Packaging mechanism used during chocolate production

A technology for chocolate and packaging boxes, which is applied in packaging, transportation packaging, and food packaging, etc. It can solve the problems of manual placement of chocolates, inability to realize automation, and low efficiency of sealing boxes, so as to improve production packaging efficiency, realize automation, The effect of high packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

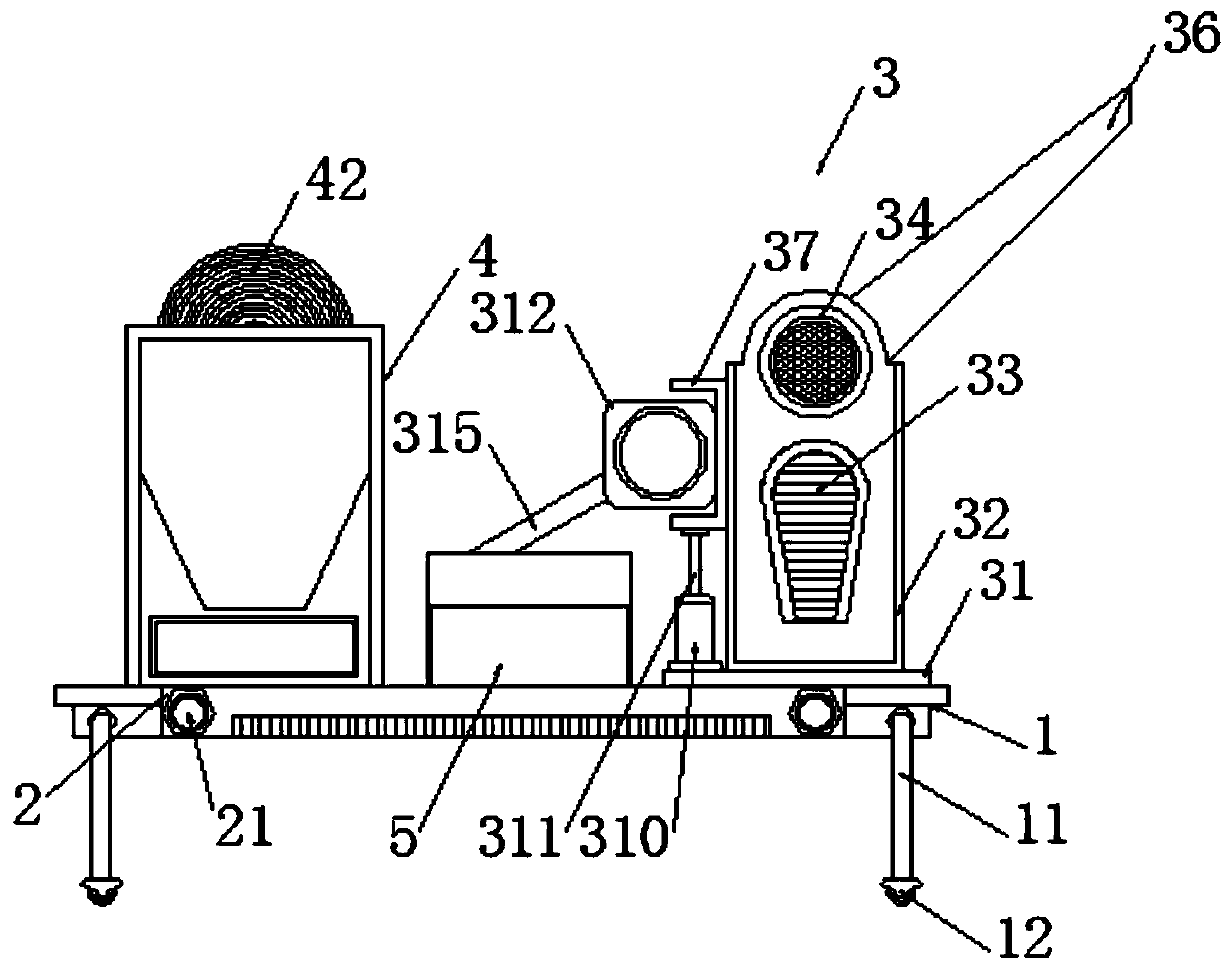

[0024] A packaging mechanism for chocolate production, including a workbench 1, a conveying shell 2, a placement mechanism 3, a sealing shell 4 and a packing box 5, a workbench 1, a conveying shell 2 embedded in the center of the upper end surface, and the workbench 1 A placement mechanism 3 is fixedly installed near one side of the end surface, a sealing shell 4 is fixedly installed on the other side of the upper end surface of the workbench 1 , and a packing box 5 is arranged above the conveying shell 2 .

