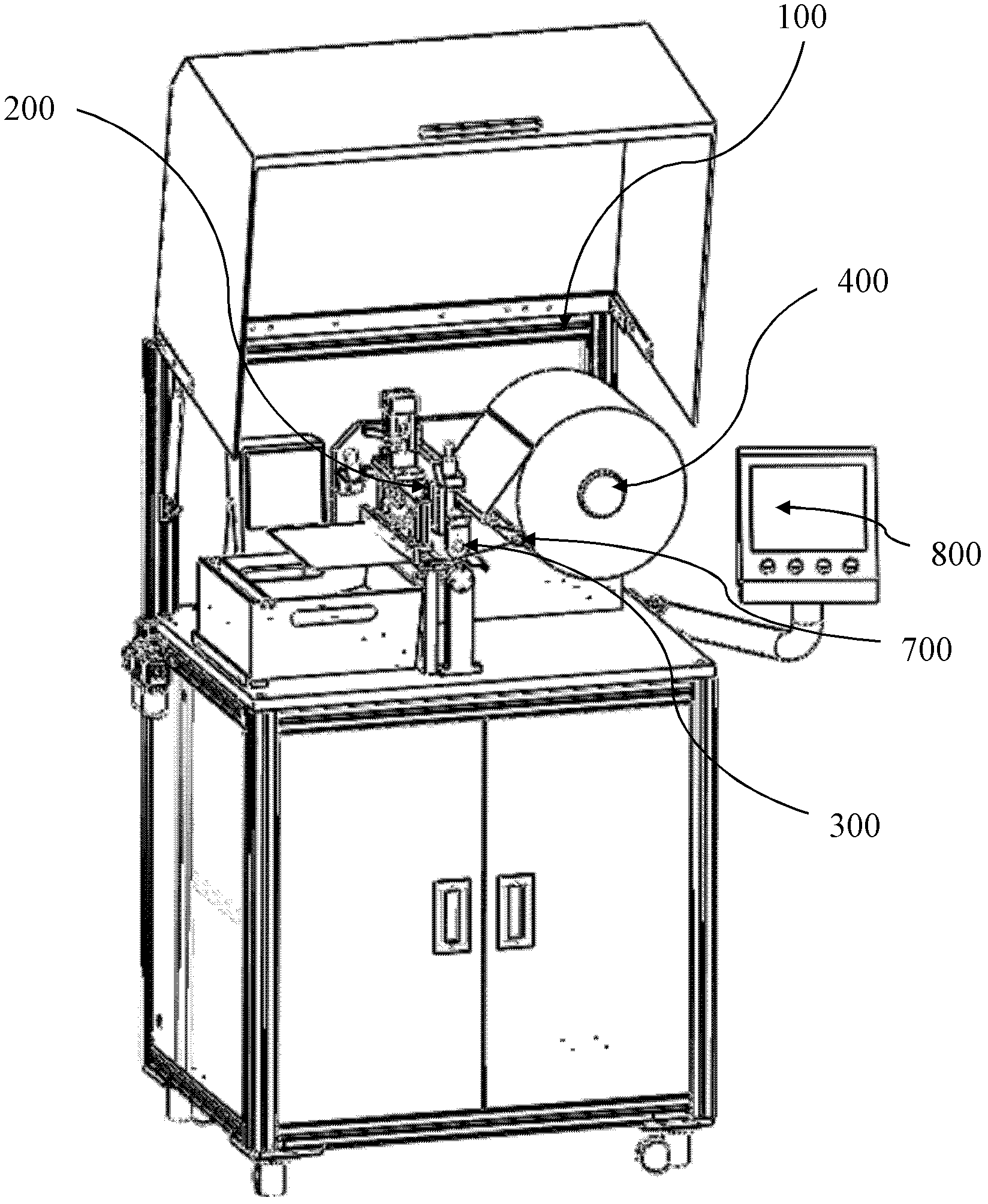

The invention discloses an outer clamp type bevelling machine, which comprises a power mechanism, a driving transmission gear, left and right movable rings, left and right gear rings and left and right fixed rings, wherein the left and right movable rings are respectively and fixedly arranged on the left and right gear rings, a plurality of eccentric shafts are respectively and fixedly arranged on the left and right fixed rings in the circumferential direction, each eccentric shaft comprises a shaft body and a cylindrical bulge part arranged at one end of the shaft body, the axial line of each shaft body and the axial line of the corresponding cylindrical bulge part are parallel but do not coincide, the shaft body of each eccentric shaft is fixedly arranged on the left and right fixed rings, a rolling wheel bearing is arranged on each cylindrical bulge part, a plurality of rolling wheel bearings are movably embedded in grooves of the inner side surfaces of the left and right gear rings, the driving transmission gear is engaged with the left and right gear rings, the power mechanism drives the driving transmission gear to rotate, a knife rest holder is fixedly arranged on the front end surface of the left movable ring or the right movable ring, and the front end surface of the left movable ring or the right movable ring is fixedly provided with a knife impacting mechanism. The outer clamp type bevelling machine has the advantages that the relative rotation can be realized, good coaxiality is also realized, during the cutting, the operation stability is high, the stable and smooth rotation can be realized, the cutting precision is high, and the risk of gear clamping and gear stubbing is also greatly reduced.

Owner:苏州博合雅工程材料科技有限公司

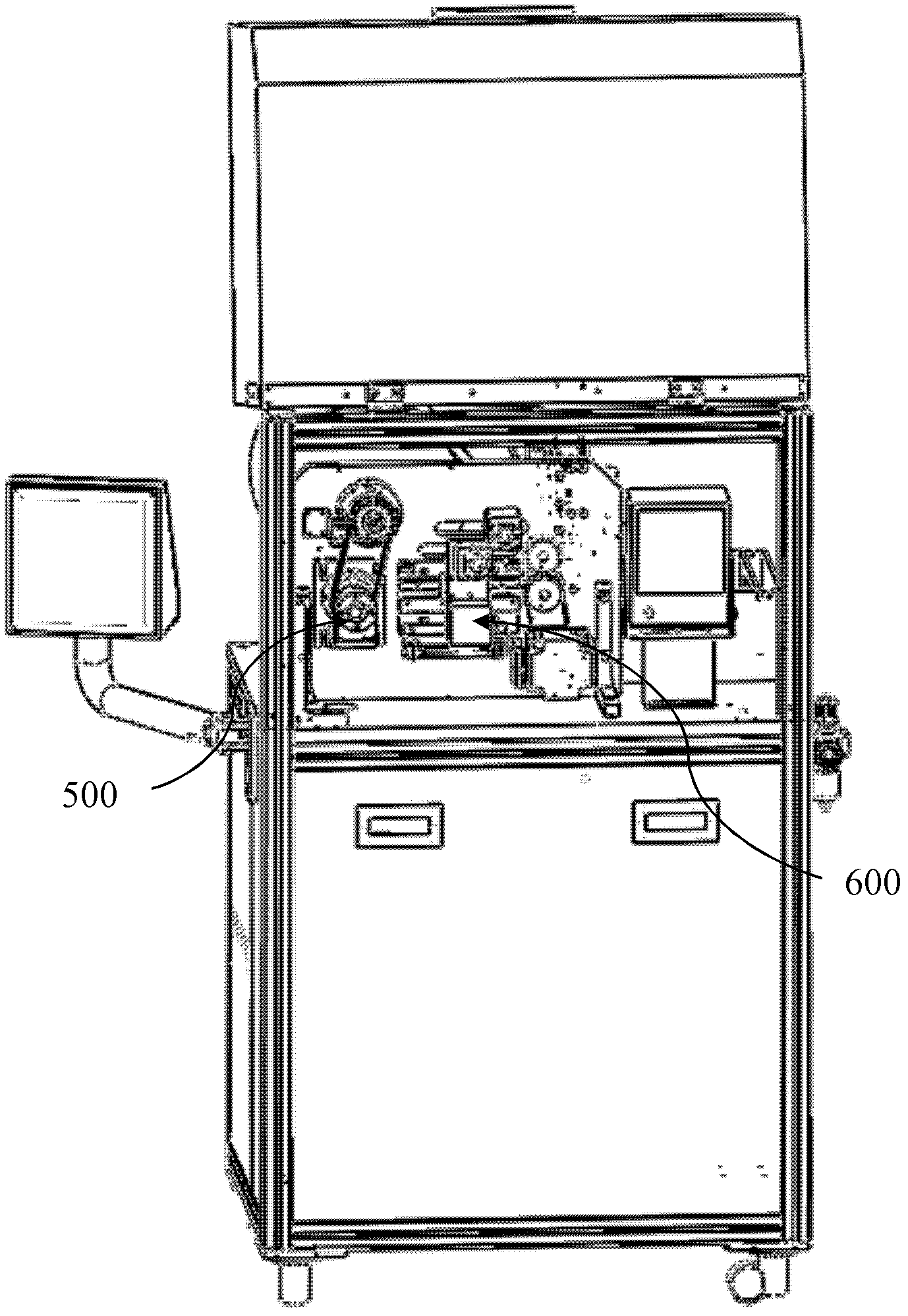

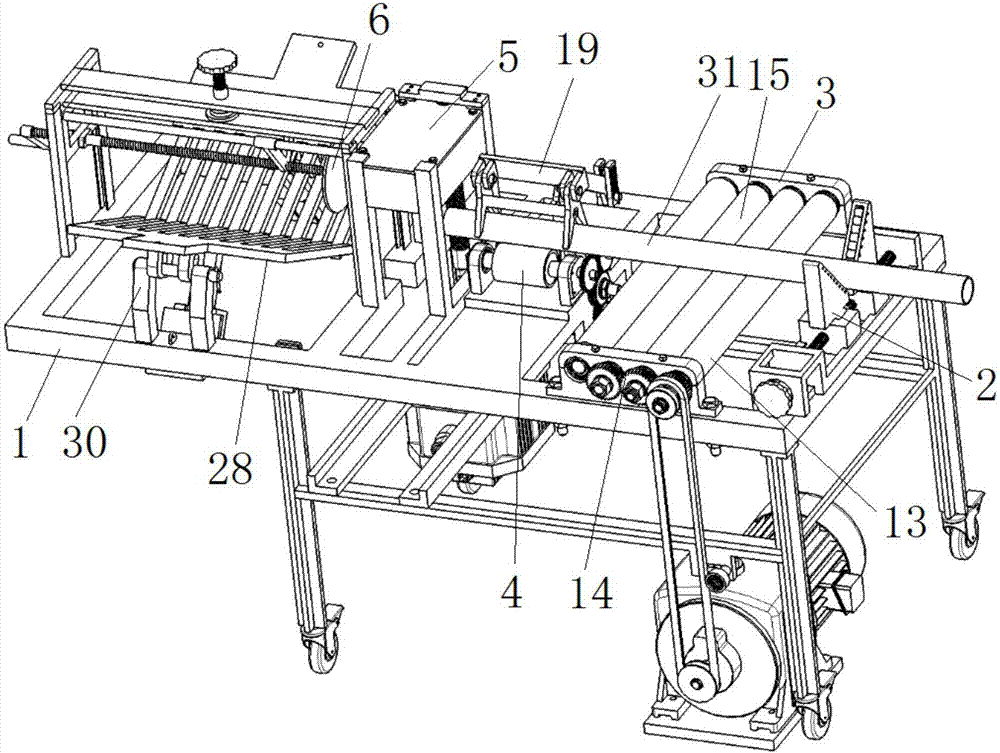

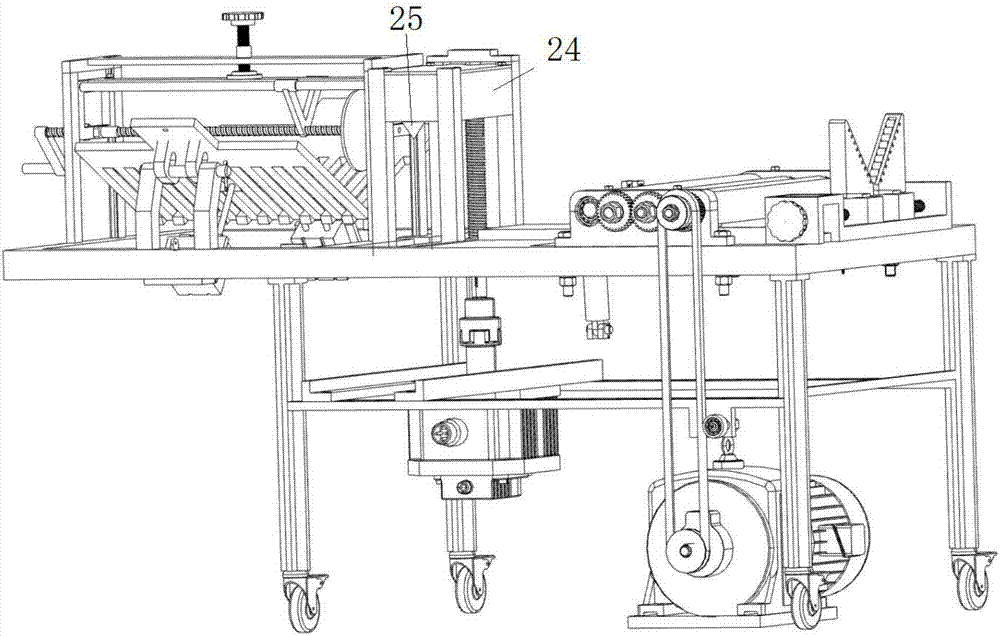

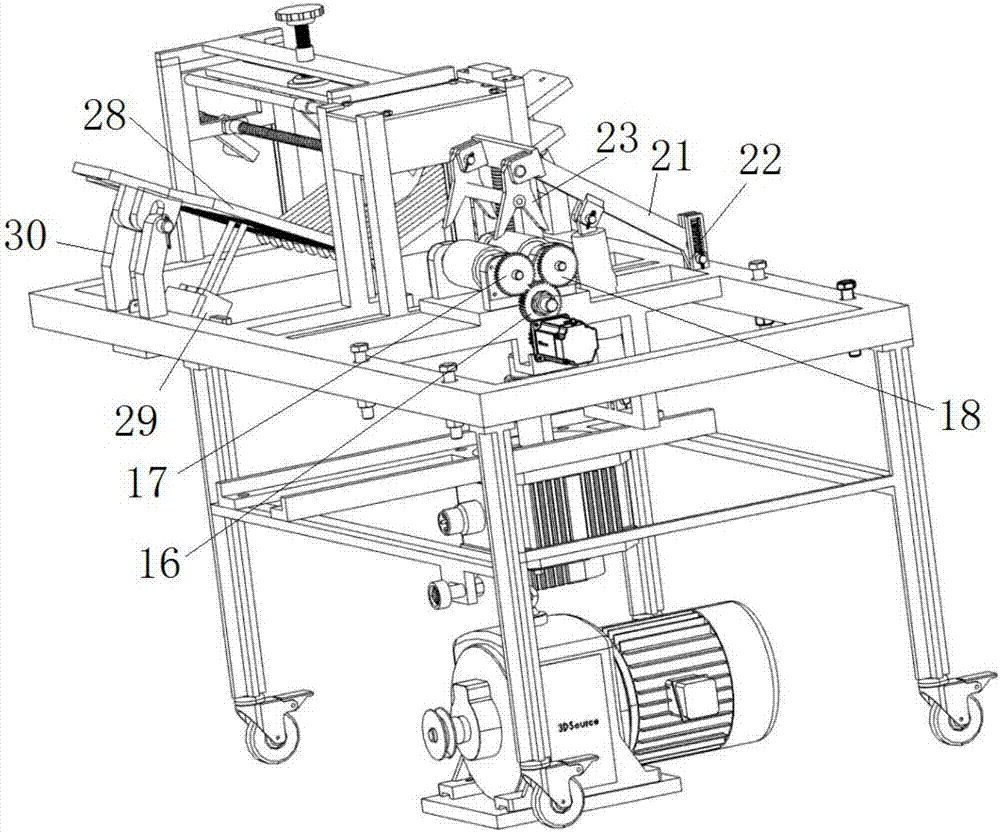

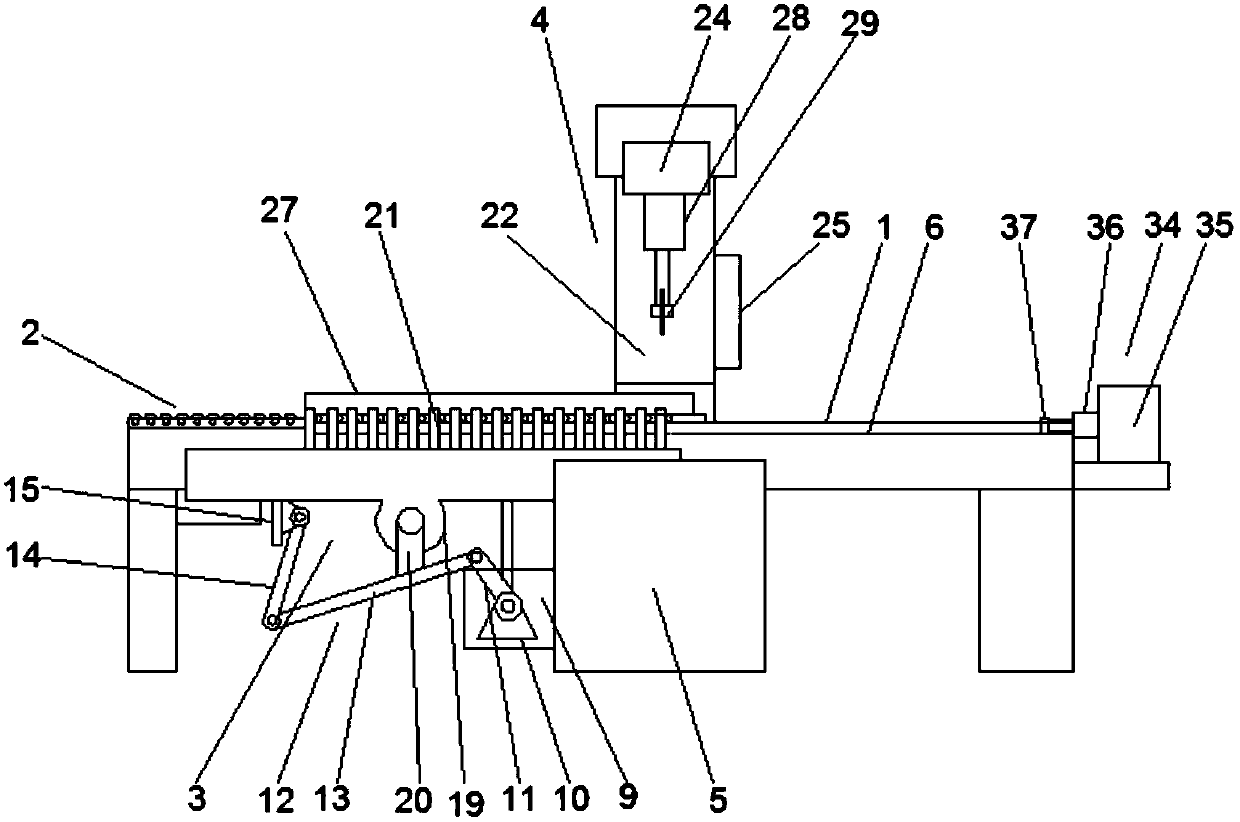

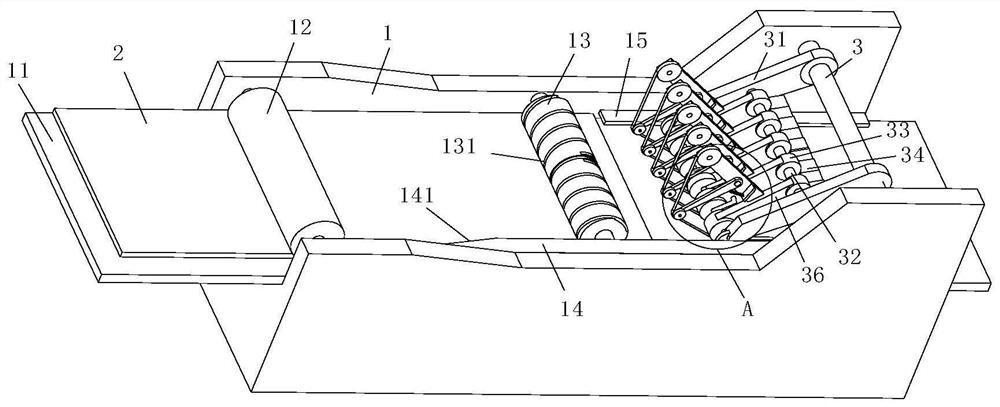

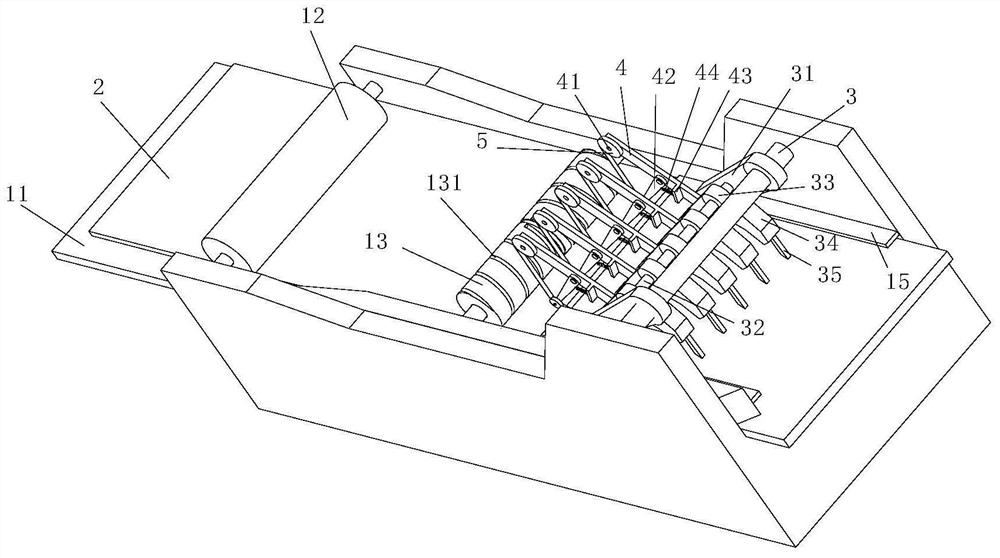

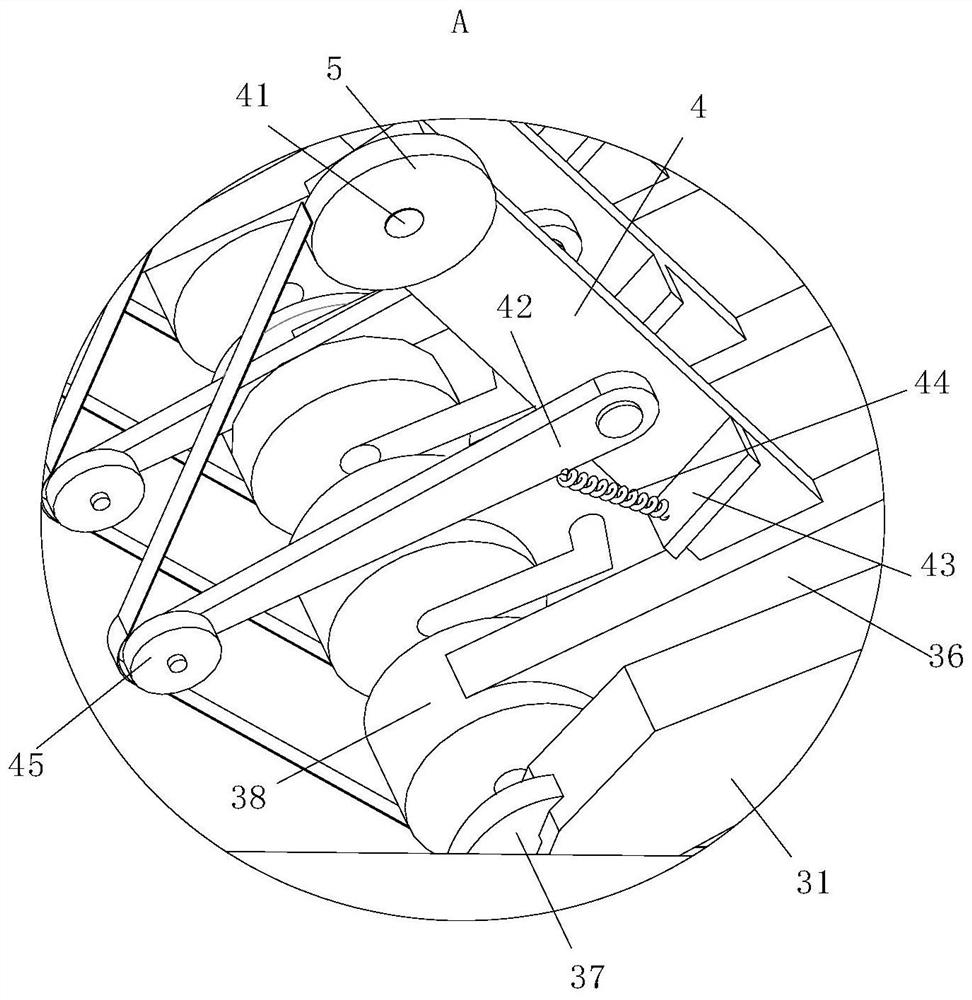

Full-automatic release paper cutting machine

InactiveCN102490198ARealize fully automatic cuttingReduce labor intensityMetal working apparatusArticle deliveryProgrammable logic controllerControl system

