Patents

Literature

36results about How to "Realize fully automatic packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

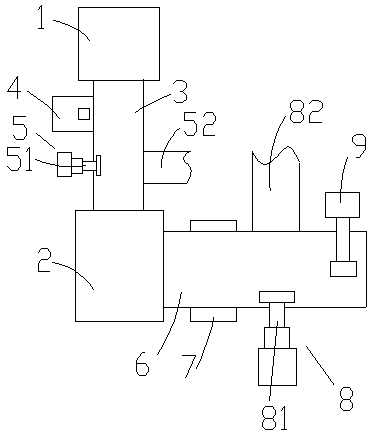

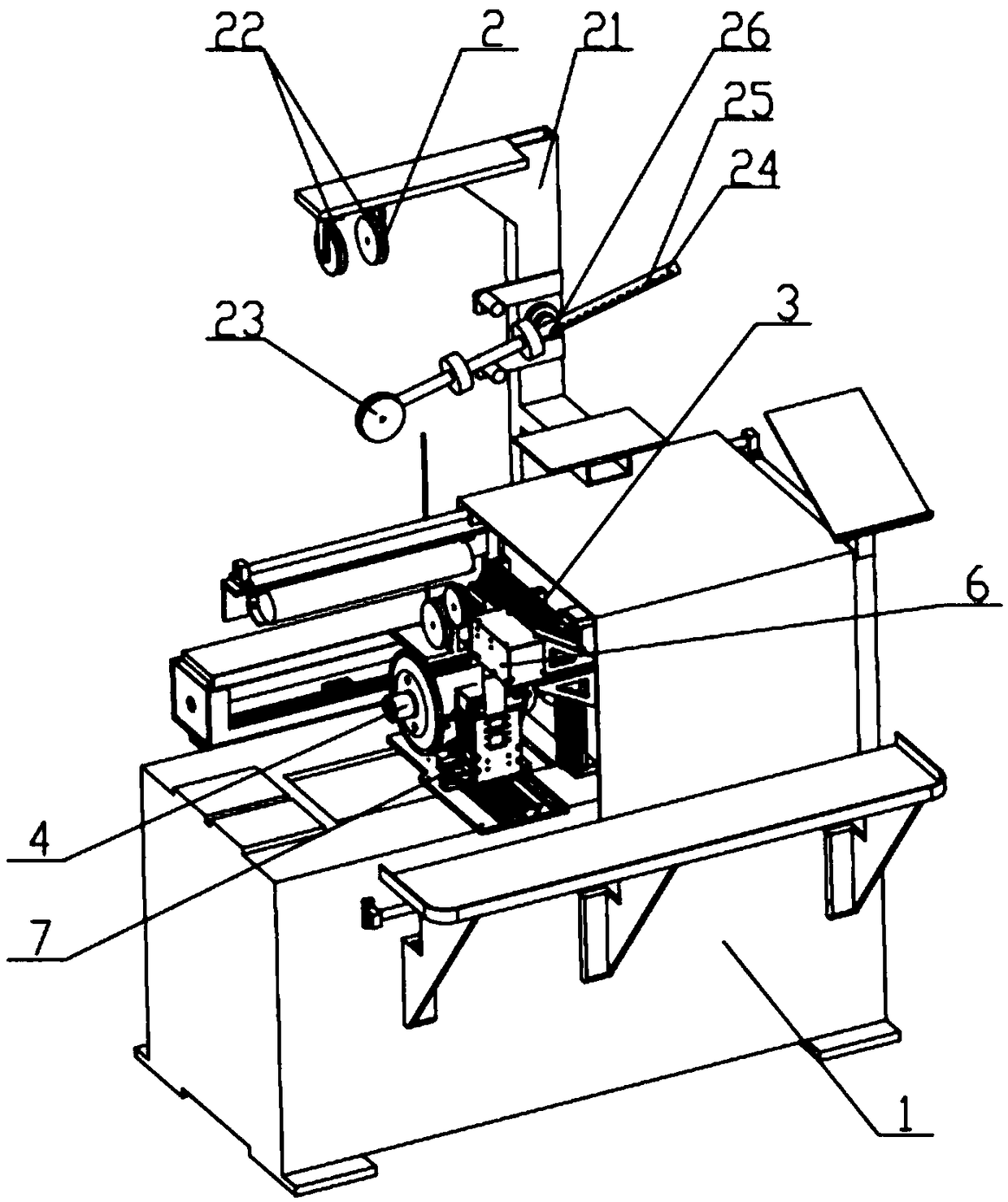

Tableware packing machine

PendingCN110002052ARealize fully automatic packagingImprove packaging qualityWrappingWrapper twisting/gatheringEngineeringHermetic packaging

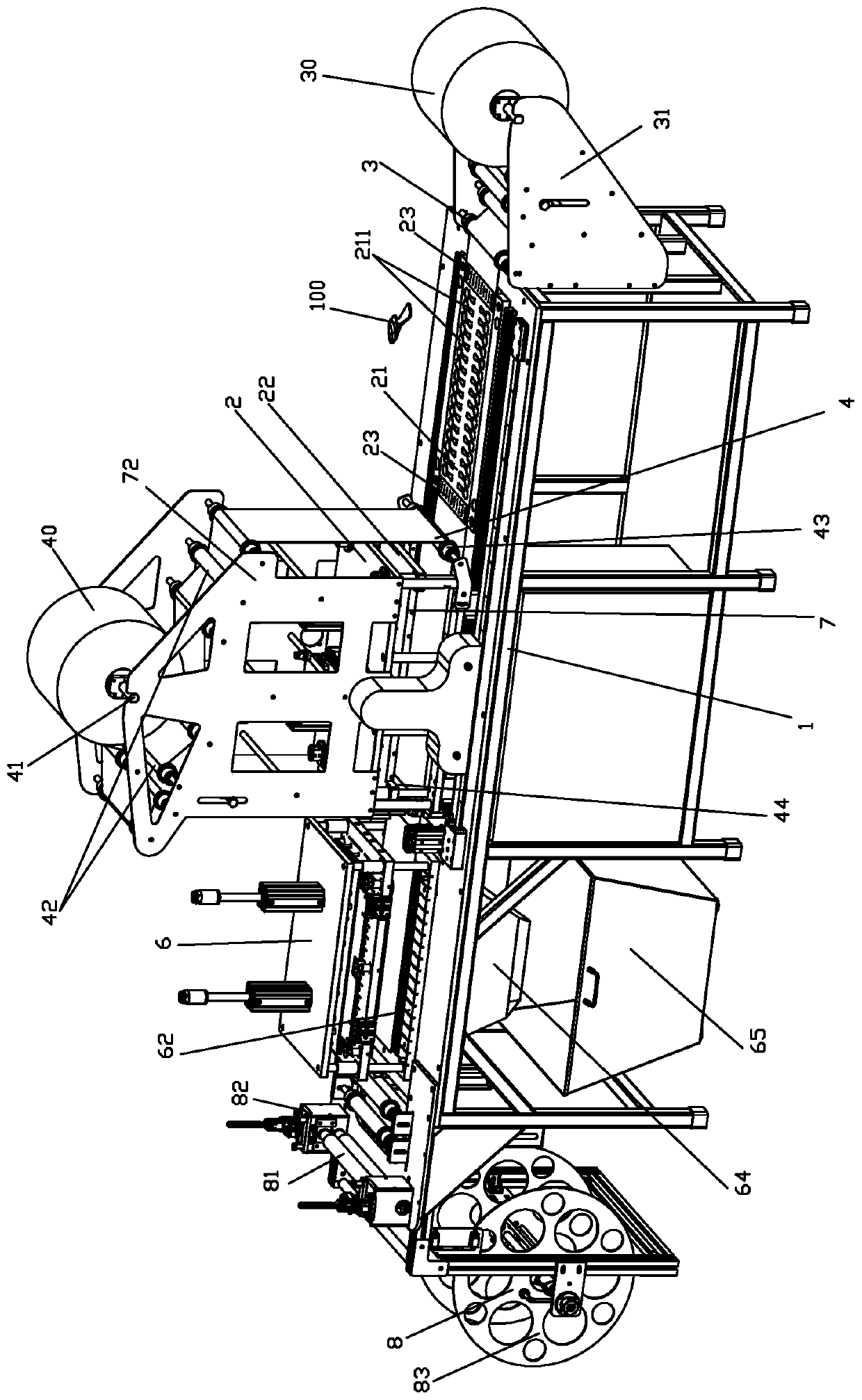

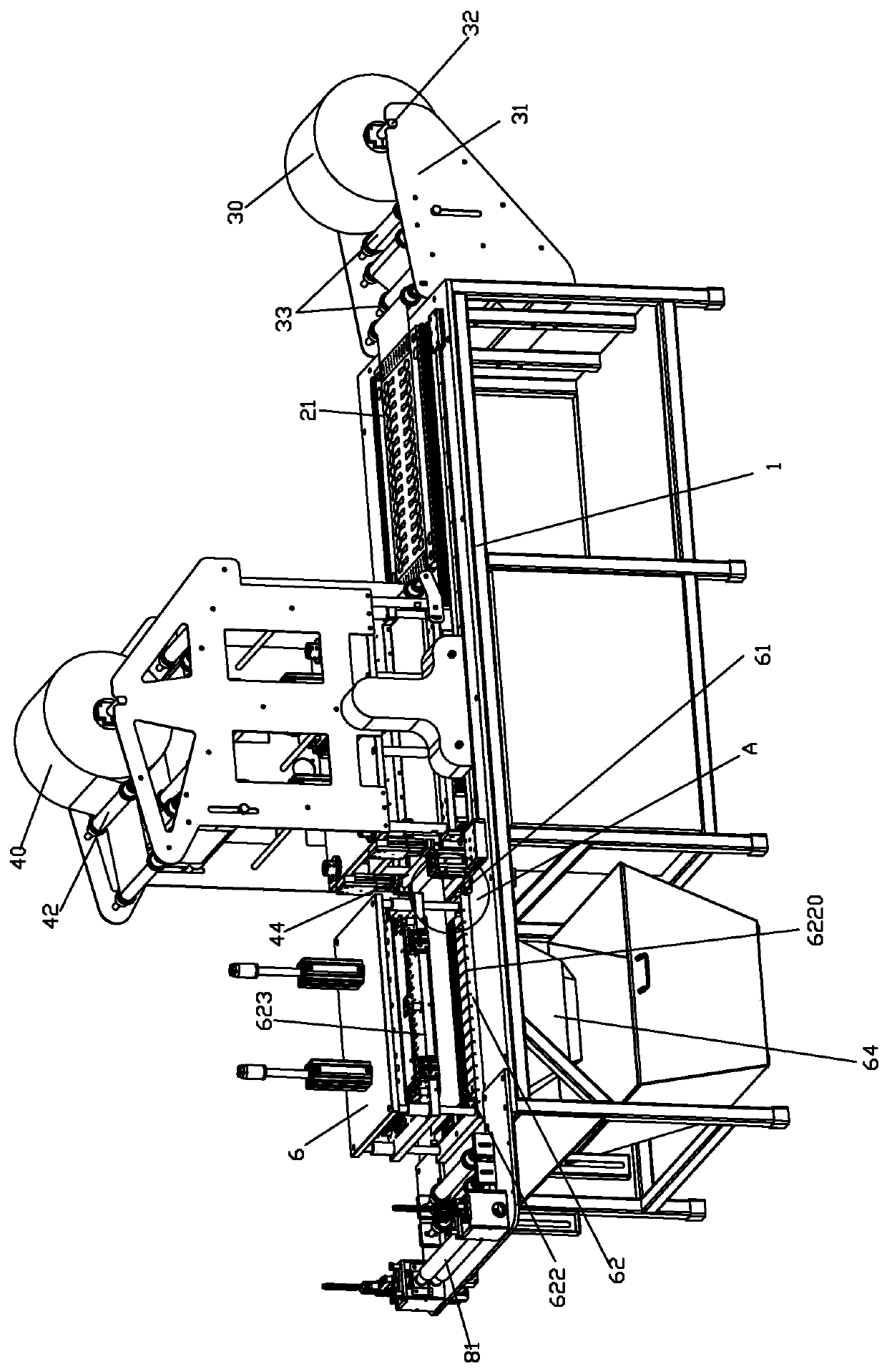

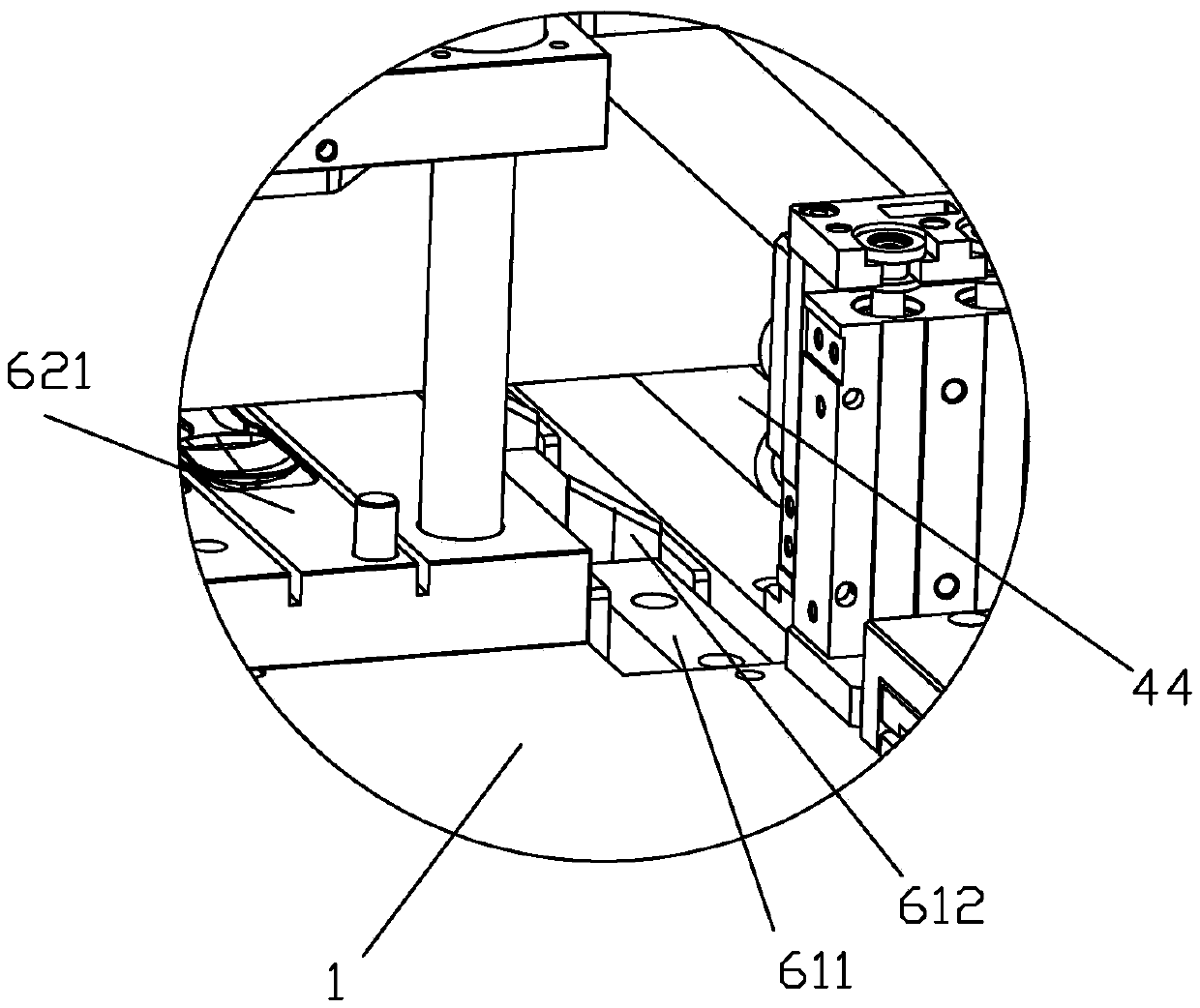

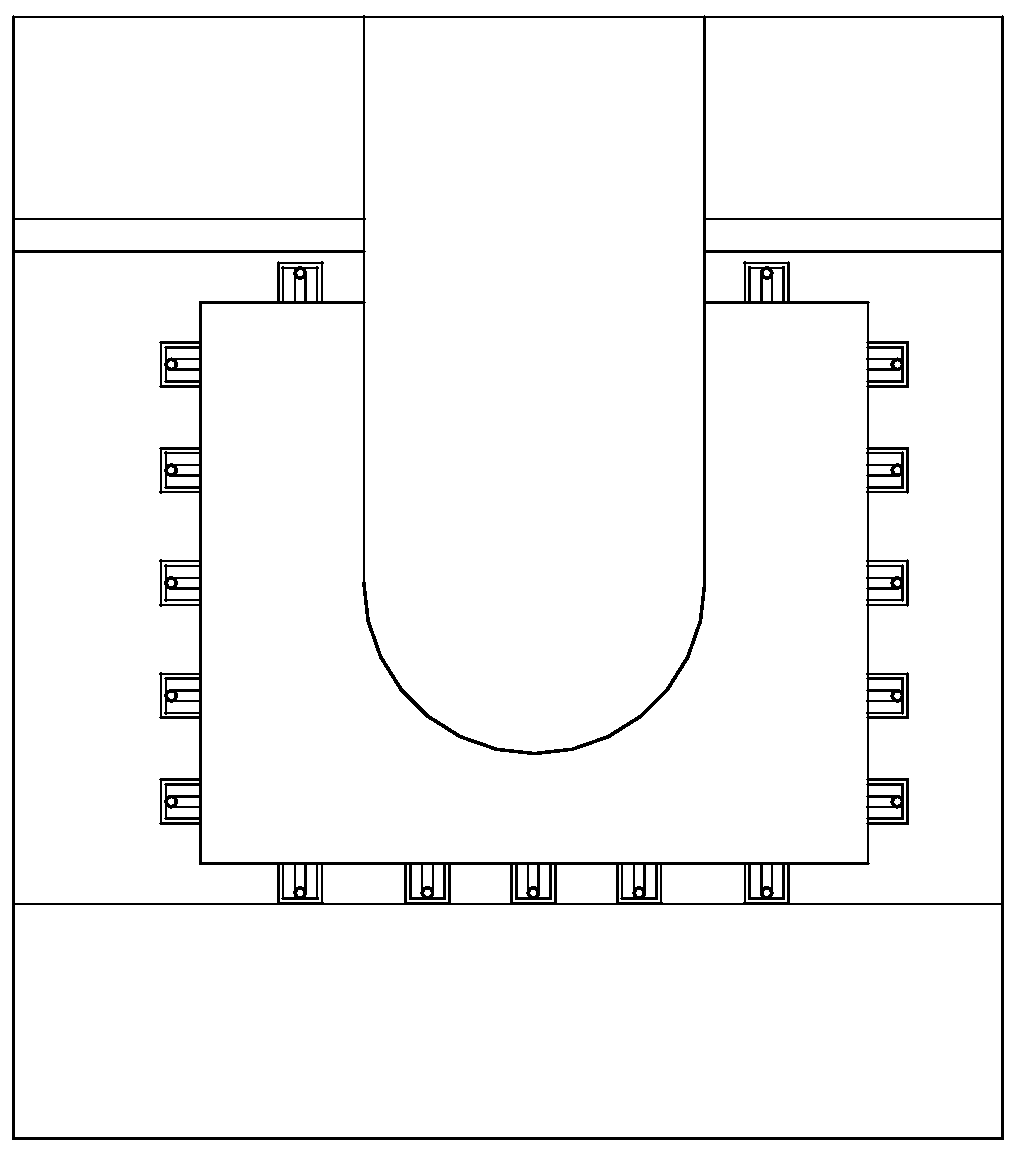

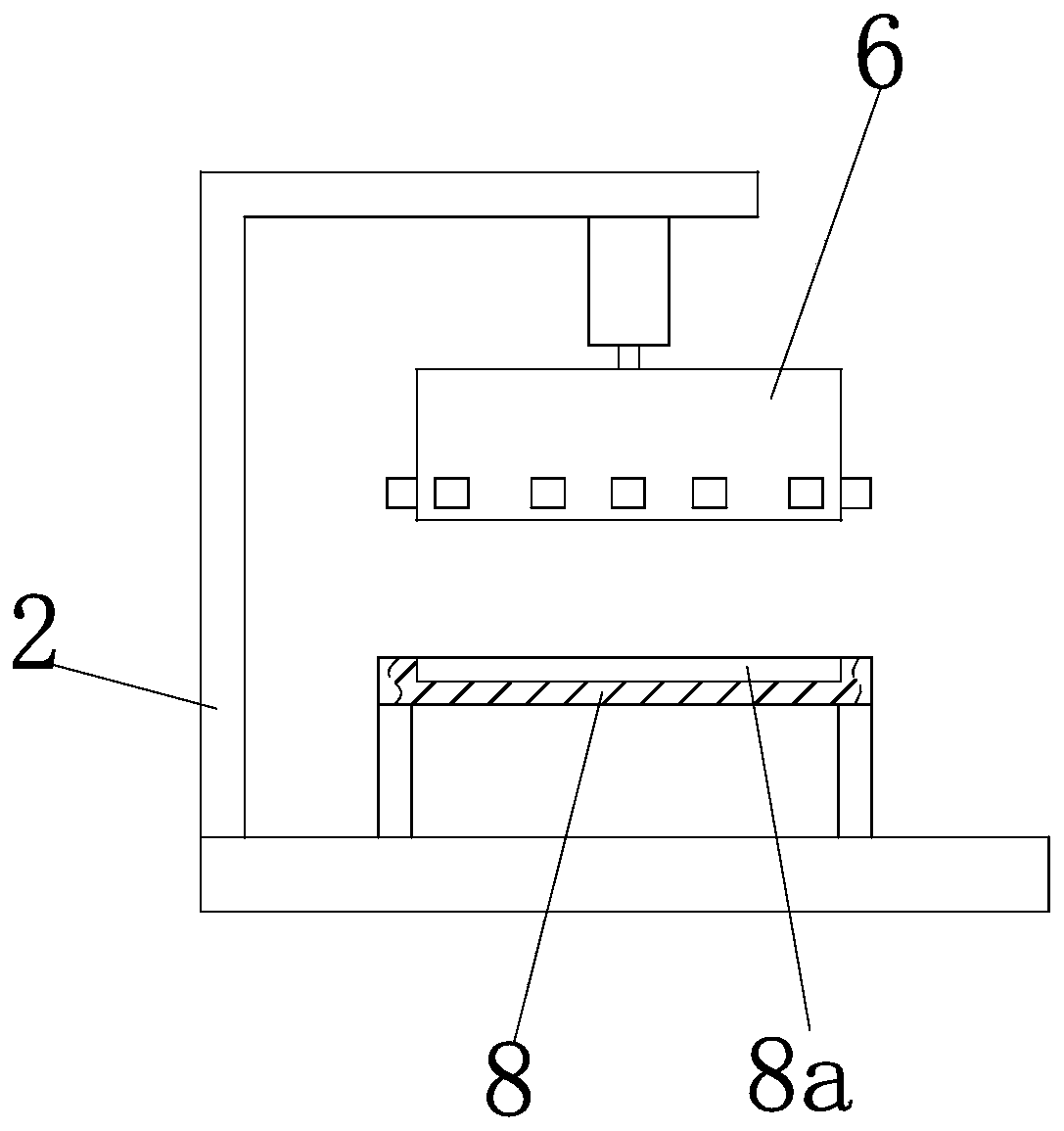

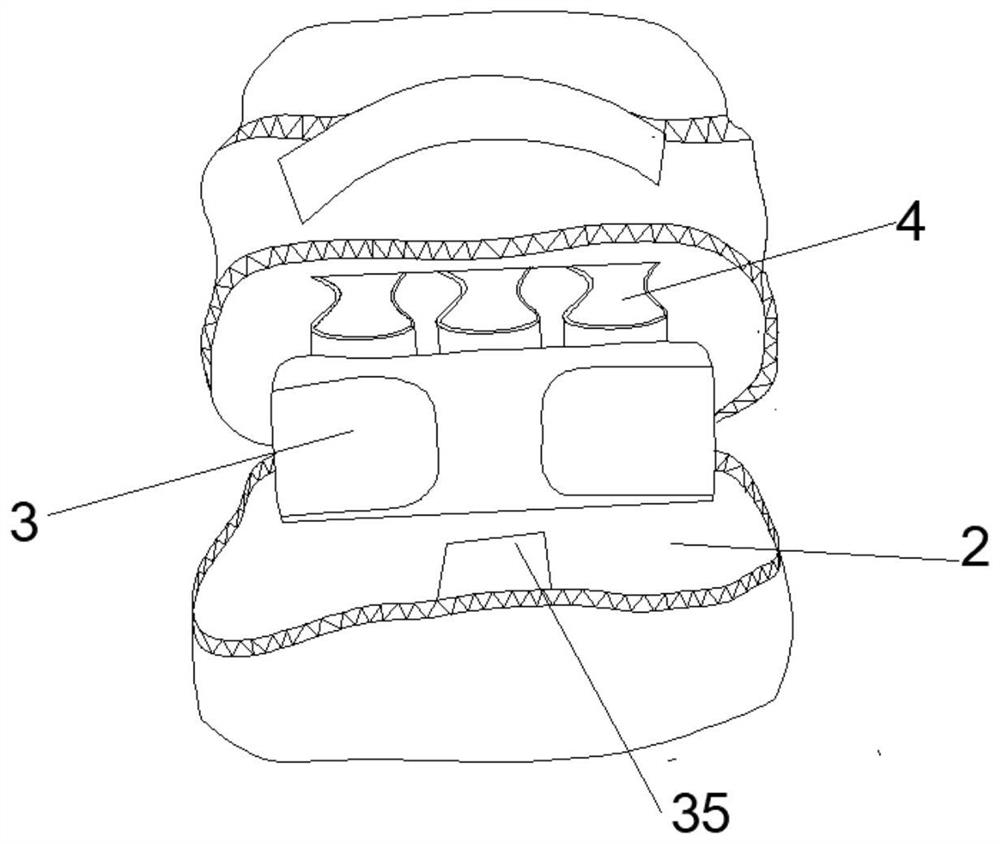

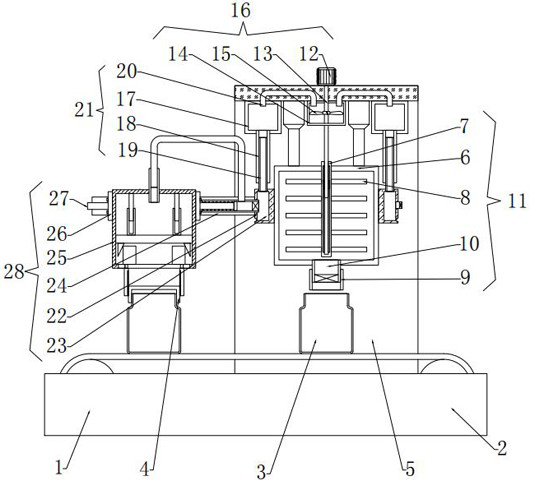

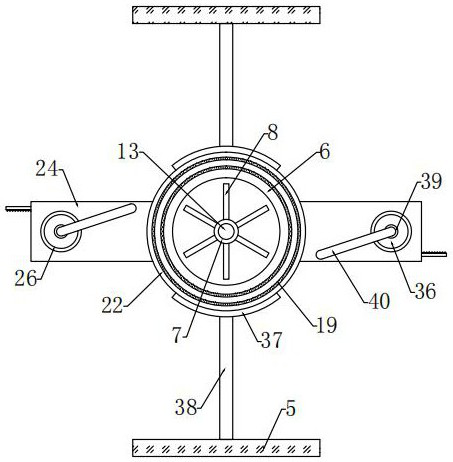

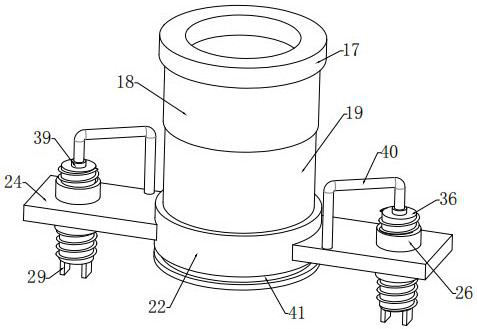

The invention discloses a tableware packing machine. The tableware packing machine comprises a machine frame and a sealing and packing mechanism used for sealing and packing tableware. The sealing andpacking mechanism comprises a bottom plate, a heat seal plate, a movement device, a bottom film assembly, an upper film assembly and a cutting mechanism. By means of the movement device, the bottom plate and the heat seal plate can be closed to conduct heat sealing and packing. Tableware lower containing cavities are formed in the bottom plate, wherein the tableware lower containing cavities areformed in multiple rows, and the number of the tableware lower containing cavities in each row is larger than one. The bottom film assembly is able to convey a bottom film and make the bottom film pasted on the bottom plate. The upper film assembly is able to convey an upper film and make the bottom plate, containing tableware, covered with the upper film. The cutting mechanism comprises a longitudinal cutter device and a transverse cutter device, wherein the longitudinal cutter device and the transverse cutter device can cut multiple sealed and packed tableware packages into single packed tableware. The tableware sealing and packing machine is high in packing efficiency, dozens of pieces of plastic tableware can be packed at a time, time and manpower are saved, full-automatic plastic tableware packing can be achieved, and the packing quality is good.

