Full-automatic multifunctional IGBT packaging machine

A multi-functional, packaging machine technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problem of inability to achieve vacuum nozzles, automatic replacement of syringes, inability to be compatible with chip packaging operations at the same time, and inability to achieve full solder tabs. Automatic cutting and other problems to achieve the effect of saving production space, improving cutting efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

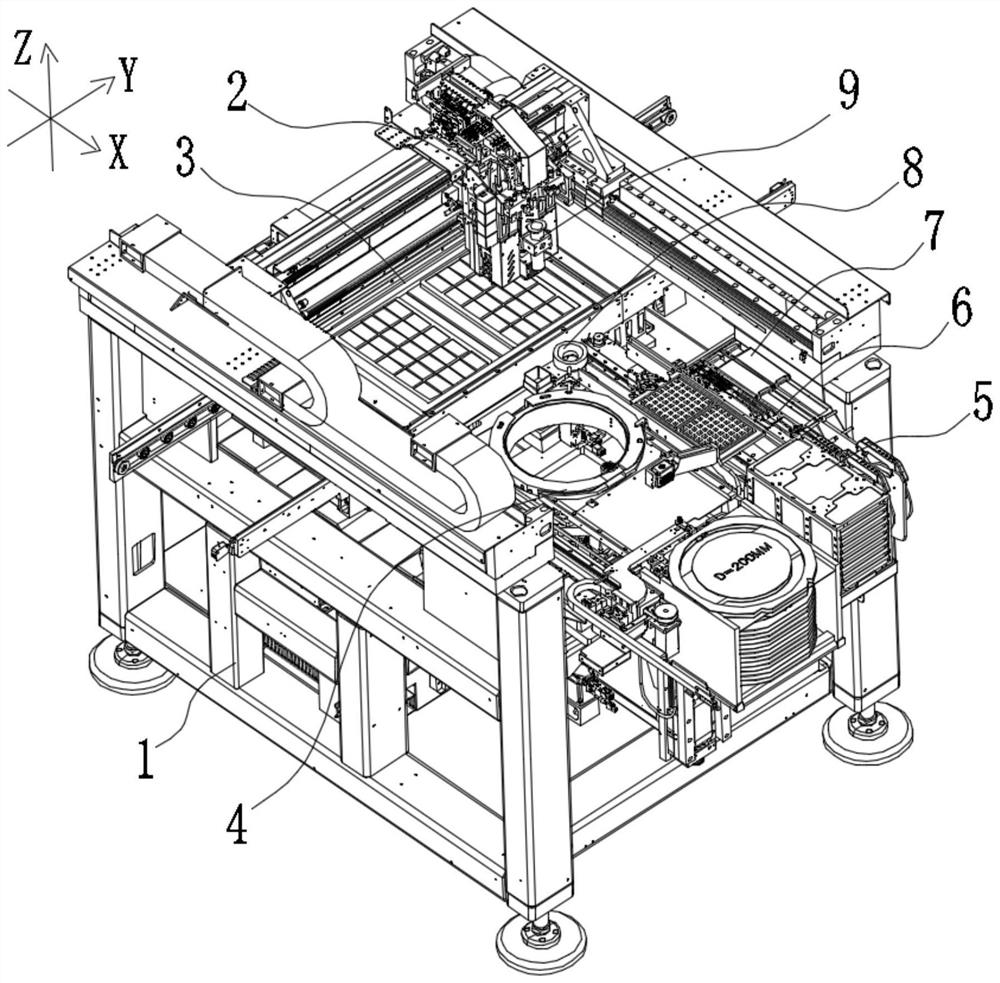

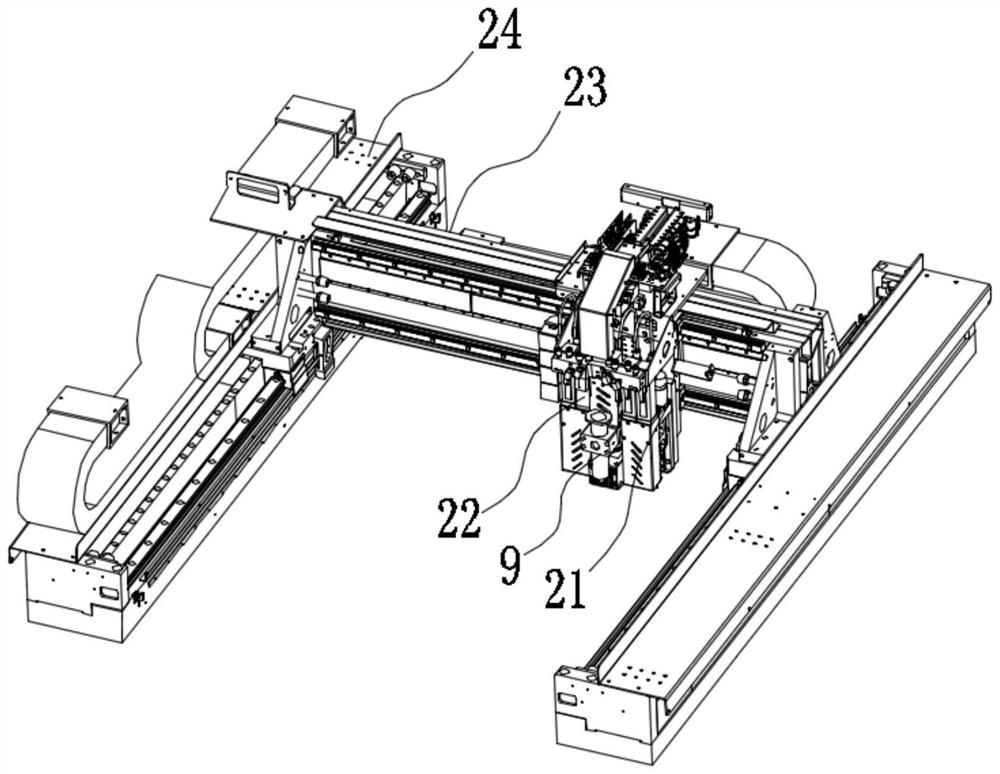

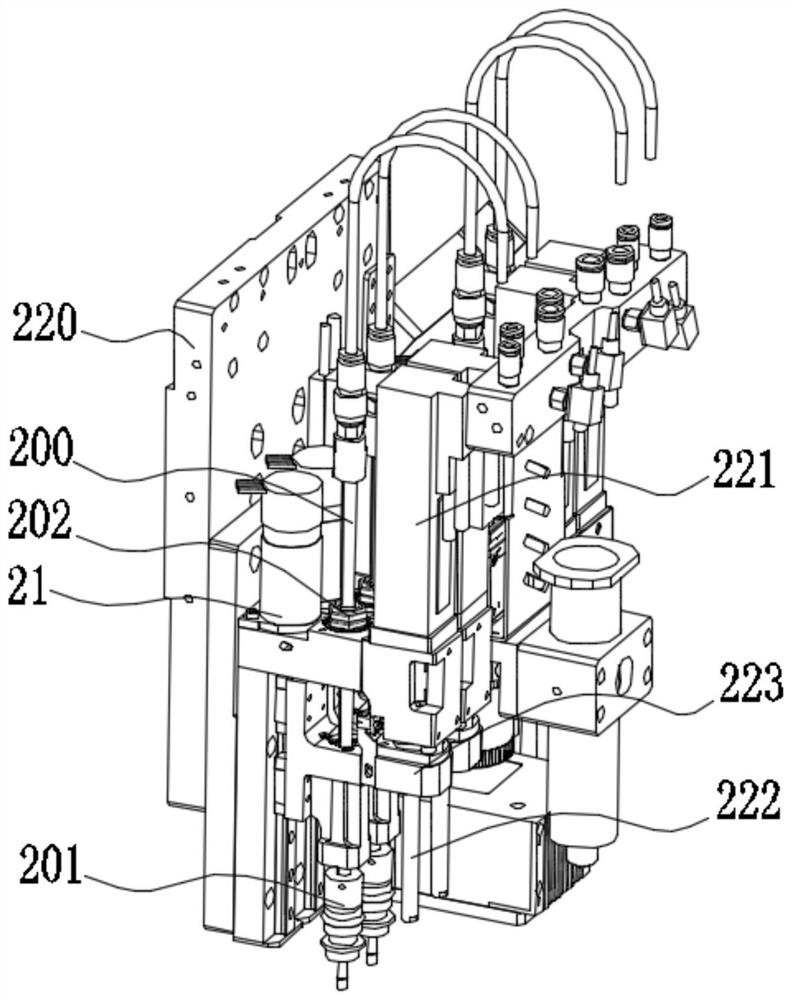

[0038] Please refer to Figure 1-Figure 15 , the present invention provides a fully automatic multifunctional IGBT packaging machine, comprising: a frame 1, a packaging mechanism 2 arranged on the frame 1, a jig tray conveying mechanism 3 arranged on the lower side of the packaging mechanism 2, Crystal ring feeding jacking mechanism 4, TRAY tray feeding mechanism 5, component feeding mechanism 6, solder sheet feeding and cutting mechanism 7; the jig plate conveying mechanism 3 is used to transport the jig plate equipped with IGBT to The lower side of the packaging mechanism 2, and transport it to the discharge end of the jig plate conveying mechanism 3 after the packaging is completed. A chip or a second chip or an electronic component (such as a resistor) or an IGBT packaged with a solder tab, the IGBT is provided with solder (pre-packaged)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com