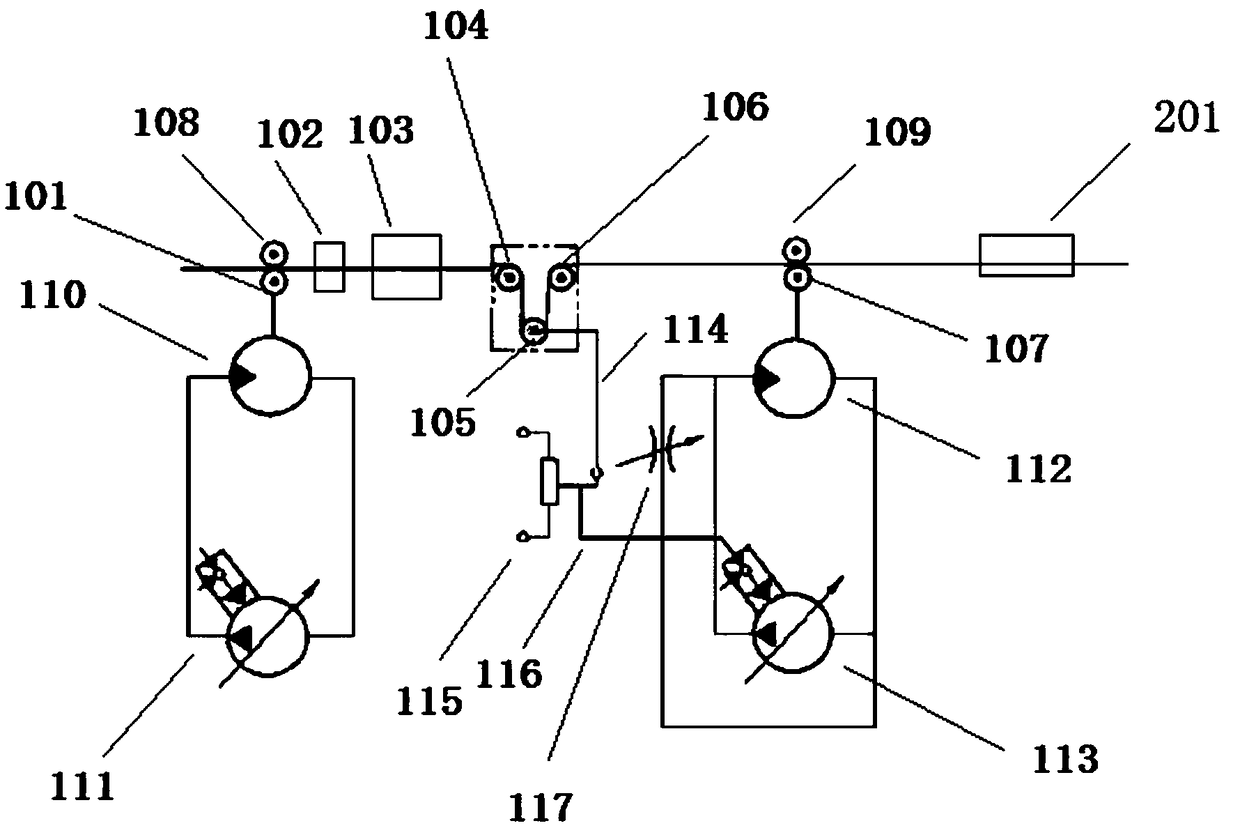

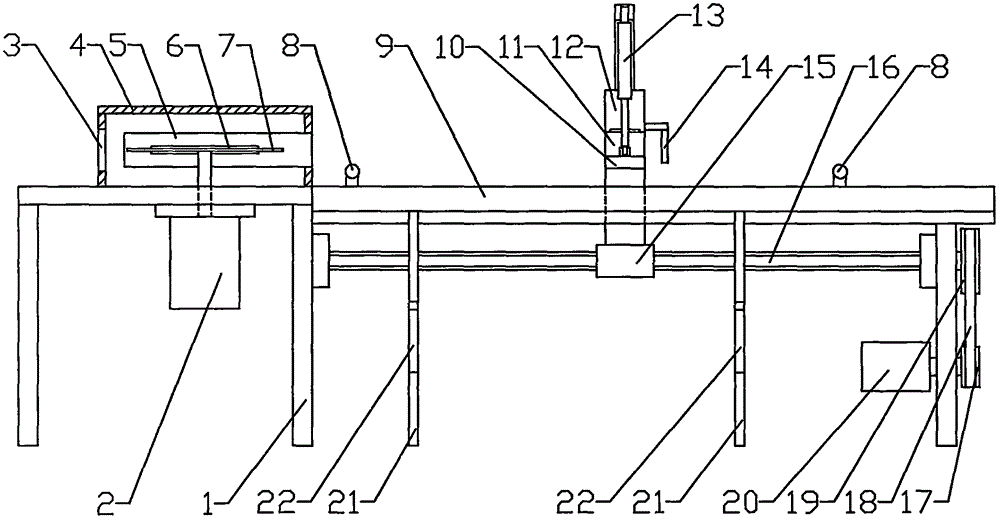

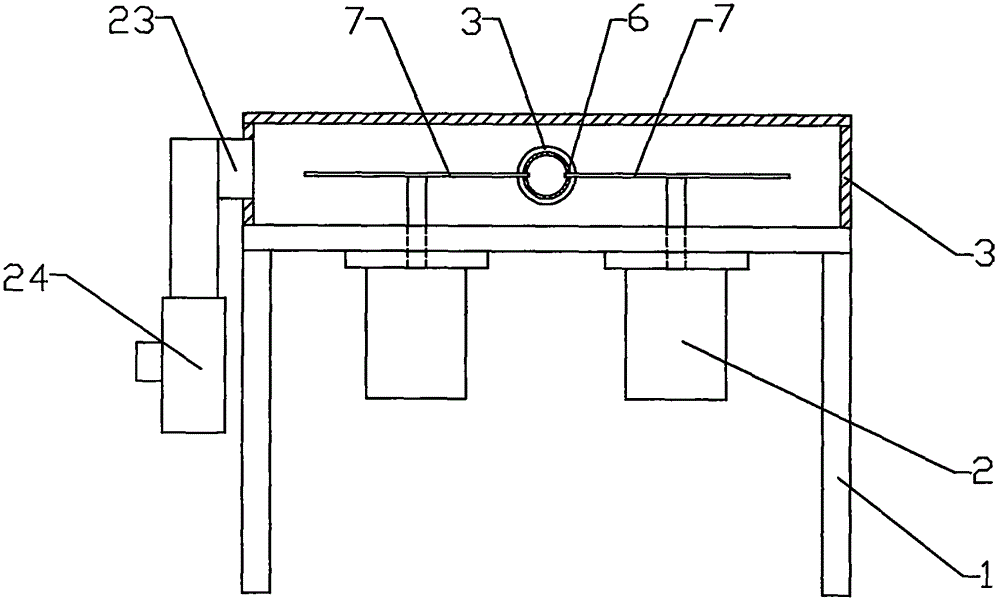

The invention relates to a full-automatic release paper cutting machine. The machine comprises a frame, a paper cutting mechanism, a paper feeding mechanism, a paper clamping mechanism, a paper feeding braking mechanism, a paper guiding mechanism, a paper straightening mechanism and a programmable logic controller (PLC) and touch screen control system, wherein the paper cutting mechanism is arranged above the frame and used for cutting release paper off; the paper feeding mechanism is arranged above the frame and in front of the paper cutting mechanism and used for feeding the release paper; the paper clamping mechanism is arranged above the frame and in front of the paper feeding mechanism and used for fixing the release paper; the paper feeding braking mechanism is arranged above the frame and below the paper clamping mechanism and used for braking paper feeding; the paper straightening mechanism is arranged between the paper feeding mechanism and the paper clamping mechanism and used for straightening the release paper; the paper guiding mechanism is arranged above the paper straightening mechanism and used for guiding the release paper; and the PLC and touch screen control system is arranged on the frame and used for controlling the movement of each mechanism. The full-automatic release paper cutting machine has the characteristics that: the whole roll of paper is fed into a release paper machine type by the paper clamping mechanism, and the release paper is guided and straightened by the paper guiding mechanism and the paper straightening mechanism, so that the release paper can straightly enter the paper feeding mechanism, and is continuously and fully automatically cut off by the paper cutting mechanism, manual operation is not needed in the paper cutting process, and high automation is achieved.

Owner:厦门市弘瀚电子科技有限公司

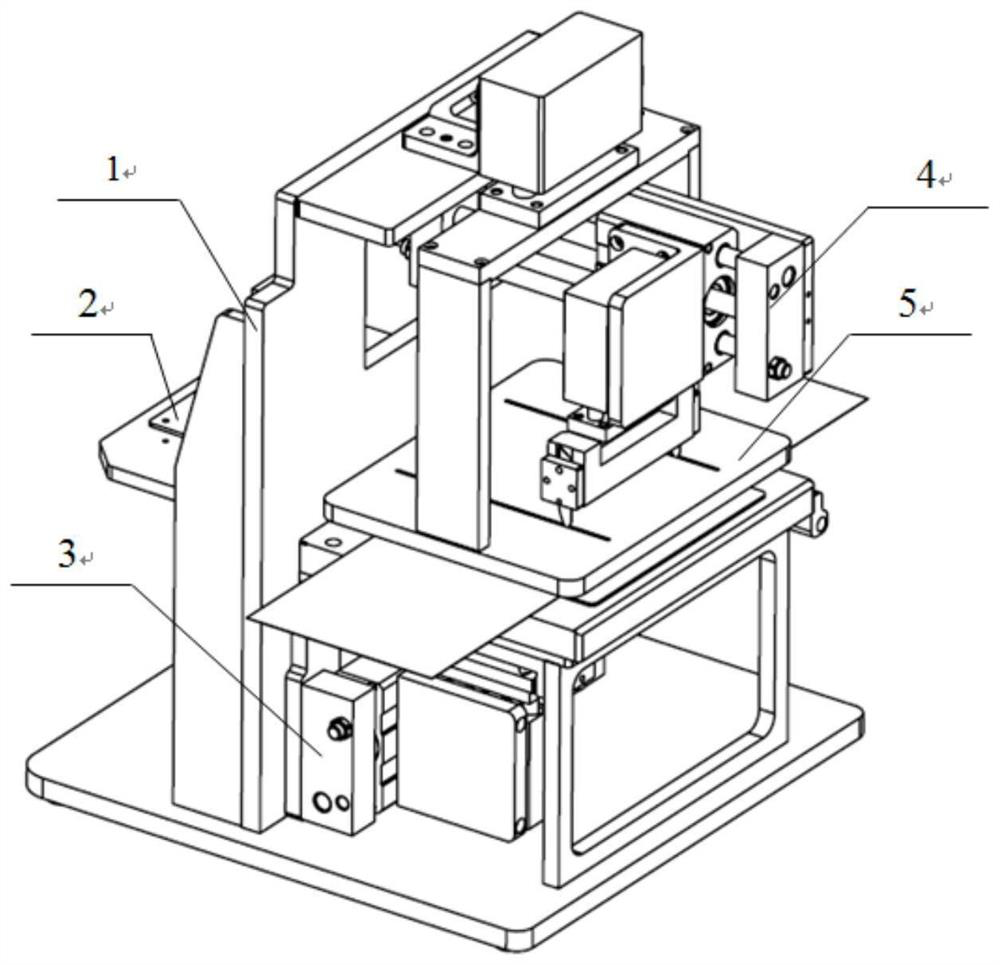

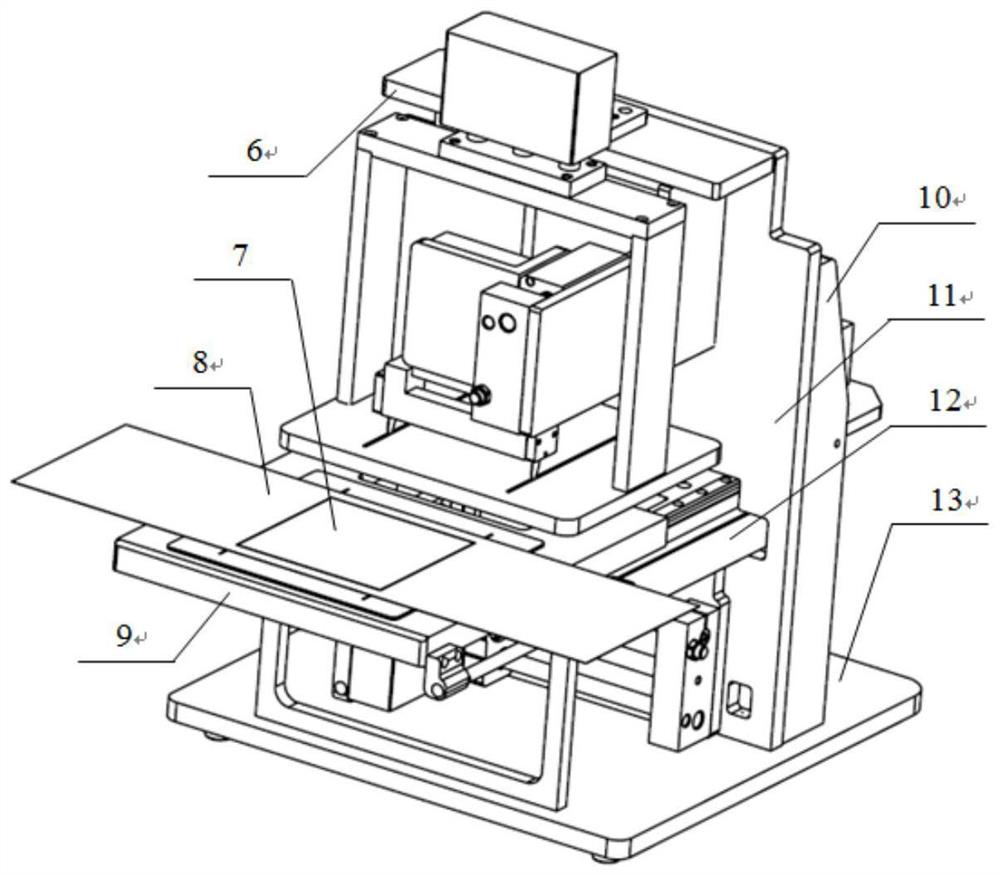

Automatic bean product slicer

ActiveCN103481315ARealize fully automatic cuttingNo manual operationCleaning using liquidsMetal working apparatusReducerConveyor belt

The invention discloses an automatic bean product slicer, comprising a conveyor belt and multiple molds fixed on the conveyor belt; a horizontal die cutting device and a longitudinal die cutting device are arranged above the conveyor belt; the horizontal die cutting device comprises a bottom plate; a movable support plate capable of moving up and down is fixed below the bottom plate by a guide post; a first transmission screw is fixedly connected below the movable support plate; the transmission screw is provided with a cutting knife shaft capable of horizontally moving along the transmission screw. Horizontal and longitudinal cutting knives are arranged above the conveyor belt, when the molds reach a cutting station, the conveyor belt is stopped, a cylinder is pushed out to fall the cutting knife shaft, and the cutting knives work and are rotated and move along the transmission screw by the driving of a speed reducer, so bean products are cut open according to a set standard; when the cutting knives cut out of the molds, the cylinder is reset, the cutting knives ascend, the conveyor belt walks to send the molds on the next station to the cutting station, the operations are recycled in sequence, full-automatic cutting is realized, no manual operation is needed, the cutting efficiency is high and the cutting quality is high.

