Patents

Literature

34results about How to "Automate the connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

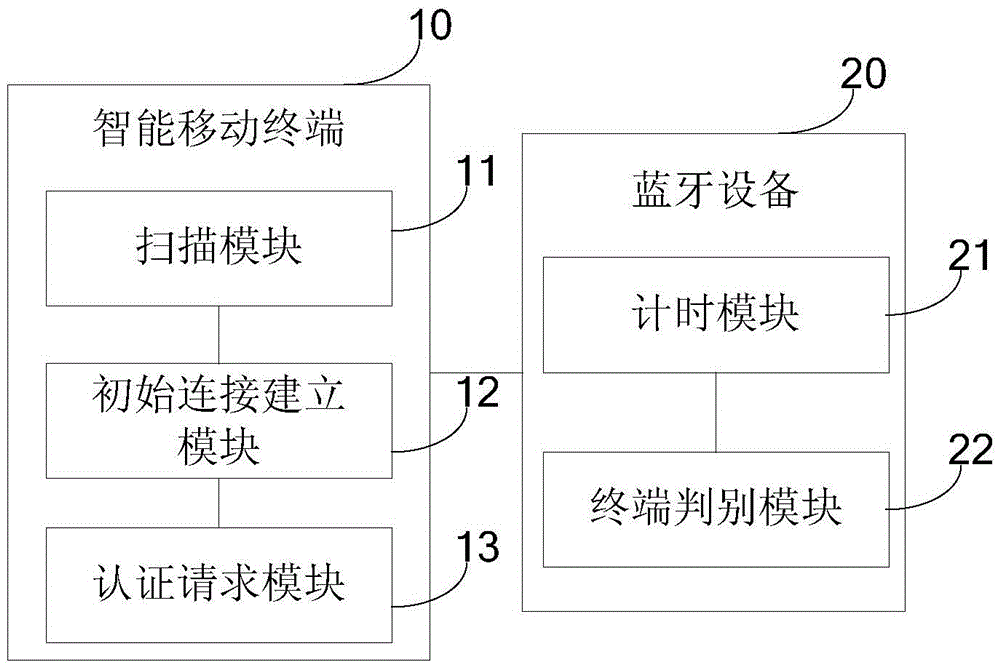

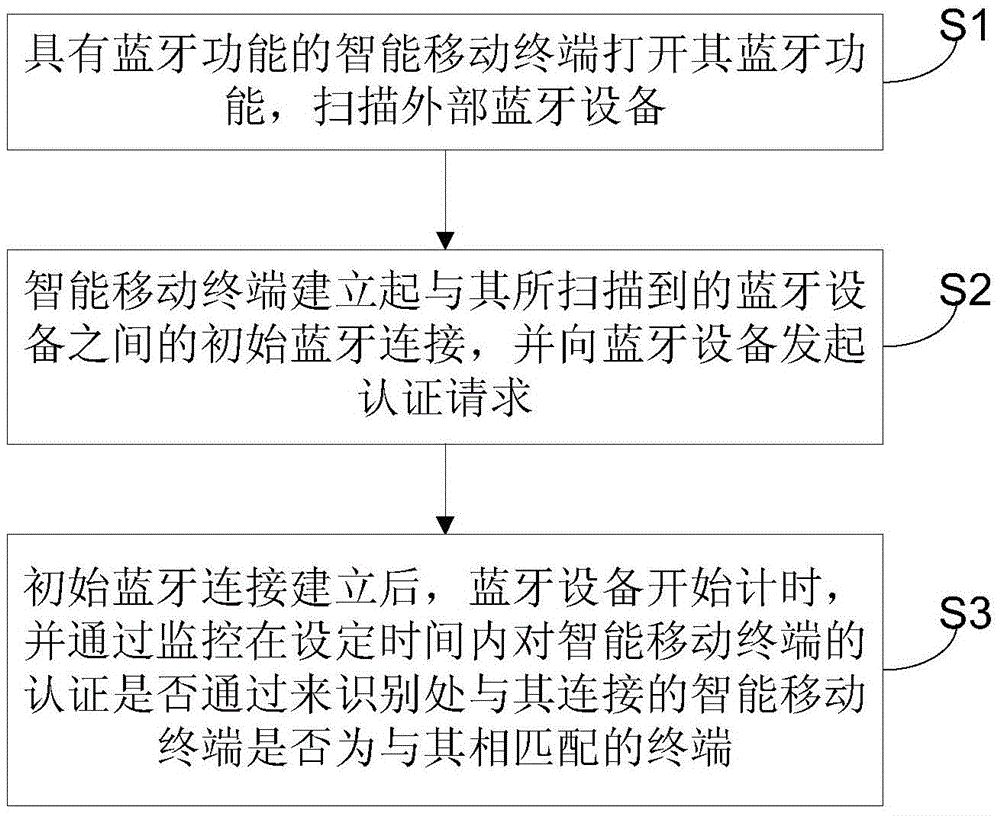

Secure connection method and system for Bluetooth equipment

InactiveCN105430603AImprove user experienceAvoid Illegal Terminal ConnectionsAssess restrictionConnection managementSafety ConnectBluetooth

The invention discloses a secure connection method and system for Bluetooth equipment, and belongs to the technical field of Bluetooth. The secure connection method comprises the following steps: starting the Bluetooth function of an intelligent mobile terminal with the Bluetooth function to scan external Bluetooth equipment; establishing initial Bluetooth connection between the intelligent mobile terminal and the scanned Bluetooth equipment, and sending an authentication request to the Bluetooth equipment from the intelligent mobile terminal; and starting timing of the Bluetooth equipment as long as the initial Bluetooth connection is established, monitoring whether the authentication of the intelligent mobile terminal passes or not in a set time, and determining that the Bluetooth connection between the Bluetooth equipment and the intelligent mobile terminal is fulfilled if the authentication of the intelligent mobile terminal passes, otherwise disconnecting the Bluetooth equipment from the Bluetooth of the intelligent mobile terminal. The secure connection method has the advantages that automatic connection between the Bluetooth equipment and the matched intelligent mobile terminal is realized; manual operation of a user is avoided; user experience is improved; and the phenomenon that the Bluetooth equipment is connected with an illegal terminal is avoided effectively.

Owner:WATCHDATA SYST

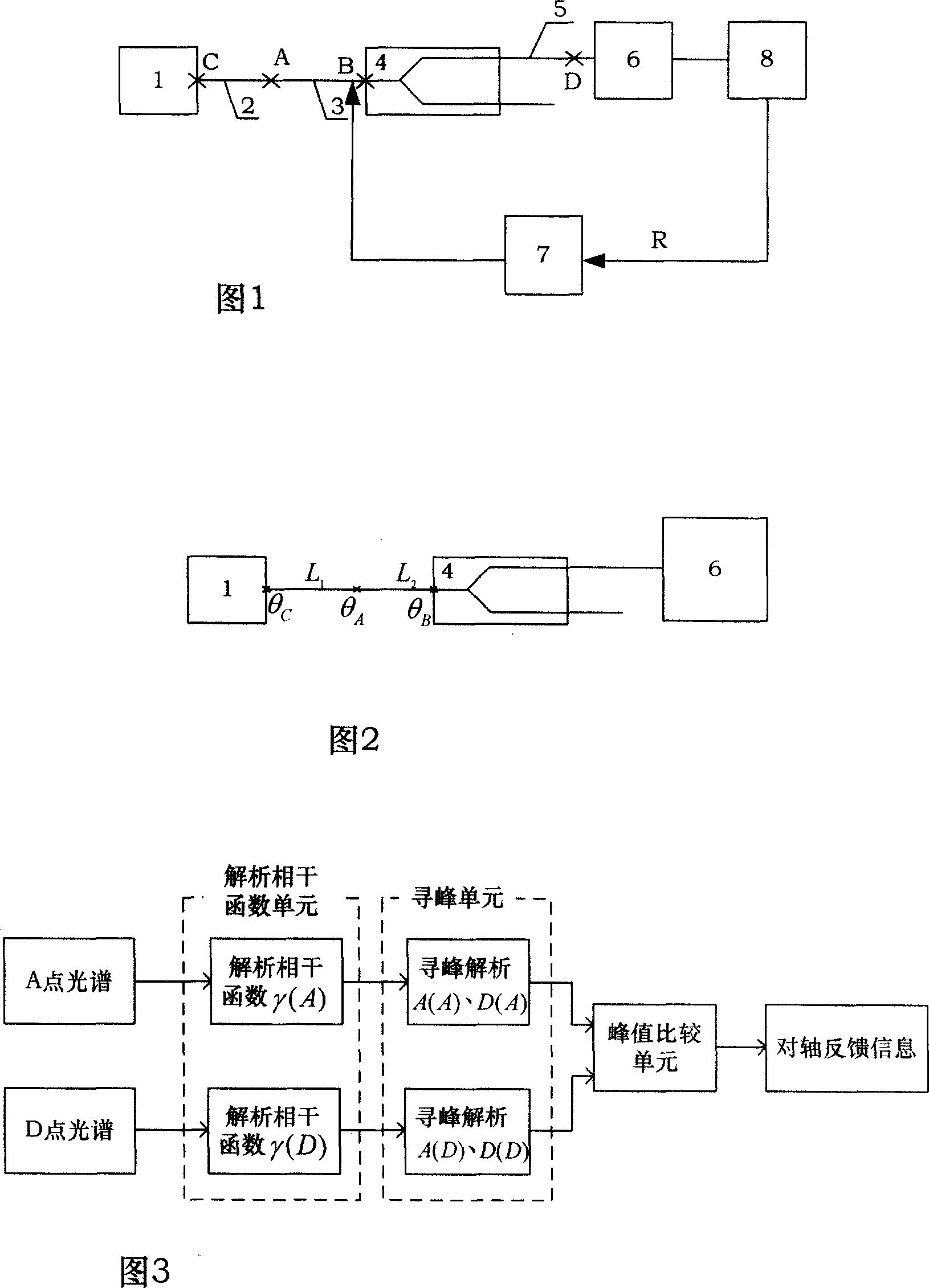

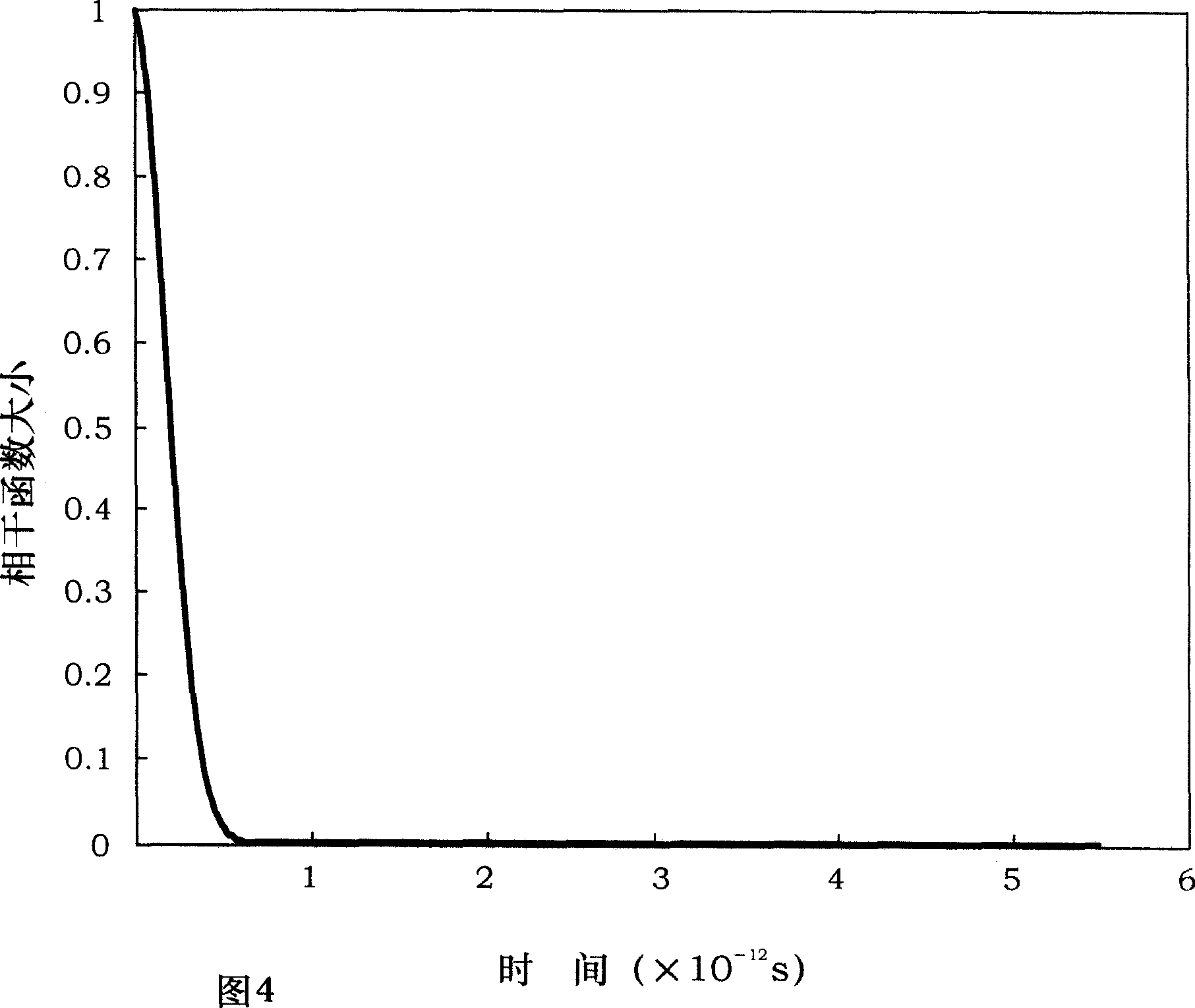

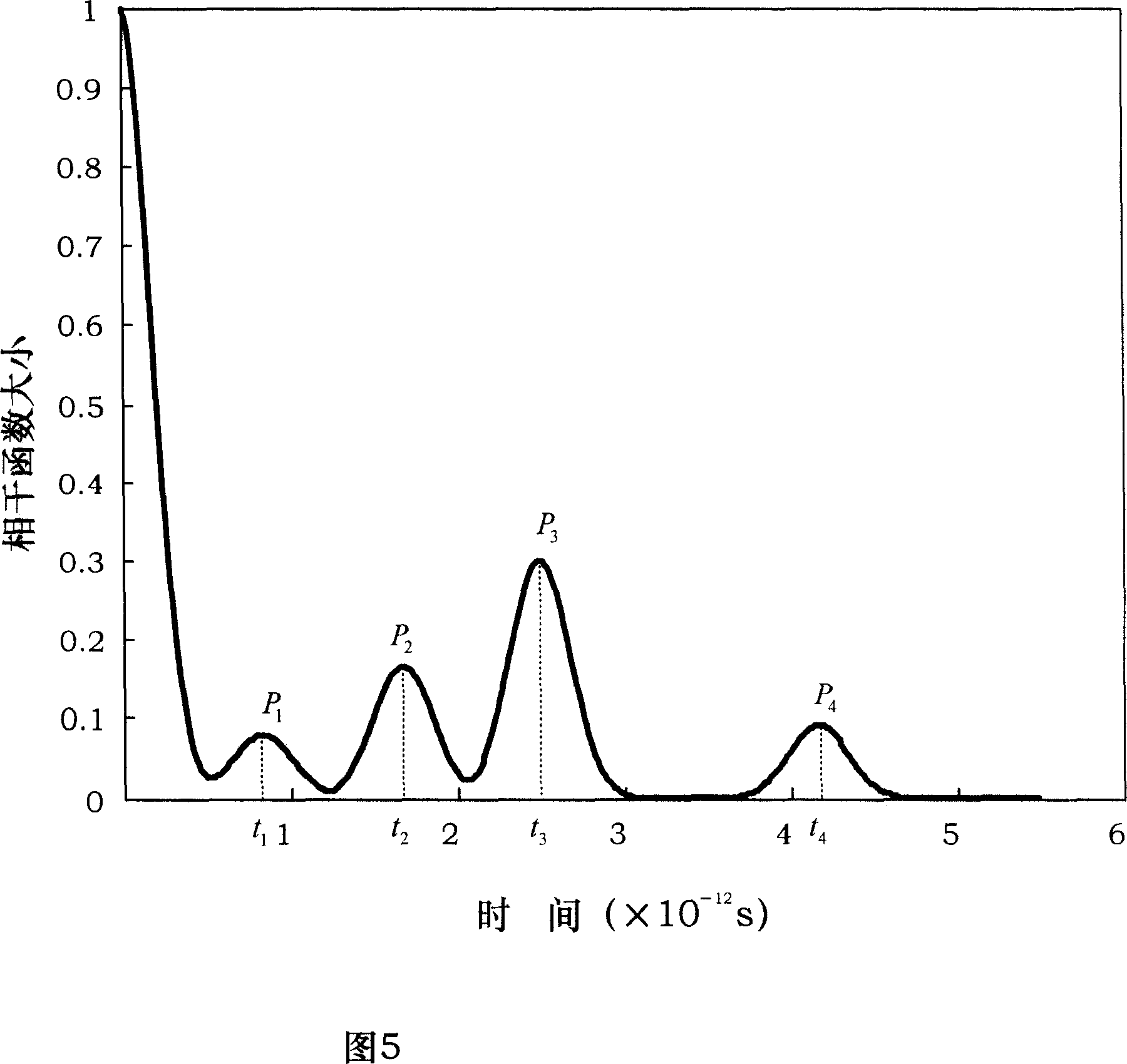

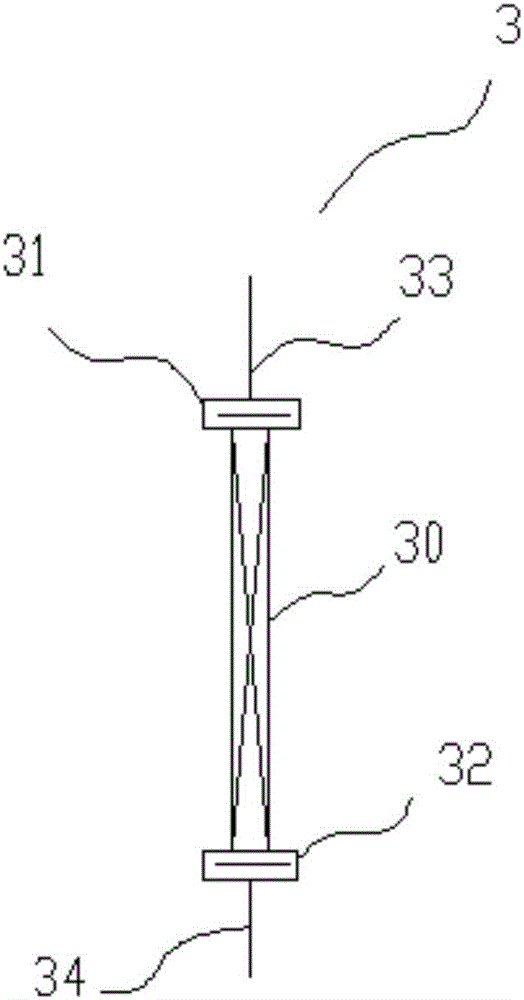

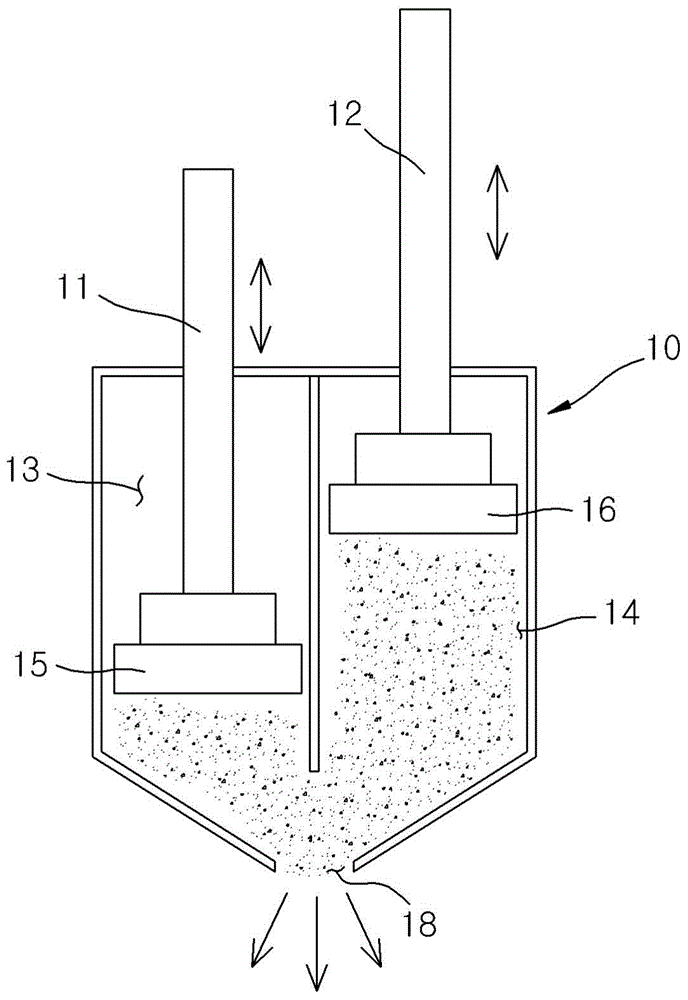

Online alignment device of Y-type waveguide chip and polarization maintaining fiber and online alignment method thereof

This invention discloses one Y waveguide chip and ensures bias fiber online alignment method, wherein, the device is set with light source, bias fiber, Y waveguide chip, light spectrum device, computer, pair axis feedback module and executive structure to rotate fiber. The invention method comprises the following steps: using light source emission light through Y wave guide chip to connect D point spectrum by the device and to analyze relative function information by use of feedback module; then using said relative function information to analyze Y wave guide chip and the bias fiber and feedback information R to executive structure.