Owner:中山市美图实业有限公司

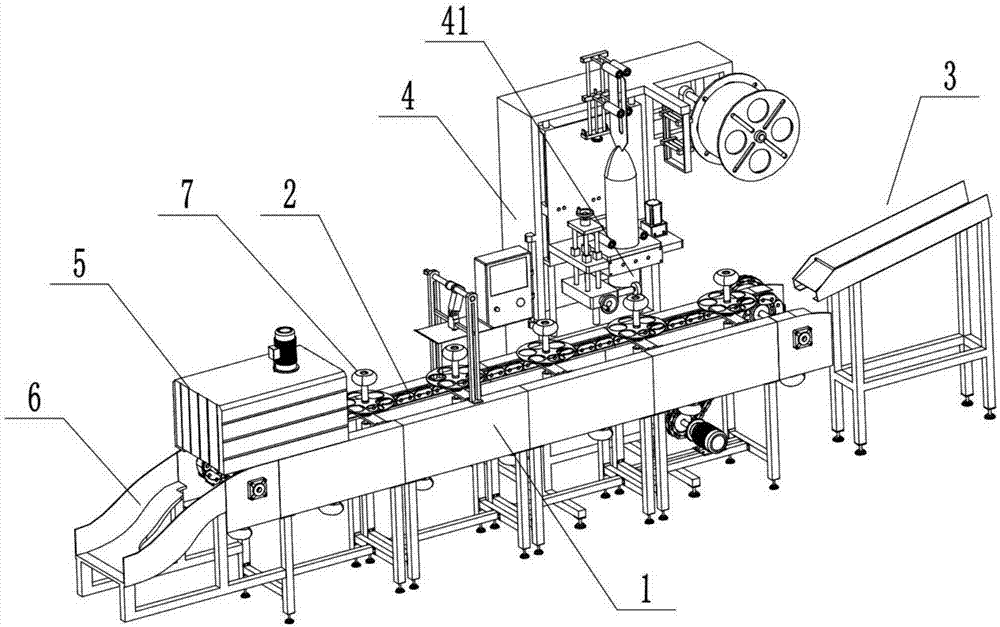

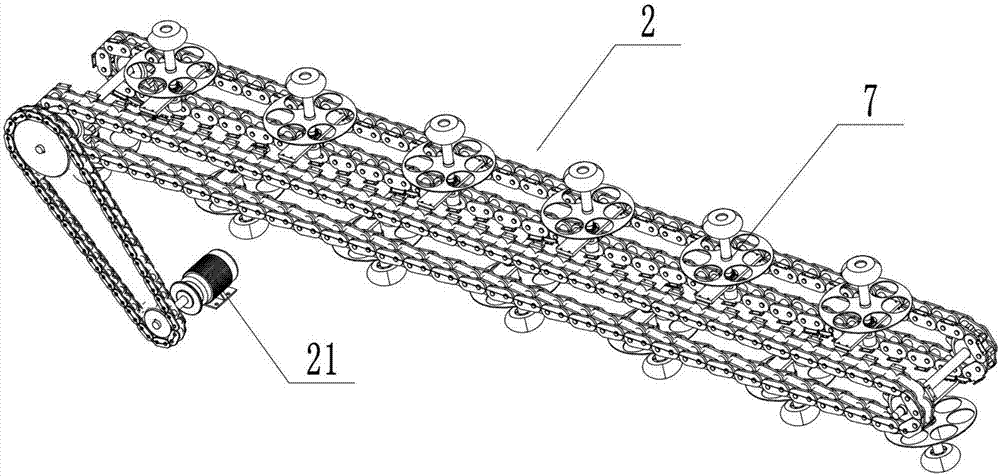

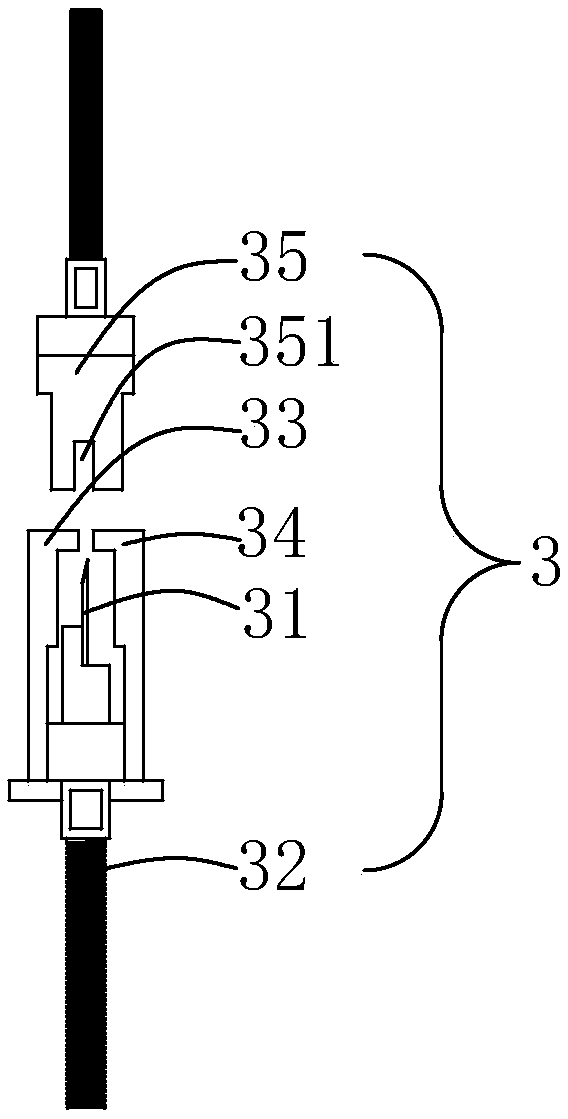

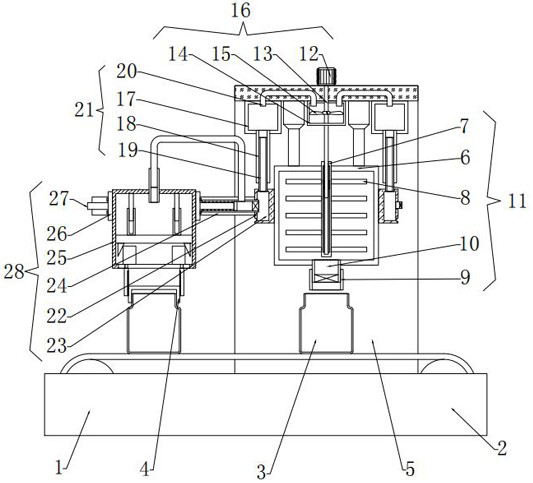

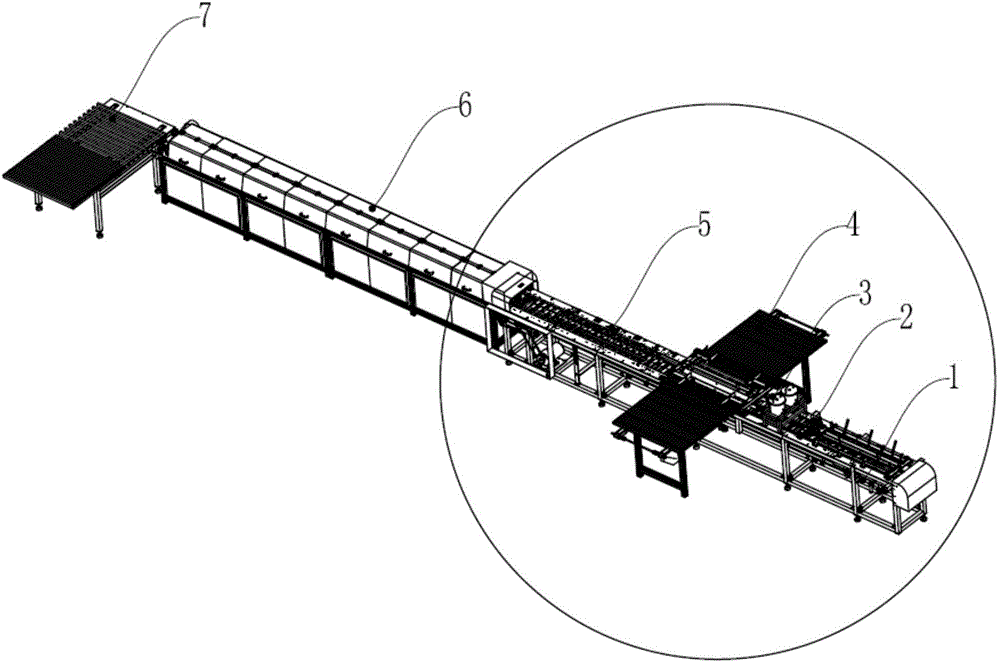

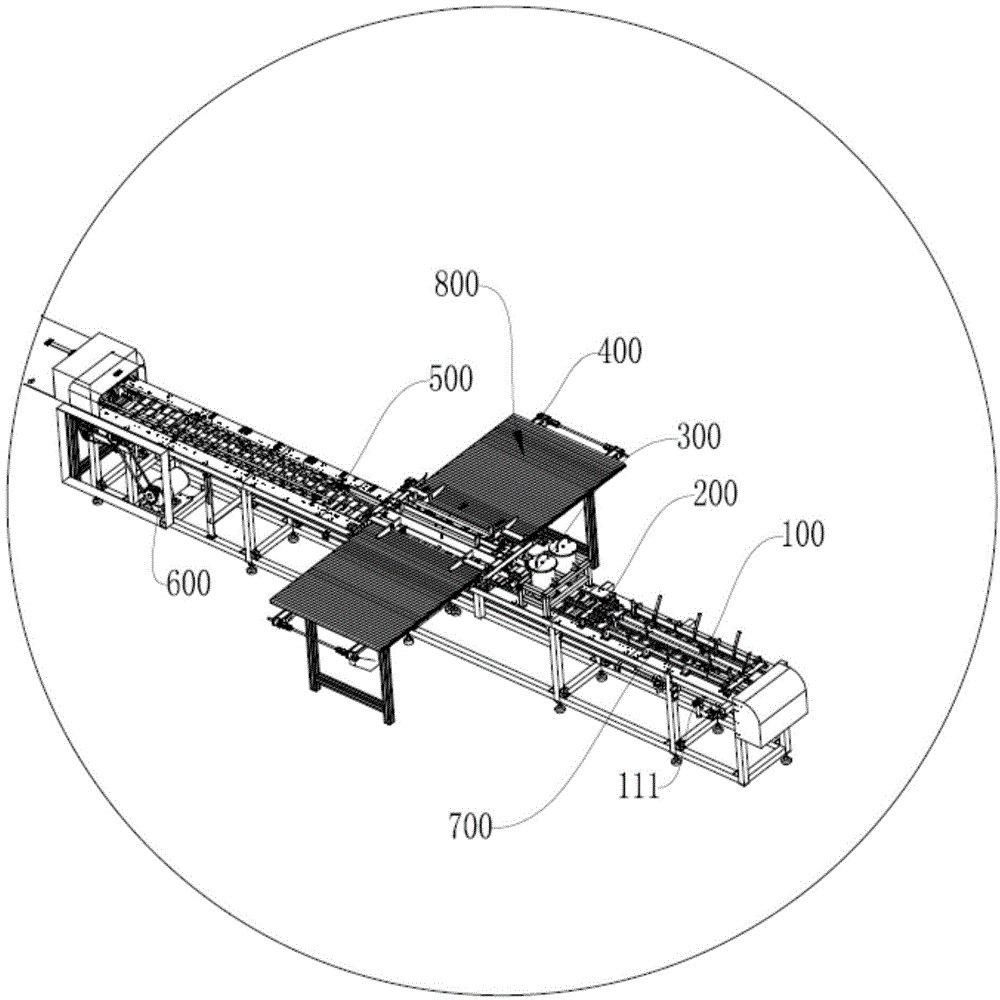

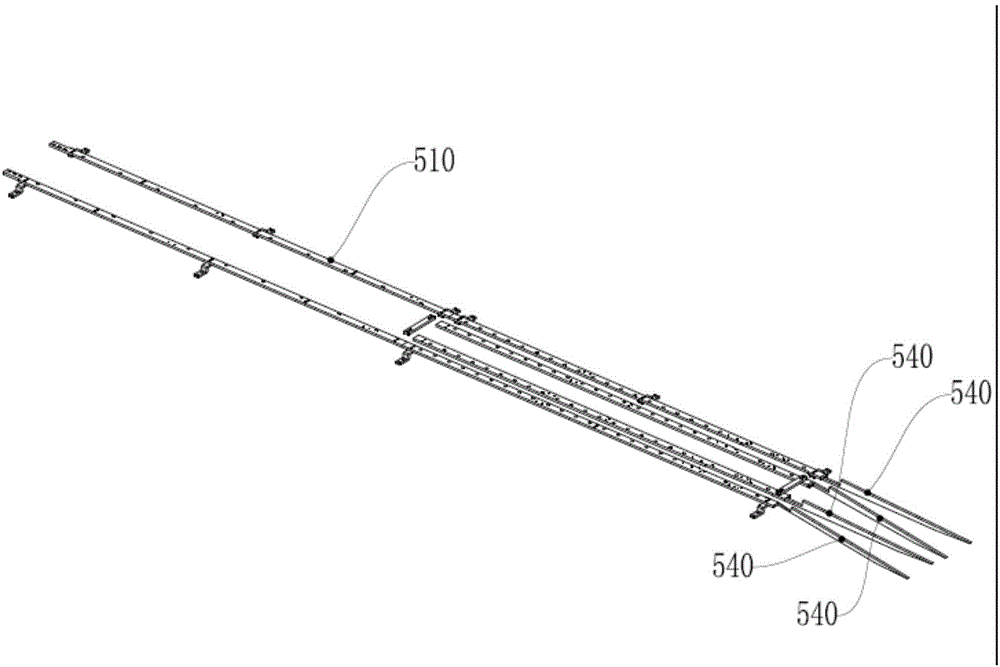

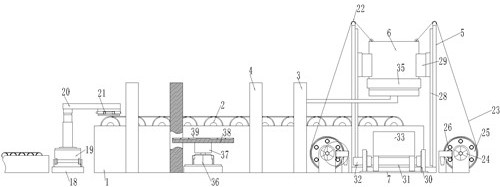

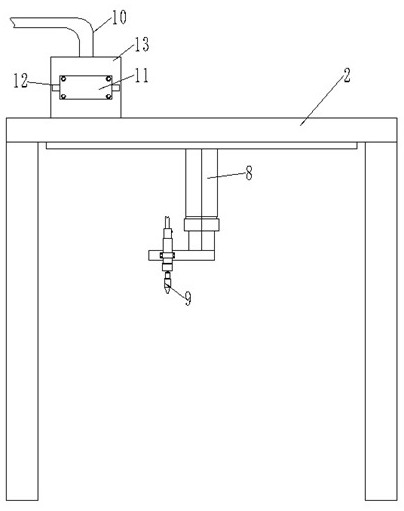

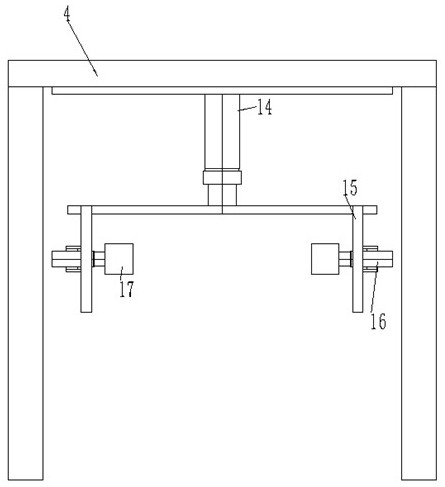

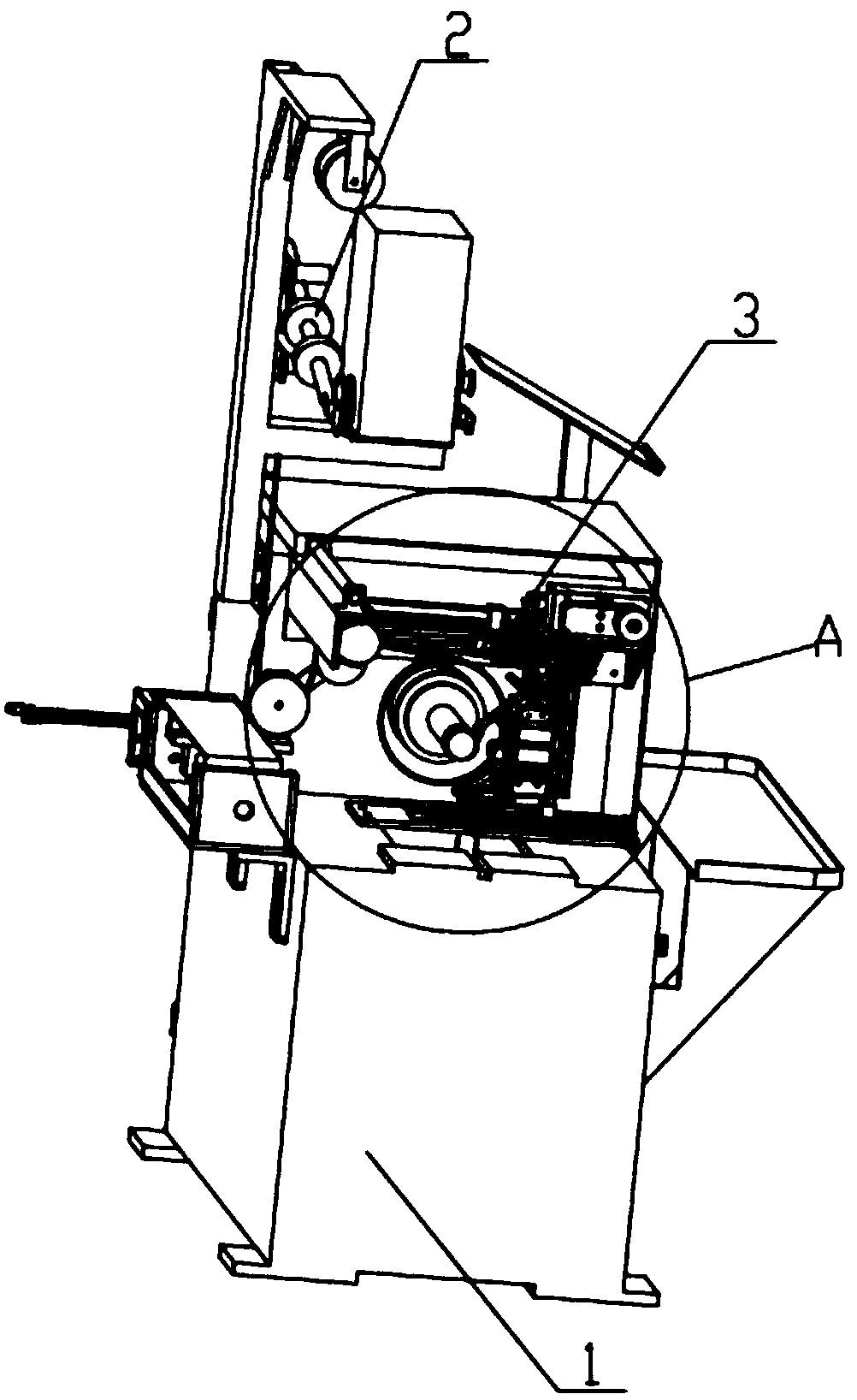

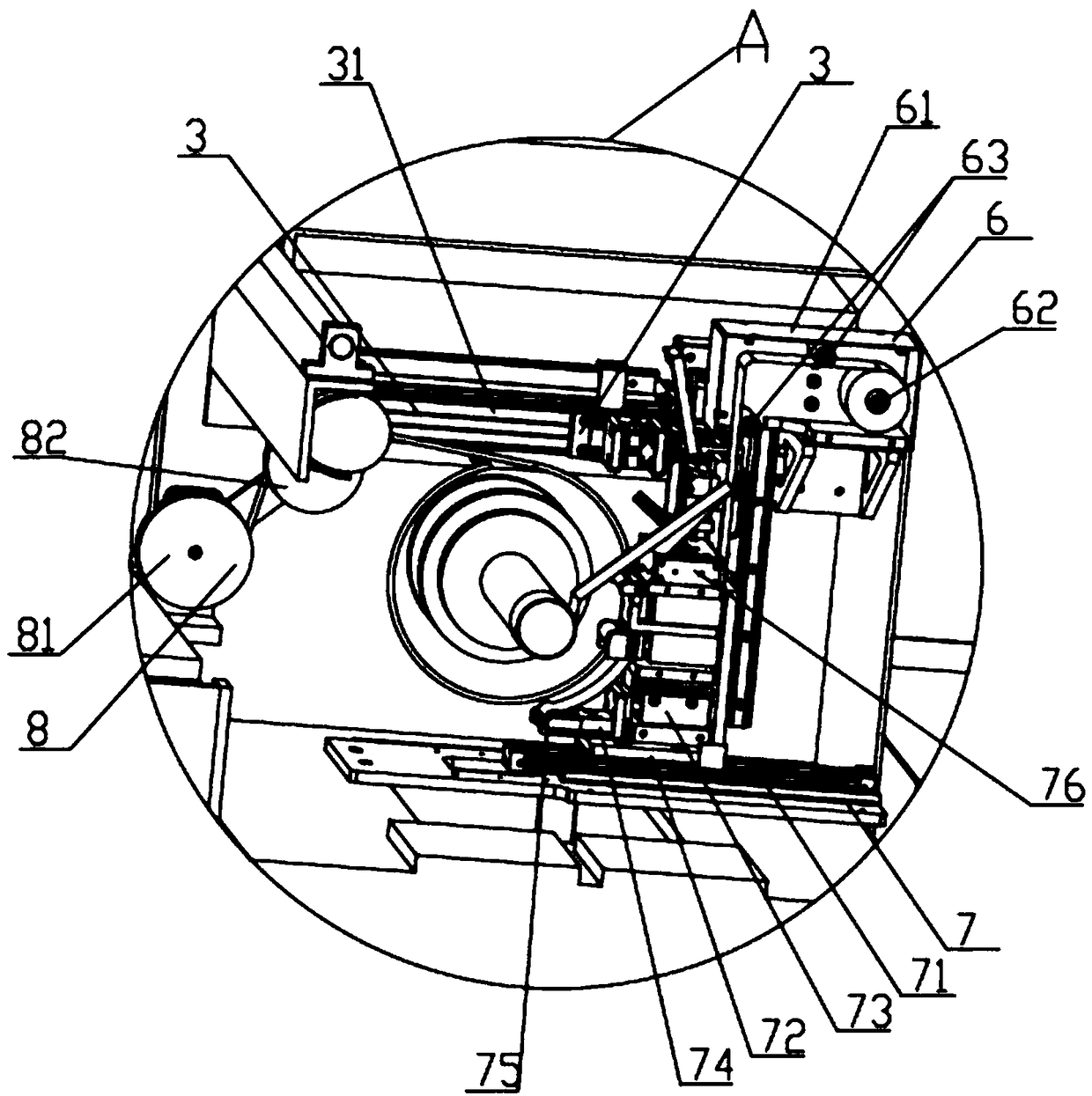

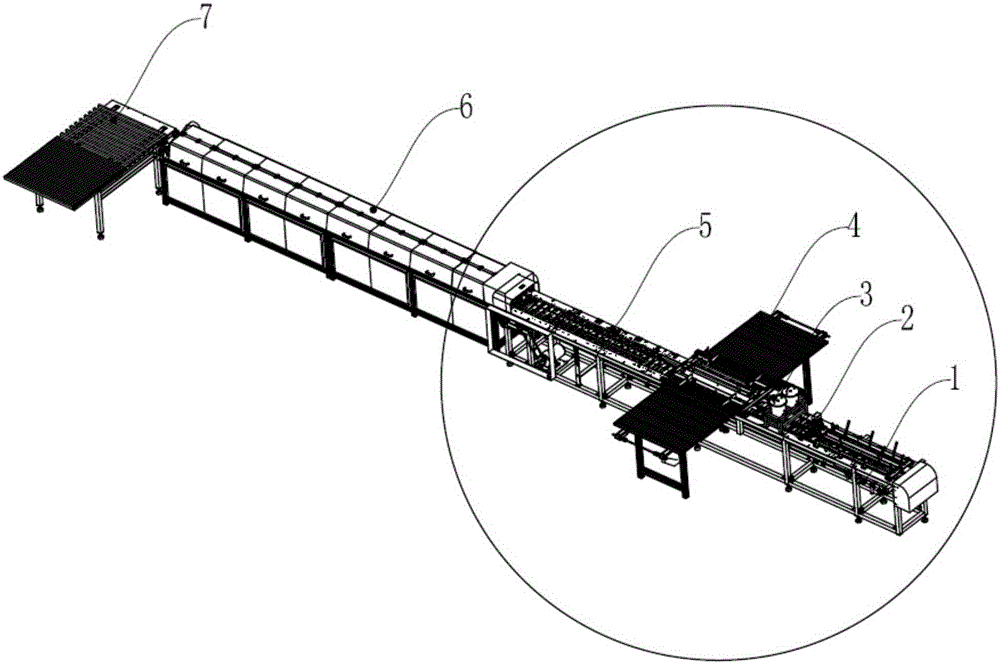

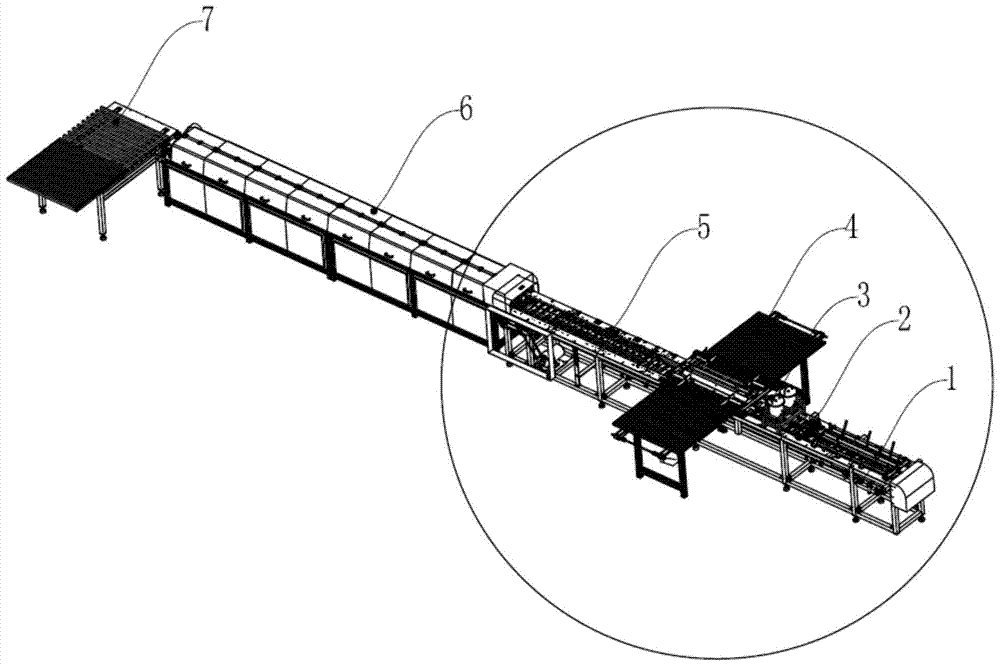

Electric wire coil automatic wrapping packaging machine and packaging method thereof

