Shrinkable adhesive film packaging mechanism

A technology of film and support sheet, applied in the direction of shrinkage of wrapping paper, packaging, wrapping paper, etc., can solve the problems of unchangeable diameter and single pertinence, so as to fill the technical gap, improve the efficiency of production and packaging, and reduce the cost of manual packaging. effect of spending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

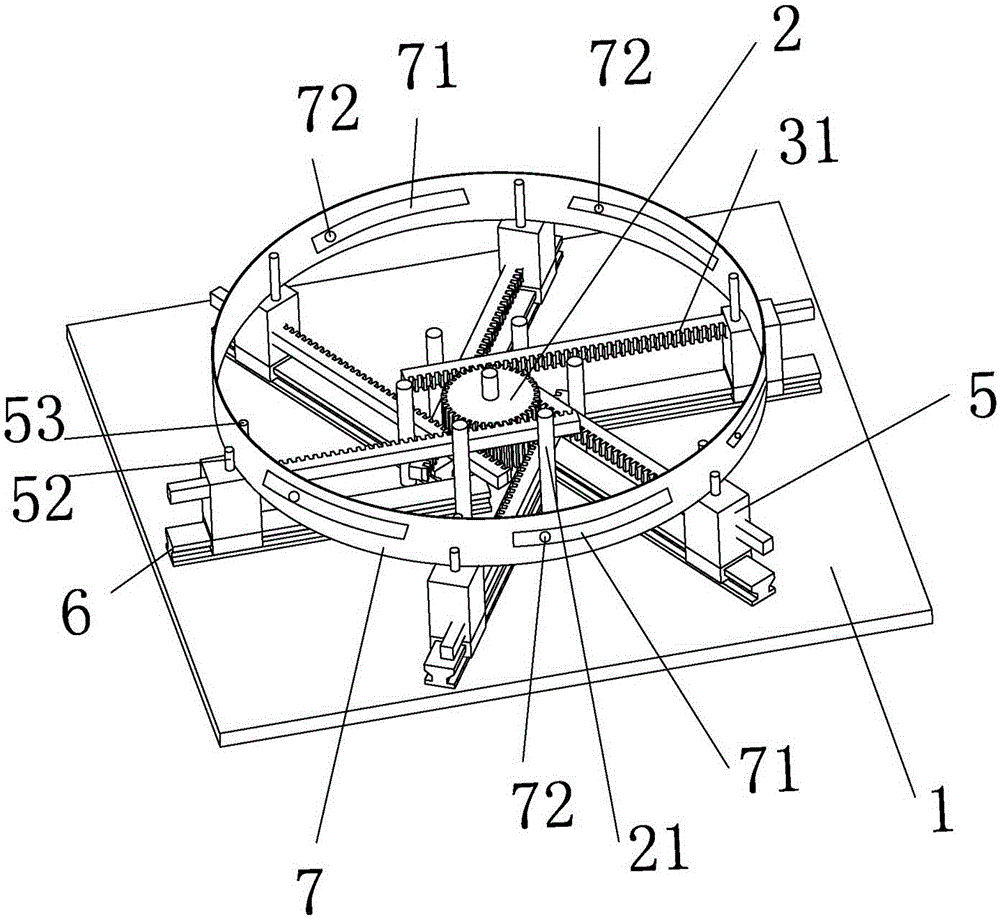

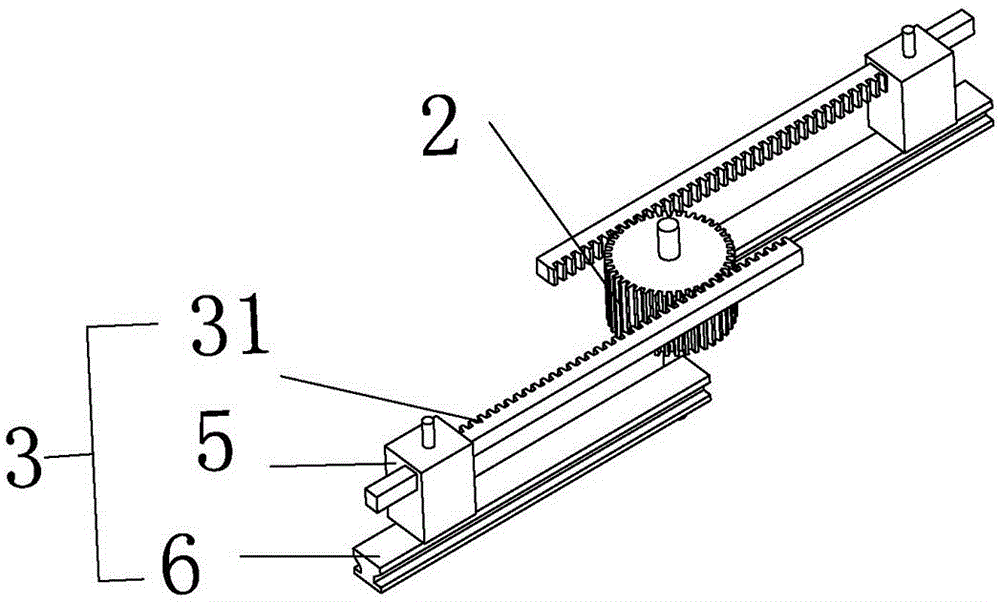

[0014] The present invention will be further described below in conjunction with accompanying drawing and preferred specific embodiment: the first embodiment, a kind of shrinkable adhesive film encapsulating mechanism, comprises substrate 1, and the central position of described substrate 1 is provided with central gear 2 and drive The driving device for rotating the central gear 2, the central gear 2 is connected with at least two sets of rack structures 3, each set of rack structures 3 includes two parallel racks 31, and the end of each rack 31 is connected with Slider 5, described slider 5 is connected on the base plate 1 by slide rail 6, and described slider 5 is also provided with stopper 51, and described stopper 51 is provided with elastic arc-shaped support sheet 7; The sliders 5 of the group rack structure 3 are distributed in a circle, and the elastic arc-shaped support pieces 7 on the position-limiting members 51 form a circular ring, and two adjacent elastic arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com