Owner:NOVEL FOOD (SUZHOU) CO LTD

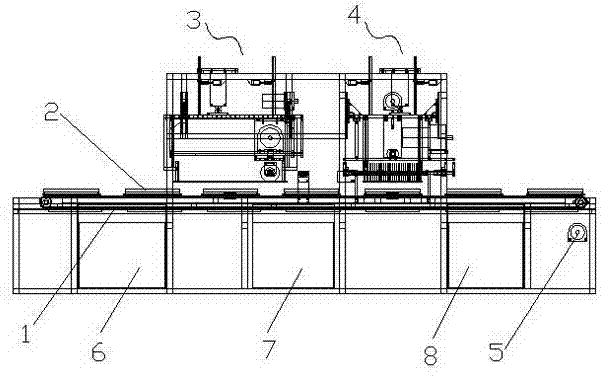

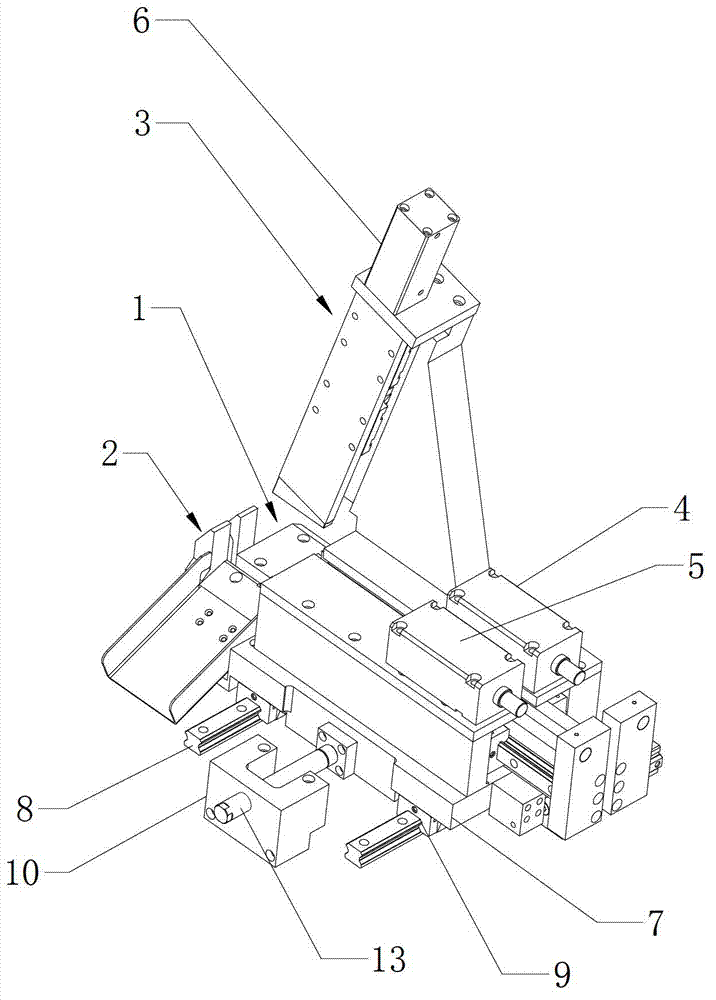

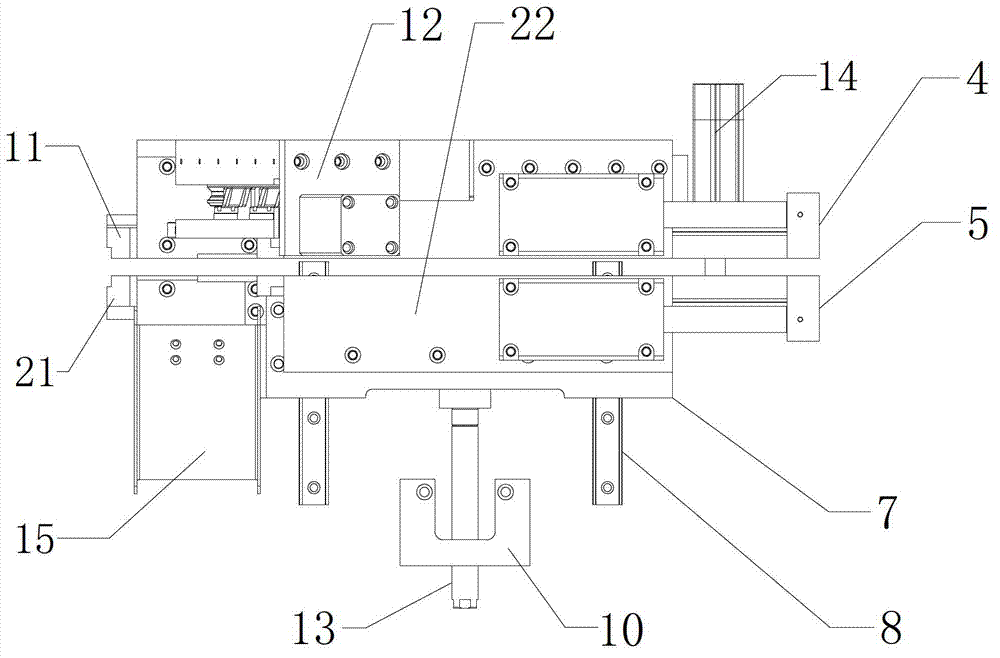

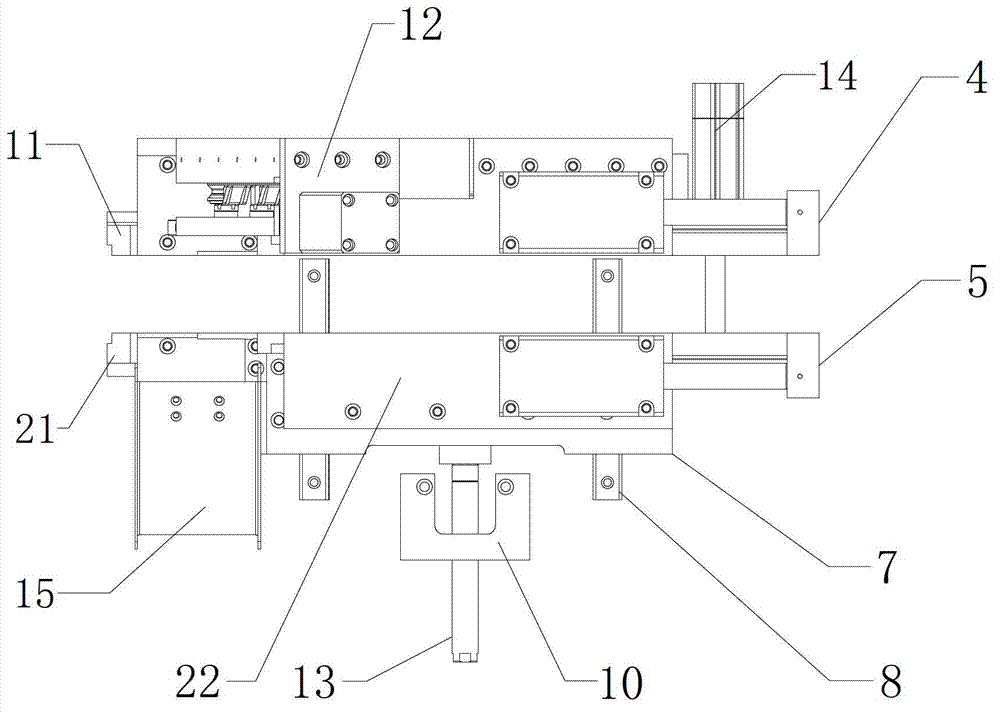

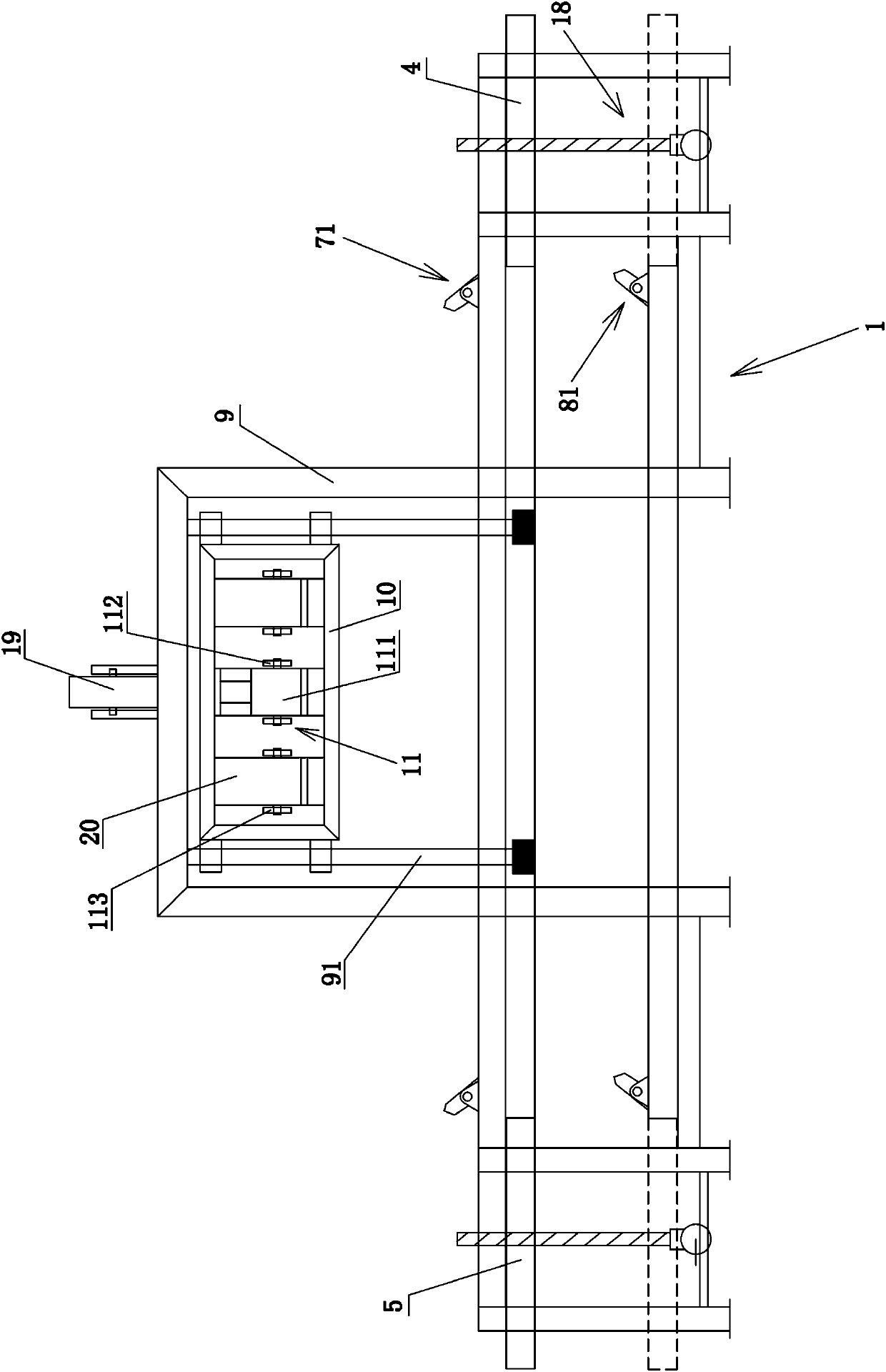

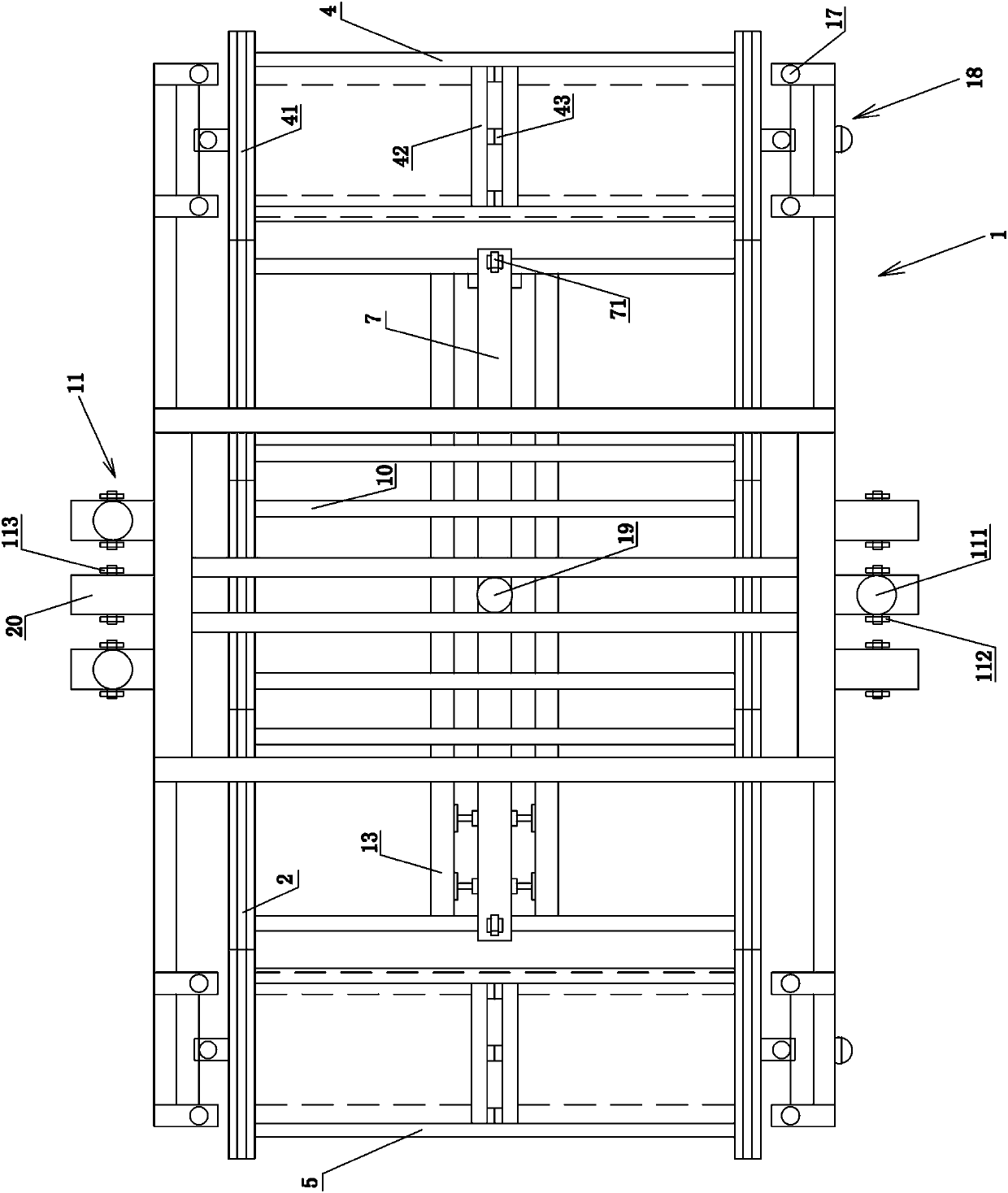

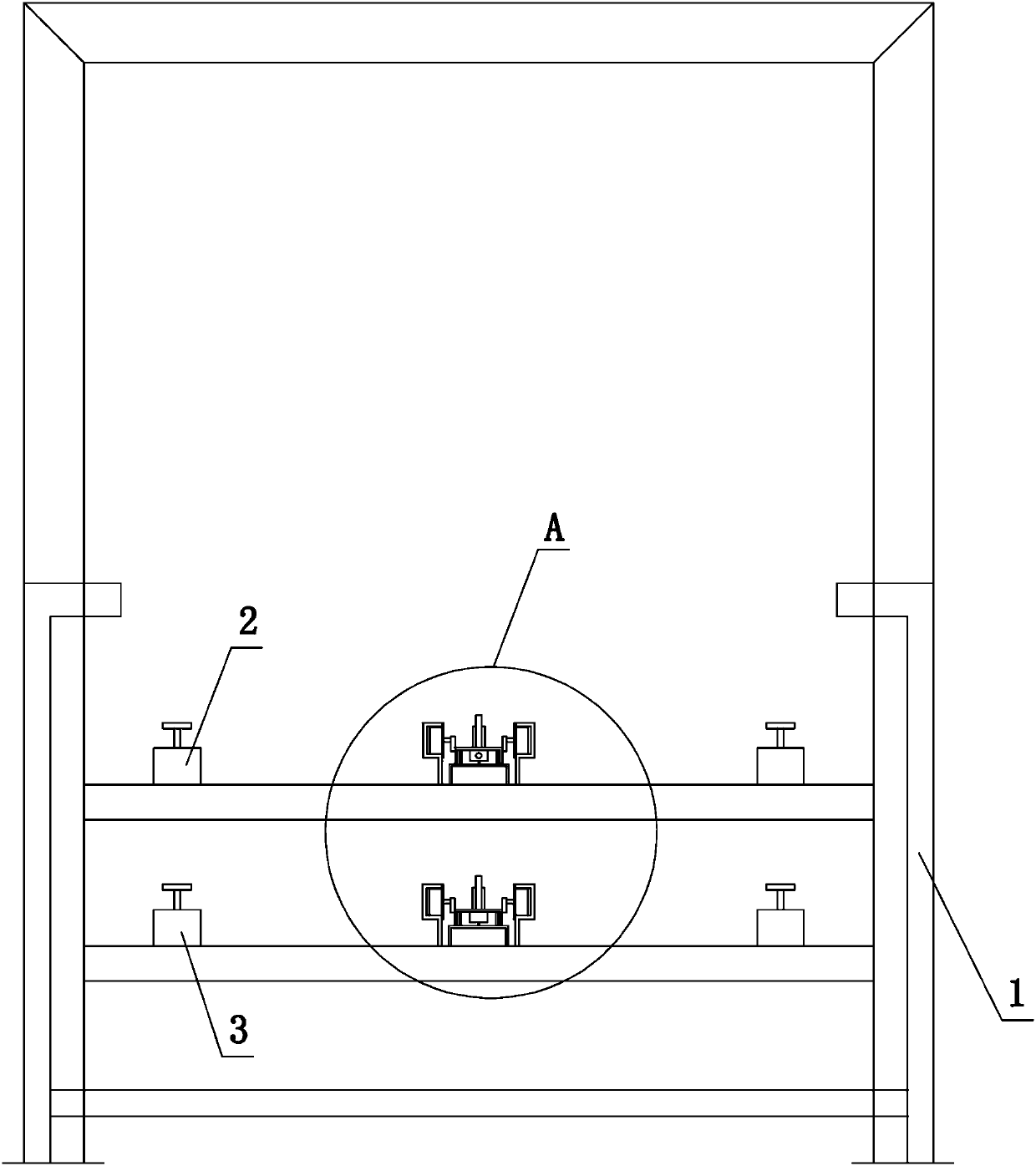

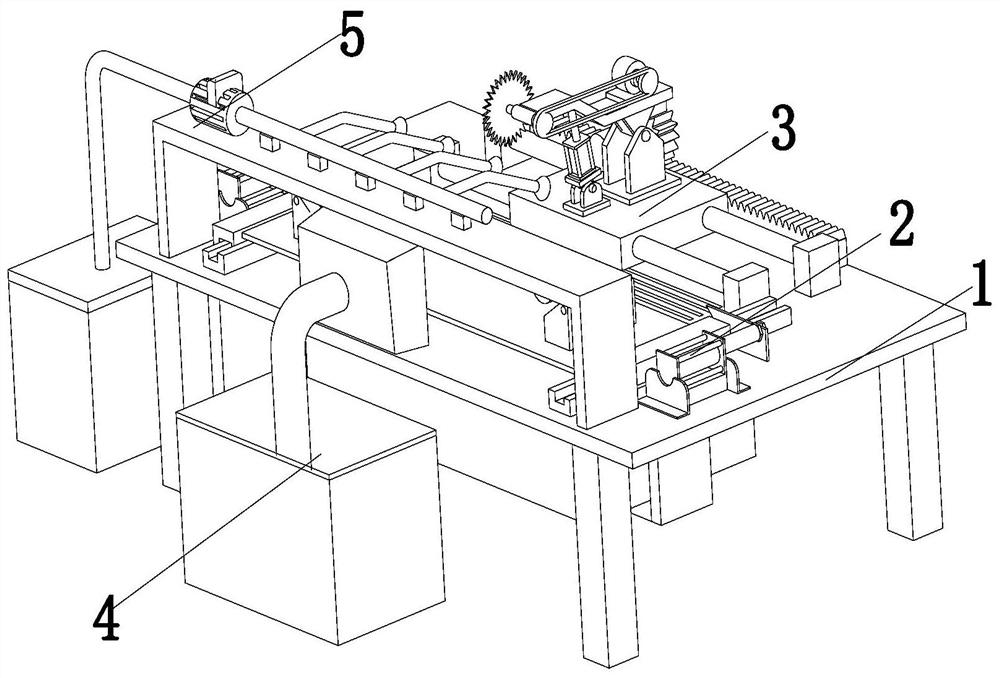

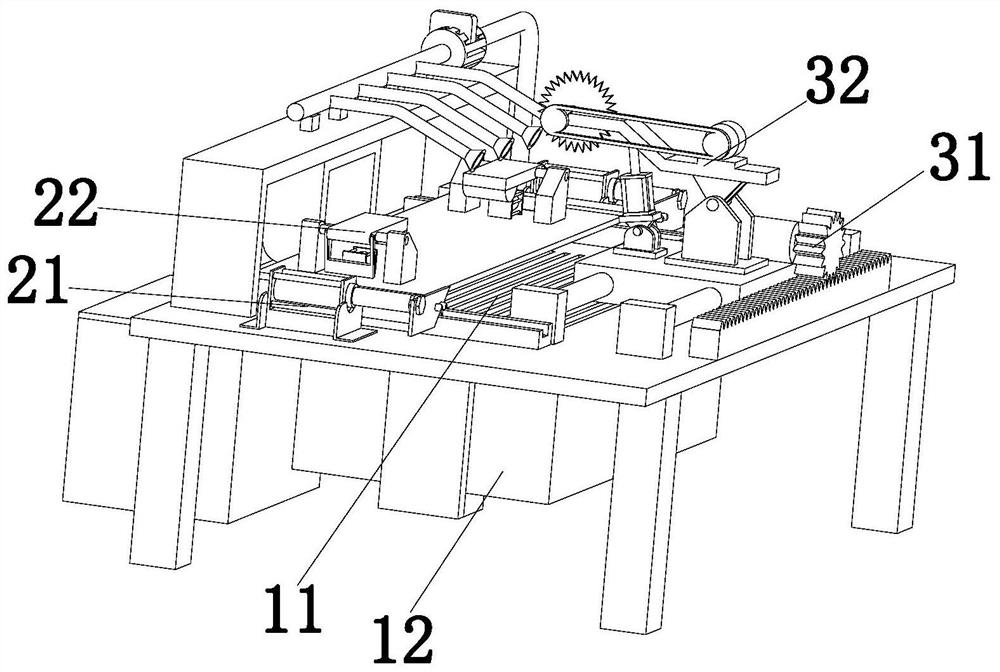

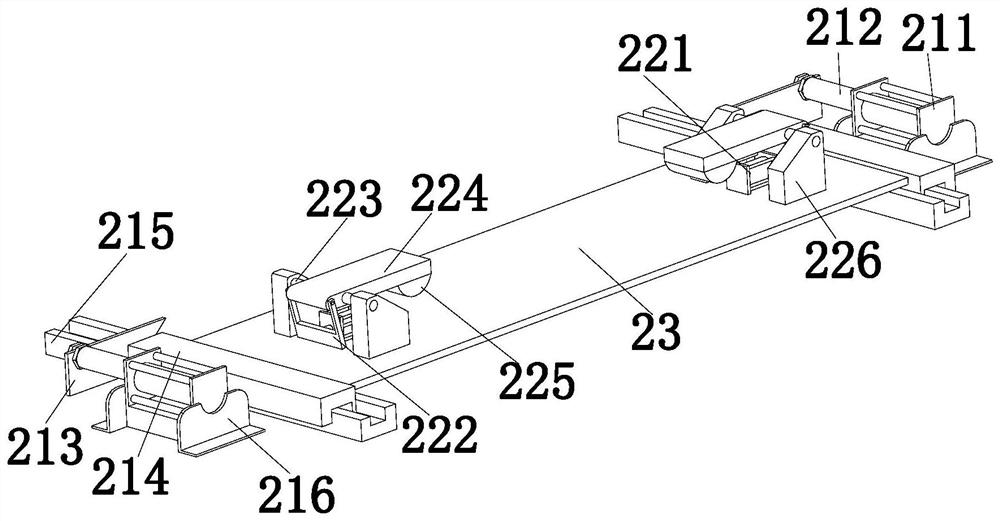

Automatic cutting device for bobbins and cutting method for automatic cutting device

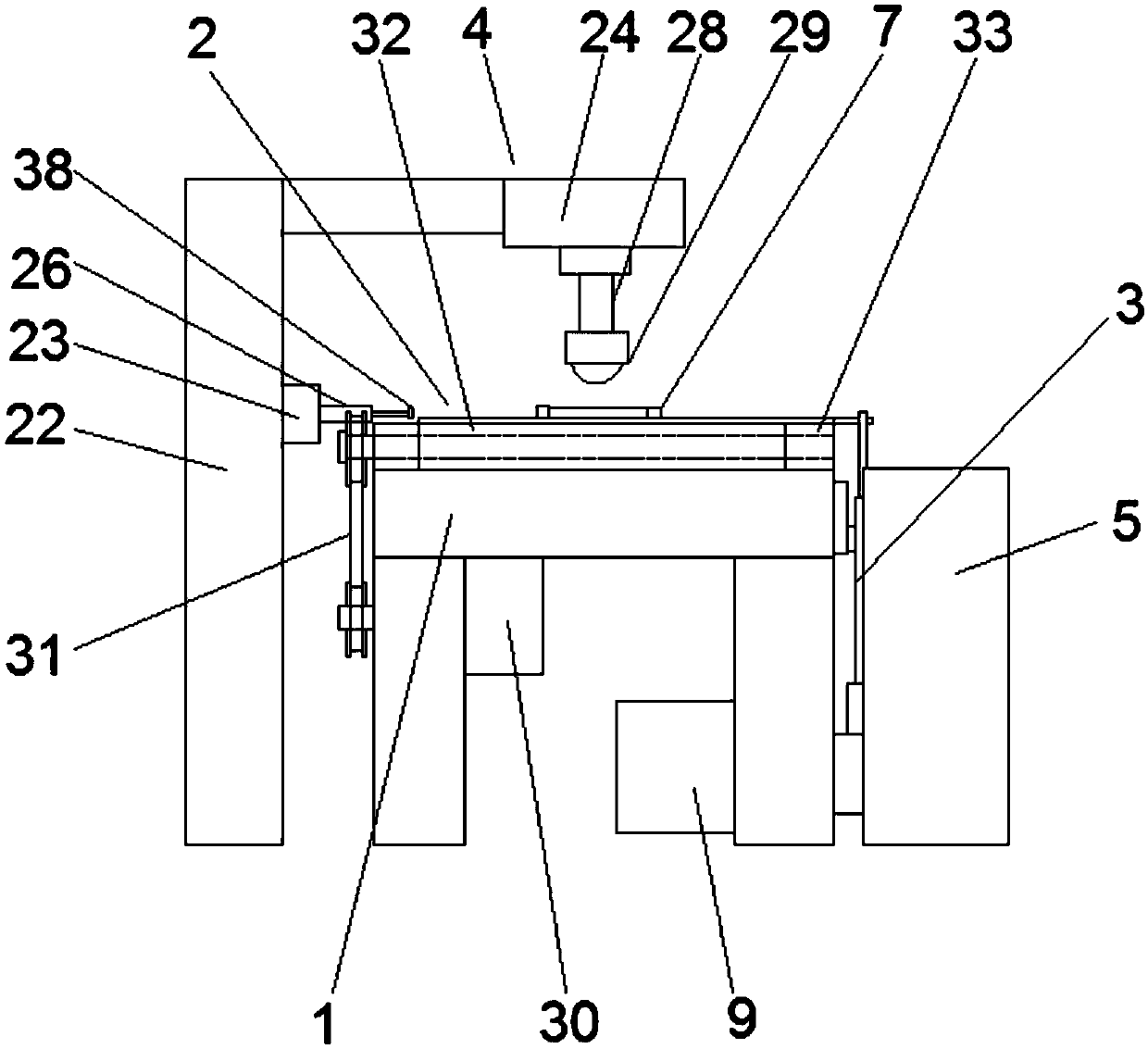

ActiveCN107877005ARealize fully automatic cuttingSmall sizeTextile disintegration and recoveryLaser beam welding apparatusBobbinStructural engineering

The invention discloses an automatic cutting device for bobbins. The automatic cutting device comprises a rack, wherein a loading axial supporting roller mechanism, a loading transverse feeding mechanism, a loading rotary feeding mechanism, a cutting mechanism, and an unloading floating mechanism are sequentially arranged on the rack; and a limiting baffle plate is arranged above the unloading floating mechanism. A cutting method for the automatic cutting device for the bobbins comprises the following steps of: putting to-be-cut bobbins onto the loading axial supporting roller mechanism, driving the bobbins to move forwards by the loading transverse feeding mechanism, and enabling the front ends of the bobbins to be in contact with the limiting baffle plate for limiting; and cutting the bobbins by a laser head of the cutting mechanism. With the adoption of the structure and the method, the automatic cutting device has the advantages that: firstly, bobbins of a gas storage tank are automatically cut, workpiece dimension is accurate, and workpiece cut is flat; secondly, working efficiency is improved, and a blank qualification rate is increased; and thirdly, self-adaptive feeding canbe performed for workpieces of different tube diameters.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

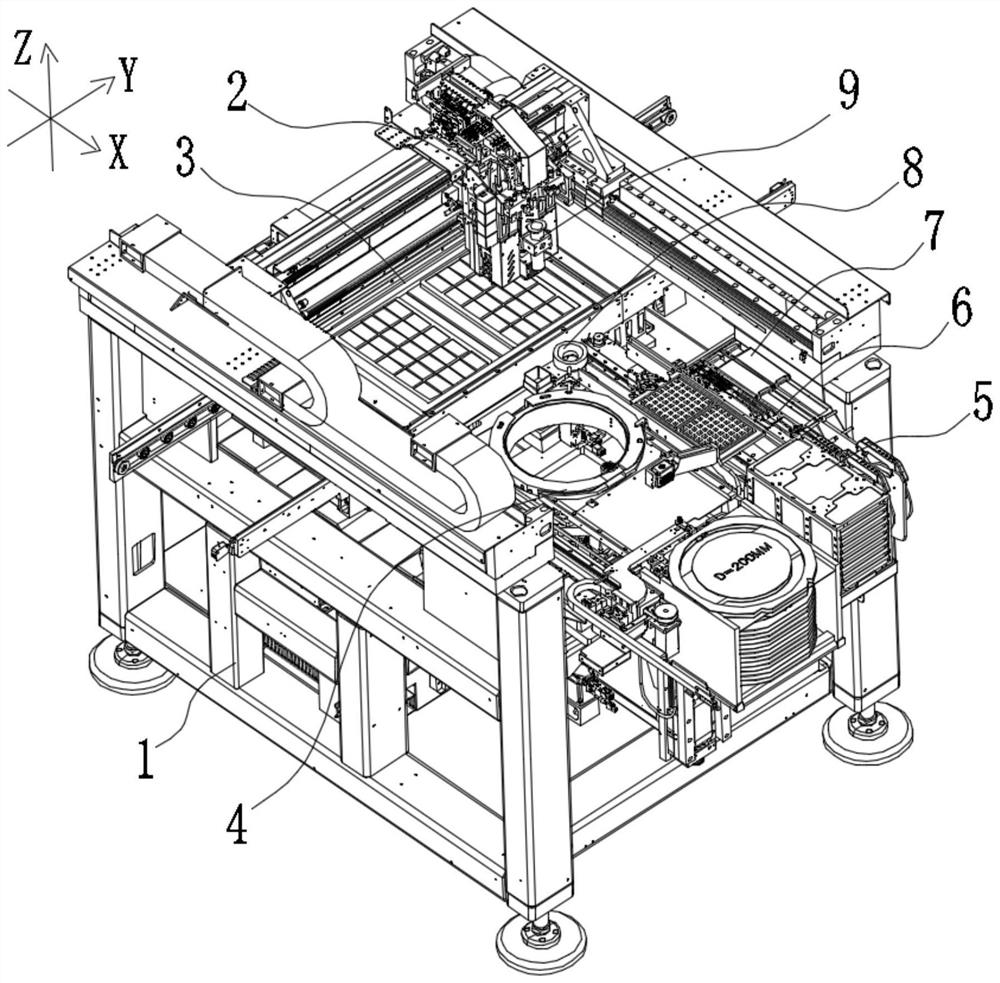

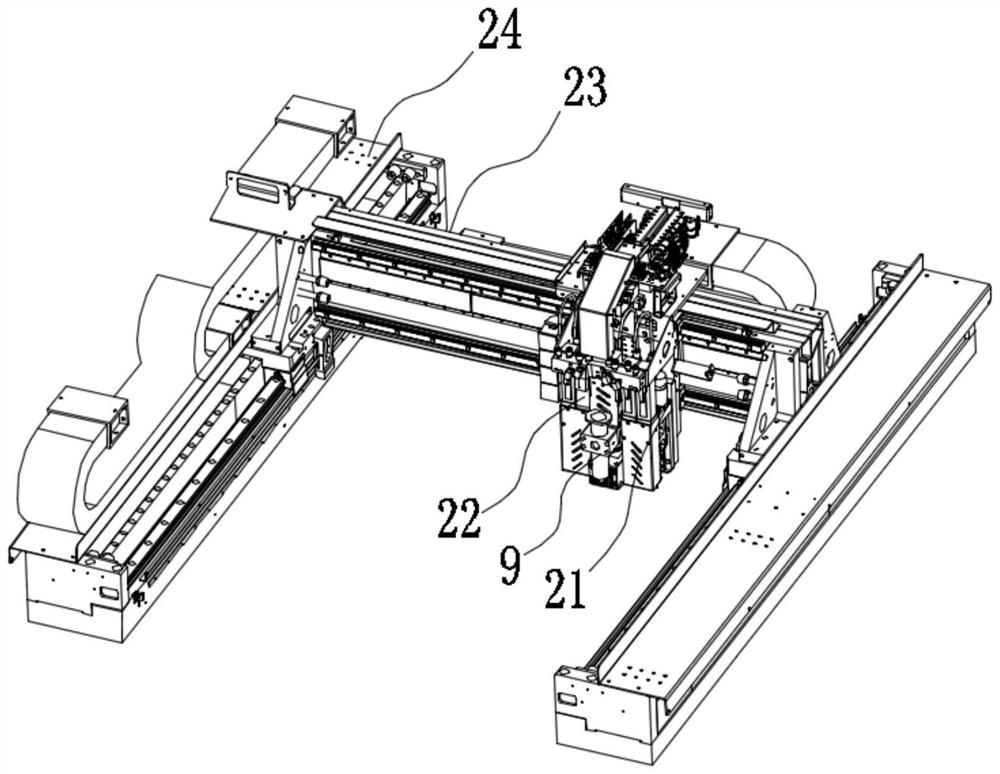

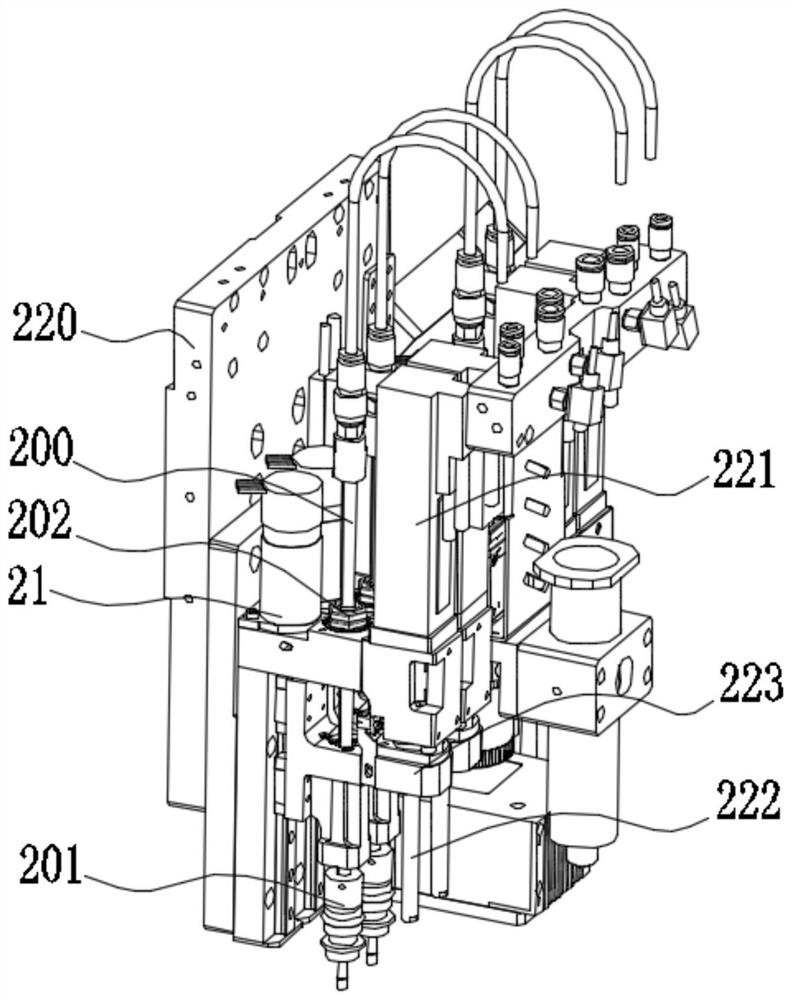

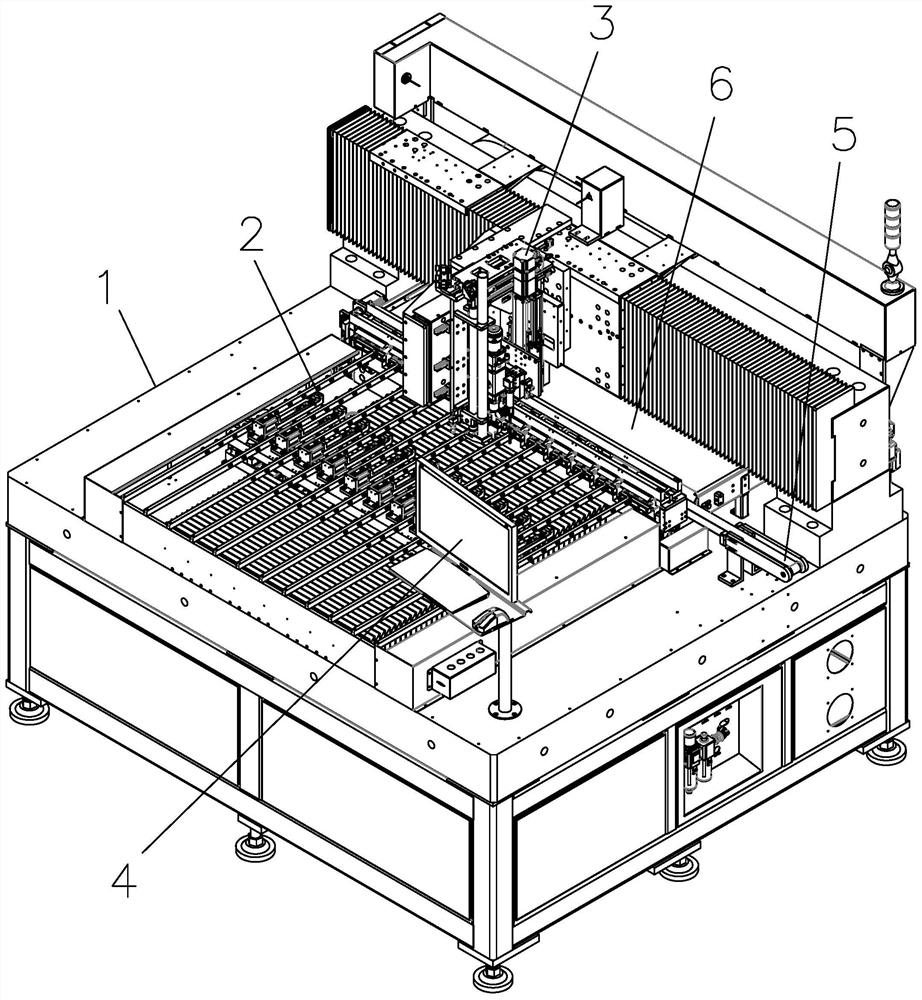

Full-automatic multifunctional IGBT packaging machine

PendingCN114464554ARealize fully automatic packagingIncrease productivitySemiconductor/solid-state device manufacturingWaferingElectronic component

