Patents

Literature

33results about How to "Improve production and packaging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

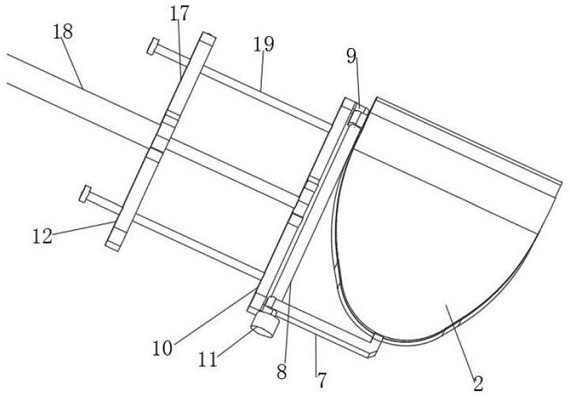

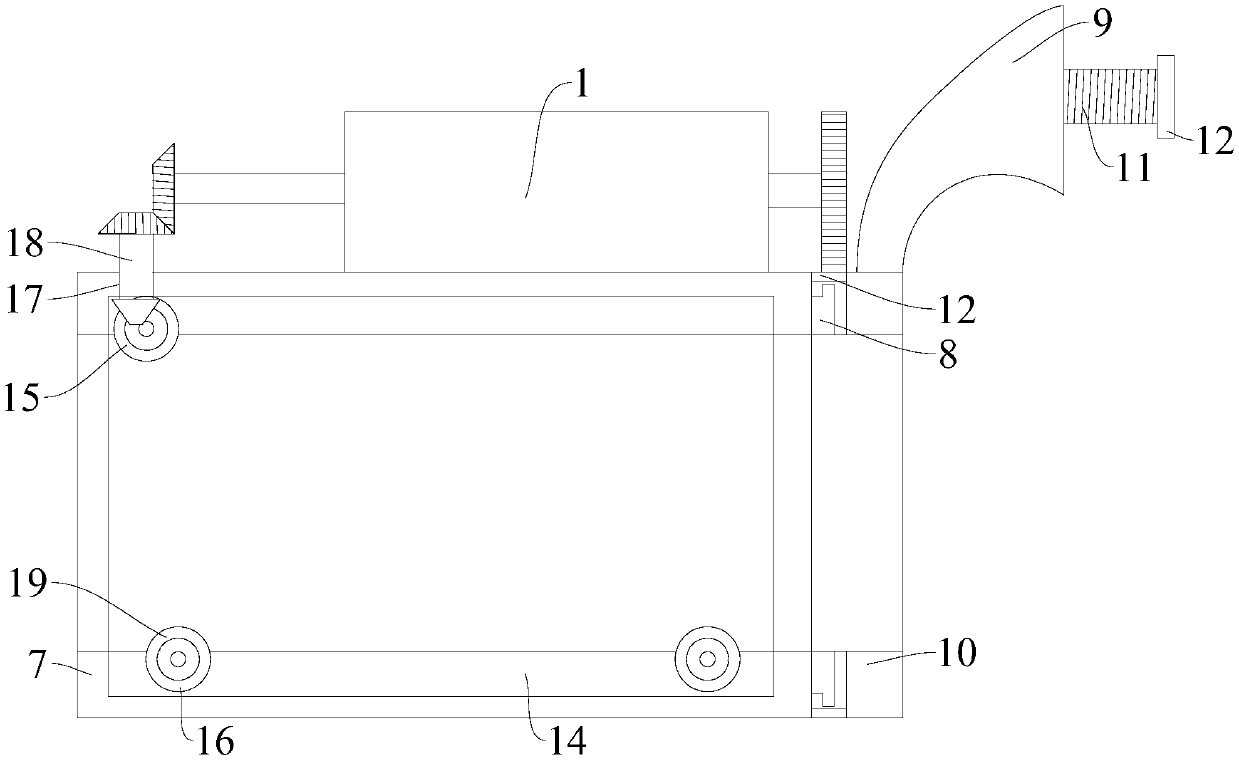

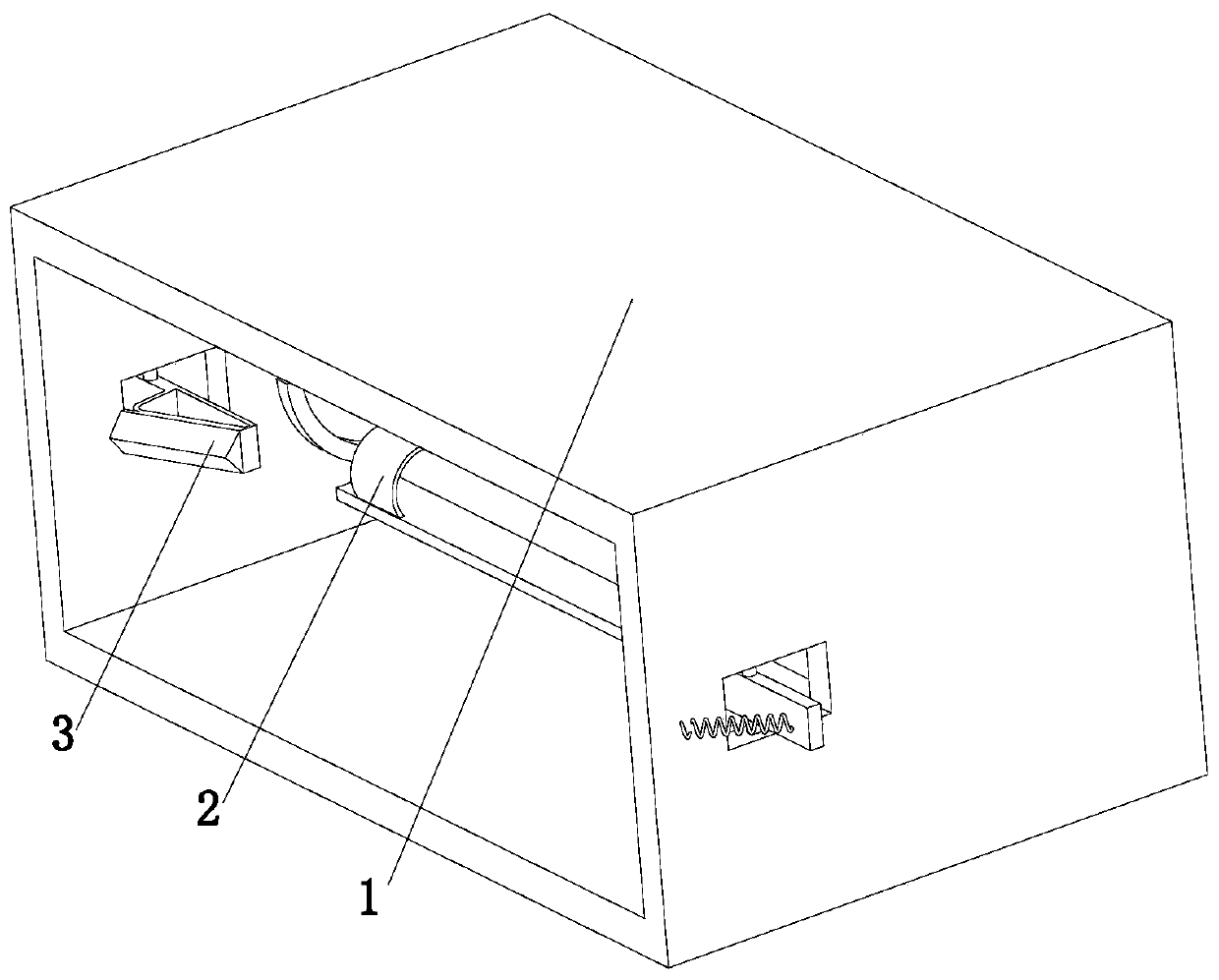

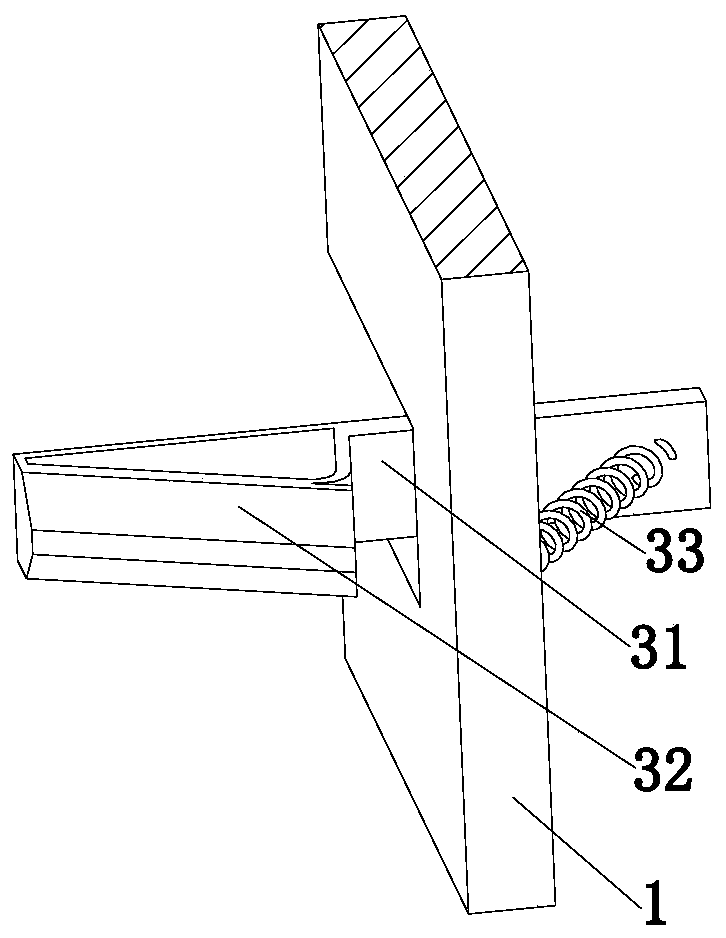

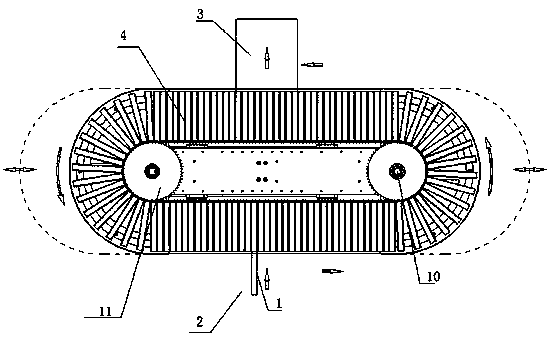

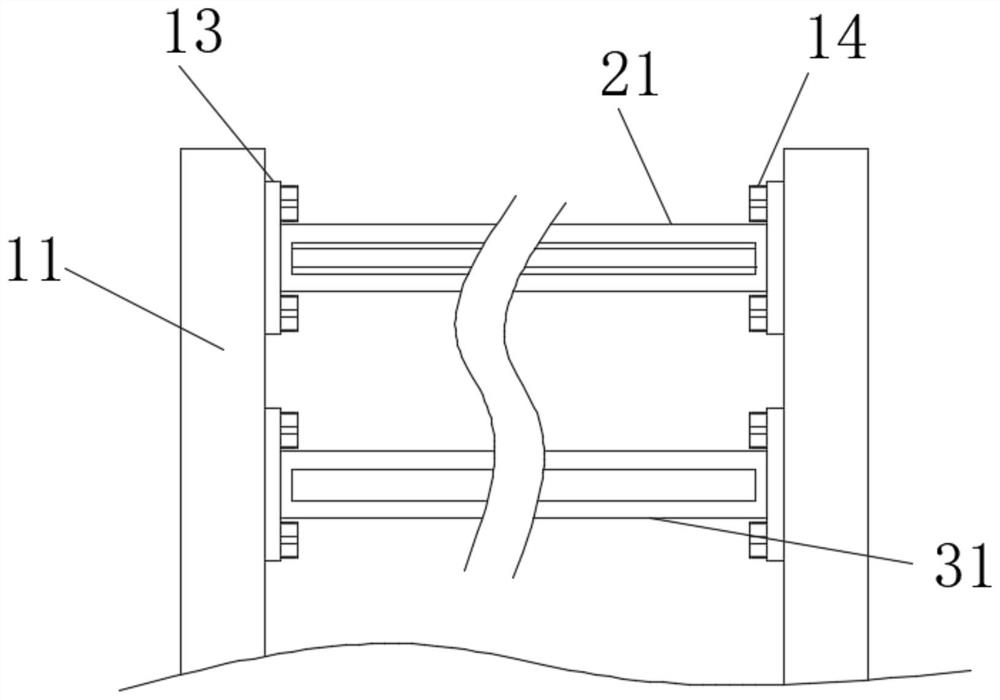

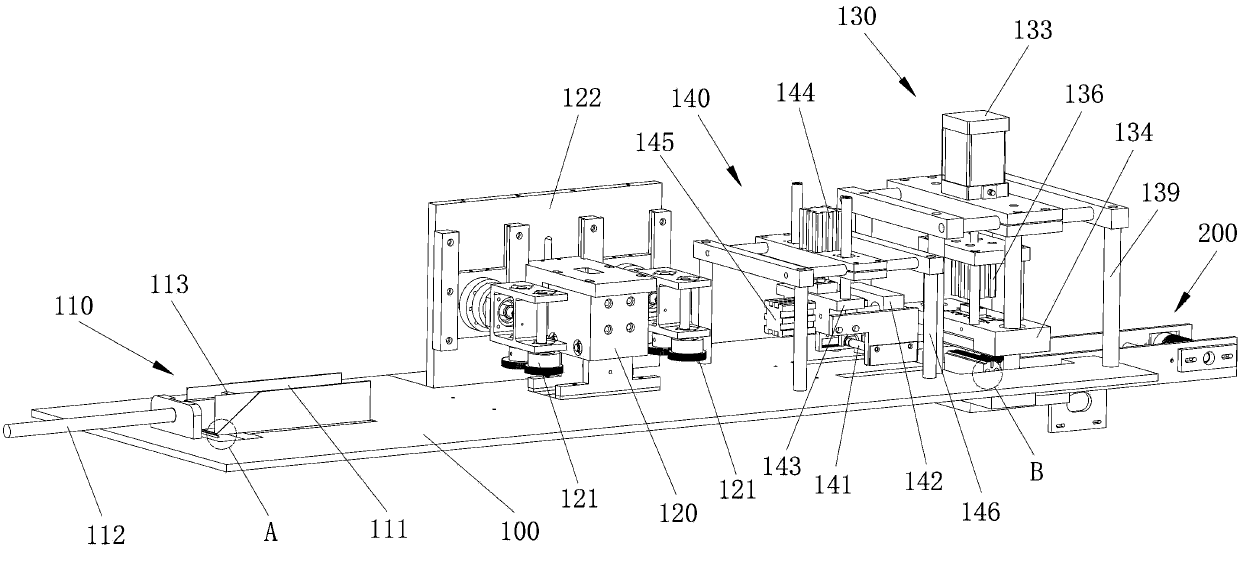

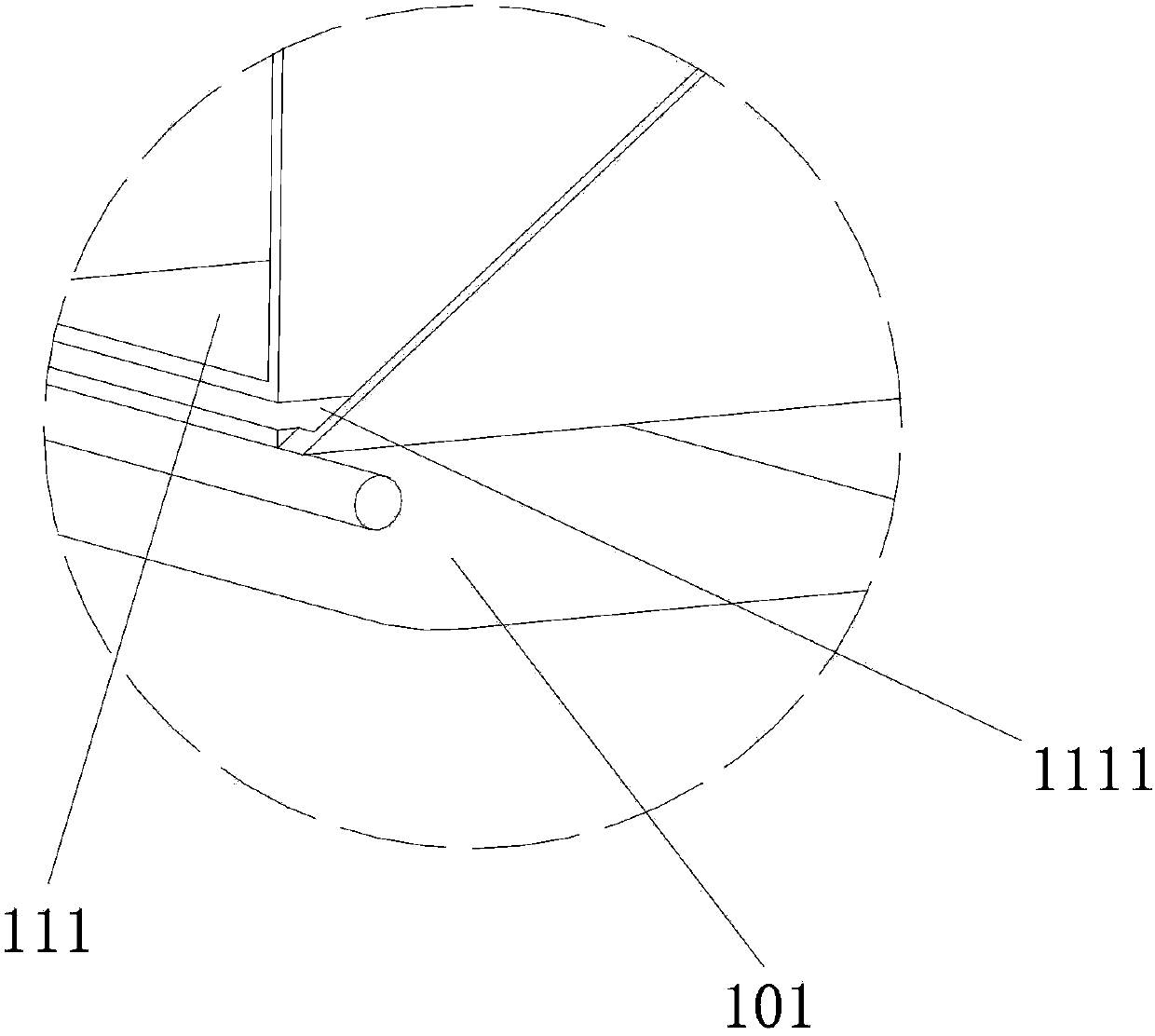

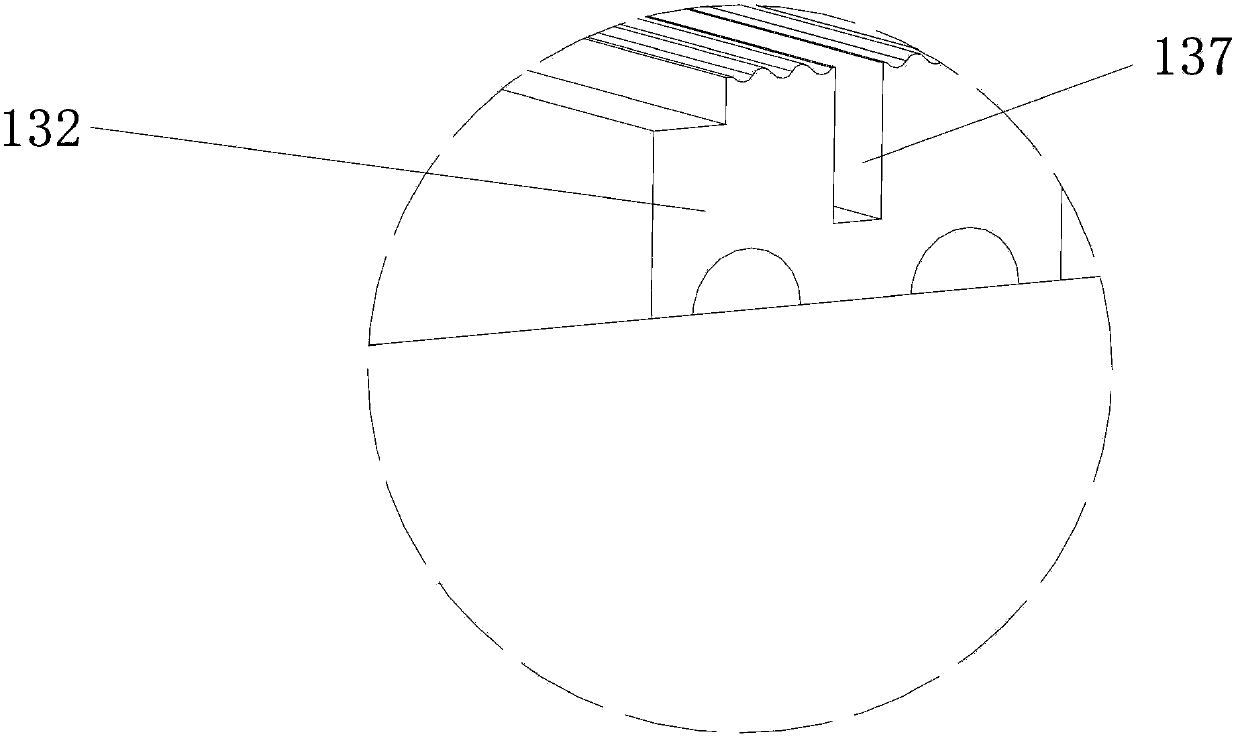

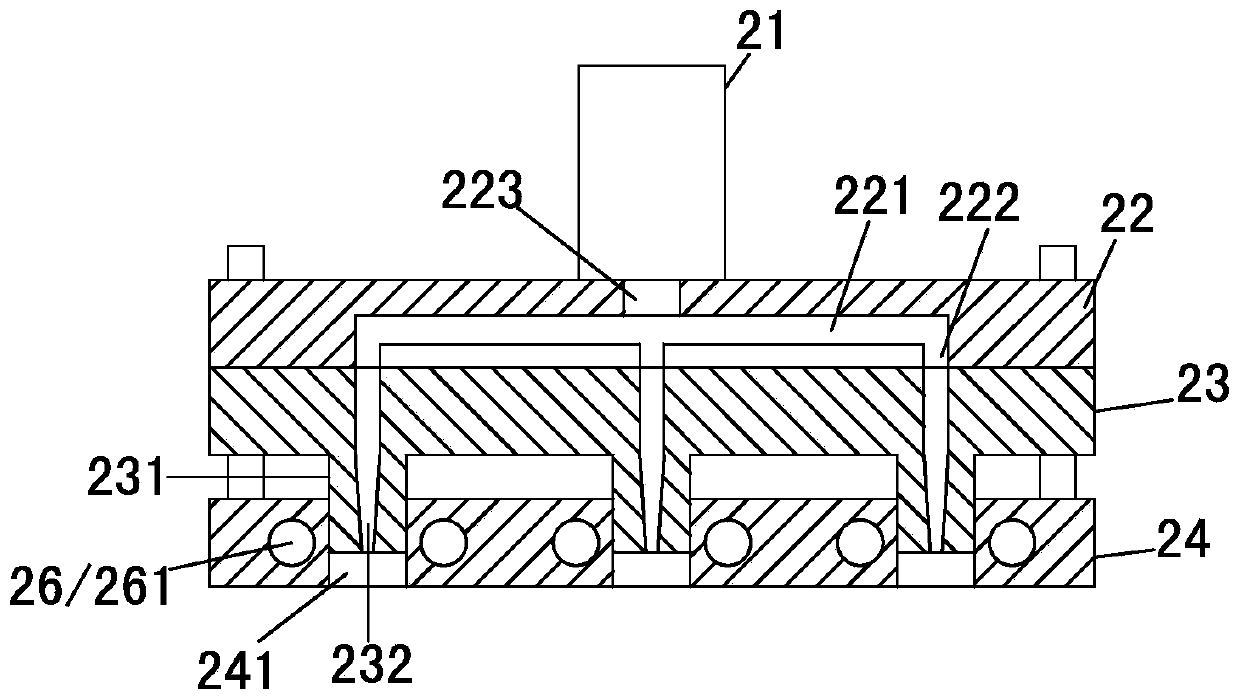

Packaging mechanism of automatic packaging machine for medical cotton swabs

InactiveCN103112610ASimplify the packaging processImprove production and packaging efficiencyWrapper twisting/gatheringRod-shaped articlesCotton swabHot press

The invention relates to the technical field of cotton swab packaging equipment, in particular to a packaging mechanism of an automatic packaging machine for medical cotton swabs. The packaging mechanism of the automatic packaging machine for the medical cotton swabs comprises a conveying platform, wherein a material pushing device, an upper edge sealing device and a hot pressing sealing and trimming device are arranged on the conveying platform in sequence. The hot pressing sealing and trimming device comprises a hot pressing sealing upper mold, a hot pressing sealing lower mold, a first cylinder, a first movable plate, a sealing cutter, a fixing device and a second cylinder. When the packaging mechanism of the automatic packaging machine for the medical cotton swabs works, the upper edge sealing device is capable of sealing the upper edge of a packaging film bag which contains the medical cotton swabs to be packaged and is conveyed by material pushing device, and then sealing and trimming of the packaging film bag with the upper edge well sealed and conveyed by the upper edge sealing device are achieved through the hot pressing sealing and trimming device. The sealing process and the trimming process are carried out at the same time, and therefore packaging processes are enabled to be simple and production and packaging efficiency is high.

