Glass fiber cotton VIP core material aluminum foil packaging vacuumizing heat-sealing device

A technology of glass fiber cotton and heat sealing device, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., to save loading time and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

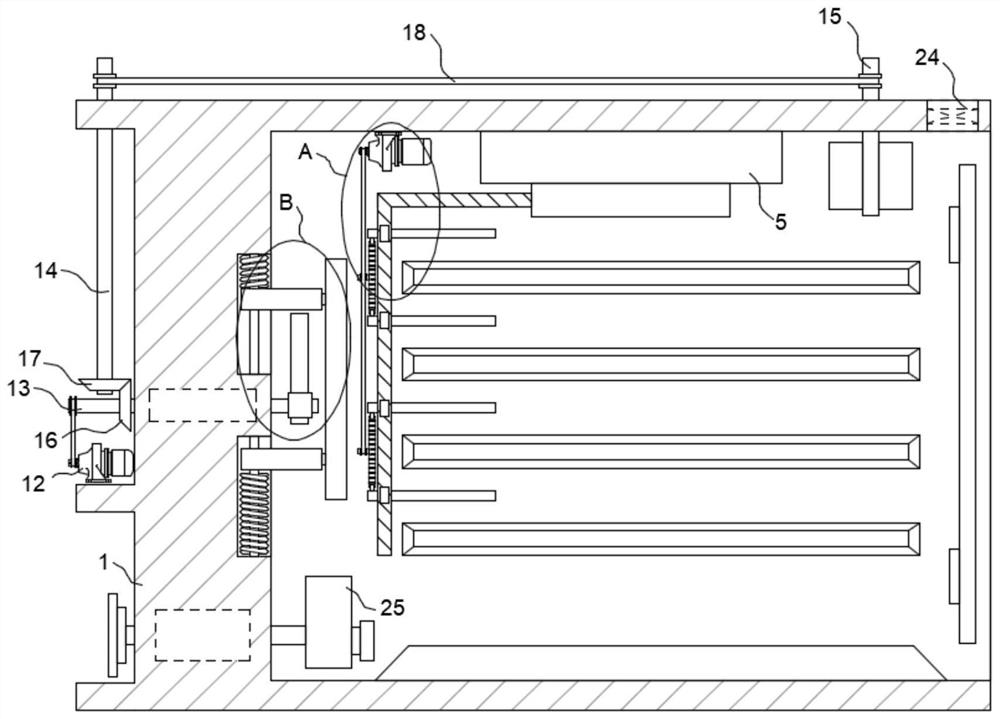

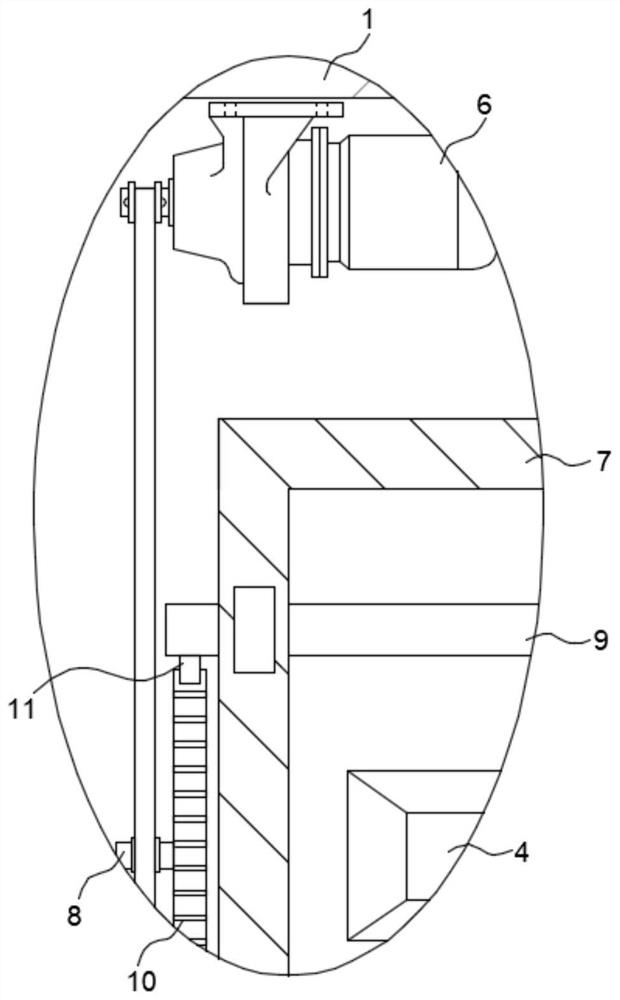

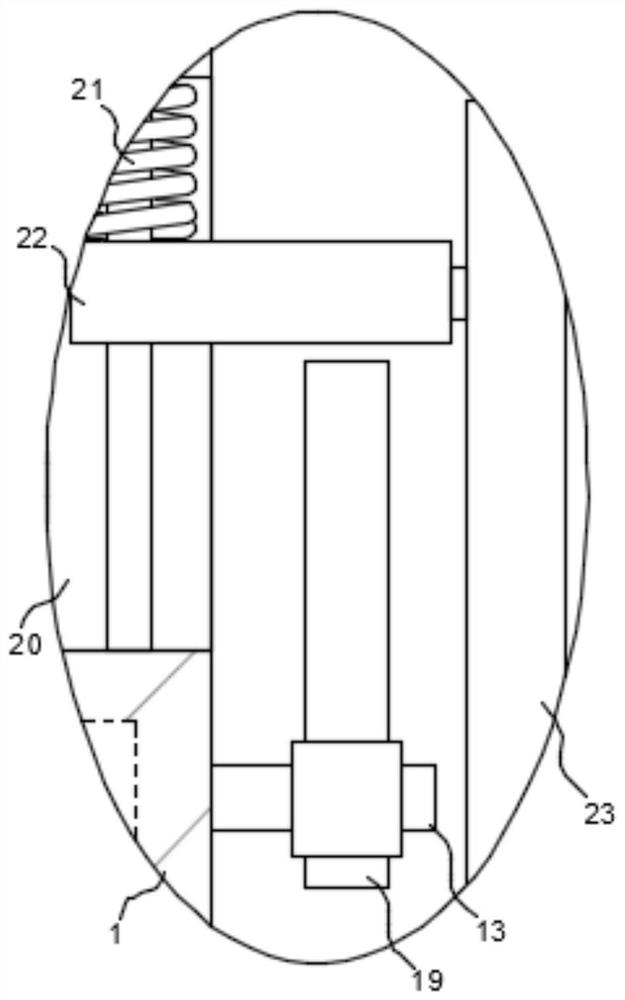

[0027] refer to Figure 1-5 , a glass fiber cotton VIP core material aluminum foil packaging vacuum heat sealing device, including a box 1 that can be opened and closed on one side, a base 2 fixed on the ground and a rotatable loading frame 3, the two sides of the box 1 The inner wall is correspondingly equipped with guide rails 4. It should be noted that the base 2 can be used to simultaneously carry two loading racks 3 for movement, so as to put the loading racks 3 into the box body 1 or take out the loading racks 3 from the box body 1. For details, refer to the attached figure 1 It can be seen that the guide rail 4 is used to guide and limit the loading rack 3 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com