The invention discloses a full-automatic multifunctional IGBT packaging machine which comprises a rack, a packaging mechanism, a jig disc conveying mechanism, a crystal ring feeding and jacking mechanism, a TRAY disc feeding mechanism, a component feeding mechanism and a soldering lug feeding and cutting mechanism. The soldering lug feeding and cutting mechanism is used for stretching a soldering lug roll and cutting a single soldering lug of which the length is equal to a preset soldering lug length; the packaging mechanism comprises an adsorption machine head, a machine head rotating assembly and a three-direction movement driving assembly. The IGBT packaging of the first wafer, the second wafer, the electronic component and the soldering lug can be compatible, multiple packaging devices do not need to be arranged, the overall structure is simplified, the production space is saved, and the production cost is reduced; meanwhile, full-automatic cutting of the soldering lug belt can be achieved, the manual participation degree is low, the automation degree is high, the cutting efficiency of the soldering lug is effectively improved, the single soldering lug with the fixed length can be cut according to the production requirement so as to meet different production requirements, and compatibility is high.

Owner:SHENZHEN BAOCHUANG ELECTRONICS EQUIP CO LTD

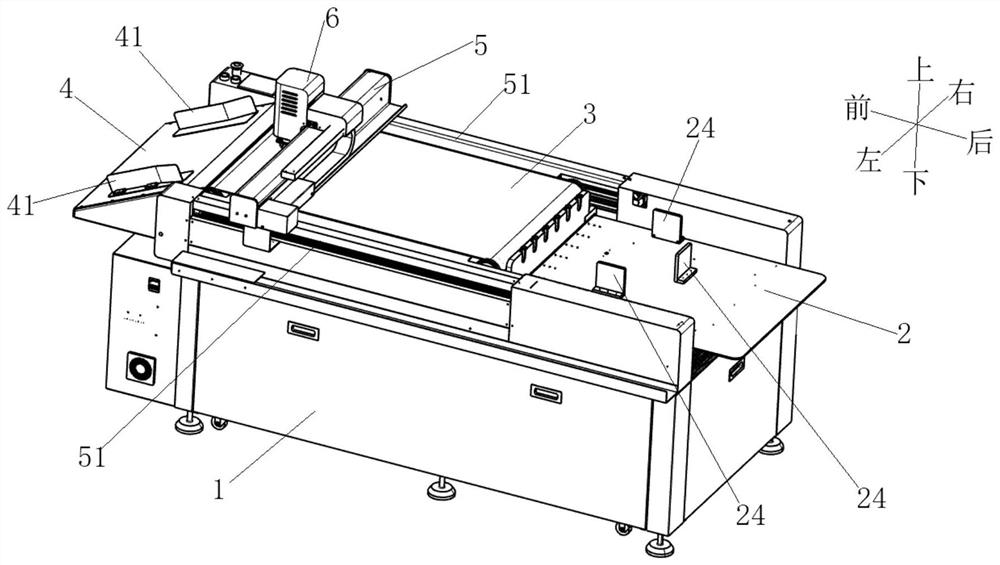

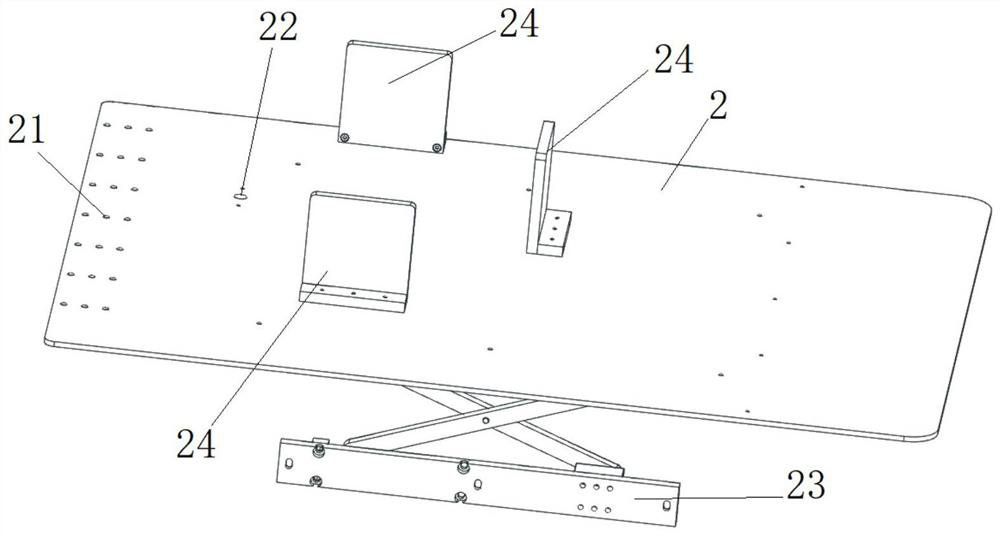

Paper feeding cutting machine

PendingCN112405688AIntegrity guaranteedRealize fully automatic cuttingMetal working apparatusArticle feedersTool bitEngineering

The invention provides a paper feeding cutting machine which comprises a rack. The rack is provided with a paper placing platform, a cutting table top, a material receiving hopper and a cross beam. Linear guide rails are arranged on the two sides of the rack, the cross beam is connected with the linear guide rails, and a machine head is arranged on the cross beam. The machine head comprises a fixing plate, a tool rest, a cutting part, a machine head lifting mechanism and a machine head rotating mechanism. A tool rest guide rod is arranged on the fixing plate, the tool rest is connected with the tool rest guide rod, and the machine head lifting mechanism is connected with the tool rest and used for driving the tool rest to ascend and descend. The cutting part comprises at least two tool bitassemblies. The tool bit assemblies are installed on the tool rest, and the machine head rotating mechanism is connected with the tool bit assemblies and used for driving the tool bit assemblies to rotate. According to the paper feeding cutting machine, the tool bit assemblies are controlled to rotate through the machine head rotating mechanism, the angle of the tool bit assemblies is adjusted atany time according to set cutting lines, the generated cutting lines are flawless, and the integrity of cut patterns is guaranteed.

Owner:NINGBO JINGWEI SYSTEMTECHNIK LTD

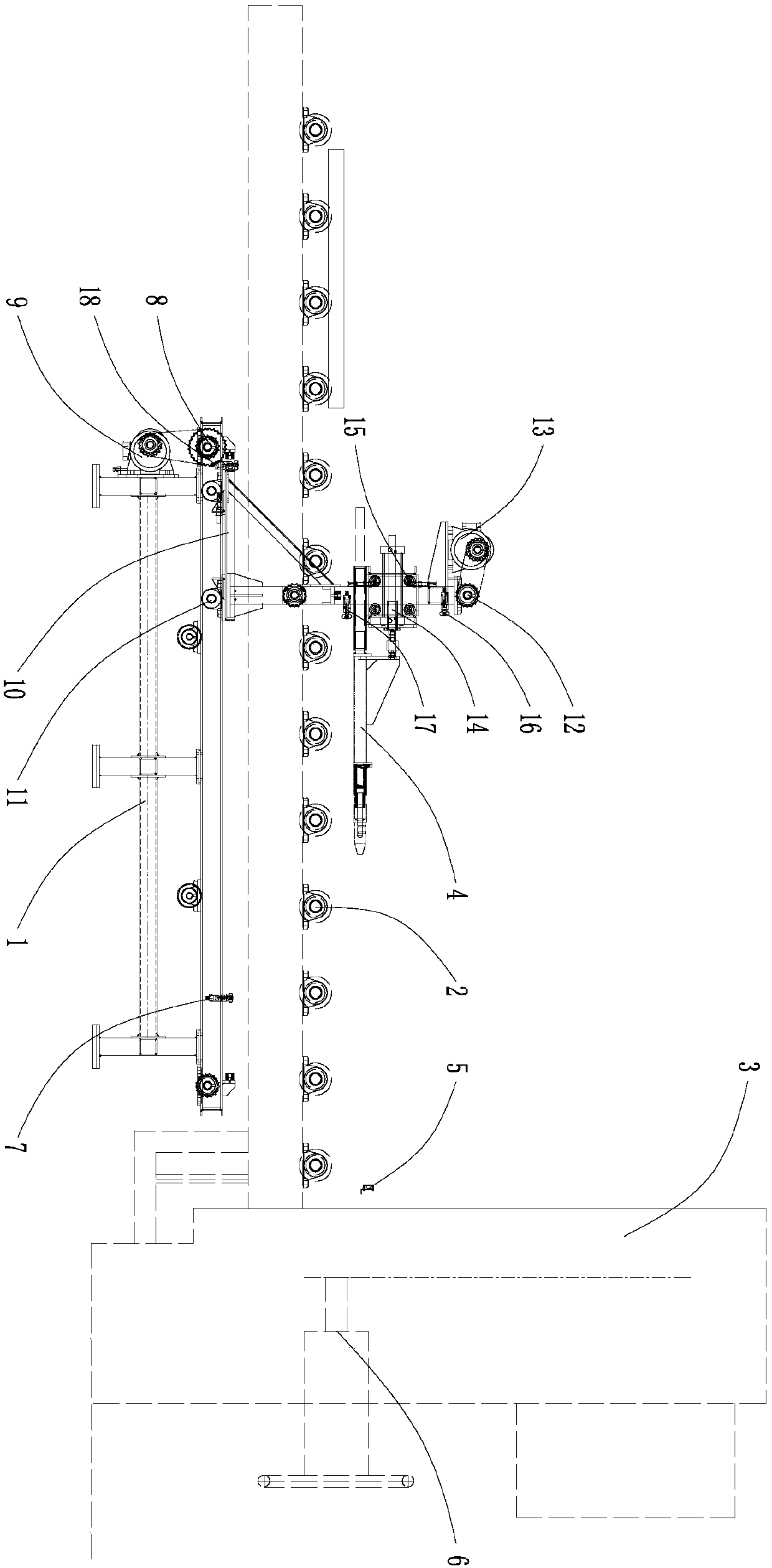

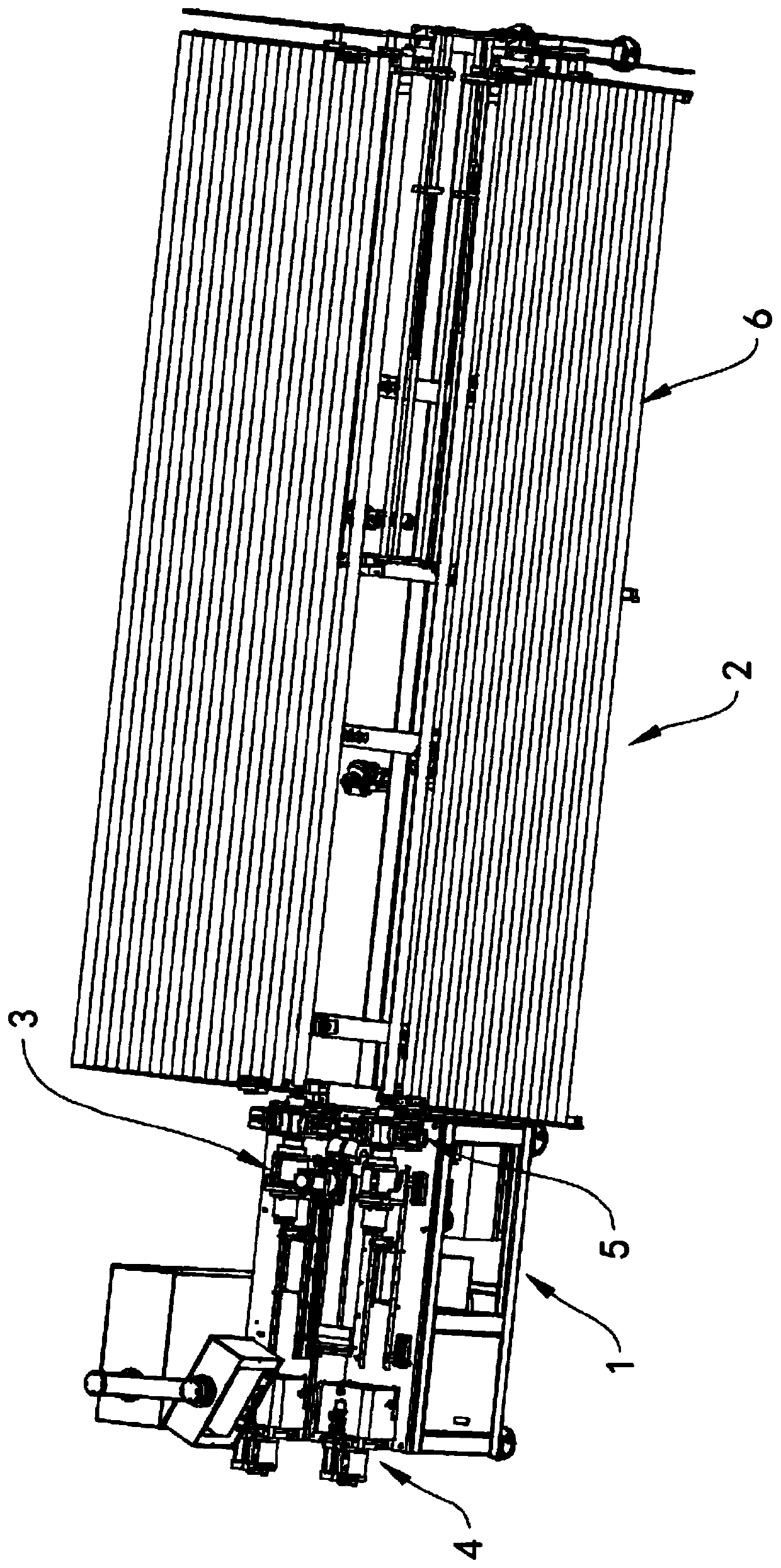

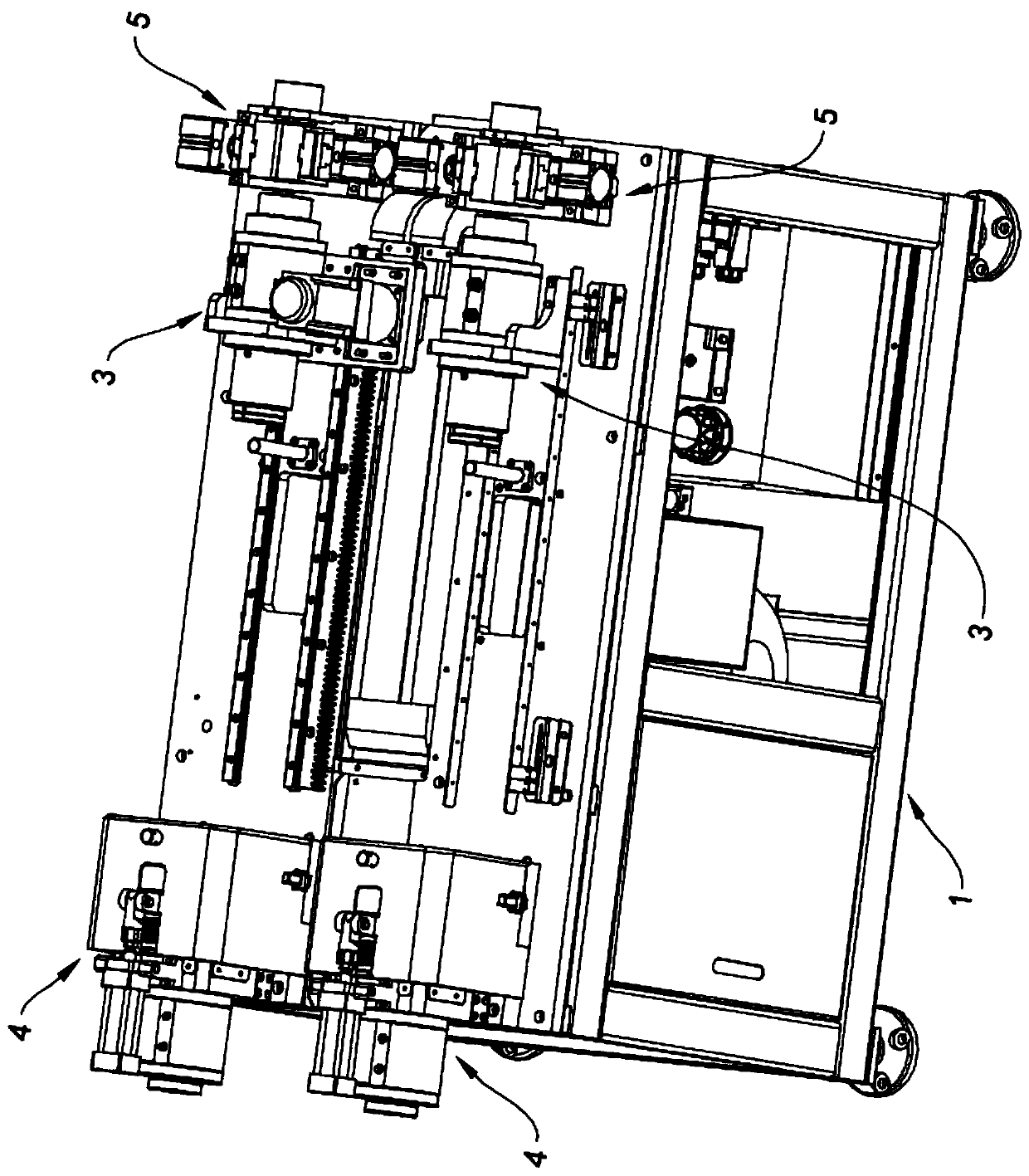

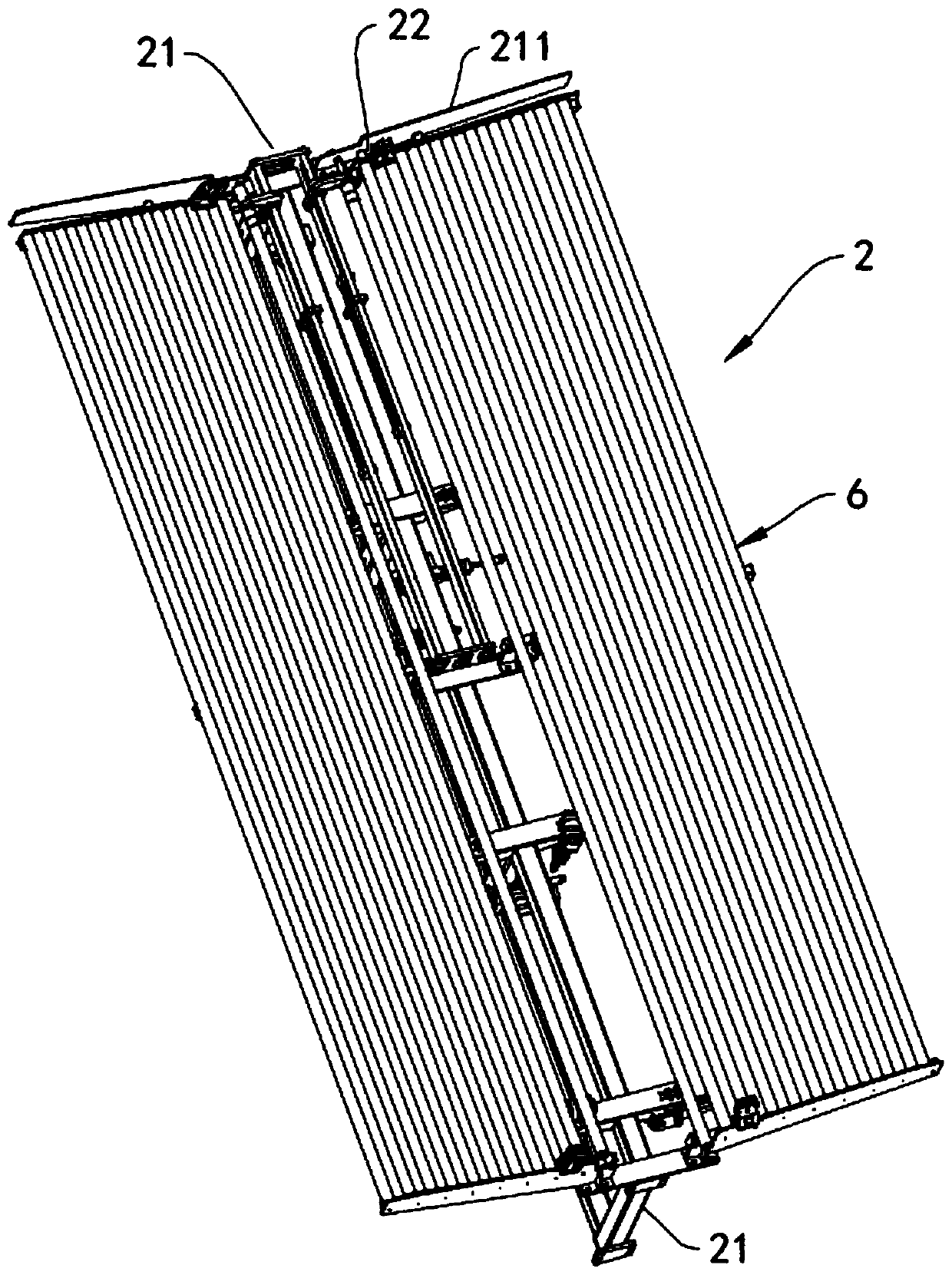

Panel cutting, slotting and trimming production line

PendingCN109986643ARealize fully automatic cuttingIncrease productivityMetal working apparatusManufacturing cost reductionProduction line

The invention discloses a panel cutting, slotting and trimming production line which comprises a control system, a loading device, a conveying device, a discharging device, a horizontal cutting device, a longitudinal cutting device and a slotting and trimming device. The loading device, the conveying device and the discharging device are in electronic control connection with the control system; the horizontal cutting device, the longitudinal cutting device and the slotting and trimming device are in electronic control connection with the control system; and the loading device, the horizontal cutting device, the longitudinal cutting device, the slotting and trimming device and the discharging device are arranged sequentially from front to back according to a production process and are connected through the conveying device. According to the panel cutting, slotting and trimming production line provided by the invention, a panel can be full-automatically cut, slotted and trimmed so as tobe formed at a time, so that the product production efficiency is improved, and the manufacturing cost is reduced.