Owner:东莞市万江鸿浩五金电器厂

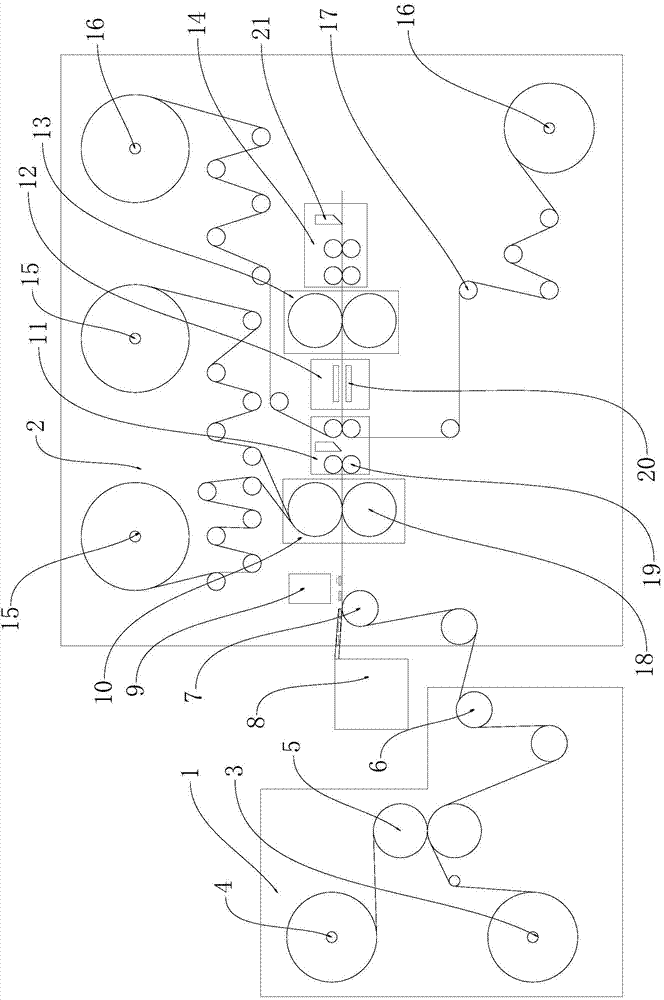

Corn paste combined packaging machine

ActiveCN103767877BReduce pollutionImprove production and packaging efficiencyPharmaceutical product form changeWrappingButt jointEngineering

