A bagging device for liquid crystal display production

A technology of liquid crystal display and bagging device, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reducing production capacity, increasing costs, and low efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

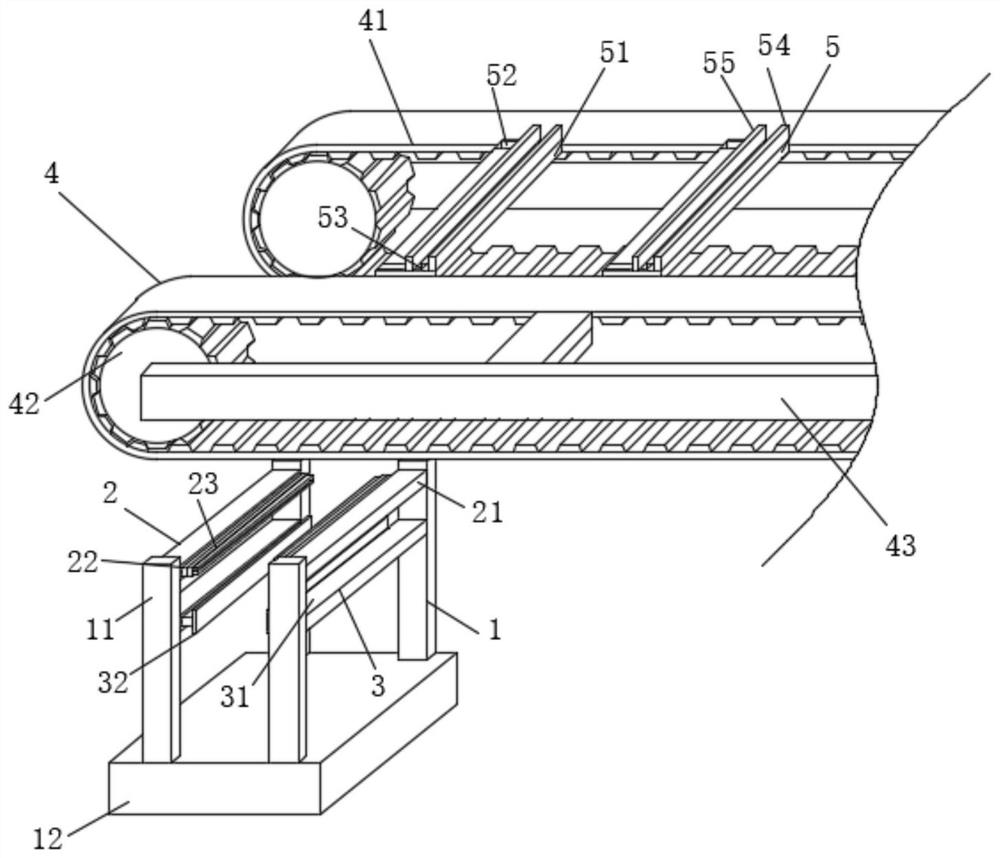

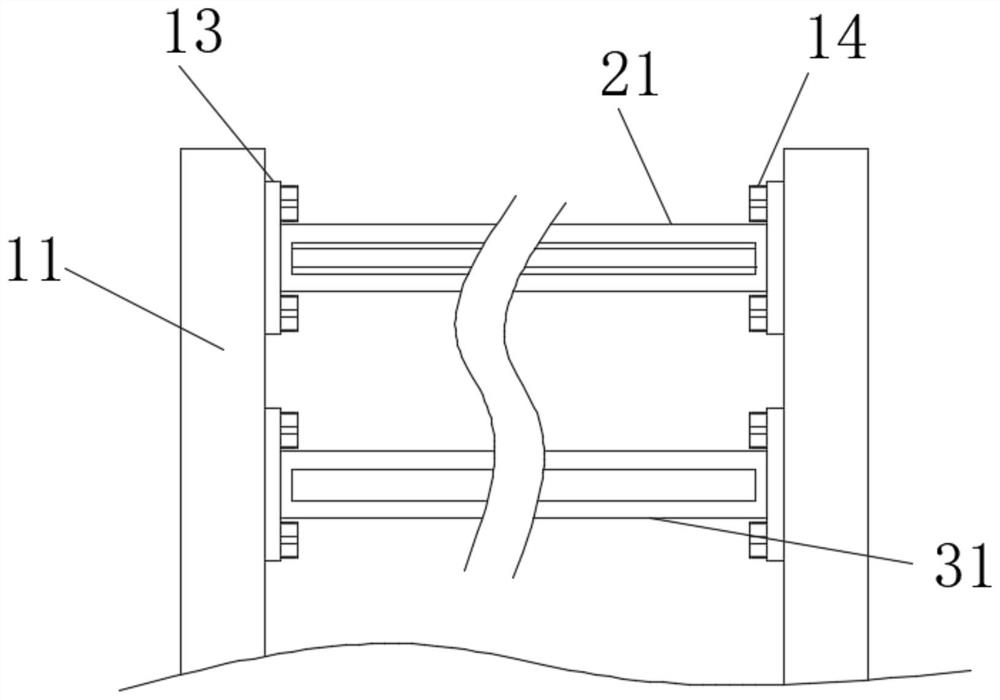

[0026] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a bagging device for liquid crystal display production, including a packaging structure 1, a conveying structure 4 is arranged above the packaging structure 1, and a plurality of A clamping structure 5, a connecting structure 2 is connected to the packaging structure 1, a driving structure 23 is connected to the connecting structure 2, and a sealing structure 3 is provided below the connecting structure 2;

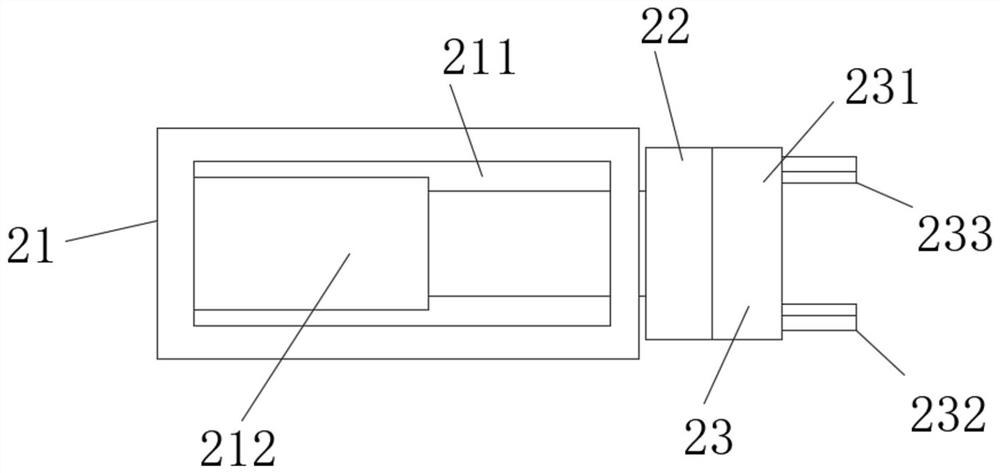

[0027] Described drive structure 23 comprises cylinder 231, and described cylinder 231 is provided with two altogether, and the output end of two described cylinders 231 is all movably connected with two grippers 232, two grippers 232 on the same described cylinder 231 The sides close to each other are fixedly connected with a cushion layer 233;

[0028] Described sealing structure 3 comprises butt joint plate 31, and described butt joint plate 31 is provided with two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com