Material sorting process based on annular conveying device

A technology of circular conveying and cyclic conveying, which is applied to conveyor objects, transportation and packaging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

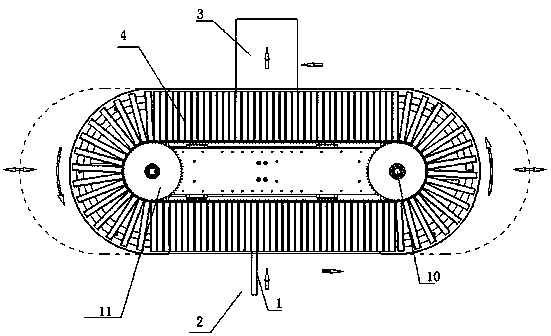

[0025] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0026] A material sorting process based on an annular conveying device, in which materials are conveyed to the annular conveying device one by one from the feed end 2, and arranged side by side at equal intervals on the annular conveying device; the circular conveying device rotates and conveys in a circular manner; Material end 3, the material is output from the discharge end 3; at the discharge end 3, the materials are arranged with a set number of N materials to form a group of materials, and the group of materials is output from the discharge end 3 to the circular conveying device at one time; in a unit Within a period of time, the circular conveying device rotates half a material interval per cycle, and the annular conveying device moves half a material interval along the material arrangement direction of the feeding end 2, so that the feeding end...

Embodiment 2

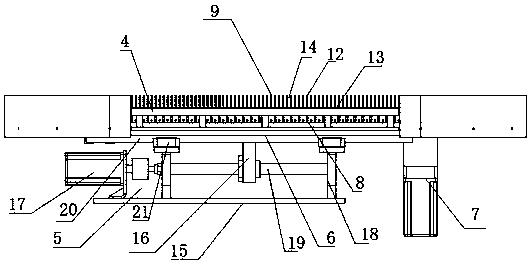

[0029] As another preferred embodiment of the present invention, with reference to the attached Figure 1-3 , this example discloses:

[0030]A material sorting process based on an annular conveying device, in which materials are conveyed to the annular conveying device one by one from the feed end 2, and arranged side by side at equal intervals on the annular conveying device; the circular conveying device rotates and conveys in a circular manner; Material end 3, the material is output from the discharge end 3; at the discharge end 3, the materials are arranged with a set number of N materials to form a group of materials, and the group of materials is output from the discharge end 3 to the circular conveying device at one time; in a unit Within a period of time, the circular conveying device rotates half a material interval per cycle, and the annular conveying device moves half a material interval along the material arrangement direction of the feeding end 2, so that the fee...

Embodiment 3

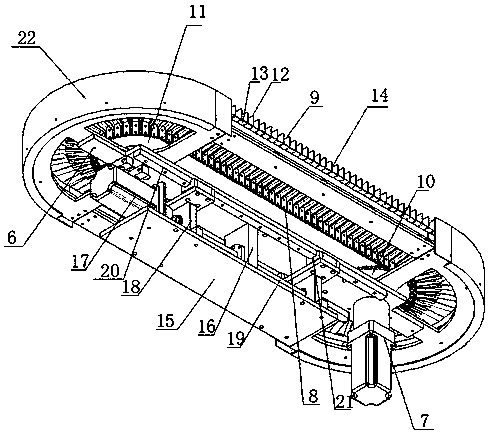

[0034] As another preferred embodiment of the present invention, with reference to the attached Figure 1-3 , this example discloses:

[0035] A material sorting process based on an annular conveying device, in which materials are conveyed to the annular conveying device one by one from the feed end 2, and arranged side by side at equal intervals on the annular conveying device; the circular conveying device rotates and conveys in a circular manner; Material end 3, the material is output from the discharge end 3; at the discharge end 3, the materials are arranged with a set number of N materials to form a group of materials, and the group of materials is output from the discharge end 3 to the circular conveying device at one time; in a unit Within a period of time, the circular conveying device rotates half a material interval per cycle, and the annular conveying device moves half a material interval along the material arrangement direction of the feeding end 2, so that the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com