Owner:广大住品科技发展有限公司

Special clamp for circular saw cutting machine

InactiveCN102962717ARealize fully automatic cuttingReduce wasteMetal working apparatusCircular sawEngineering

The invention discloses a special clamp for a circular saw cutting machine. The special clamp comprises a rack as well as an inner clamp and an outer clamp which are mounted on the rack, wherein the inner clamp and the outer clamp are respectively positioned on the upstream and the downstream of the circular saw cutting machine; the inner clamp comprises an inner fixed clamp mouth and an inner movable clamp mouth; the inner fixed clamp mouth is fixed on the rack; the inner movable clamp mouth is driven by an inner movable clamp mouth power device to be matched with the inner fixed clamp mouth to clamp sections conveyed from the upstream from two sides; the outer clamp comprises an outer clamp work platform, an outer fixed clamp mouth and an outer movable clamp mouth; the outer clamp work platform is mounted on the rack in the conveying direction of the sections in a sliding manner and is driven by an outer clamp power device; the outer fixed clamp mouth is fixed to the outer clamp work platform; the outer movable clamp mouth is mounted to the outer clamp work platform in a sliding manner; the sliding direction of the outer movable clamp mouth is perpendicular to the conveying direction of the sections; and the outer movable clamp mouth is driven by the outer movable clamp mouth power device. According to the special clamp, the full automatic cutting of the circular saw cutting machine is realized, the input of labor force and equipment is reduced, the manual mistaken operation is avoided and the tailing is fully utilized.

Owner:SUZHOU KINKALTECK MACHINERY TECH

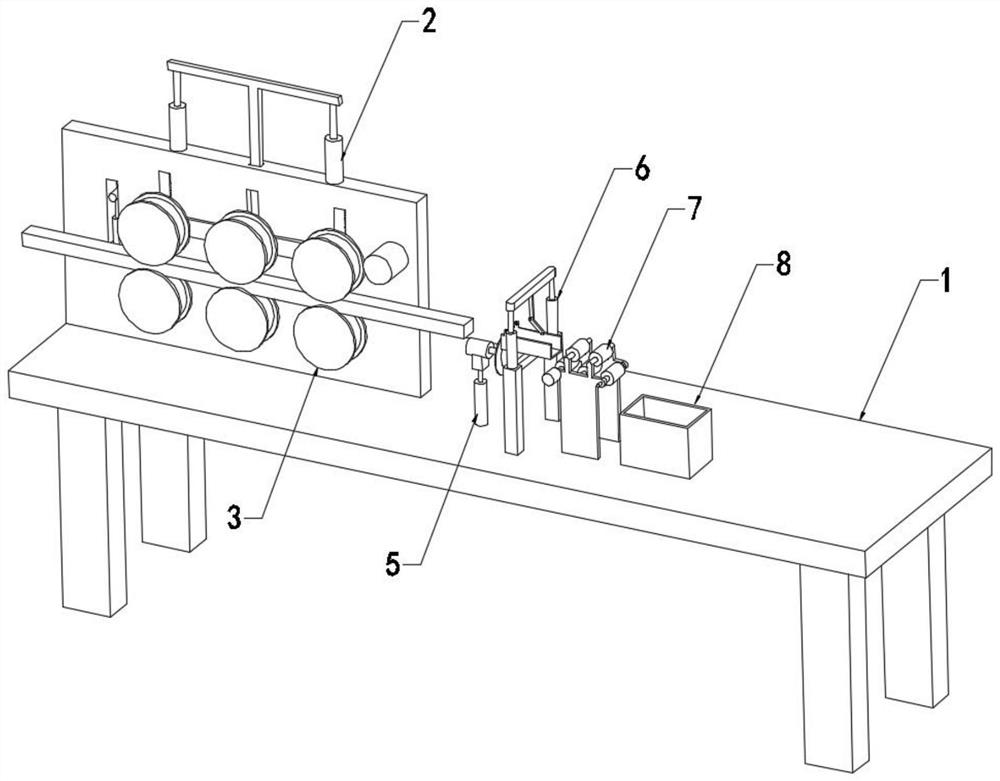

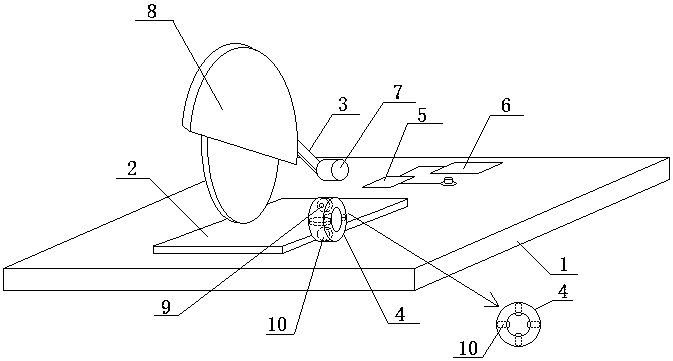

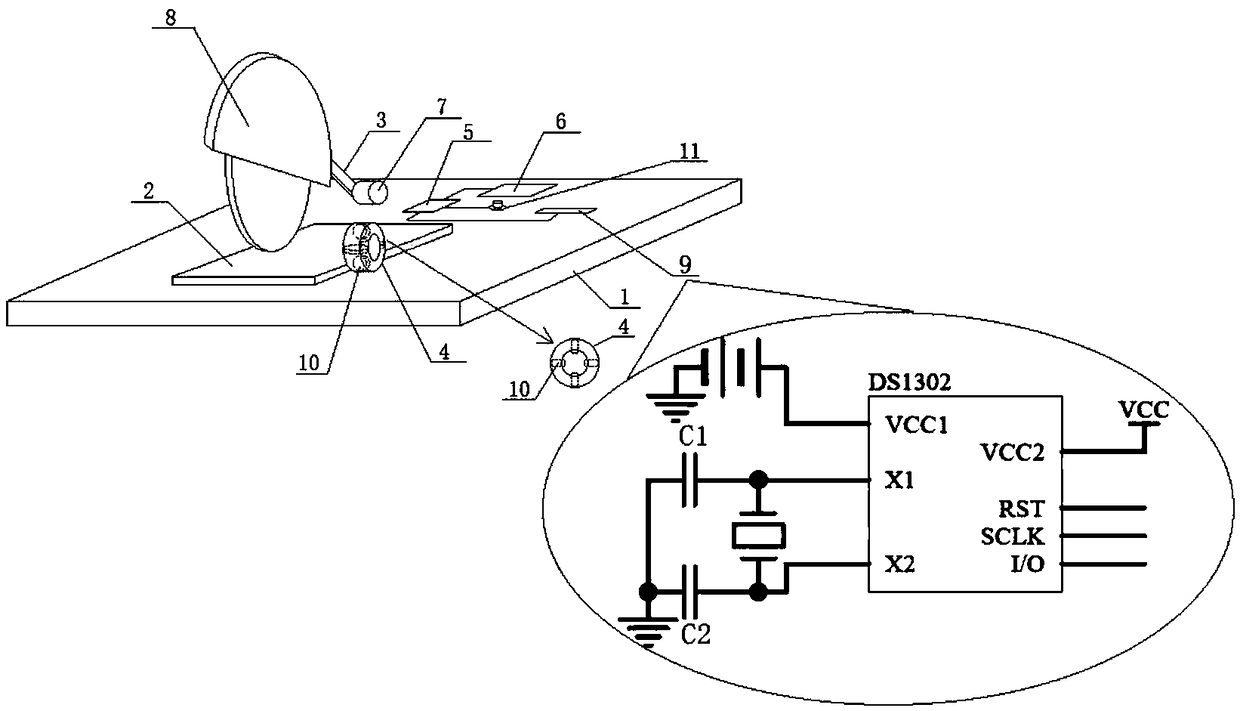

Platform type wire harness cutting machine

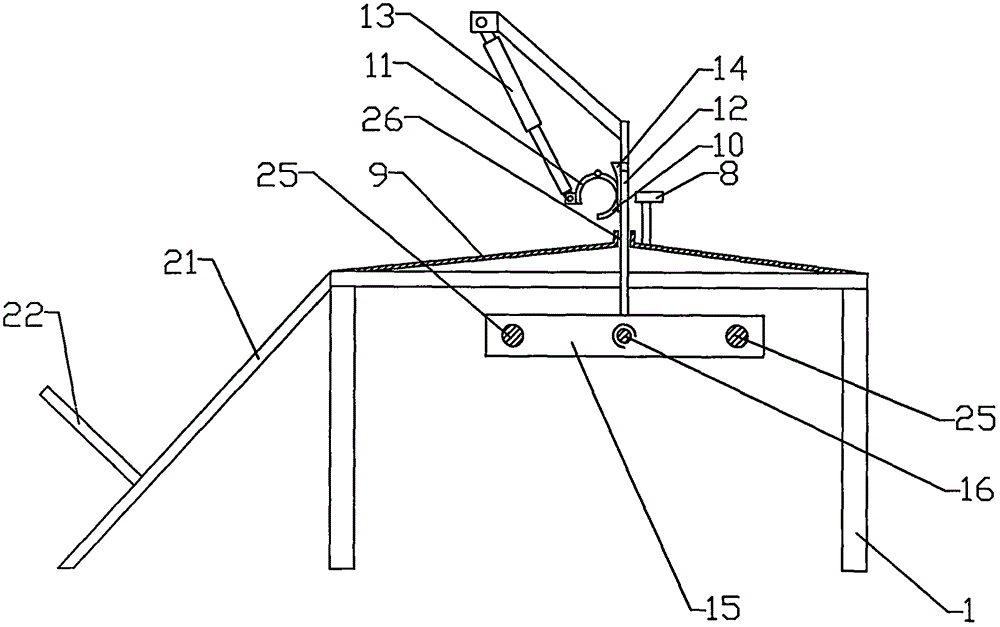

ActiveCN107457335AImprove cutting efficiencyRealize fully automatic cuttingEngineeringIntelligent control

The invention relates to a platform type wire harness cutting machine. The platform type wire harness cutting machine adopted the design of a brand new structure. A mechanical-electronic hybrid electronic control structure is introduced. Based on application of an electronic control rotary cutter disk (8), a wire harness is clamped and fixed through a clamping sleeve (4) internally provided with electronic control driving wheels (10) and conveyed to the electronic control rotary cutter disk (8). The full-automatic cutting process is realized. A rotational speed sensor (9) is introduced for the electronic control driving wheels (10). According to the perimeter of the electronic control driving wheels (10) and the distance from the point, making contact with the upper surface of a heightening plate (2), of the electronic control rotary cutter disk (8) to the clamping sleeve (4), the length of a wire harness passing the point of the cutter disk making contact with the upper surface of the heightening plate (2) is acquired in real time. Thus, intelligent control over a rotation motor for controlling the cutting action of the electronic control rotary cutter disk (8) is realized. The wire harness is cut accurately. The cutting efficiency of the wire harness can be effectively improved.

Owner:南通北外滩建设工程有限公司

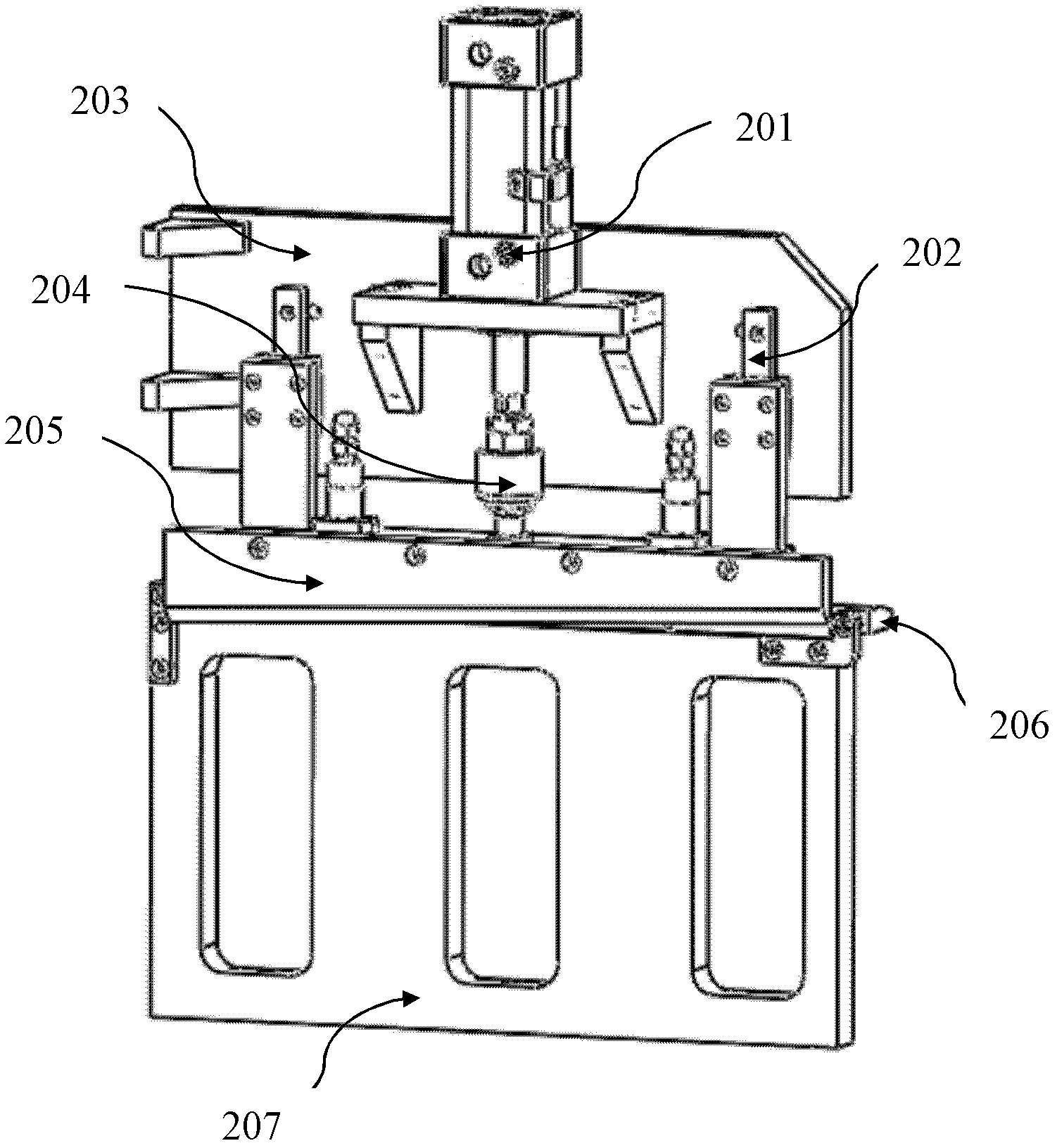

Full-automatic transverse and vertical cutting device for furniture decoration veneer

InactiveCN108058199ARealize fully automatic cuttingMetal working apparatusWebs handlingHydraulic cylinderEngineering