Owner:BEIHANG UNIV

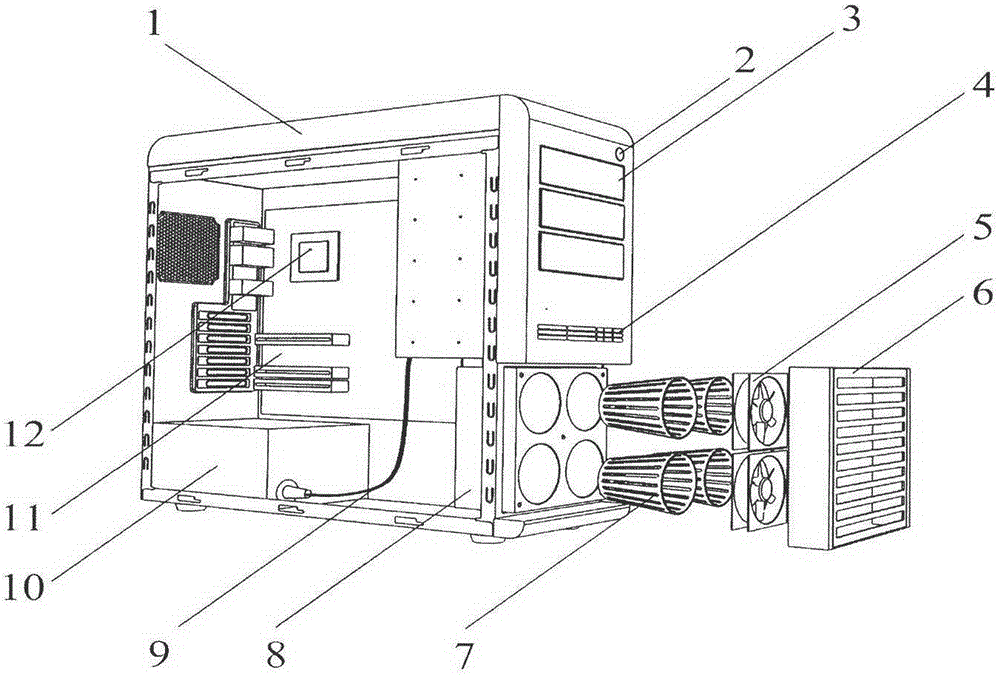

Electronic computer with air filtering and monitoring functions

InactiveCN104007790AAutomate the connectionReduce areaDispersed particle filtrationDigital data processing detailsInformation processingFiber

The invention discloses an electronic computer with air filtering and monitoring functions. Available space in a machine case is utilized for containing a component with the air filtering and monitoring functions, the air filtering and monitoring functions are organically combined by taking the electronic computer as a carrier, ultrafine filter films are adopted on the lower portion of a front panel of the machine case or / and a second side panel of the machine case to be used as air filtering media, information processing and network communication functions are utilized for performing intelligent control and humanized prompt on the air filtering function and effect, a detection head of a temperature measuring element is arranged beside a computer CPU, the computer enables the temperature change amplitude to be compared with the set value in real time, and intelligent monitoring and replacement prompt of the filter screen blocking condition can be achieved. A melt electrostatic spinning method or a water base environment-friendly solution electrostatic spinning method or other methods can be adopted for manufacturing hollow filling material ultrafine fibers of a filter screen cup and a filter screen plate, the toxic action does not exist, the hollow position of the filter plate can be directly filled with the output fibers, the product machining technological process is reduced, production time is saved, and production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH +1

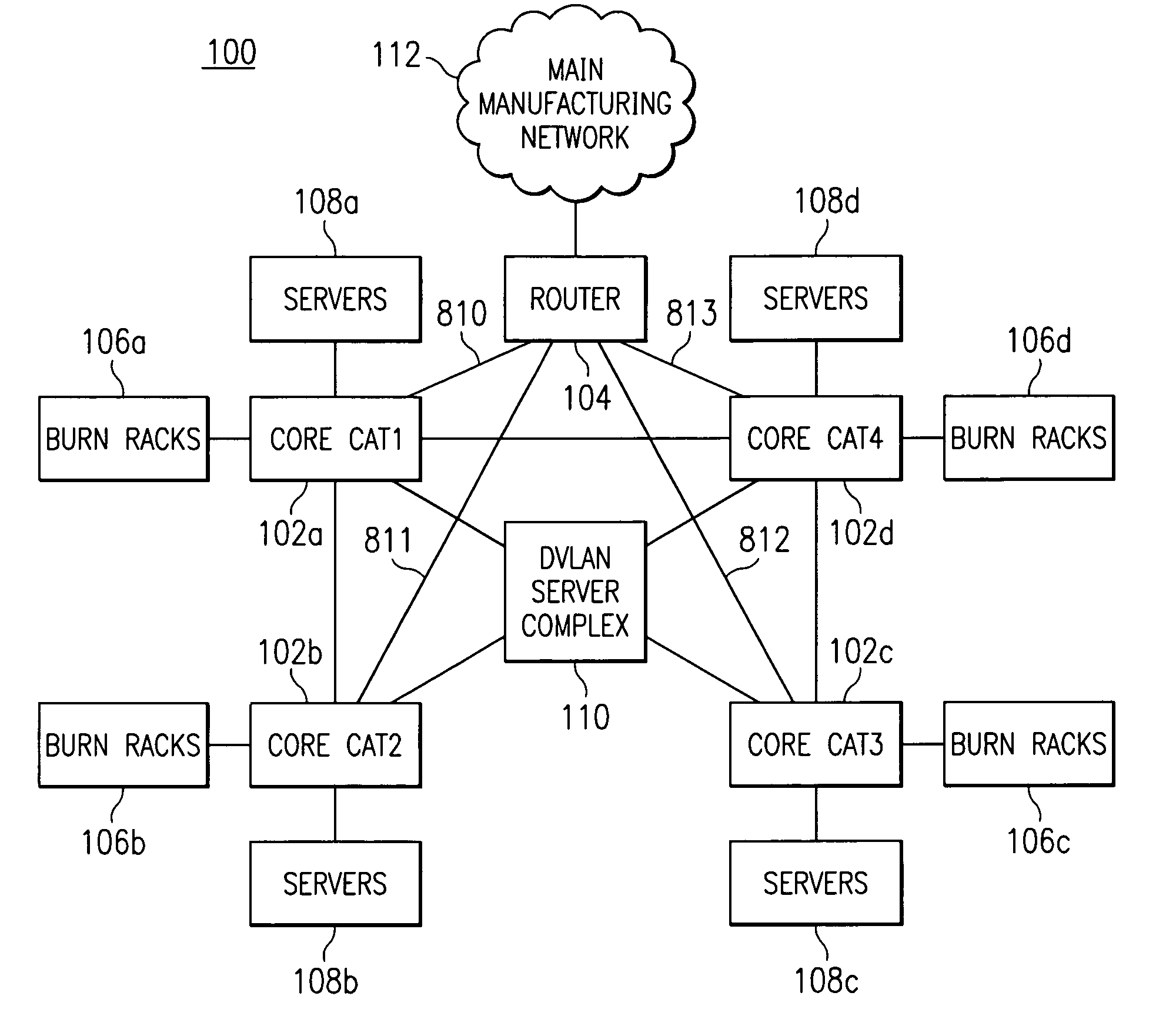

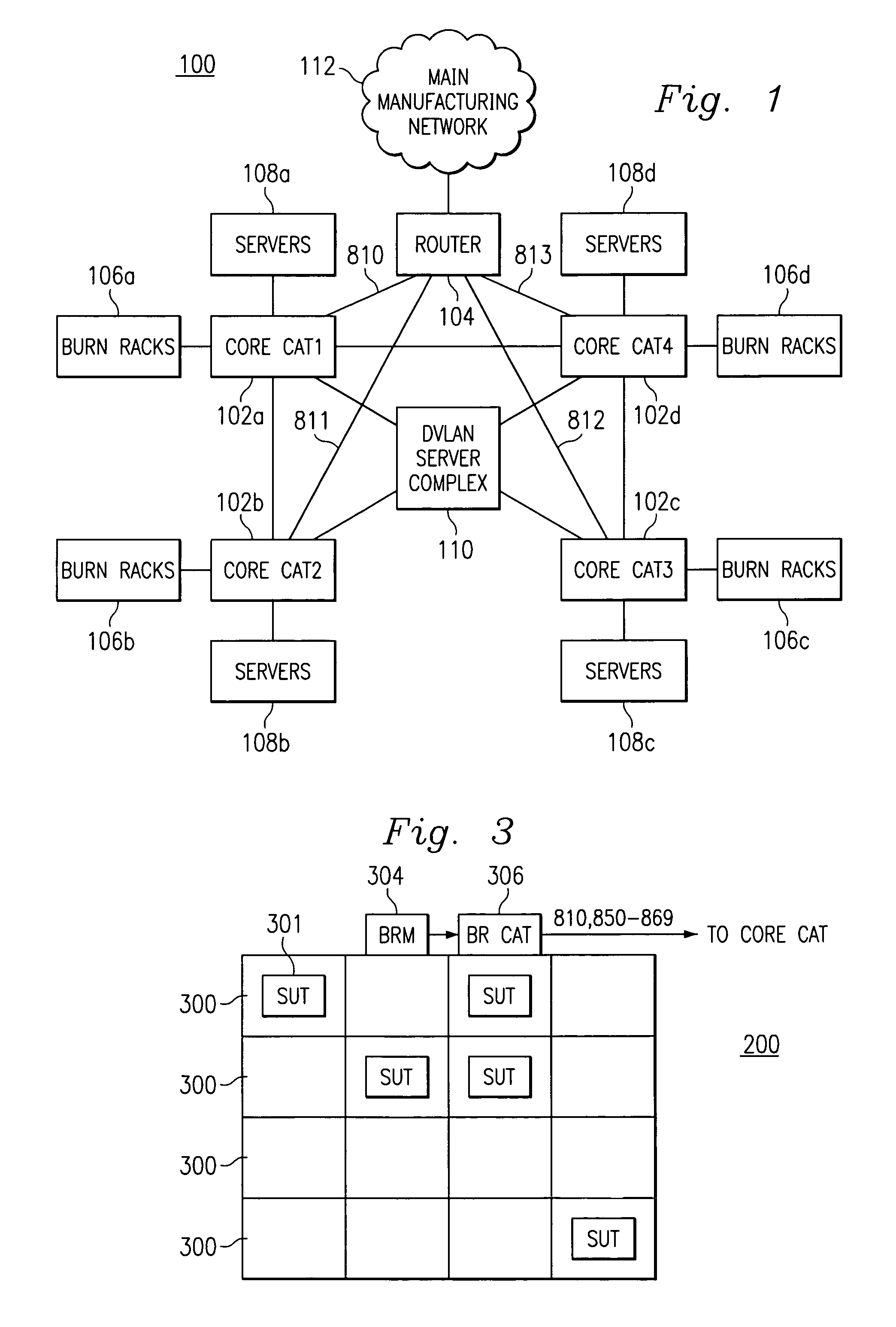

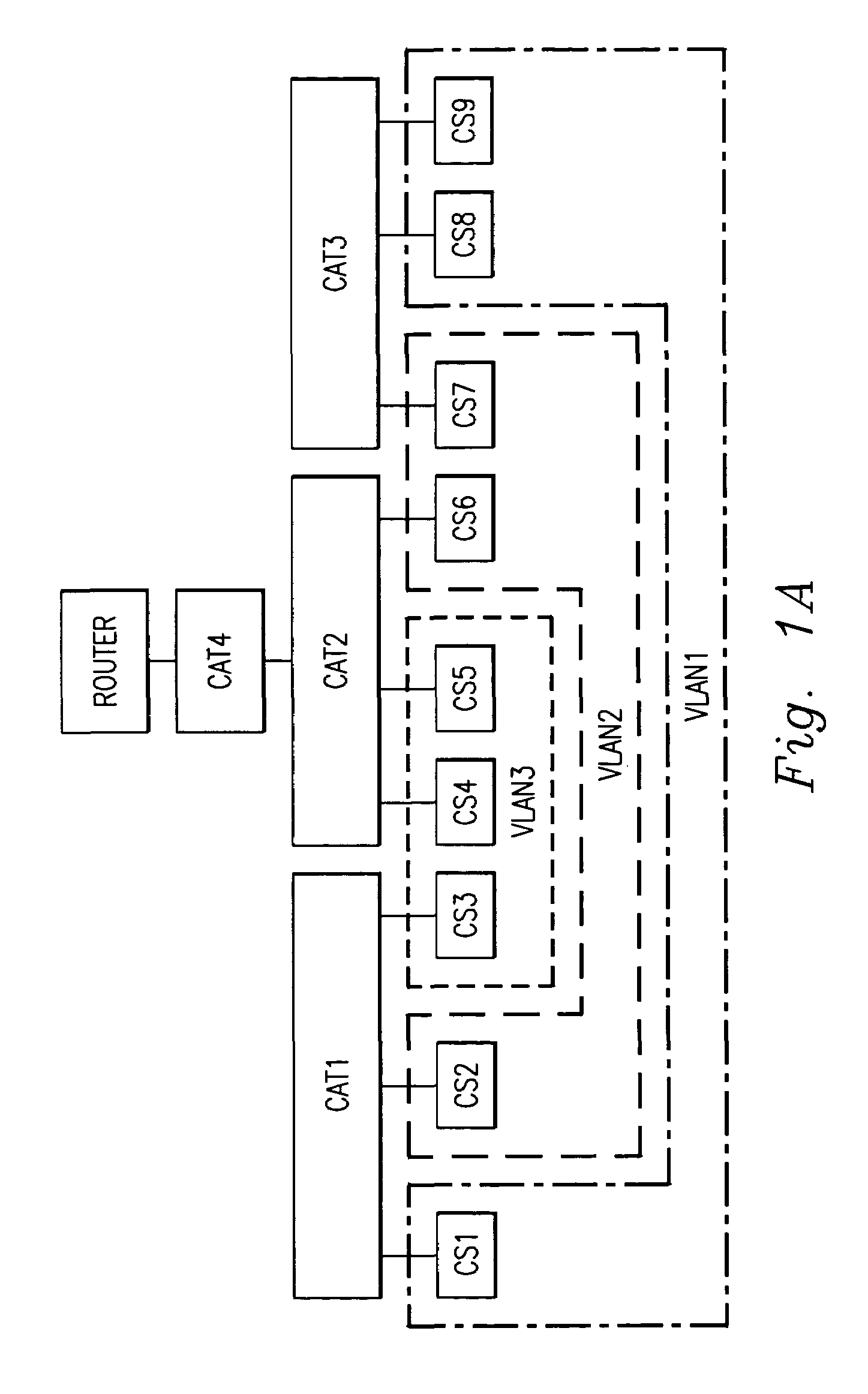

Site-to-site dynamic virtual local area network

InactiveUS6977900B2Reduce the amount requiredOptimizationError preventionFrequency-division multiplex detailsVirtual LANPrivate network

A system for dynamically implementing a plurality of virtual local area networks (“VLANs”) across multiple sites is provided. The system includes a first VLAN-capable switch at a first site; a first system under test (“SUT”) connected to the first VLAN-capable switch via a first burn rack switch; a second VLAN-capable switch located at a second site remote from the first site; a second SUT connected to the second VLAN-capable switch via a second burn rack switch. The first and second VLAN-capable switches are connected such that the first and second SUTs are connected to a single virtual private network (“VPN”). The connection may include either first and second routers respectively connected to the first and second VLAN-capable switches and interconnected via a T1 line or an ATM connection. The system may also include a first VLAN-capable switch located at a first site; a first system under test (“SUT”) connected to the first VLAN-capable switch via a first burn rack switch; a second VLAN-capable switch located at a second site remote from the first site; a customer network located at a customer site remote from the first and second sites and connected to the second VLAN-capable switch via a router; and an ATM connection between the first and second VLAN-capable switches such that the first SUT and the customer network are connected to a single virtual private network (“VPN”). In this embodiment, the connection between the second site and customer site may be either an Internet connection or a high speed point-to-point connection.