Owner:ZHEJIANG DINGTAI PHARMA

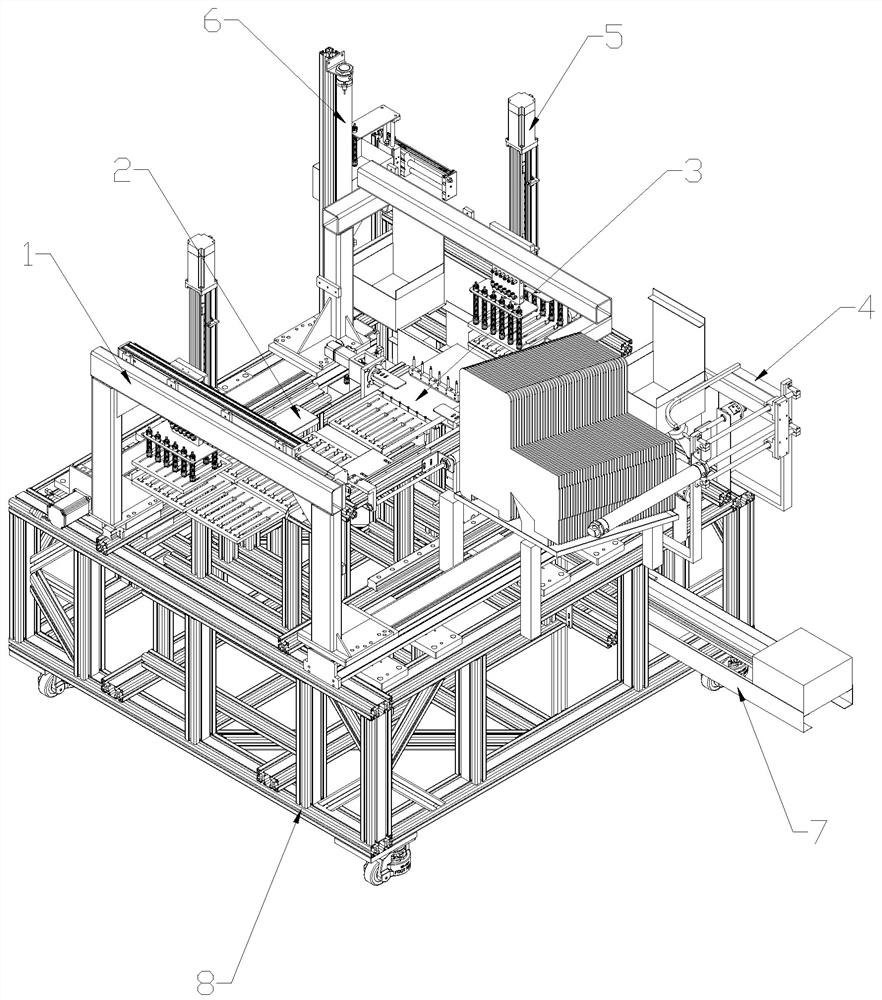

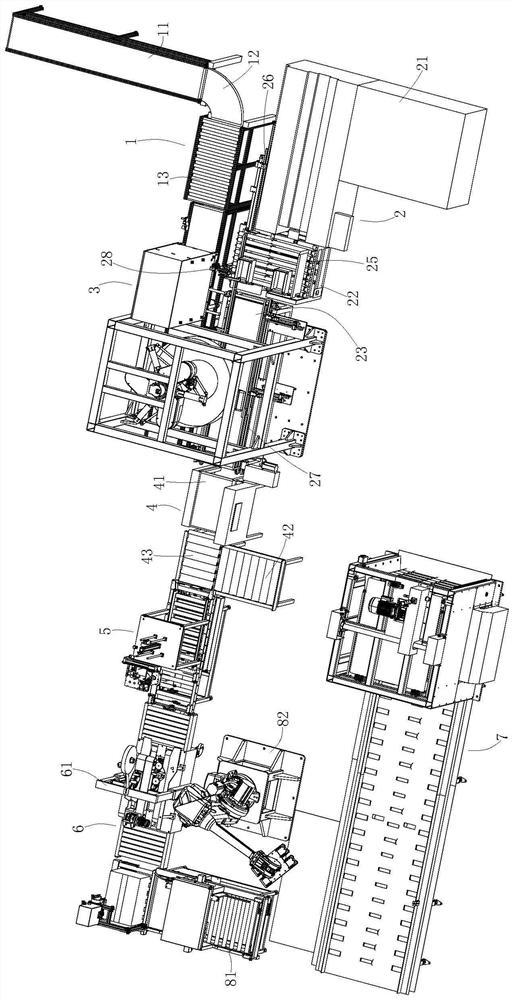

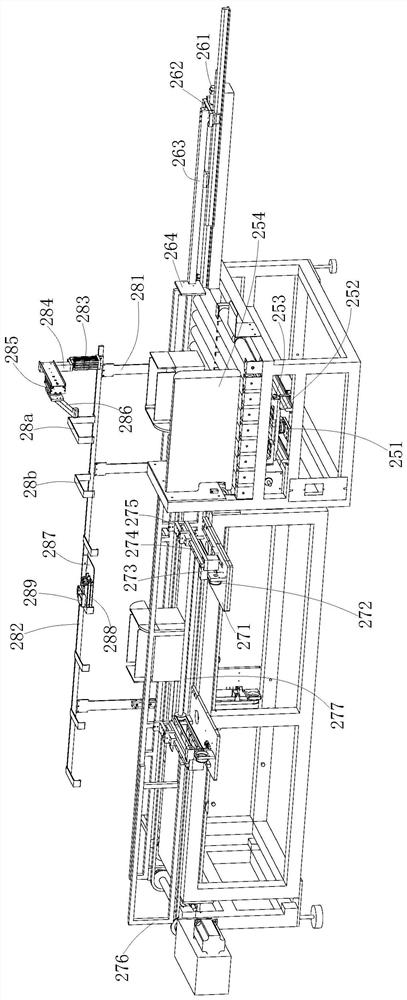

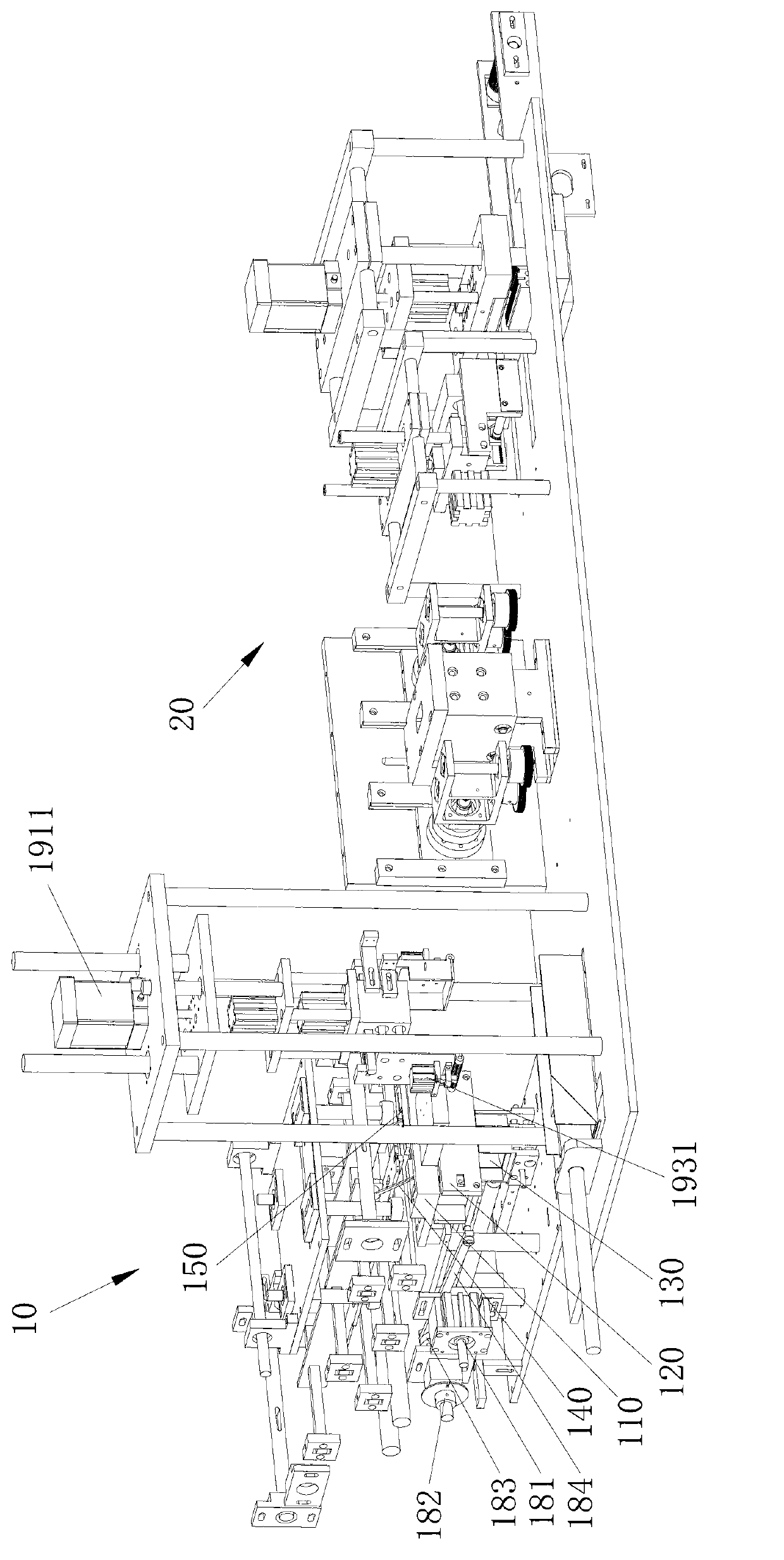

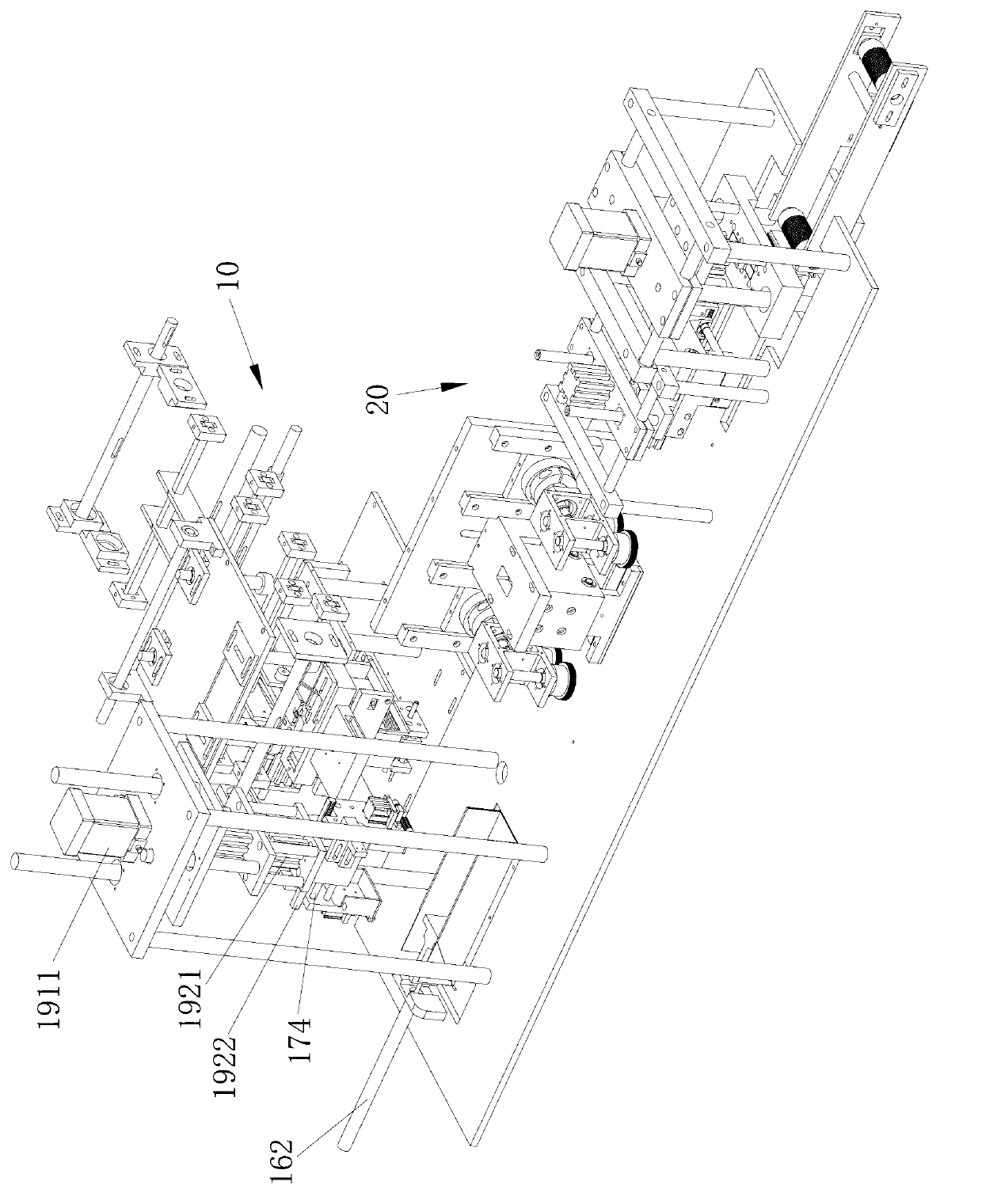

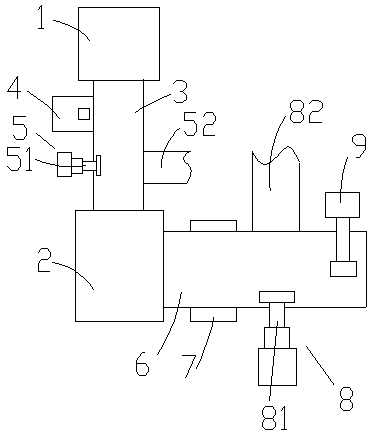

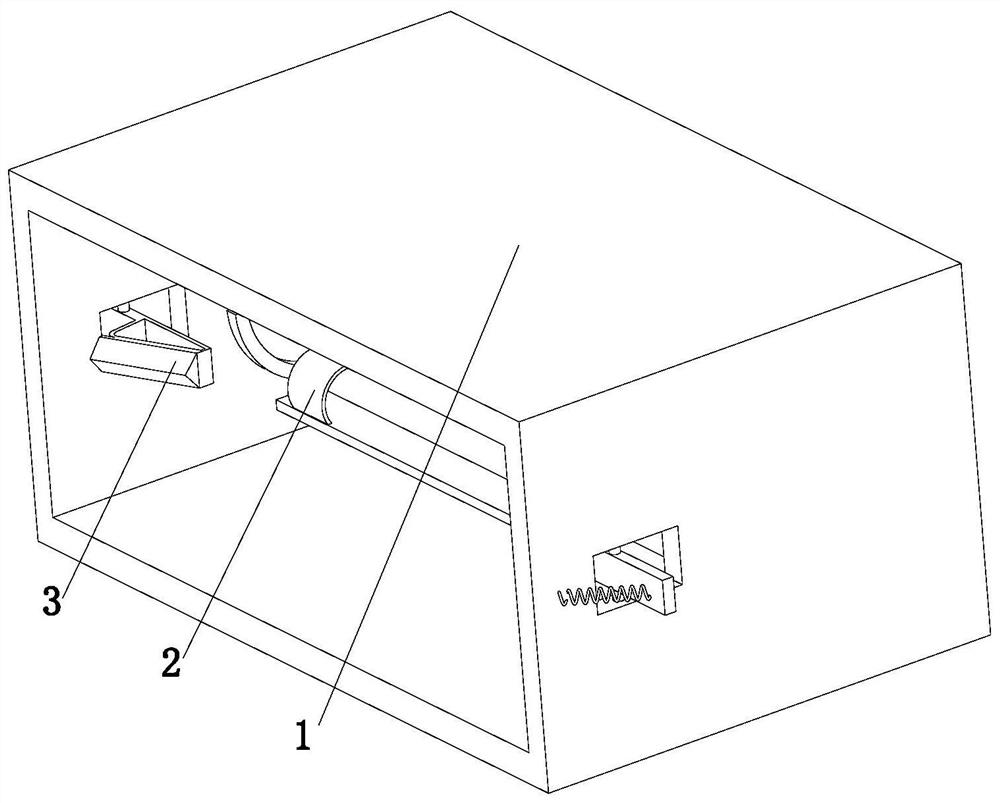

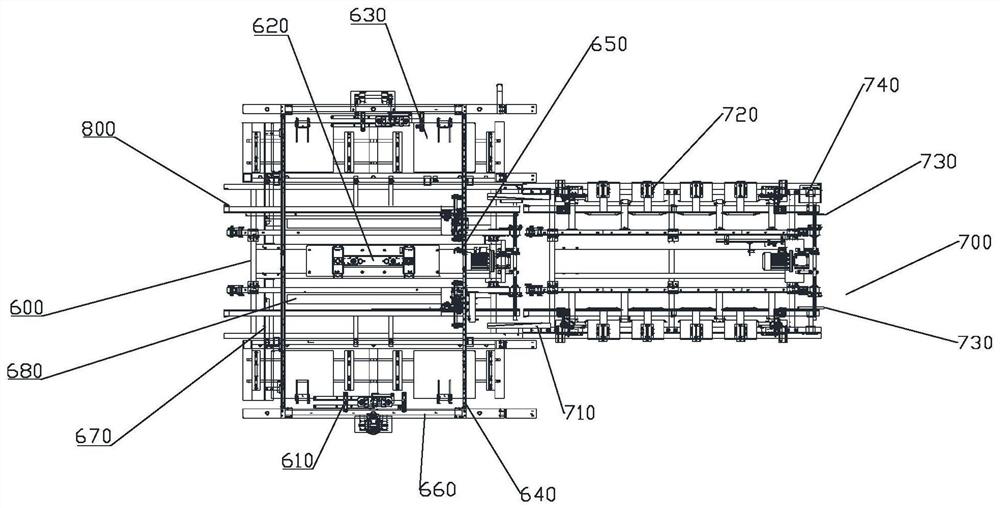

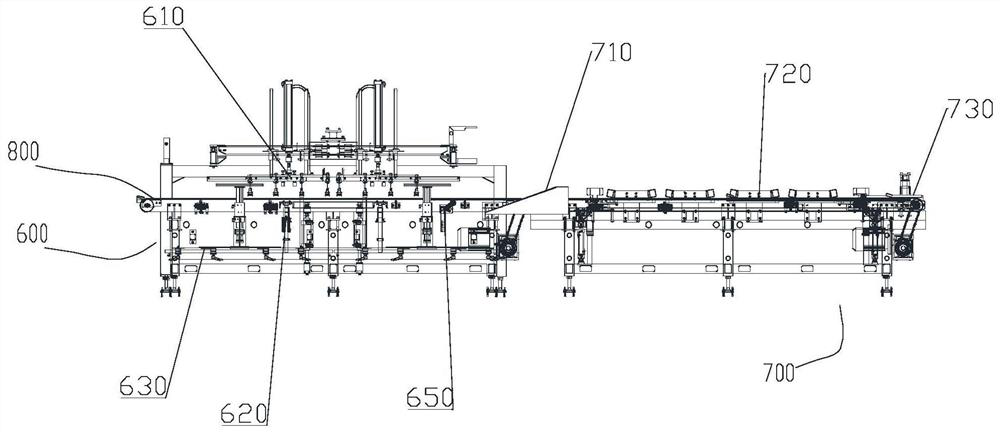

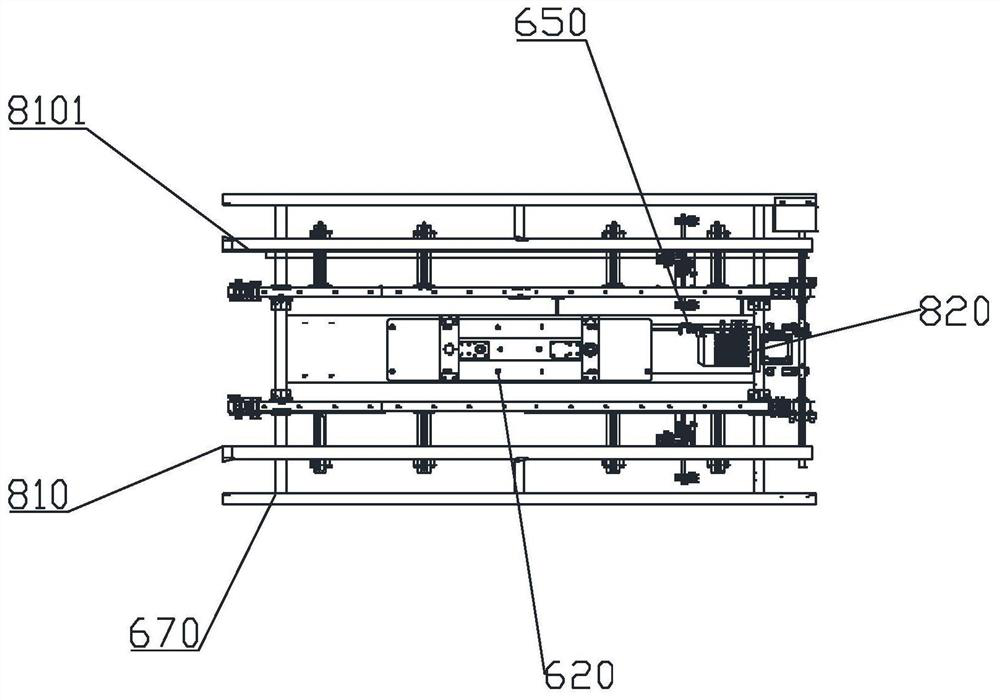

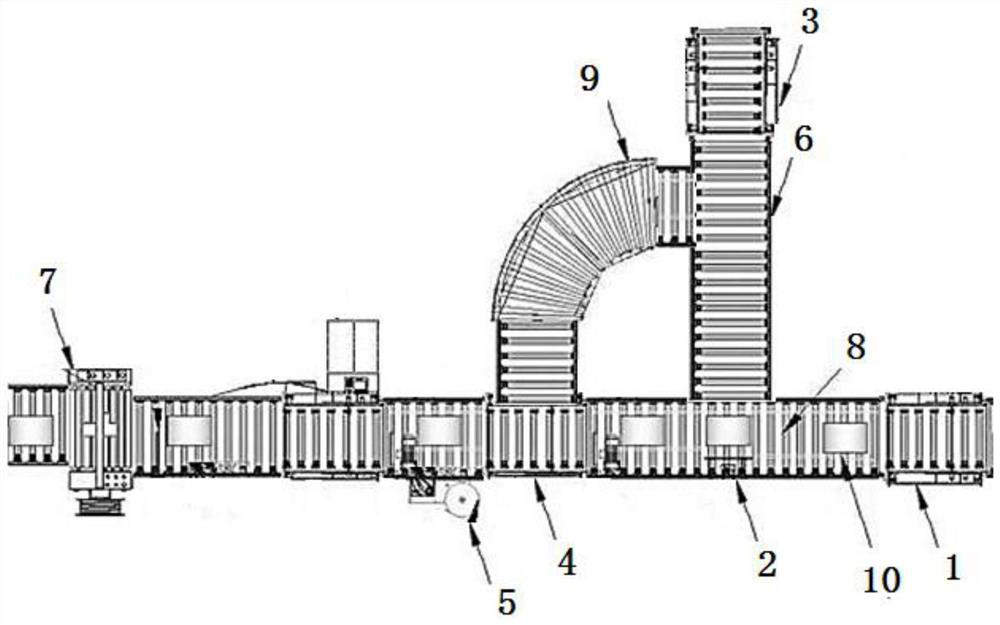

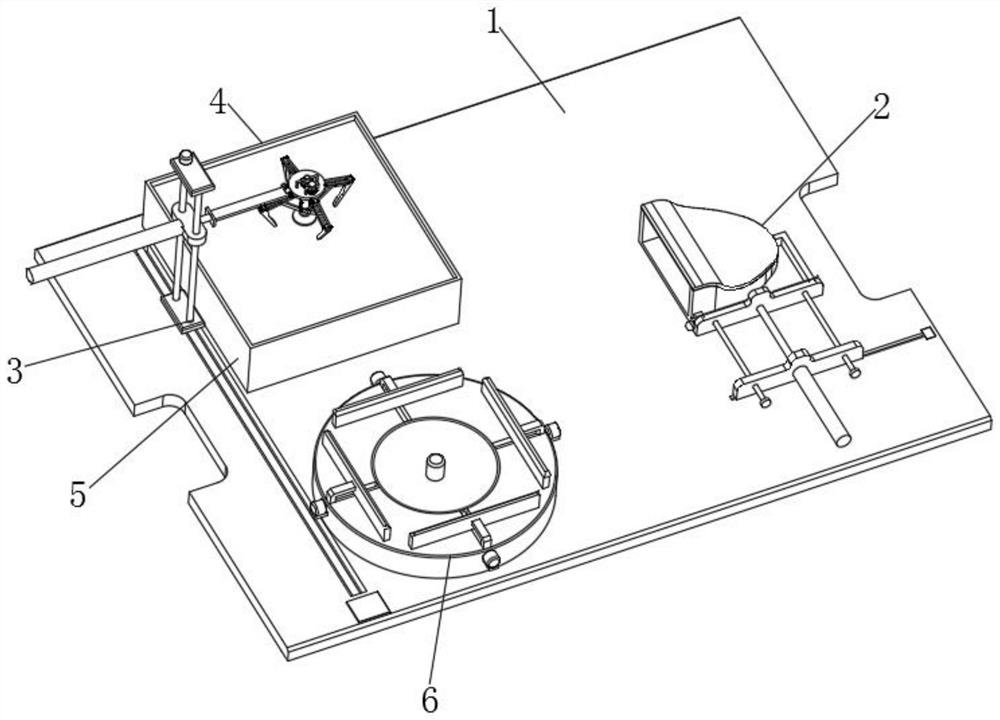

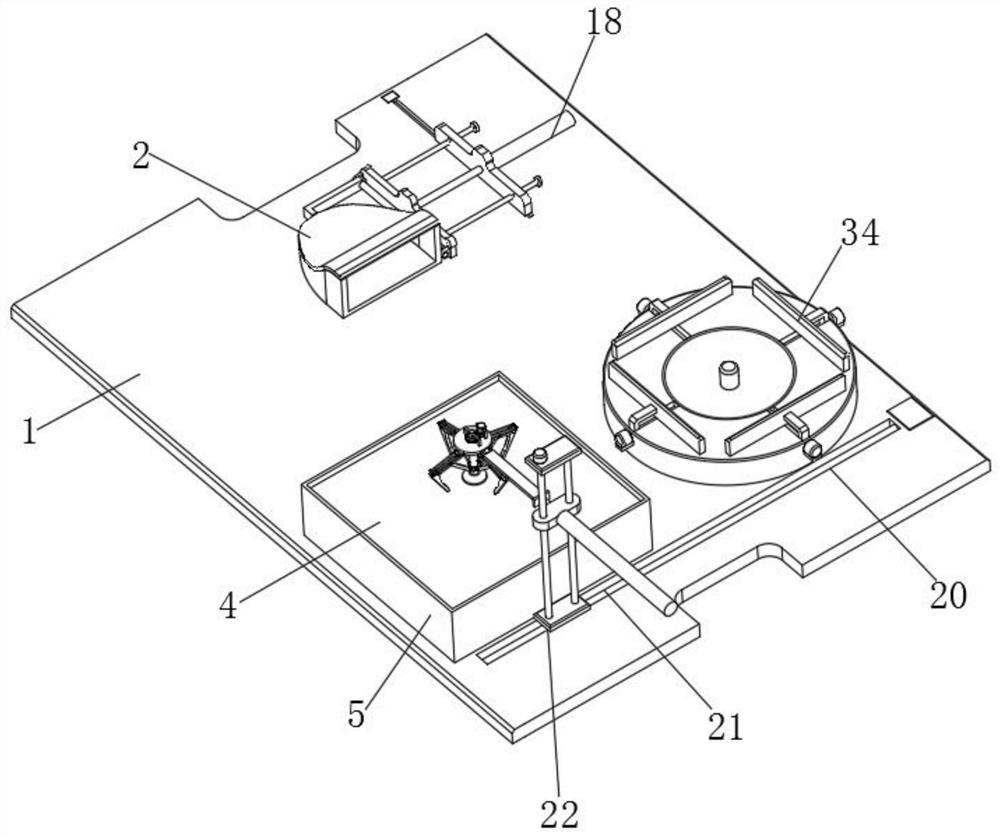

Boxing and packaging machine for medical syringes

PendingCN113716150AFree laborReasonable and ingenious space designPackaging automatic controlIndividual articlesSyringeSmall footprint

The invention discloses a boxing and packaging machine for medical syringes. The boxing and packaging machine comprises a main rack, a supplied material butt joint assembly, a detection assembly, a material in-situ turnover platform, a boxing assembly, a box opening assembly, a lifting material supplementing assembly and a box sealing assembly. The supplied material butt joint assembly is located in front of the material in-situ turnover platform, and the boxing assembly is located above the material in-situ turnover platform; and the box opening assembly is located on one side of the material in-situ turnover platform and extends to the rear portion of the material in-situ turnover platform, the box sealing assembly is located below the box opening assembly, the upper end of the lifting material supplementing assembly is connected with the rear end of the box opening assembly, and the lower end of the lifting material supplementing assembly is connected with the front end of the box sealing assembly. According to the boxing and packaging machine for the medical syringes, the medical syringes can be detected and boxed according to specifications, the labor force of workers is released, the space design is reasonable and ingenious, the occupied area is small, the space is fully utilized, the boxing and packaging machine can be directly in butt joint with front-end equipment, the practicability is high, the overall production and packaging efficiency is improved, and the packaging effect is good.

Owner:吴均

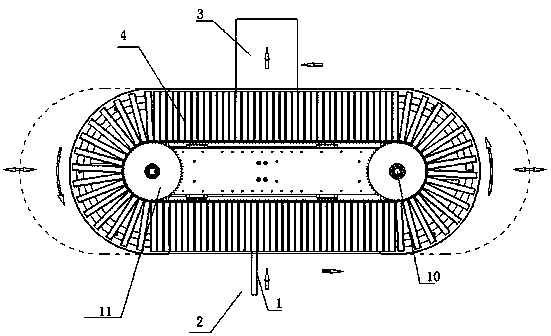

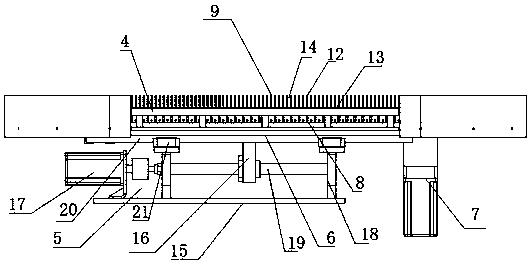

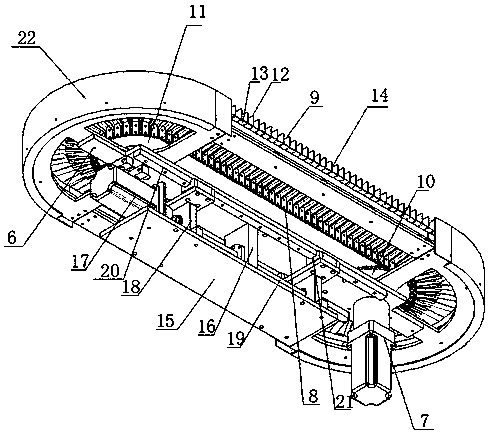

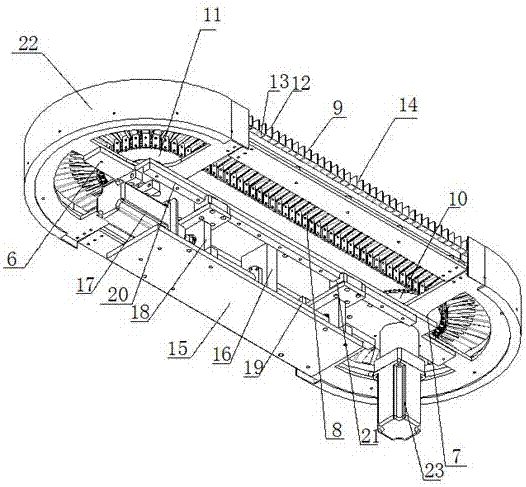

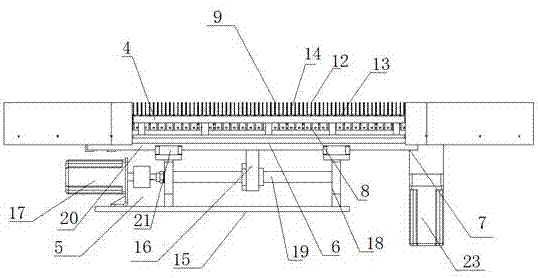

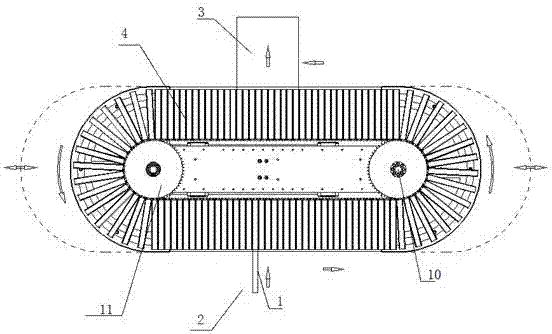

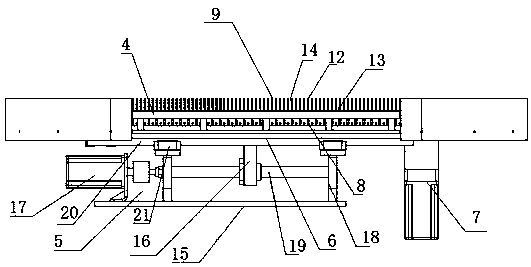

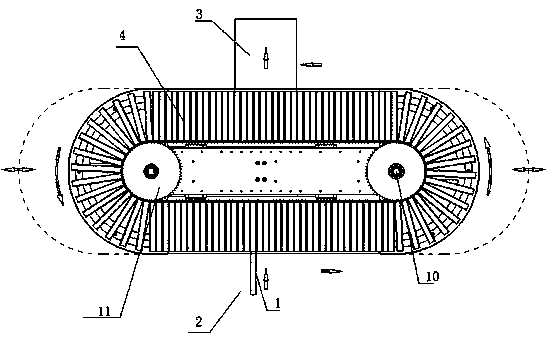

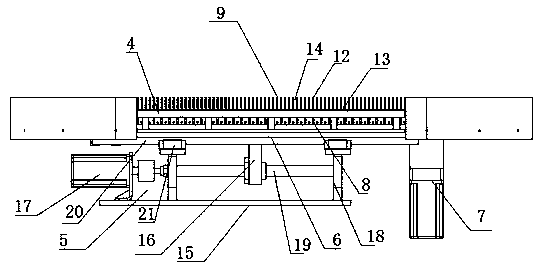

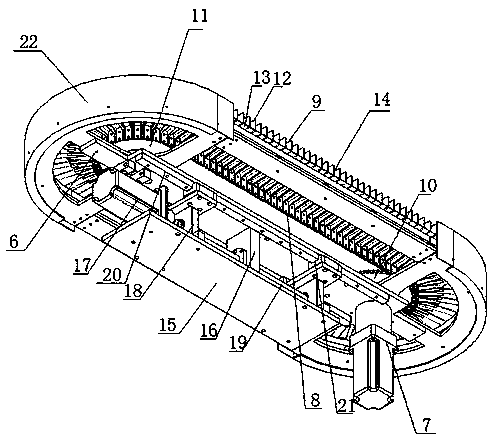

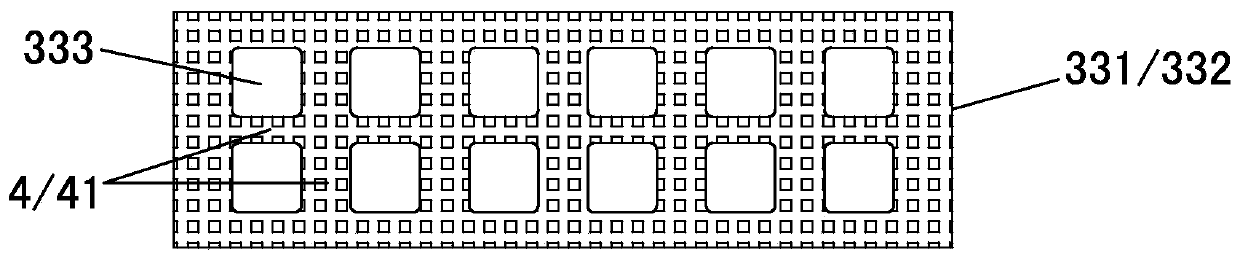

Material sorting process based on annular conveying device

The invention discloses a material sorting process based on an annular conveying device and relates to the technical field of the packaging process. Through the annular conveying device, materials arefed one by one and arranged side by side; the arranged materials arrive at the discharge end, a set number of materials are arranged to form a group of materials to be discharged from the discharge end; when discharged, the materials are static relative to the discharge end; the materials are fed one by one at the feed end. Through the material sorting process, the materials are arranged and sorted through a conveyor belt; feeding and discharging have no influence on each other; the materials are continuously arranged one by one; and the material sorting efficiency and production efficiency can be effectively improved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

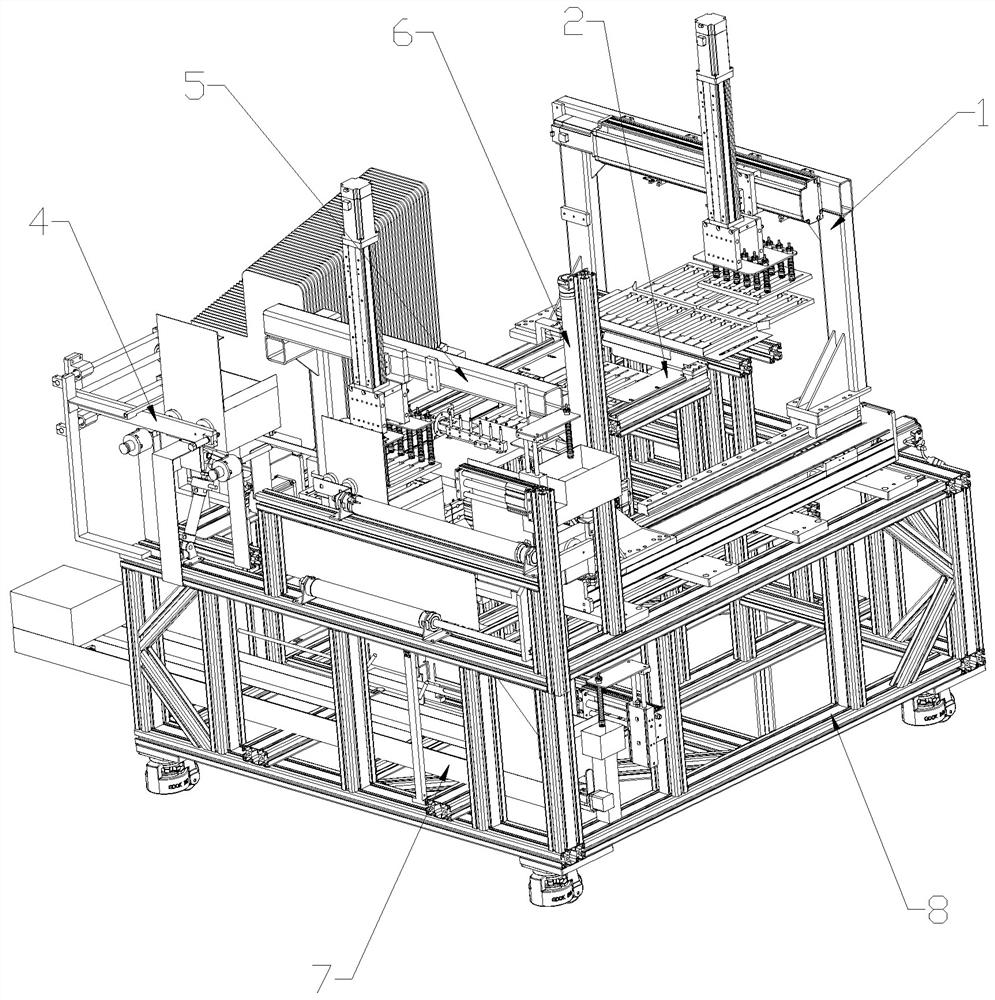

Automatic packaging system and packaging method for bagged products

ActiveCN113665874AImprove production and packaging efficiencyReduce manufacturing costWrapper twisting/gatheringPackaging automatic controlProcess engineeringEngineering

The invention belongs to the technical field of frozen food bagged product packaging, and particularly relates to an automatic packaging system and a packaging method for bagged products. The automatic packaging system comprises a conveying device, a packaging box feeding and loading device, a bagged product information collecting and carrying device and a bagged product label correcting device, wherein the conveying device is used for being in butt joint with a front-section processing station, and the front-section processing station conveys the bagged products; the packaging box feeding and loading device is used for opening a packaging box and sealing the bottom of the packaging box and bending the upper sealing edge of the packaging box; the bagged product information collecting and carrying device is used for collecting appearance information of the bagged products conveyed by the conveying device, grabbing the bagged products according to the appearance information and loading the bagged products into packaging box located on the packaging box feeding and loading device; and the bagged product label correcting device is used for conducting vibration operation on the bagged products in the packaging box so that the bagged products in the packaging box can be flattened, and then labels are placed in the bagged products. According to the automatic packaging system, the bagged products can be automatically subjected to feeding, boxing, packaging and discharging procedures, and the production and packaging efficiency of the bagged products is greatly improved.