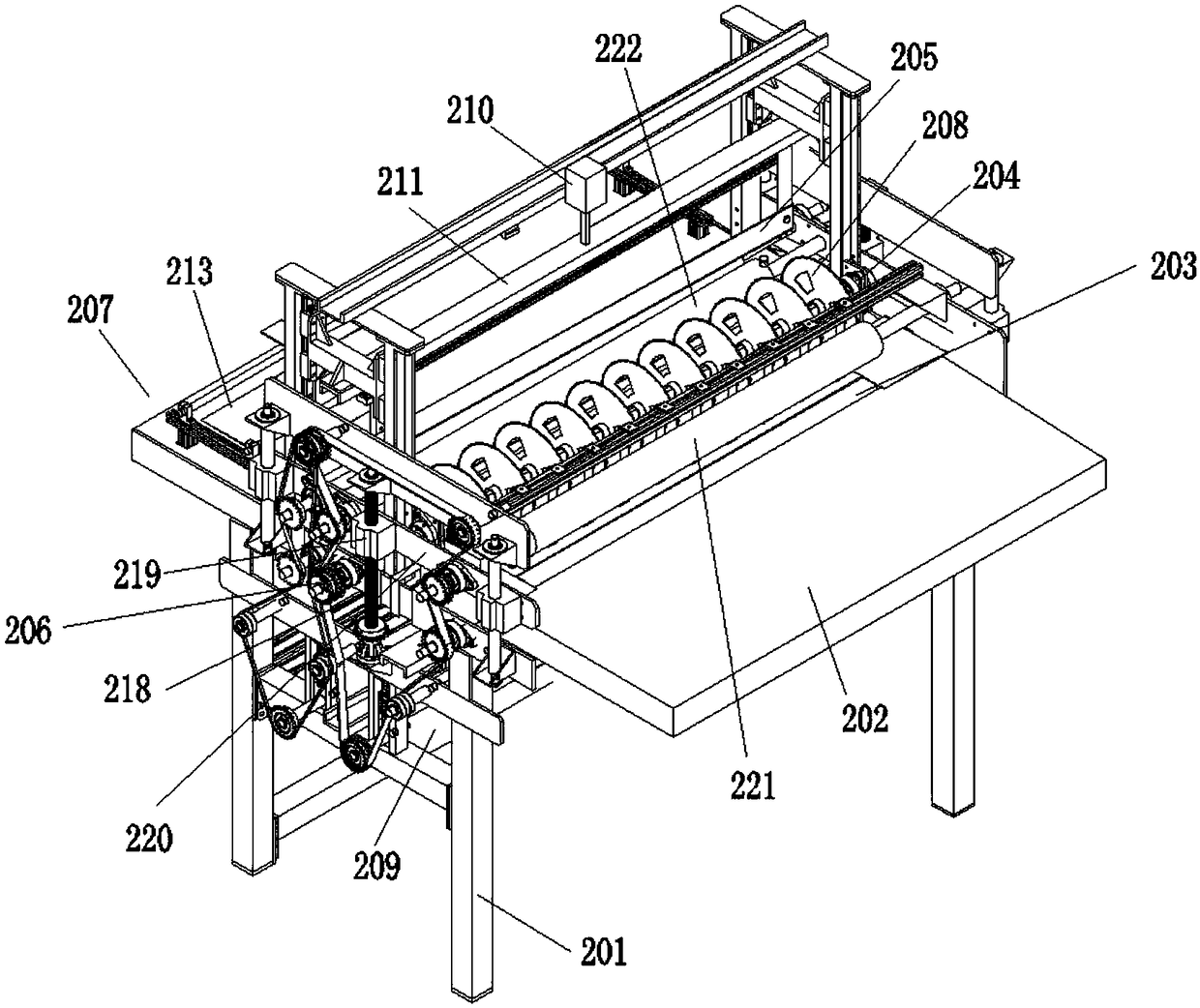

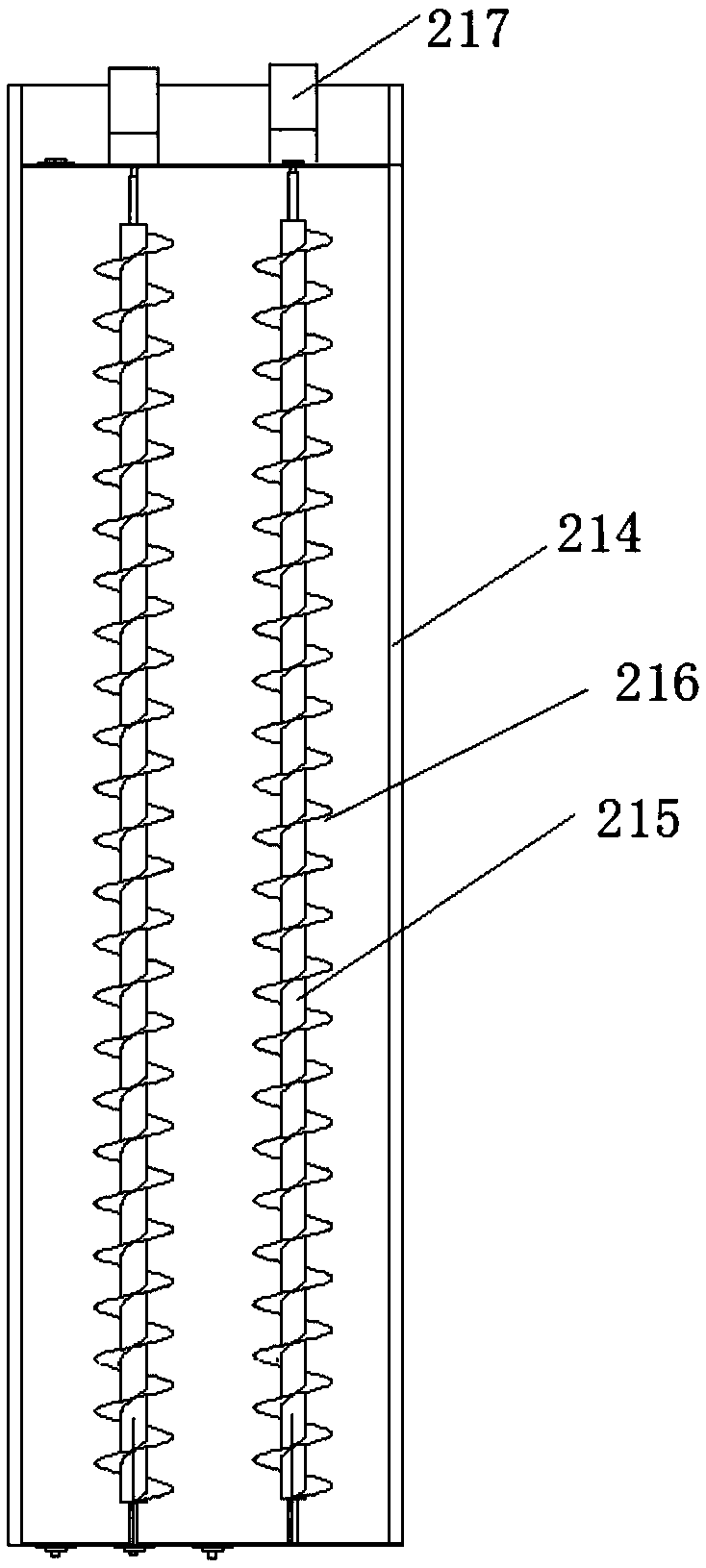

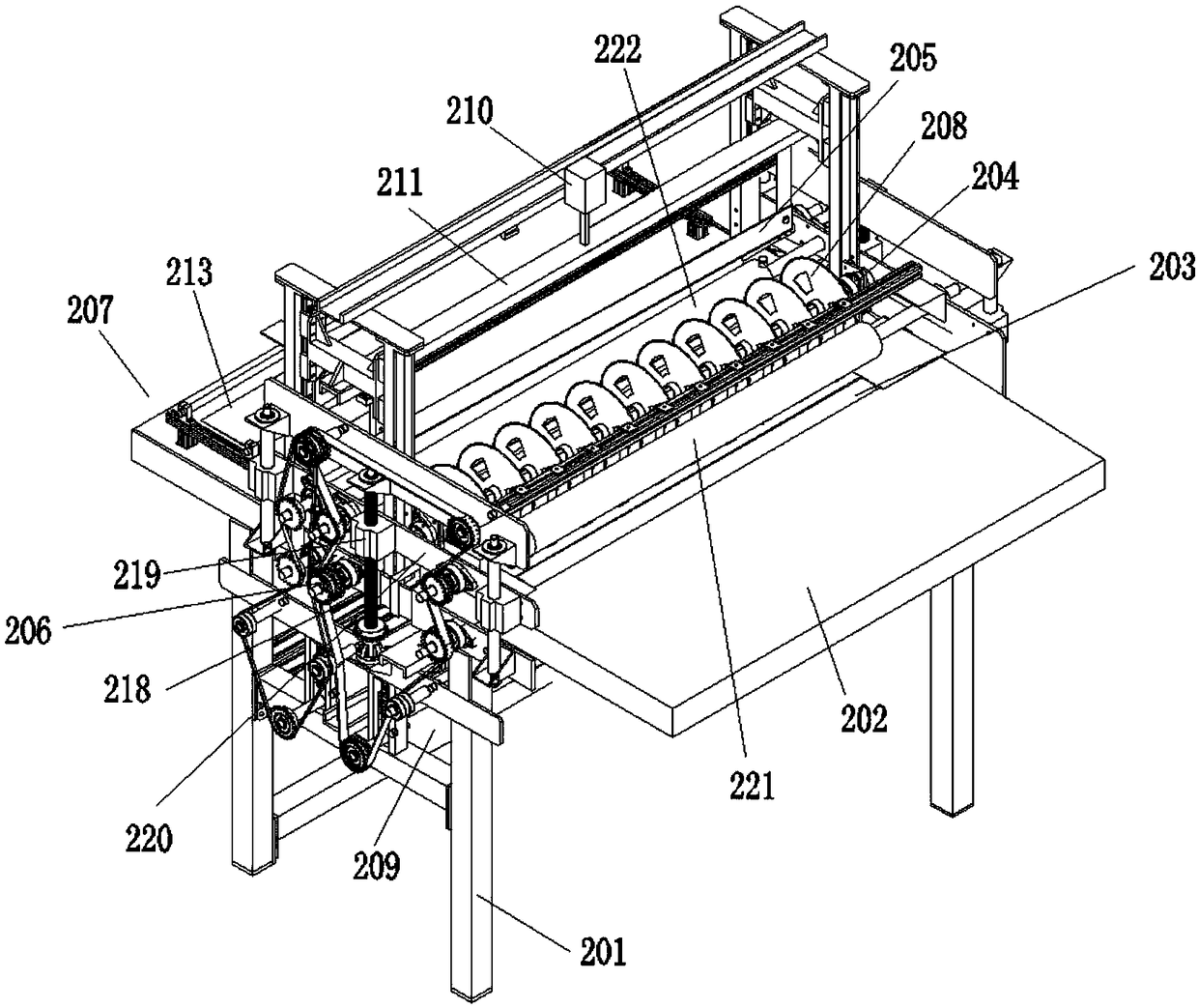

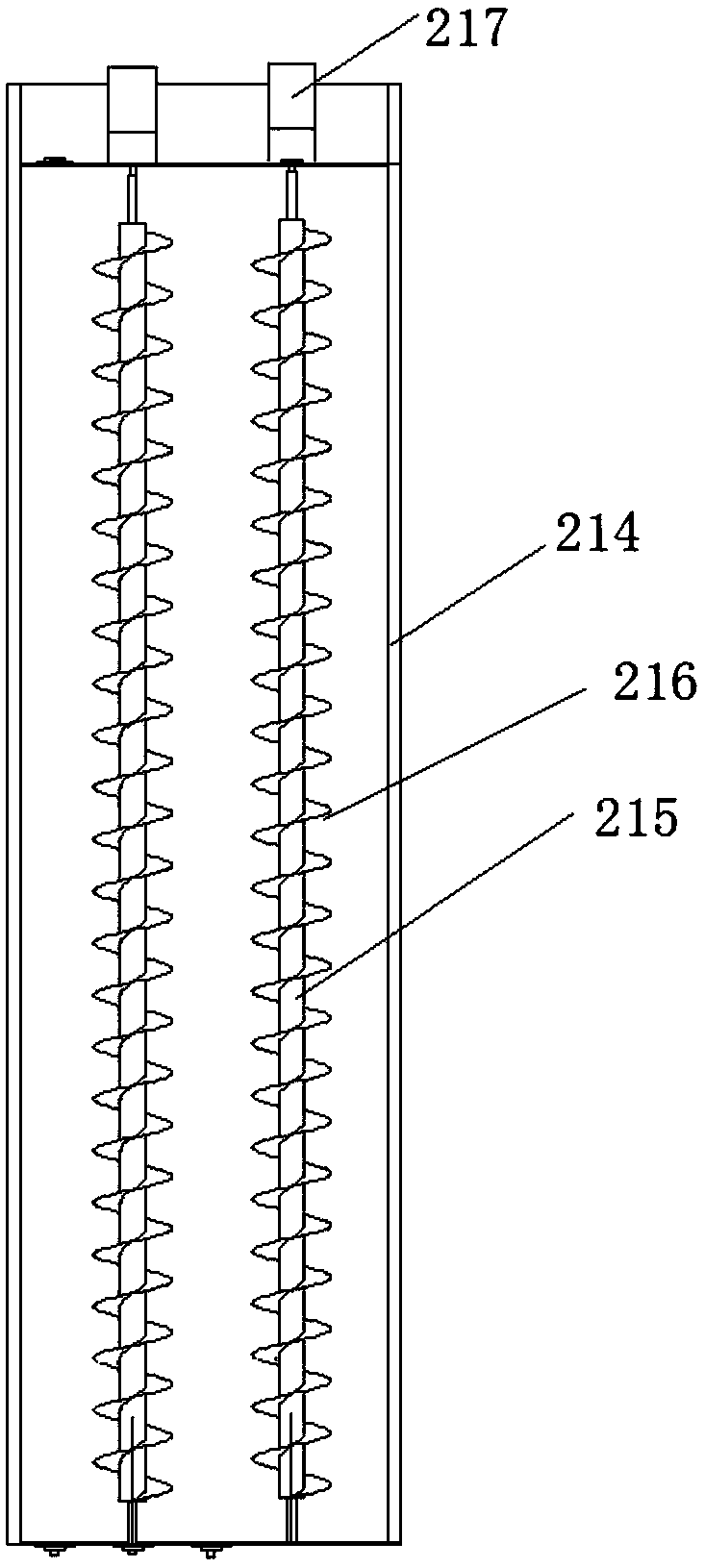

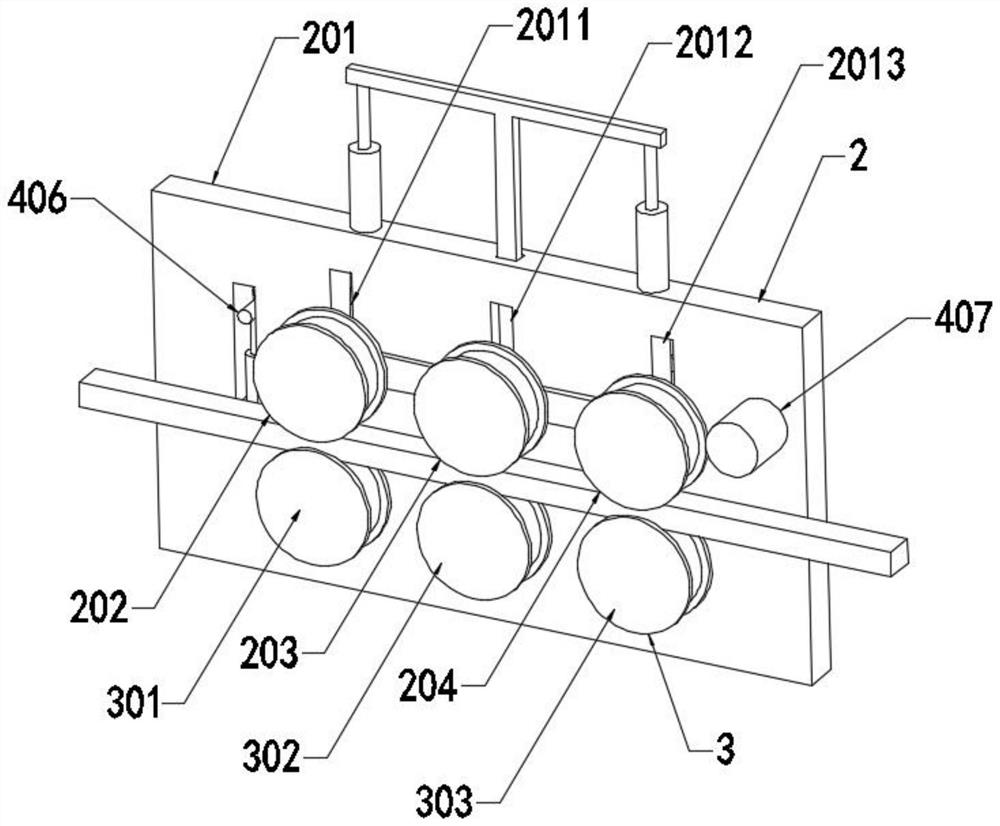

The invention discloses a full-automatic transverse and vertical cutting device for a furniture decoration veneer. The full-automatic transverse and vertical cutting device comprises a rack (201), wherein the rack (201) is provided with a feeding platform (202), a feeding roller (203), a vertical cutting shaft (204), a transverse smashing and pressing sheet (205), a discharging roller (206) and adischarging opening (207) in sequence along a feeding direction of materials; the vertical cutting shaft (204) is provided with a vertical cutting blade group (208); a motor (209) is arranged at the bottom of the rack (201); the motor (209) is connected with the a feeding roller (203), the vertical cutting shaft (204) and the discharging roller (206) through a chain; a hoisting hydraulic cylinder(210) is arranged above the rack (201); a stretching-out end of the hoisting hydraulic cylinder (210) is connected with a transverse smashing framework (211); a transverse smashing blade (205) is fixed at the bottom of the transverse smashing framework (211).

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Cutting mechanism for furniture decorating veneers

InactiveCN108145804ARealize fully automatic cuttingMulti-purpose machinesBark-zones/chip/dust/waste removalEngineeringMechanical engineering

The invention discloses a cutting mechanism for furniture decorating veneers. The cutting mechanism comprises a rack (201). The rack (201) is sequentially provided with a feeding table (202), a feeding roller (203), a vertical cutting shaft (204), a transverse smashing and pressing sheet (205), a discharging roller (206) and a discharging opening (207) in the feeding direction of materials. The vertical cutting shaft (204) is provided with a vertical cutting blade set (208). A motor (209) is arranged on the bottom of the rack (201). The motor (209) is connected with the feeding roller (203), the vertical cutting shaft (204) and the discharging shaft (206) through a chain. The cutting mechanism can cut the veneers fully automatically, efficiency is high, the cutting effect is good, and lesslabor is used.

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Full-automatic grooving machine

InactiveCN106393237AHigh grooving precisionHigh grooving efficiencyMetal working apparatusHigh volume manufacturingPulp and paper industry

The invention provides a full-automatic grooving machine. The full-automatic grooving machine comprises a rack. A guide barrel is arranged at one end of the rack. Cutters are arranged on the lateral portion of the guide barrel. The guide barrel is provided with through grooves for accommodating the cutters, and the cutters penetrate through the through grooves and are located inside the guide barrel. The full-automatic grooving machine realizes full-automatic cutting of paper tubes, is high in cutting precision, and realizes volume production of paper tubes, and the production efficiency is greatly improved.

Owner:张小良

Hot shearing equipment for round steel

PendingCN109513977ARealize fully automatic cuttingImprove shear efficiencyShearing machinesShearing machine accessoriesElectrical and Electronics engineeringControl unit

The invention discloses hot shearing equipment for round steel. The hot shearing equipment for the round steel comprises a rack, feeding rolls, a hot shearing mechanism, a translation mechanism capable of being movably arranged on the rack in the length direction of the round steel, a material pushing mechanism which is arranged on the translation mechanism in a lifting mode and provided with a pushing rod, an incoming material sensor, a control unit and an abutting sensor; the incoming material sensor is used for sending a first signal to the control unit when the round steel passes through the incoming material sensor, and the control unit is used for controlling the pushing rod to fall to the height equal to that of the round steel and controlling the translation mechanism to achieve translation to enable the pushing rod to push the round steel to enter the hot shearing mechanism; the abutting sensor is used for sending a second signal to the control unit when the round steel abutsagainst the abutting sensor, and the control unit is used for controlling the translation mechanism to stop and further used for controlling the hot shearing mechanism to act; and the abutting sensoris used for stopping sending the second signal to the control unit when the round steel does not abut against the abutting sensor, and the control unit is used for controlling the translation mechanism to achieve translation towards the hot shearing mechanism and further used for controlling the hot shearing mechanism to reset. According to the hot shearing equipment for the round steel, the shearing efficiency is high, and the safety and the reliability are achieved.

Owner:JIANGSU YUTE WEAR RESISTANT TECH CO LTD

Straight pipe chip-free cutting machine

InactiveCN109732142ASimple structureRealize fully automatic cuttingTube shearing machinesShearing machine accessoriesStraight tubeCopper

The invention discloses a straight pipe chip-free cutting machine. The straight pipe chip-free cutting machine comprises a machine table, a feeding device arranged on one side of the machine table, aclamping and feeding device which is arranged on the machine table and is provided with a feeding end surface facing the discharging end of the feeding device, and a cutting device arranged on the machine table and at the discharge end of the clamping and feeding device. The straight pipe chip-free cutting machine is simple in structure, the problem that final tail material portion is too long when an existing cutting machine cuts a pipe is solved by changing the structure of the clamping and feeding device, so that the copper pipe can be automatically cut completely, and the production efficiency is improved.

Owner:白尊敏

Full-automatic cement brick cutting machine

InactiveCN105856400ARealize fully automatic cuttingImprove yieldAuxillary shaping apparatusBrickEngineering

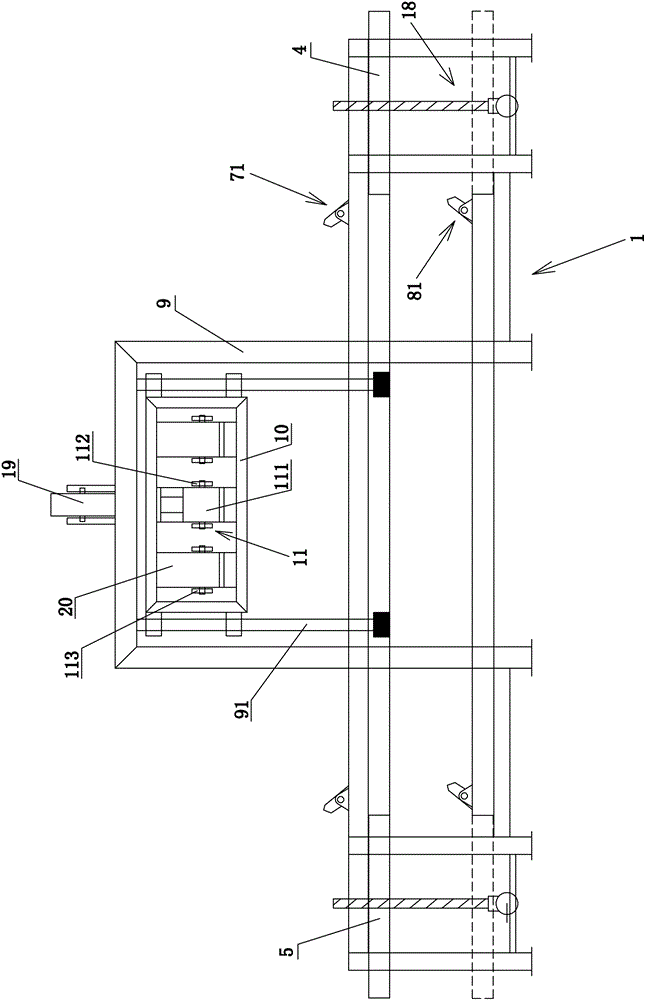

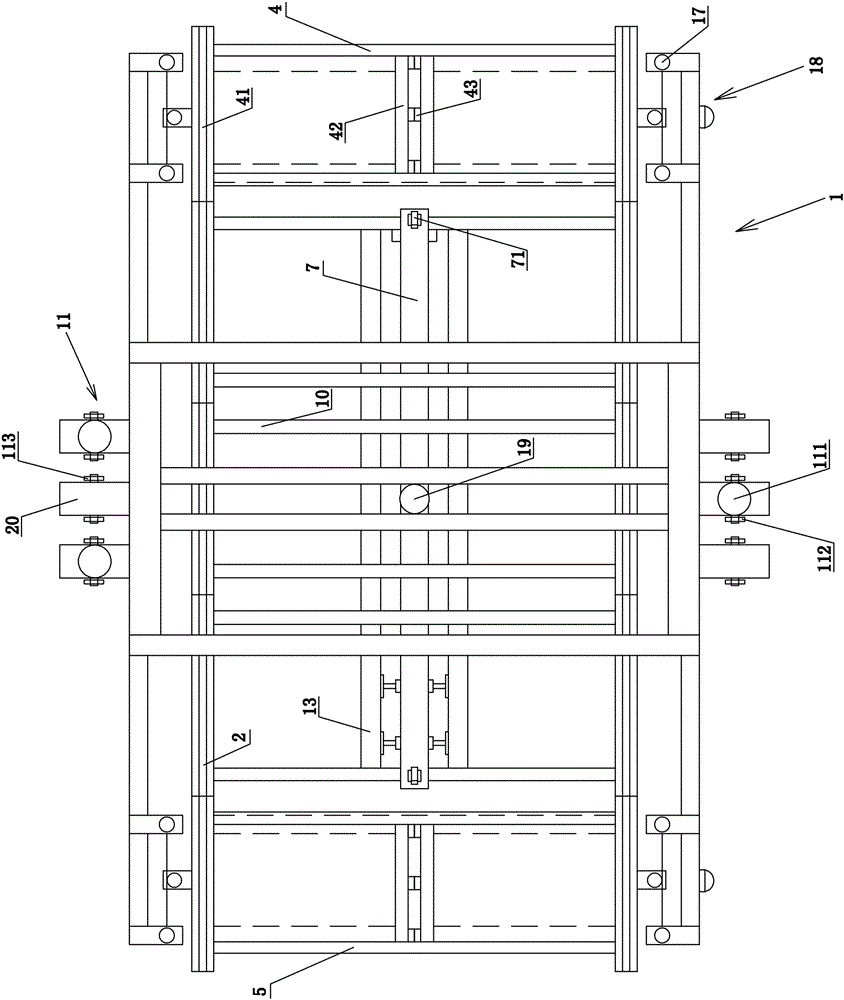

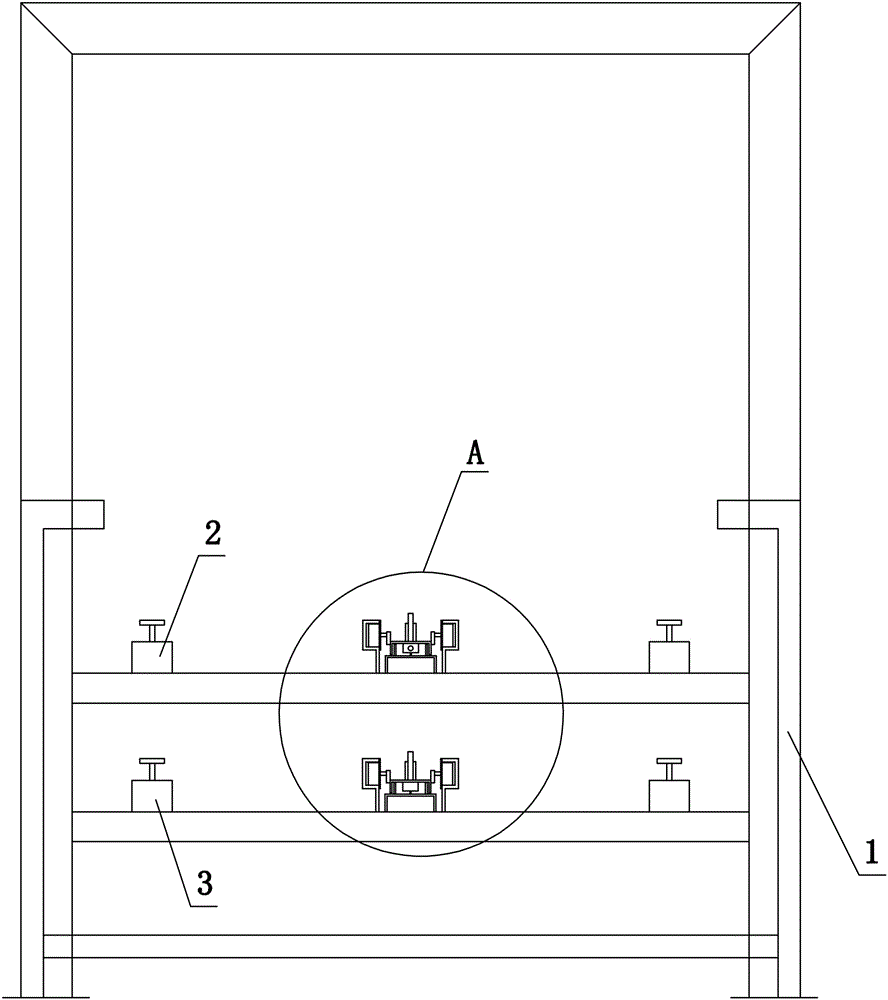

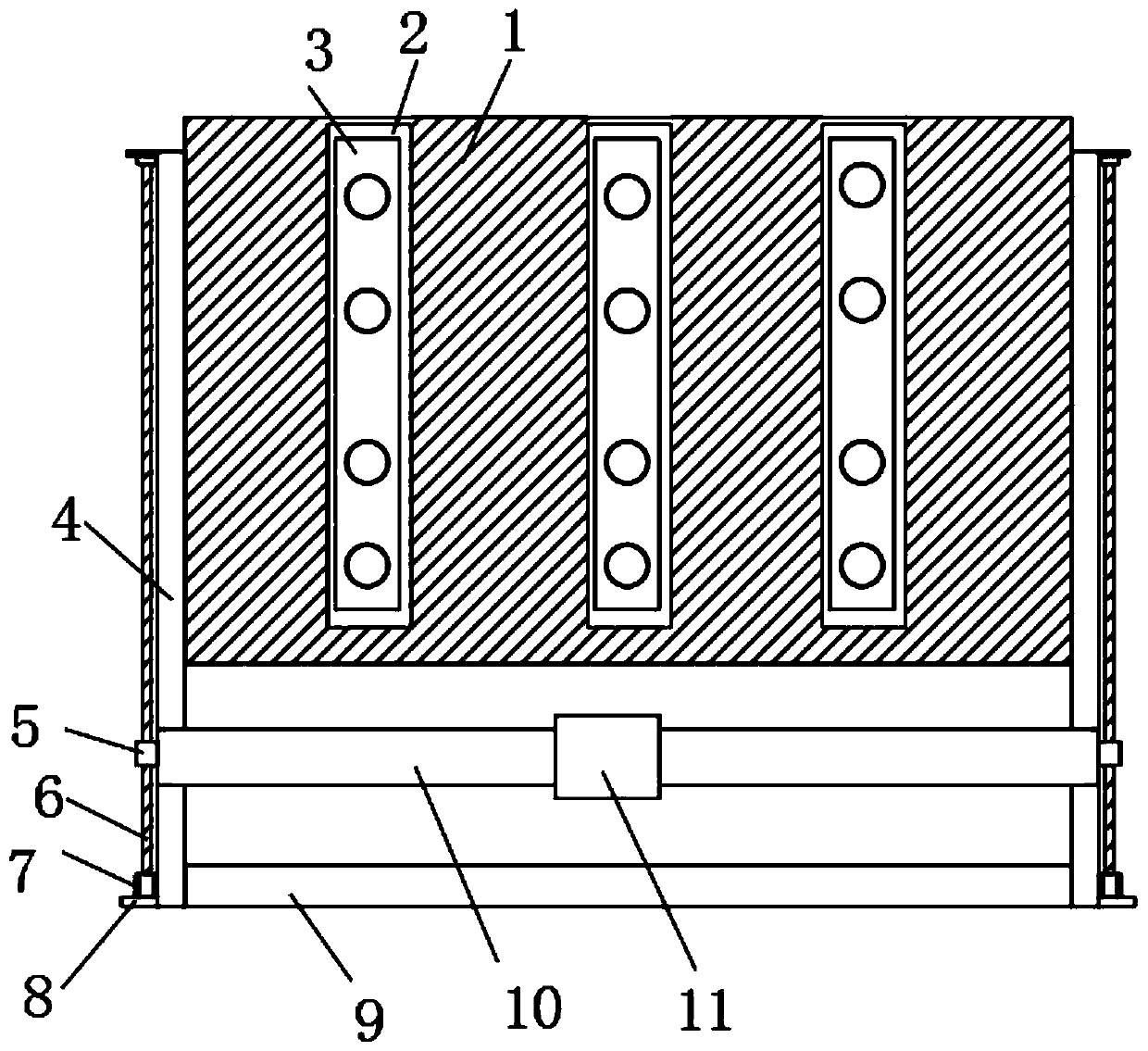

A full-automatic cement brick cutting machine comprises a machine frame. Two upper sliding rails and two lower sliding rails are arranged on the machine frame. A front lifting frame and a rear lifting frame are arranged on the front part and the rear part of the machine frame respectively. Two front sliding rails and two rear sliding rails are arranged on the top surface of the front lifting frame and the top surface of the rear lifting frame respectively. After the front lifting frame and the rear lifting frame ascend, the two front sliding rails and the two rear sliding rails are correspondingly connected with the two upper sliding rails; after the front lifting frame and the rear lifting frame descend, the two front sliding rails and the two rear sliding rails are correspondingly connected with the two lower sliding rails. A plurality of tackles capable of sliding on the front sliding rails, the upper sliding rails, the rear sliding rails and the lower sliding rails circularly are arranged on the machine frame. An upper sliding rod is arranged between the two upper sliding rails, and a plurality of upper driving pieces capable of rotating are arranged on the top surface of the upper sliding rod at intervals front and back. A lower sliding rod is arranged between the two lower sliding rails, and a plurality of lower driving pieces capable of rotating are arranged on the top surface of the lower sliding rod at intervals front and back. A support is arranged in the middle of the machine frame, a cutting frame capable of ascending and descending is arranged on the support, and a plurality of cutting devices are arranged on the cutting frame.

Owner:江苏弗林特机电科技有限公司

Glass cutting machine with automatic sheet break-off function

InactiveCN110590146AImprove practicalityRealize fully automatic cuttingGlass severing apparatusEngineeringMechanical engineering

The invention discloses a glass cutting machine with an automatic sheet break-off function. The glass cutting machine comprises a cutting table, a breaking-off plate and a slide rail, wherein a bottomplate is arranged at the bottom of the cutting table, a strip-shaped hole is formed in the upper surface of the cutting table along a width direction, the breaking-off plate is arranged inside the strip-shaped hole, and a second electric pusher bar is arranged between the bottom of the breaking-off plate and the upper surface of the bottom plate. According to the glass cutting machine, the breaking-off plate can be driven to rise through the second electric pusher bar after cutting of glass is completed so as to carry out sheet breaking-off separation on the glass, manual separation is not required, functions of the glass cutting machine with the automatic sheet break-off function are increased, the transferring of the glass is facilitated, and the use effect of the glass cutting machineis further improved; and secondly, the arranged slide rail extends to the outer side of the cutting table, and a sliding crossbeam equipped with a cutter can be slid to one end of the slide rail and is located at the outer side of the cutting table, so that the sliding crossbeam cannot affect use of the breaking-off plate on the cutting table, and the actual use effect of the glass cutting machineis further improved.