Owner:DELL PROD LP

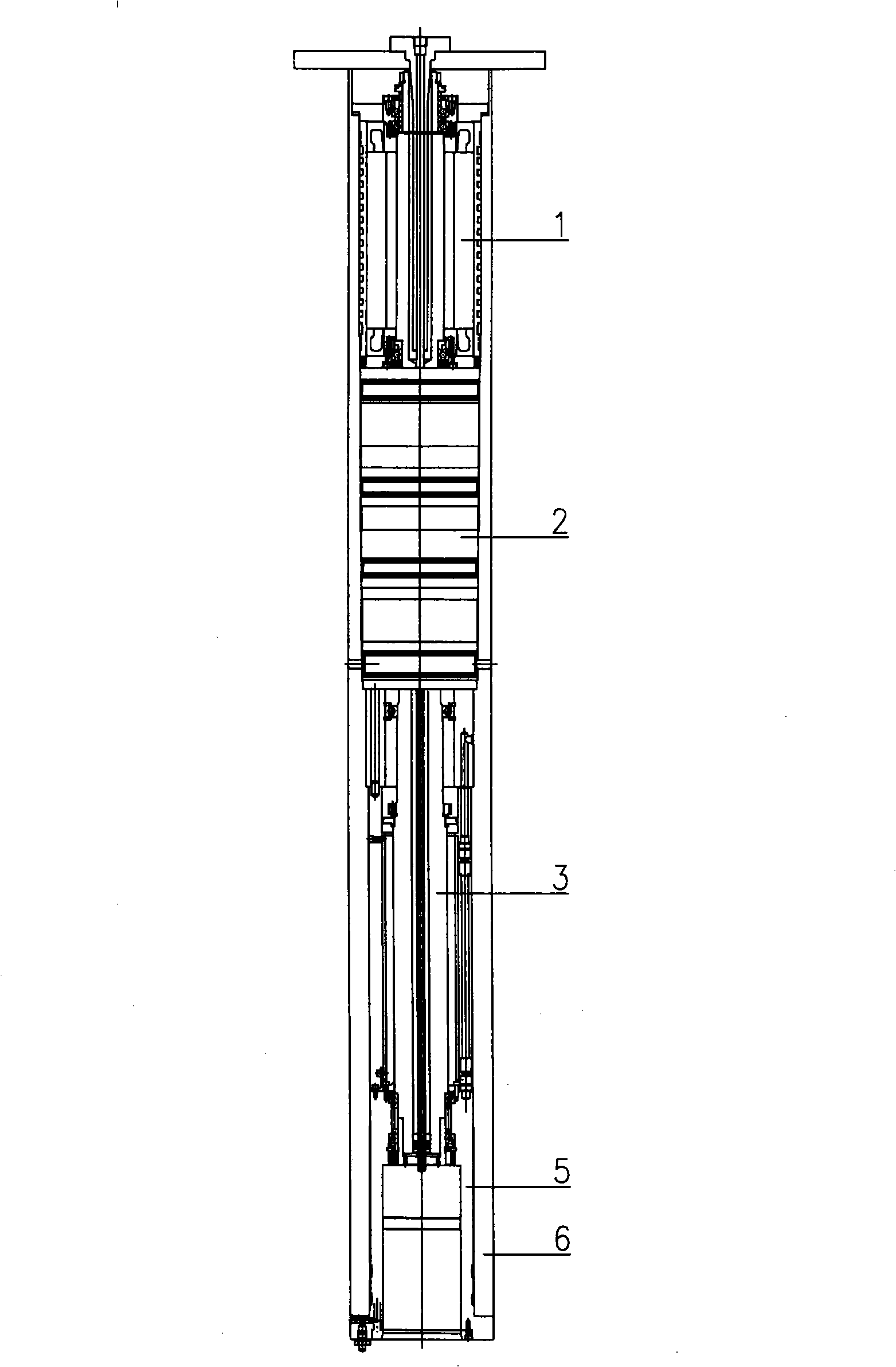

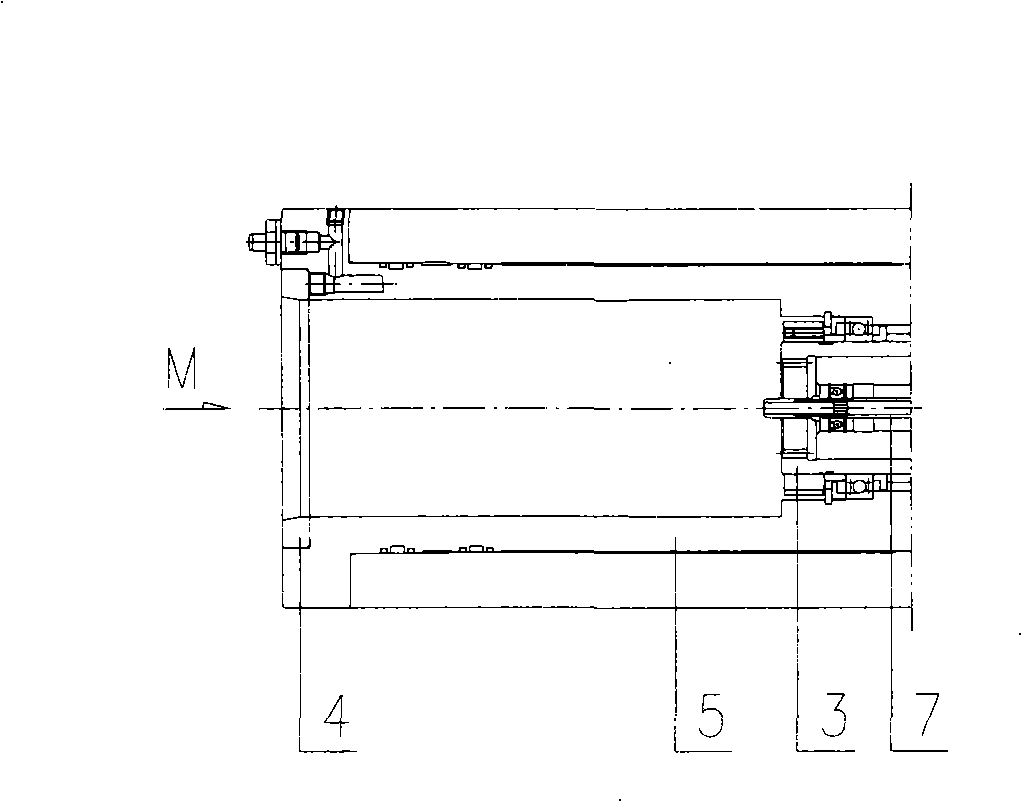

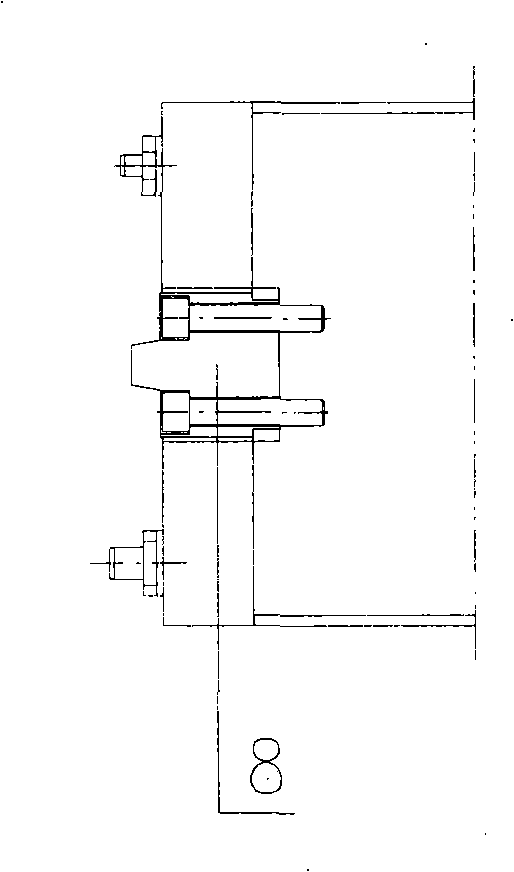

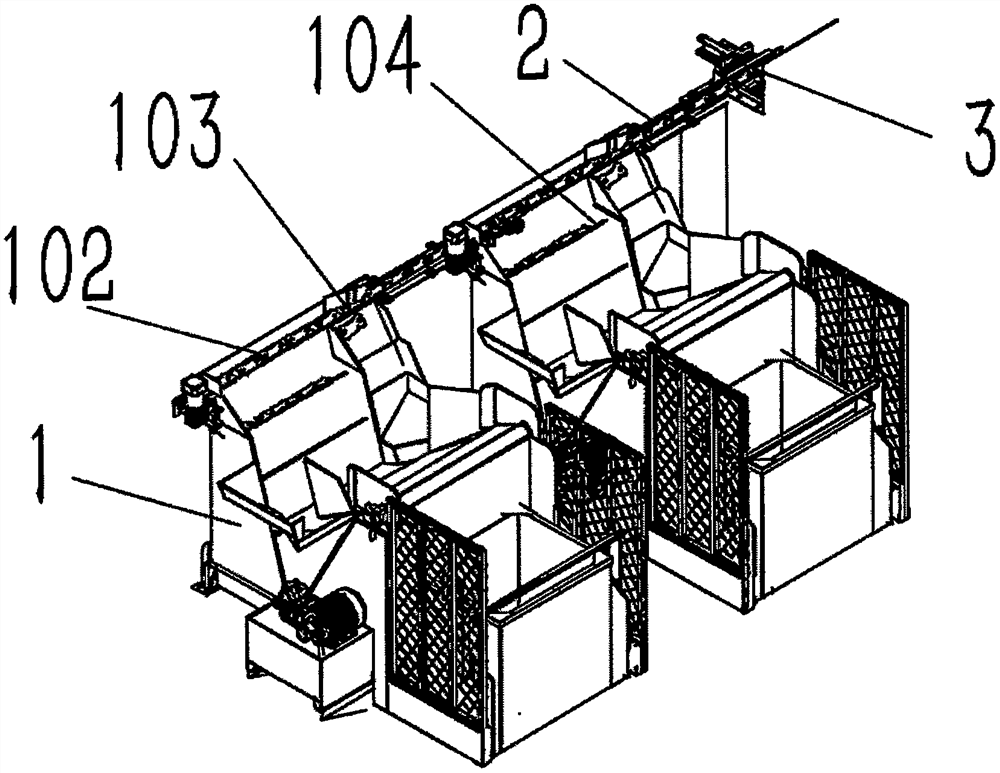

Milled composite ram apparatus

InactiveCN101342660ACompact structureReduce volumeOther manufacturing equipments/toolsLarge fixed membersGear wheelEngineering

The invention discloses a turn-milling compound ram device which comprises a motor, a gear box, an output shaft, and mechanisms and pipelines which are connected with an accessory head. The turn-milling compound ram device is characterized in that the parts are integrated in the casing of the ram. The motor and a speed reducer are arranged in the upper end of the casing. The external gear of the output shaft is connected with the gear box. The lower opening of the gear box is connected with a comparatively short power output shaft. The maximum output power reaches 52KW; torque moment reaches 2400Nm; and rotary speed reaches 3150r / min. the power output shaft is connected with a connecting structure. A connector is provided with a centering short taper, two wedge-shaped bonding transmission torque moments and four mechanical autolocking tightening mechanisms. The ram is provided with liquid, gas and electric pipe lines on the wall of the casing. The end connector of the ram is provided with line clutches thereof. The pipe lines and mechanical parts are connected automatically with the accessory head of operating parts. The turn-milling compound ram device has a compact internal structure in the ram device, has a comparatively short output shaft, improves power output ability, and has a small volume of the ram device with the section size of 280mm long and 240mm wide. The connections between the ram and the operating equipment such as a cutter, a core milling head and so on can realize the purposes of general use and automatic connection.