InactiveCN107539536ARealize fully automatic packagingGuaranteed heat shrink effectWrappers shrinkageOutput deviceThermal contraction

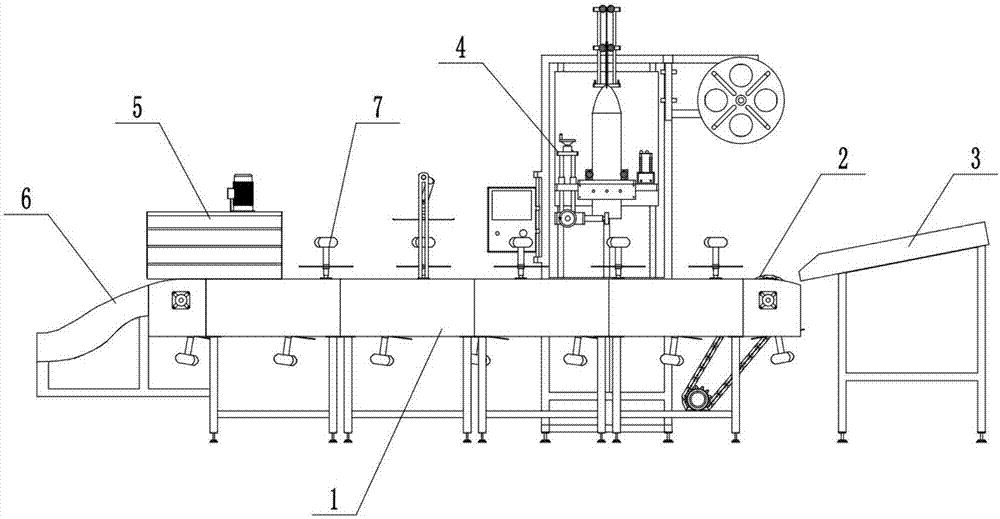

The invention relates to the field of packaging machinery, in particular to an electric wire coil automatic wrapping packaging machine. The electric wire coil automatic wrapping packaging machine comprises a conveying device mounted on a machine frame. A product input device, a film sleeving device, a thermal contraction device and a product output device are sequentially arranged in the conveyingdirection of the conveying device. Electric wire coils are subjected to thermal contraction packaging based on a thermal contraction film packaging technology, automatic seamless packaging is achieved, and the electric wire coil automatic wrapping packaging machine is attractive in packaging appearance, high in packaging quality and capable of meeting the seamless packaging requirements.

Owner:JIANGNAN UNIV

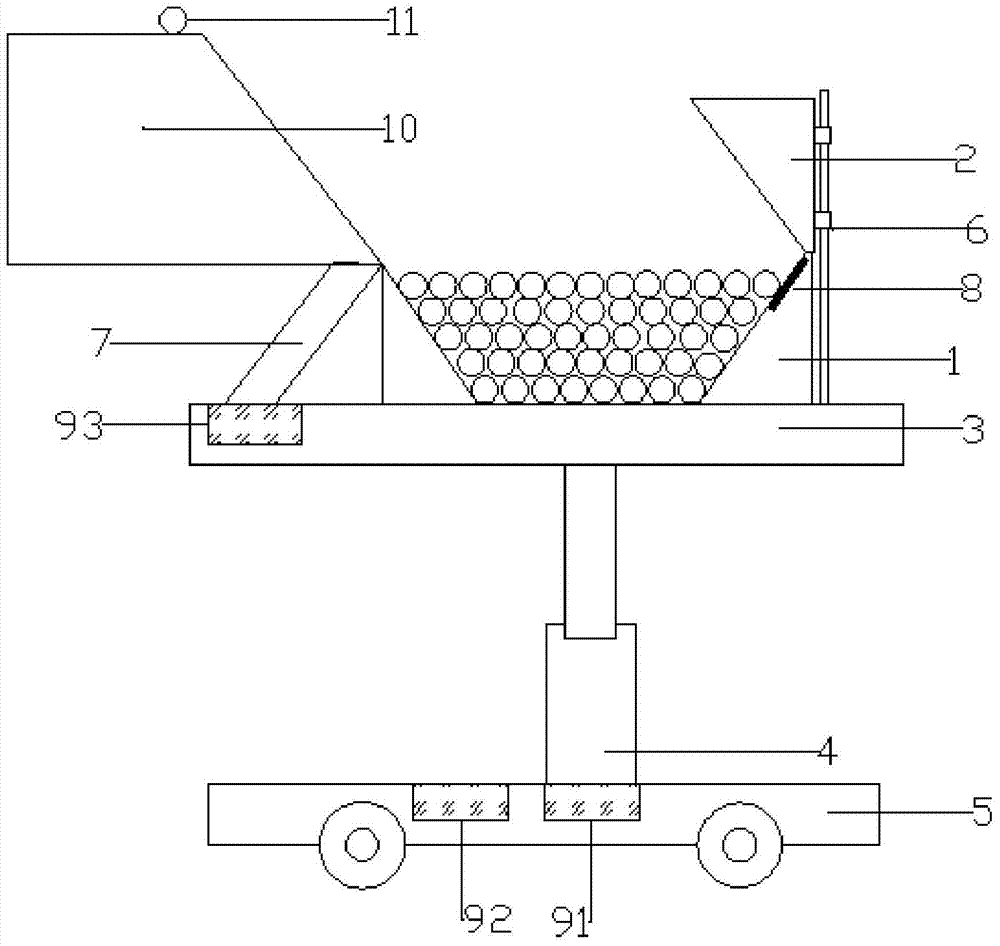

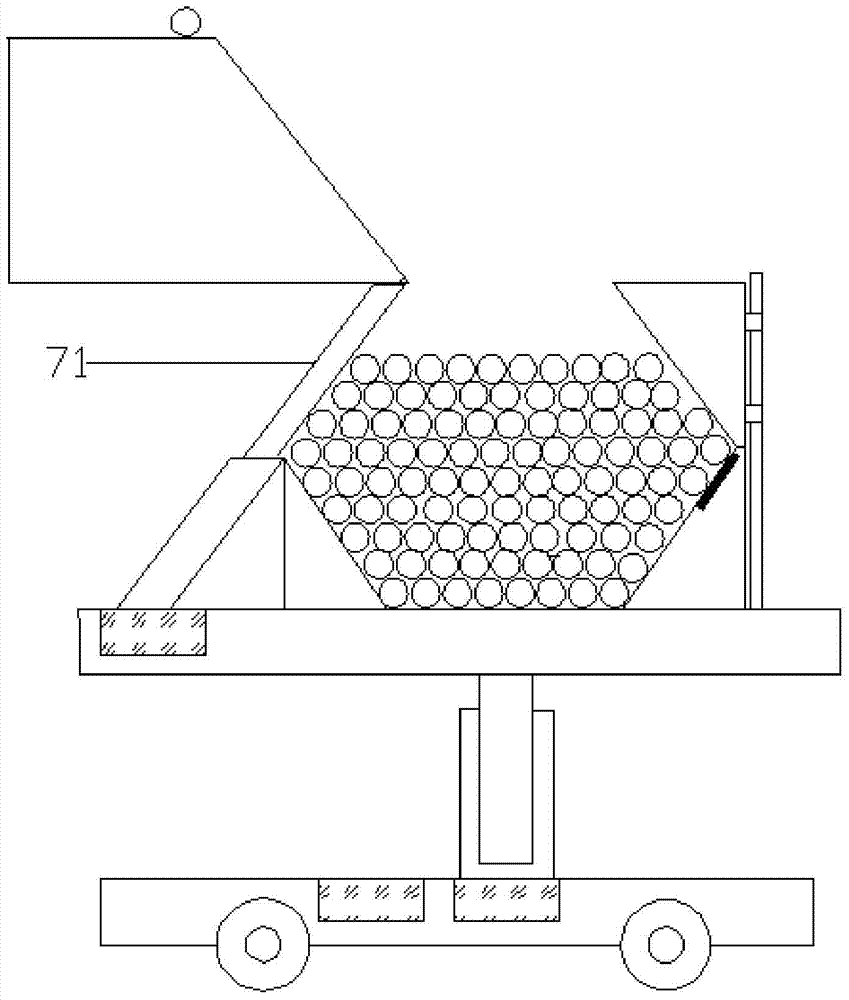

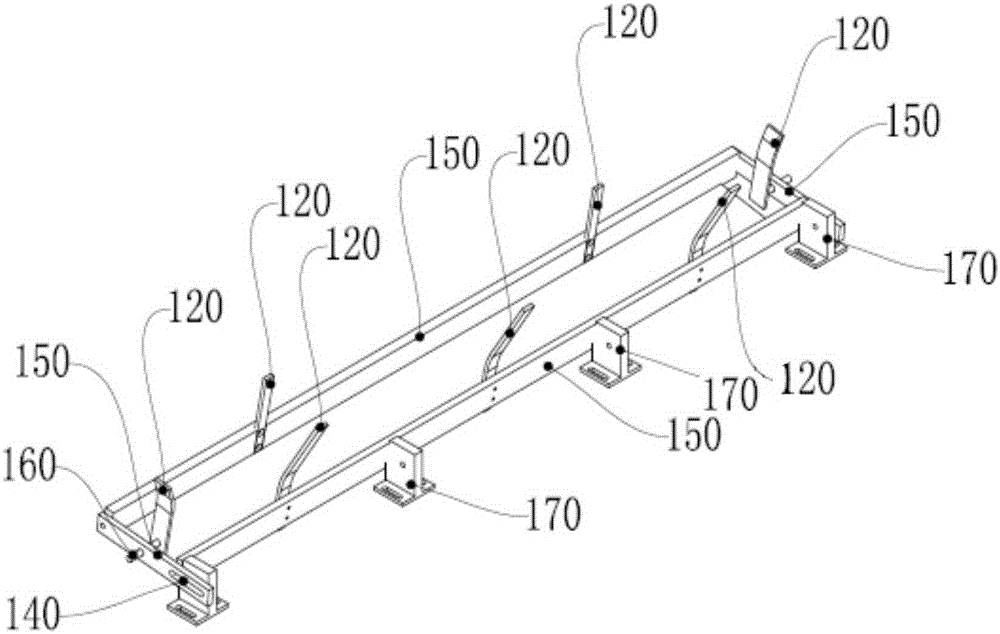

Automatic packing machine for small-caliber steel pipe

InactiveCN103482146AOvercome self-importanceSimple structurePackaging automatic controlElectrical controlSteel tube

The invention provides an automatic packing machine for a small-caliber steel pipe. The automatic packing machine comprises two first supporting frames, a second supporting frame, a fixing rod, a telescopic stop rod, a supporting seat, a lifting device and a trolley. The two first supporting frames are respectively provided with a right-angle edge fixed to two ends of the supporting seat, the fixed right-angle edges are mutually parallel or positioned on the same straight line, two bevel edges are opposite, one right-angle edge of the second supporting frame is movably connected with the fixing rod and can freely rotate around the fixing rod, the other right-angle edge of the second supporting frame is positioned above the right-angle edge of the second supporting frame, the fixing rod and the telescopic stop rod are fixedly connected to two ends of the supporting seat, the central axis of the telescopic stop rod is parallel to the plane of the bevel edges of the first supporting frames next to the fixing rod, and the supporting seat is connected with the trolley through the lifting device. The automatic packing machine is simple in structure, high in reliability and flexibly adaptable to different production lines and overcomes the shortcoming that an existing large packing device is large in dead weight, complicated in structure, noisy, high in maintenance cost and the like, and electrical control and a mechanical mechanism are integrated.