Owner:思为客(宁波)智能装备有限公司

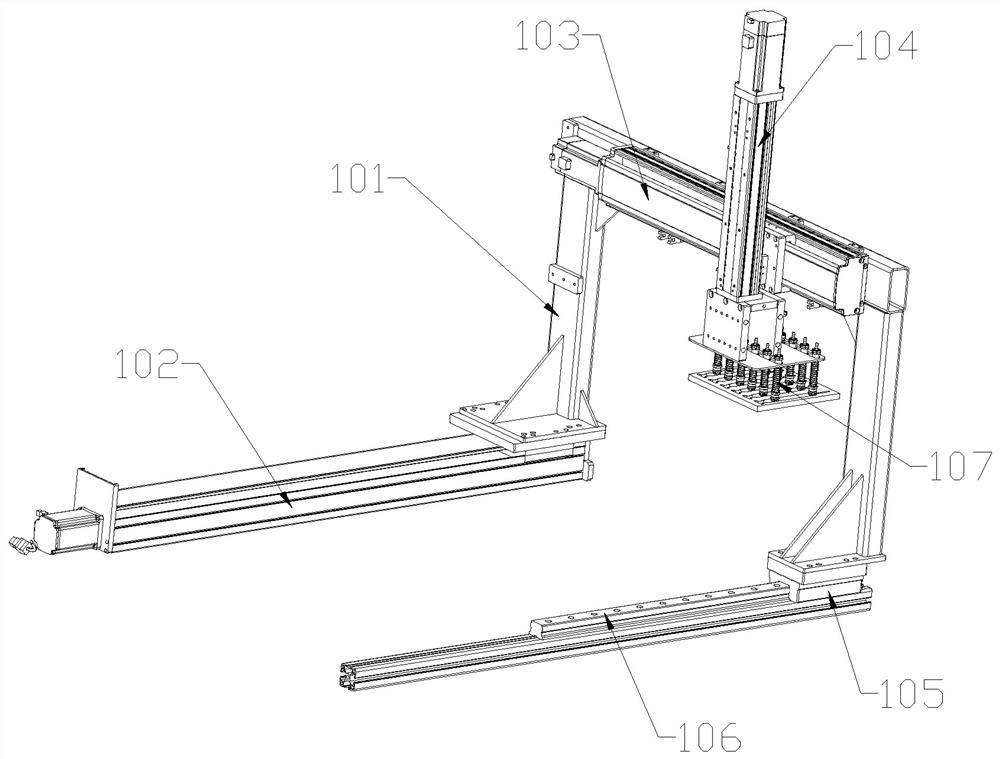

Mechanical hand for packaging

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

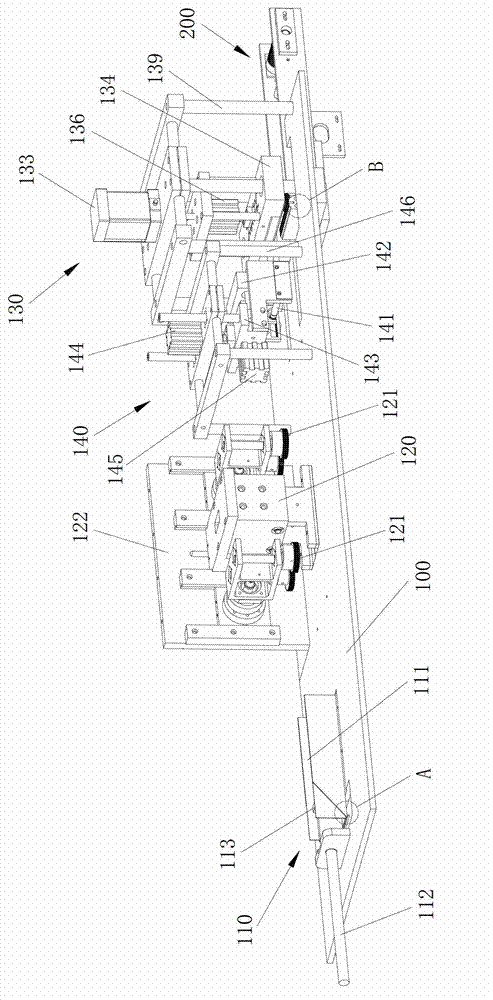

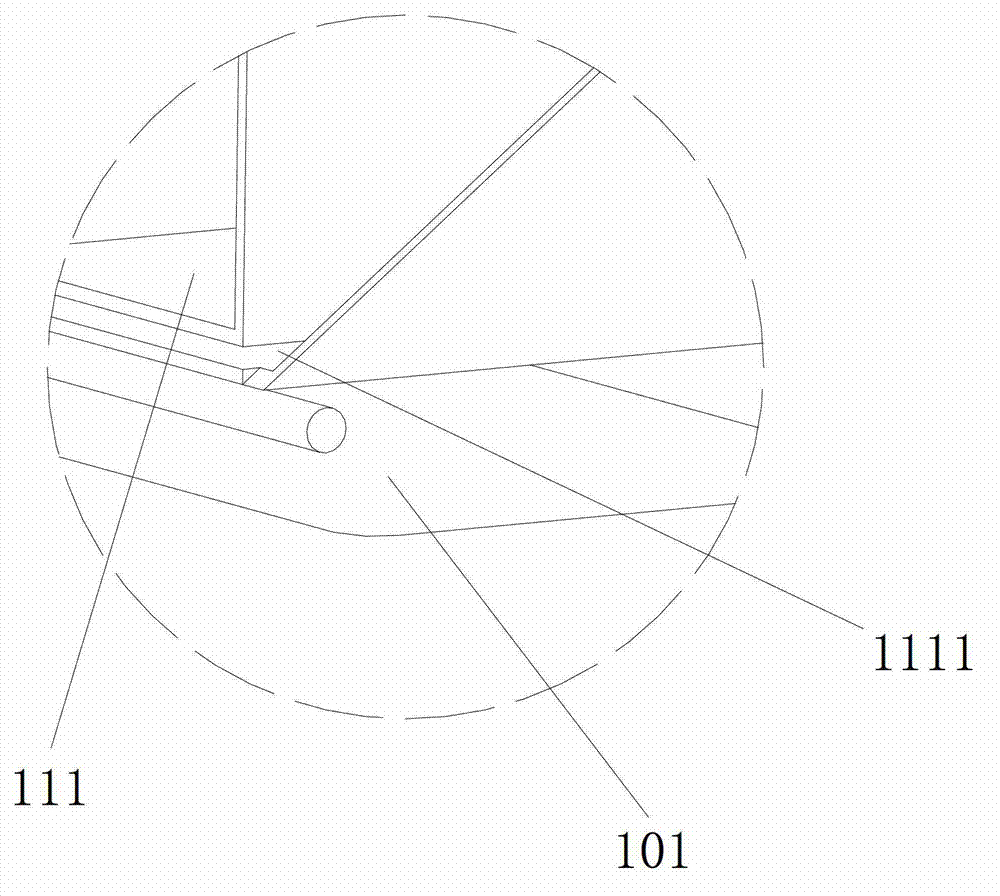

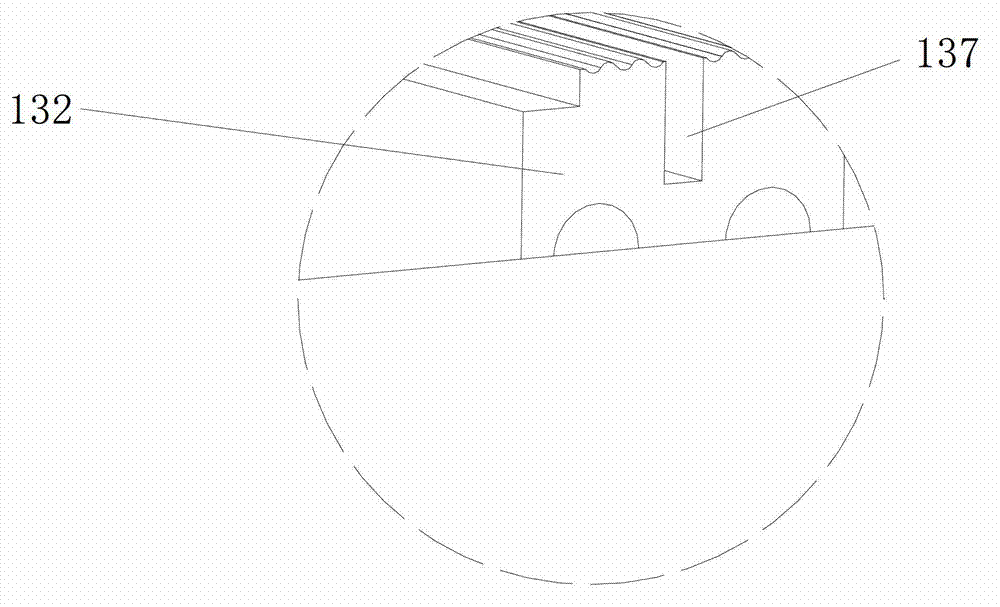

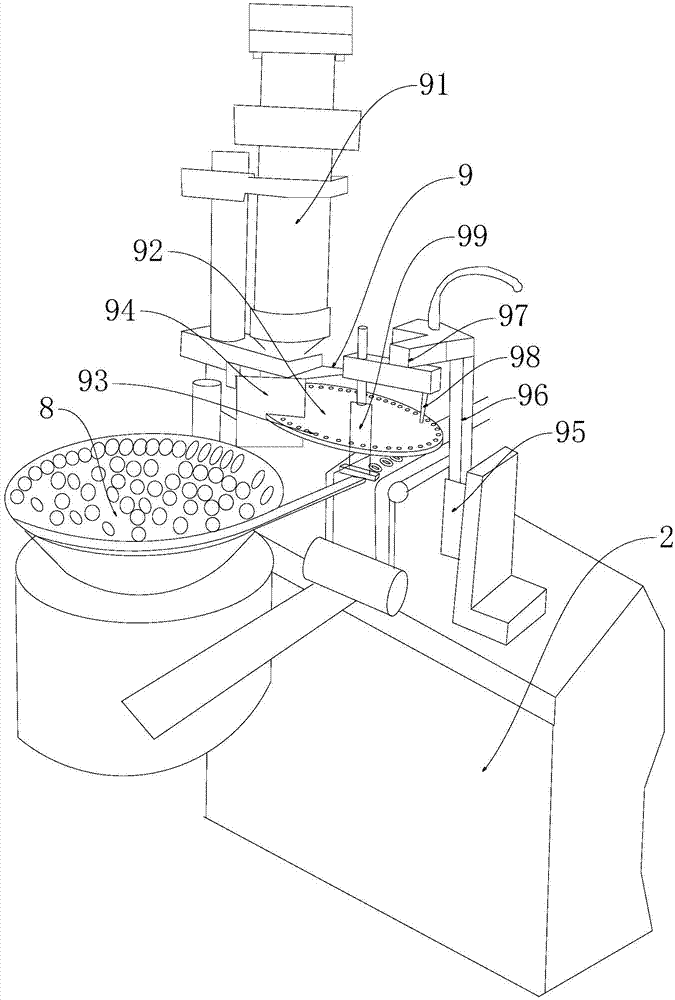

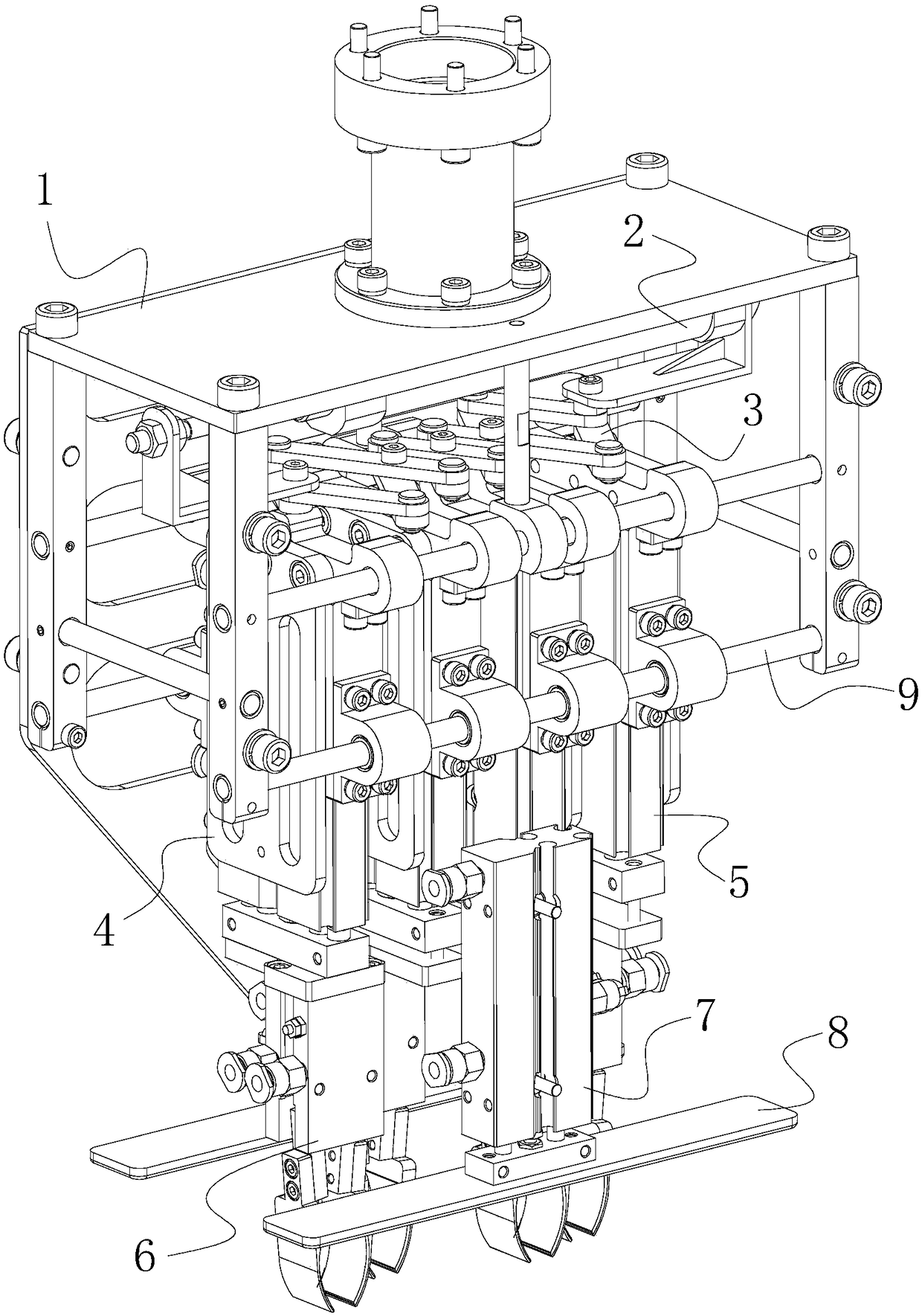

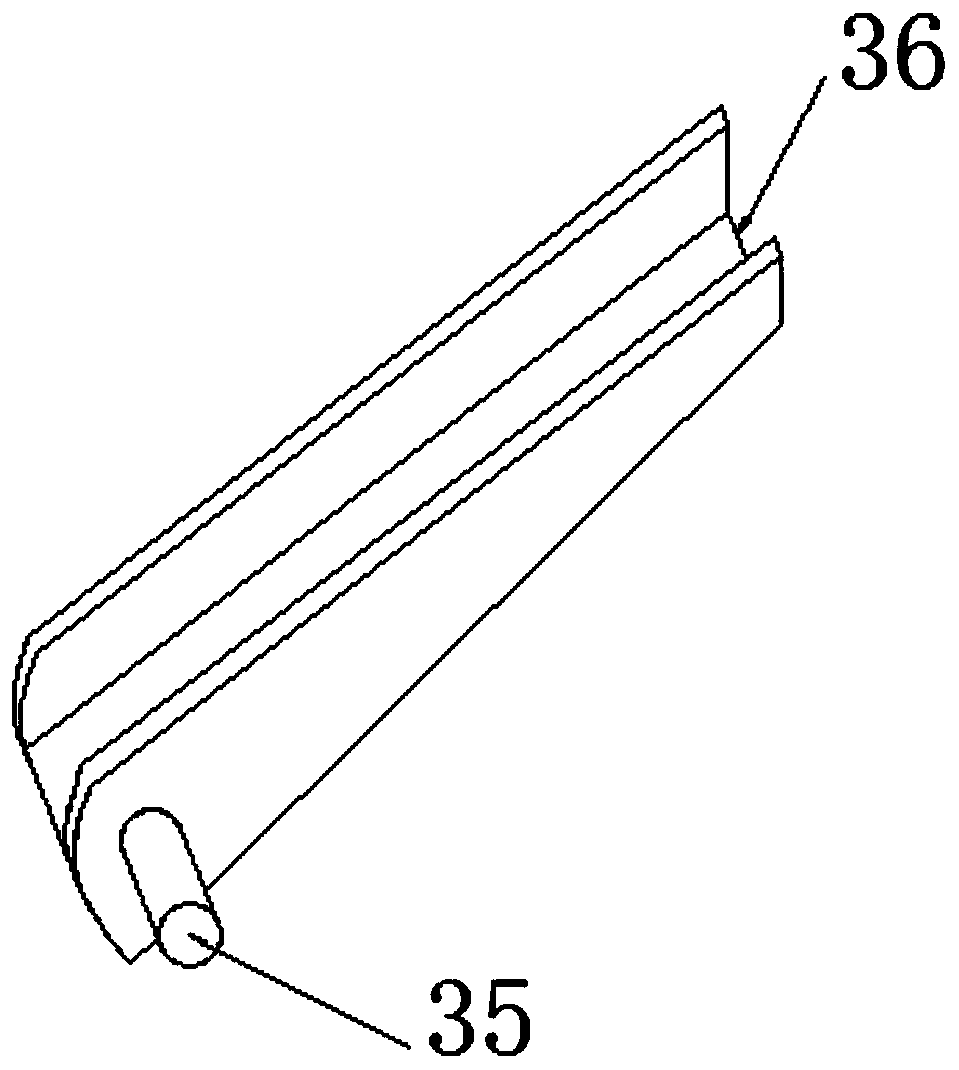

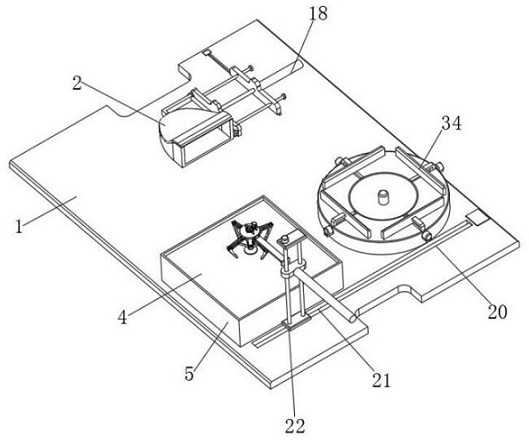

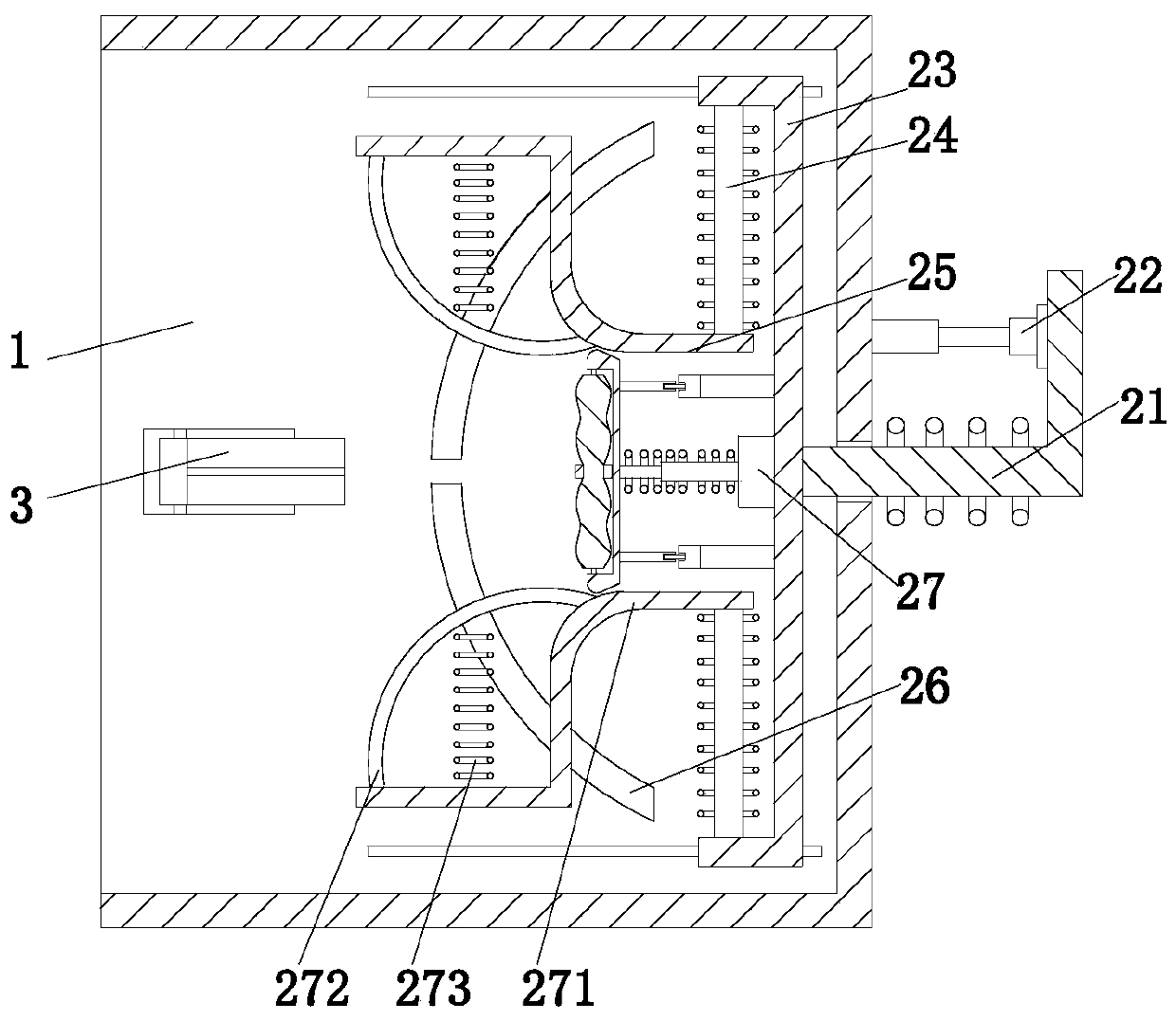

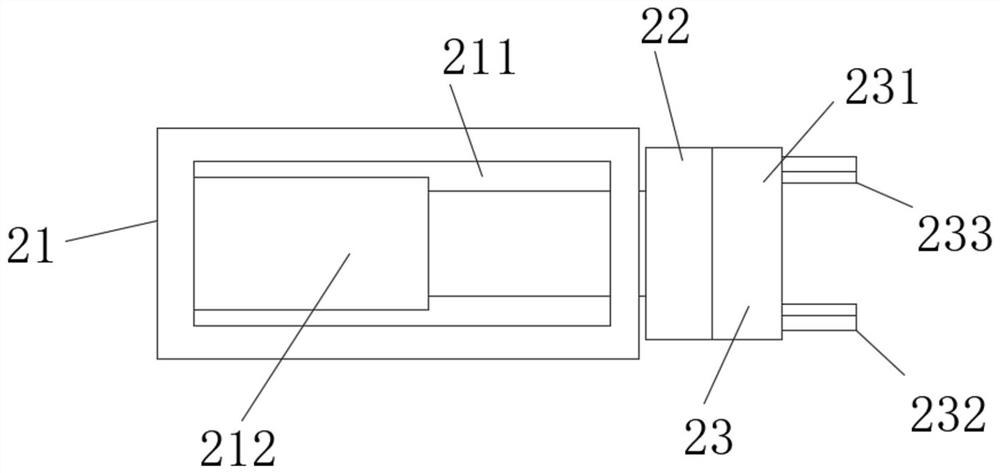

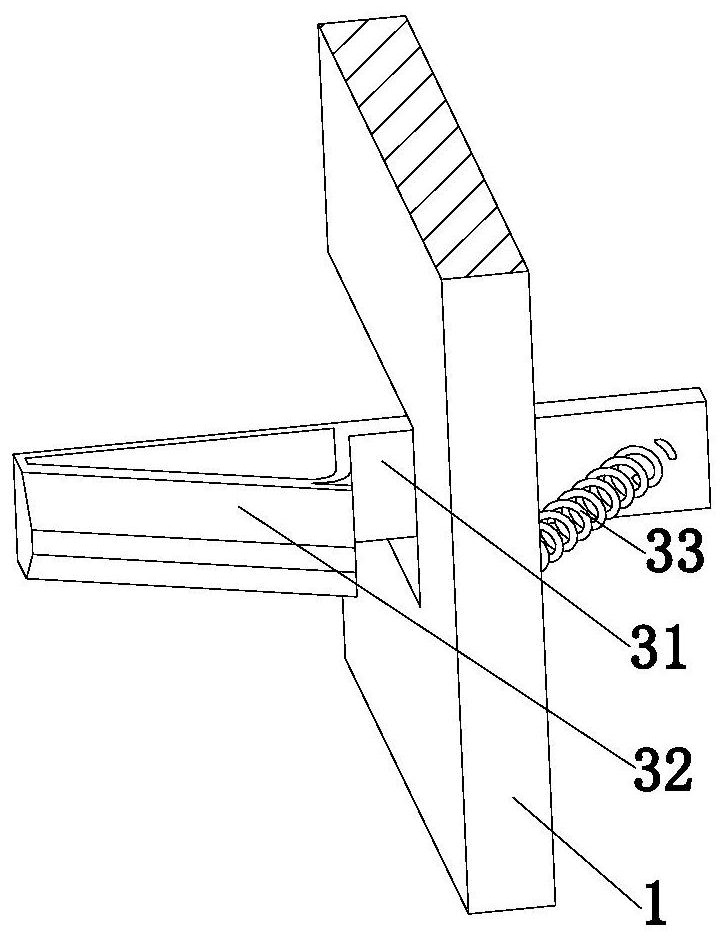

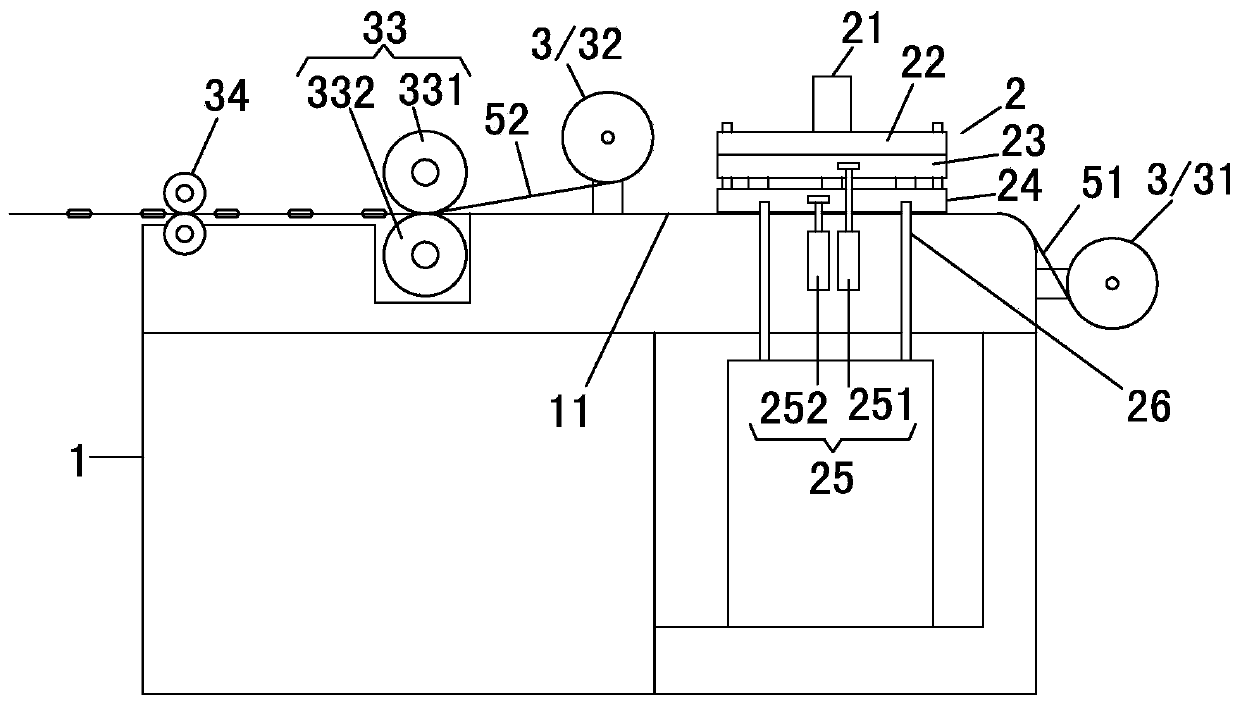

Counting mechanism of medical swab automatic packing machine

InactiveCN103101644AAccurate calculationImprove production and packaging efficiencyPackaging automatic controlSurgeryBiomedical engineering

The invention relates to the technical field of swab packing devices, in particular to a counting mechanism of a medical swab automatic packing machine. The counting mechanism comprises a first material receiving box, a second material receiving box and a feed bin. A stop bar used for guiding medical swabs is arranged on the opening position of the top of the first material receiving box, and a counting sensillum opticum corresponding to the stop bar and used for counting the number of the medical swabs guided into the first material receiving box is arranged on the top of the first material receiving box. A material receiving and pushing device is arranged on the right side of the feed bin, and comprises a material pushing groove, a material receiving bin, a first driving device, a second driving device and a third driving device. The counting mechanism of the medical swab automatic packing machine can count the number of the medical swabs falling into one packing bag accurately, achieves the purpose of accurate counting, and can push the medical swabs inside the material pushing groove to a packing mechanism following the medical swab automatic packing machine, and therefore automatic bagging operation is achieved, and producing and packing efficiency is improved.

