Automatic packaging production device and process for nursing pad

An automatic packaging and production device technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of increasing labor costs, restricting the expansion and development of production scale, and low production efficiency of manual packaging, and achieving convenient packing. The effect of warehousing, increasing production and packaging efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] In order to have a further understanding of the technical solution and beneficial effects of the present invention, the technical solution of the present invention and its beneficial effects will be described in detail below with reference to the accompanying drawings.

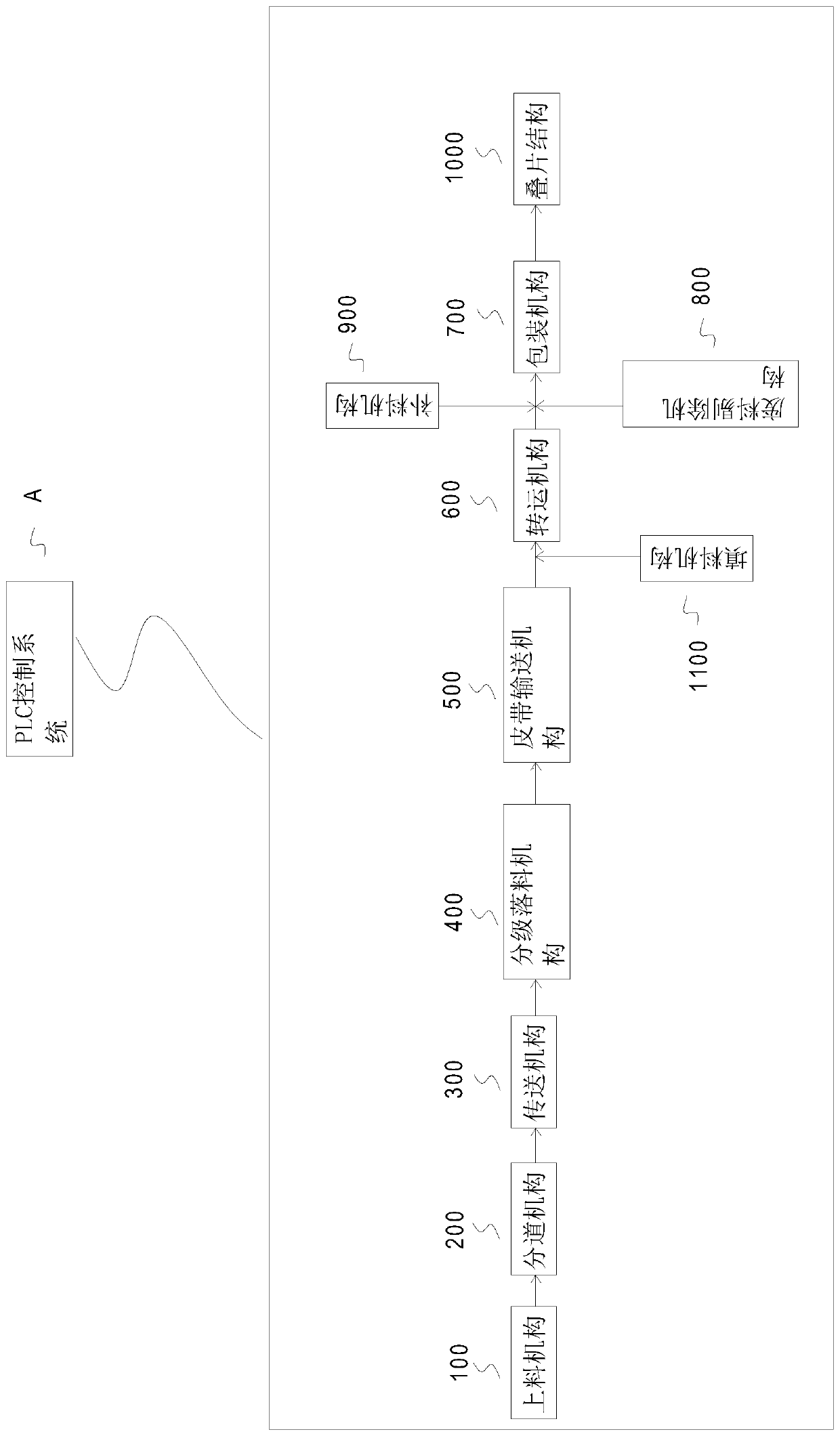

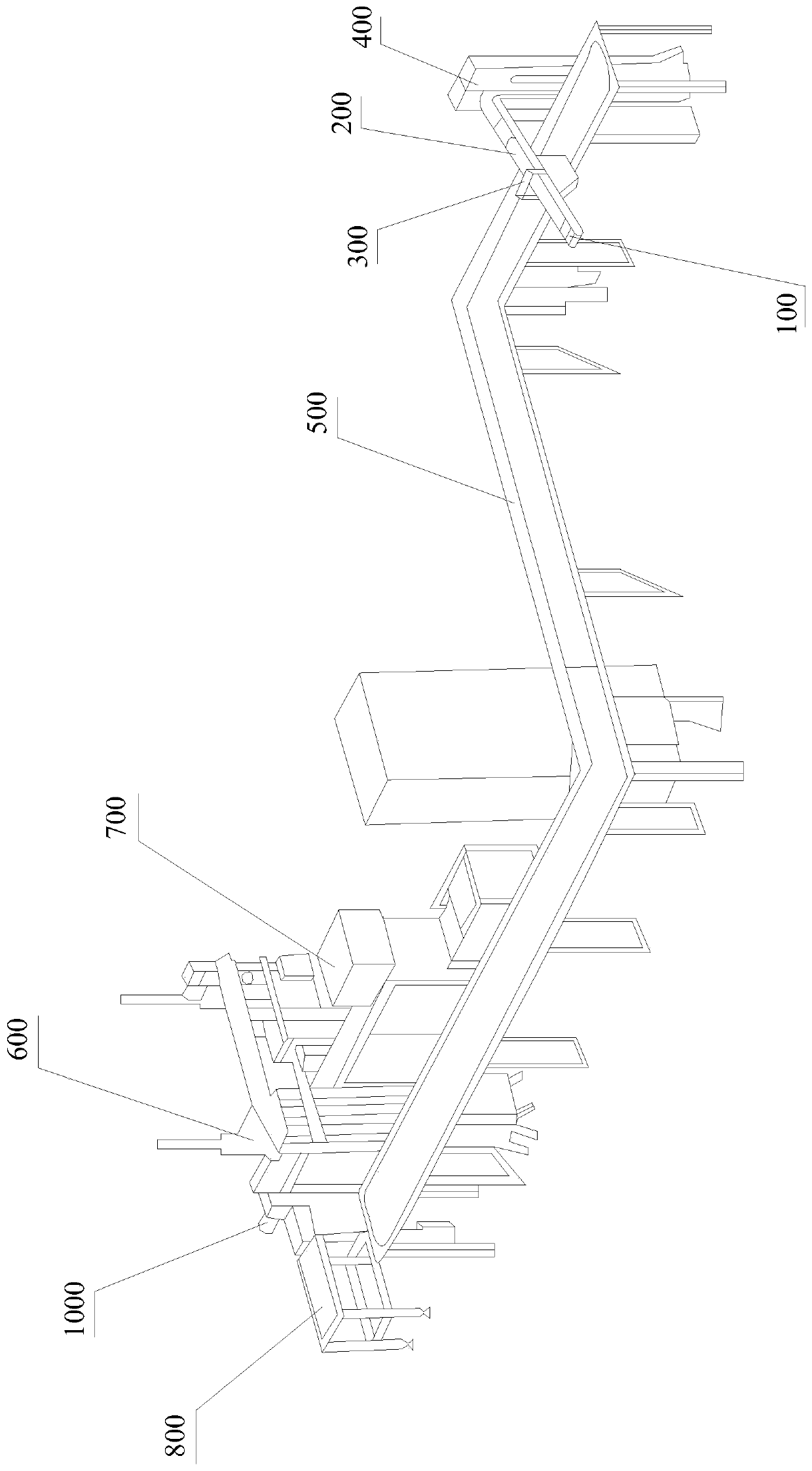

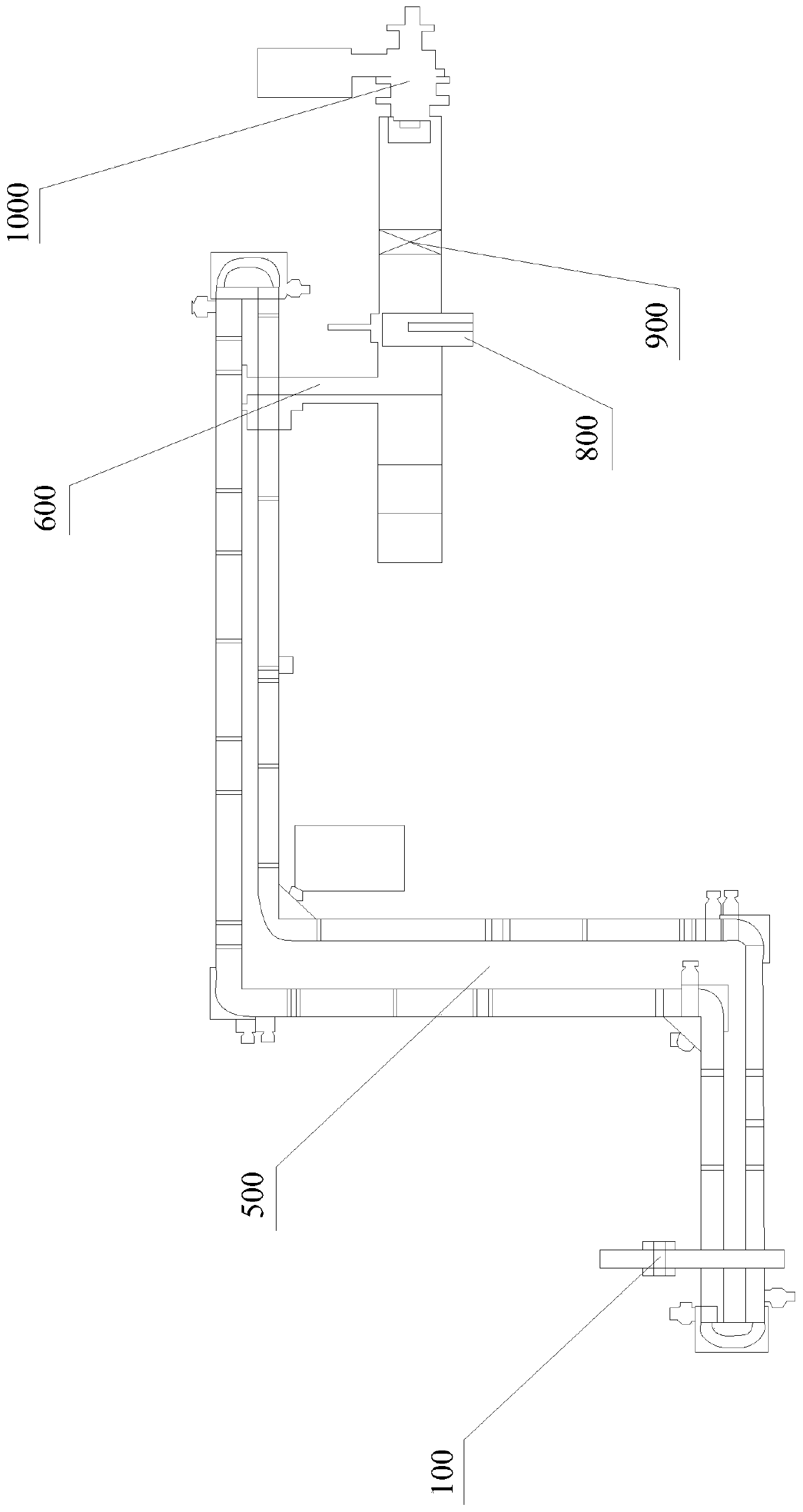

[0103] See figure 1 , figure 2 and image 3 , as shown in the figure, the nursing pad automatic packaging production device of the present invention includes a feeding mechanism 100, a conveying mechanism 200, a lane dividing mechanism 300, a grading and blanking mechanism 400, a belt conveying mechanism 500, a transfer mechanism 600 and a packaging mechanism 700, specifically The feeding mechanism 100 is connected to one end of the conveying mechanism 200, the lane separation mechanism 300 is erected on the conveying mechanism 300 close to the feeding mechanism 100, the conveying mechanism 200 is connected to the grading and blanking mechanism 400, and the belt The conveying mechanism 500 runs throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com