Automatic sorting device

A material sorting and automatic technology, applied in the directions of packaging, transportation and packaging, conveyor objects, etc., can solve the problems of poor material accumulation capacity and slow material sorting rate, so as to ensure the orderliness, improve the conveying efficiency and production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

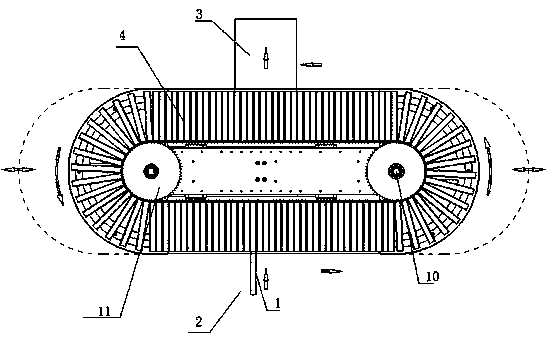

[0025] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0026] In this embodiment, the automatic material sorting device includes a circulation conveying mechanism 4 and a translation mechanism 5, the circulation conveying mechanism 4 is arranged on the translation mechanism 5, and the translation mechanism 5 drives the circulation conveying mechanism 4 to reciprocate; the circulation conveying mechanism 4 Linked with the translation mechanism 5, the circulation conveying mechanism 4 moves once, and the translation mechanism 5 moves once; the circulation conveying mechanism 4 rotates half a material interval from the circulation, and the translation mechanism 5 drives the circulation conveying mechanism 4 as a whole along the feeding end of the circulation conveying mechanism 4 at 2 places The direction of rotation moves half a material interval. The materials are conveyed to the automatic material sorting...

Embodiment 2

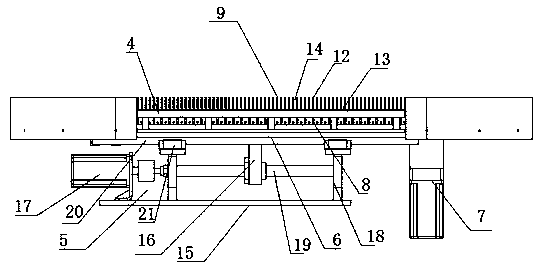

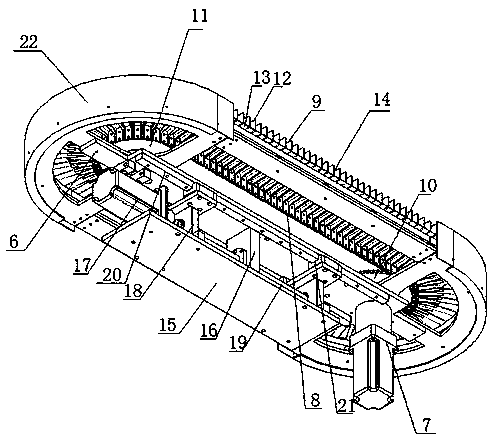

[0029] As another preferred embodiment of the present invention, with reference to the attached Figure 1-3 , this example discloses:

[0030] The automatic material sorting device includes a circulation conveying mechanism 4 and a translation mechanism 5, the circulation conveying mechanism 4 is arranged on the translation mechanism 5, and the translation mechanism 5 drives the circulation conveying mechanism 4 to reciprocate; the circulation conveying mechanism 4 is linked with the translation mechanism 5, and the circulation conveys The mechanism 4 moves once, and the translation mechanism 5 moves once; the circulation conveying mechanism 4 rotates half a material interval by itself, and the translation mechanism 5 drives the circulation conveying mechanism 4 as a whole to move half a material interval along the rotation direction of the feeding end 2 of the circulation conveying mechanism 4; The discharge end 3 of the circulation conveying mechanism 4 arranges a set amount o...

Embodiment 3

[0034] As another preferred embodiment of the present invention, with reference to the attached Figure 1-3 , this example discloses:

[0035] The automatic material sorting device includes a circulation conveying mechanism 4 and a translation mechanism 5, the circulation conveying mechanism 4 is arranged on the translation mechanism 5, and the translation mechanism 5 drives the circulation conveying mechanism 4 to reciprocate; the circulation conveying mechanism 4 is linked with the translation mechanism 5, and the circulation conveys The mechanism 4 moves once, and the translation mechanism 5 moves once; the circulation conveying mechanism 4 rotates half a material interval by itself, and the translation mechanism 5 drives the circulation conveying mechanism 4 as a whole to move half a material interval along the rotation direction of the feeding end 2 of the circulation conveying mechanism 4; The discharge end 3 of the circulation conveying mechanism 4 arranges a set amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com