Owner:天津腾飞钢管有限公司

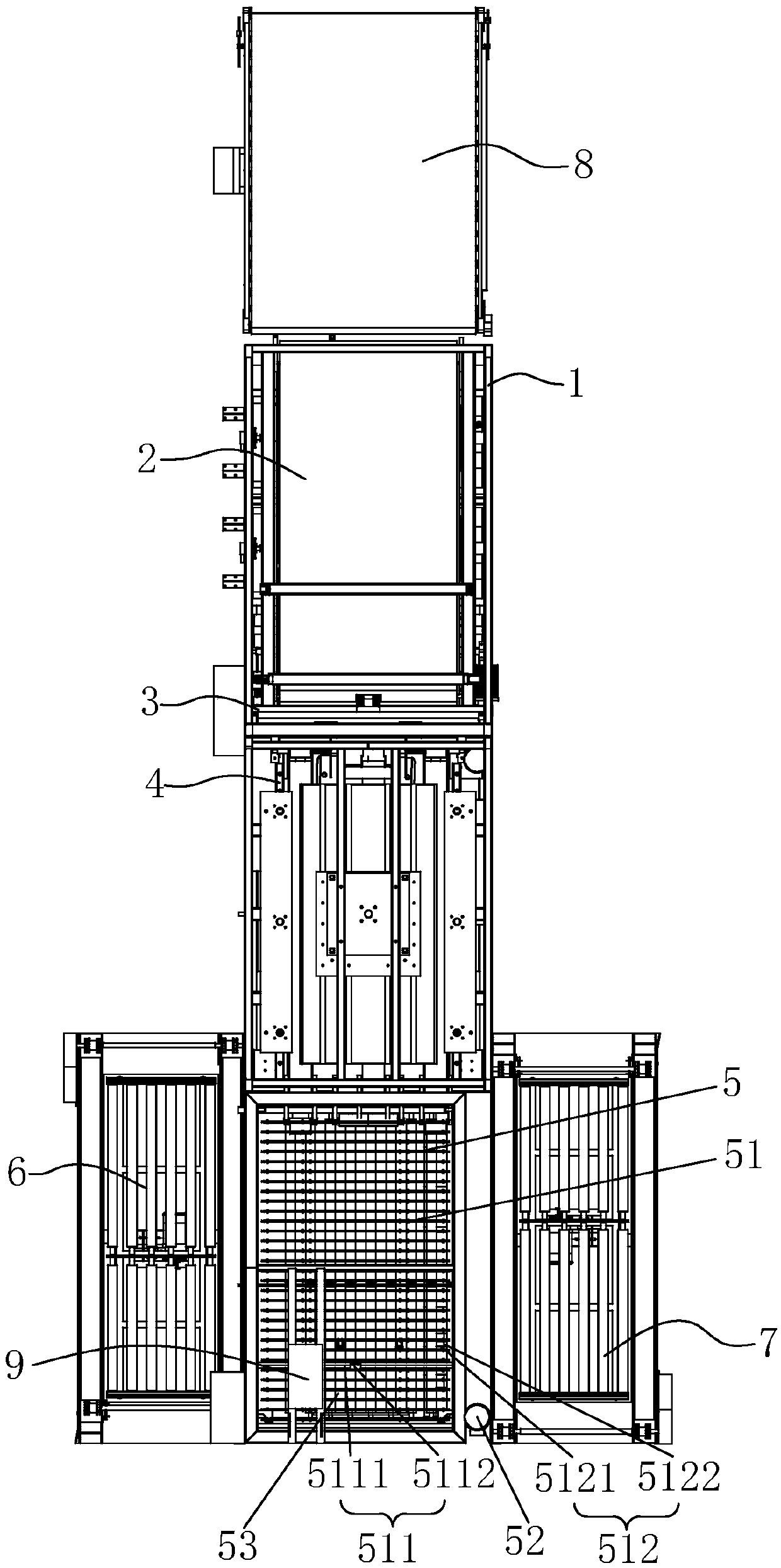

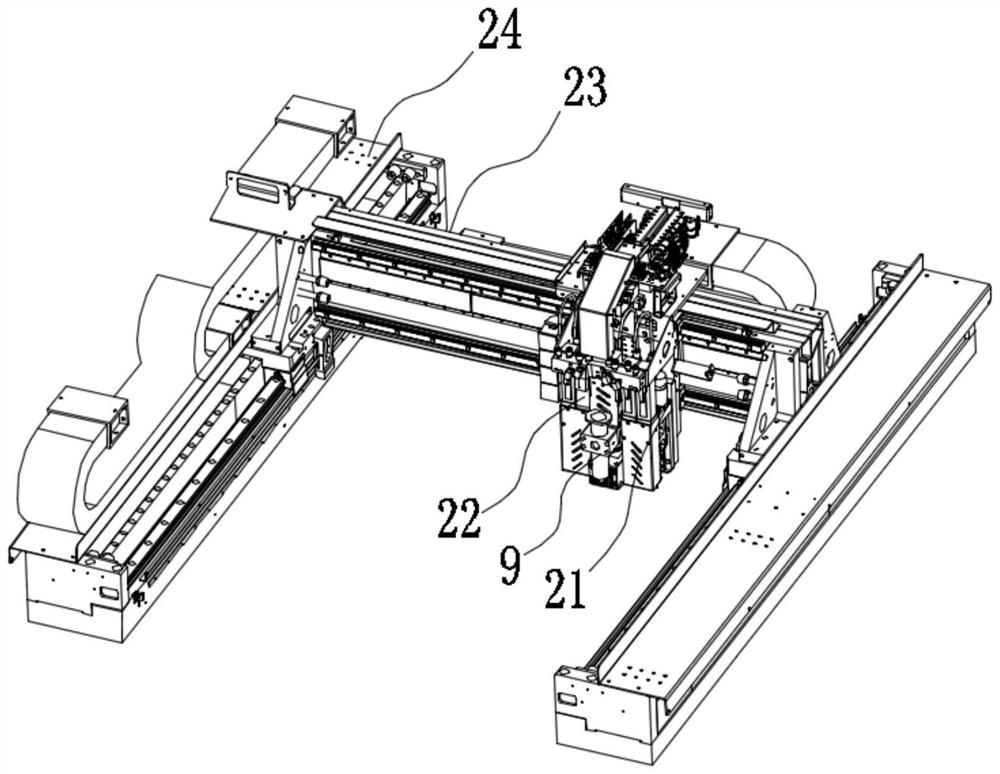

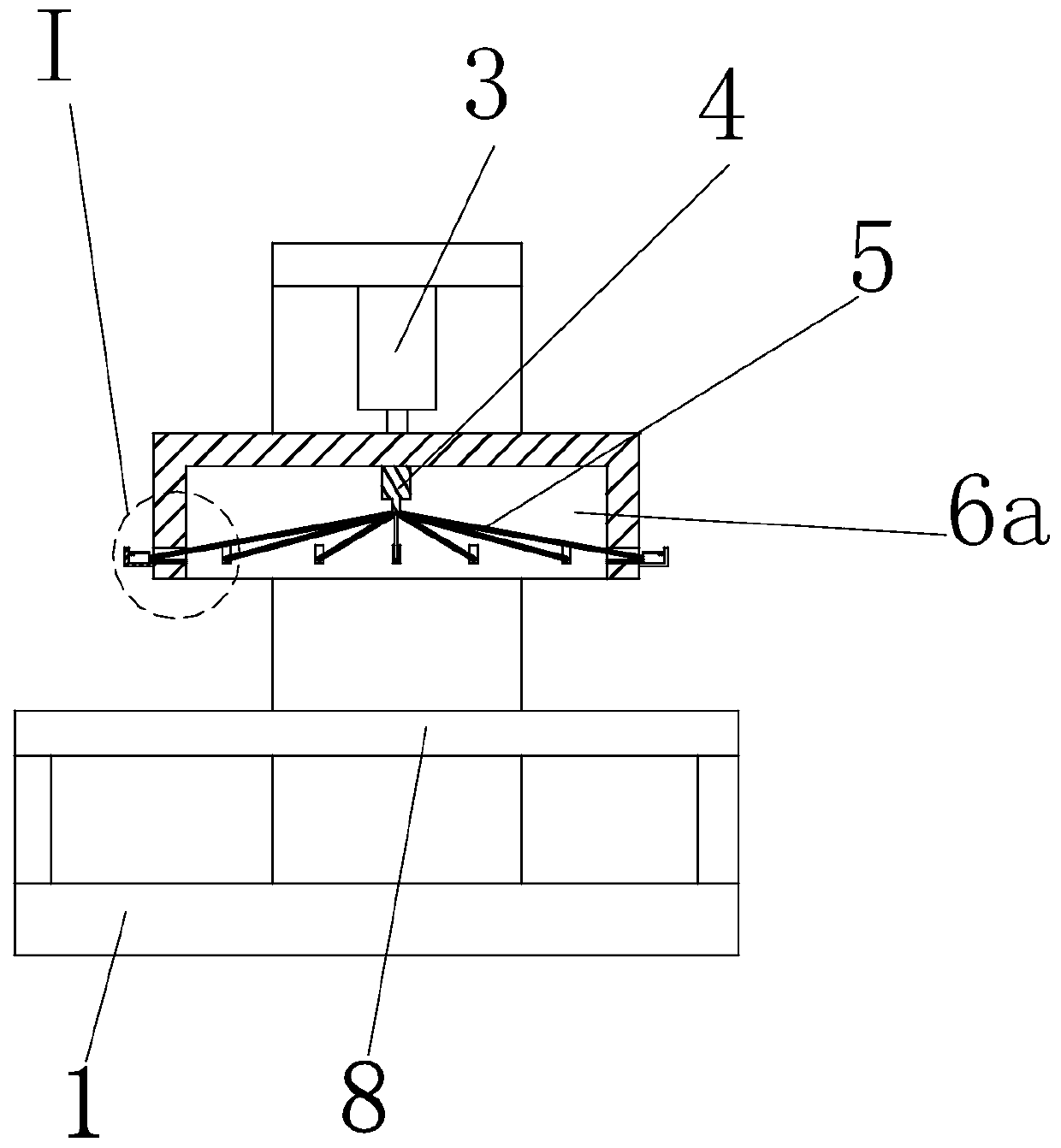

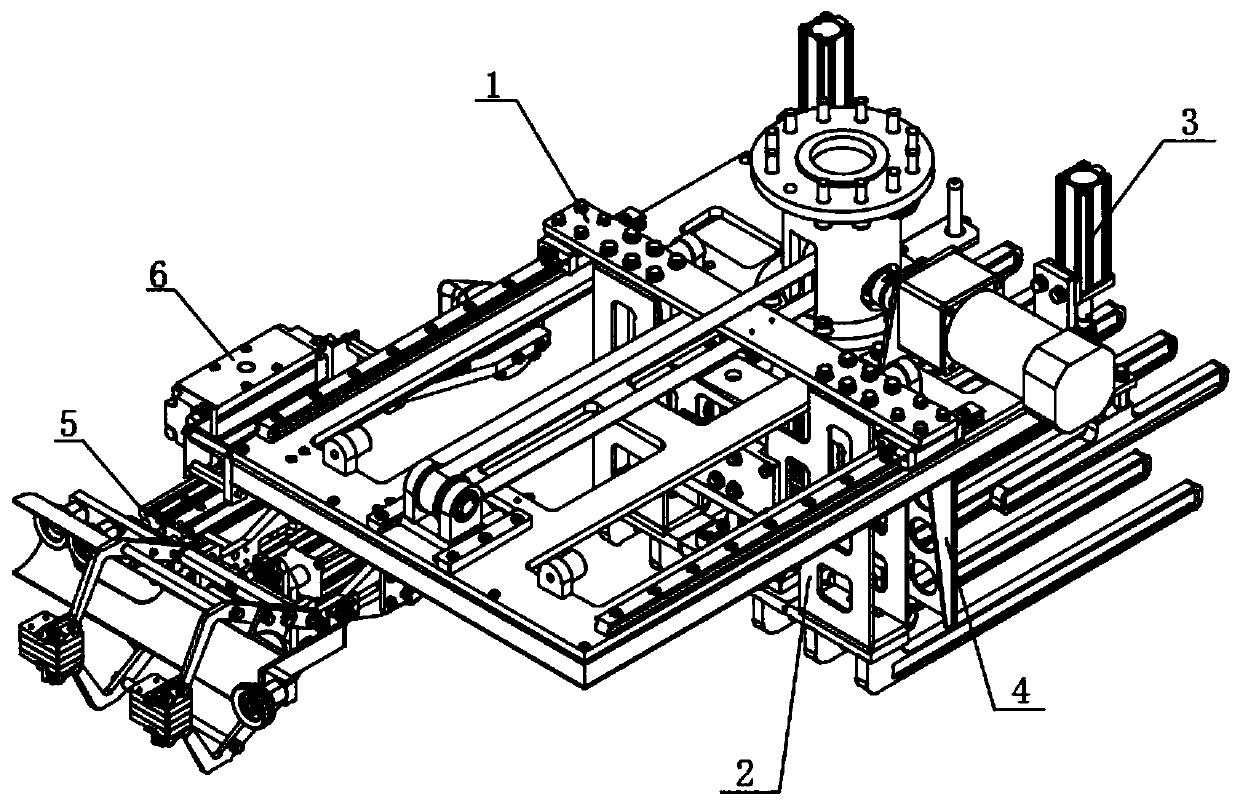

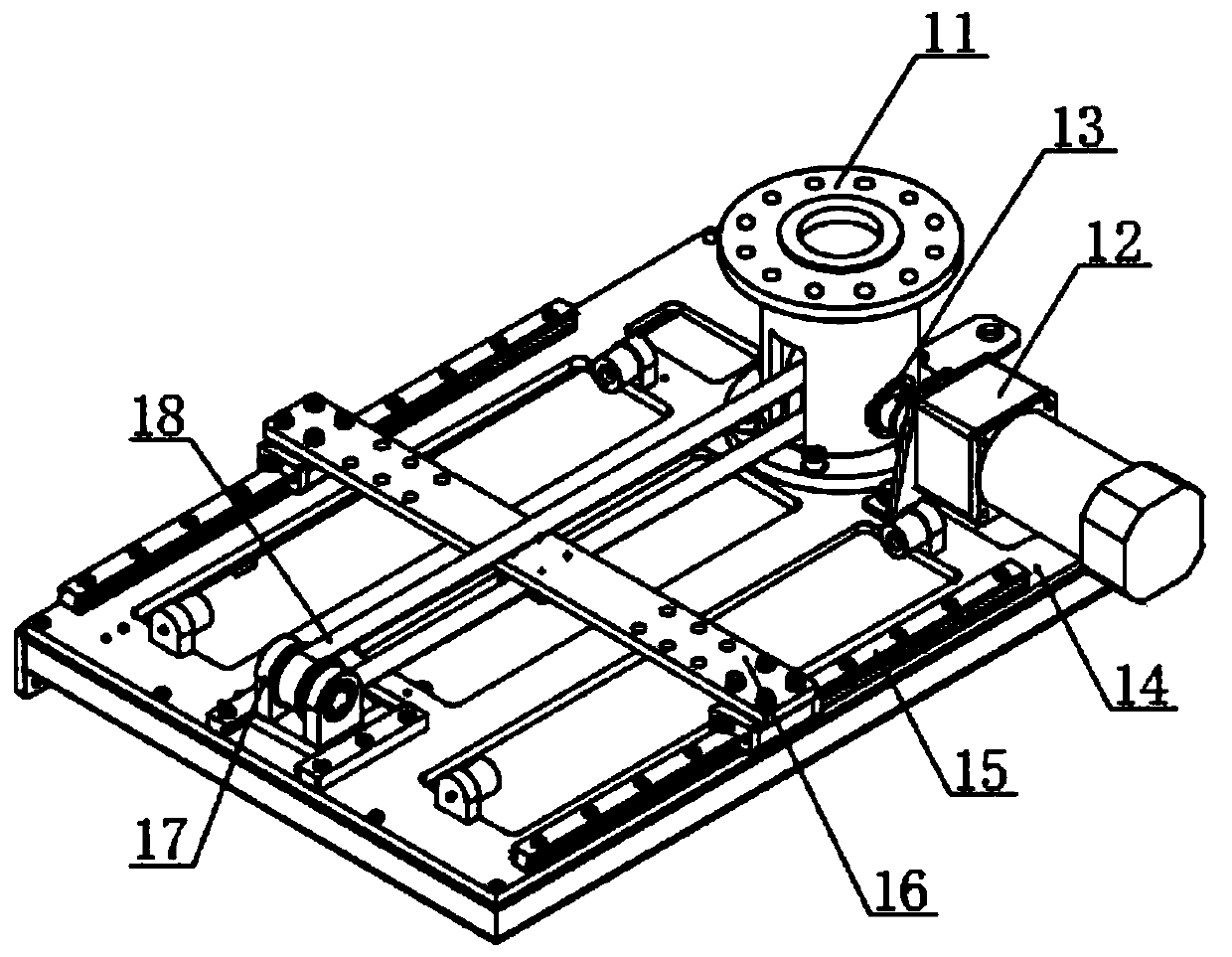

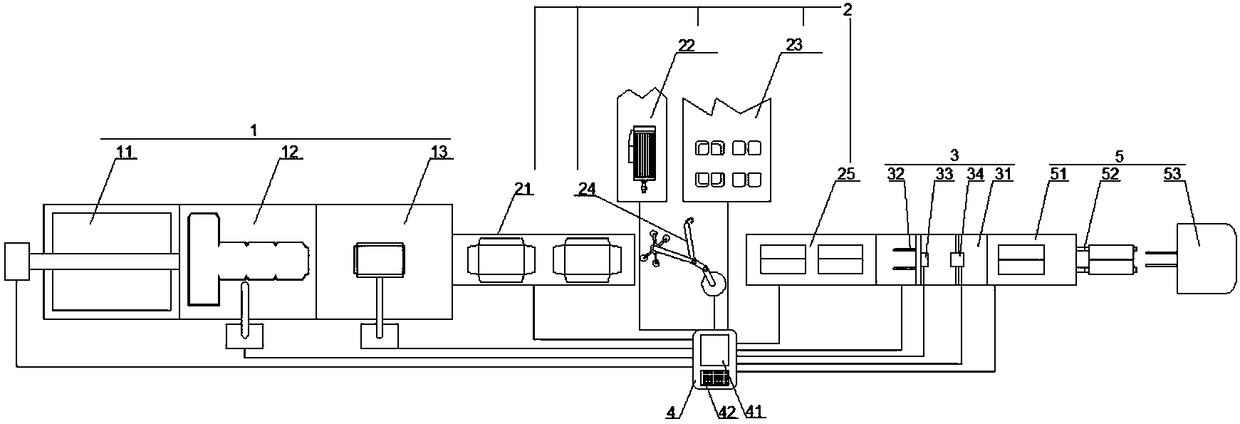

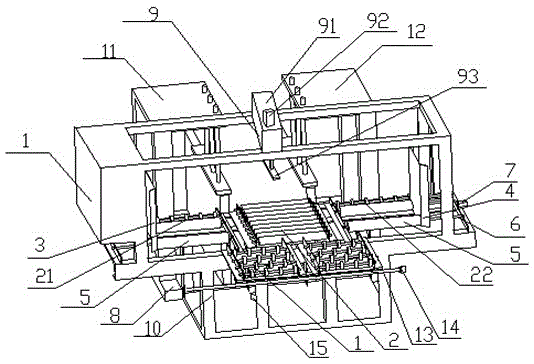

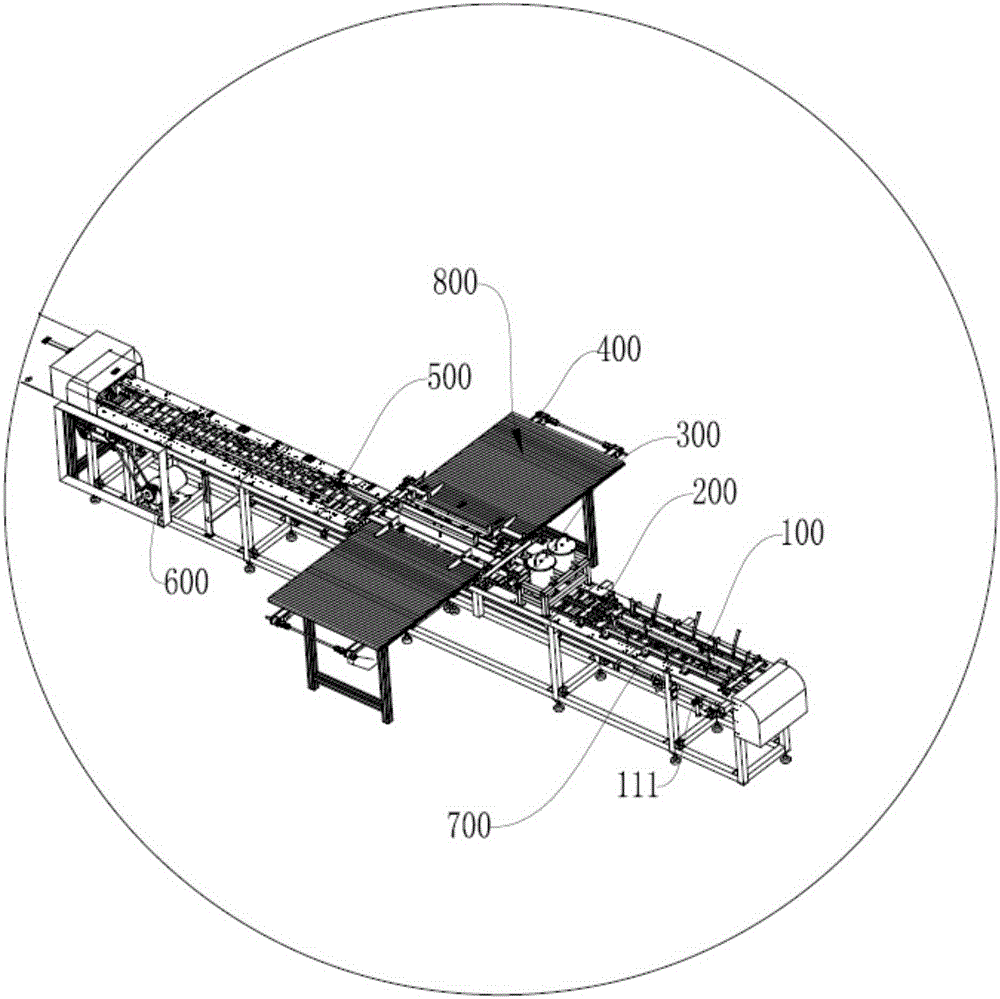

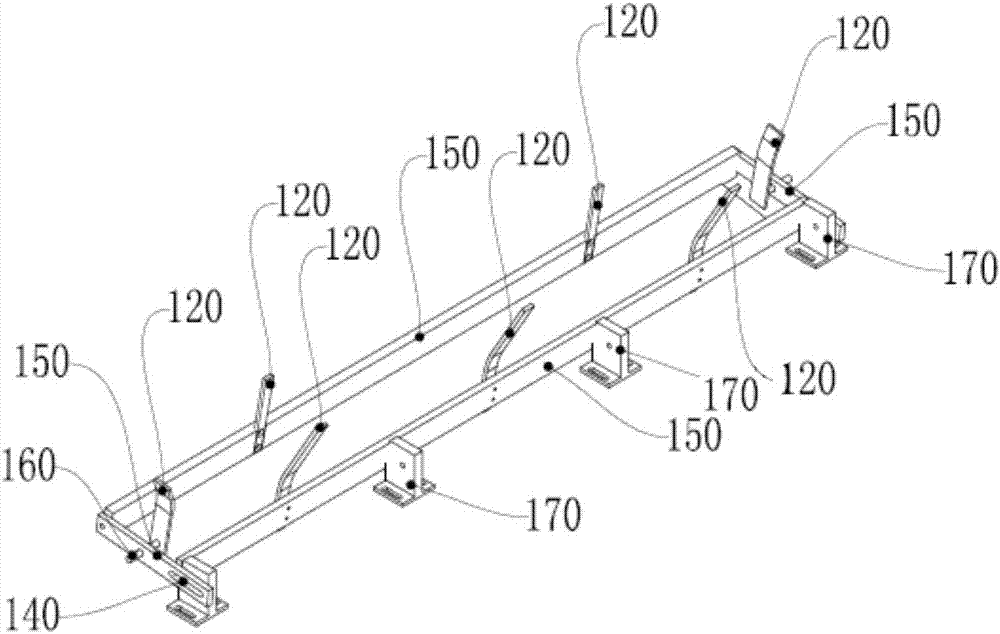

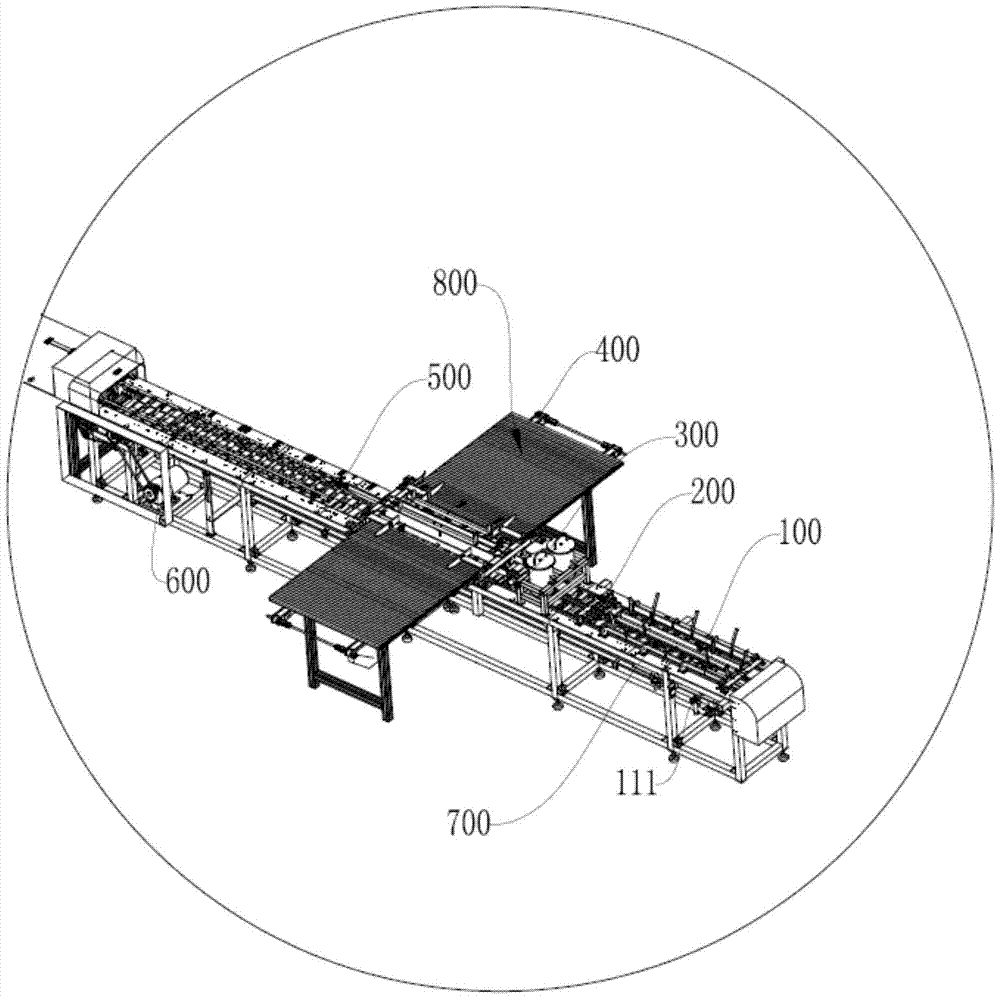

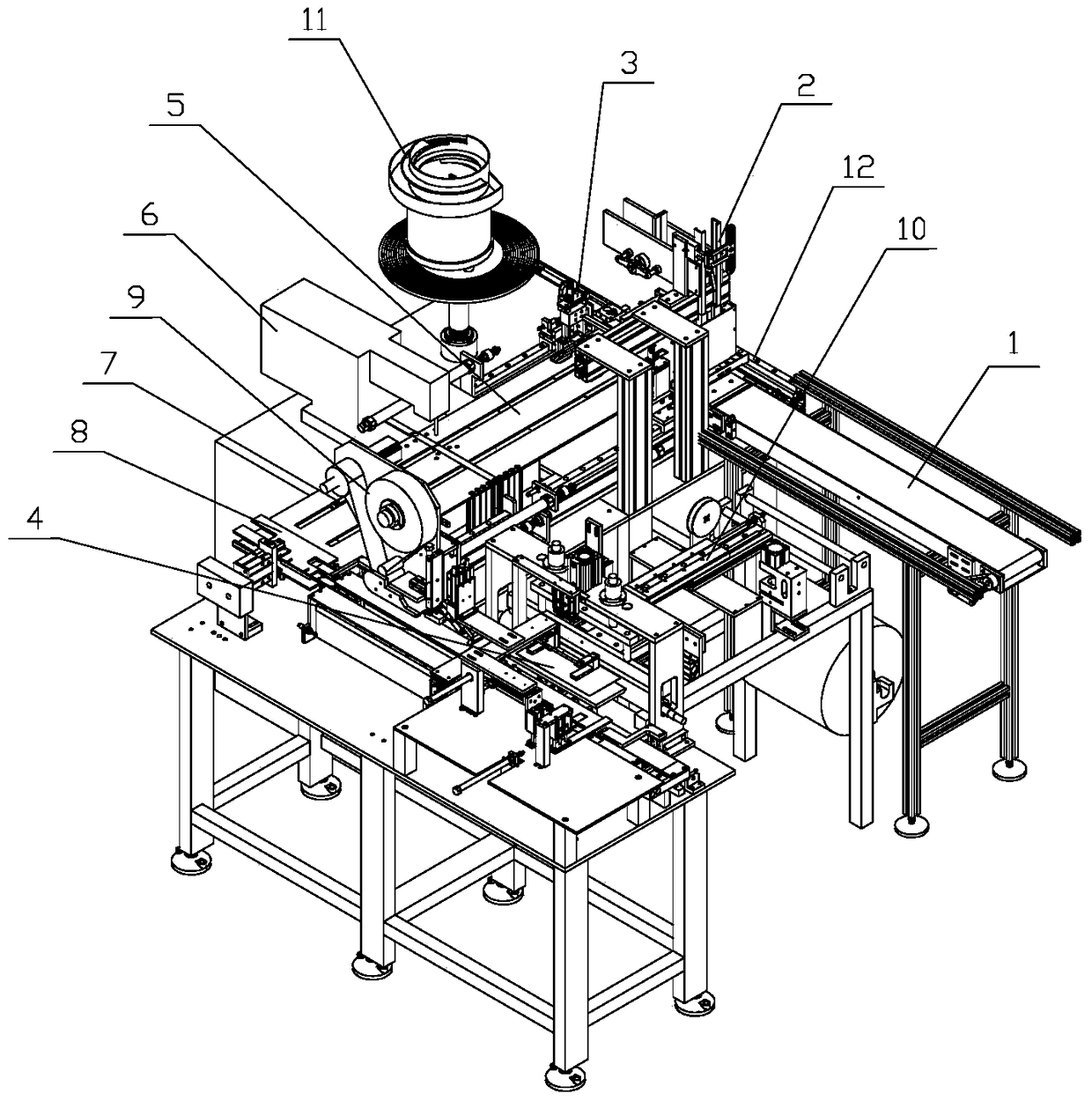

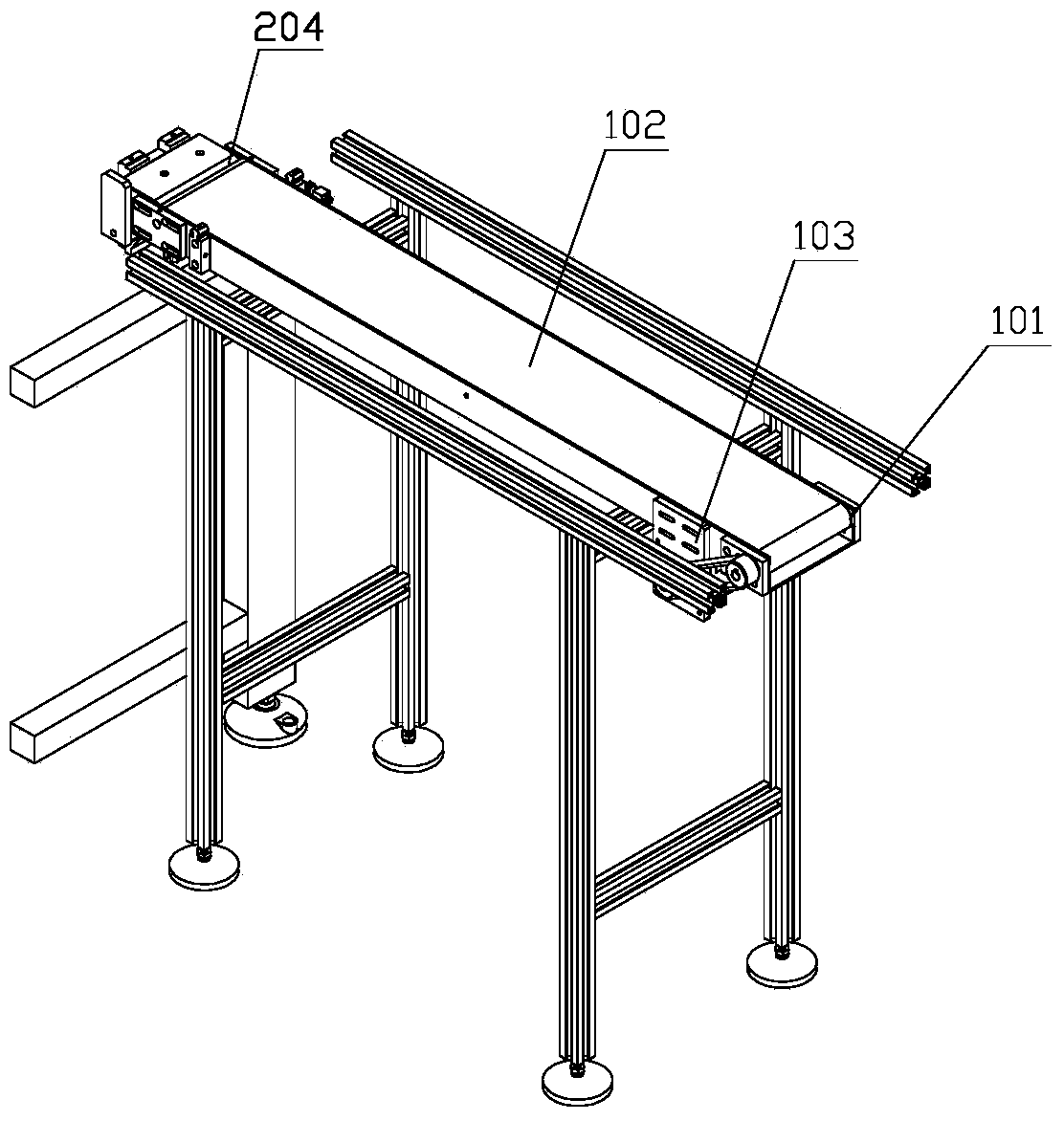

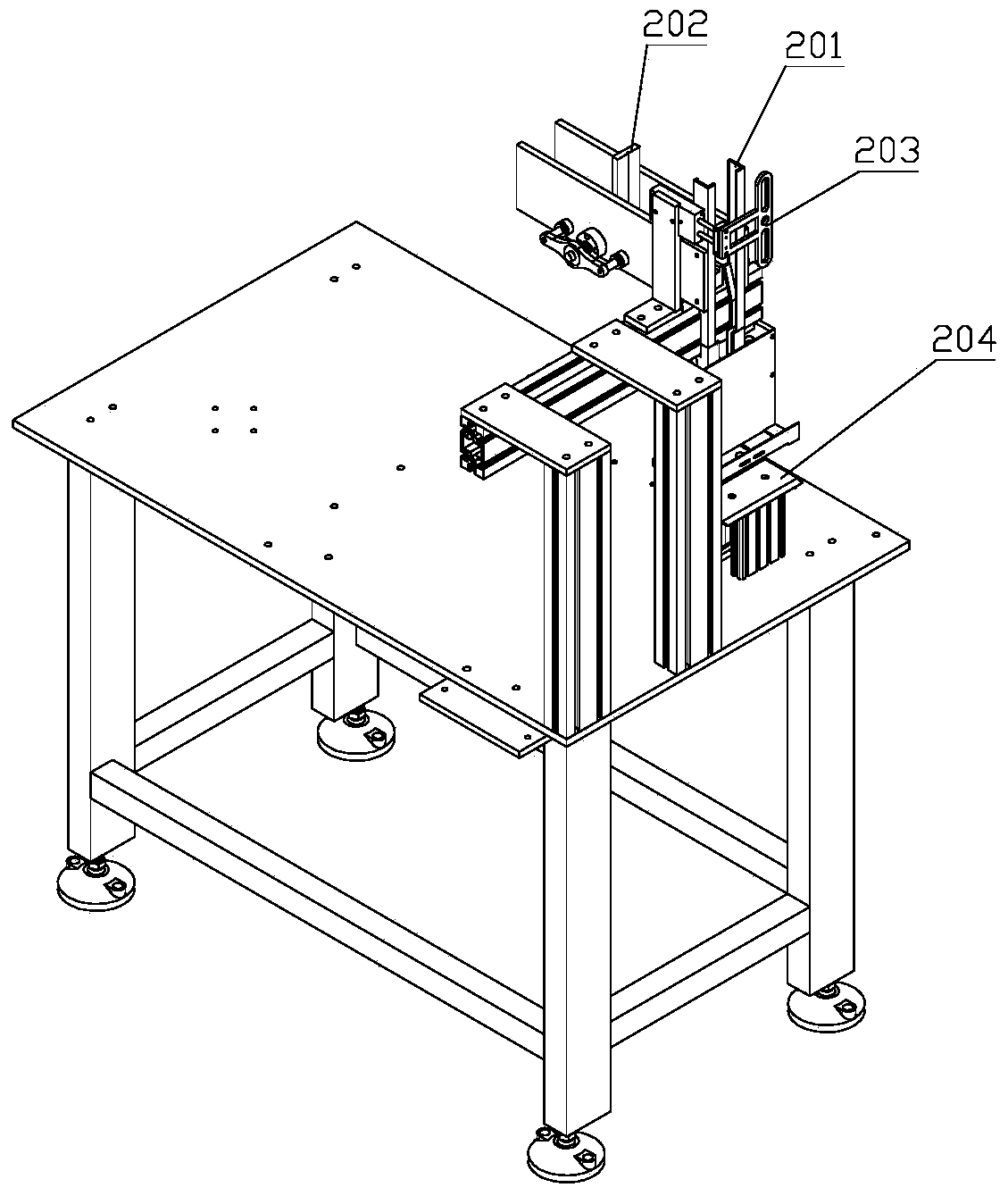

Fully automatic packing line for packing sheets

PendingCN109606799ARealize fully automatic packagingSolve the problem of non-parallelPackaging by pressurising/gasifyingWrappingEngineeringFully automatic

The invention relates to a fully automatic packing line for packaging sheets, including a frame, on which a wrapping device for wrapping sheets, a transverse cutting device for transversely cutting apackaging film for wrapping the sheets, a longitudinal cutting device for longitudinally cutting the packaging film for wrapping the sheets, and a stacking pallet device for stacking the wrapped sheets are sequentially arranged. The transverse cutting device is arranged at the discharging position of the wrapping device. The longitudinally cutting device is arranged at the lateral part of the transverse cutting device. The stacking pallet device is arranged at the discharging side of the longitudinal cutting device. A pallet feeding device for transporting pallets to the stacking pallet deviceis arranged at one side of the stacking pallet device. A pallet discharging device is arranged at the other side of the stacking pallet device. The fully automatic packing line automatically weighs the sheets, wraps and seals the sheets, prints and pastes labels on the sheets, counts the number of the sheets and stacks the sheets onto the pallets, to realize connected and fully automatic packaging. At the same time, the wrapped products only need to be sealed on three sides, thus solves the important technical problems such as wrinkles and air leakage caused by sealing.