Owner:东莞市万江鸿浩五金电器厂

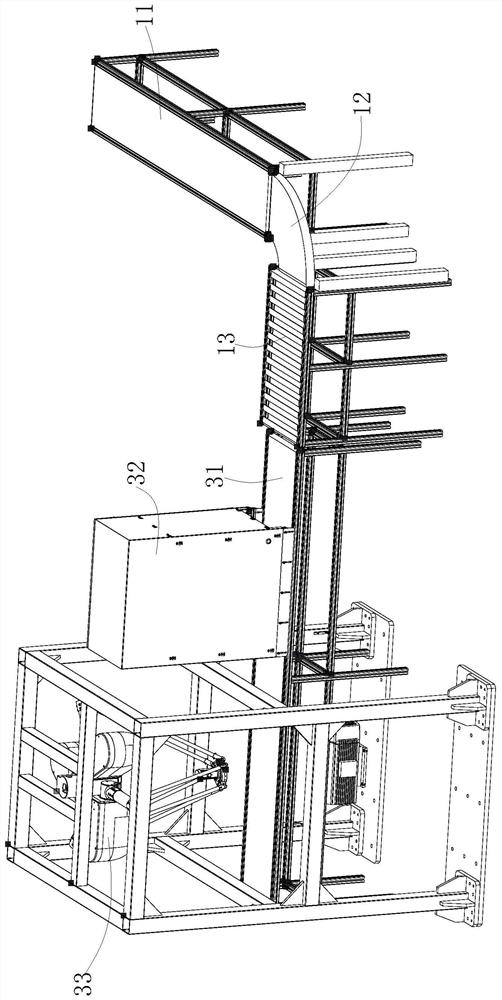

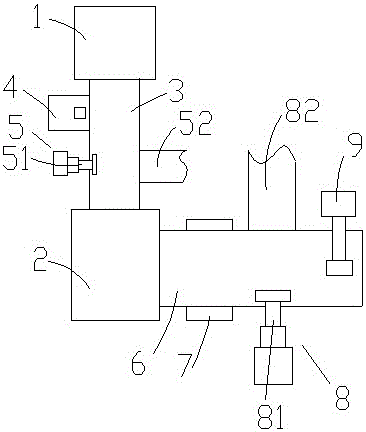

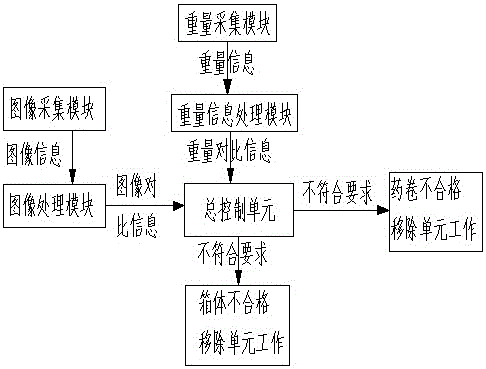

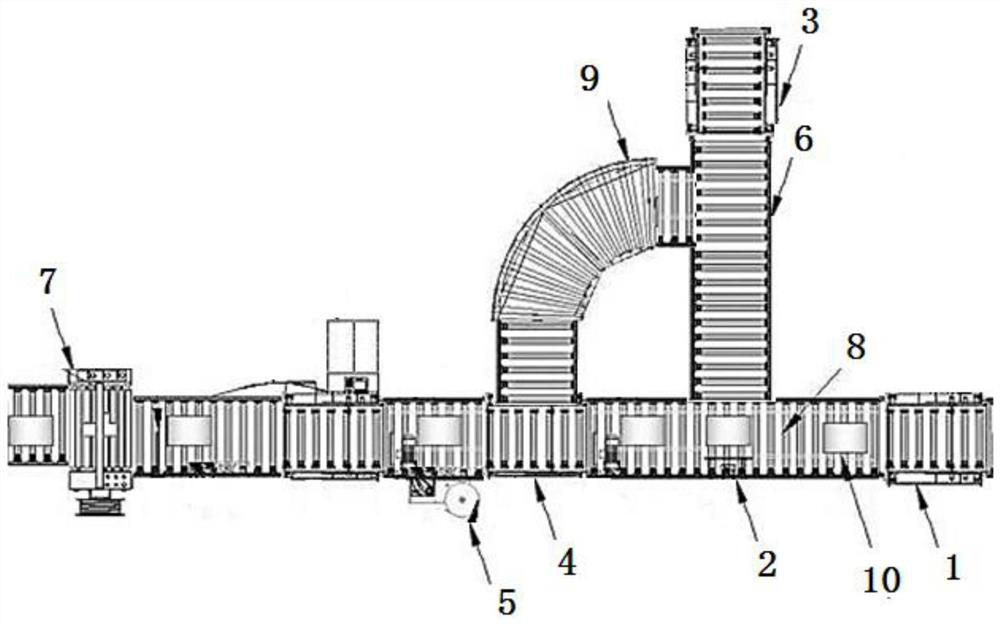

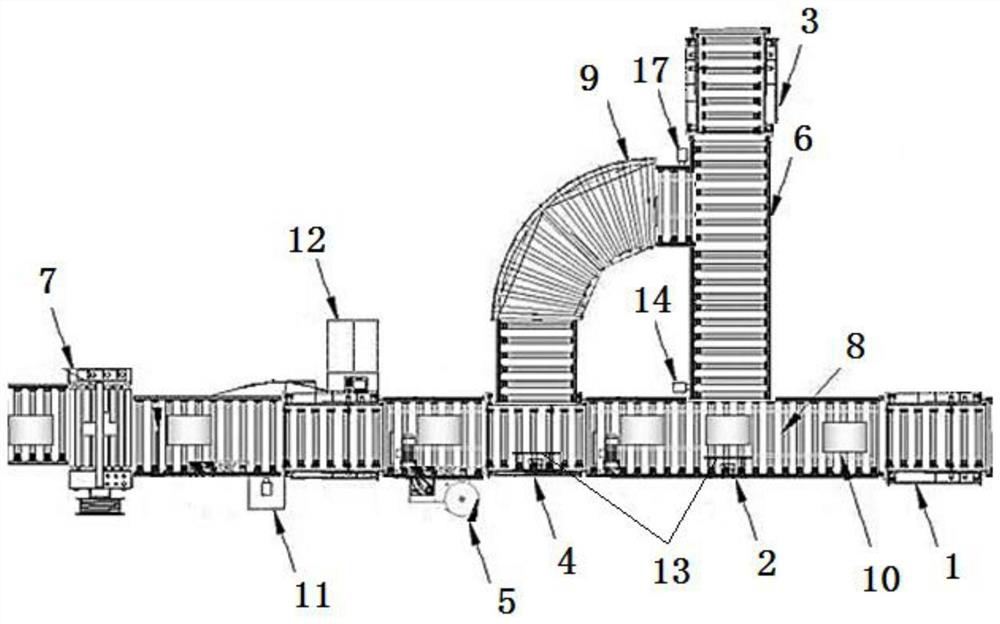

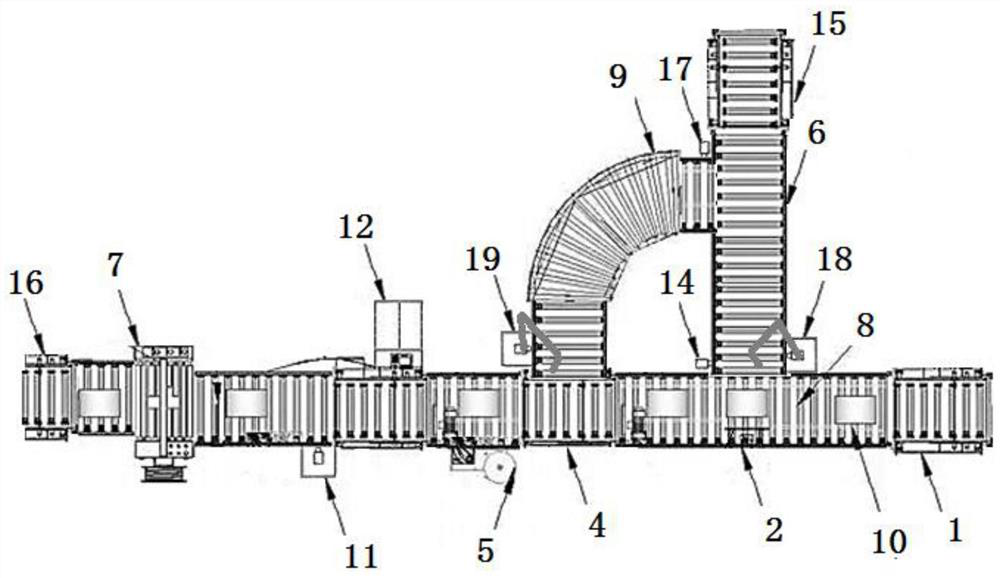

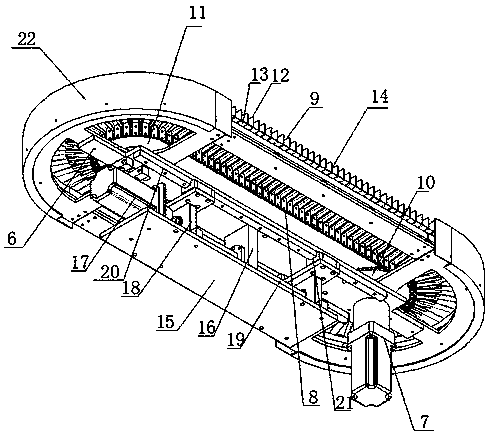

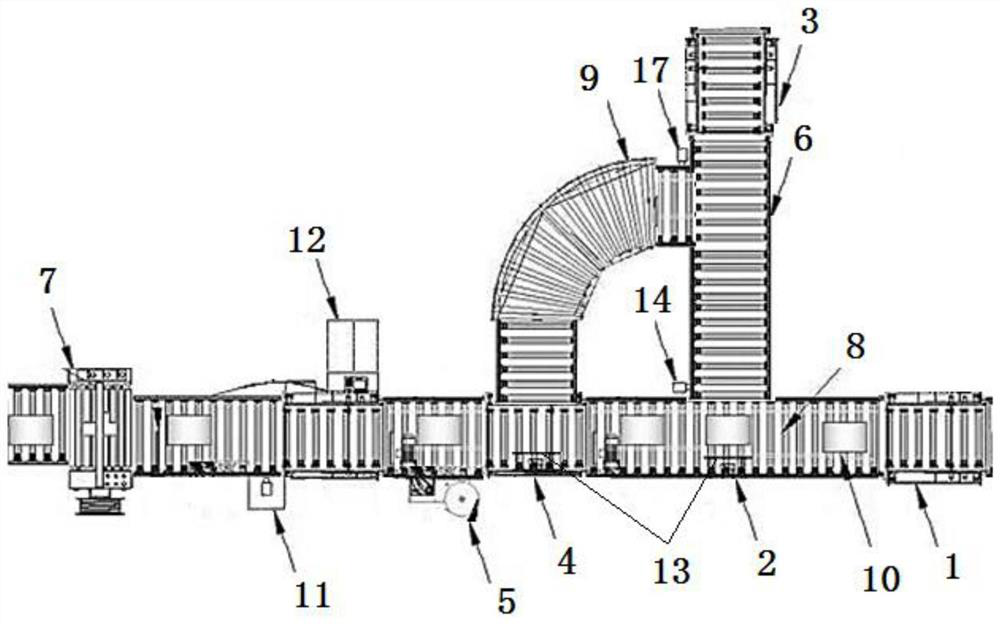

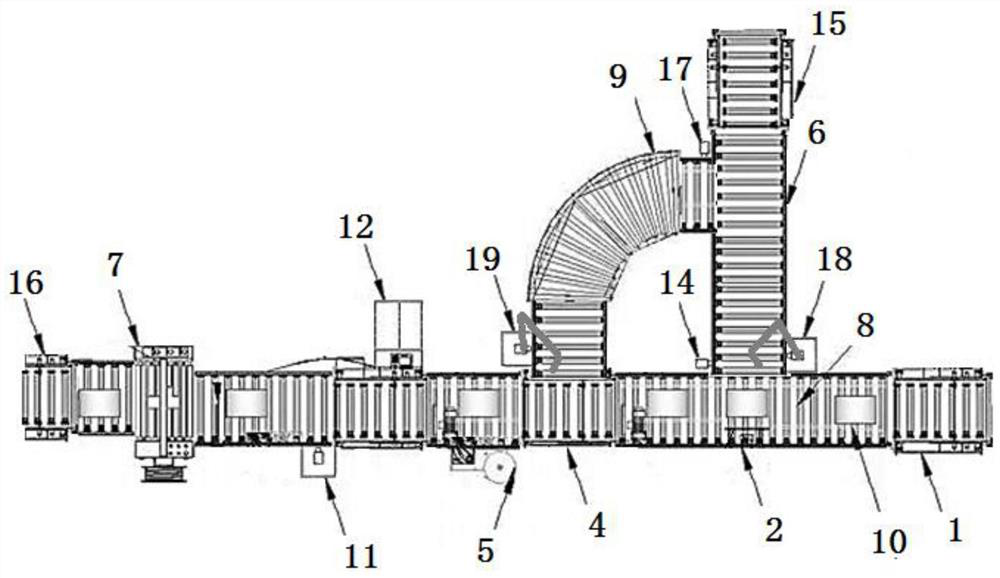

Automatic industrial explosive packaging line

ActiveCN106494703ARealize fully automatic packagingReasonable design layoutSortingPackaging machinesProduction lineEngineering

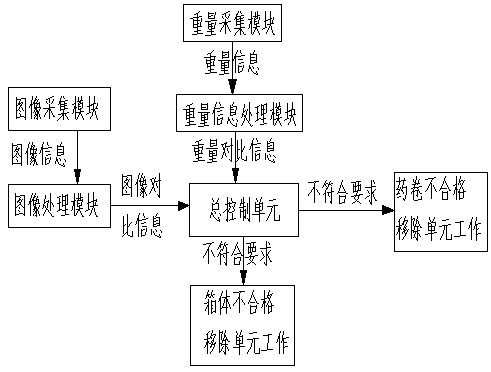

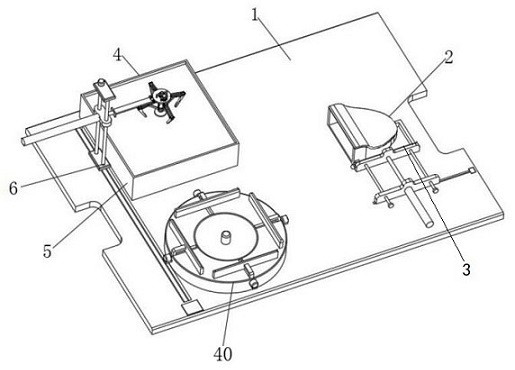

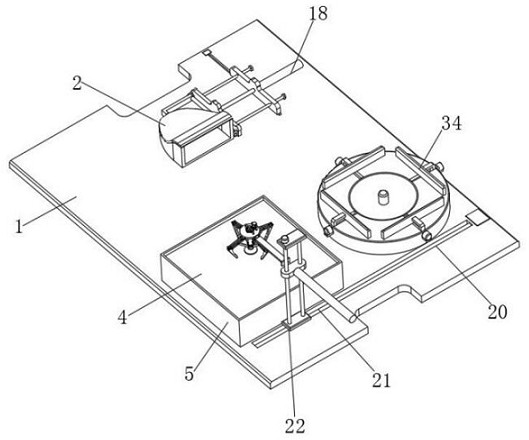

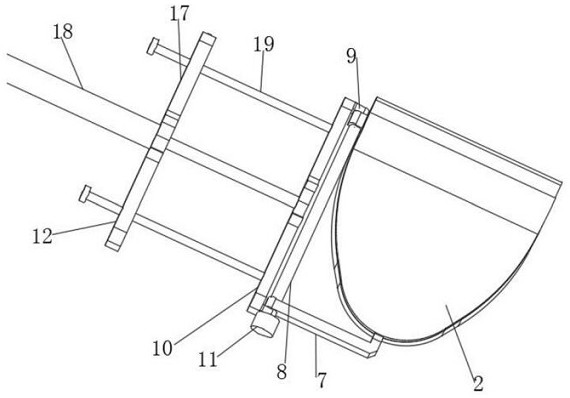

The invention relates to the technical field of packaging production lines, and discloses an automatic industrial explosive packaging line. The automatic industrial explosive packaging line comprises an explosive roll packaging unit, an explosive roll encasement unit, an explosive roll conveying unit and a master control unit, and an explosive roll detection unit and an unqualified explosive roll removing unit are sequentially arranged on the explosive roll conveying unit; and a box conveying unit is installed at the back of the explosive roll encasement unit, a box weight detection unit and an unqualified box removing unit are sequentially installed on the box conveying unit, and the explosive roll detection unit, the unqualified explosive roll removing unit, the box weight detection unit and the unqualified box removing unit are in signal connection with the master control unit. The automatic industrial explosive packaging line is reasonable in design layout, easy to install, simple and practical, full-automatic packaging of industrial explosives can be achieved, the packaging quality is guaranteed, the labor intensity of workers is greatly reduced, and the producing and packaging efficiency is improved.