Owner:SHENYANG MASCH TOOL CO LTD

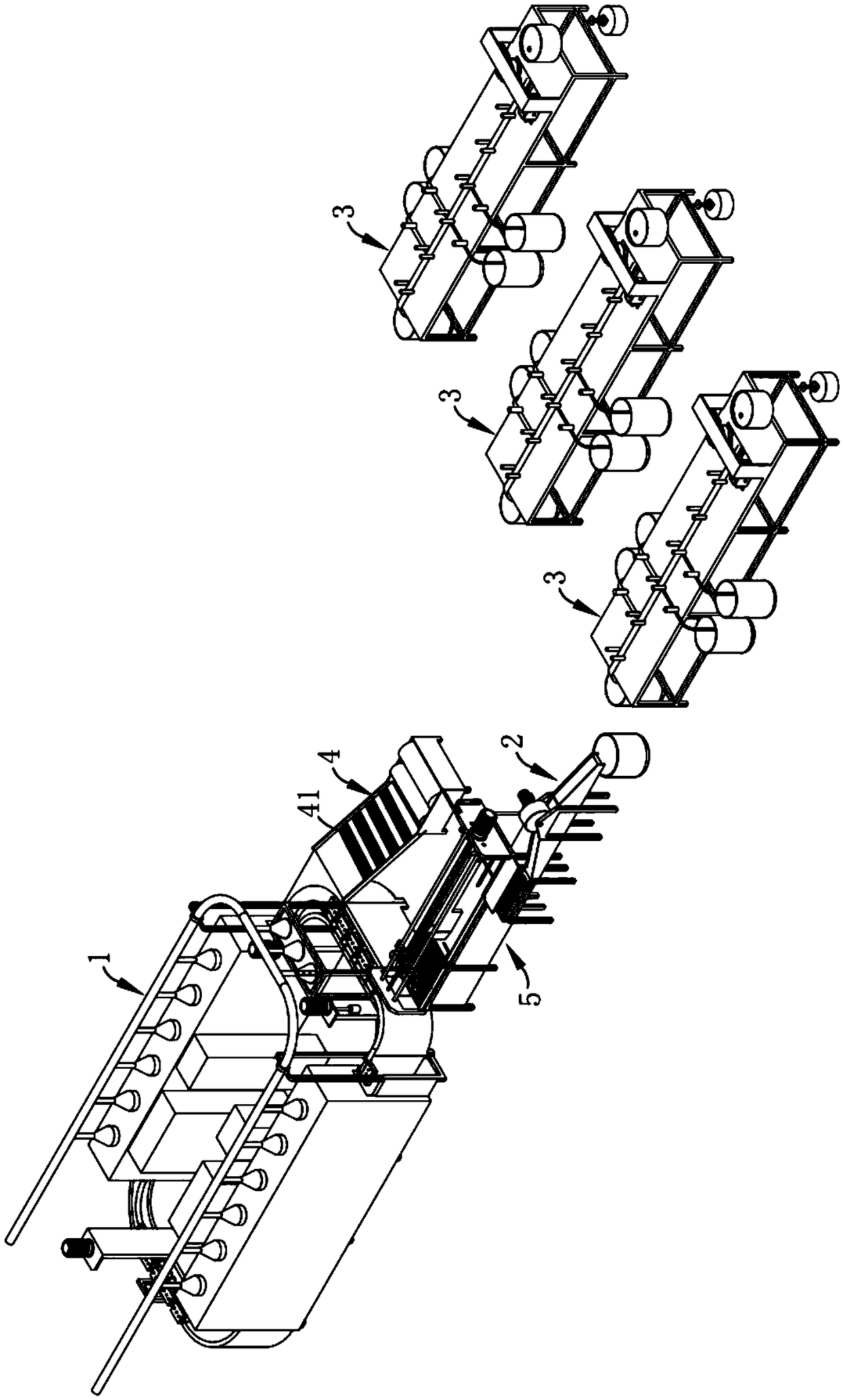

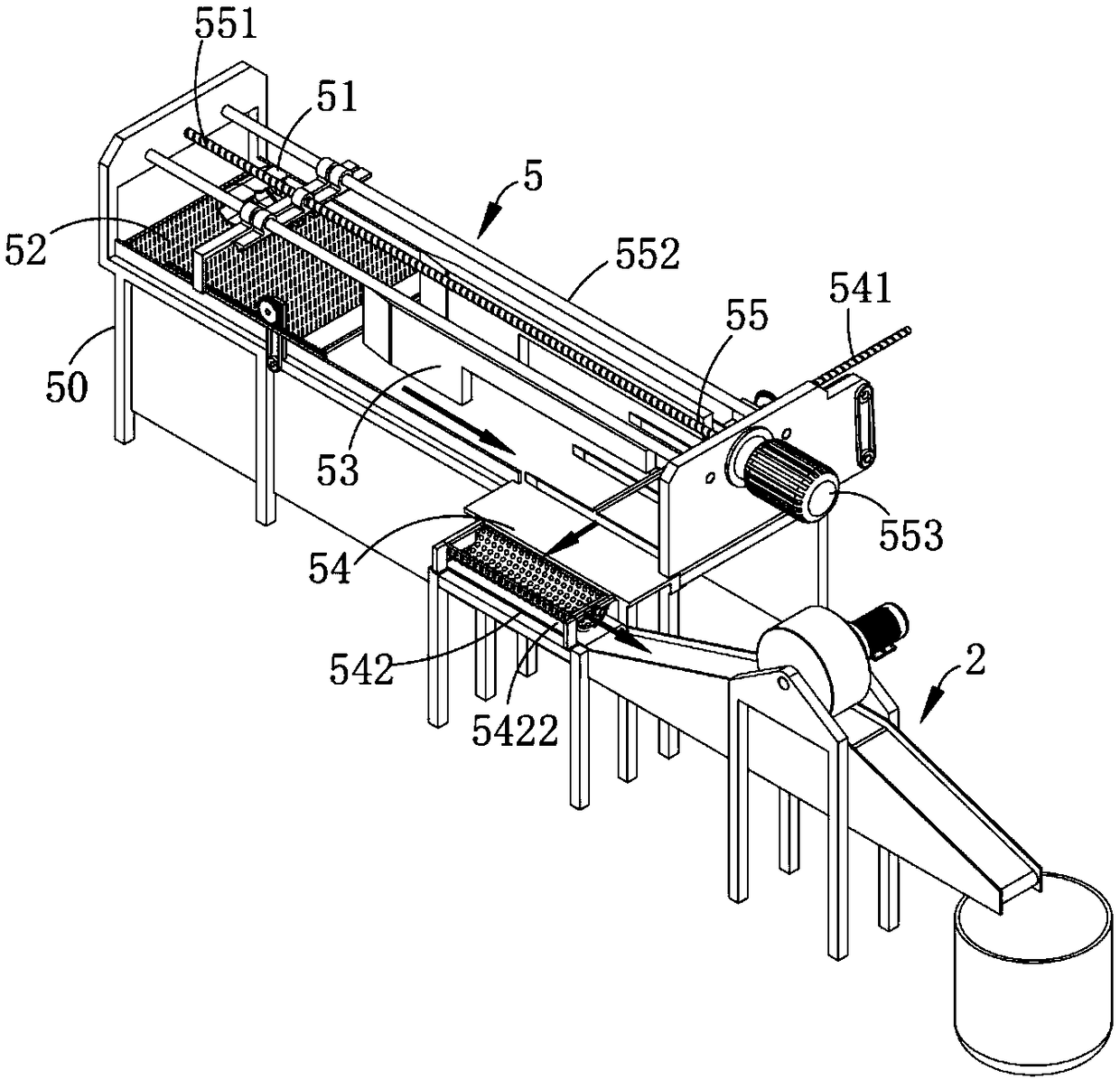

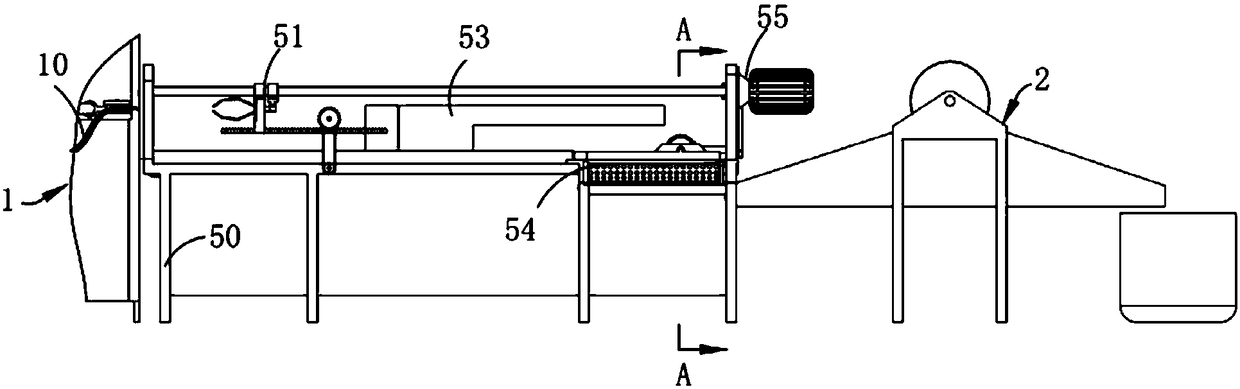

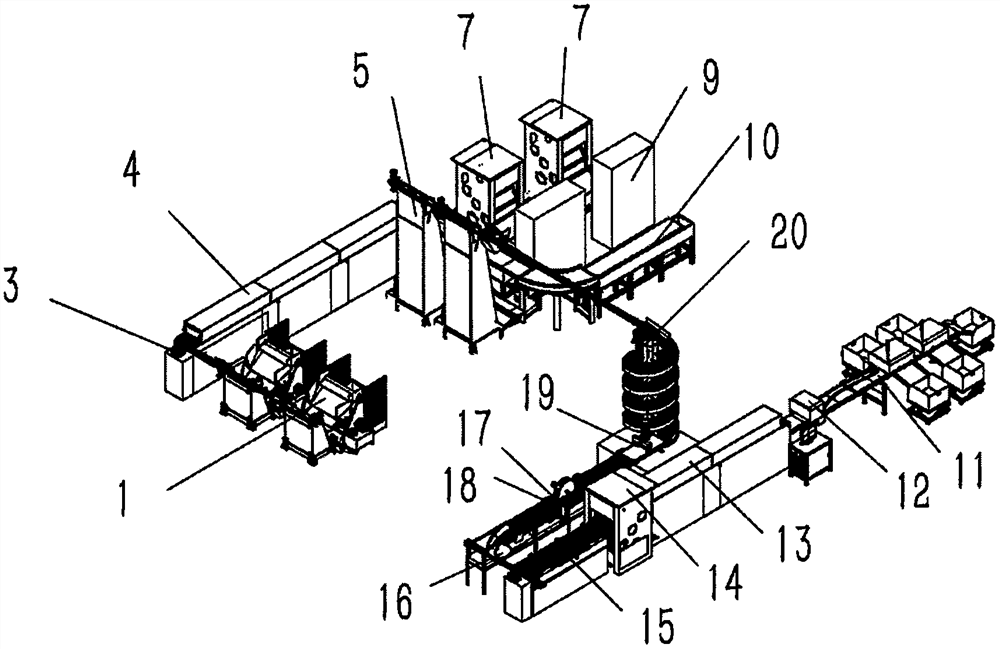

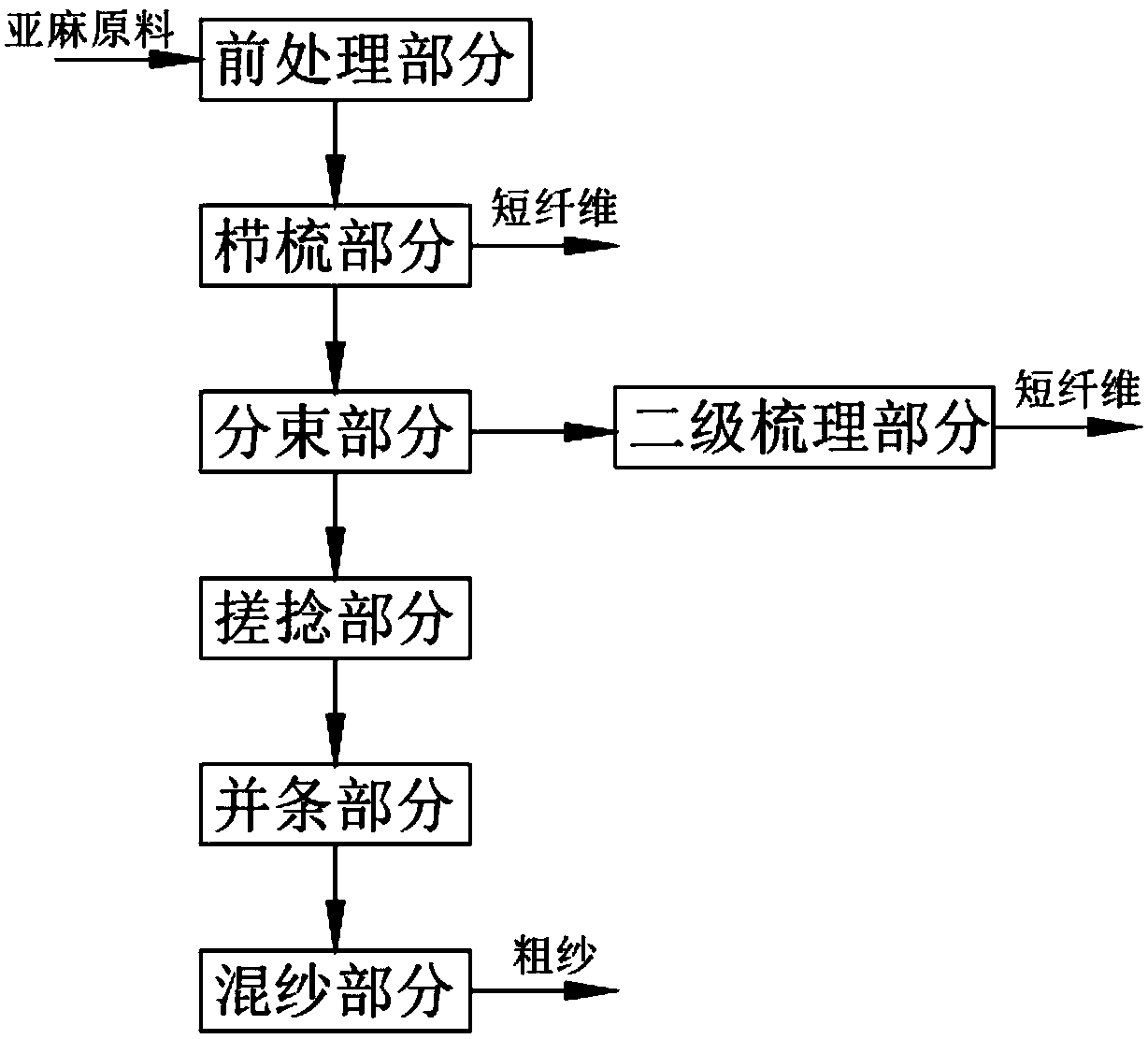

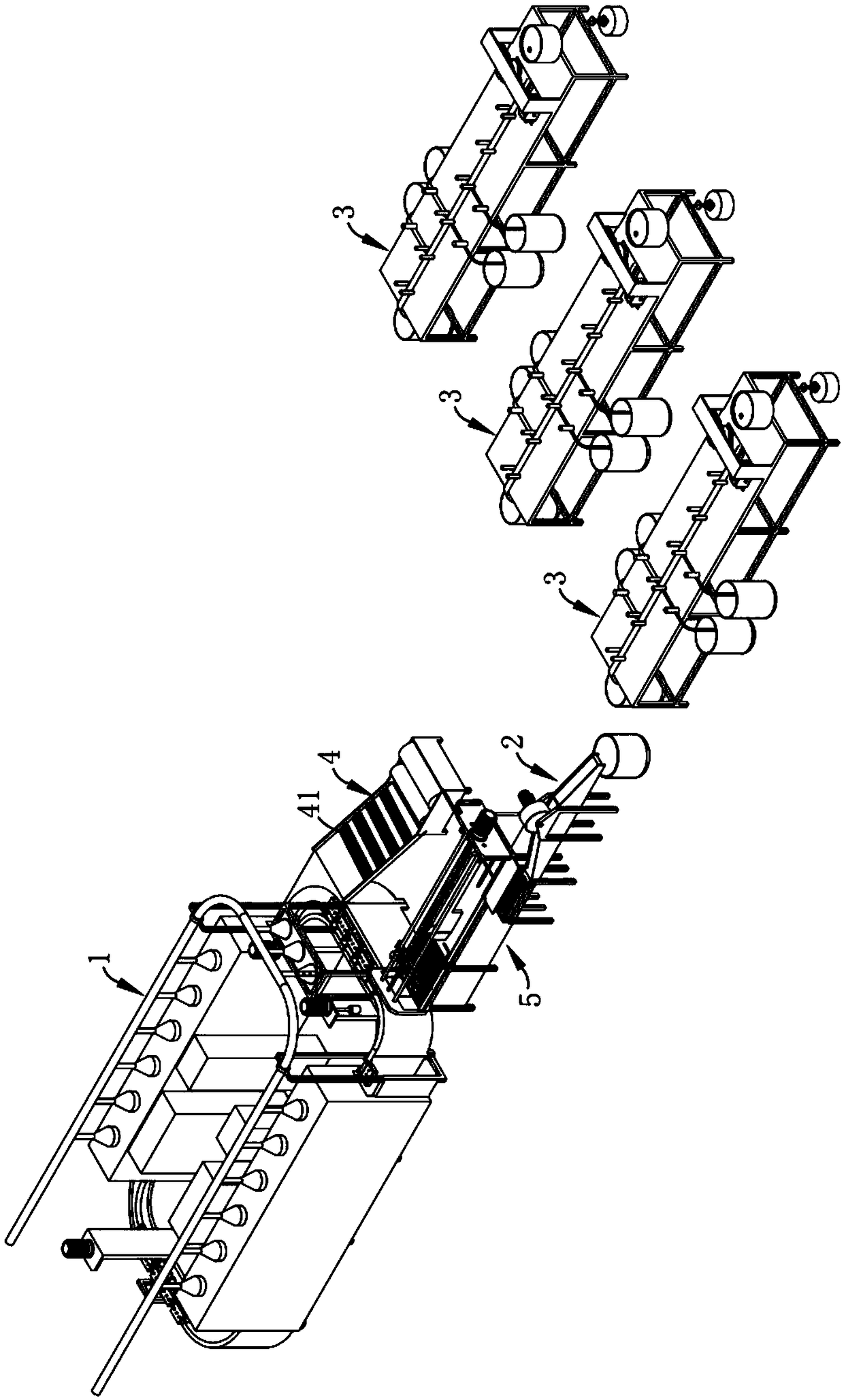

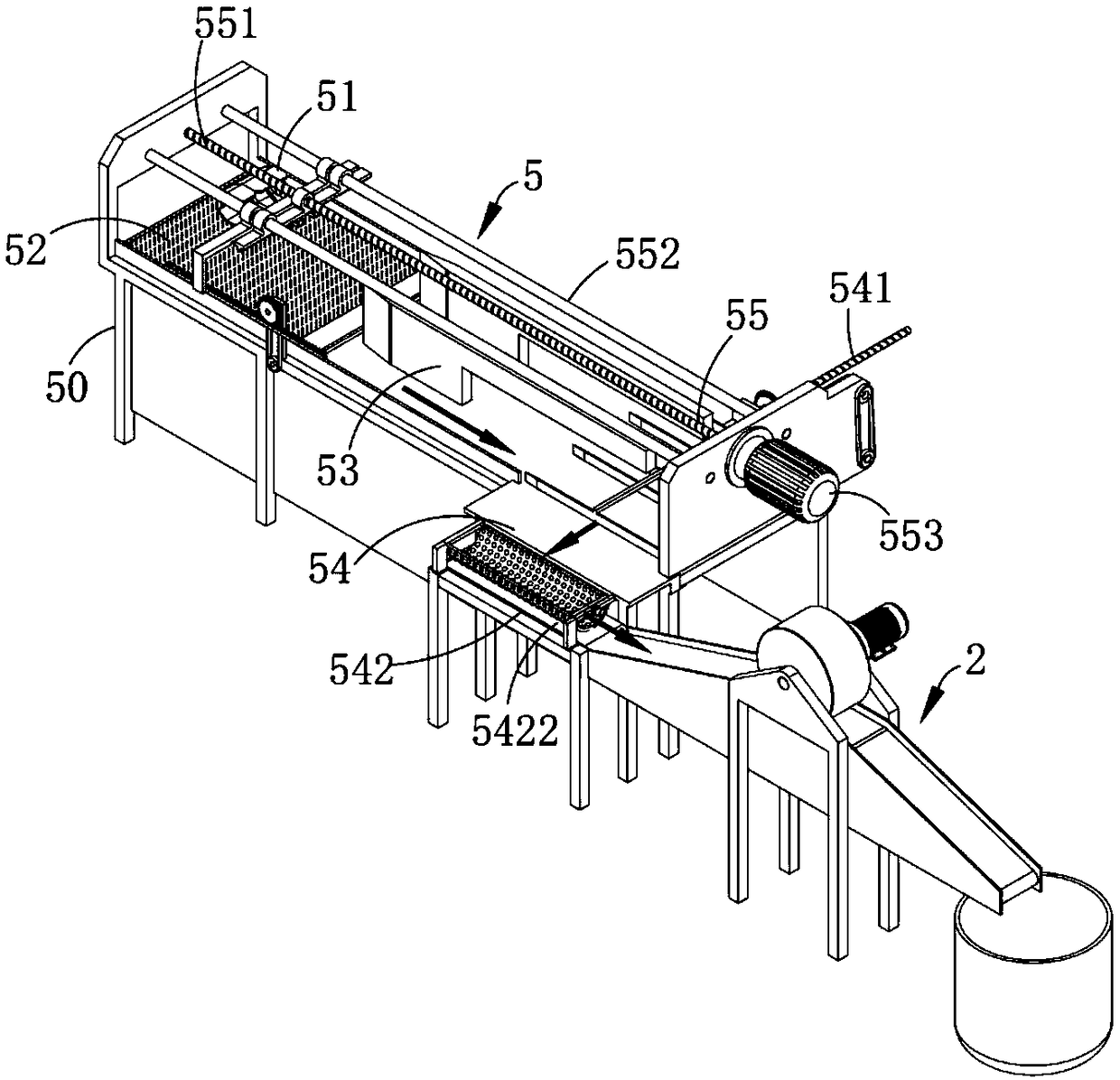

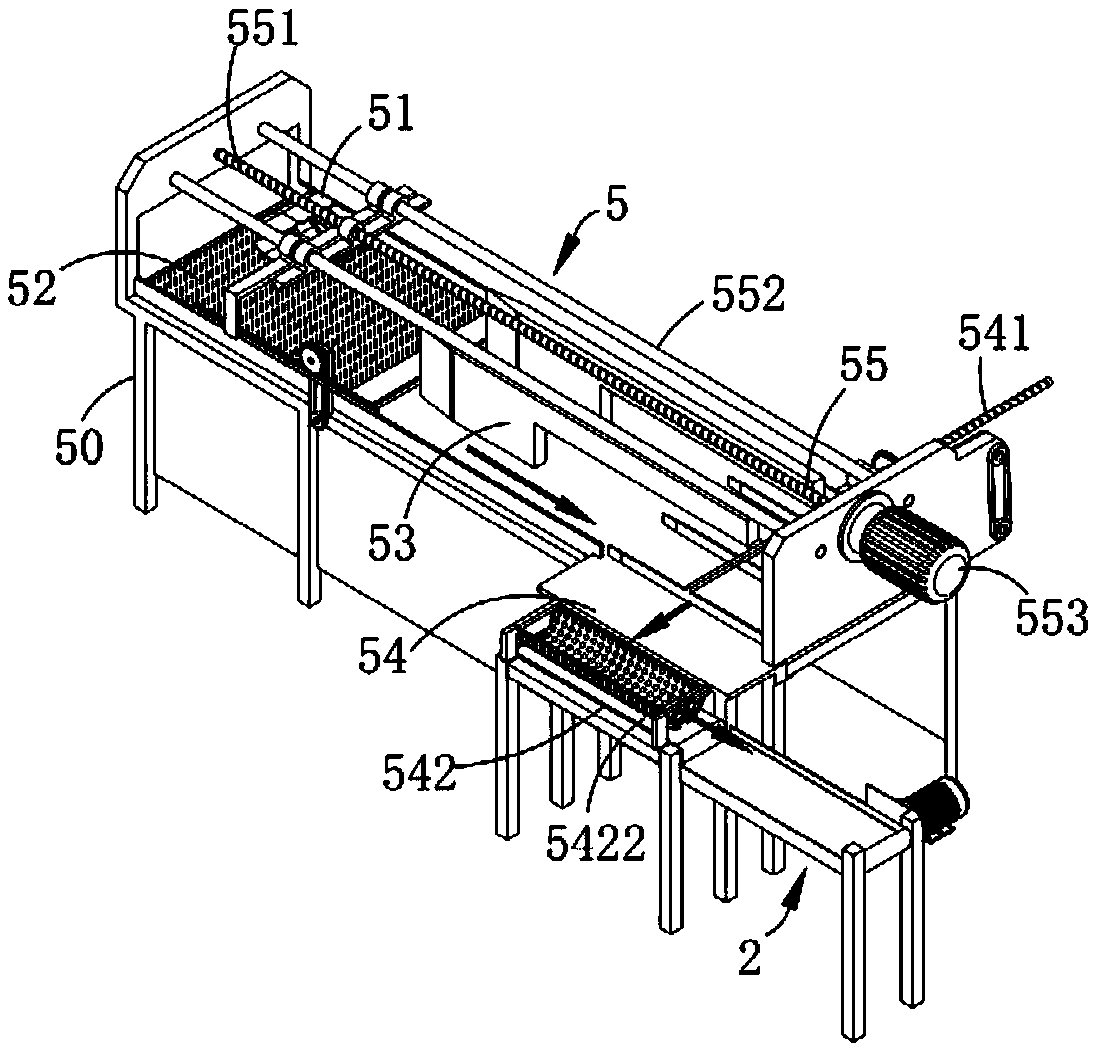

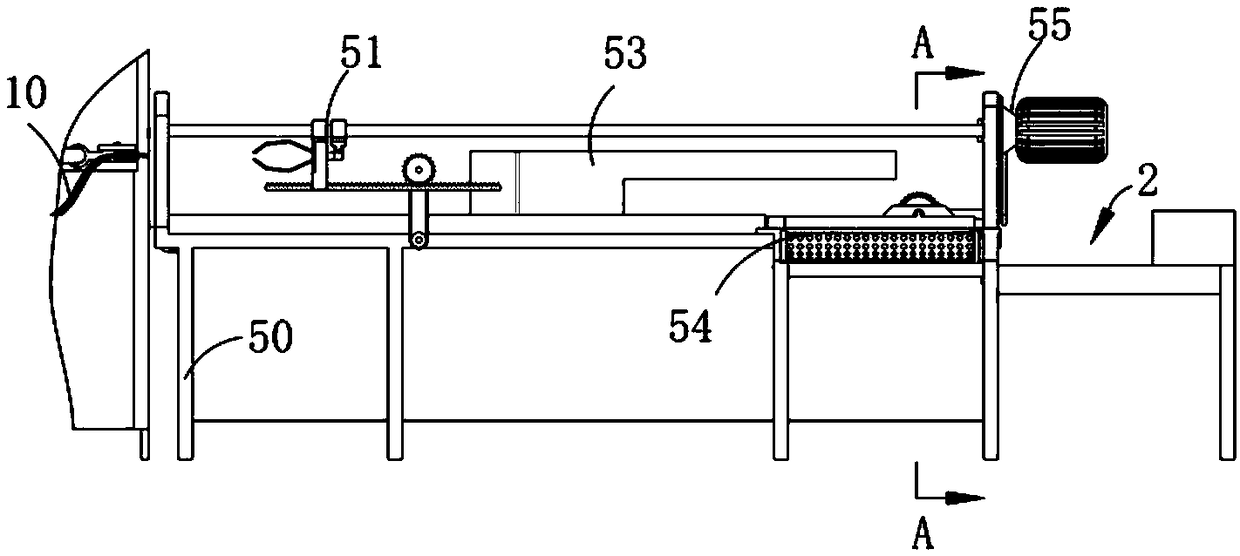

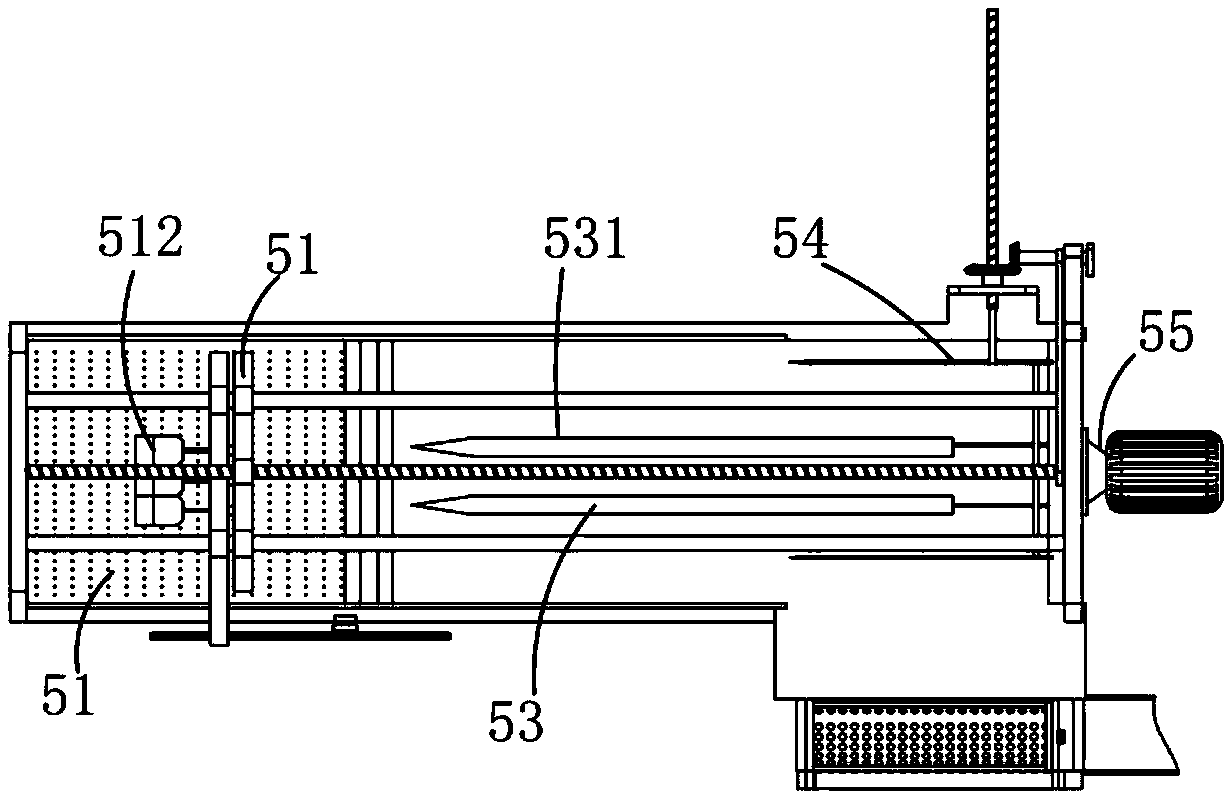

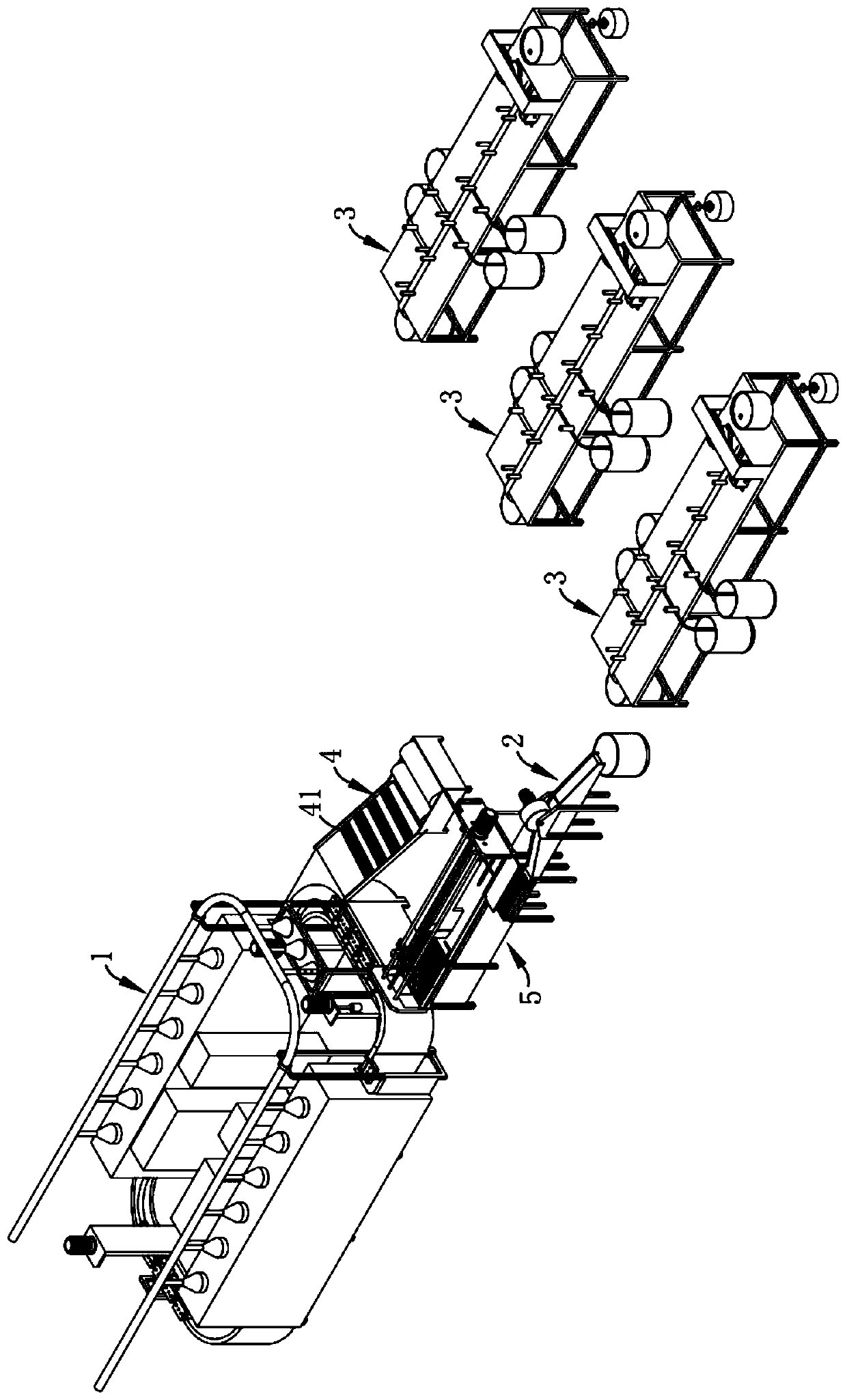

Continuous automatic production line for flax yarn

InactiveCN108950750AAutomate the connectionImprove reliabilityPiercing arrangementsContinuous processingState of artYarn

The invention relates to the technical field of flax yarn production, in particular to a continuous automatic production line for flax yarn. The production line comprises a raw material pretreatment device, a hackling machine, an automatic flax fiber material adding device, a drawing frame and a yarn mixing machine; the automatic flax fiber material adding device comprises a traction mechanism, asplitting mechanism and a material adding mechanism; a fiber bundle obtained after overlapping and winding is transferred into the drawing frame, a fiber rod is formed, and the fiber rod is made intorough yarn through the yarn mixing machine; by means of the traction mechanism, in the process of conducting directional transfer o the flax yarn, short fiber removing and fiber bundle separation areconducted on the flax yarn by cooperating with a carding mechanism and the splitting mechanism respectively, by combining the transmission connection characteristic of a lap joint mechanism and a driving mechanism, automatic winding in the end-to-end lapping process of the fiber bundle is achieved, high-quality automatic production of flax splitting and lapping is achieved, and the technical problem that in the prior art, due to the fact that manual splitting it not uniform, the yarn quality is not stable is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