Owner:QUALIPAC ZHONGSHAN PACKAGING

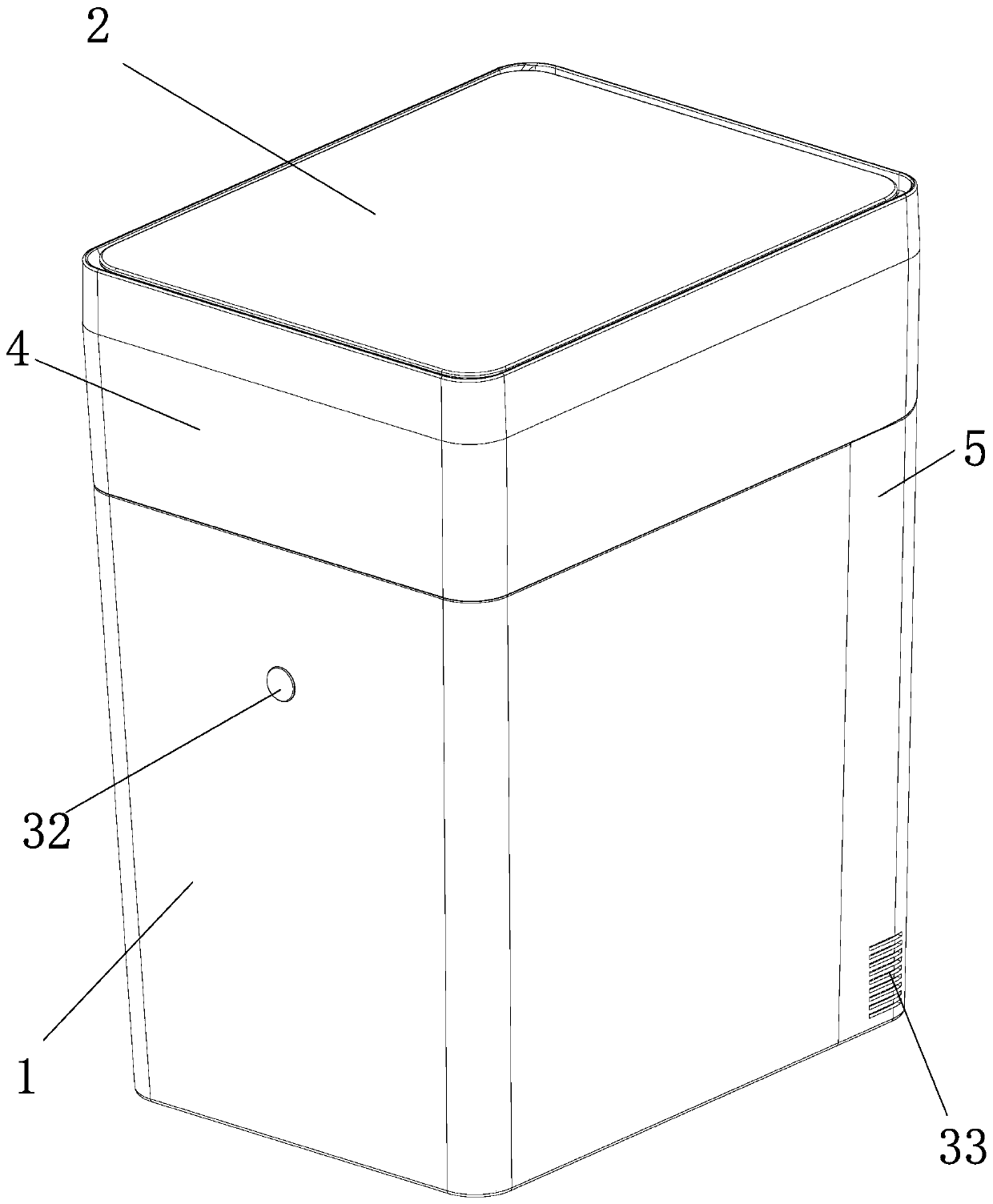

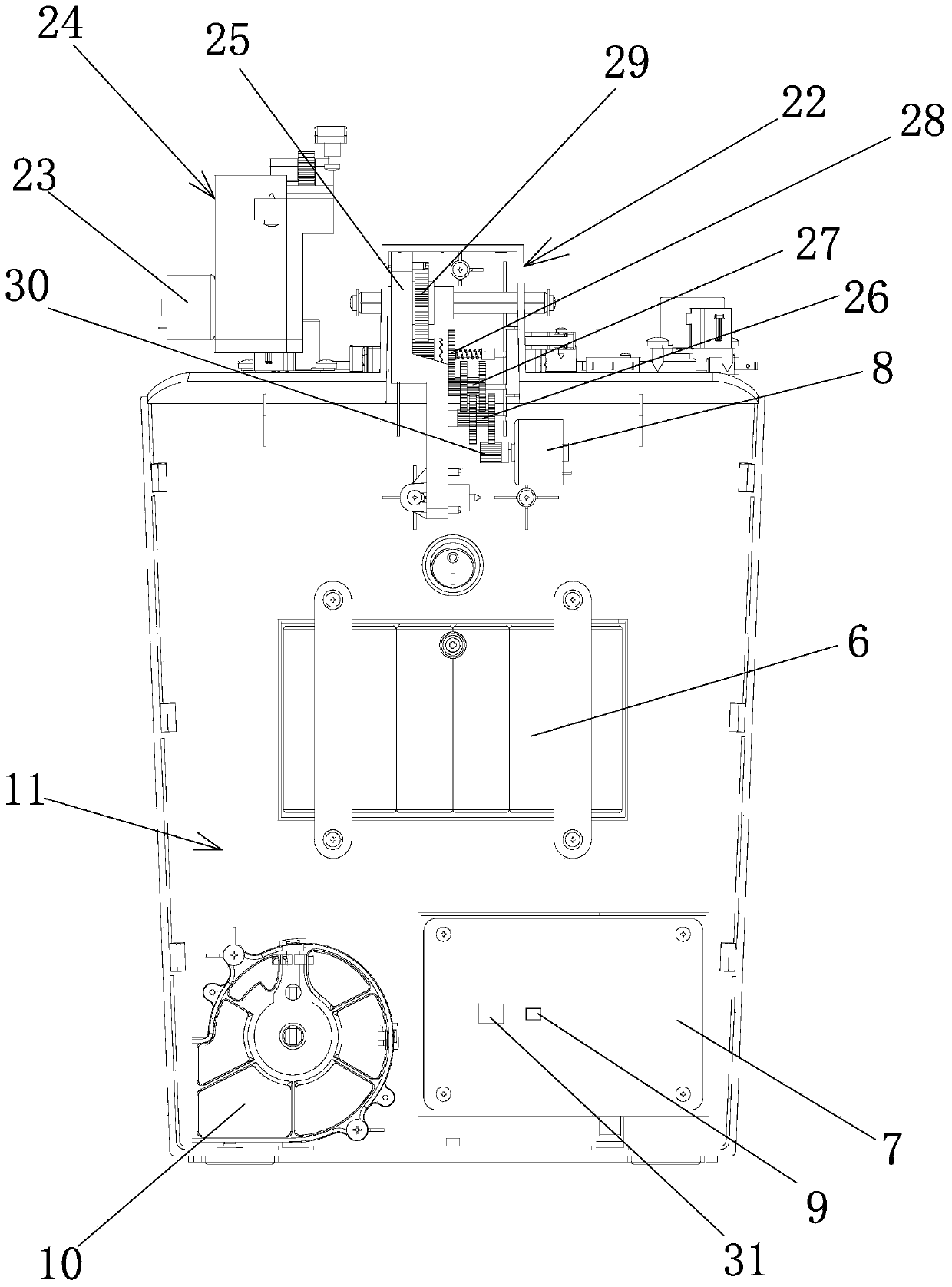

Intelligent garbage can capable of realizing automatic packaging

PendingCN111301901ARealize fully automatic packagingEasy to put awayRefuse receptaclesWrapper twisting/gatheringEmbedded systemElectric machinery

The invention provides an intelligent garbage can capable of realizing automatic packaging, belongs to the technical field of intelligent garbage cans, and solves the problems that existing intelligent garbage cans are simple in inside structure, single in function and low in intelligence. The intelligent garbage can capable of realizing automatic packaging comprises a can body, an upper cover anda garbage bag box; a can cover is connected at the upper end of the can body in an opening and closing manner; the upper cover is connected at the upper end of the can cover in an opening and closingmanner; a back cover is detachably connected at the back end of the can body; a power supply, a controller, a motor I, a sensor and a vacuum pumping device controlled by the controller are arranged in the back cover; a garbage bag is laid in the can body by the aid of the working vacuum pumping device; a garbage bag storage cavity allowing the garbage bag to be laid is formed in the can body; a garbage throwing opening communicating with the garbage bag storage cavity is formed in the can cover; and an automatic packaging device is arranged in the position, located at the garbage throwing opening, inside the can cover. The intelligent garbage can has the advantages that the inside structure is optimized, and the garbage can is abundant in intelligence and perfect in function.

Owner:浙江柒灵智能科技有限责任公司

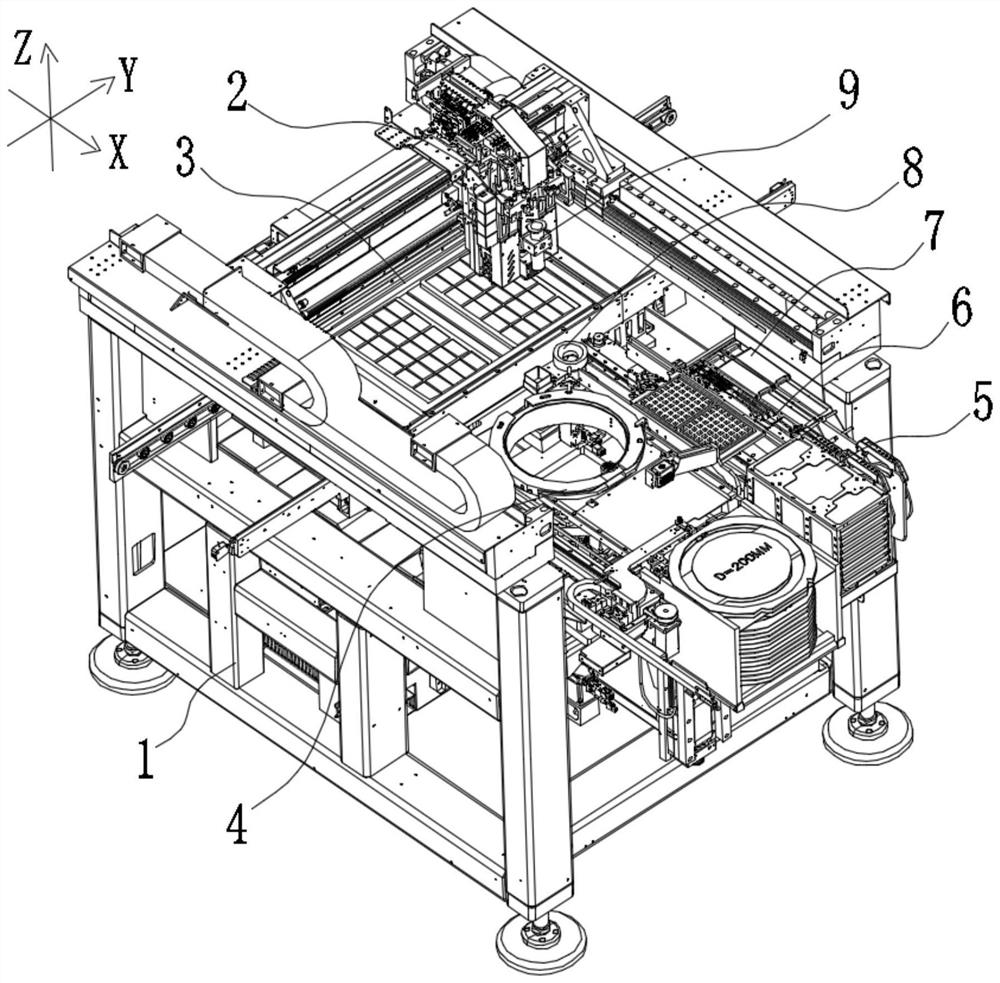

Full-automatic multifunctional IGBT packaging machine

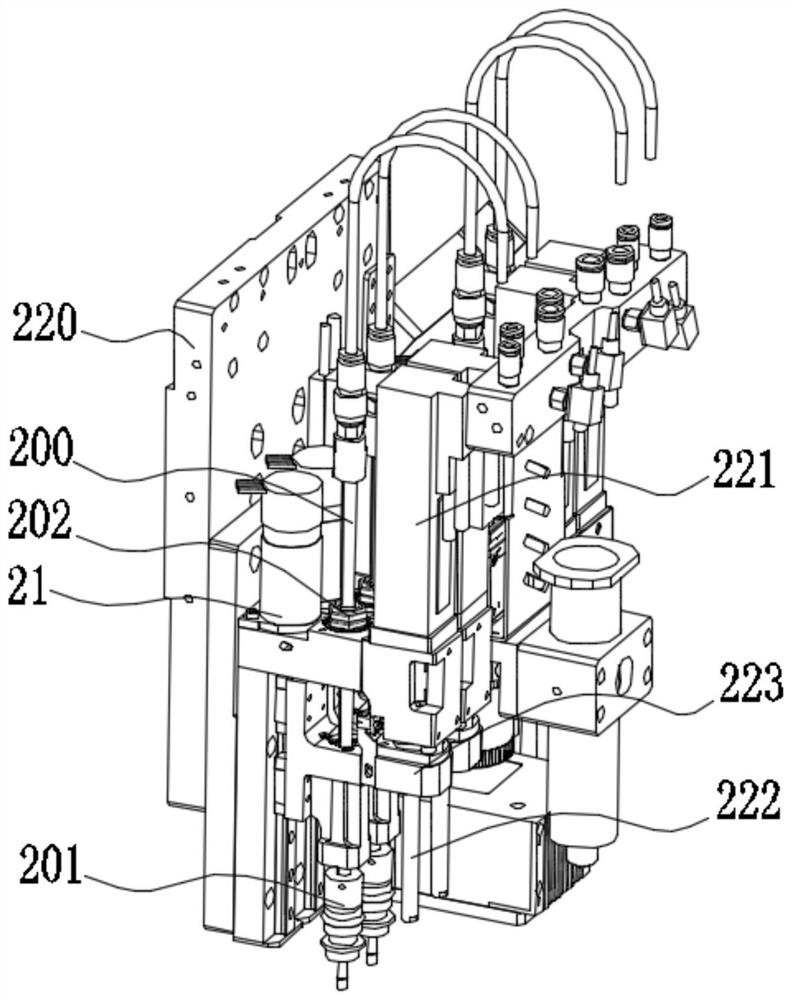

PendingCN114464554ARealize fully automatic packagingIncrease productivitySemiconductor/solid-state device manufacturingWaferingElectronic component

The invention discloses a full-automatic multifunctional IGBT packaging machine which comprises a rack, a packaging mechanism, a jig disc conveying mechanism, a crystal ring feeding and jacking mechanism, a TRAY disc feeding mechanism, a component feeding mechanism and a soldering lug feeding and cutting mechanism. The soldering lug feeding and cutting mechanism is used for stretching a soldering lug roll and cutting a single soldering lug of which the length is equal to a preset soldering lug length; the packaging mechanism comprises an adsorption machine head, a machine head rotating assembly and a three-direction movement driving assembly. The IGBT packaging of the first wafer, the second wafer, the electronic component and the soldering lug can be compatible, multiple packaging devices do not need to be arranged, the overall structure is simplified, the production space is saved, and the production cost is reduced; meanwhile, full-automatic cutting of the soldering lug belt can be achieved, the manual participation degree is low, the automation degree is high, the cutting efficiency of the soldering lug is effectively improved, the single soldering lug with the fixed length can be cut according to the production requirement so as to meet different production requirements, and compatibility is high.

Owner:SHENZHEN BAOCHUANG ELECTRONICS EQUIP CO LTD

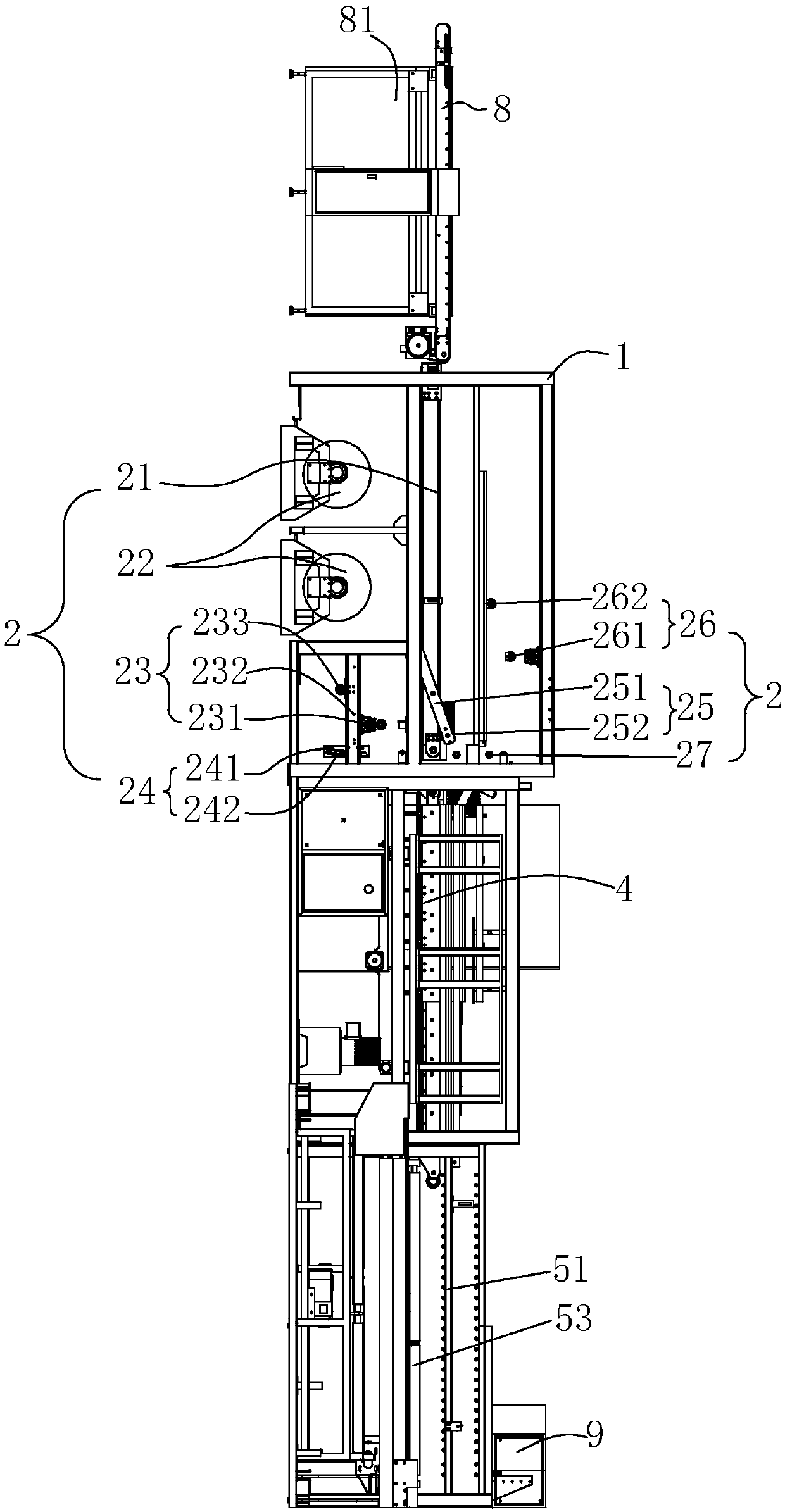

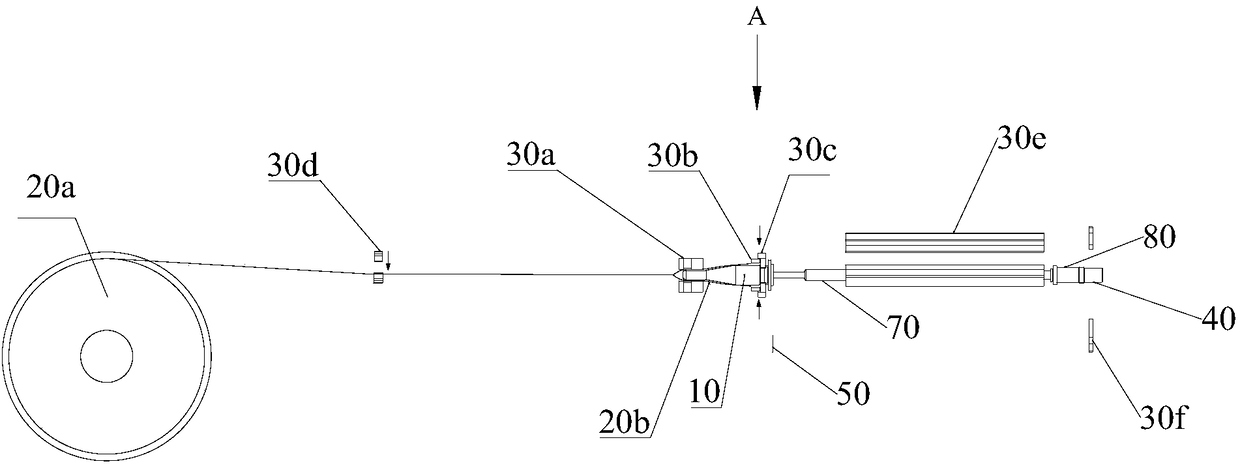

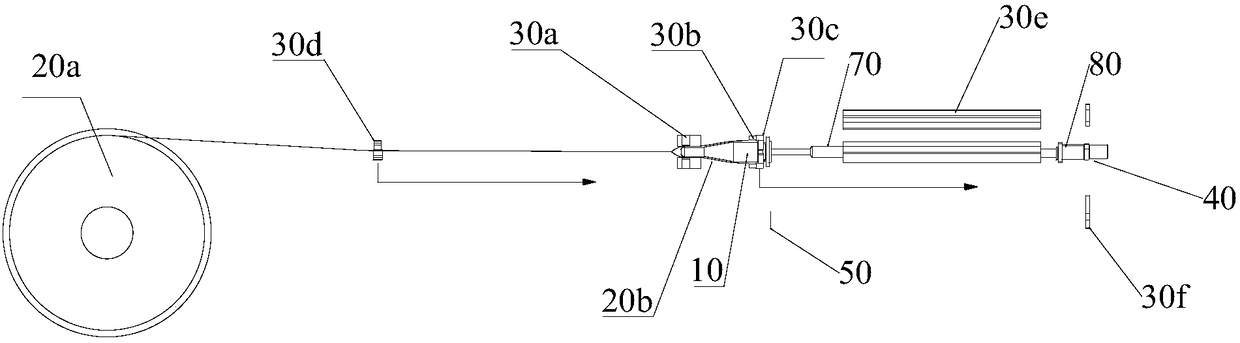

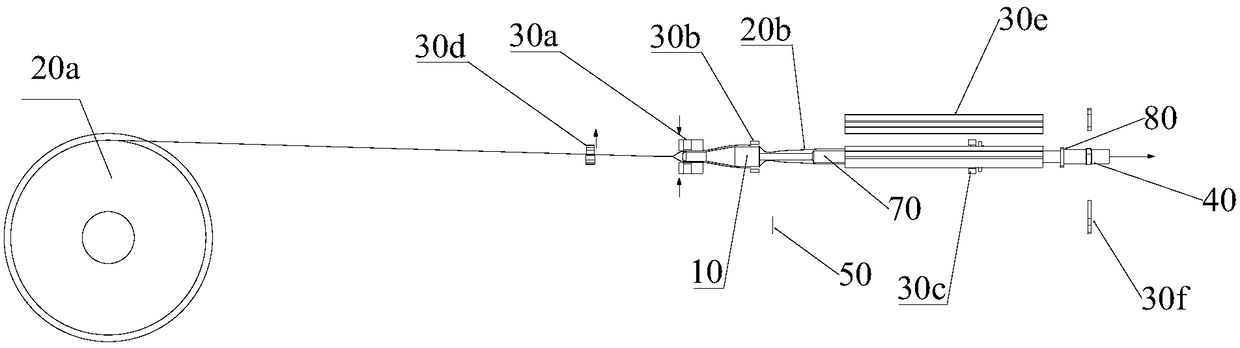

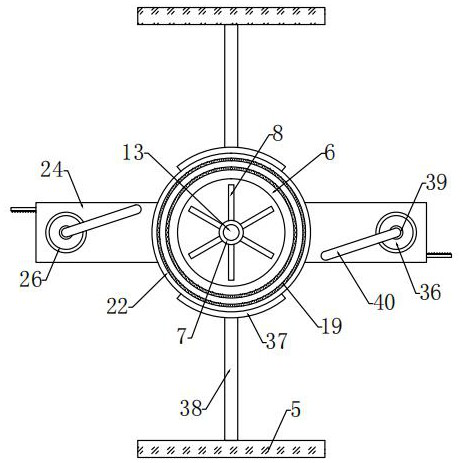

Packaging equipment, sleeving and shrinking machine and packaging method for performing continuous and automatic mesh sleeving of sausage casings

ActiveCN108477273ARealize fully automatic packagingSkinless sausage makingSausage casing manufactureReciprocating motionBiomedical engineering

The invention relates to packaging equipment, a sleeving and shrinking machine and a packaging method for performing continuous and automatic mesh sleeving of sausage casings. The packaging equipmentcomprises a shuttle (10), a first clamp hand (30a), a second clamp hand (30b), a third clamp hand (30c) and a fourth clamp hand (30d), wherein the shuttle (10) is used for sleeving mesh bags (20b); the first clamp hand (30a) can be opened or closed to release or fixedly clamp the shuttle (10); when closed, the second clamp hand (30b) can drive an open end of the mesh bag (20b) to perform reciprocating motion between a first position and a second position on the shuttle (10), and when opened, the second clamp hand (30b) can allow the mesh bag (20b) to move freely along a conveying direction ofthe mesh bag; the third clamp hand (30c) is used for clamping the open end of the mesh bag (20b) and dragging the mesh bag to sleeve a whole sleeved and shrunk sausage casing (70); and the fourth clamp hand (30d) is used for dragging the mesh bag (20b) to unwind the mesh bag (20b) from a mesh bag roll (20a), and the fourth clamp hand (30d) is designed in a form of capable of moving together with the third clamp hand (30c).