Owner:PANZHIHUA HENGWEI CHEM +1

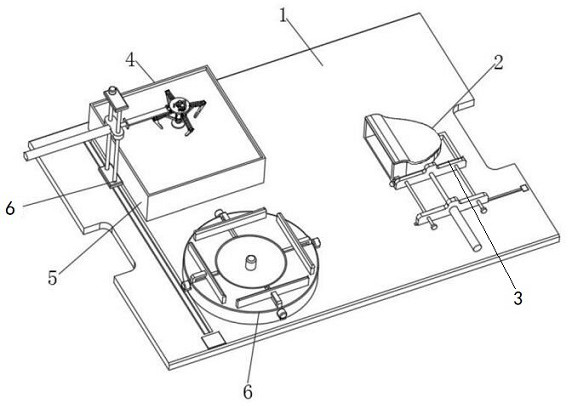

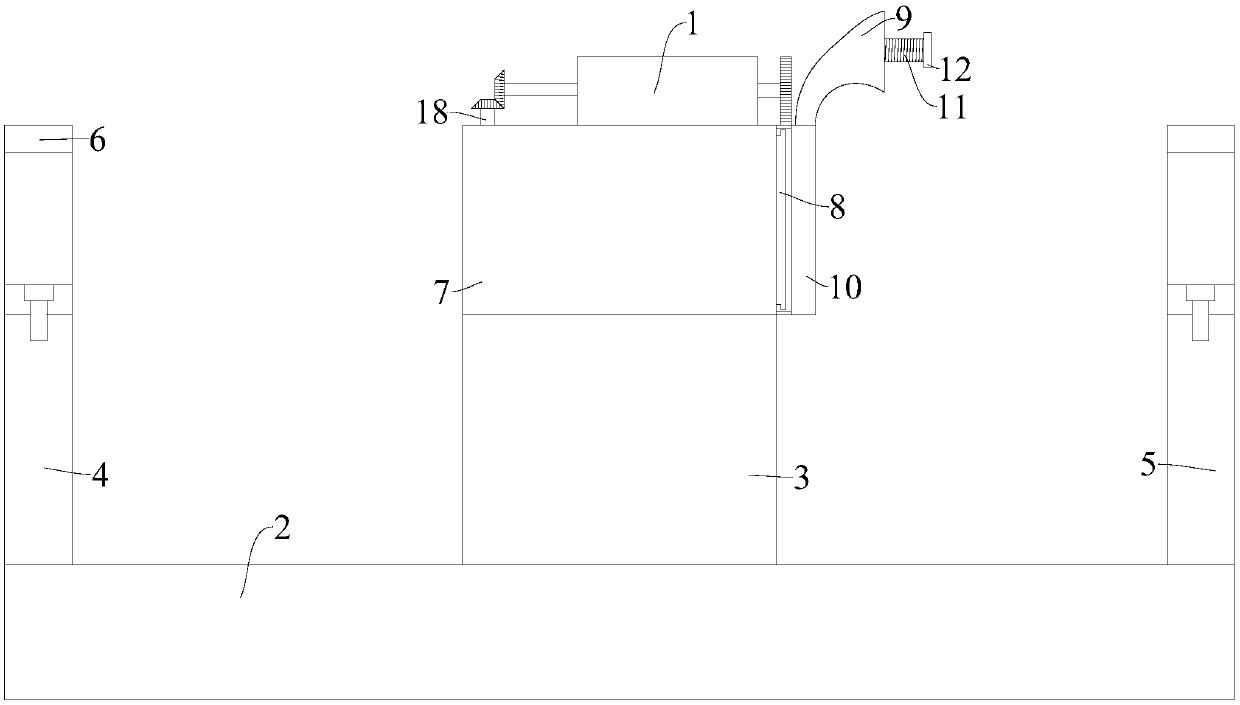

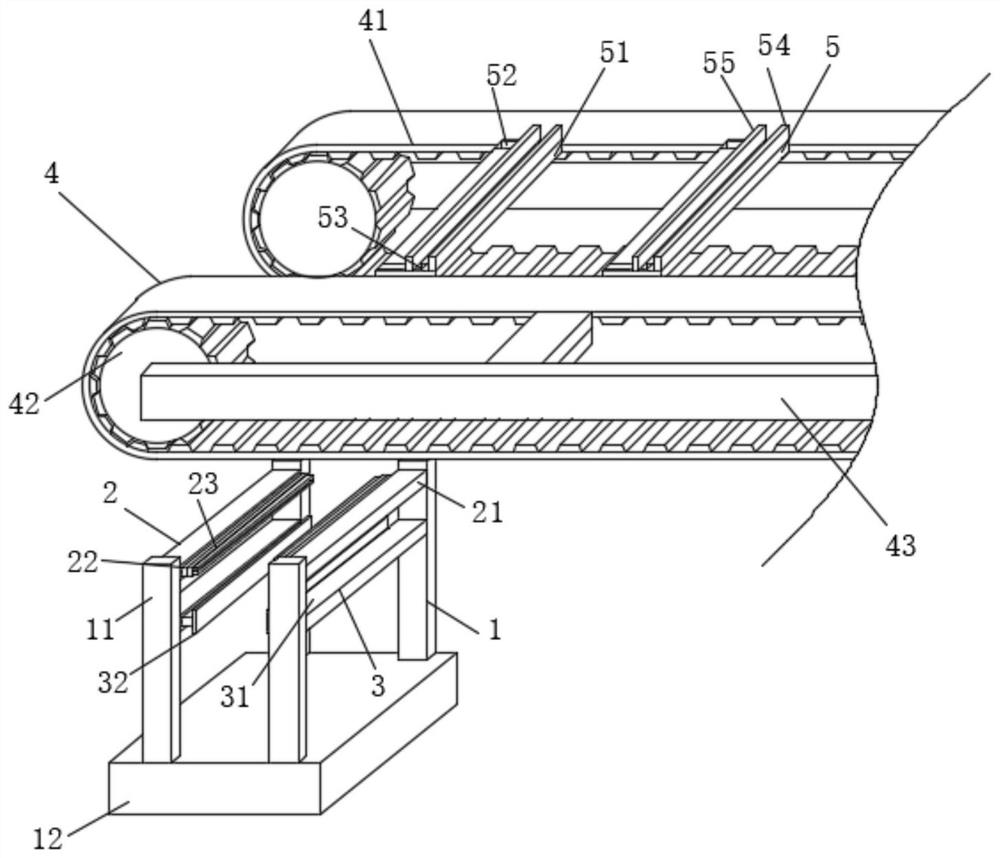

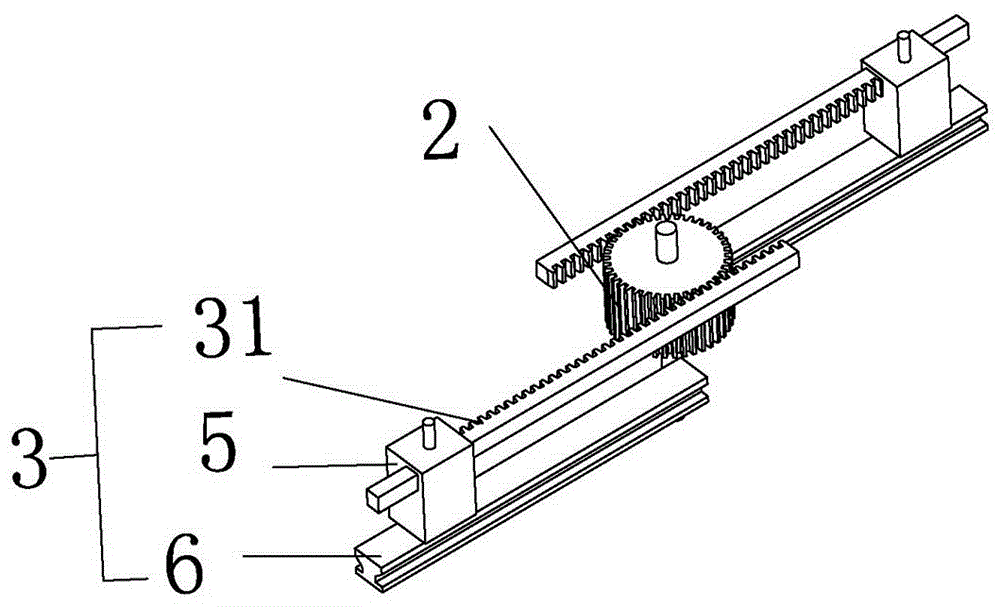

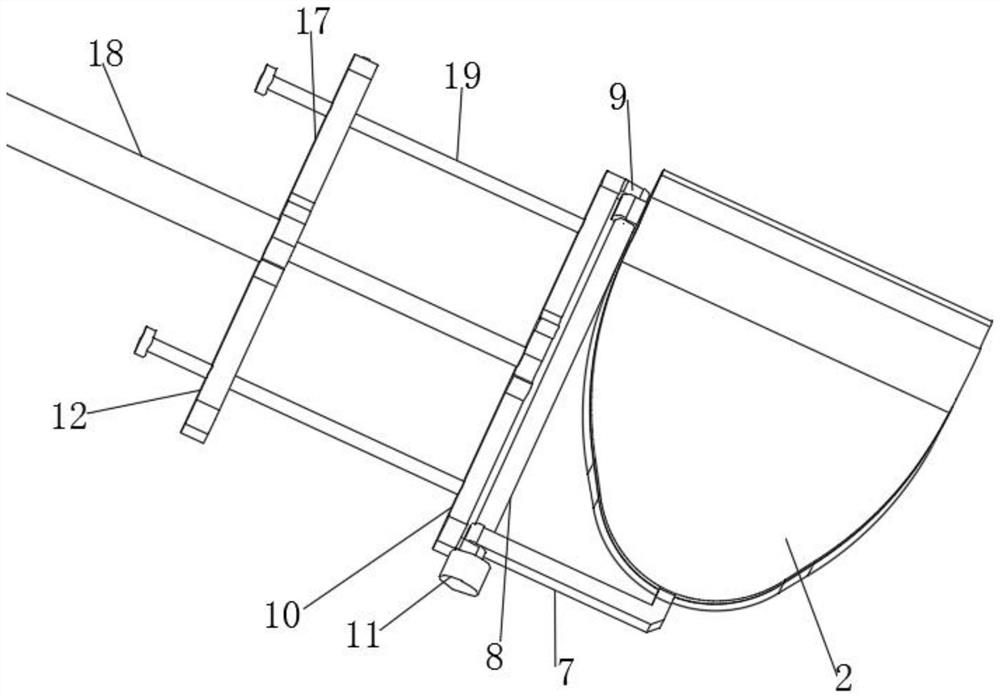

Shrinkable adhesive film packaging mechanism

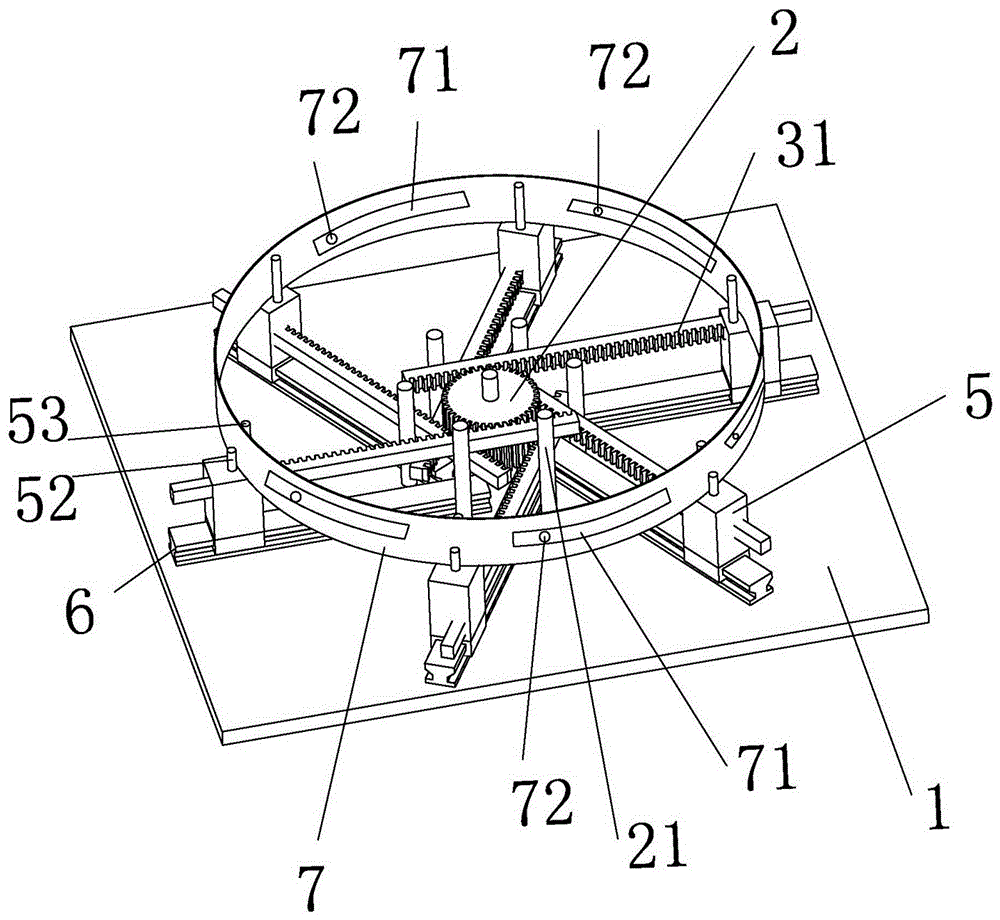

InactiveCN105083645AEasy to packImprove production and packaging efficiencyWrappers shrinkageMechanical engineering

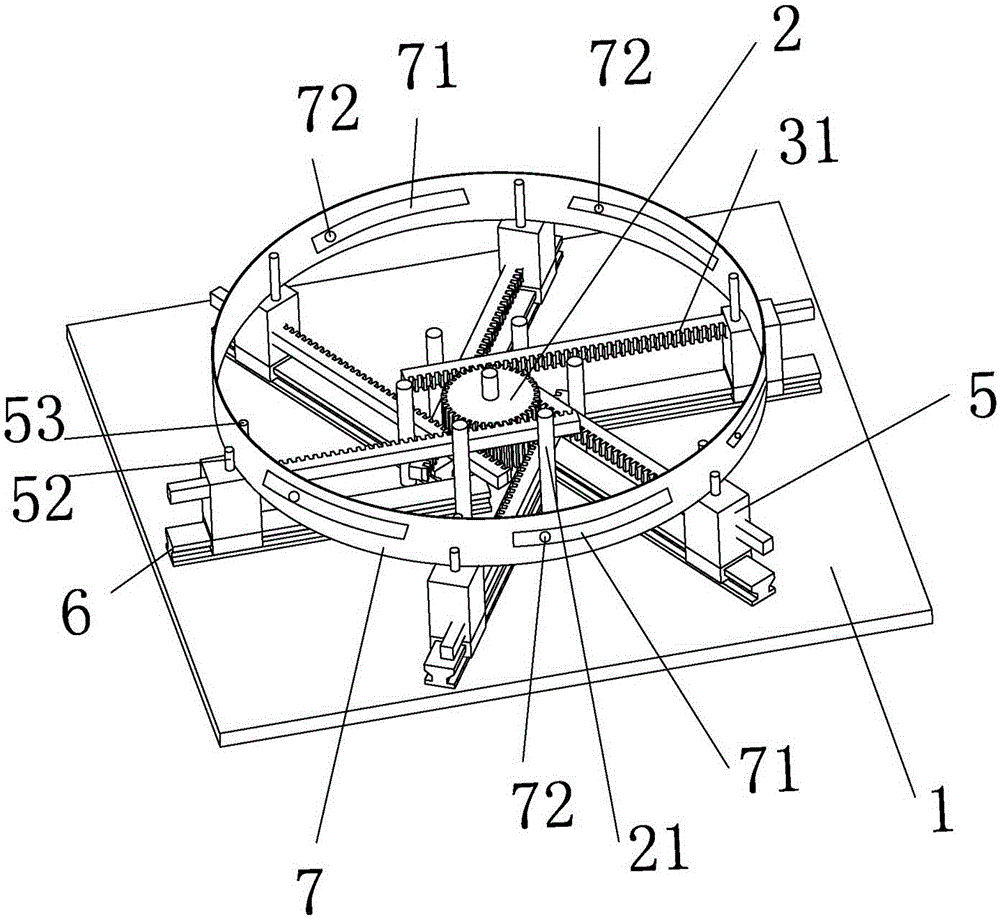

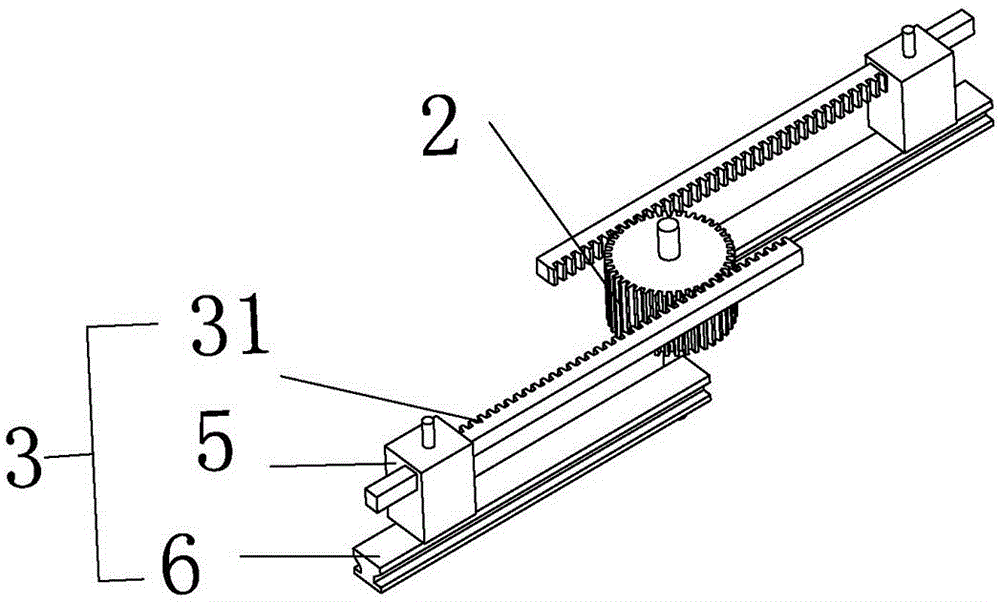

The invention relates to the field of packaging equipment of object packaging films, in particular to a shrinkable adhesive film packaging mechanism. The shrinkable adhesive film packaging mechanism comprises a base plate, wherein a center gear and a driving device for driving the center gear to rotate are arranged in the center position of the base plate; the center gear is connected with at least two sets of rack structures; each set of rack structures comprises two parallel racks; the tail ends of the racks are connected with slide blocks; the slide blocks are connected to the base plate through slide rails; limiting pieces are arranged on the slide blocks, and are provided with arc support pieces; the slide blocks of each set of rack structures are peripherally distributed; and the arc support pieces on each limiting piece are formed to a ring shape. The shrinkable adhesive film packaging mechanism packages products, to be packed through film sealing, with different diameter sizes, so that the production packaging efficiency is greatly improved, the payment of manual packaging costs is reduced, and the technical blank incapable of using one piece of equipment for the products, to be packed through film sealing, with different sizes in the prior art is filled.