Owner:安徽福瑞斯特玻璃制品有限公司

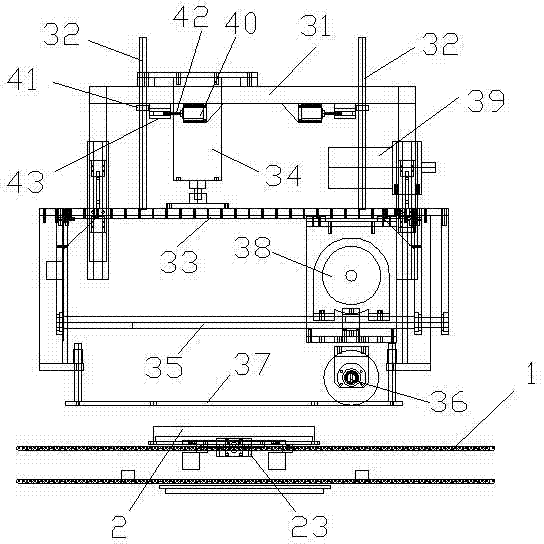

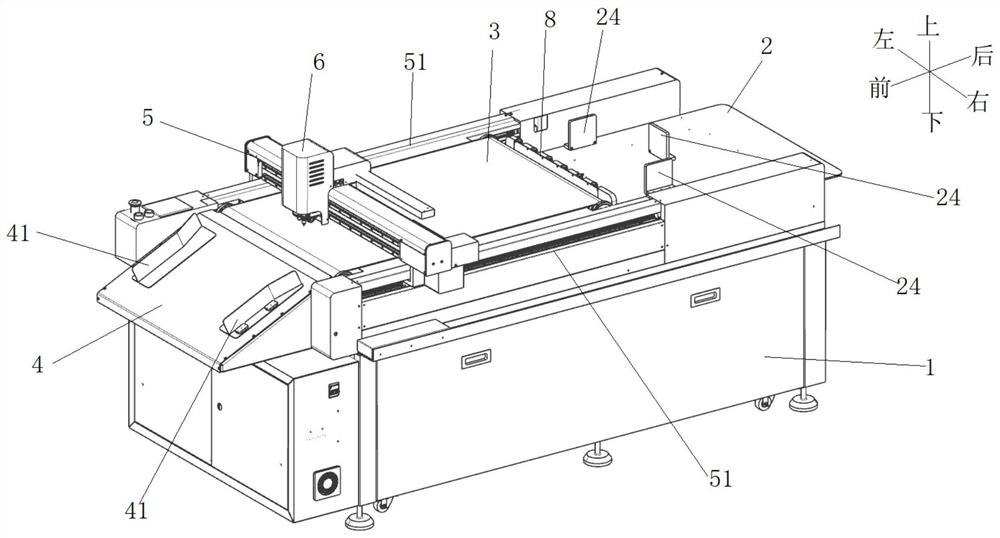

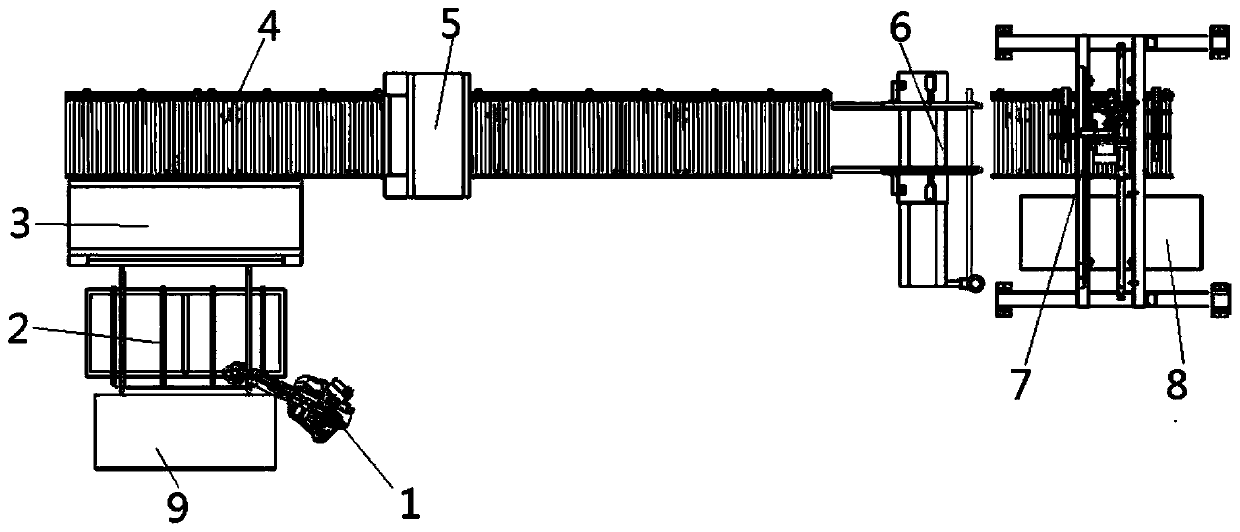

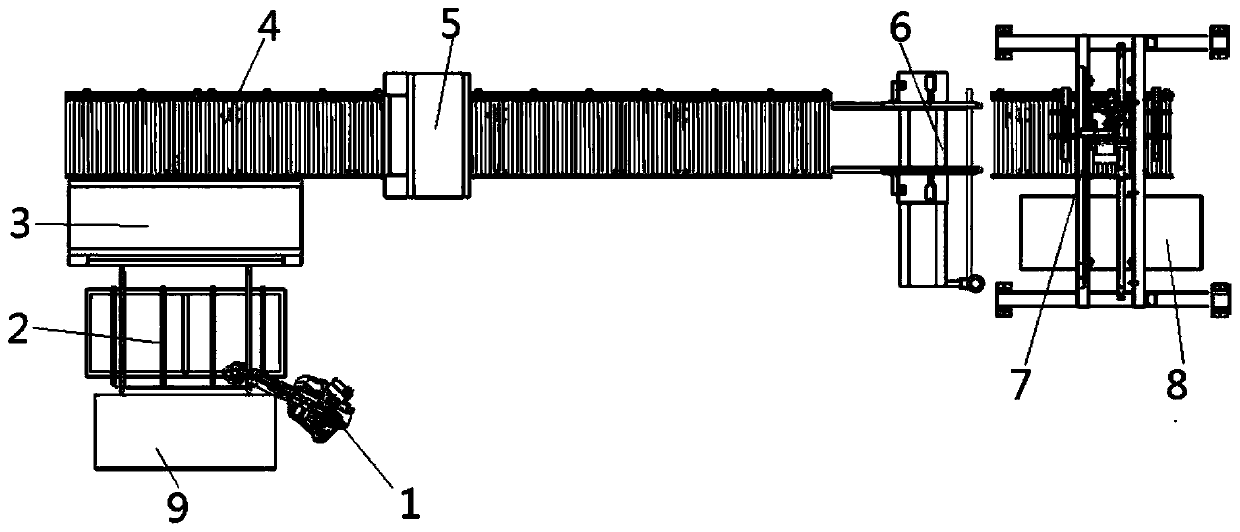

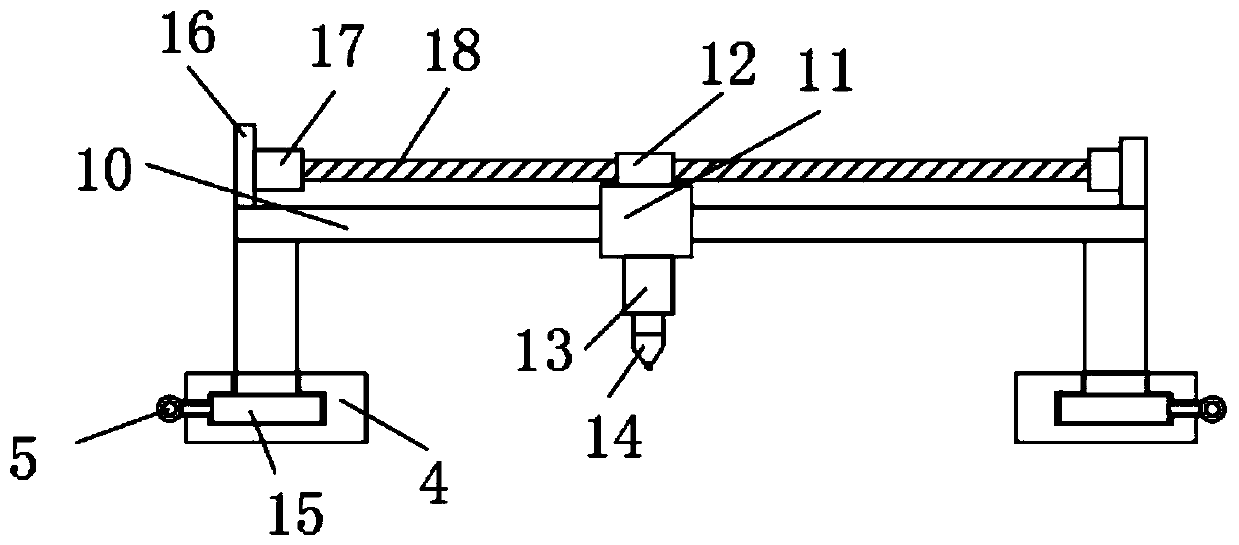

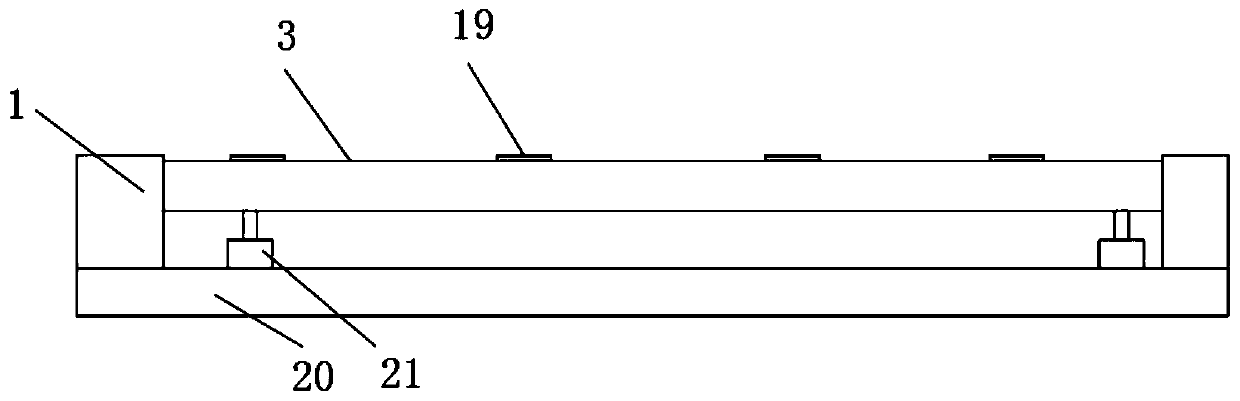

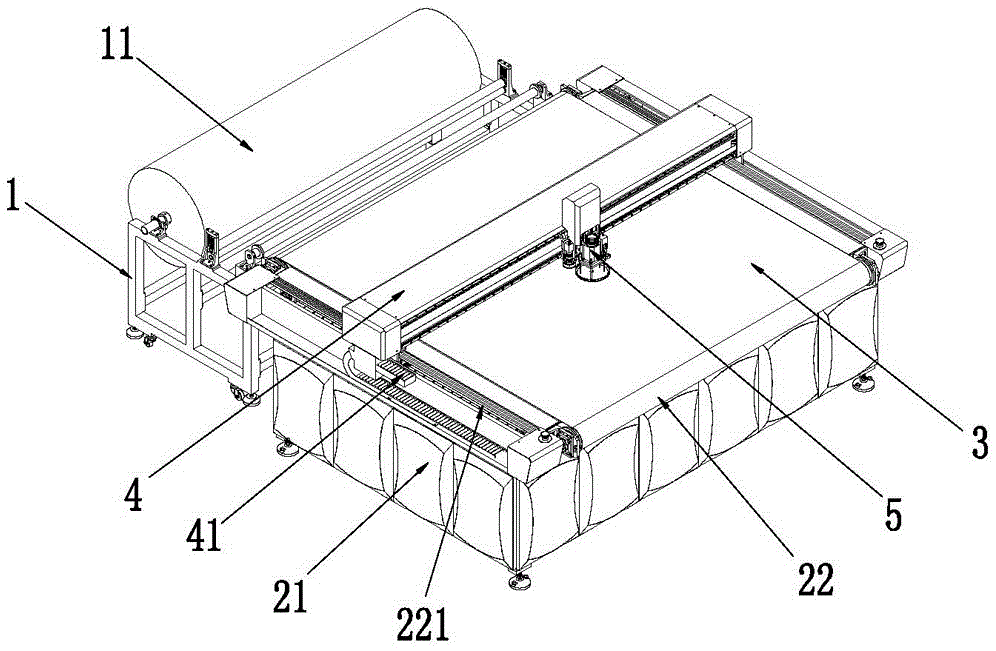

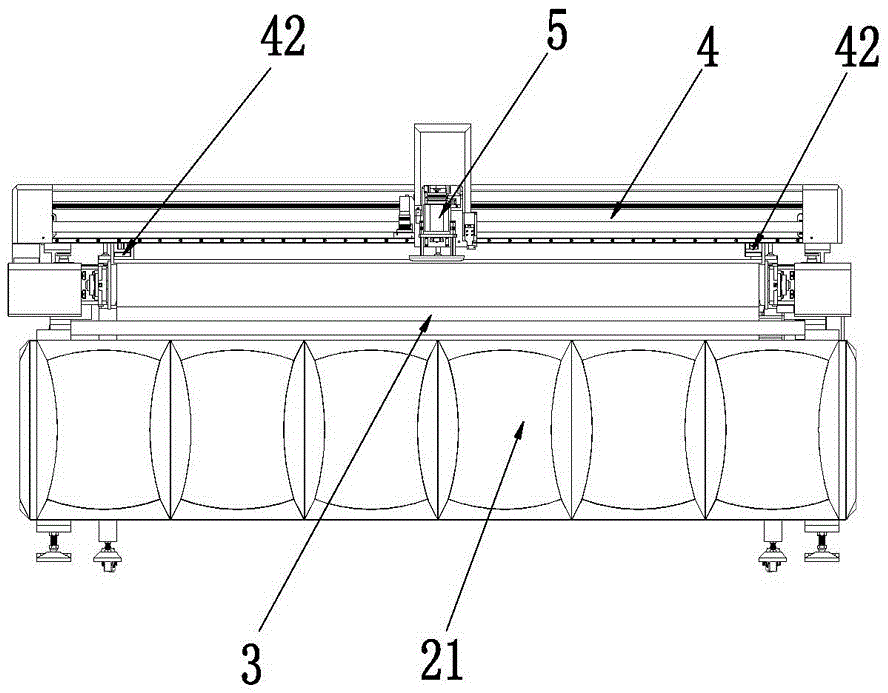

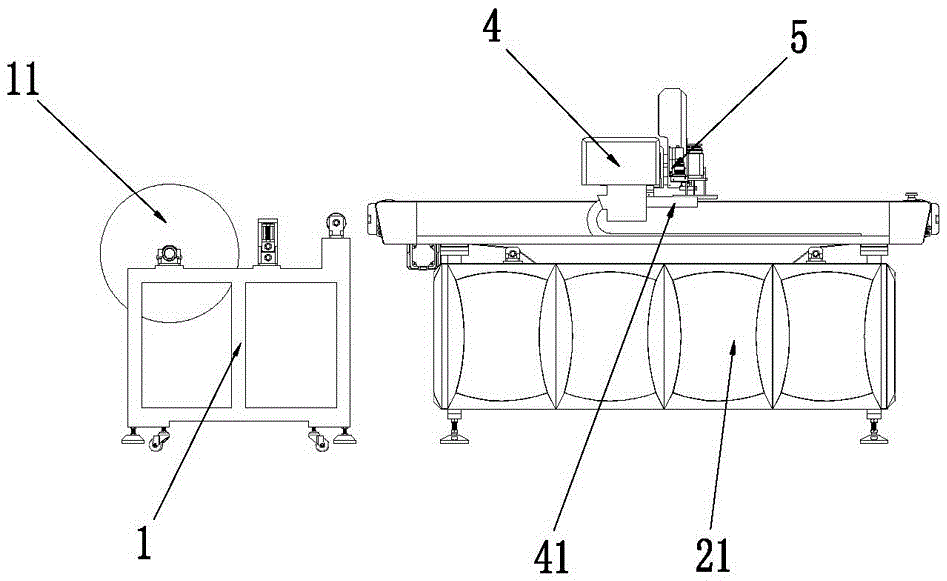

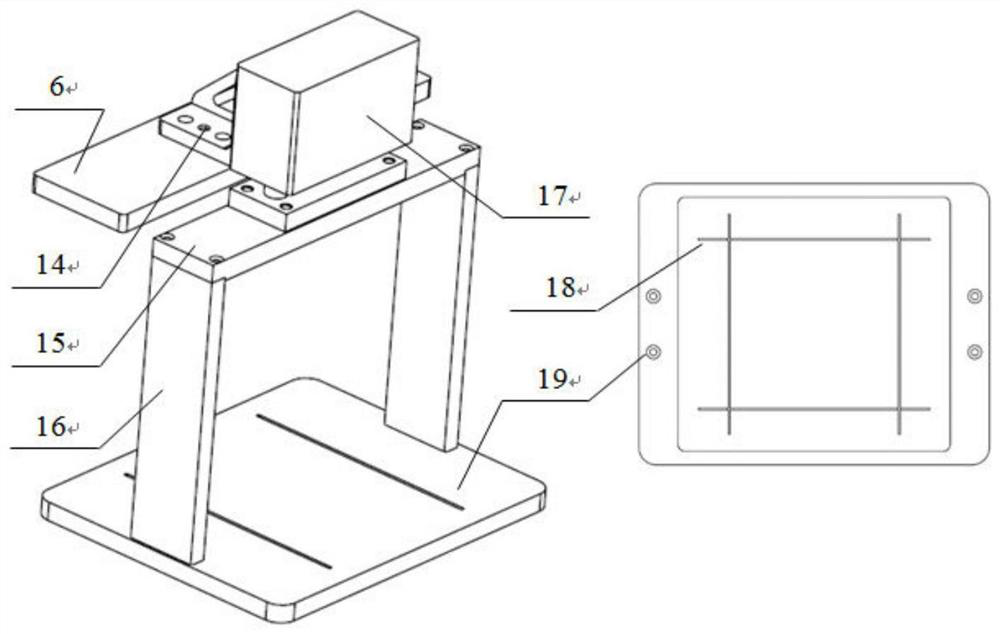

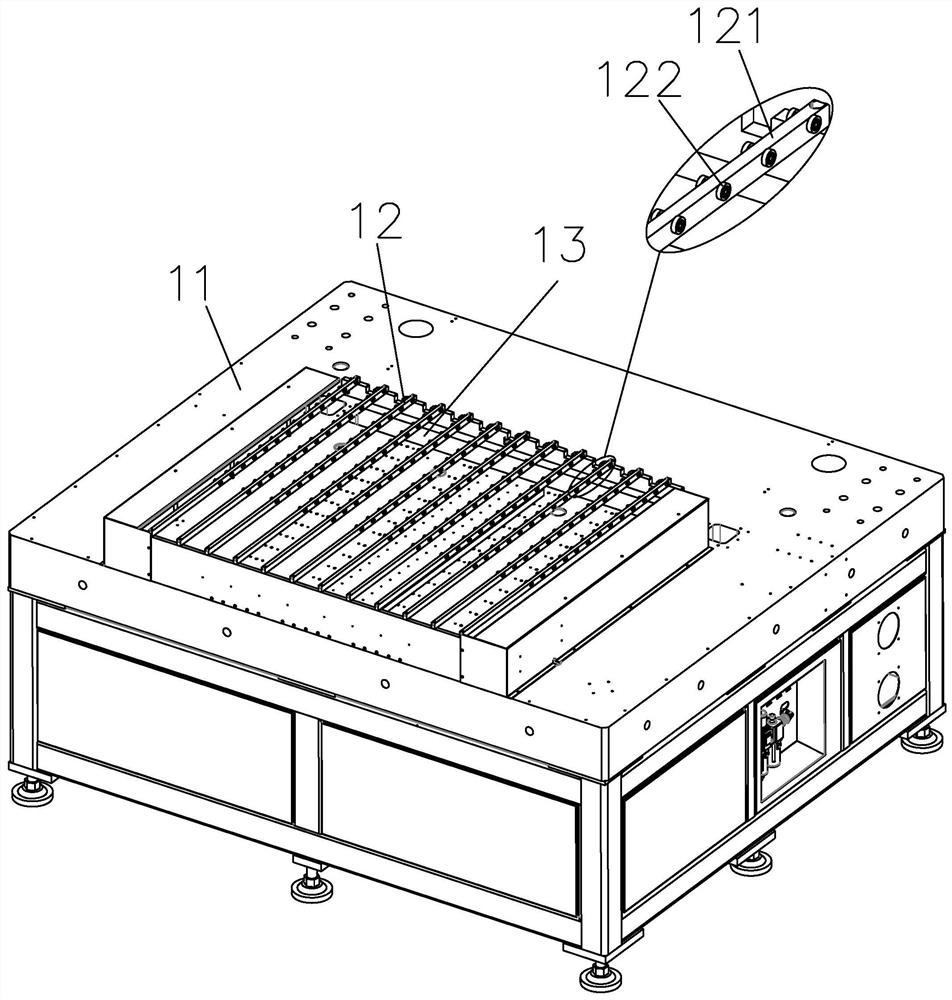

A kind of numerical control coil vibrating knife cutting equipment

InactiveCN104608162BRealize fully automatic cuttingSolve the technical problem that the roll material with image cannot be cutMetal working apparatusNumerical controlEngineering

The invention belongs to the technical field of cutting machines, and particularly relates to numerical control coil stock vibration knife cutting equipment. The numerical control coil stock vibration knife cutting equipment comprises a machine frame and a feeding frame. The feeding frame is arranged behind the machine frame. The machine frame comprises a lower machine frame body and an upper machine frame body arranged at the upper end of the lower machine frame body. The top end face of the upper machine frame body is provided with a fiber panel and a cutting device. The cutting device comprises a beam capable of longitudinally moving and a cutting machine head capable of transversely moving. The beam is in transmission connection with the upper machine frame body. The cutting machine head is in sliding connection with the beam. The cutting machine head is provided with a shooting station, a cutting station and a drawing station. According to the numerical control coil stock vibration knife cutting equipment, fully automatic cutting of coil stock with printed images can be achieved, positioning is achieved through a camera, fully automatic cutting can be achieved on the normal machine working state without manual intervention, the technical problem that a traditional automatic feeding machine cannot cut coil sock with images is solved, laser cutting is avoided, and the phenomenon that noxious gas is generated and pollutes environment is completely eradicated.

Owner:DONGGUAN UNIV OF TECH +1

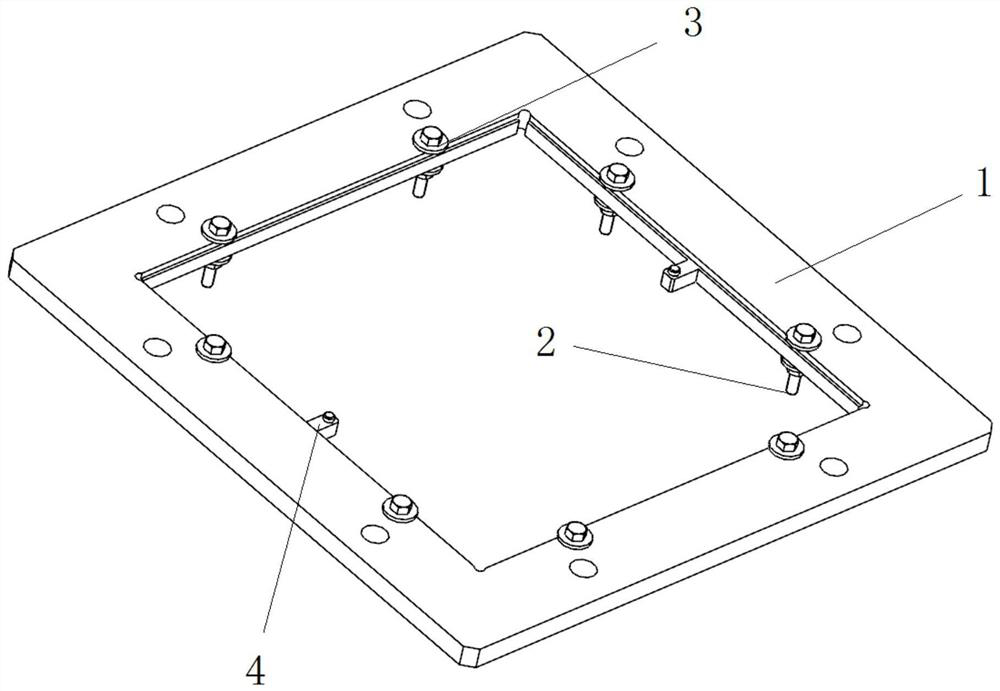

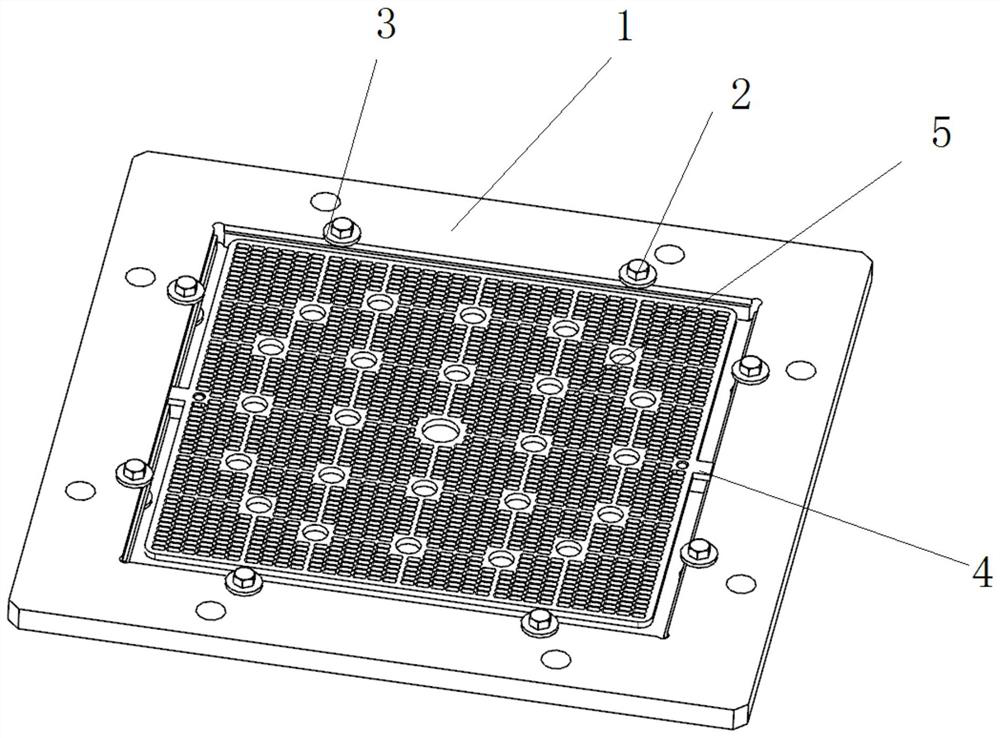

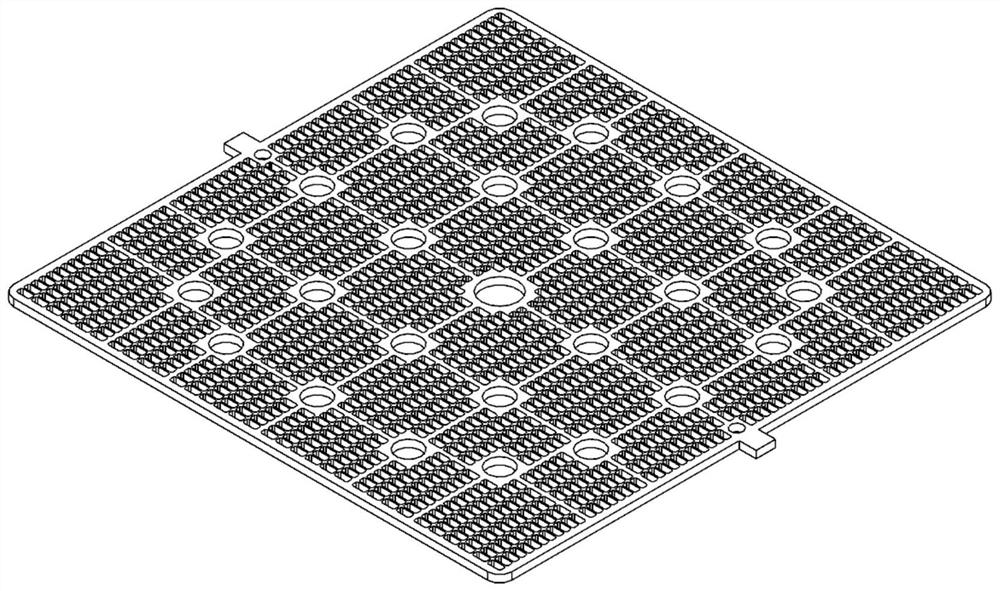

Water jet cutting manufacturing method for chip prevention plate

PendingCN112792745AAvoid normal workReduce wasteAbrasive machine appurtenancesWater jet cutterMechanical engineering

The invention particularly relates to a water jet cutting manufacturing method for a chip prevention plate which comprises a water jet cutting pretreatment process, a water jet cutting process, a water jet cutting aftertreatment process and a water jet cutting quality process control method; in the water jet cutting process, a chip prevention plate water jet cutting clamp is used for clamping a to-be-cut workpiece; garnet is adopted as a water jet cutting abrasive material; and the cutting precision is controlled. According to the water jet cutting manufacturing method for the chip prevention plate, it can be guaranteed that after water jet cutting of the chip prevention plate is completed, the product size precision and surface quality meet product manufacturing requirements.