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

Automatic industrial explosive packaging line

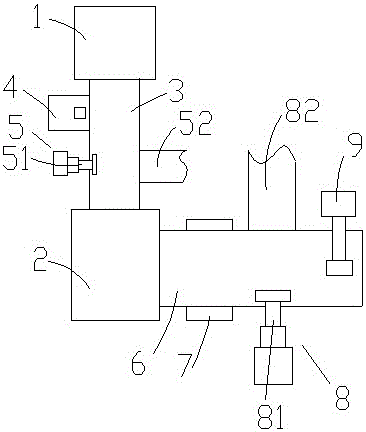

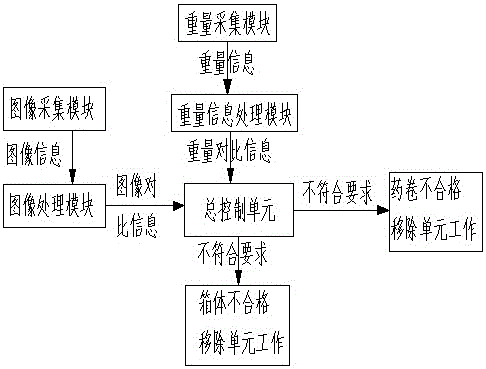

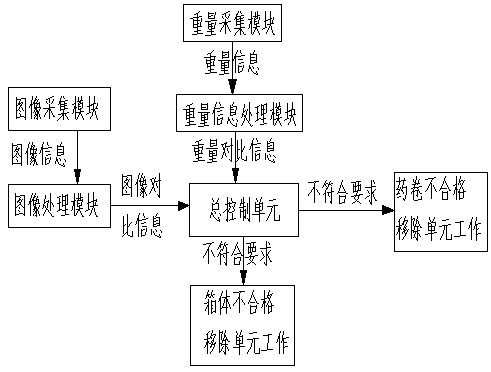

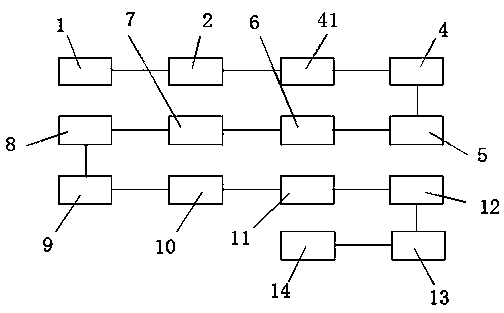

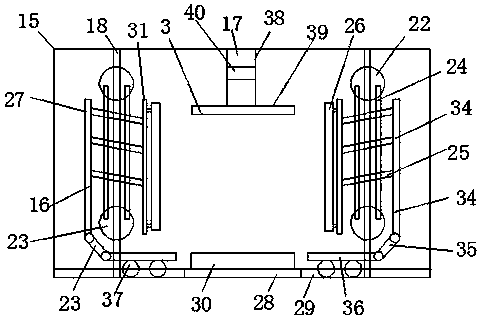

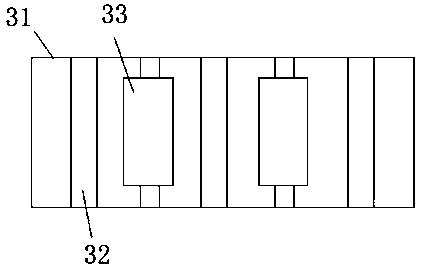

ActiveCN106494703ARealize fully automatic packagingReasonable design layoutSortingPackaging machinesProduction lineEngineering

The invention relates to the technical field of packaging production lines, and discloses an automatic industrial explosive packaging line. The automatic industrial explosive packaging line comprises an explosive roll packaging unit, an explosive roll encasement unit, an explosive roll conveying unit and a master control unit, and an explosive roll detection unit and an unqualified explosive roll removing unit are sequentially arranged on the explosive roll conveying unit; and a box conveying unit is installed at the back of the explosive roll encasement unit, a box weight detection unit and an unqualified box removing unit are sequentially installed on the box conveying unit, and the explosive roll detection unit, the unqualified explosive roll removing unit, the box weight detection unit and the unqualified box removing unit are in signal connection with the master control unit. The automatic industrial explosive packaging line is reasonable in design layout, easy to install, simple and practical, full-automatic packaging of industrial explosives can be achieved, the packaging quality is guaranteed, the labor intensity of workers is greatly reduced, and the producing and packaging efficiency is improved.

Owner:PANZHIHUA HENGWEI CHEM +1

Food packaging machine

ActiveCN113264489AAutomate the packaging processRealize fully automatic packagingCapsThreaded caps applicationFood packagingFood processing

The invention relates to the technical field of food processing machinery, in particular to a food packaging machine. The machine comprises a base and a conveying belt which are connected, a supporting frame arranged on the outer side of the conveying belt and fixedly connected with the base, a packaging mechanism arranged on the inner side of the supporting frame, and a driving mechanism arranged between the packaging mechanism and the supporting frame. The packaging mechanism comprises a discharging assembly arranged on the inner side of the supporting frame and connected with the driving mechanism, a disassembling and assembling assembly arranged on the outer side of the discharging assembly in a threaded connection mode, and an air guide transmission assembly arranged on the outer side of the disassembling and assembling assembly. The packaging mechanism and the driving mechanism are arranged, the driving mechanism is used for driving the discharging assembly and the disassembling and assembling assembly, the discharging assembly ascends and descends to drive the disassembling and assembling assembly to rotate, and full-automatic packaging of food can be achieved.

Owner:徐州天浩机械制造有限公司

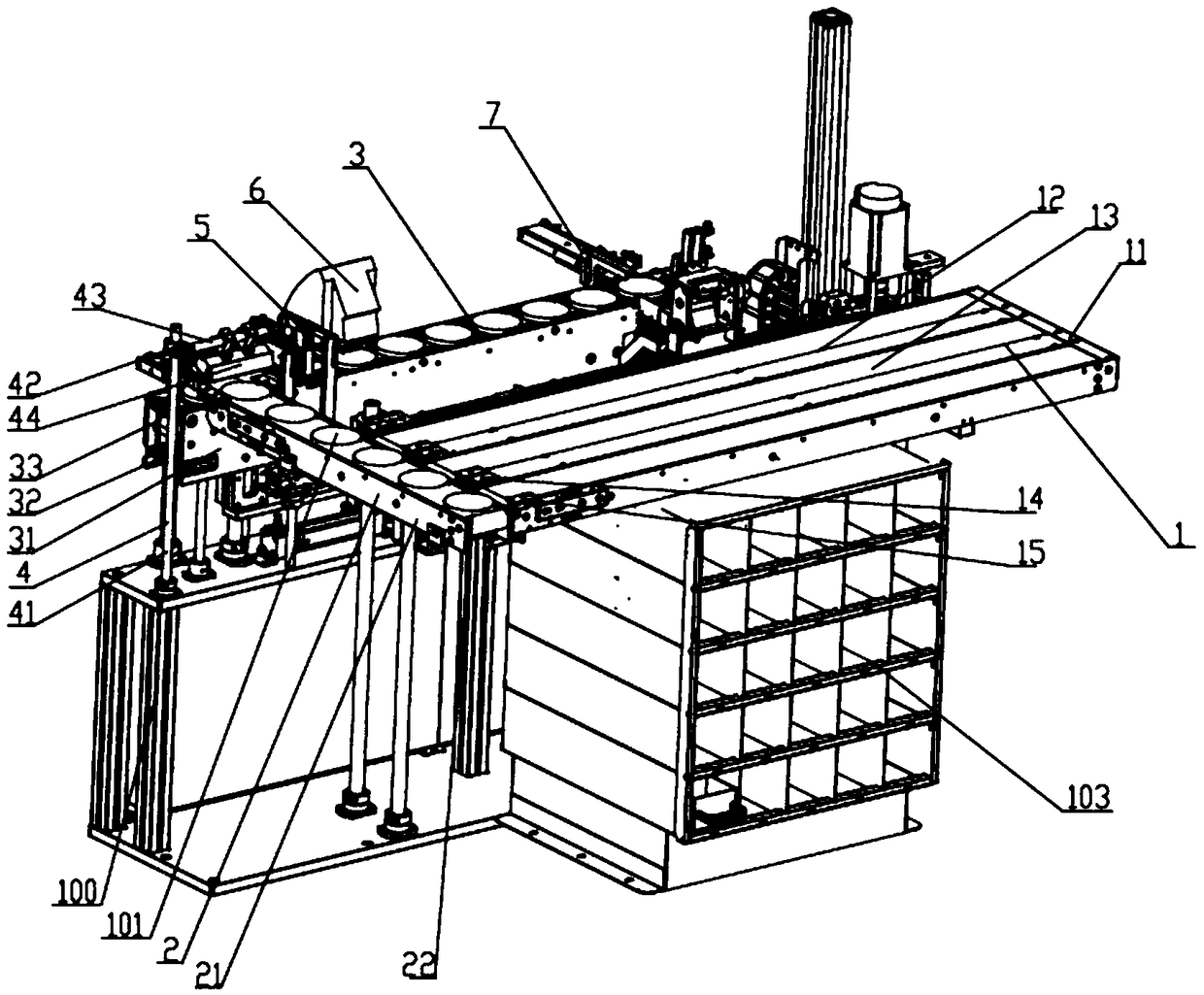

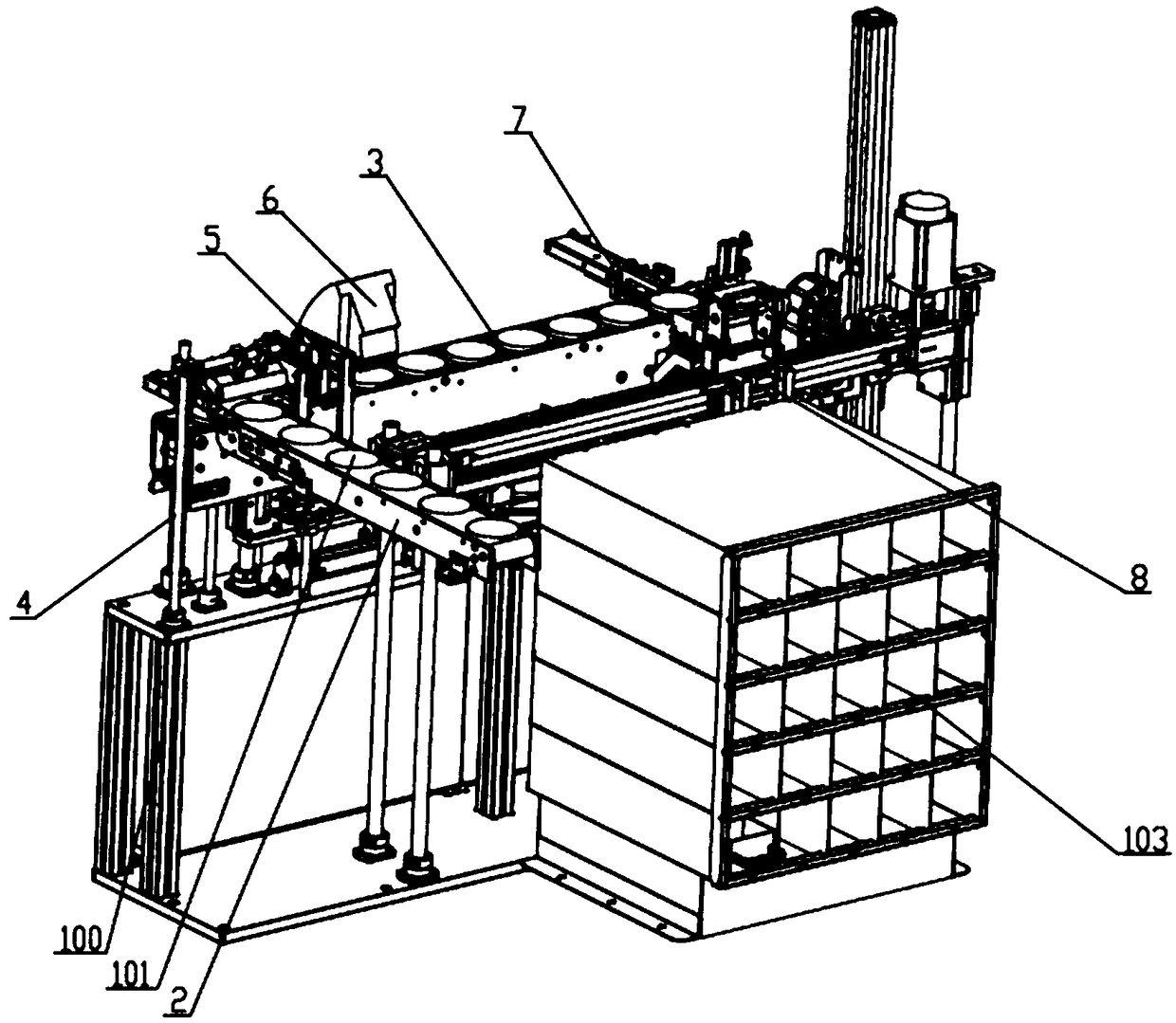

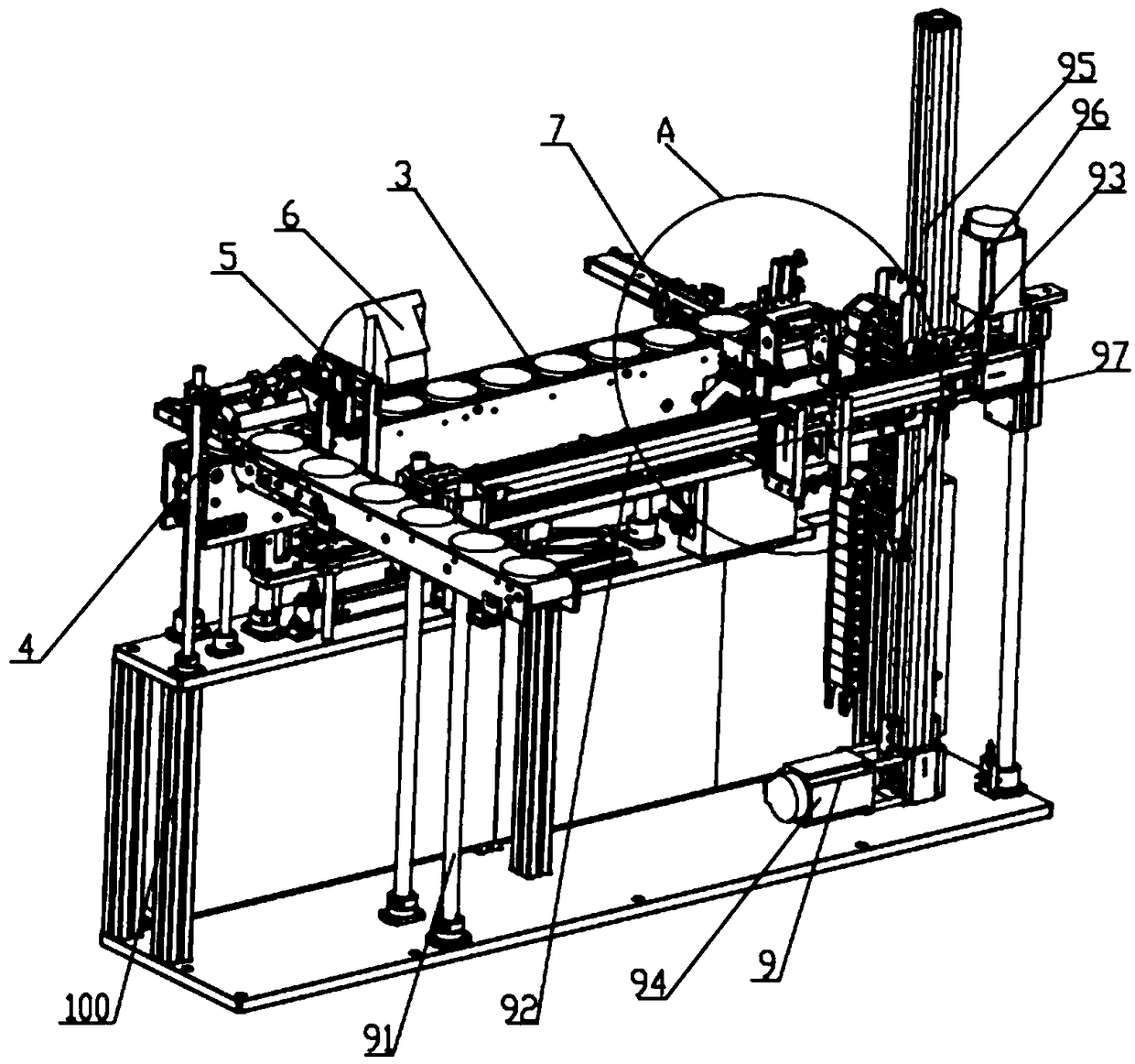

Full-automatic lens sorting and packaging machine

PendingCN109110170AReduce work intensityReduce working errorsShock-sensitive articlesSortingEngineeringUltimate tensile strength

The invention discloses a full-automatic lens sorting and packaging machine. The full-automatic lens sorting and packaging machine at least comprises a machine frame and a feeding conveyance assemblyarranged on the machine frame. A lens on the feeding conveyance assembly is conveyed to a driving conveyance assembly through a connection conveyance assembly. The machine frame is further provided with an anti-static assembly, a lens centering and thickness detecting assembly and a focal power detecting assembly, wherein the anti-static assembly, the lens centering and thickness detecting assembly and the focal power detecting assembly are located above the connection conveying assembly or the driving conveyance assembly. One side of the tail end of the driving conveyance assembly is providedwith a packaging assembly used for packaging the lens on the driving conveyance assembly. The lens packaged by the packaging assembly is classified and pushed into a collecting frame by a pushing assembly. The full-automatic lens sorting and packaging machine has the beneficial effects of being simple in structure, ingenious in design, organically combines multiple kinds of equipment, achieves full-automatic detection, packaging and sorting, can greatly improve the production efficiency, lower the work intensity of workers and lower the product measurement error.

Owner:苏州申科谱自动化科技有限公司

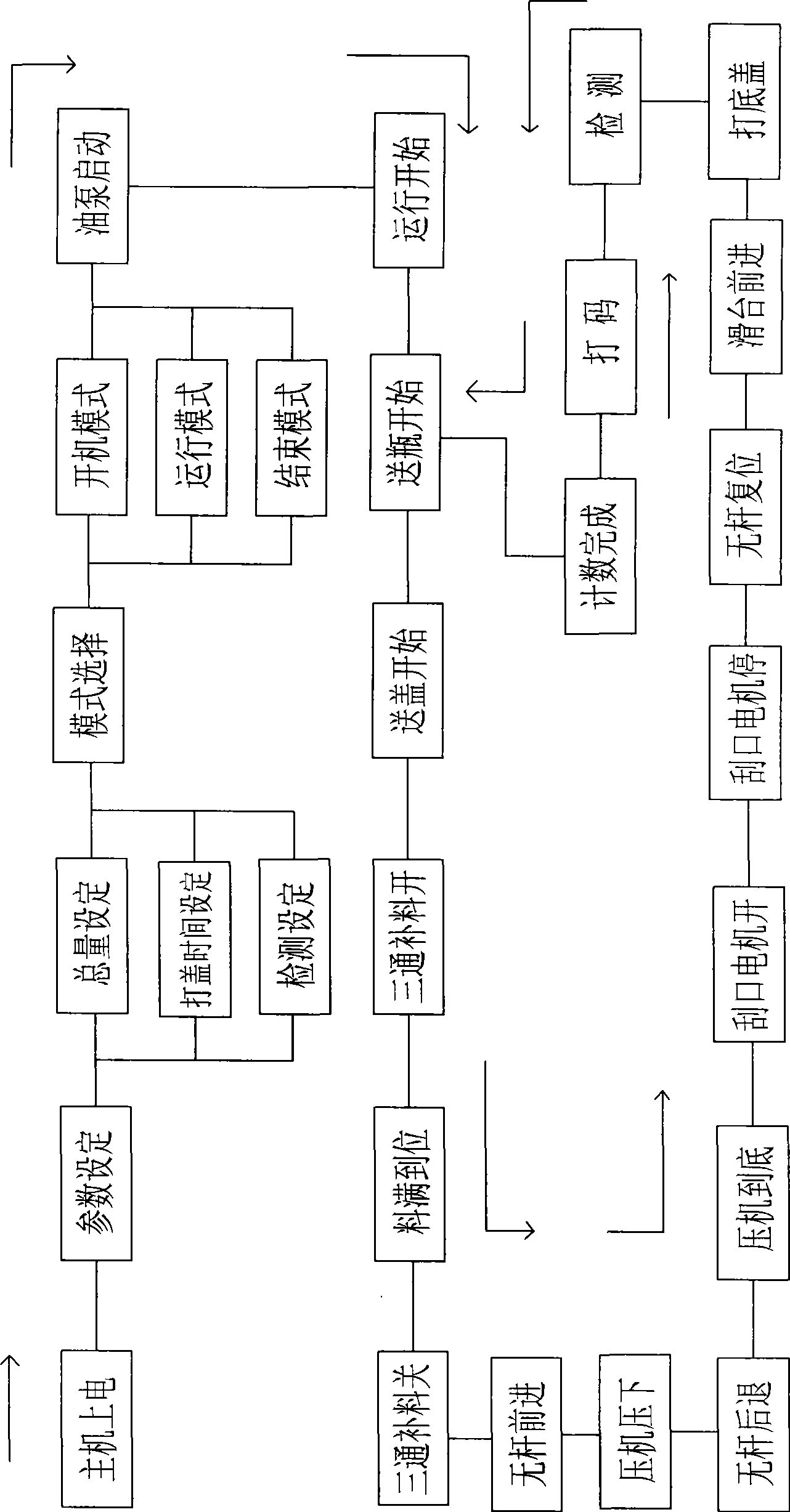

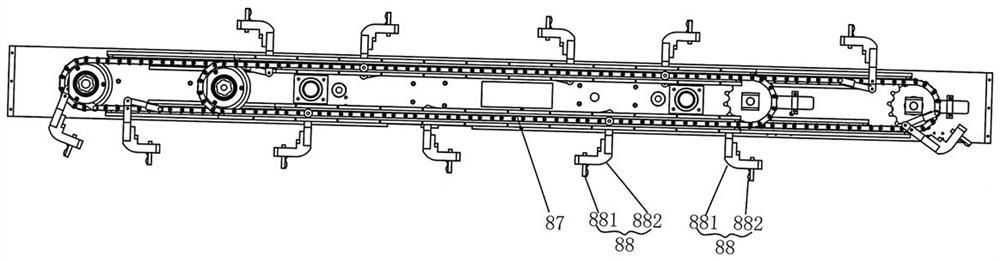

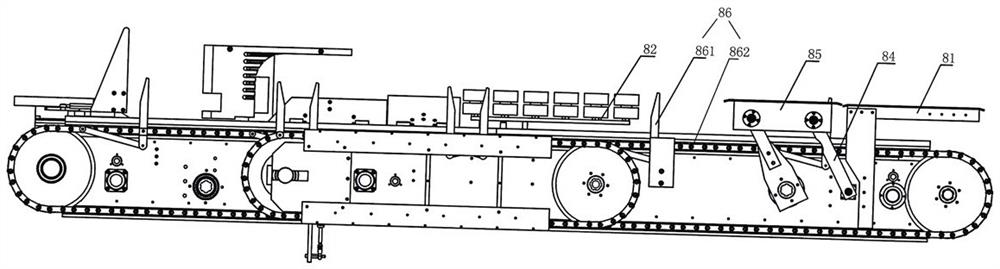

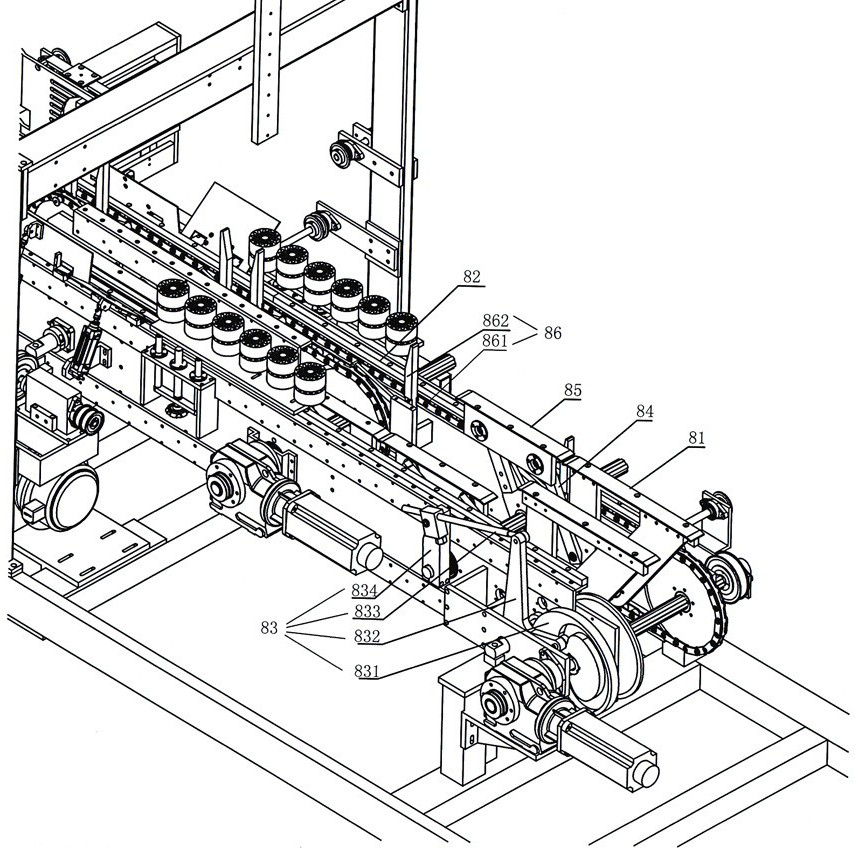

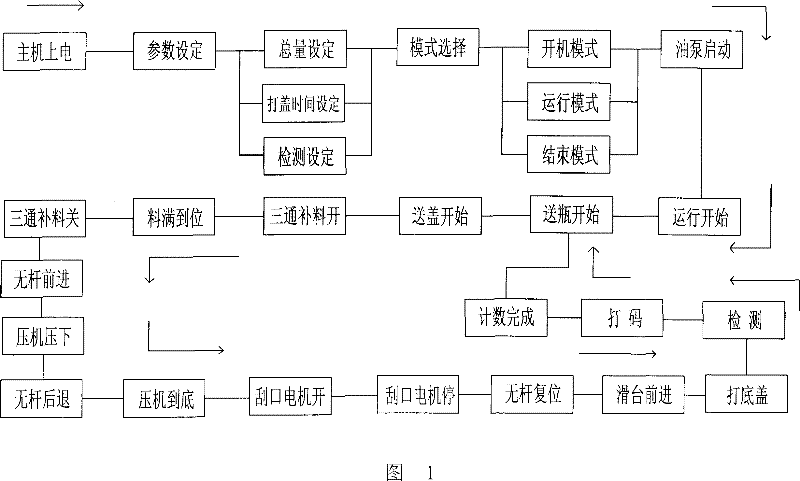

Method for full automatically subpackaging sealing structure glue

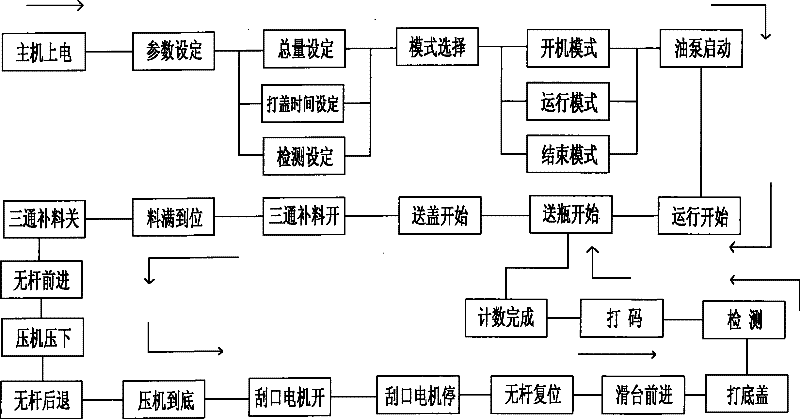

InactiveCN101531332ARealize fully automatic packagingNo leaksBottle-handling machinesLiquid bottlingEngineeringBottle cap

The invention discloses a method for full automatically subpackaging sealing structure glue. The method can subpackage the sealing structure glue by repeatedly carrying out the following steps of A. setting parameters during running process; B. sending and loading bottles and gradually sending the structure glue into the packaging bottles; C. supplementing materials for the structure glue in the packaging bottles so that the structure glue achieves the arranged material position; D. opening a scraping motor and scraping the bottle mouth; and E. arranging the bottle cover at the bottle mouth and sealing the bottle. The method can subpackage the sealing structure glue full automatically, has high subpackaging efficiency and exact measurement, and has no splash or leakage of the sealing structure glue during the subpackaging process.