Owner:高林堃

Packaging mechanism used during chocolate production

InactiveCN110683105AHigh degree of automationImprove packaging efficiencyWrapper twisting/gatheringPackaging foodstuffsCartonWorkbench

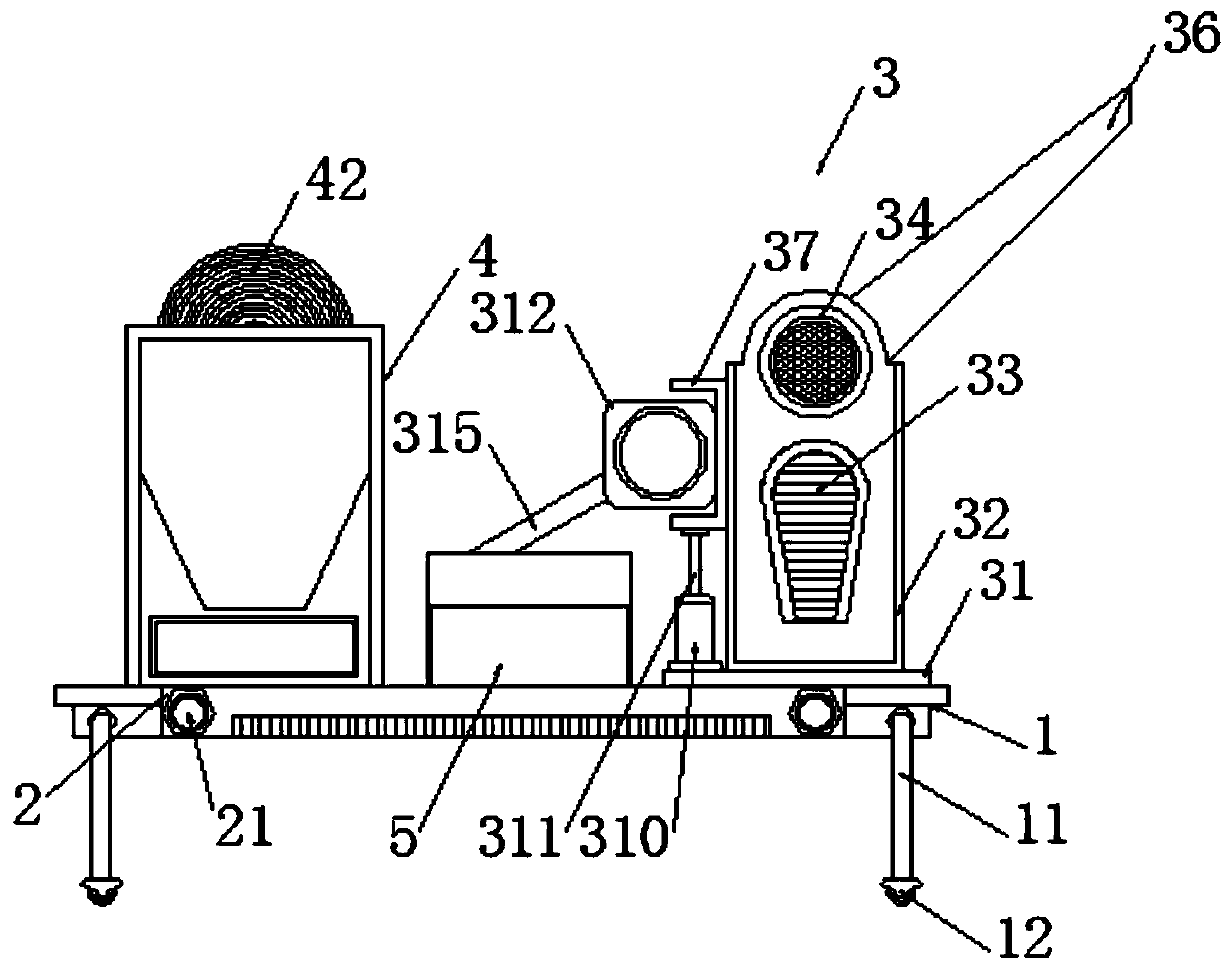

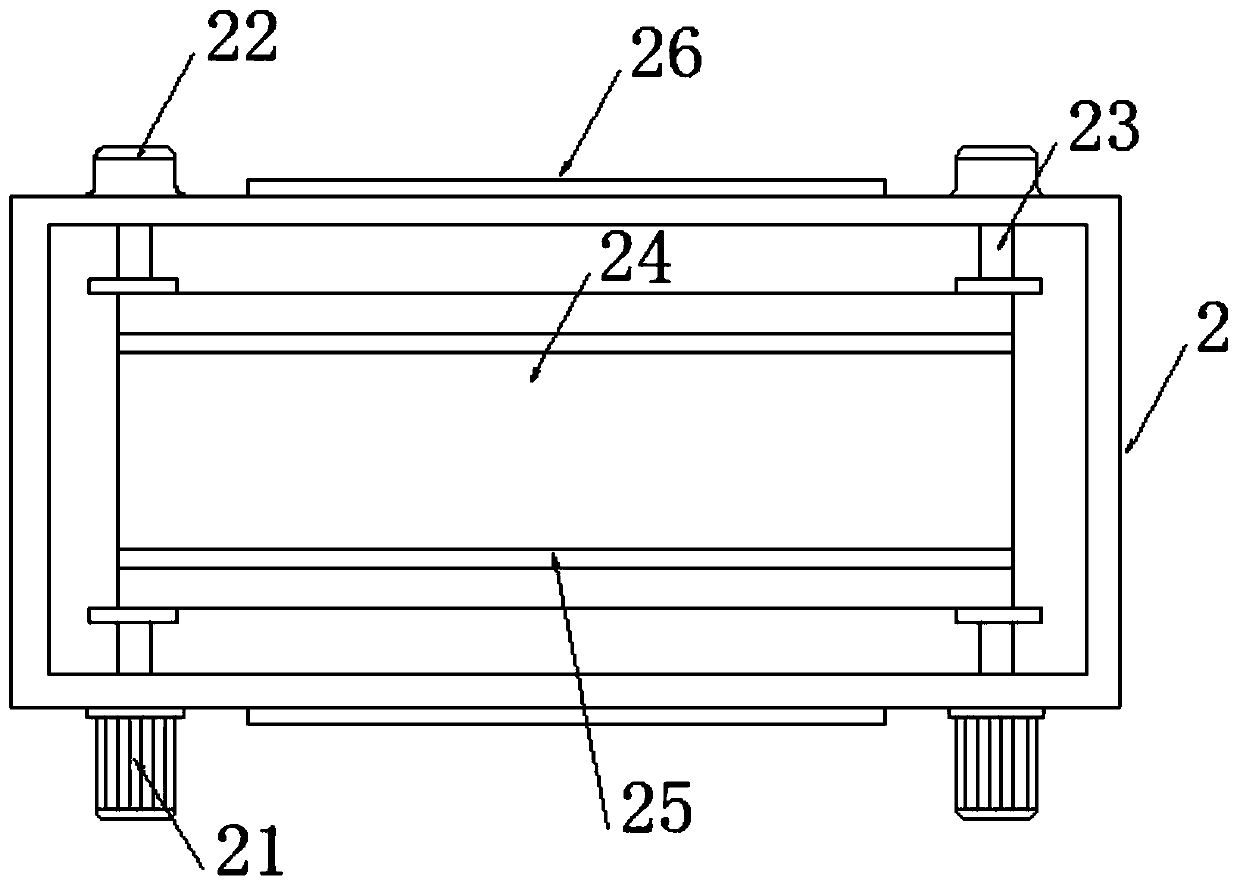

The invention discloses a packaging mechanism used during chocolate production. The packaging mechanism comprises a workbench, a conveying shell, a placing mechanism, a box sealing shell, and a packaging box, wherein the conveying shell is embedded into the center position of the upper end face of the workbench, the placing mechanism is fixedly installed at the position, close to one side edge, ofthe upper end face of the workbench, the other side edge of the upper end face of the workbench is fixedly provided with the box sealing shell, and the packaging box is arranged above the conveying shell. According to the packaging mechanism used during chocolate production, automatic driving in the X-axis direction is achieved in a mode that a belt conveys a carton to displace in the horizontaldirection, a threaded shaft is driven to rotate through a third servo motor 312, automatic driving of a material arranging plate in the Y-axis direction is achieved, a first air cylinder drives a first rod to push Y-axis parts including the material arranging plate to realize automatic driving in the Z-axis direction, chocolate in small package falling into the material arranging plate from a feeding plate can be placed at a fixed point, automation is comprehensively achieved, and the production packaging efficiency is improved.

Owner:JIANGSU AISHINONG BIOLOGICAL TECH CO LTD

Control method of automatic sorting system

The invention discloses a control method of an automatic sorting system. The control method of the automatic sorting system relates to the technical field of packaging equipment control, and comprisesa control flow A, a control flow B and a control flow C, wherein the control flow A is mainly characterized by arranging materials between a feed inlet and a discharge hole, and arranging the materials with the setting number on the discharge hole; the control flow B is characterized by controlling a circulating transportation mechanism to be still relative to the discharge hole, and controllingthe circulating transportation mechanism to rotate at a trough gap relative to the feed inlet; and the control flow C is characterized by controlling the circulating transportation mechanism to move troughs with the setting number relative to the discharge hole, and controlling the circulating transportation mechanism to rotate at the trough gap relative to the feed inlet. According to the controlmethod of the automatic sorting system provided by the invention, the sorting and transporting efficiency can be effectively improved, the material sorting accumulation amount is improved, and the packaging efficiency is further improved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Automatic packaging production line for swim ring production

ActiveCN111605840AImprove production and packaging efficiencyReduce labor intensityPackaging machinesCross connectionManufacturing line

The invention relates to the technical field of industrial intelligent production, and provides an automatic packaging production line for swim ring production. The automatic packaging production linecomprises an automatic forming and bottom sealing machine, an online weighing device, a bar code printing and pasting machine and an automatic cover folding and box sealing machine which are sequentially arranged according to a packaging production process flow and are connected through automatic rollers, wherein a boxing position is connected between the automatic forming and bottom sealing machine and the online weighing device, the boxing position is connected with the tail end of a swim ring production line in a crossed mode, a branch point is arranged at the tail of the swim ring production line, turning rollers are arranged on the automatic roller at the branch point at intervals, and the branch point is connected with the online weighing device through a branch roller. According tothe automatic packaging production line for swim ring production, through scientific process arrangement and operation arrangement, automatic swim ring boxing and packaging are achieved, the labor intensity of production personnel is effectively reduced, unmanned participation can be achieved, the boxing number fault-tolerant function is achieved, the intelligent degree is high, and the swim ringproduction and packaging efficiency can be greatly improved.

Owner:YANCHENG JIAHUA PLASTIC PROD CO LTD

Flexible self-adaptive conveying device

ActiveCN113548263AImprove production and packaging efficiencyStuffed paperPackaging protectionArticle separationProduction lineIndustrial engineering

The invention discloses a flexible self-adaptive conveying device. The flexible self-adaptive conveying device comprises a feeding plate used for placing children shoes during production of the children shoes, wherein front-end shoe covers used for protecting the front ends of the children shoes when the children shoes move on a production line are arranged on the feeding plate, and matching devices enabling the front-end shoe covers to be matched with and separated from the front ends of the children shoes are arranged on the front-end shoe covers. According to the self-adaptive feeding mechanism of the robot flexible production line, the shoe covers are arranged on the feeding plate, and the shoe covers can be arranged according to the sizes of different children shoes; the matching devices are arranged on the outer sides of the shoe covers, when the device and the shoe covers are used for packaging the children shoes, on one hand, the front ends of the children shoes can be matched and shaped, and on the other hand, the dustproof effect can be achieved in the packaging and transporting process of the children shoes; and meanwhile, a shaping and feeding device is arranged on the feeding plate, so that paper can be shaped into paper balls with a certain size, meanwhile, under the condition that the shoe covers are matched, the paper balls can be stably stuffed into the children shoes, and deformation caused when the paper is stuffed into the children shoes is prevented.

Owner:ZHEJIANG DEYUAN INTELLIGENT TECH CO LTD

Transverse winding device for production of chrome-plated belt

InactiveCN108682514AImprove production and packaging efficiencyWind evenlyApparatus for feeding conductors/cablesEngineeringConductor Coil

Owner:张家港保税区鸿卓光电材料科技有限公司

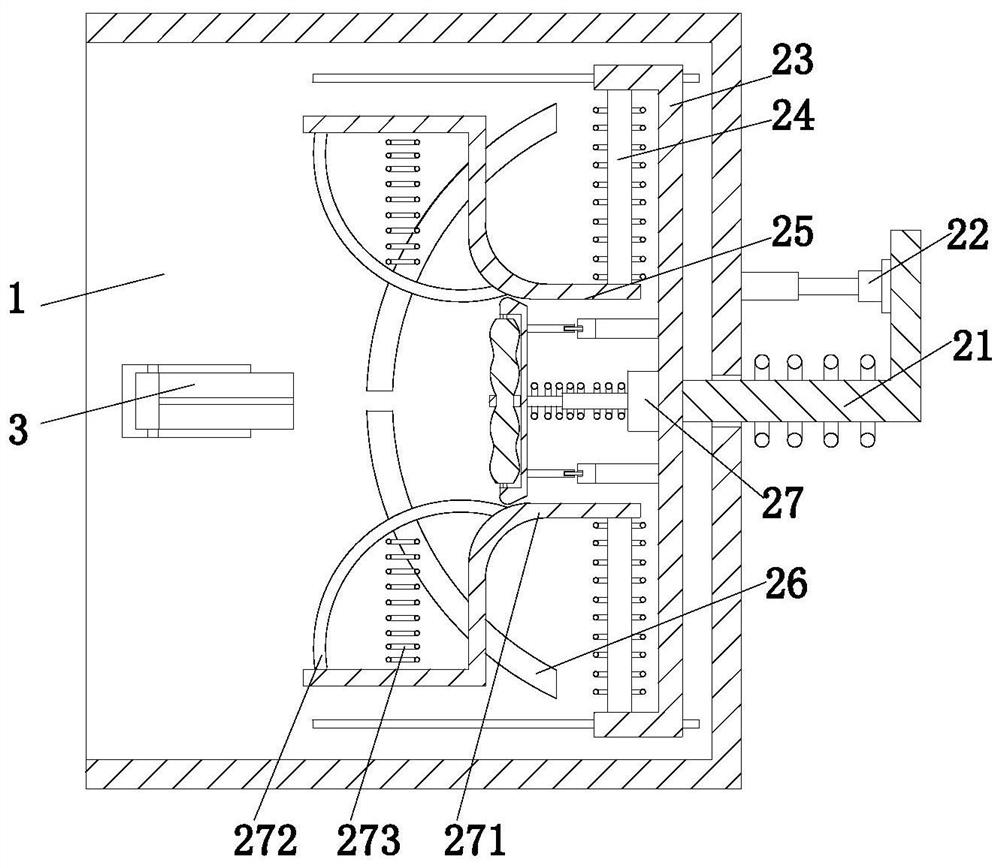

Packaging machine for producing polymer lithium battery with rectangular structure and using method thereof

ActiveCN110329592AImprove production and packaging efficiencyIncrease pressureWrapper folding/bending apparatusComposite filmElectrical battery

The invention relates to a packaging machine for producing a polymer lithium battery with a rectangular structure and a using method thereof. The packaging machine comprises an operation framework, wherein a telescopic hole is formed in the rear end of the operation framework, a folding mechanism is arranged in the telescopic hole, installation grooves are symmetrically formed in the front side and the rear side of the operation framework, and edge folding mechanisms are arranged in the installation grooves. The packaging machine for producing the polymer lithium battery with the rectangular structure can solve the following problems existing in existing production of the polymer lithium battery with the rectangular structure, and the problems are that a, aluminum-plastic composite film wrapped on the battery needs to be folded manually, the manual folding speed is low, and the working efficiency is low; and b, the effect of the aluminum-plastic composite film wrapped on the battery bymanual folding is poor, so that the aluminum-plastic composite film is easy to fall off, and the service life of the battery is influenced.

Owner:HANGZHOU SANWO INTELLIGENT TECH CO LTD

Industrial Explosives Automatic Packing Line

ActiveCN106494703BRealize fully automatic packagingReasonable design layoutSortingPackaging machinesProduction lineEngineering

The invention relates to the technical field of packaging production lines, and discloses an automatic industrial explosive packaging line. The automatic industrial explosive packaging line comprises an explosive roll packaging unit, an explosive roll encasement unit, an explosive roll conveying unit and a master control unit, and an explosive roll detection unit and an unqualified explosive roll removing unit are sequentially arranged on the explosive roll conveying unit; and a box conveying unit is installed at the back of the explosive roll encasement unit, a box weight detection unit and an unqualified box removing unit are sequentially installed on the box conveying unit, and the explosive roll detection unit, the unqualified explosive roll removing unit, the box weight detection unit and the unqualified box removing unit are in signal connection with the master control unit. The automatic industrial explosive packaging line is reasonable in design layout, easy to install, simple and practical, full-automatic packaging of industrial explosives can be achieved, the packaging quality is guaranteed, the labor intensity of workers is greatly reduced, and the producing and packaging efficiency is improved.

Owner:PANZHIHUA HENGWEI CHEM +1

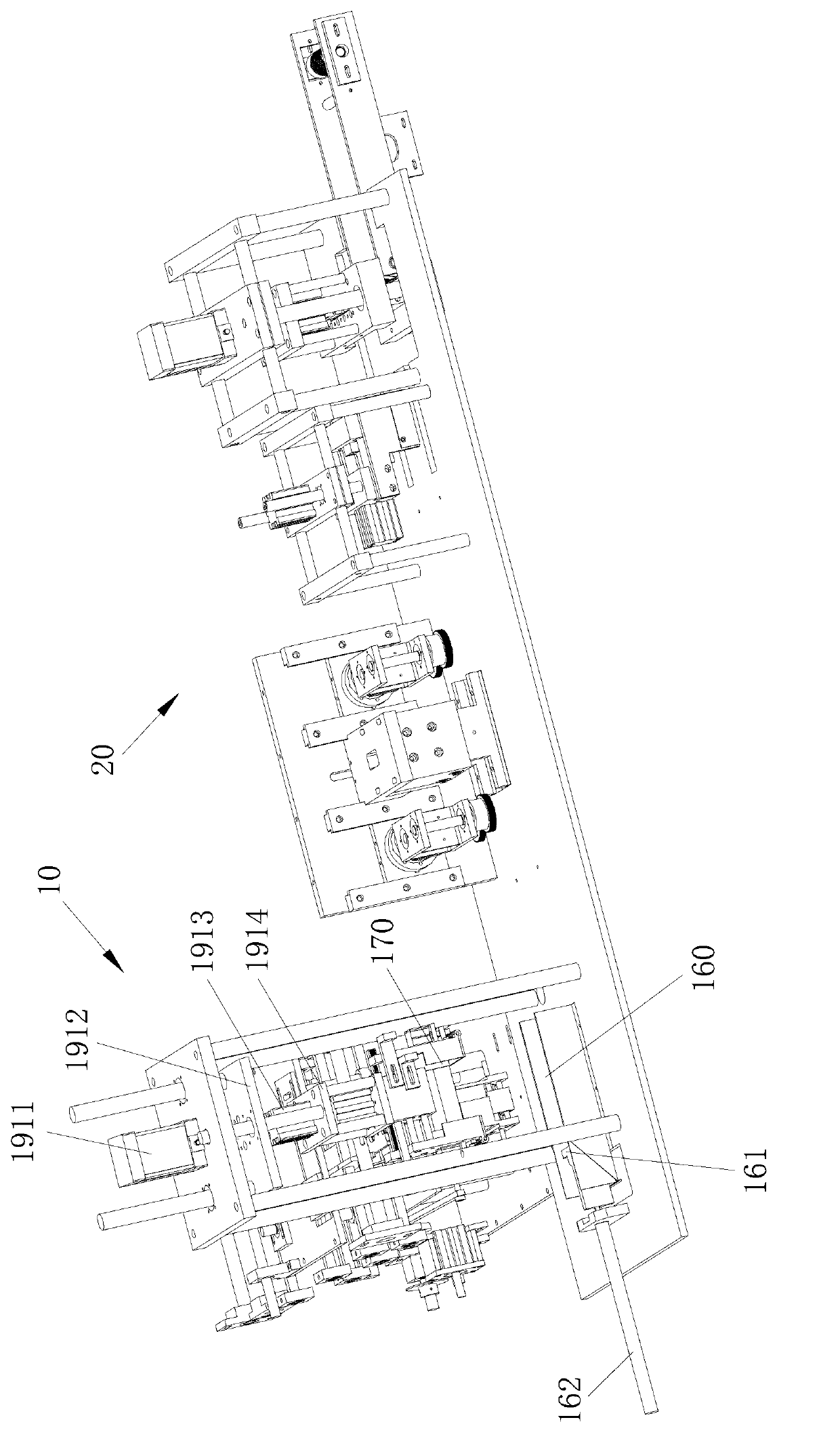

Adaptive feeding mechanism of robot flexible production line

ActiveCN112744413BImprove production and packaging efficiencyStuffed paperPackaging protectionArticle separationManufacturing lineIndustrial engineering

The invention discloses an adaptive feeding mechanism for a robot flexible production line, which includes a feeding plate for placing children's shoes during the production of children's shoes. The feeding plate is provided with a front shoe cover for protecting the front end of children's shoes when they move on the production line. The front-end shoe cover is provided with a matching device that makes it fit and disengage with respect to the front end of the children's shoes. The size of the children's shoes is set, and there is a matching device on the outside of the shoe cover. When the device and the shoe cover are packaged in the children's shoes, on the one hand, it can match and shape the front end of the children's shoes; It has the function of dust prevention, and at the same time, the paper can be shaped into paper balls of a certain size through the shaping and feeding device on the feeding plate. At the same time, under the condition of shoe covers, the paper balls can be stably stuffed into the inside of children's shoes , to prevent deformation when the inside of children's shoes is stuffed with paper.

Owner:浙江德源智能科技股份有限公司

A sorting process based on circular conveying device

ActiveCN108016850BStable deliveryIncrease productivityConveyor partsProcess engineeringConveyor belt

The invention discloses a material sorting process based on an annular conveying device and relates to the technical field of the packaging process. Through the annular conveying device, materials arefed one by one and arranged side by side; the arranged materials arrive at the discharge end, a set number of materials are arranged to form a group of materials to be discharged from the discharge end; when discharged, the materials are static relative to the discharge end; the materials are fed one by one at the feed end. Through the material sorting process, the materials are arranged and sorted through a conveyor belt; feeding and discharging have no influence on each other; the materials are continuously arranged one by one; and the material sorting efficiency and production efficiency can be effectively improved.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

A bagging device for liquid crystal display production

ActiveCN112623345BQuick sealing operationImprove production and packaging efficiencyWrapper twisting/gatheringIndividual articlesLiquid-crystal displayElectric machine

The invention discloses a bagging device for liquid crystal display production. A conveying structure is connected with a plurality of clamping structures, a packaging structure is connected with a connecting structure, a driving structure is connected with the connecting structure, and a sealing structure is arranged under the connecting structure. The present invention clamps the assembled display screen through the clamping structure, and drives the adjustment column to rotate through the motor, so that the driven plate and the linkage plate move, and the linkage plate and the vertical plate are set up to clamp the display screen. The conveyor belt transports the display screen to the top of the packaging structure, and the gripper is driven by the cylinder to clamp the opening of the packaging bag, and then the cylinder is moved to the direction close to the horizontal plate through the telescopic rod to open the packaging bag, and the reverse motor drives the linkage The board is far away from the vertical board, so that the display screen naturally falls into the packaging bag, and the packaging bag is heated by the electric heating wire to make the packaging bags melt and seal.

Owner:JIANGHUA FEXDA TECH CO LTD

A kind of packaging machine for producing polymer lithium battery with rectangular structure and using method thereof

ActiveCN110329592BImprove production and packaging efficiencyIncrease pressureWrapper folding/bending apparatusBattery cellPolymer

The invention relates to a packaging machine for producing a polymer lithium battery with a rectangular structure and a using method thereof. The packaging machine comprises an operation framework, wherein a telescopic hole is formed in the rear end of the operation framework, a folding mechanism is arranged in the telescopic hole, installation grooves are symmetrically formed in the front side and the rear side of the operation framework, and edge folding mechanisms are arranged in the installation grooves. The packaging machine for producing the polymer lithium battery with the rectangular structure can solve the following problems existing in existing production of the polymer lithium battery with the rectangular structure, and the problems are that a, aluminum-plastic composite film wrapped on the battery needs to be folded manually, the manual folding speed is low, and the working efficiency is low; and b, the effect of the aluminum-plastic composite film wrapped on the battery bymanual folding is poor, so that the aluminum-plastic composite film is easy to fall off, and the service life of the battery is influenced.