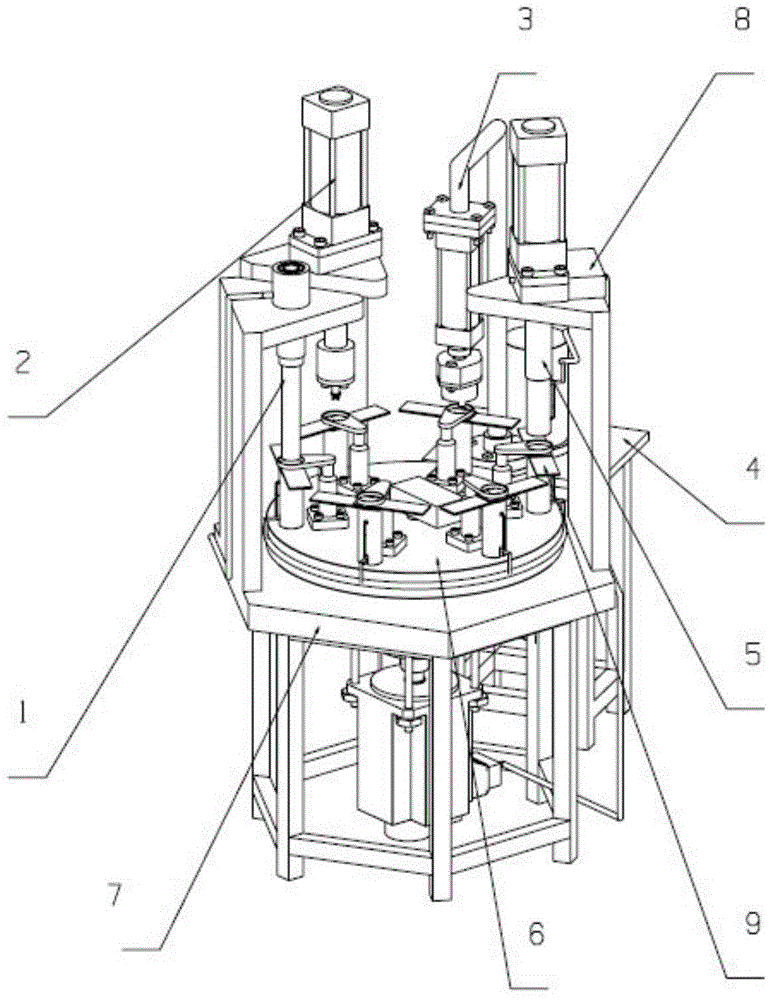

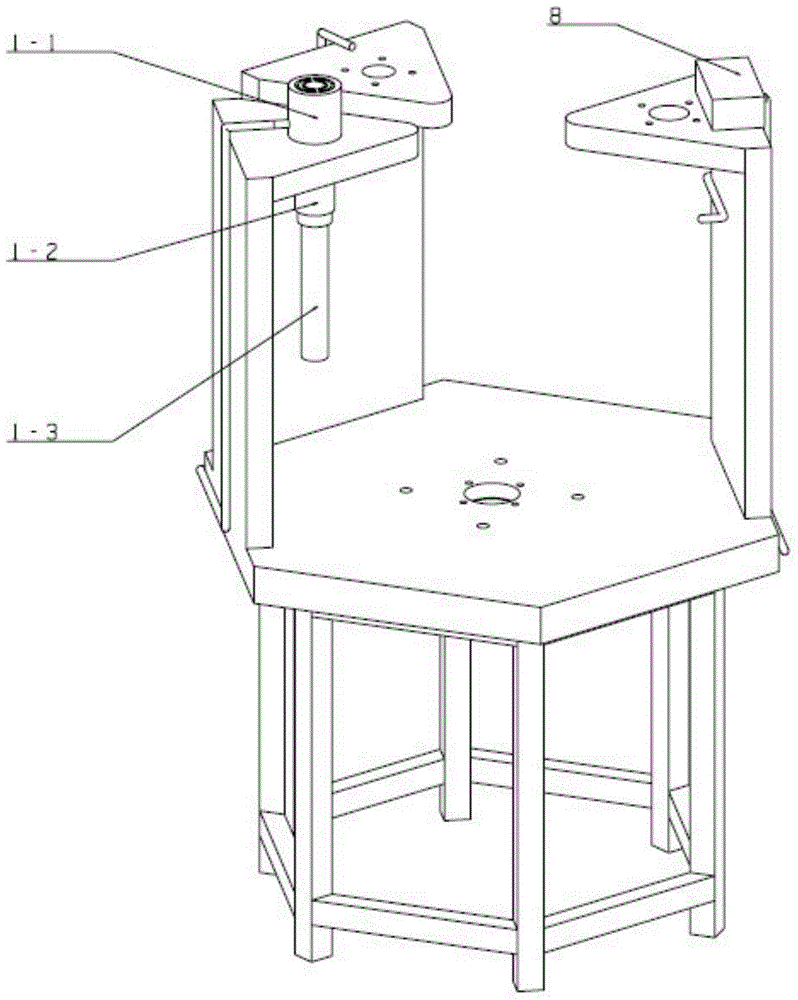

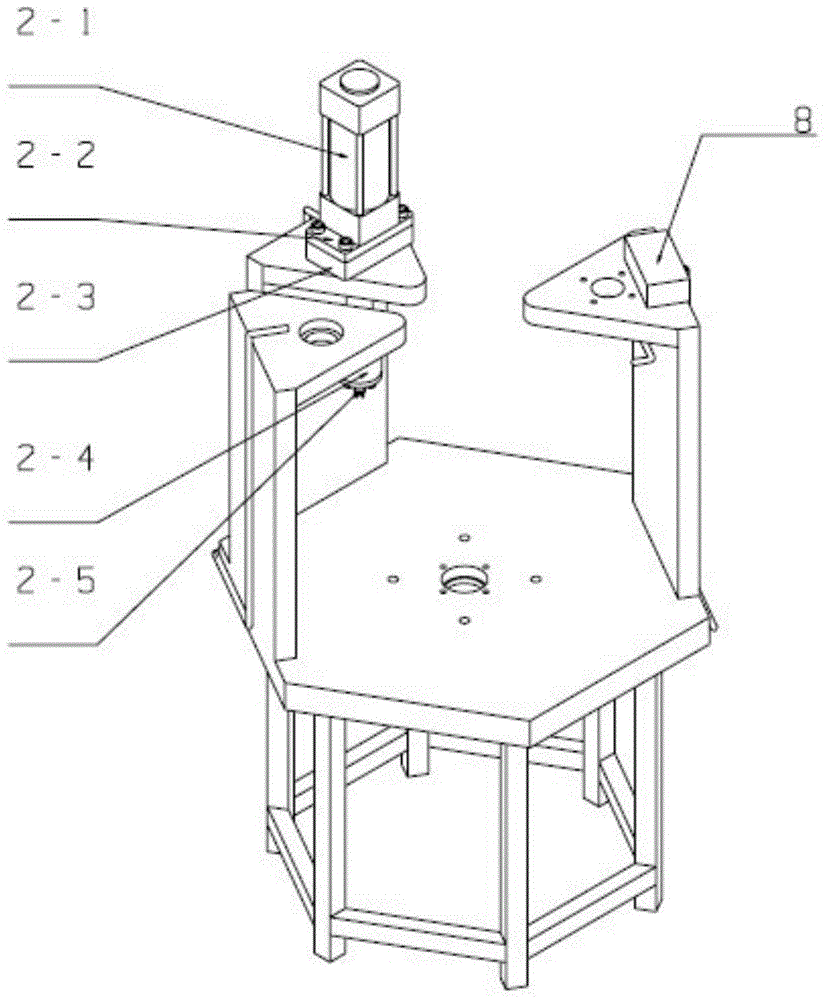

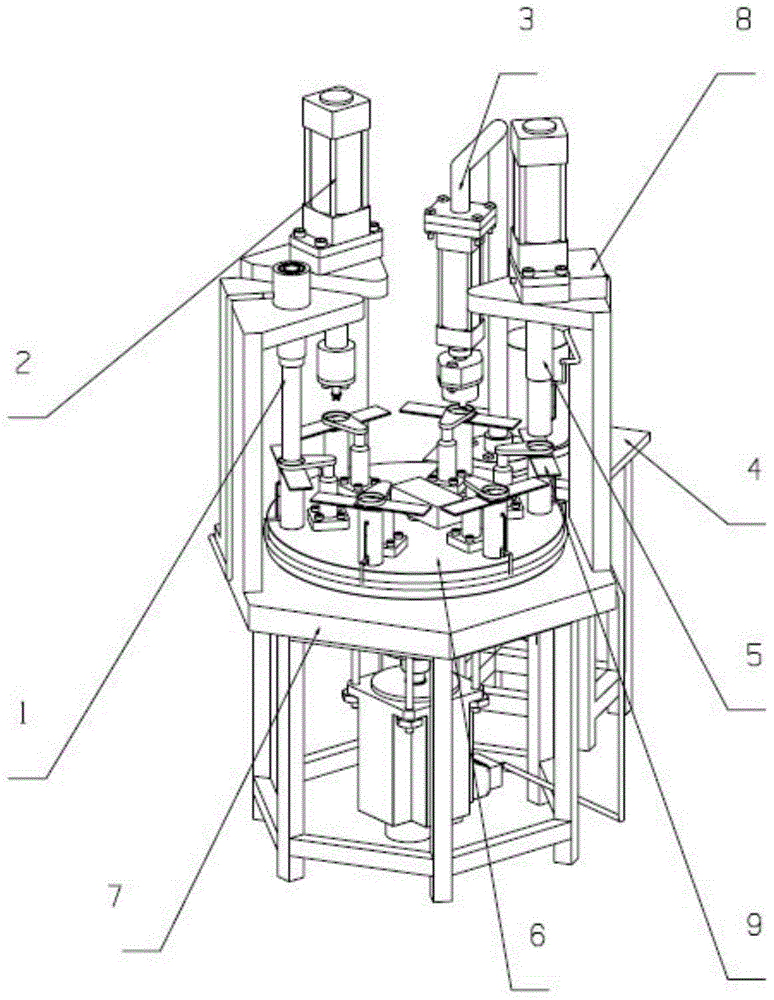

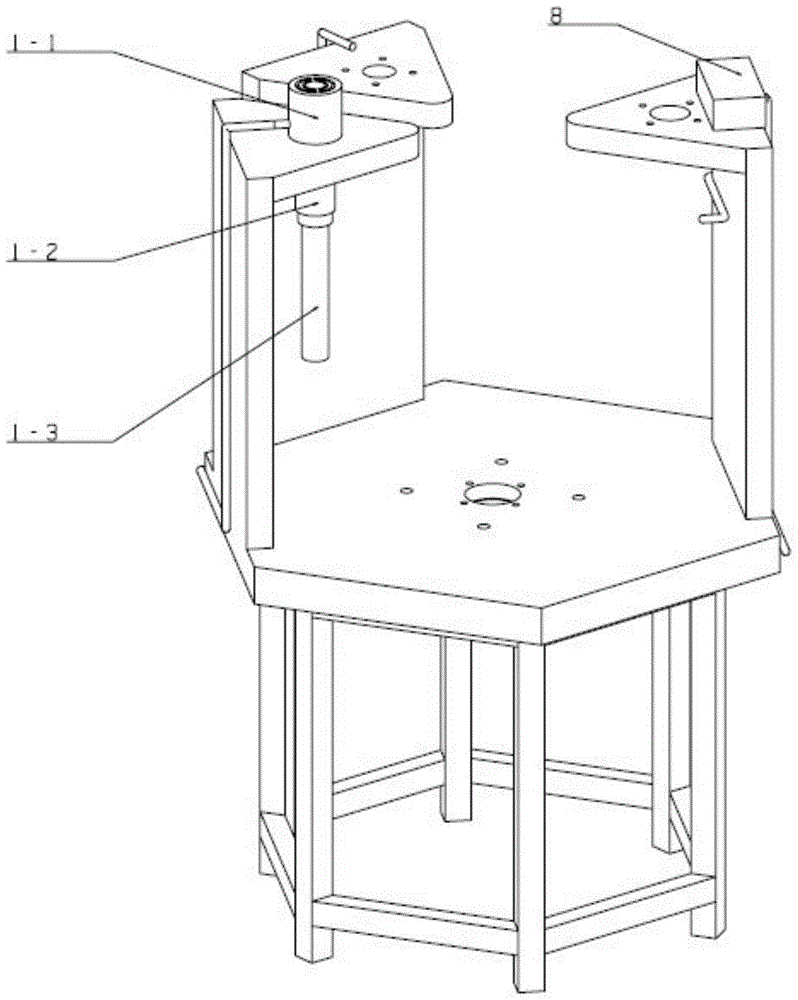

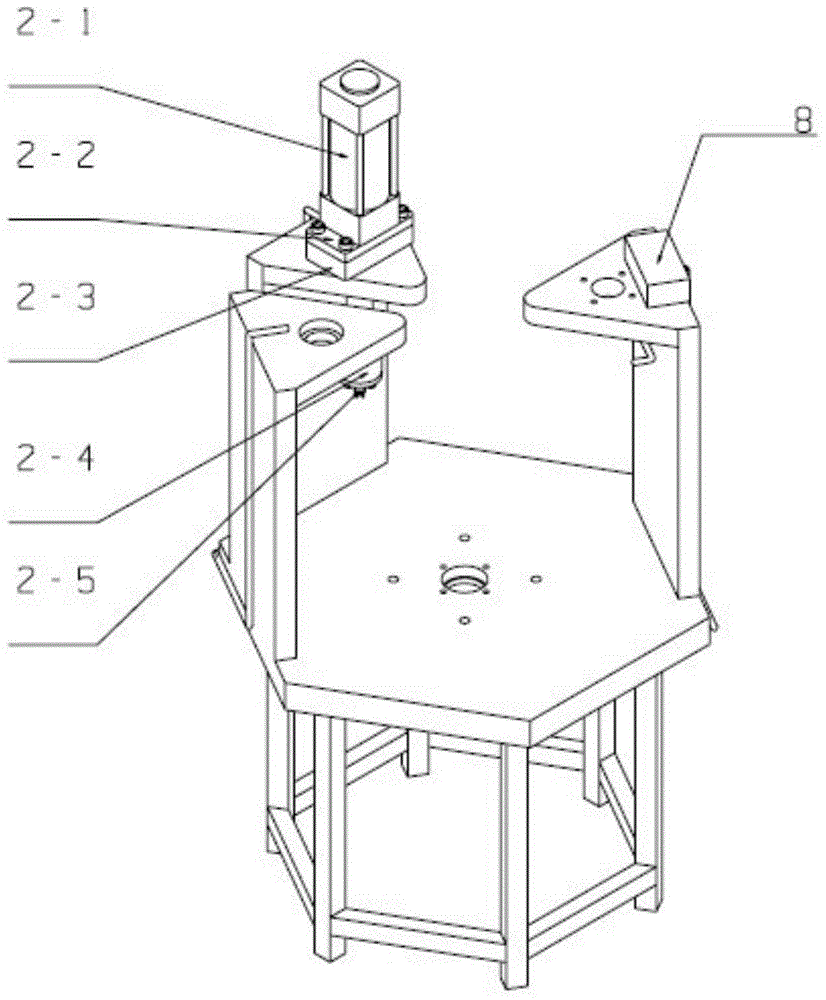

Hot-pressing jointing device for braided fiber reinforced composite plate

The invention discloses a hot-pressing jointing device for a braided fiber reinforced composite plate. The hot-pressing jointing device comprises a rivet supply system, wherein the rivet supply system is matched and connected with an automatic rivet mounting system; a hot air heating system, a plate perforating system, the automatic rivet mounting system, a riveting system and a servo turntable system are arranged on a support frame; a jointing plate is arranged on the servo turntable system through a pneumatic clamping device connected to the servo turntable system; and along with the rotation of the servo turntable system, a joint is formed by sequentially heating a connected part by the hot air heating system, perforating the connected part by the plate perforating system, mounting a rivet by the automatic rivet mounting system and hot-pressing riveting by the riveting system. By using the hot-pressing jointing device, fiber damage caused in the jointing process of the braided fiber reinforced composite plate is reduced, meanwhile, automatic production is realized, and the jointing cost is reduced.

Owner:XI AN JIAOTONG UNIV +1

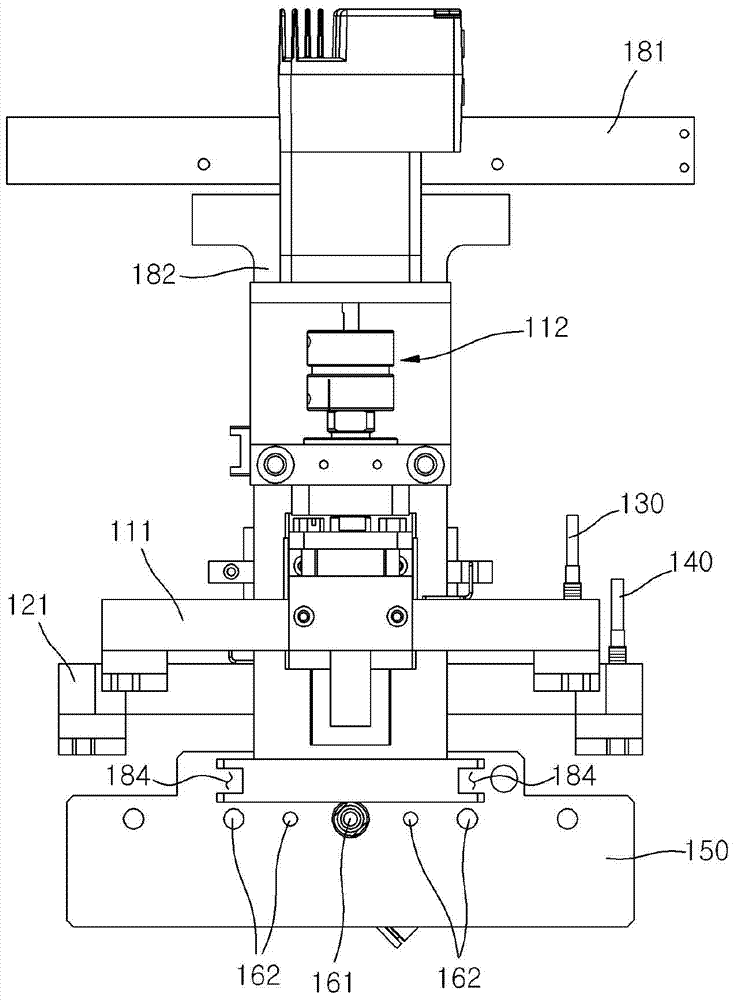

Pump type scraper head matched device

ActiveCN103770457AAchieve joinSimple structurePrinting press partsSolder pasteMechanical engineering

The invention relates to a pump type scraper head matched device. The pump type scraper head matched device comprises a first drive assembly, a second drive assembly, a sensor assembly and a controller, and further comprises an installation assembly, a guide assembly and an even number of shock absorption mechanisms. The first drive assembly is used for driving a first pressing rod to rise and fall. The second drive assembly is used for driving a second pressing rod to rise and fall. The sensor assembly is used for sensing a position signal of the first pressing rod and a position signal of the second pressing rod. The controller is connected with the sensor assembly and controls the first drive assembly and the second drive assembly. The installation assembly is used for installation of a pump type scraper head. The guide assembly plays a role in guiding horizontal installation of the pump type scraper head. The even number of shock absorption mechanisms are arranged inside a first supporting part, divided into two sets and evenly and symmetrically distributed on the two edges with a rotating shaft serving as a center line. According to the pump type scraper head matched device, a pump type scraper head can be accurately and automatically installed and controlled, solder paste can be automatically extruded and jetted, and the amount of extruded solder paste can be accurately controlled.

Owner:HONGYI TECH AUTOMATION EQUIP HUIZHOU CO LTD

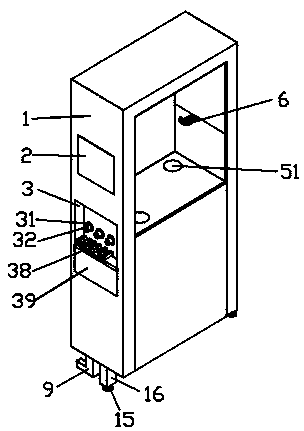

Charging device suitable for various new energy vehicles

InactiveCN108674201AAutomate the connectionAchieve recyclingCharging stationsElectric vehicle charging technologyNew energyEngineering

The invention provides a charging device suitable for various new energy vehicles. The charging device comprises a box body and a control screen arranged on one side of the box body, a charging head containing box is arranged at the part, located below the control screen, of the box body, a rotating device is arranged in the charging head placing box, and the rotating device is rotatably connectedwith a second rotating motor. The rotating device is rotatably connected with a charging gun, the charging gun is movably connected with a charging gun containing box arranged on one side of the boxbody, two first winding rollers are arranged on the inner side of the lower end of the box body, and the two first winding rollers are rotatably connected with a fixed box, and first wire outlet pipesare arranged at the parts, located below the first winding rollers, of the box body. The first wire outlet pipes are located in a sliding rail and the box body is slidably connected with the slidingrail through rolling wheels at the lower end of the box body. A charging head and the charging gun are separated, the charging head containing box is arranged on one side of the box body, the charginghead is located in the rotating device, the charging head can be automatically replaced conveniently through the rotation of a second motor, and meanwhile, the sliding rail is arranged at the lower end of the box body for convenient moving.