Owner:叶迪光

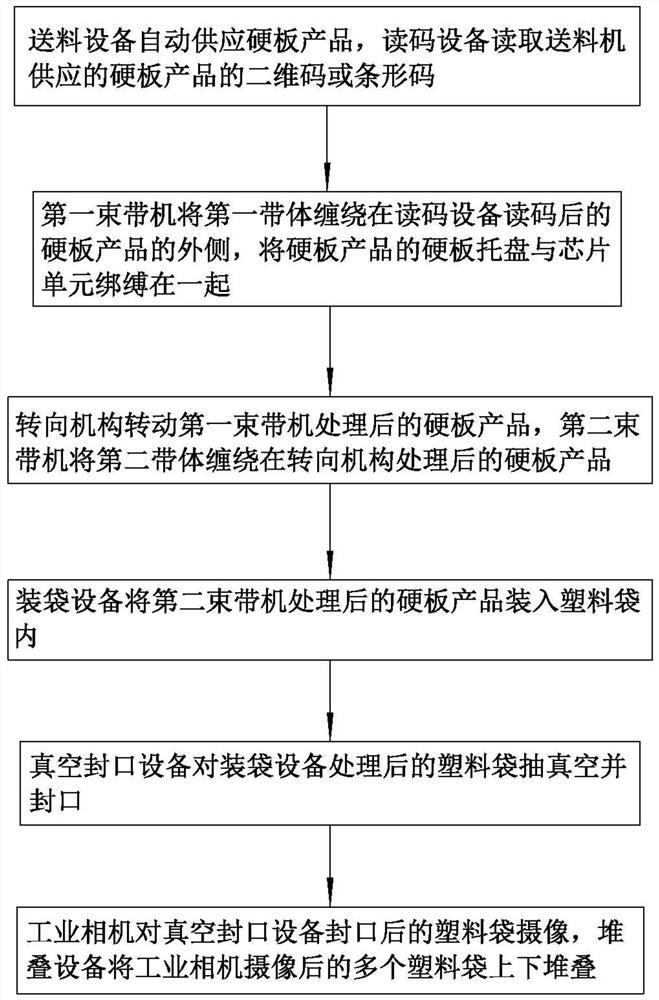

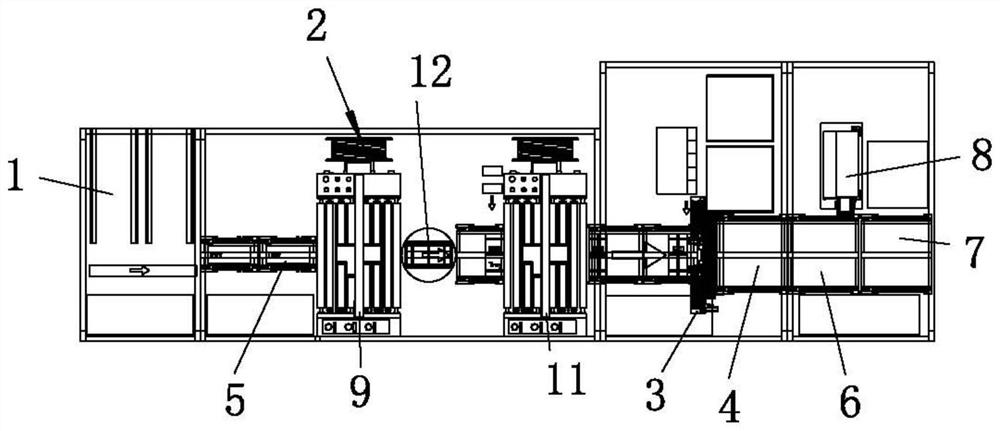

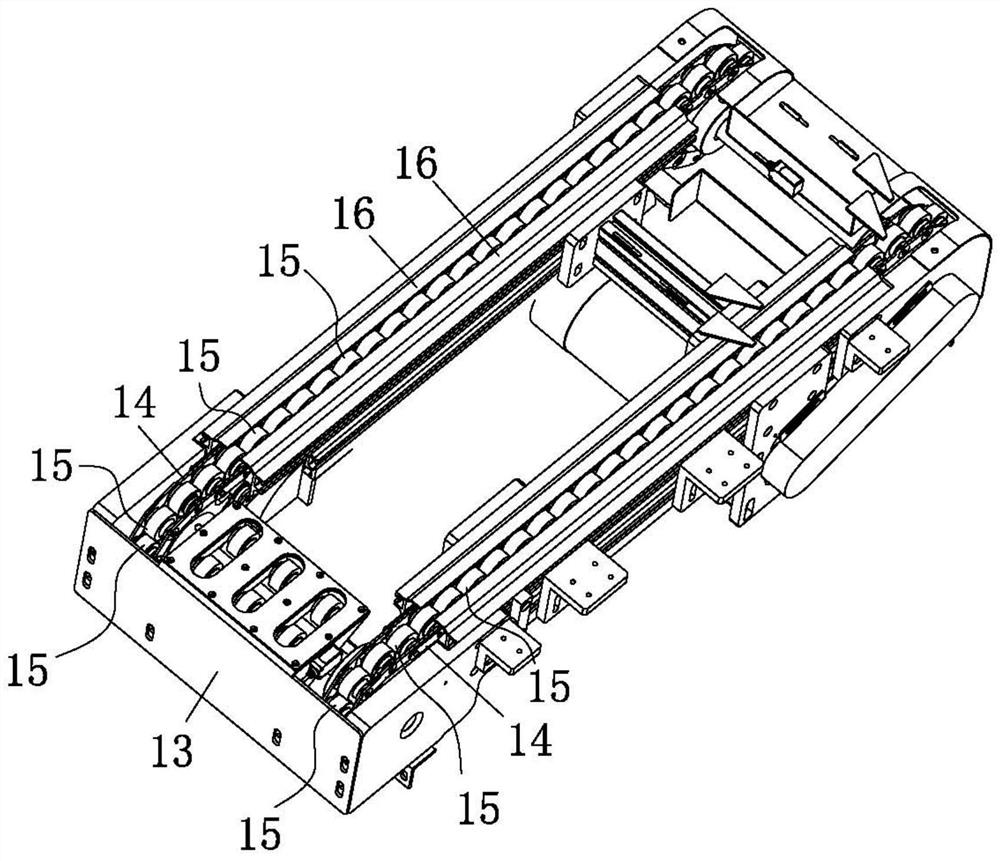

Full-automatic packaging process for hard board products

ActiveCN113104278ARealize fully automatic packagingImprove packaging efficiencyWrapper twisting/gatheringIndividual articlesFully automatedPlastic bag

The invention relates to the technical field of material packaging, in particular to a full-automatic packaging process for a hard board product. The hard board product is automatically input through feeding equipment; the hard board product comprises a chip unit and a hard board tray used for bearing the chip unit; and the hard board tray is provided with a limiting blind groove used for containing the chip unit; a belt body is wound on the hard board product input by the feeding equipment through a belt binding device; the belt body is a ring arranged on the hard board product in a sleeving mode; the ring is used for shielding and packaging the chip unit in the limiting blind groove; the hard board product treated by the banding equipment is loaded into a plastic bag by utilizing bagging equipment; the plastic bag containing the hard board product is vacuumized and sealed through vacuum sealing equipment; the chip unit is stably bound on the hard board tray through the belt body of the belt binding device; automatic bagging and automatic bag sealing of hard board products are achieved through the bagging equipment and the vacuum sealing equipment; full-automatic packaging of hard board products is achieved; and the packaging efficiency of the hard board products is improved.

Owner:XUNDE MACHINERY DONGGUAN CO LTD

Efficient strip-shaped article packaging line

InactiveCN105173165ARealize fully automatic packagingNo manual operation requiredConveyor wrappingEngineeringMechanical field

The invention relates to the field of packaging machines, in particular to an efficient strip-shaped article packaging line. The efficient strip-shaped article packaging line comprises a bottom frame, a conveying chain, a paper sheet feeding device, a paper sheet kneading part, a gluing device, a strip-shaped article feeding device, a folded gluing device and a transmission device. A sliding groove is formed in the upper surface of the bottom frame. A drive device drives the conveying chain to slide in the sliding groove. In the sliding direction of the conveying chain, the paper sheet feeding device, the paper sheet kneading part, the gluing device, the strip-shaped article feeding device and the folded gluing device are sequentially arranged in the sliding groove. According to the efficient strip-shaped article packaging line, the process of feeding, kneading, gluing and folded gluing of paper sheets can be achieved through the packaging line, the process is totally full automatic, manual operation is not needed, labor input is greatly saved, and production efficiency is improved. More superiorly, in the process of paper box forming through paper sheet folding and gluing, strip-shaped articles can be wrapped in a formed paper box, and therefore the full-automatic packaging of the strip-shaped articles is achieved.

Owner:佛山市方悦机械科技有限公司

Implementation device of a bed surface wrapping device

ActiveCN108247799BRealize fully automatic packagingHigh degree of automationWood working apparatusHydraulic cylinderClassical mechanics

The invention relates to an implementation device of a bed surface wrapping device. The implementation device comprises a base plate, a table is fixedly installed on the base plate, and a containing groove is formed in the right side of the table. A hoisting support is installed on the back side of the base plate and is provided with a hydraulic cylinder, the bottom of the hydraulic cylinder is connected with a wrapping pressing support, the bottom of the wrapping pressing support is provided with a pressing groove matched with the containing groove, the four side walls of the pressing grooveare provided with square grooves in the length direction, and auxiliary supports matched with the square grooves in a one-to-one correspondence manner are welded to the outer side wall of the wrappingpressing support. According to the implementation device, on the basis that a bed board is placed, the wrapping pressing support is controlled to achieve downward pressing, multiple steel nails are pulled to slide, penetration of gauze and the bed board is achieved, the gauze can completely and automatically wrap a bed surface of the bed board, and manpower is relatively saved.

Owner:芜湖市夏氏世家家具有限公司

Slip sheet material box receiving device

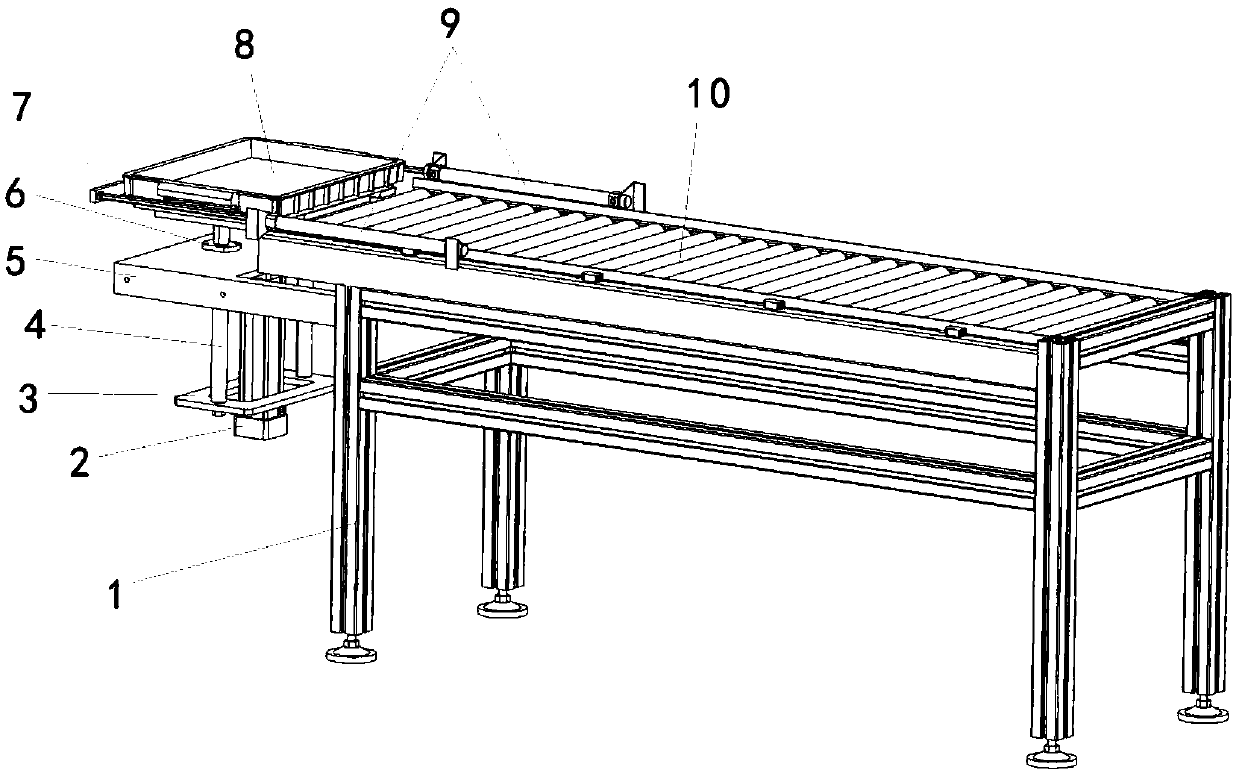

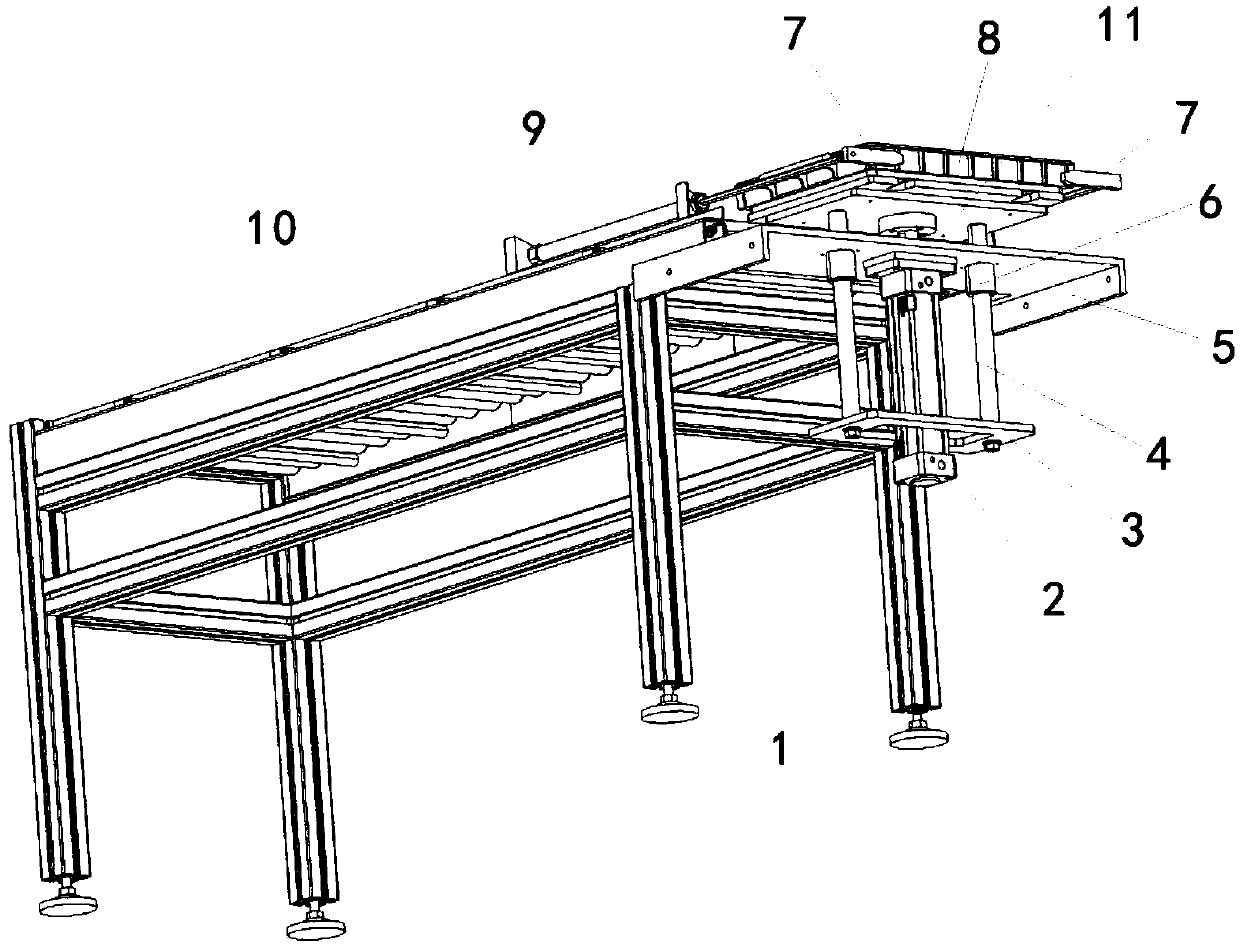

PendingCN109573214ARealize fully automatic packagingFully automatic packing conveniencePackagingSlip sheetEngineering

The invention discloses a slip sheet material box receiving device. The slip sheet material box receiving device includes a machine frame and a conveying belt mounted at the top of the machine frame,a fixed plate is fixedly connected with the front end of the machine frame, a receiving cylinder is fixedly mounted on the fixed plate, and two sliding sleeves are symmetrically and fixedly mounted onthe positions, located on two sides of the receiving cylinder, of the fixed plate; and a guiding rod is slidably connected within each sliding sleeve, the lower ends of the two guiding rods are fixedly connected with a synchronous plate, the upper ends of the two guiding rods are fixedly connected with receiving plates after penetrating through the sliding sleeves, two drawing cylinders in the same conveying direction of the conveying belt are symmetrically fixed on both sides of the front end of the conveying belt, and a scraping plate is fixedly connected with a telescopic rod of each drawing cylinder. The slip sheet material box receiving device can receive a material box filled with flip sheets through the receiving plates, then the material box is drawn into the conveying belt through the scraping plates on the telescopic rods of the drawing cylinders to realize the automatic discharge of the material box, the way of material box manual transfer in the prior art is replaced, thework efficiency is improved, and the slip sheet material box receiving device provides convenience for realizing the automatic packing of the slip sheets.

Owner:XINAN TOOLS GUIZHOU PROV

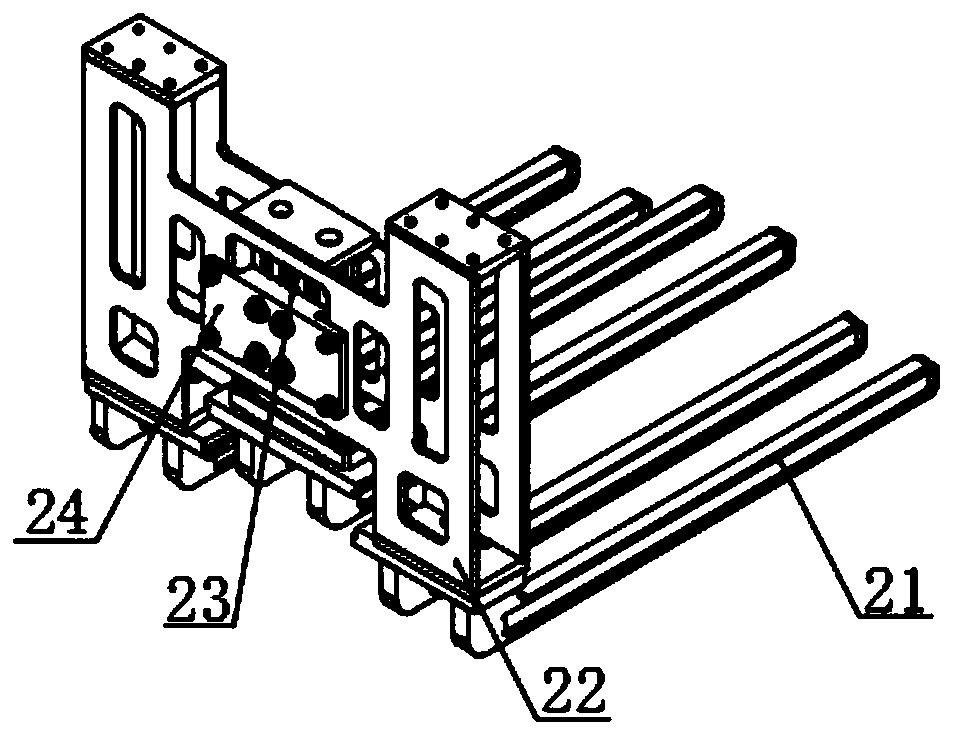

Multifunctional robot gripper

InactiveCN110217438ARealize fully automatic packagingImprove functionalityPackagingStacking articlesEngineeringMechanical engineering

The invention discloses a multifunctional robot gripper and relates to the technical field of packaging stacking equipment. The multifunctional robot gripper mainly solves the problem that the function of an existing robot gripper is single. The multifunctional robot gripper comprises a machine base and transmission part, an insertion claw part, a pressing claw part, a blocking bag and suction partition part, a bag taking gripper part and a bag opening shaping part. The machine base and transmission part comprises a robot connecting seat connected with the tail end of a six-axis robot. An insertion claw frame in the insertion claw part is fixedly connected with a connecting plate in the machine base and transmission part through a bolt. The pressing claw part, the blocking bag and suctionpartition part, the bag taking gripper part and the bag opening shaping part are fixed to the machine base and transmission part. Functionality of the robot gripper is greatly improved.

Owner:江苏安捷智能制造有限公司

Industrial Explosives Automatic Packing Line

ActiveCN106494703BRealize fully automatic packagingReasonable design layoutSortingPackaging machinesProduction lineEngineering

The invention relates to the technical field of packaging production lines, and discloses an automatic industrial explosive packaging line. The automatic industrial explosive packaging line comprises an explosive roll packaging unit, an explosive roll encasement unit, an explosive roll conveying unit and a master control unit, and an explosive roll detection unit and an unqualified explosive roll removing unit are sequentially arranged on the explosive roll conveying unit; and a box conveying unit is installed at the back of the explosive roll encasement unit, a box weight detection unit and an unqualified box removing unit are sequentially installed on the box conveying unit, and the explosive roll detection unit, the unqualified explosive roll removing unit, the box weight detection unit and the unqualified box removing unit are in signal connection with the master control unit. The automatic industrial explosive packaging line is reasonable in design layout, easy to install, simple and practical, full-automatic packaging of industrial explosives can be achieved, the packaging quality is guaranteed, the labor intensity of workers is greatly reduced, and the producing and packaging efficiency is improved.

Owner:PANZHIHUA HENGWEI CHEM +1

A fully automatic packaging and palletizing device for 2,6-di-tert-butyl-4-methylphenol

ActiveCN106742427BRealize fully automatic packagingShorten production timePackaging machinesPulp and paper industryTert butyl

The invention relates to a full-automatic packaging and stacking device used for BHT. The full-automatic packaging and stacking device comprises a spiral feeding machine, a stock bin, a spiral feeding machine, a full-automatic packaging machine, a bag-sewing machine, a right-angle bag guiding machine, a conveyor, a metal testing machine, a quality testing machine, a removing shaping conveyor, a bag pressing shaping machine, a capturing conveyor, a robot palletizer and a transporting machine. One spiral feeding machine is sequentially connected with the other spiral feeding machine, the full-automatic packaging machine, the bag-sewing machine, the right-angle bag guiding machine, the conveyor, the metal testing machine, the quality testing machine, the removing shaping conveyor, the bag pressing shaping machine, the capturing conveyor, the robot palletizer and the transporting machine through the stock bin. The full-automatic packaging and stacking device can achieve full automatic packaging of produced antioxidant BHT, automatic spiral feeding, full-automatic packaging, bag sewing, metal testing, quality testing, bag pressing shaping, capturing conveying and stacking are effectively achieved, the production time is shortened, and the production efficiency is improved.