Owner:HANGZHOU SANWO INTELLIGENT TECH CO LTD

Automatic sorting device

ActiveCN107814176BIncrease delivery speedStable deliveryConveyorsPackagingMutual influenceManufacturing engineering

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Automatic packaging production device and process for nursing pad

PendingCN110395435AAchieve the appearanceQuality improvementWrappingSortingControl systemEngineering

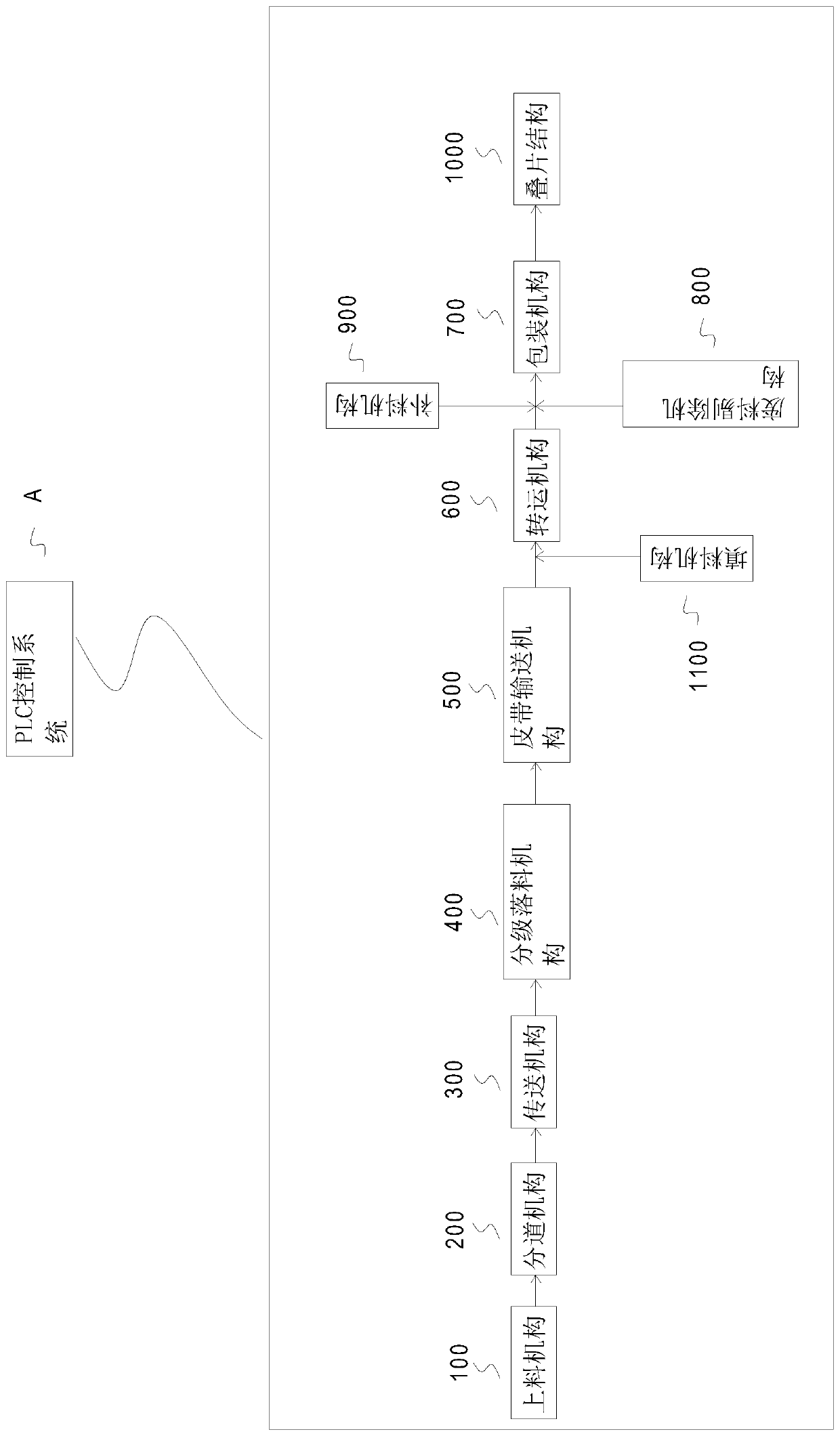

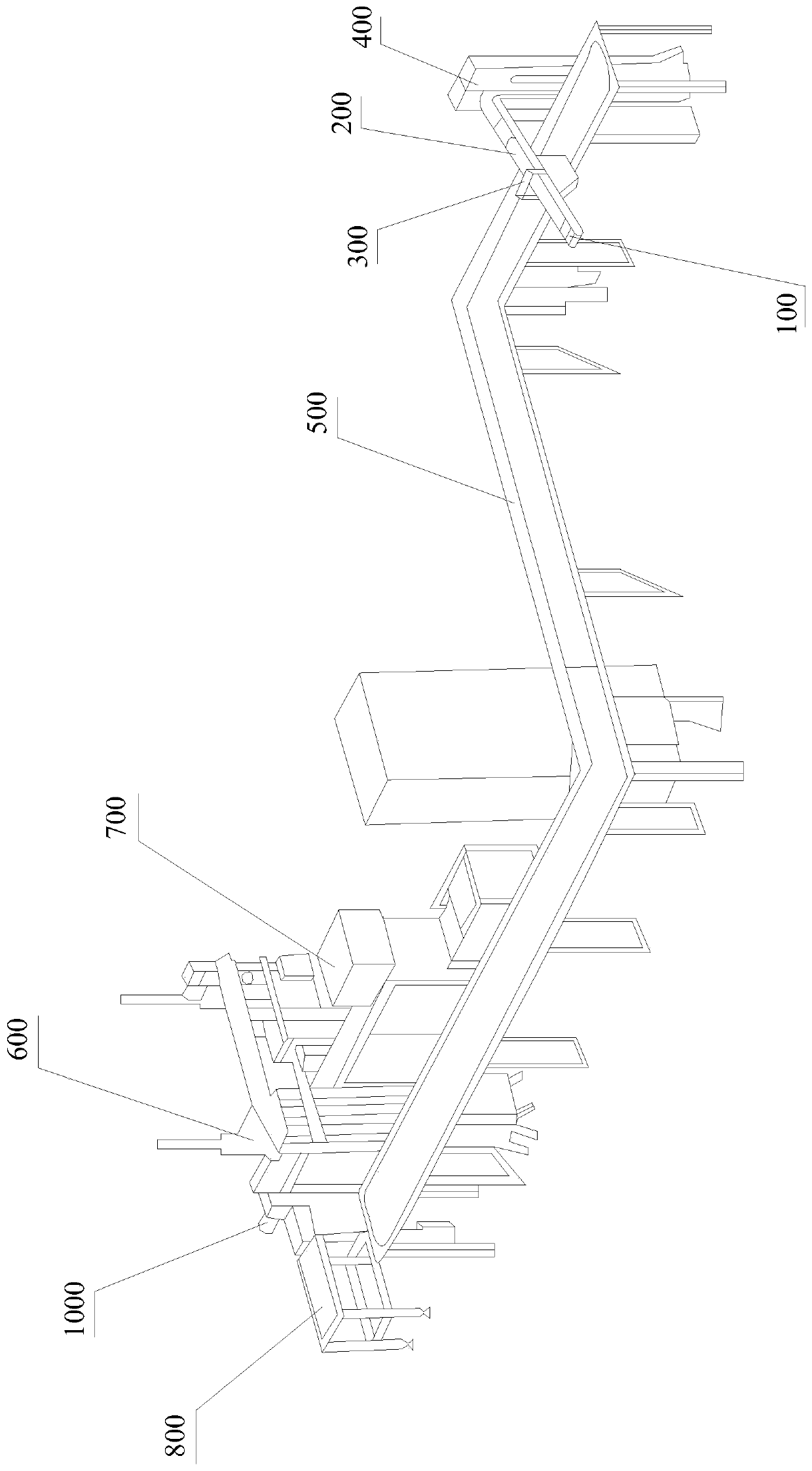

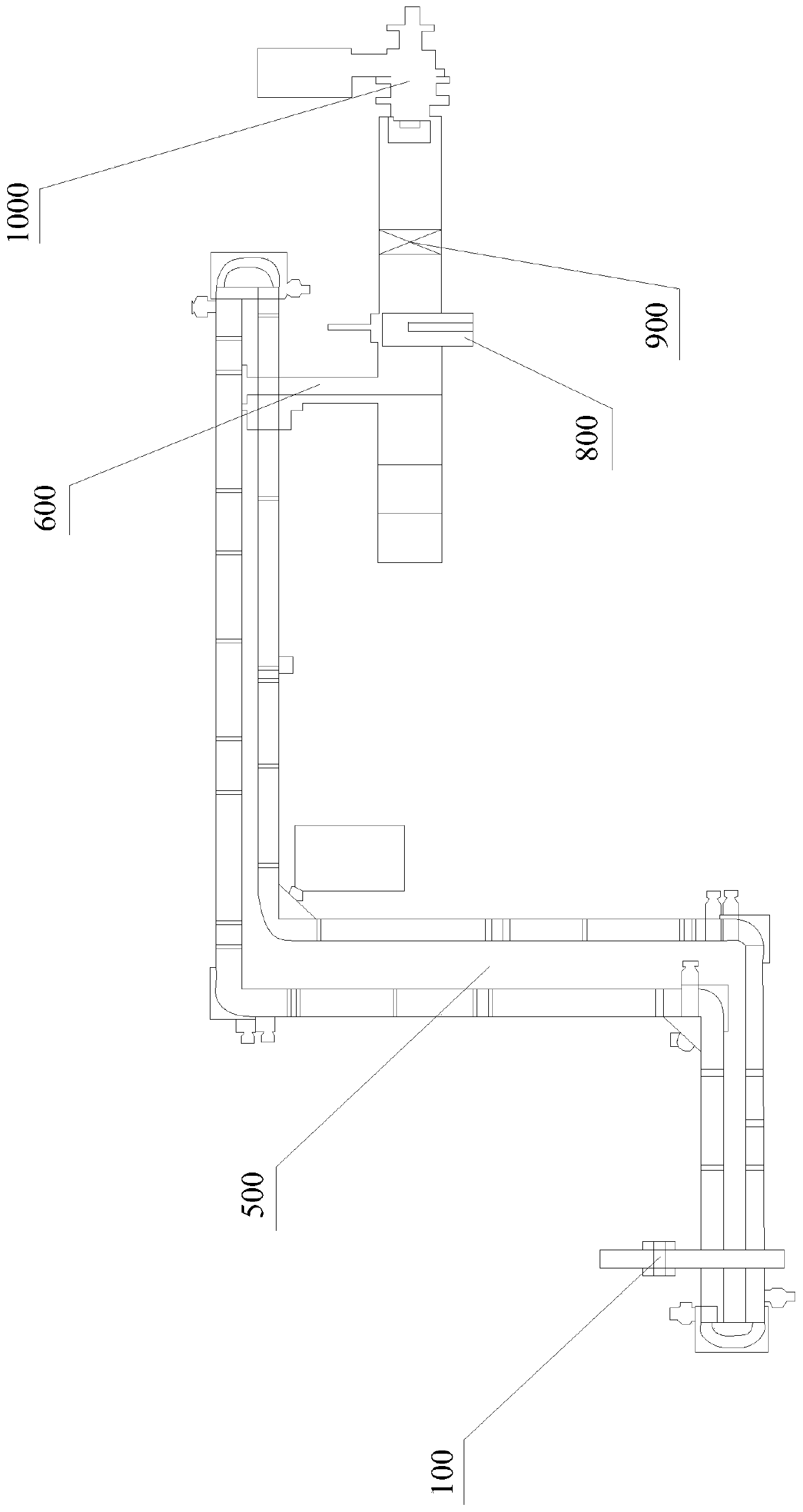

The invention provides an automatic packaging production device for a nursing pad. The automatic packaging production device comprises a feeding mechanism, a conveying mechanism, a branching mechanism, a grading falling mechanism, a belt conveying mechanism and a transferring device, wherein the feeding mechanism comprises a flow guide groove and a sensor, the sensor is in communication connectionwith a PLC control system, one end of the conveying mechanism is connected with the flow guide groove, the branching mechanism comprises a first driving device, a first driving pushing handle, a second driving device and a second driving pushing handle, the grading falling mechanism is arranged at the other end of the conveying mechanism and comprises a falling frame, a falling channel, a third driving device and a movable baffle are arranged on the falling frame, the belt conveying mechanism penetrates through the whole automatic packaging production device, a semi-finished tray is arrangedon the belt conveying mechanism, the transferring mechanism is arranged at the other end, far away from the feeding mechanism, the conveying mechanism, the branching mechanism and the grading fallingmechanism, of the belt conveying mechanism, and comprises a support, a fourth driving device and a mechanical claw.

Owner:北京雪莲生物科技有限公司

A shrinkable adhesive film packaging mechanism

InactiveCN105083645BEasy to packImprove production and packaging efficiencyWrappers shrinkageGear wheelEngineering

The invention relates to the field of packaging equipment of object packaging films, in particular to a shrinkable adhesive film packaging mechanism. The shrinkable adhesive film packaging mechanism comprises a base plate, wherein a center gear and a driving device for driving the center gear to rotate are arranged in the center position of the base plate; the center gear is connected with at least two sets of rack structures; each set of rack structures comprises two parallel racks; the tail ends of the racks are connected with slide blocks; the slide blocks are connected to the base plate through slide rails; limiting pieces are arranged on the slide blocks, and are provided with arc support pieces; the slide blocks of each set of rack structures are peripherally distributed; and the arc support pieces on each limiting piece are formed to a ring shape. The shrinkable adhesive film packaging mechanism packages products, to be packed through film sealing, with different diameter sizes, so that the production packaging efficiency is greatly improved, the payment of manual packaging costs is reduced, and the technical blank incapable of using one piece of equipment for the products, to be packed through film sealing, with different sizes in the prior art is filled.

Owner:高林堃

Covering machine

PendingCN112722475AImprove production and packaging efficiencyReduce manufacturing costWrapping material feeding apparatusWrapper folding/bending apparatusMechanical engineeringIndustrial engineering

The invention discloses a covering machine, and belongs to the field of ceramic machinery. The covering machine comprises a paper taking and feeding mechanism, a paper folding mechanism and a conveying device, wherein the paper taking and feeding mechanism and the paper folding mechanism are connected end to end, the conveying device is arranged on the paper taking and feeding mechanism and the paper folding mechanism, the conveying device comprises a plurality of conveying assemblies and a conveying driving device, and the conveying assemblies are arranged on the paper taking and feeding mechanism and the paper folding mechanism in parallel. The paper taking and feeding mechanism comprises a jacking mechanism, a paper bin and a paper taking mechanism, wherein the jacking mechanism is located in the middle of the conveying device, the paper bin is located on one side of the conveying device, and the paper taking mechanism is located above the conveying device. The paper folding mechanism comprises guide blocks and a paper folding portion, wherein the guide blocks are located on one side of the paper folding portion, and the positions of the guide blocks and the paper folding portion can be adjusted in the width direction of a plurality of conveying devices. The covering machine is used for covering the edges of ceramic tiles, the whole process is automatic, the working efficiency is high, moreover, different ceramic tiles can be packaged, and the application range is wide.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Packaging mechanism of automatic packaging machine for medical cotton swabs

InactiveCN103112610BSimplify the packaging processImprove production and packaging efficiencyWrapper twisting/gatheringRod-shaped articlesThin membraneEngineering

The invention relates to the technical field of cotton swab packaging equipment, in particular to a packaging mechanism of an automatic packaging machine for medical cotton swabs. The packaging mechanism of the automatic packaging machine for the medical cotton swabs comprises a conveying platform, wherein a material pushing device, an upper edge sealing device and a hot pressing sealing and trimming device are arranged on the conveying platform in sequence. The hot pressing sealing and trimming device comprises a hot pressing sealing upper mold, a hot pressing sealing lower mold, a first cylinder, a first movable plate, a sealing cutter, a fixing device and a second cylinder. When the packaging mechanism of the automatic packaging machine for the medical cotton swabs works, the upper edge sealing device is capable of sealing the upper edge of a packaging film bag which contains the medical cotton swabs to be packaged and is conveyed by material pushing device, and then sealing and trimming of the packaging film bag with the upper edge well sealed and conveyed by the upper edge sealing device are achieved through the hot pressing sealing and trimming device. The sealing process and the trimming process are carried out at the same time, and therefore packaging processes are enabled to be simple and production and packaging efficiency is high.

Owner:东莞市万江鸿浩五金电器厂

An automatic packaging production line for swimming ring production

ActiveCN111605840BImprove production and packaging efficiencyReduce labor intensityPackaging machinesChemical transformationBarcode

The invention relates to the technical field of industrial intelligent production, and provides an automatic packaging production line for swimming ring production, which includes an automatic forming and bottom sealing machine arranged in sequence according to the packaging production process and connected by automatic rollers, an online weighing device, a barcode printing and pasting machine and Automatic folding and sealing machine, the automatic forming bottom sealing machine and the online weighing device are connected with a boxing position, and the boxing position is cross-connected with the tail end of the swimming ring production line, and the tail of the swimming ring production line is provided with a branch point, the automatic rollers of the branch point are provided with direction-changing rollers at intervals, and the branch point is connected with the online weighing device by branch line rollers. The automatic packaging production line for swimming ring production of the present invention realizes automatic boxing and packaging of swimming rings through scientific process arrangement and operation arrangement, effectively reduces the labor intensity of production personnel, can realize unmanned participation, has the function of fault tolerance for packing quantity, and is intelligent The high degree of automation can greatly improve the production and packaging efficiency of swimming rings.

Owner:YANCHENG JIAHUA PLASTIC PROD CO LTD

Self-adaptive feeding mechanism of robot flexible production line

ActiveCN112744413AImprove production and packaging efficiencyStuffed paperPackaging protectionArticle separationProduction lineEngineering

The invention discloses a self-adaptive feeding mechanism of a robot flexible production line. A feeding plate used for containing children shoes when the children shoes are produced is included, the feeding plate is provided with a front end shoe cover used for protecting the front ends of the children shoes when the children shoes move on the production line, and the front end shoe cover is provided with a matching device enabling the front end shoe cover to be matched with and separated from the front ends of the children shoes. According to the self-adaptive feeding mechanism for the robot flexible production line, the shoe cover is arranged on the feeding plate and can be arranged according to the sizes of different children shoes, and the matching device is arranged on the outer side of the shoe cover, so that when the device and the shoe cover are used for packaging the children shoes, on one hand, the front ends of the children shoes can be matched and shaped, and on the other hand, the dustproof effect can be achieved in the packaging and transporting process of the children shoes. Meanwhile, through a shaping and feeding device arranged on the feeding plate, paper can be shaped into paper balls of a certain size, under the condition of cooperation of the shoe cover, the paper balls can be stably stuffed into the children shoes, and deformation is prevented when the paper is stuffed into the children shoes.

Owner:浙江德源智能科技股份有限公司

Tooth cup cleaning agent

InactiveCN110938497ASlightly sweet tasteGood effectInorganic/elemental detergent compounding agentsSurface-active detergent compositionsCleansing AgentsDentistry

The invention belongs to the field of cleaning agents specially used for cleaning tooth cups, and specifically discloses a tooth cup cleaning agent and a preparation method thereof. The tooth cup cleaning agent is prepared from components comprising honeysuckle flower powder, xylitol, thymol, glycyrrhiza powder, ethanol, poloxamer, sodium chloride and purified water by mixing. The tooth cup cleaning agent containing the above-mentioned components has the following advantages: the pertinence is high; harmful bacteria bred in a tooth cup can be eliminated; the tooth cup is effectively cleaned; materials are simple, easily-available and cheap; the components of the tooth cup cleaning agent are free of toxic and side effects; and the preparation method disclosed by the invention comprises a method for producing a packaged finished product, so the tooth cup cleaning agent can be used more conveniently and more hygienically.

Owner:LIMING VOCATIONAL UNIV

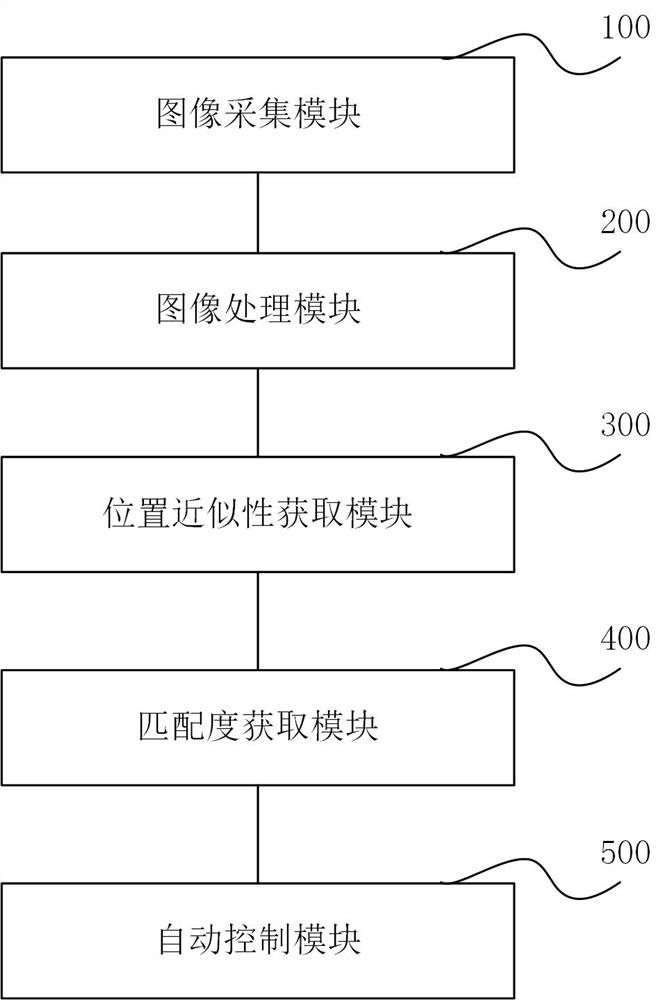

Automatic control system for quantitative packaging multi-head combined scale

ActiveCN114852435AImprove production and packaging efficiencySolid materialPackaging automatic controlAutomatic controlSelf adaptive

The invention relates to the technical field of intelligent control, in particular to an automatic control system for a quantitative packaging multi-head combined scale, and the system collects multiple frames of material images through an image collection module; obtaining a binary image of a change area of two adjacent frames of material images through an image processing module, identifying a plurality of connected domains of the binary image, and obtaining a corresponding center point coordinate; obtaining an image partial region corresponding to each connected domain; obtaining the circle center of an outlet of the collecting tank; taking each connected domain as a target connected domain through a position approximation acquisition module, and acquiring the position approximation of the target connected domain and the same alternative connected domain; obtaining the matching degree of the target connected domain and the same alternative connected domain through a matching degree obtaining module; and the blanking interval time of different combined hoppers is controlled through the automatic control module. According to the invention, the blanking interval time of different combined hoppers of the multi-head combined scale can be adjusted in a self-adaptive manner, and blanking is carried out at the highest speed on the premise of ensuring no blockage.

Owner:青岛锐智智能装备科技股份有限公司

Producing and packaging method for facial mask

InactiveCN111392151AImprove production and packaging efficiencyCompact processPackage sterilisationWrapper twisting/gatheringPunchingComputer science

The invention discloses a producing and packaging method for a facial mask. The method comprises following steps: step S1, collecting; step S2, stacking; step S3, charging; step S4, transporting; stepS5, opening sealing; step S6, inspection; step S7, punching; step S8, cleaning; step S9, arranging and stacking; step S10, bin packing and step S11, weighing. The invention relates to the technical field of facial mask packaging. According to the producing and packaging method for the facial mask, the producing and packaging efficiency of the facial mask can be increased, a series of process steps can be completed according to steps when the facial mask is packaged, the process is compact when the facial mask is produced and packed, and on the premise that packaging quality is guaranteed, theproblem about of time efficiency during producing and packaging of the facial mask is solved.

Owner:王玉玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com