Owner:南京陶卓信息技术有限公司

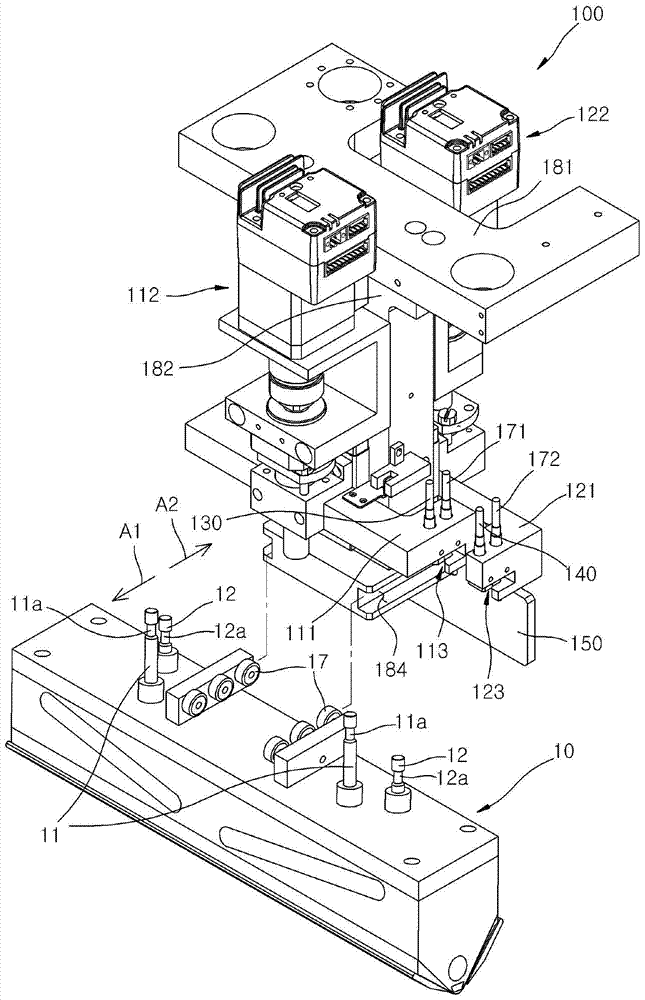

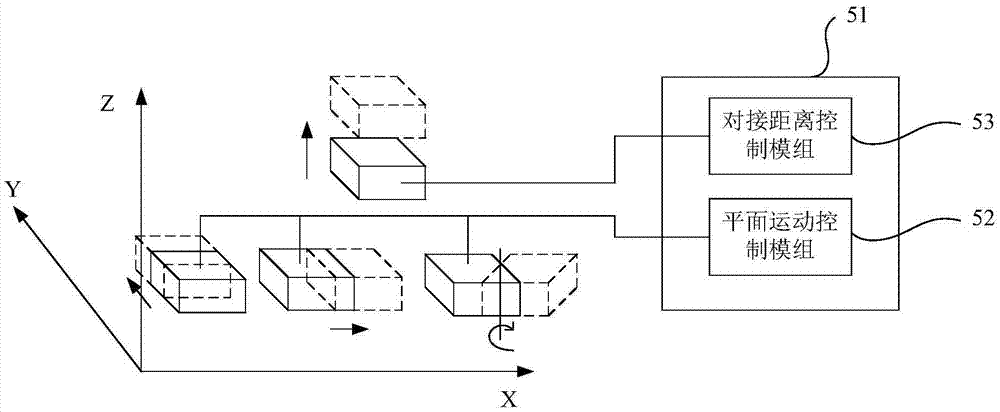

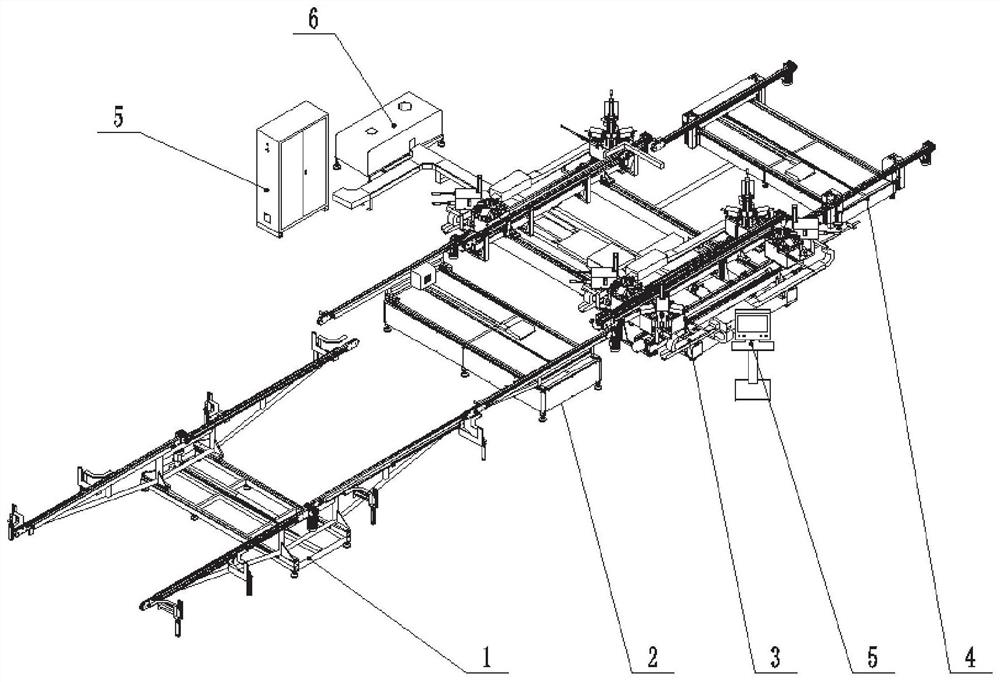

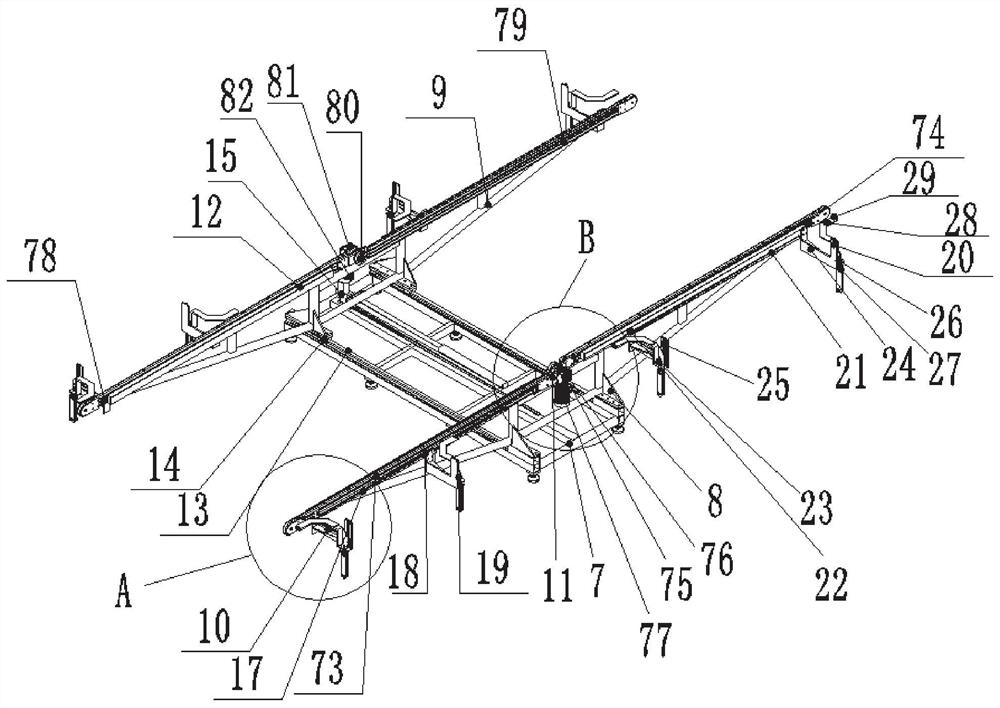

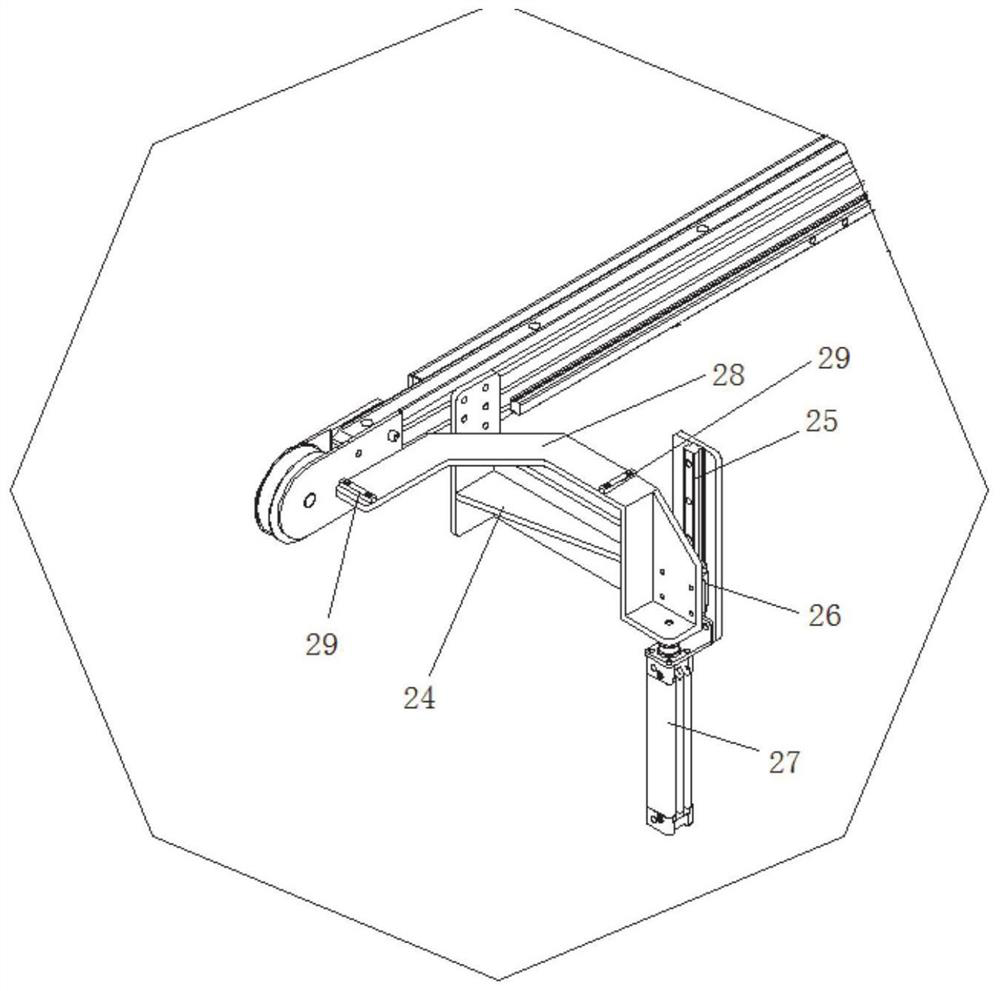

Signal docking device and signal interface docking method

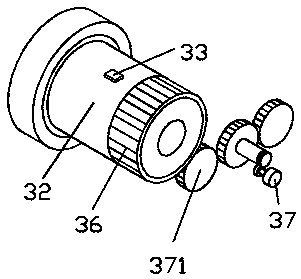

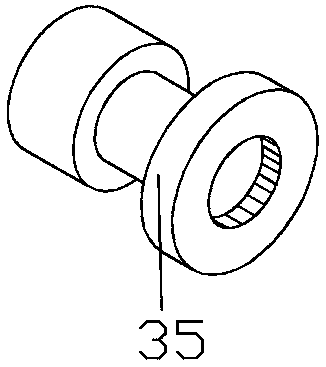

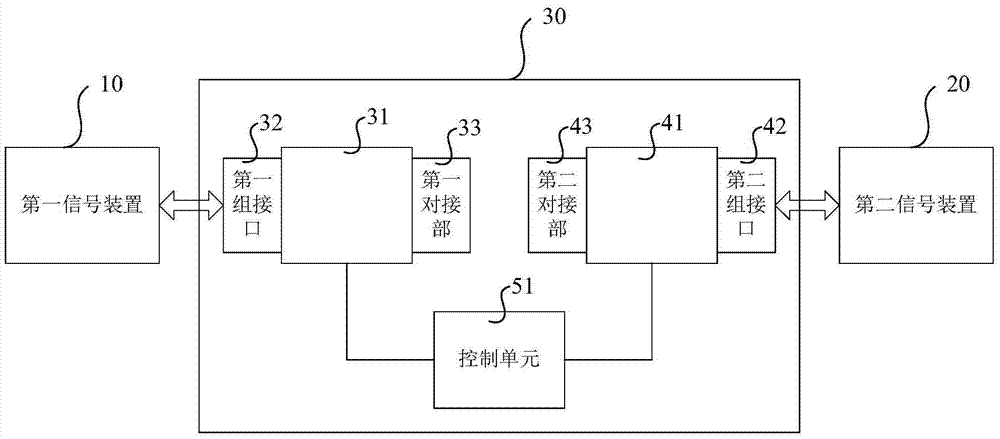

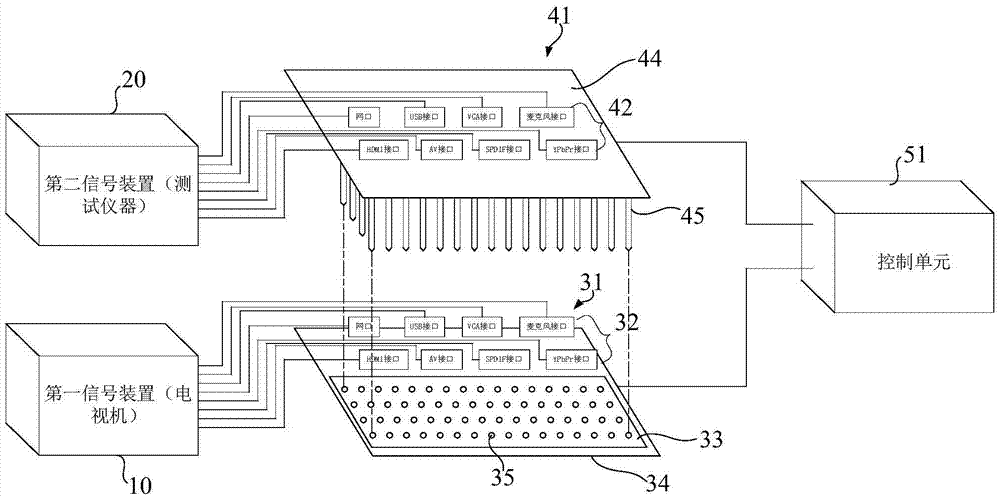

The invention relates to a signal docking device and a signal interface docking method. The signal docking device comprises a first docking unit, a second docking unit and a control unit, wherein the first docking unit is provided with a first group interface corresponding to a first signal device and a first docking part that is connected with the first group interface and is extended; the first group interface is used to connect the first docking unit to the first signal device; the second docking unit is provided with a second group interface corresponding to a second signal device and a second docking part that is connected with the second group interface and is extended; the second group interface is used to connect the second docking unit to the second signal device; and the control unit is used to connect with at least one of the first docking unit and the second docking unit, and is used to control at least one of the first docking unit and the second docking unit to ensure that the first docking unit and the second docking unit move oppositely and to finally ensure that the first docking part and the second docking part are correspondingly connected or mutually separated. By adopting the device and the method disclosed by the invention, the automatic docking of signals can be achieved.

Owner:EVOC INTELLIGENT TECH

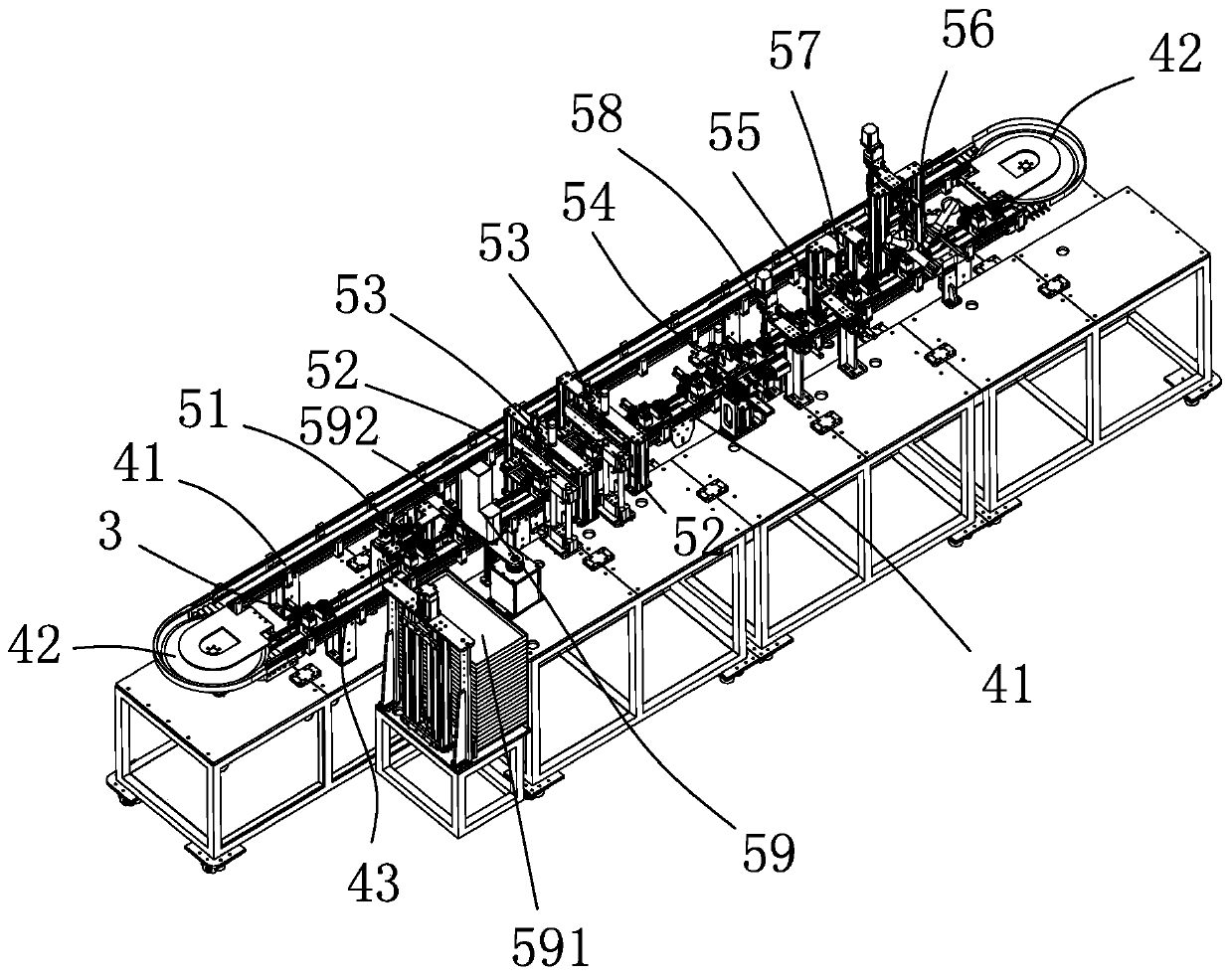

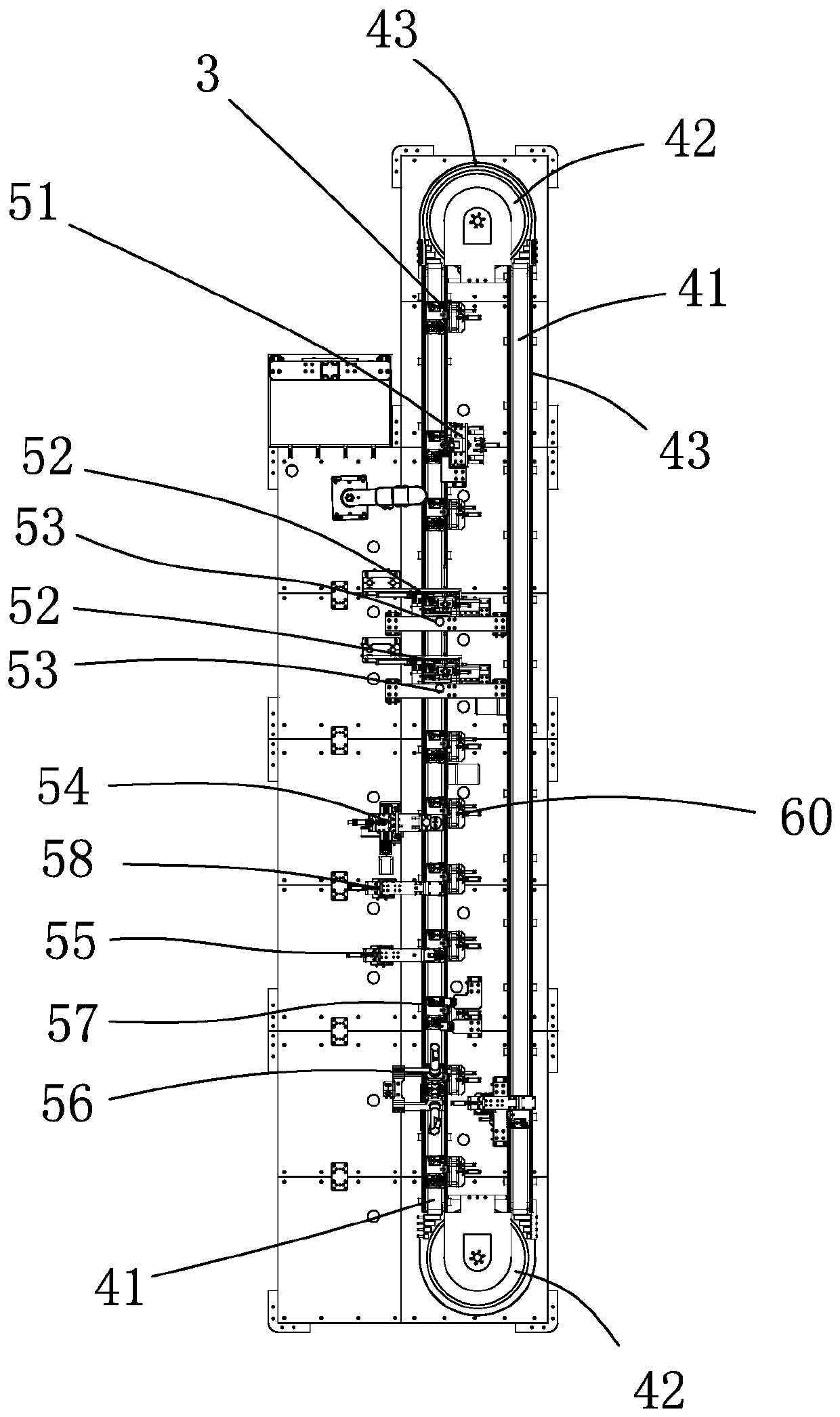

Corner combining production line for aluminum alloy doors and windows

PendingCN113245838AAutomate the connectionReduce labor intensityAssembly machinesMetal working apparatusProduction lineMachine

The invention relates to a corner combining production line for aluminum alloy doors and windows. The corner combining production line comprises an assembling device, a corner combining device and a conveying device which are sequentially arranged in the first direction. The assembling device comprises a first conveying component arranged in the first direction, and a frame body of the first conveying component is connected with an assembling component used for assembling sectional material connectors through lifting mechanisms. The corner combining device comprises a first moving part and a second moving part which can move in the second direction perpendicular to the first direction to get close to each other and get away from each other, and the first moving part and the second moving part are provided with machine head assemblies. the inner sides are connected with second conveying parts which are arranged in the first direction and can receive sectional materials conveyed by the first conveying part, and the machine head assemblies are provided with the lifting mechanisms used for conveying the sectional materials between the second conveying parts and the machine head assemblies; and the conveying device can receive the sectional materials conveyed by corner combining conveying components and convey the sectional materials to the next procedure. The production line is high in working efficiency.