Owner:CNNC JIANZHONG NUCLEAR FUEL

A film sample automatic cutting method and device

ActiveCN110587679BFully automatic cuttingOvercome sizePreparing sample for investigationMetal working apparatusSolenoid valveControl system

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Metal machining cutting device

PendingCN107824861ARealize fully automatic cuttingRealize the collectionShearing machinesShearing machine accessoriesMetal machiningDrive motor

The invention discloses a metal machining cutting device. The metal machining cutting device comprises a cutting table, a first conveying mechanism, a second conveying mechanism, a cutting mechanism and a material collecting box; the first conveying mechanism is located at one end of a feeding inlet of the cutting table; a slide groove is formed in the position, located in one side of the first conveying mechanism, of the cutting table; the top of the cutting table is provided with a metal conveying seat matched with the slide groove; the second conveying mechanism is arranged on one side of the cutting table; one side of the metal conveying seat is provided with a plurality of fixing rods corresponding to the second conveying mechanism; and the second conveying mechanism comprises a driving motor, the driving motor is located on one side of the lower portion of the cutting table, one side of the driving motor is provided with a first fixing seat, and the end, penetrating through the first fixing seat, of an output shaft of the driving motor is fixedly connected with a first connection rod. The metal machining cutting device can achieve full-automatic metal cutting and collecting through cooperative operation of the first conveying mechanism, the second conveying mechanism, the cutting mechanism and the material collecting box, and is safe, reliable, good in quality and high incutting efficiency.

Owner:昆山万马五金有限公司

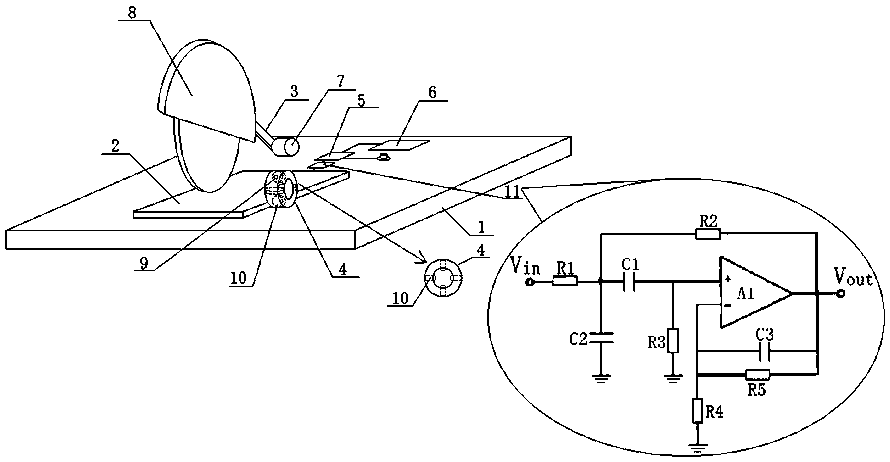

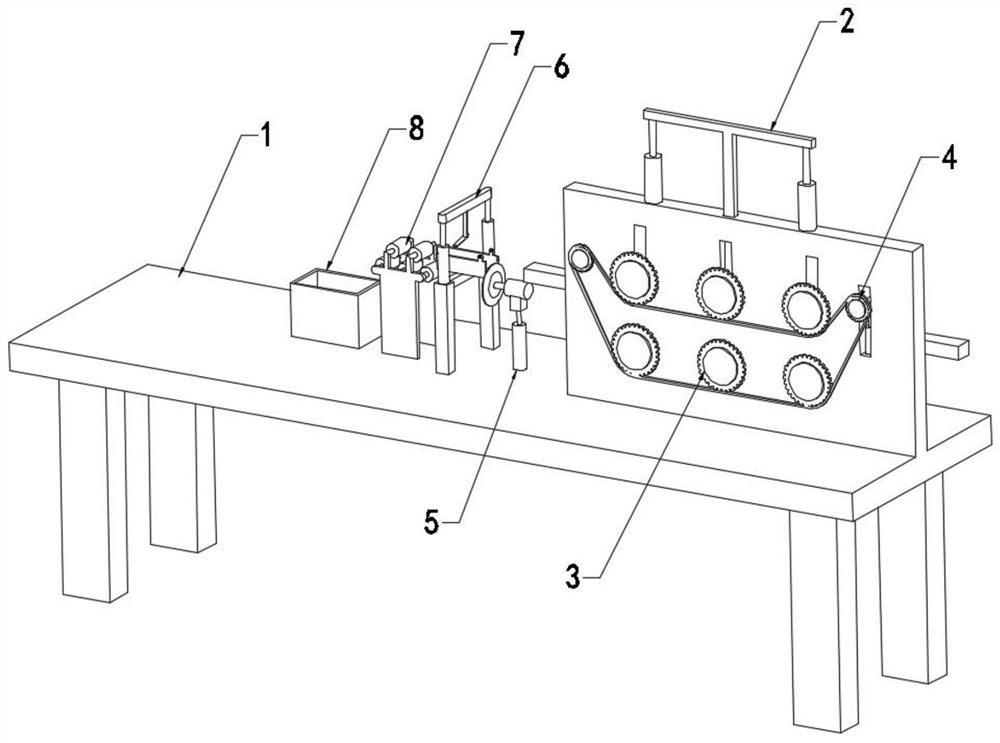

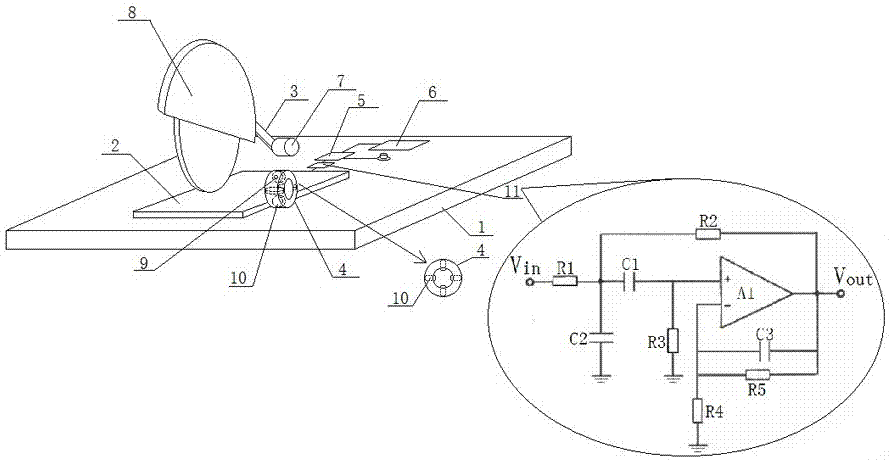

A card position-driven translational wire harness cutting machine based on rotational speed detection

ActiveCN107335760BImprove cutting efficiencyRealize fully automatic cuttingMetal working apparatusDrive wheelWire cutting

The invention relates to a clamping-position driven horizontally moving wire cutting machine based on rotational speed detection. A brand new structural design is adopted and an electromechanical hybrid electrically controlled structure is introduced, and a built-in clamping casing pipe (4) of each electrically controlled drive wheel (10) is designed based on the application of an electrically controlled rotary cutter (8); a fully automatic cutting process is achieved through the fixing of a clamping position for a wire harness and the function of transporting to the electrically controlled rotary cutter (8) through the clamping casing pipe (4); a rotation speed sensor (9) is introduced for the electrically controlled drive wheels (10), based on a specifically designed filter circuit (11); according to the perimeter of the electrically controlled drive wheels (10) and in combination with the distance from the upper surface contact points of an upper cutter of the electrically controlled rotary cutter (8) and a padding plate (2) to the clamping casing pipe (4), the length of the wire harness going through the upper surface contact points of the cutter and the padding plate (2) is acquired in real time; accordingly, the intelligent control of a rotating motor for controlling the cutting action of the electrically controlled rotary cutter (8) is achieved, accurate cutting is achieved for the wire harness, and the cutting efficiency of the wire harness can be effectively improved.

Owner:南通北外滩建设工程有限公司

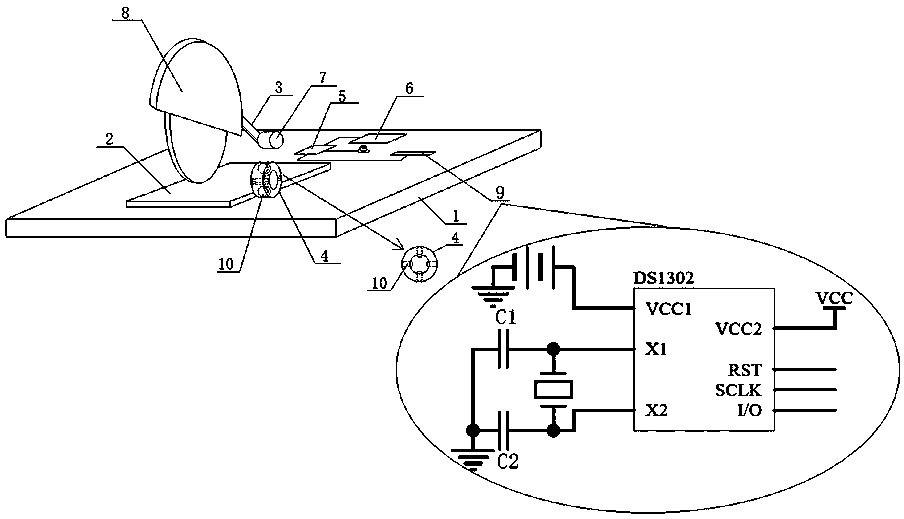

Time-length calculating type harness translational intelligent cutting device

ActiveCN107584046AImprove cutting efficiencyRealize fully automatic cuttingMetal working apparatusEngineeringMechanical engineering

The invention relates to a time-length calculating type harness translational intelligent cutting device, which adopts a novel structure design and introduces an electromechanical hybrid electronic control structure. Based on the application of an electronically controlled rotary cutterhead (8), a clamping sleeve (4) with each built-in constant speed electronically controlled driving wheel (10) isprovided. The function of clamping fixing and delivering the harness to the electronically controlled rotary cutterhead (8) is achieved by adopting the clamping sleeve (4) to achieve automatic cutting process, and a timing circuit (9 ) is introduced to obtain the length of the harness passing through the contact point of the cutterhead and the upper surface of a padding plate (2) in real time, according to the perimeter of the constant speed electronically controlled driving wheel (10) and the constant rotating speed of the constant speed electronically controlled driving wheel (10), and in combination with the distance from the contact point of the upper cutterhead of the electrically controlled rotary cutterhead (8) and the upper surface of the padding plate (2) to the clamping sleeve (4). Accordingly, the intelligent control of a rotary motor for controlling the cutting action of the electrically controlled rotary cutterhead (8) can be achieved, the precise cutting of the harness can be achieved, and the cutting efficiency of the harness can be effectively improved.

Owner:徐州美欣生物材料有限公司

A fully automatic cement brick cutting machine

InactiveCN105856400BRealize fully automatic cuttingImprove yieldAuxillary shaping apparatusBrickEngineering

A full-automatic cement brick cutting machine comprises a machine frame. Two upper sliding rails and two lower sliding rails are arranged on the machine frame. A front lifting frame and a rear lifting frame are arranged on the front part and the rear part of the machine frame respectively. Two front sliding rails and two rear sliding rails are arranged on the top surface of the front lifting frame and the top surface of the rear lifting frame respectively. After the front lifting frame and the rear lifting frame ascend, the two front sliding rails and the two rear sliding rails are correspondingly connected with the two upper sliding rails; after the front lifting frame and the rear lifting frame descend, the two front sliding rails and the two rear sliding rails are correspondingly connected with the two lower sliding rails. A plurality of tackles capable of sliding on the front sliding rails, the upper sliding rails, the rear sliding rails and the lower sliding rails circularly are arranged on the machine frame. An upper sliding rod is arranged between the two upper sliding rails, and a plurality of upper driving pieces capable of rotating are arranged on the top surface of the upper sliding rod at intervals front and back. A lower sliding rod is arranged between the two lower sliding rails, and a plurality of lower driving pieces capable of rotating are arranged on the top surface of the lower sliding rod at intervals front and back. A support is arranged in the middle of the machine frame, a cutting frame capable of ascending and descending is arranged on the support, and a plurality of cutting devices are arranged on the cutting frame.

Owner:江苏弗林特机电科技有限公司

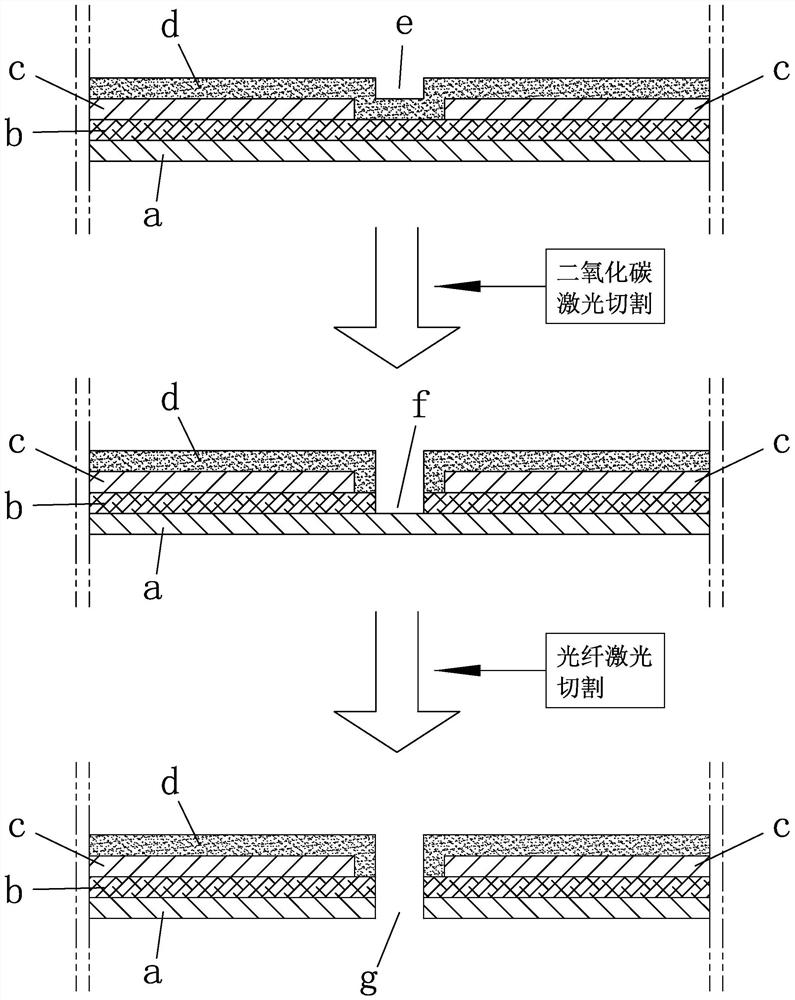

Aluminum-based circuit board laser cutting process and equipment thereof

PendingCN114101929AImprove cutting accuracyImprove cutting efficiencyPrinted circuitsWelding/soldering/cutting articlesCarbon dioxide laser lightCopper foil

The invention discloses an aluminum-based circuit board laser cutting process and equipment thereof. An aluminum-based circuit board comprises an aluminum substrate, an insulating layer is arranged on the aluminum substrate, a copper foil circuit formed by etching a copper foil and a sunken position are arranged on the insulating layer, a paint layer is arranged on the copper foil circuit and the sunken position, and a groove is formed in the sunken position by the paint layer; a joint cutting mode of carbon dioxide laser and optical fiber laser is adopted, the energy density of the carbon dioxide laser is relatively low, the cutting effect on a paint layer and an insulating layer in the aluminum-based circuit board is good, after the paint layer and the insulating layer are cut, the edges are free of dust, burrs and deformation, and a copper foil circuit is free of damage, blackening and oxidation; and the energy density of the optical fiber laser is relatively high, the cutting effect on the aluminum substrate is relatively high, and the edge of the cut aluminum substrate is smooth and neat.

Owner:广东洛克智能科技设备有限公司

Full-automatic metal plate cutting device

InactiveCN114453667AShorten cutting timeImprove efficiencyMetal sawing devicesStructural engineeringManufacturing engineering

The invention discloses a full-automatic metal plate cutting device which comprises a workbench, a movable roller conveying assembly, a static roller conveying assembly, a transmission assembly, a cutting assembly, a fixing assembly, a conveying assembly and a collecting assembly. A first groove, a second groove and a third groove are formed in the vertical plate, a first rotating shaft is rotationally installed in the first groove, and a second rotating shaft is rotationally installed in the second groove. According to the full-automatic metal plate cutting device, through cooperation of the workbench, the movable roller conveying assembly, the static roller conveying assembly, the transmission assembly, the cutting assembly, the fixing assembly, the conveying assembly and the collecting assembly, cutting of a metal plate is completed, full-automatic cutting is achieved, manual operation is not needed, then the cutting time is shortened, and the cutting efficiency is improved.

Owner:苏州爱科德精密仪器有限公司

Gift paper slitting machine

InactiveCN113478529ARealize fully automatic cuttingReduce labor intensityMetal working apparatusPaperboardElectric machinery

The invention relates to the technical field of slitting equipment, in particular to a gift paper slitting machine which comprises a rack, a workbench is arranged at the upper end of the rack, and blocking edges are arranged on the portions, on the front side and the rear side of the workbench, of the rack. A conveying roller and a slitting structure are sequentially arranged on the workbench in the left-right direction, and a driving motor in transmission connection with the conveying roller is arranged on one side of the rack. Through the arrangement of the conveying roller and the slitting structure, full-automatic slitting of to-be-slit paperboards is achieved, the labor intensity of workers is reduced, the machining efficiency is improved, meanwhile, cutters can be prevented from hurting people, and safety is improved.

Owner:WENZHOU WINRICH MACHINERY CO LTD

Aluminum alloy door cutting equipment

InactiveCN112355391AGood effectEasy to cutMetal sawing devicesMetal sawing accessoriesScrapManufacturing engineering

The invention relates to the technical field of aluminum alloy door production and machining, in particular to aluminum alloy door cutting equipment which comprises a workbench, a fixing device, a cutting device, a scrap removing device and a cleaning device. The workbench is arranged on a horizontal plane, the fixing device is arranged on the workbench, and the cutting device is arranged on the workbench; the cutting device comprises a moving assembly and a cutting assembly, and the moving assembly is arranged on the workbench; the cutting assembly is arranged at the moving end of the movingassembly, and the scrap removing device is arranged on the horizontal plane; and the cleaning device is arranged on the top of the workbench, and the cleaning end of the cleaning device is located above the cutting end of the cutting assembly. A aluminum alloy door is placed on the fixing device, fixed through the fixing device, and cut through the cutting assembly moved through the moving assembly; and scraps generated by cutting are sucked and removed through the scrap removing device, and the aluminum alloy door and the cutting device are cleaned through the cleaning device.

Owner:安徽黎搏装饰工程有限公司

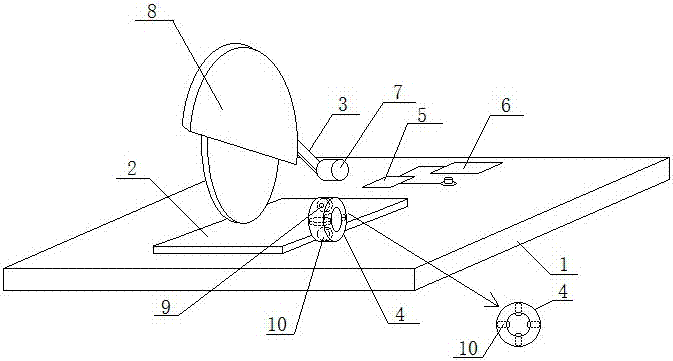

Clamping-position driven horizontally moving wire cutting machine based on rotational speed detection

ActiveCN107335760AImprove cutting efficiencyRealize fully automatic cuttingMetal working apparatusDrive wheelWire cutting

The invention relates to a clamping-position driven horizontally moving wire cutting machine based on rotational speed detection. A brand new structural design is adopted and an electromechanical hybrid electrically controlled structure is introduced, and a built-in clamping casing pipe (4) of each electrically controlled drive wheel (10) is designed based on the application of an electrically controlled rotary cutter (8); a fully automatic cutting process is achieved through the fixing of a clamping position for a wire harness and the function of transporting to the electrically controlled rotary cutter (8) through the clamping casing pipe (4); a rotation speed sensor (9) is introduced for the electrically controlled drive wheels (10), based on a specifically designed filter circuit (11); according to the perimeter of the electrically controlled drive wheels (10) and in combination with the distance from the upper surface contact points of an upper cutter of the electrically controlled rotary cutter (8) and a padding plate (2) to the clamping casing pipe (4), the length of the wire harness going through the upper surface contact points of the cutter and the padding plate (2) is acquired in real time; accordingly, the intelligent control of a rotating motor for controlling the cutting action of the electrically controlled rotary cutter (8) is achieved, accurate cutting is achieved for the wire harness, and the cutting efficiency of the wire harness can be effectively improved.

Owner:南通北外滩建设工程有限公司

A platform type wire harness cutting machine

The invention relates to a platform type wire harness cutting machine. The platform type wire harness cutting machine adopted the design of a brand new structure. A mechanical-electronic hybrid electronic control structure is introduced. Based on application of an electronic control rotary cutter disk (8), a wire harness is clamped and fixed through a clamping sleeve (4) internally provided with electronic control driving wheels (10) and conveyed to the electronic control rotary cutter disk (8). The full-automatic cutting process is realized. A rotational speed sensor (9) is introduced for the electronic control driving wheels (10). According to the perimeter of the electronic control driving wheels (10) and the distance from the point, making contact with the upper surface of a heightening plate (2), of the electronic control rotary cutter disk (8) to the clamping sleeve (4), the length of a wire harness passing the point of the cutter disk making contact with the upper surface of the heightening plate (2) is acquired in real time. Thus, intelligent control over a rotation motor for controlling the cutting action of the electronic control rotary cutter disk (8) is realized. The wire harness is cut accurately. The cutting efficiency of the wire harness can be effectively improved.

Owner:南通北外滩建设工程有限公司

A time-length calculation type wire harness translation intelligent cutting device

ActiveCN107584046BImprove cutting efficiencyRealize fully automatic cuttingMetal working apparatusDrive wheelEngineering

The invention relates to a time-length calculating type harness translational intelligent cutting device, which adopts a novel structure design and introduces an electromechanical hybrid electronic control structure. Based on the application of an electronically controlled rotary cutterhead (8), a clamping sleeve (4) with each built-in constant speed electronically controlled driving wheel (10) isprovided. The function of clamping fixing and delivering the harness to the electronically controlled rotary cutterhead (8) is achieved by adopting the clamping sleeve (4) to achieve automatic cutting process, and a timing circuit (9 ) is introduced to obtain the length of the harness passing through the contact point of the cutterhead and the upper surface of a padding plate (2) in real time, according to the perimeter of the constant speed electronically controlled driving wheel (10) and the constant rotating speed of the constant speed electronically controlled driving wheel (10), and in combination with the distance from the contact point of the upper cutterhead of the electrically controlled rotary cutterhead (8) and the upper surface of the padding plate (2) to the clamping sleeve (4). Accordingly, the intelligent control of a rotary motor for controlling the cutting action of the electrically controlled rotary cutterhead (8) can be achieved, the precise cutting of the harness can be achieved, and the cutting efficiency of the harness can be effectively improved.

Owner:徐州美欣生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com