Owner:江苏迈达新材料股份有限公司

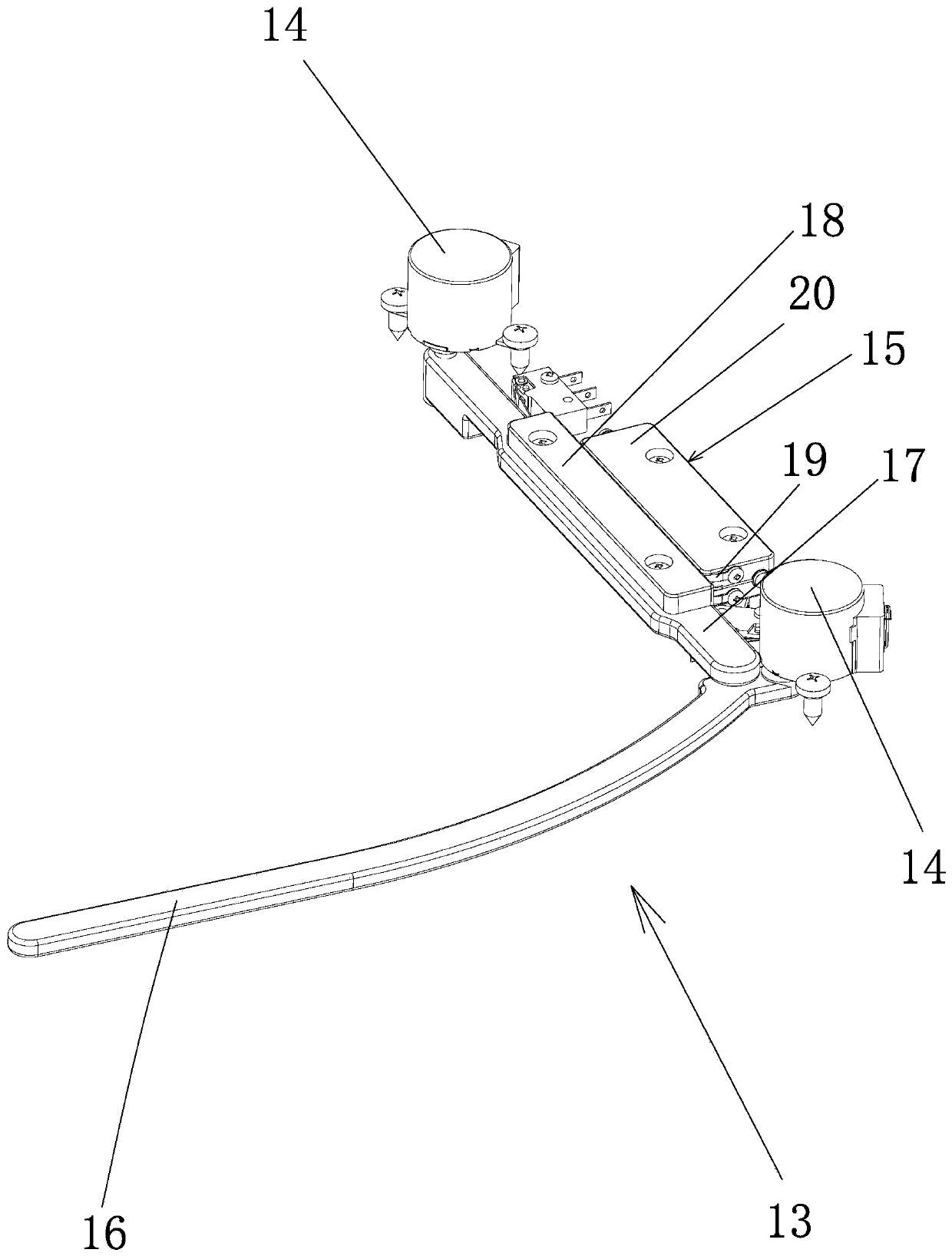

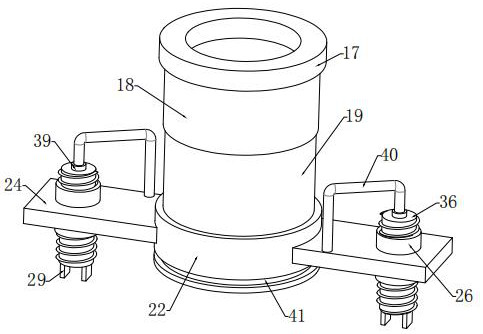

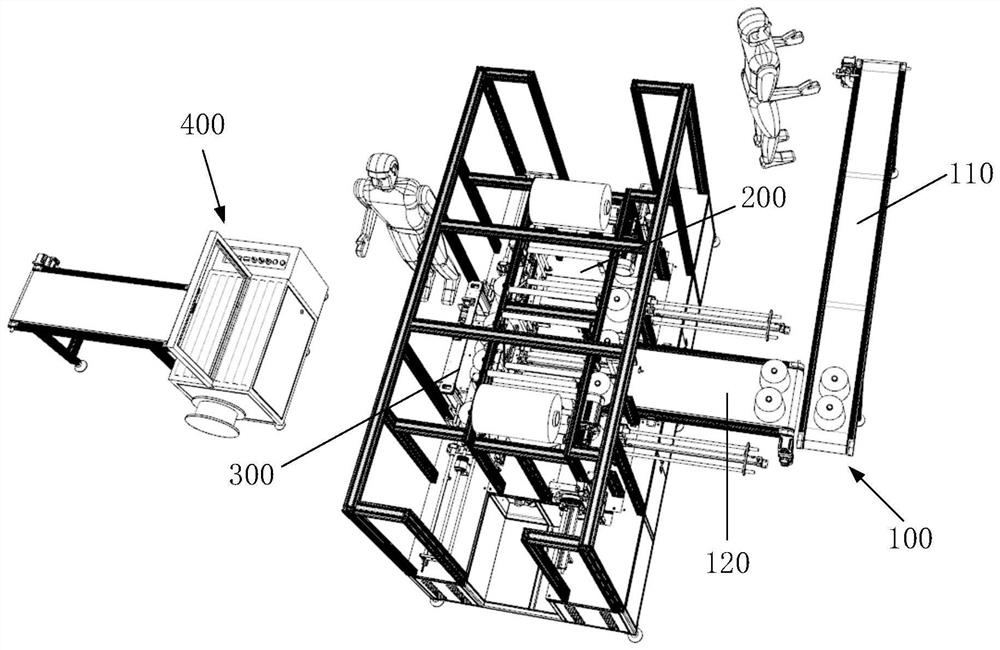

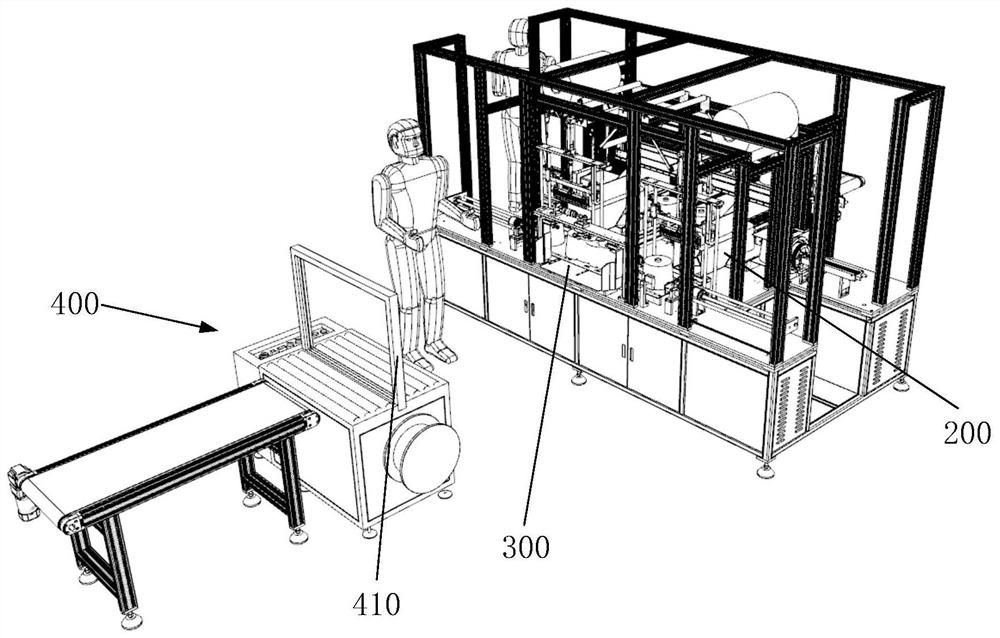

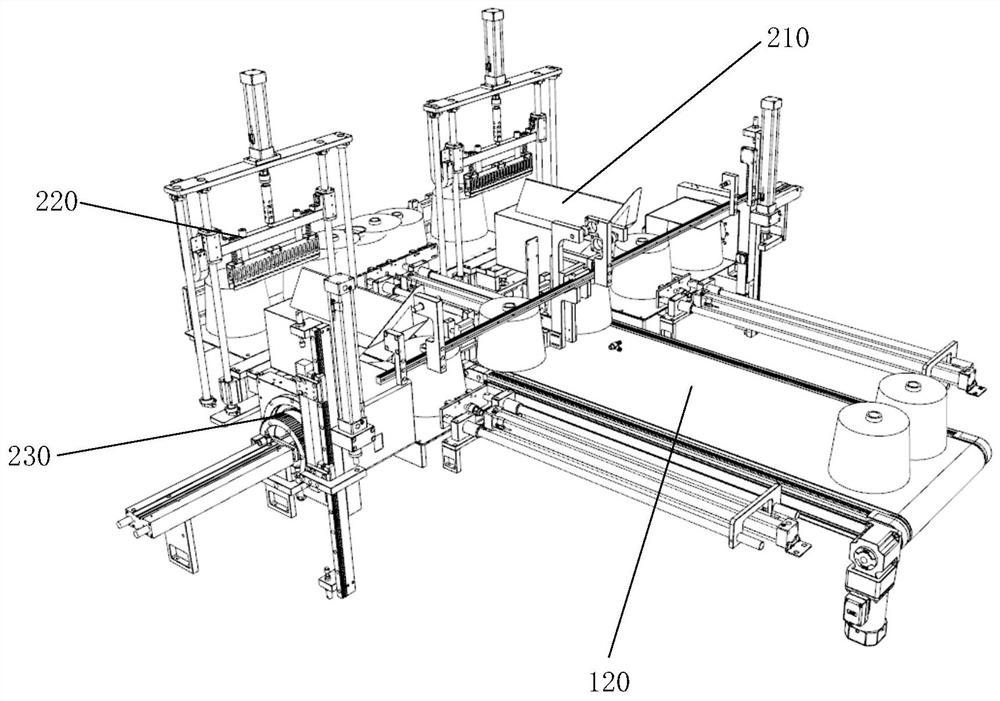

Cone yarn packaging device

PendingCN113060350ARealize fully automatic packagingIncrease productivityWrapper twisting/gatheringIndividual articlesYarnEngineering

The invention relates to a cone yarn packaging device which sequentially comprises a feeding station, a film covering station, a bagging station and a sealing and bundling station. The feeding station comprises a feeding belt and a flow dividing belt which are connected in sequence, and the feeding station is used for conveying cone yarns and dividing the cone yarns according to the specifications of the cone yarns; the film covering station comprises a film covering forming mechanism and a film sealing mechanism, the cone yarns penetrate out of the film covering forming mechanism, and the film sealing mechanism is installed at an outlet of the film covering forming mechanism; and the bagging station comprises a confluence mechanism, an opening mechanism and a bagging mechanism, the confluence mechanism is used for collecting a set of cone yarn subjected to film covering, the opening mechanism is used for opening an opening of a woven bag, and the bagging mechanism is used for pushing the cone yarns into the woven bag through the opening; and the sealing and bundling station comprises a sealing mechanism and a bundling mechanism and is used for sealing and bundling the filled woven bag. Full-automatic packaging of the cone yarns can be achieved, and the production efficiency is improved.

Owner:苏州点动智能装备有限公司

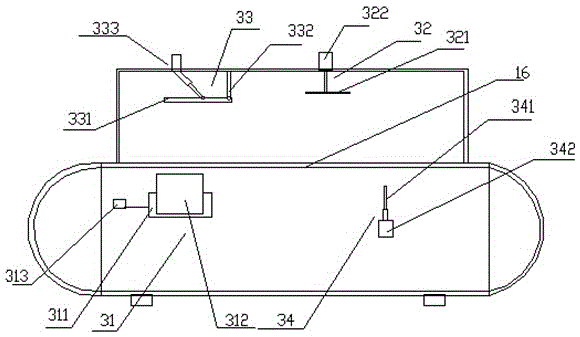

Metal powder packaging, labeling and boxing integrated device and process

PendingCN112407440ARealize fully automatic packagingImprove work efficiencyFlanged caps applicationSolid materialPackaging TankMetal powder

The invention discloses a metal powder packaging, labeling and boxing integrated device and process. The metal powder packaging, labeling and boxing integrated device comprises a conveying seat, a conveyor, a first door-shaped frame, a second door-shaped frame, a material tank frame, a packaging tank and a feeding base. The metal powder packaging, labeling and boxing integrated device is characterized in that the conveyor is arranged on the conveying seat, wherein the first door-shaped frame and the second door-shaped frame both stretch across the conveying seat, the conveyor is located on theconveying seat, a material taking structure is arranged between the conveyor and the conveying seat, a feeding structure is arranged on the feeding base, a filling structure is arranged on the firstdoor-shaped frame, and a code printing structure is arranged on the second door-shaped frame. The metal powder packaging, labeling and boxing integrated device and process have the beneficial effectsthat the processing equipment different from a traditional means is provided, the device can achieve full-automatic packaging and full-automatic code printing of materials, the working efficiency is effectively improved, and the problems mentioned in the background technology are solved.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

A motor packaging line

ActiveCN106394958BRealize fully automatic packagingGuarantee product qualityPaper article packagingIndividual articlesElectricityCarton

The invention discloses a motor packaging assembly line. The motor packaging assembly line comprises an unpacking mechanism, a filling mechanism, a packing mechanism and a controller. A discharge port of the unpacking mechanism communicates with a feed inlet of the filling mechanism, a discharge port of the filling mechanism communicates with a feed inlet of the packing mechanism, and a discharge port of the packing mechanism communicates with a feed inlet of a stacking mechanism; the controller is electrically connected to the unpacking mechanism and the packing mechanism. By adoption of the motor packaging assembly line disclosed by the invention, full-automatic packaging can be realized, production can be organized only with extremely less manual work, and the production quality of products can be guaranteed. The size of a packaging box can be self-designed according to the sizes of the products, production changes of the products can be coped with, and the occupied plant area by carton boxes can be reduced; the packaged products can be automatically transferred, so that the manual work input can be reduced and management is facilitated; the motor packaging assembly line disclosed by the invention is simple in structure and convenient to manufacture, the human cost of an enterprise is greatly reduced with only investment at one time, and the packaging quality is guaranteed, and manual management is further facilitated.

Owner:探骊动力科技(重庆)有限公司

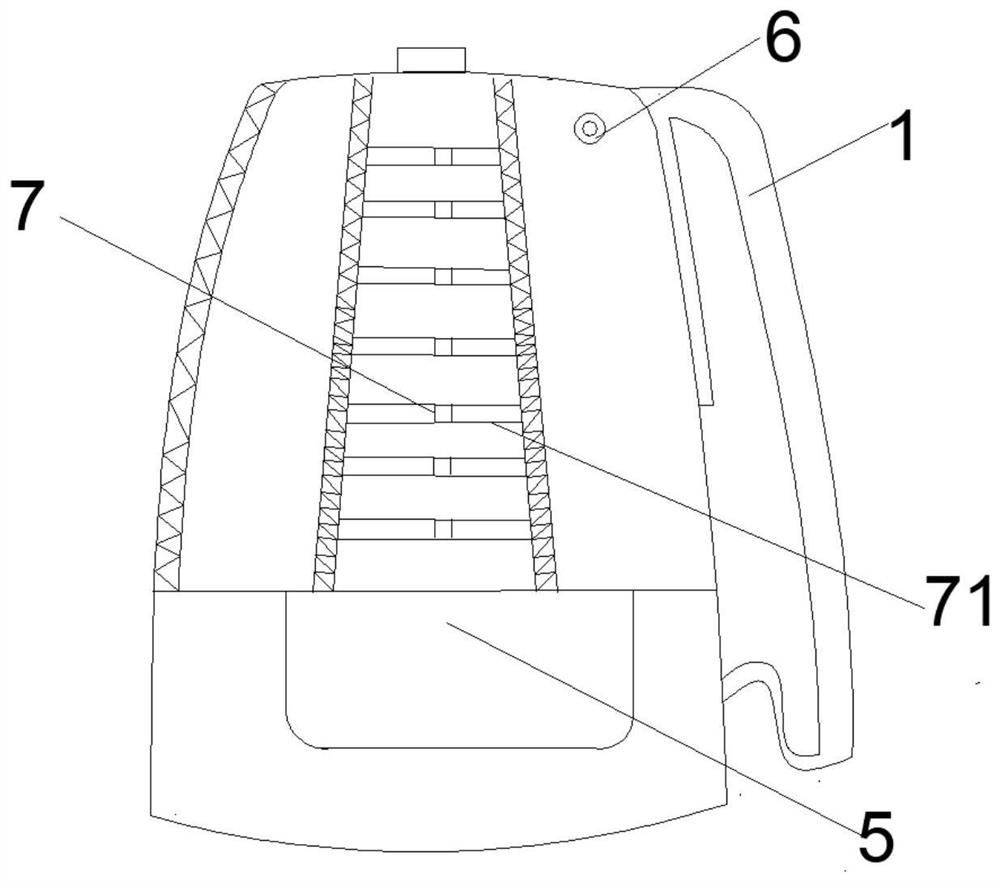

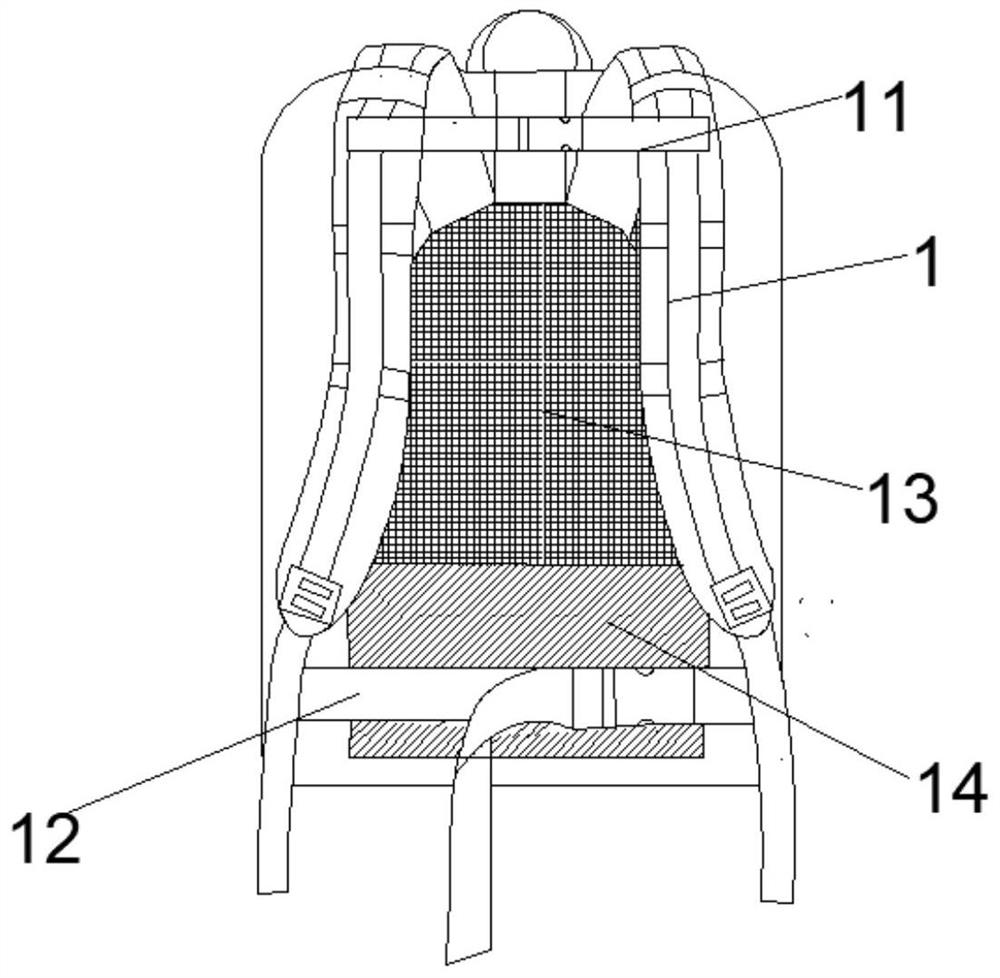

A combat backpack for preventing damage from multi-angle fall and impact and its production process

ActiveCN111972818BAvoid damageEasy to useTravelling sacksOther accessoriesRadio equipmentProcess engineering

The invention discloses an anti-multi-angle drop-impact-damaged combat backpack and a production process thereof, which comprises a buffer protection box, a sandwich bag, an antenna punching hole, and a side bag, wherein the side bag is provided with a through hole, thereby realizing The convenience of storage and use of military equipment (such as radio equipment), military equipment and its related accessories can be stored and taken easily and can be used normally in combat backpacks. At the same time, due to the protective effect of the buffer protection box, its impact resistance performance It is strong and more suitable for combat needs. Its production process includes material preparation → backpack body production → strap production → buffer protection box production → sandwich bag production → perforation processing → splicing and stitching → partition production → quality inspection → packaging. The packaging device includes a bracket on which a feeding conveying device, a grabbing mechanism, a bag-supporting device, a heat-sealing device and a discharging device are sequentially fixed, which realizes the full automation of the packaging process of the combat backpack and improves the work efficiency. Reduced labor costs.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

Full-automatic carton packing machine

InactiveCN105059587ARealize fully automatic packagingImprove packaging efficiencyPaper article packagingCartonEngineering

The invention discloses a full-automatic carton packing machine. The full-automatic carton packing machine comprises a first rack, a conveying mechanism and an air cylinder main valve, wherein the conveying mechanism and the air cylinder main valve are arranged on the first rack. The exterior of the conveying mechanism comprises a compression mechanism and a controller used for controlling the conveying mechanism, the air cylinder main valve and the compression mechanism. An upper extension device is arranged between the first rack and the compression mechanism. Through the devices, the full-automatic carton packing machine conducts packing operation on cartons, achieves full-automatic packing, is high in packing efficiency and capable of reducing labor force and meets the requirements for modernized social development.

Owner:NINGBO HAISHU JINAO SUPPLIES CO LTD

A food packaging machine

ActiveCN113264489BAutomate the packaging processRealize fully automatic packagingCapsThreaded caps applicationFood packagingConveyor belt

The invention relates to the technical field of food processing machinery, in particular to a food packaging machine, comprising: a base and a conveyor belt, the conveyor belt is connected to the base; a support frame, the support is erected on the outside of the conveyor belt and fixed to the base connection; a packaging mechanism, the packaging mechanism is arranged inside the support frame; and a driving mechanism, the driving mechanism is arranged between the packaging mechanism and the support frame, wherein the packaging mechanism includes: a blanking assembly , the blanking assembly is arranged on the inner side of the support frame and is connected with the driving mechanism; the disassembly assembly is threaded and arranged on the outside of the blanking assembly; the air guide transmission assembly, the air guide The transmission component is arranged outside the assembly and disassembly assembly. By setting a packaging mechanism and a drive mechanism, the drive mechanism is used to drive the blanking assembly and the assembly and disassembly assembly, and the assembly and disassembly assembly is driven to rotate by lifting the blanking assembly. Fully automatic packaging of food.

Owner:徐州天浩机械制造有限公司

Full-automatic steel wire rope winding and packaging device and method

PendingCN108726268ASimple structureHigh degree of automationFilament handlingWrappingPaper sheetEngineering

The invention discloses a full-automatic steel wire rope winding and packaging device. The full-automatic steel wire rope winding and packaging device at least comprises a rack, the rack is provided with a feed component for accommodating a steel wire rope and a clamping component used for clamping the steel wire rope of the feed component, the rack is further provided with a compressing componentused for pressing the steel wire rope between the clamping component and the feed component to a winding component; the full-automatic steel wire rope winding and packaging device further comprises an attaching component arranged on the rack and used for tightly attaching the steel wire rope on the winding component and a pressing component arranged on one side of the winding component and used for pressing attaching paper on the attaching component to the winding component. The full-automatic steel wire rope winding and packaging device has the main beneficial effects that: the structure issimple, the design is ingenious, the steel wire rope is fully automatically packaged, the degree of automation is high, the operation is convenient, and the working efficiency is greatly improved.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

Rapid packaging method of strip-shaped articles and packaging line with method

ActiveCN105173164ARealize fully automatic packagingNo manual operation requiredConveyor wrappingPaper sheetPacking method

The invention relates to the field of packaging machines, in particular to a packaging method of strip-shaped articles and a packaging line with the method. According to the packaging method, a conveying chain arranged on the packaging line carries paper sheets to slide on a bottom frame, the paper sheets pass a paper sheet discharging device, a paper sheet kneading part, a gluing device, a strip-shaped article discharging device and a folded gluing device in sequence, and the process of discharging, paper sheet kneading, gluing and folded gluing of the paper sheets is achieved. Meanwhile, the process is completely full automatic, manual operation is not needed, labor input is greatly saved, and production efficiency is improved. More superiorly, in the process of paper box forming through paper sheet folding and gluing, the strip-shaped articles can be wrapped in a formed paper box, and therefore the full-automatic packaging of the strip-shaped articles is achieved.

Owner:佛山市方悦机械科技有限公司

A fast packaging method for strips and a packaging line applying the method

ActiveCN105173164BRealize fully automatic packagingNo manual operation requiredConveyor wrappingPulp and paper industryChassis

The invention relates to the field of packaging machines, in particular to a packaging method of strip-shaped articles and a packaging line with the method. According to the packaging method, a conveying chain arranged on the packaging line carries paper sheets to slide on a bottom frame, the paper sheets pass a paper sheet discharging device, a paper sheet kneading part, a gluing device, a strip-shaped article discharging device and a folded gluing device in sequence, and the process of discharging, paper sheet kneading, gluing and folded gluing of the paper sheets is achieved. Meanwhile, the process is completely full automatic, manual operation is not needed, labor input is greatly saved, and production efficiency is improved. More superiorly, in the process of paper box forming through paper sheet folding and gluing, the strip-shaped articles can be wrapped in a formed paper box, and therefore the full-automatic packaging of the strip-shaped articles is achieved.

Owner:佛山市方悦机械科技有限公司

A fully automatic cotton socks packaging machine

InactiveCN105292568BRealize fully automatic packagingImprove work efficiencyPackagingCardboardButt joint

The invention relates to a fully-automatic cotton sock packaging machine which comprises a sock feeding mechanism. The fully-automatic cotton sock packaging machine is characterized in that the outlet end of the sock feeding mechanism is in butt joint with a paperboard delivery mechanism. The paperboard delivery mechanism is in butt joint with a sock hook insertion mechanism. One side of the sock hook insertion mechanism is provided with a sock hook vibration disc in butt joint with the sock hook insertion mechanism. The sock hook insertion mechanism is in butt joint with a sock conveying platform. One side of the sock conveying platform is provided with a sock paperboard knotting machine delivery mechanism. The outlet end of the sock conveying platform is provided with a sock clamping and pushing mechanism and a sock overturning machine. One side of the sock overturning machine is provided with a labeling mechanism. The labeling mechanism is in butt joint with a sock bag forming mechanism and a sock bagging mechanism. By means of the fully-automatic cotton sock packaging machine, fully-automatic packaging of socks can be achieved, the fully-automatic cotton sock packaging machine has the beneficial effects of being high in working efficiency, low in labor intensity, high in packaging accuracy and not prone to generating errors and the like and further has the beneficial effects of being high in automation degree, speed and reliability.

Owner:YIWU GECHUANG AUTOMATIC CONTROL TECH CO LTD

A copy paper packing machine

ActiveCN108382641BRealize fully automatic packagingSave resourcesPackagingCartoning machineIndustrial engineering

The invention discloses a copy paper packing machine. The complete machine comprises a pushing device pushing stacked copy paper into a lower cover, a carton lower cover forming device, a carton uppercover forming device and a conveying channel. The copy paper packing machine is characterized in that the conveying channel comprises front and rear high conveying channels and a middle low conveyingchannel; the pushing device is arranged at the front high conveying channel; the carton upper cover forming device is arranged at the rear high conveying channel; the carton lower cover forming device is arranged at the middle low conveying channel; front and rear copy paper receiving devices are arranged in the positions of the high and low difference between the high and low conveying channels;full-automatic packing of the copy paper is achieved through the pushing device, the front copy paper receiving device, a lower cover feeding-in device, the carton lower cover forming device, an upper cover feeding-in device and the carton upper cover forming device, manpower is replaced by the copy paper packing machine, resources are saved, and production efficiency is improved greatly.

Owner:RUIAN DONGTENG MACHINERY

Method for full automatically subpackaging sealing structure glue

InactiveCN101531332BRealize fully automatic packagingNo leaksBottle-handling machinesLiquid bottlingEngineeringBottle

The invention discloses a method for full automatically subpackaging sealing structure glue. The method can subpackage the sealing structure glue by repeatedly carrying out the following steps of A. setting parameters during running process; B. sending and loading bottles and gradually sending the structure glue into the packaging bottles; C. supplementing materials for the structure glue in the packaging bottles so that the structure glue achieves the arranged material position; D. opening a scraping motor and scraping the bottle mouth; and E. arranging the bottle cover at the bottle mouth and sealing the bottle. The method can subpackage the sealing structure glue full automatically, has high subpackaging efficiency and exact measurement, and has no splash or leakage of the sealing structure glue during the subpackaging process.

Owner:叶迪光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com