Owner:JINAN CGMA CNC MACHINERY CO LTD

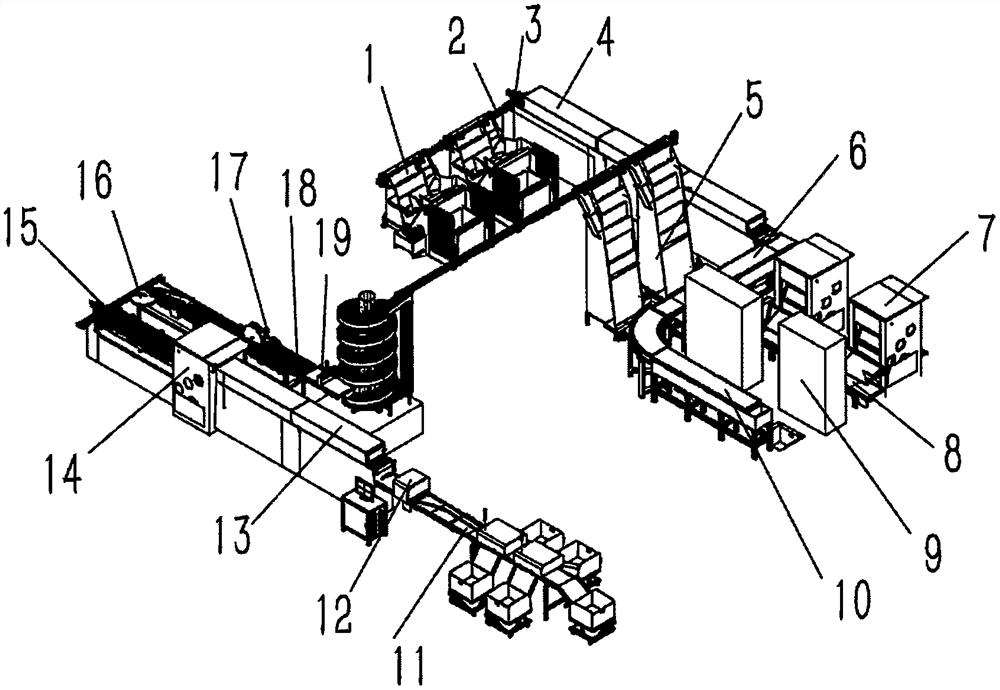

Automatic production line for steel backing surface treatment

ActiveCN113086543AImplement sortingImplement automatic classificationLiquid surface applicatorsControl devices for conveyorsProduction lineSand blasting

The invention discloses an automatic production line for steel backing surface treatment. The automatic production line is used for transforming an existing steel backing surface treatment production line and comprises a steel backing cleaning machine, a steel backing sand blasting machine and a steel backing glue spraying machine and further comprises an automatic feeding and conveying device, a cleaning, sequencing and conveying device, a cleaning, discharging and conveying device, a sand blasting, feeding and conveying device, a sand blasting, discharging and conveying device, a transferring, sequenching and conveying device, a sorting, overturning and conveying device, a glue spraying and sequencing device and a drying, discharging and sorting device according to the production sequence. The automatic production line for steel backing surface treatment has the beneficial effects that full automation, automatic feeding, automatic sequenching, automatic transferring, automatic glue spraying, automatic drying and automatic sorting of steel backing surface treatment are achieved.

Owner:RIZHAO POLYTECHNIC

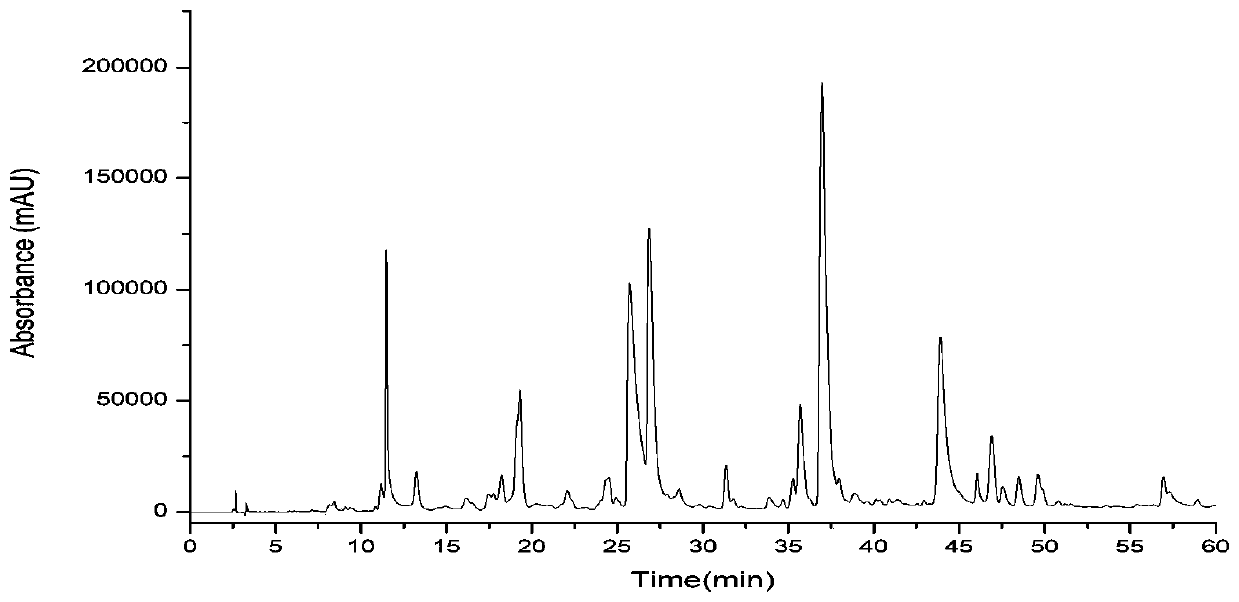

Method for separating gelsemium elegans alkaloid monomers from gelsemium elegans alkaloids by combining high-speed counter-current chromatography with preparative liquid chromatography

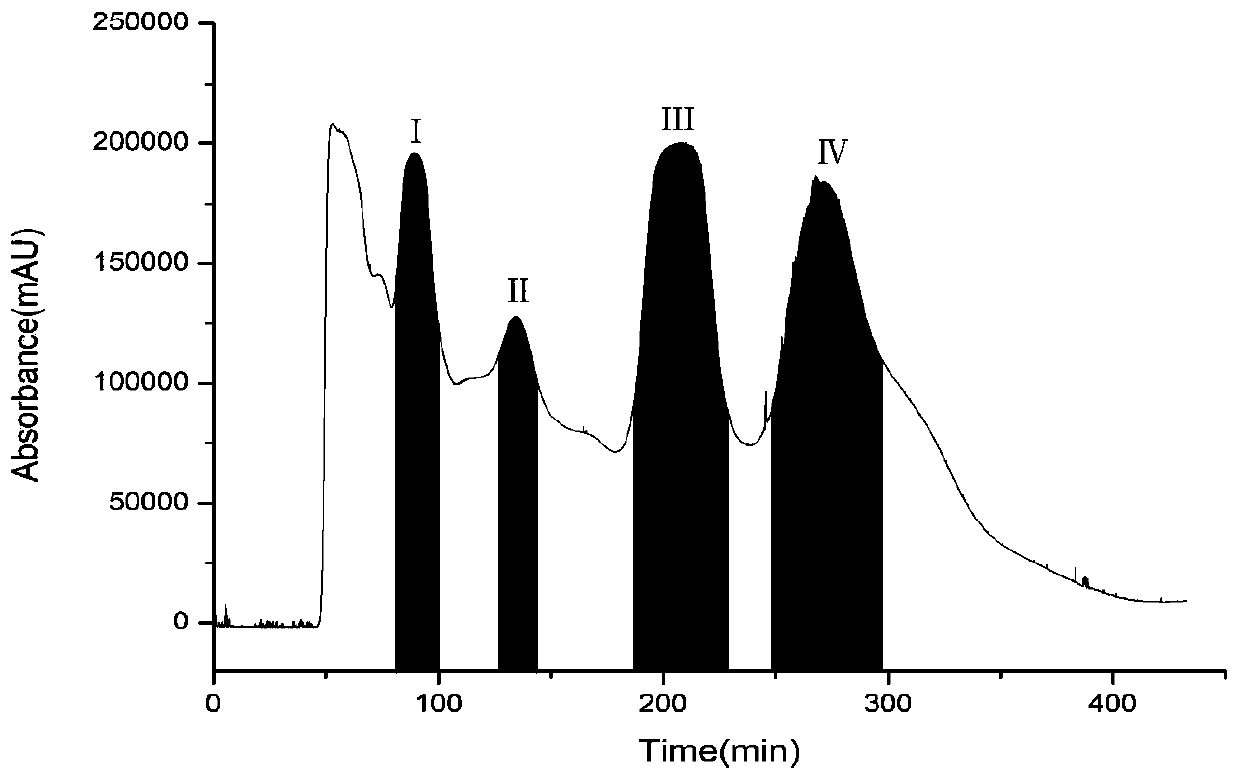

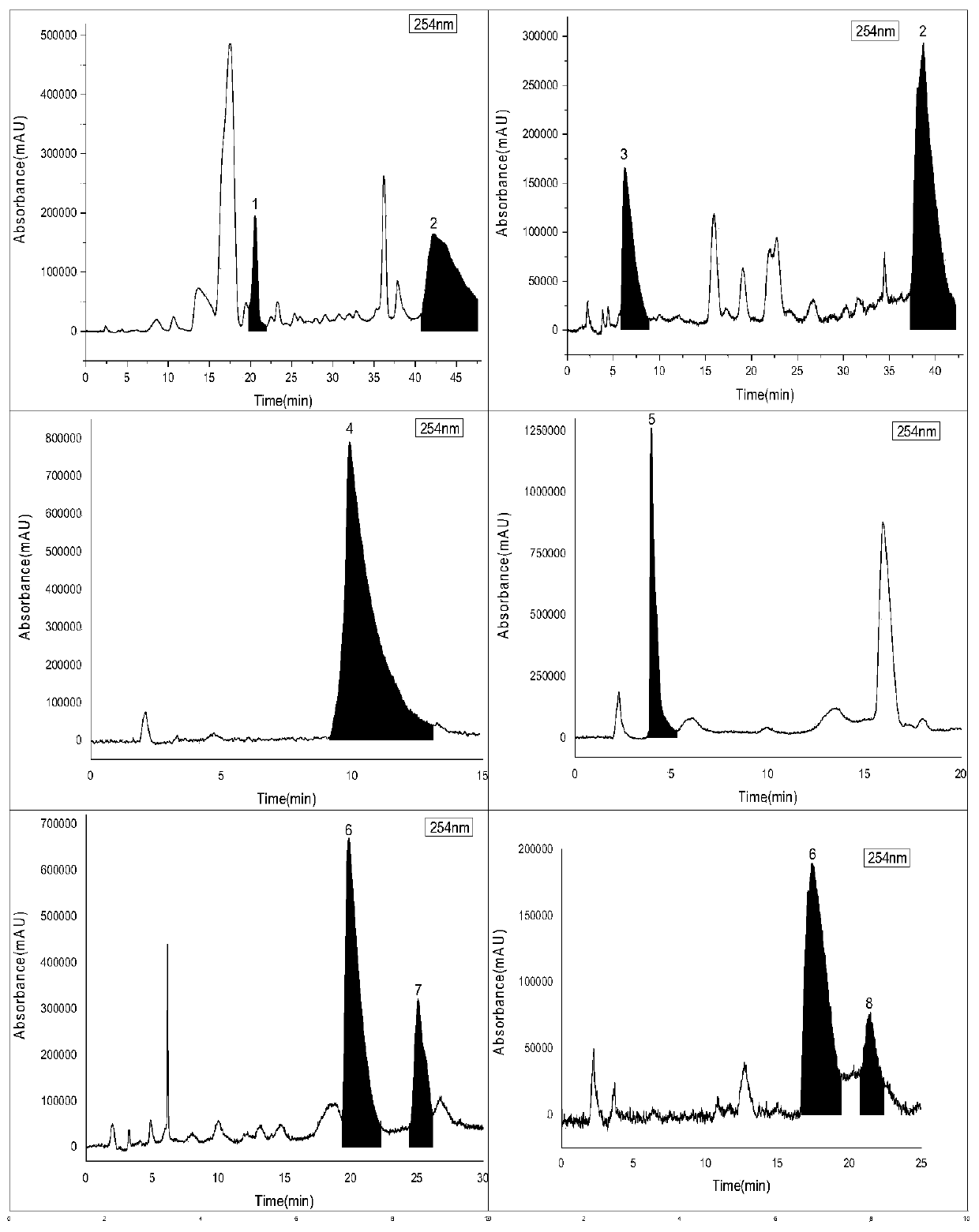

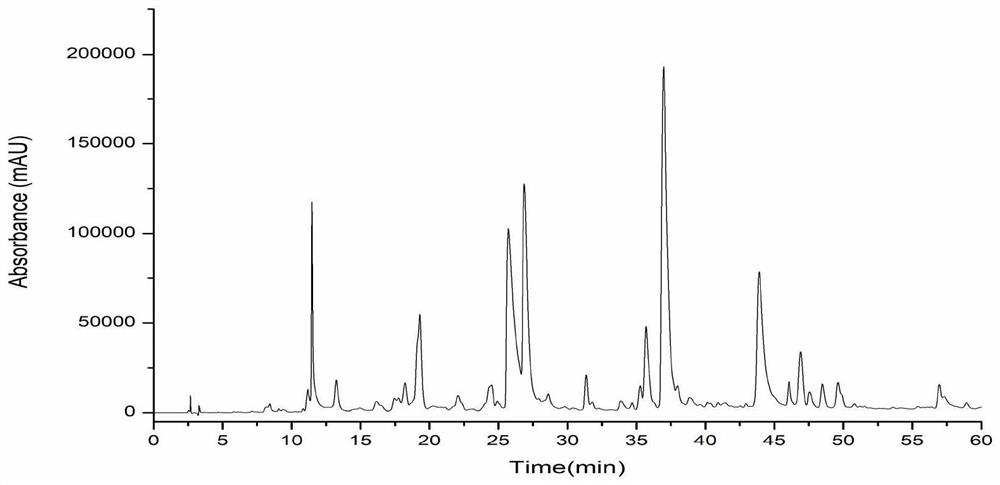

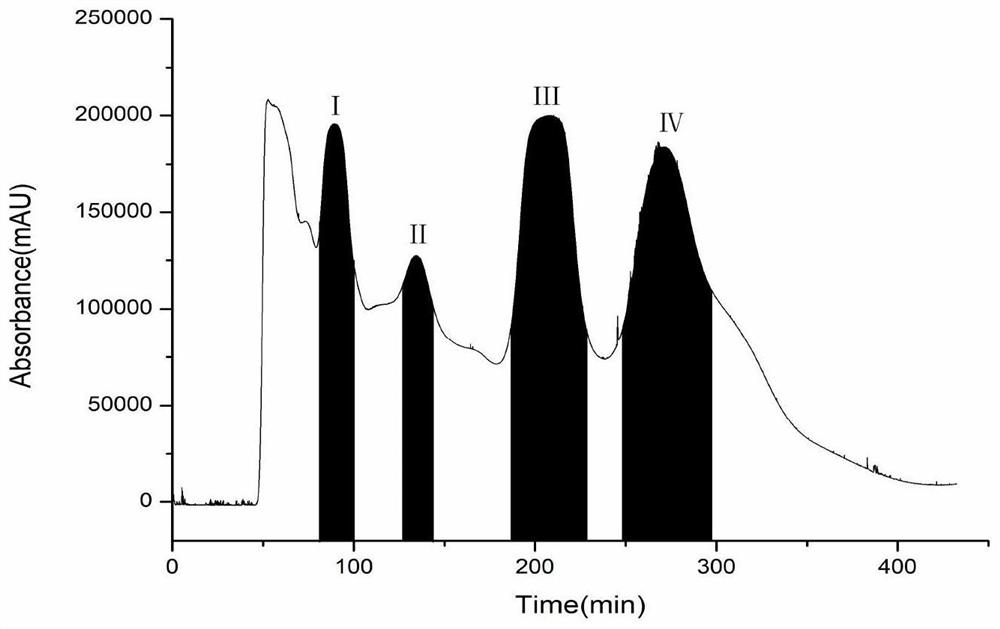

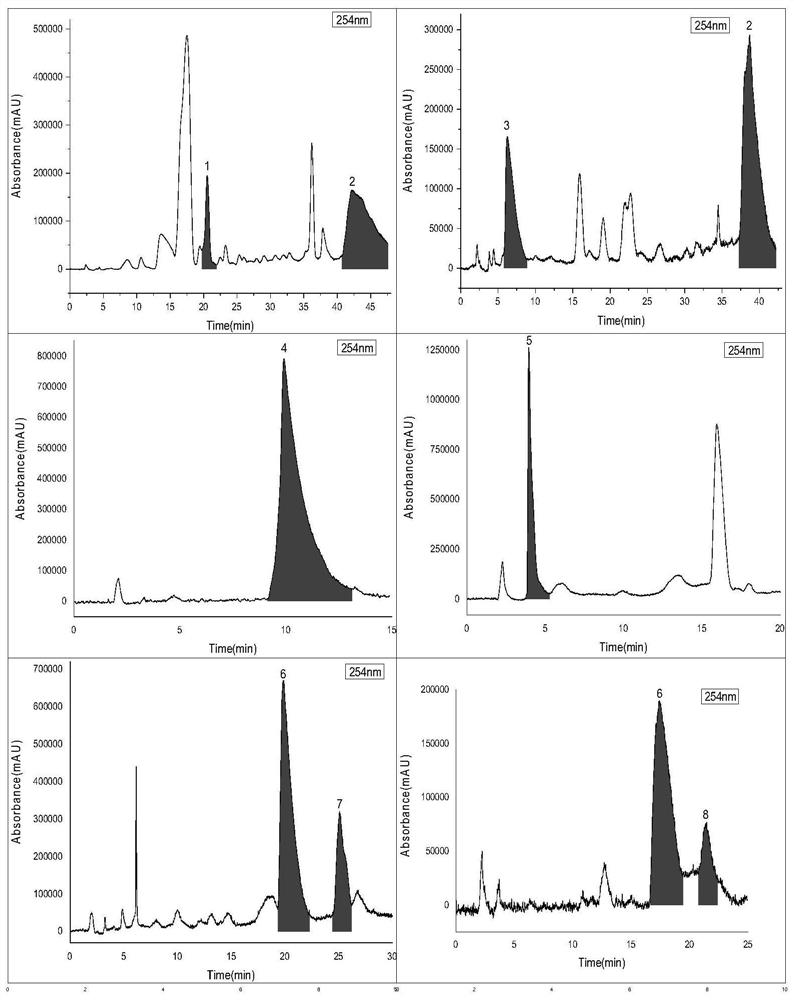

ActiveCN111560024ALarge amount of preparationShort cycleOrganic chemistryFluid phaseMolecular biology

The invention discloses a method for separating gelsemium elegans alkaloid monomers from gelsemium elegans alkaloids by combining high-speed counter-current chromatography with preparative liquid chromatography. The method comprises the following steps: determining target gelsemium elegans alkaloid monomer components from a gelsemium elegans extract by adopting high performance liquid chromatography, sequentially carrying out primary separation by virtue of high-speed counter-current chromatography and secondary separation by virtue of preparative liquid chromatography, and respectively collecting each target gelsemium elegans alkaloid monomer component. According to the method, a plurality of chromatographic instruments are combined to separate the gelsemium elegans monomers, so that themethod has the advantages of large preparation amount, short period, high purity and the like, eight gelsemium elegans alkaloid monomers can be separated at the same time, and the method has controllability, automatic productivity and wide application prospect.