[0025] Among them, the sides of the two opposite ends of the workbench 1 are fixedly installed with support columns 11, the four support columns 11 have the same specifications and are distributed in a rectangular array with each other, and the ends of the four support columns 11 away from the workbench 1 are fixedly installed with Universal wheel 12, four universal wheels 12 specifications are consistent.

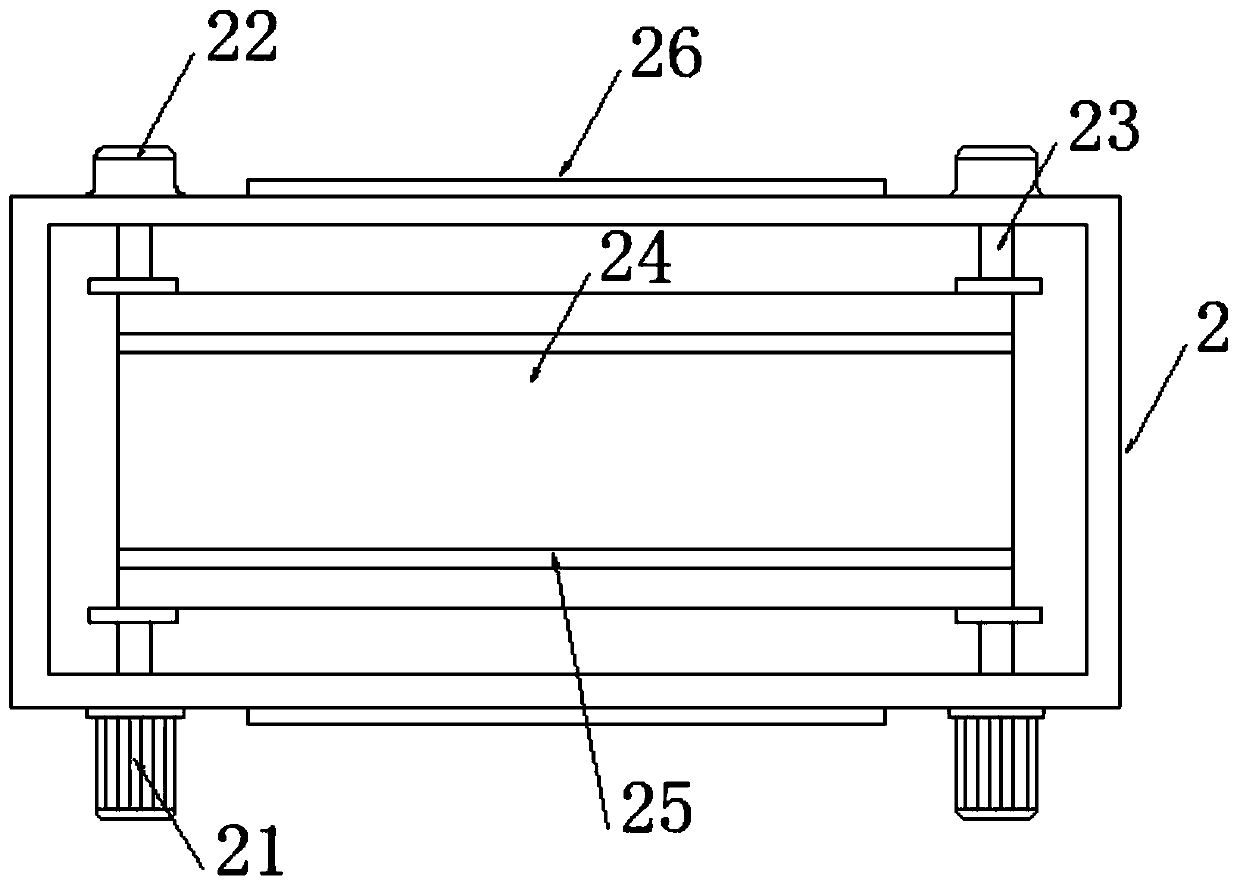

[0026] Among them, the same side of the conveying shell 2 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com