Automatic industrial explosive packaging line

A technology for automatic packaging and industrial explosives, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as the inability to realize automatic packaging lines, manual inspection of packaging quality, and high labor intensity of workers, so as to improve production packaging efficiency and design The layout is reasonable and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

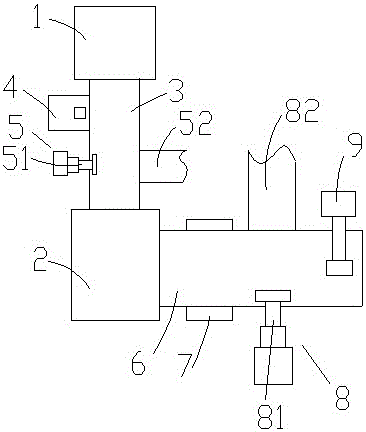

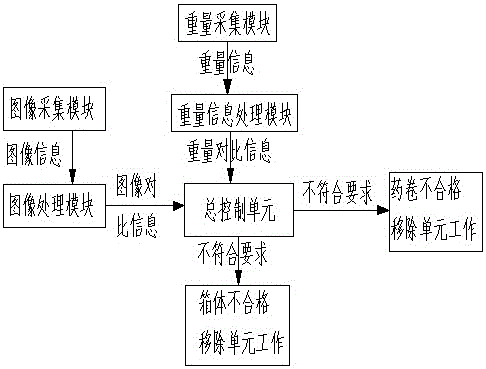

[0018] Such as figure 1 , 2 As shown, the present invention provides an automatic packaging line for industrial explosives, including a drug roll packaging unit 1, a drug roll packing unit 2, a drug roll delivery unit 3, and a general control unit. The drug roll packaging unit 1 is installed on the drug roll At the front end of the conveying unit 3, the medicine coil packing unit 2 is installed at the rear end of the medicine coil conveying unit 3, and the medicine coil conveying unit 3 between the medicine coil packaging unit 1 and the medicine coil packing unit 2 is also sequentially provided with a medicine coil detection unit 4. Unqualified drug volume removal unit 5, the unqualified drug roll removal unit 5 includes a drug roll push rod 51 installed on one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com