Corn paste combined packaging machine

A packaging machine and eye corn paste technology, which is applied in the direction of packaging, transportation and packaging, packaging/binding items, etc., can solve the problems of eye corn pollution, product quality and yield rate, etc., to reduce pollution, improve production packaging efficiency, and feed materials uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

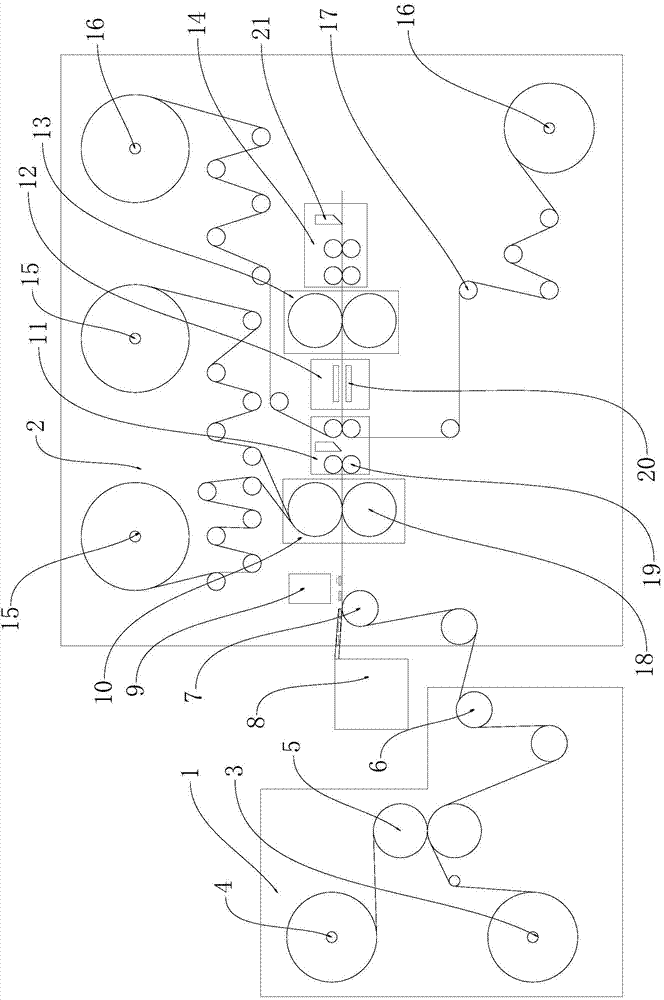

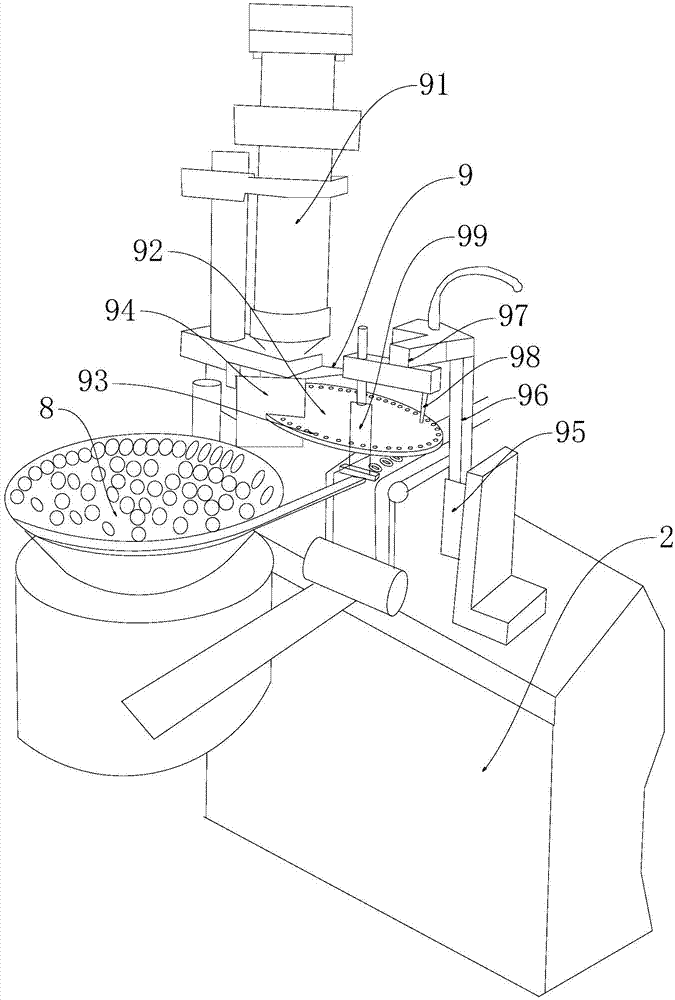

[0012] Such as figure 1 As shown, the corn ointment combined packaging machine described in this embodiment includes a raw material rack 1 and a packaging rack 2. The raw material rack 1 is arranged on the left side of the packaging rack 2 and at the lower end of the left side of the raw material rack 1. The rubber cloth roller 3 and the release film recovery roller 4 are respectively provided at the lower end and the rubber cloth roller 3 and the release film recovery roller 4 are provided with a peeling double roller 5 at the right end. The left side of the packaging rack 2 is provided with a guide roller 6, the rightmost guide roller 6 is the main guide roller 7, and is located in the middle of the left side of the packaging rack 2, and the packaging rack on the right side of the main guide roller 7 2 are provided with a first pressing roller mechanism 10, a first cutting mechanism 11, a thermal compound mechanism 12, a second pressing roller mechanism 13, and a second cuttin...

Embodiment 2

[0014] The corn paste combined packaging machine described in this embodiment includes a raw material rack 1 and a packaging rack 2. The raw material rack 1 is arranged on the left side of the packaging rack 2, and the lower end and the lower end of the left side of the raw material rack 1 are respectively There is a rubber cloth roller 3 and a release film recycling roll 4, and a peeling double roller 5 is provided at the right end between the rubber cloth roller 3 and the release film recycling roll 4, on the right side of the raw material rack 1 and the packaging rack 2 There is a guide roller 6 on the left side, and the rightmost guide roller 6 is the main guide roller 7, and it is located in the middle of the left side of the packaging rack 2, on the packaging rack 2 on the right side of the main guide roller 7. It is provided with a first pressing roller mechanism 10, a first cutting mechanism 11, a thermal compound mechanism 12, a second pressing roller mechanism 13 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com