Owner:HUNAN AGRICULTURAL UNIV

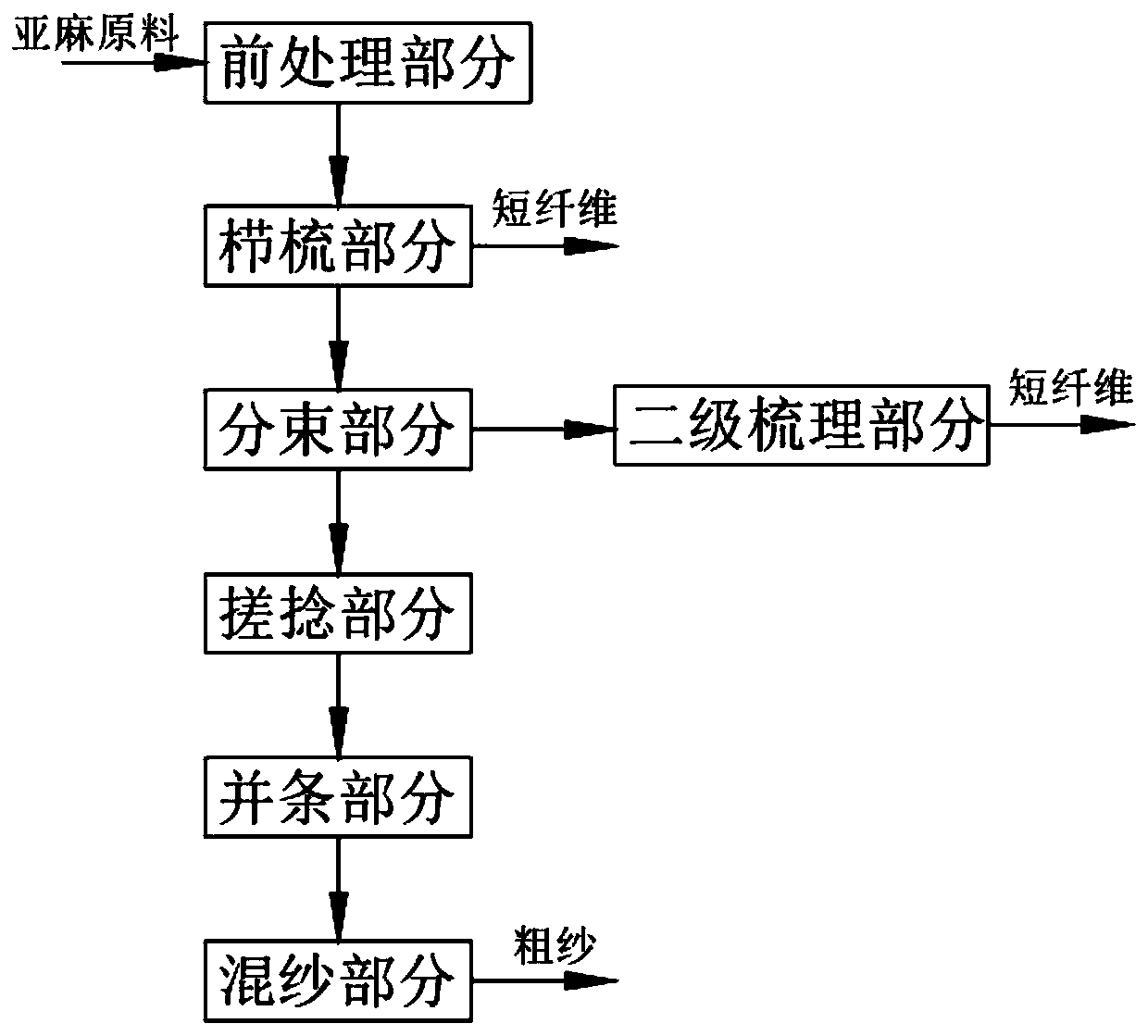

Continuous automatic production method of linen yarn

The invention relates to the linen yarn production technology field and especially relates to the continuous automatic production method of a linen yarn. A front processing portion, a heckling portion, a beam splitting portion, a twisting portion, a drawing portion and a blended yarn portion are included. After a linen raw material is split into a plurality of raw material bundles, a hackling machine carries out carding on the raw material bundles so as to obtain long fibers and short fibers. When the long fibers are transferred, the long fibers are split into bundles and the fiber bundles aresequentially pushed into an output component. Through the output component, the previous group of fiber bundles and the next group of fiber bundles in the output component are overlapped in an end-to-end mode, and during an output process, the fiber bundles are staggered and intertwined. A bundle splitting mechanism is used to split the long fibers in a directional transfer process through a guiding splitting mode, and then, the two adjacent groups of fiber bundles are directionally output in an end-to-end overlapping manner, and at the same time automatic winding is performed so as to realize the high-quality automatic production of linen splitting and lap joint. The technical problem of unstable yarn quality due to uneven artificial bundle splitting existing in the prior art is solved.

Owner:湖北蜀峰线业发展有限公司

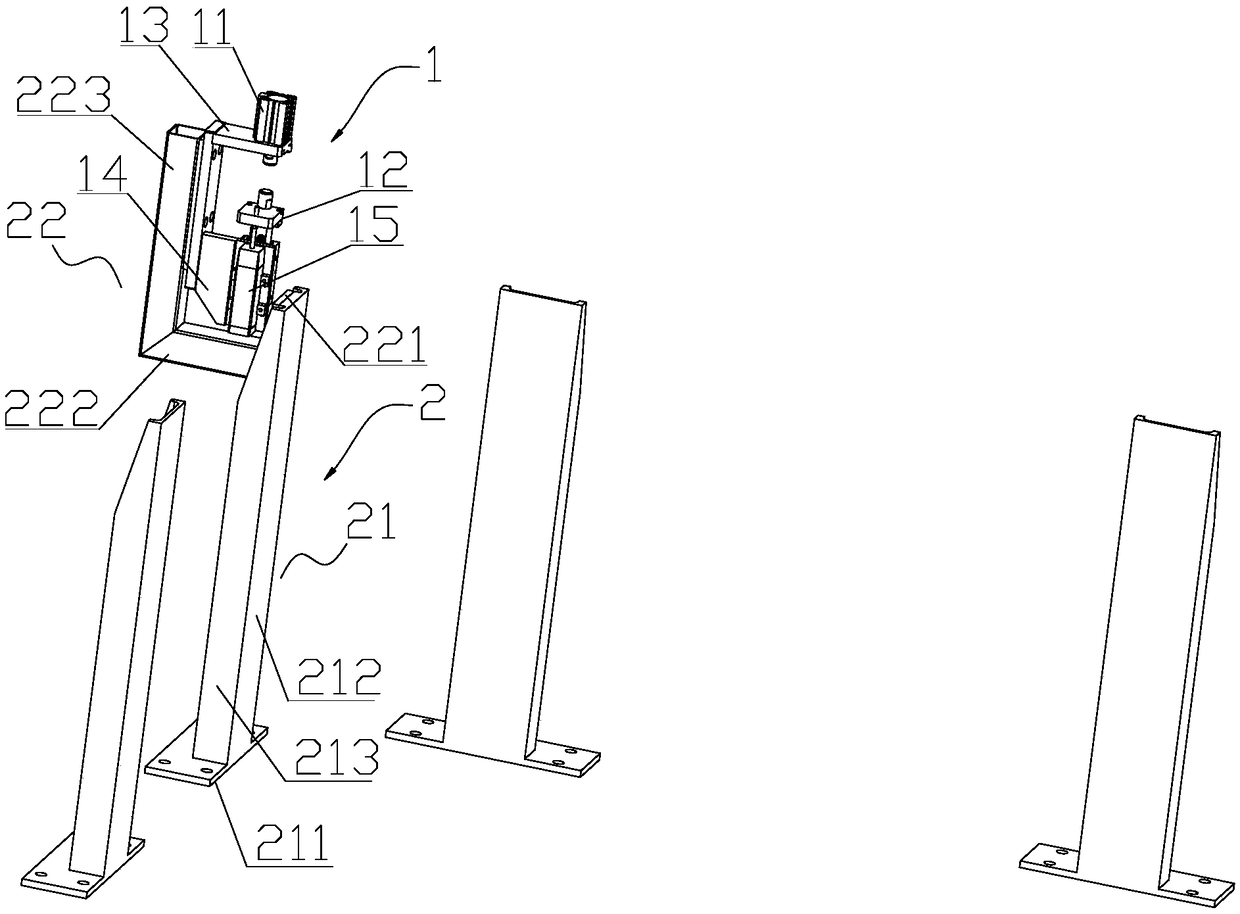

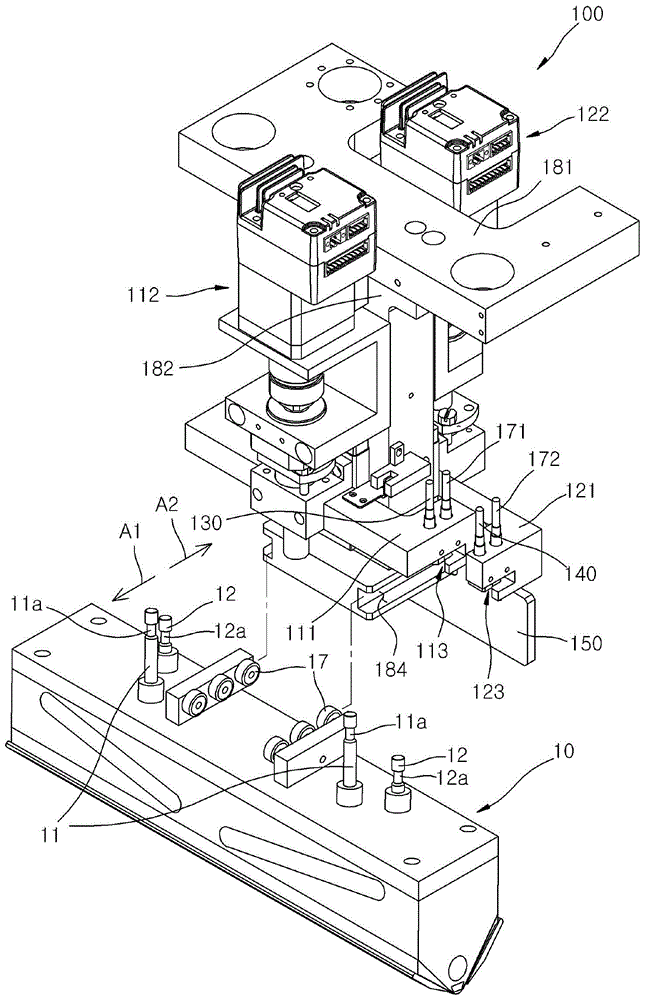

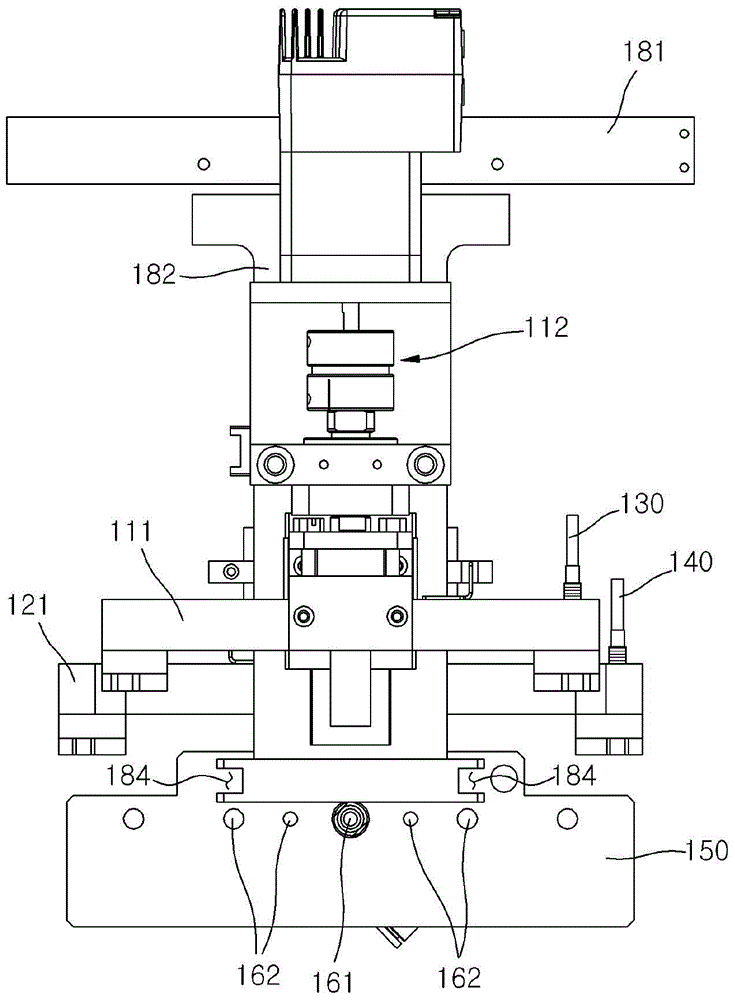

Sheet material thickness detection device

PendingCN108168486AImplement automatic detectionRealize automated detectionMeasurement devicesElectricityManipulator

The present invention belongs to the technical field of automatic processing devices, and especially relates to a sheet material thickness detection device. The sheet material thickness detection device comprises a thickness measurement mechanism, a control mechanism, a support mechanism, an alarm mechanism and a mechanical arm, wherein the support mechanism comprises a pedestal and a support arranged on the pedestal, and the thickness measurement mechanism is arranged on the support; the thickness measurement mechanism comprises a signal sending terminal and a signal receiving terminal whichare arranged on the support in an adjustable position mode; the mechanical arm is configured to grasp sheet materials to the thickness measurement mechanism for detection, the thickness measurement mechanism detects the thickness of the sheet materials; and the thickness measurement mechanism and the alarm mechanism are electrically connected with the control mechanism, and when the thickness of the sheet materials is not consistent to a preset value, the control mechanism emits alarm signals through the alarm mechanism. The thickness detection device can achieve automatic detection of sheet materials to achieve automatic connection between processes so as to improve the workpiece production efficiency.

Owner:NANHAI BRANCH OF SHENZHEN GUOCHUANG MINGCHU COMML EQUIP MFG CO LTD

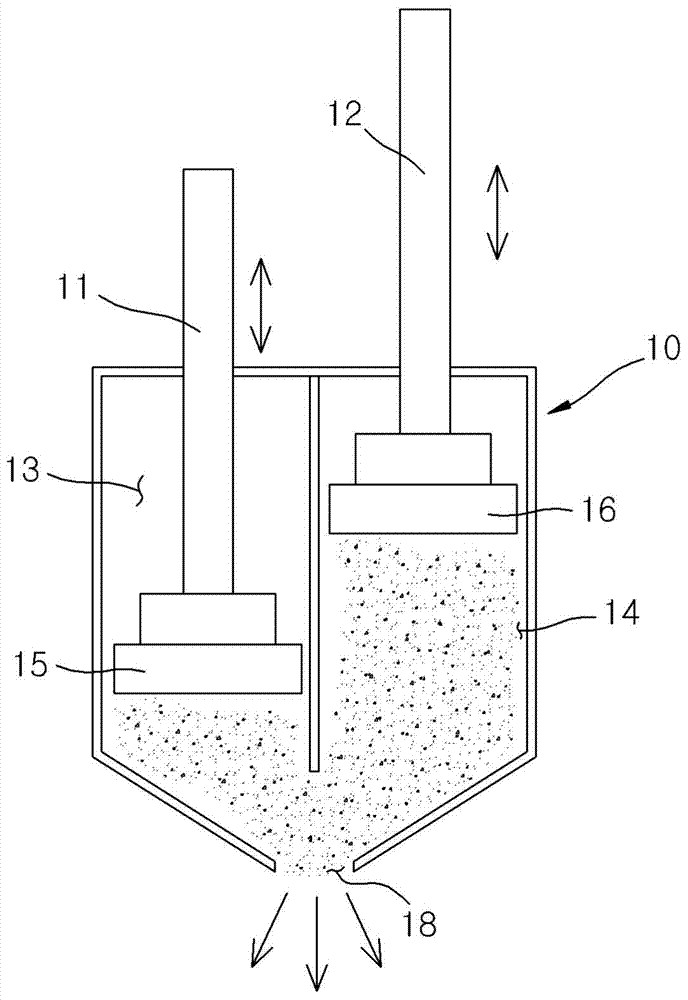

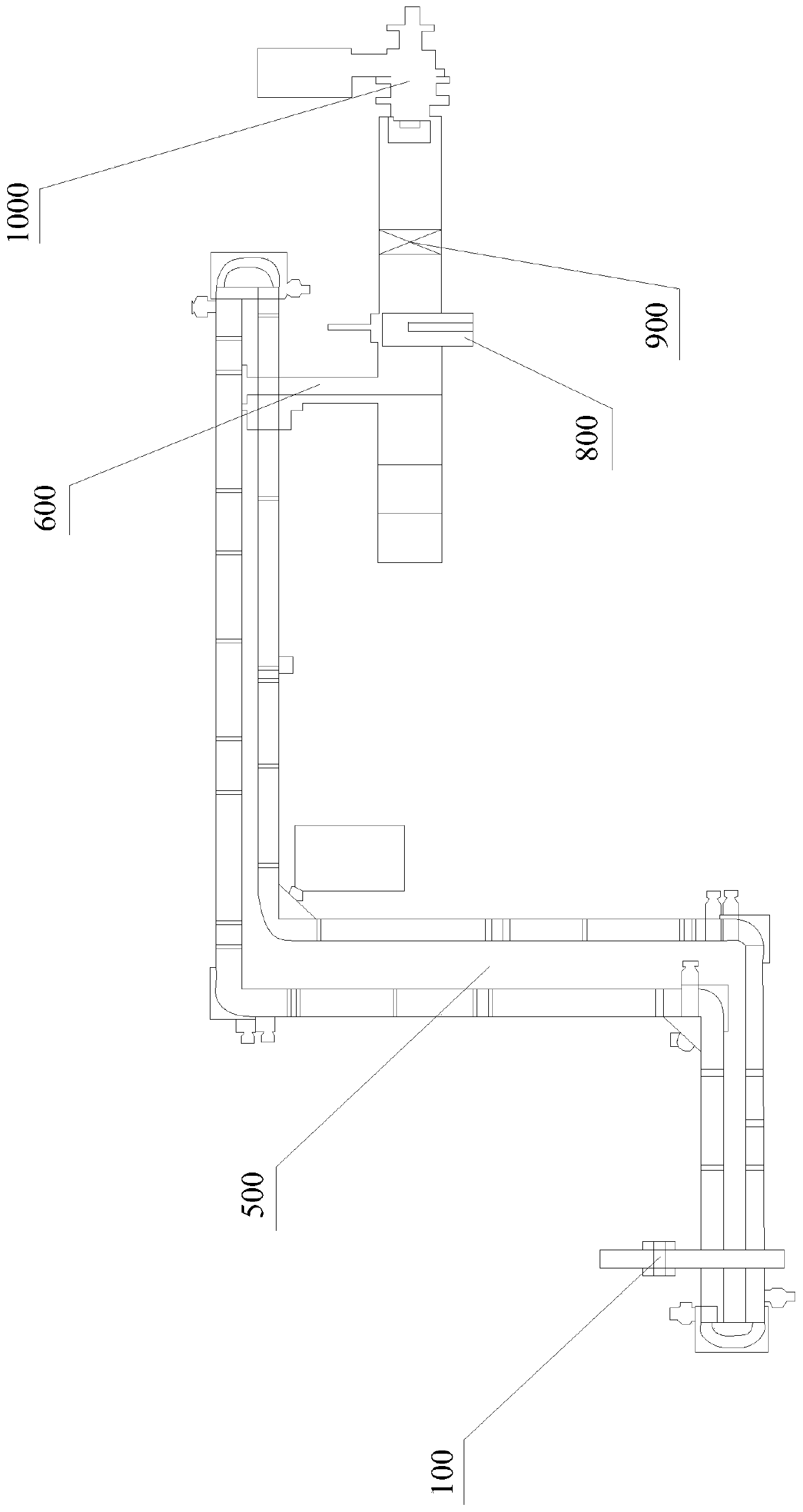

Independent screen type radiation heat recovery assembly applied to gasifier

ActiveCN106545829AReduce installation difficultySave on installation costsSteam generation heating methodsBoiler water tubesWater vaporProcess engineering

The invention discloses an independent screen type radiation heat recovery assembly applied to a gasifier. The independent screen type radiation heat recovery assembly comprises an upper gathering collection box and a lower gathering collection box; the upper gathering collection box is provided with a water vapor outlet; the lower gathering collection box is provided with a boiler water inlet; the upper gathering collection box communicates with the lower gathering collection box through shell protection screens and radiation screens; and the radiation screens are arranged on the inner sides of the shell protection screens. According to the independent screen type radiation heat recovery assembly, the problems that an existing radiation heat recovery assembly is high in equipment cost and high in manufacturing difficulty, and cannot be easily repaired are solved, and enlargement and automation of radiation heat recovery assembly manufacturing are achieved, so that the independent screen type radiation heat recovery assembly lays a foundation for the assumption of building the large-capacity high-yield energy-saving type gasifier.

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

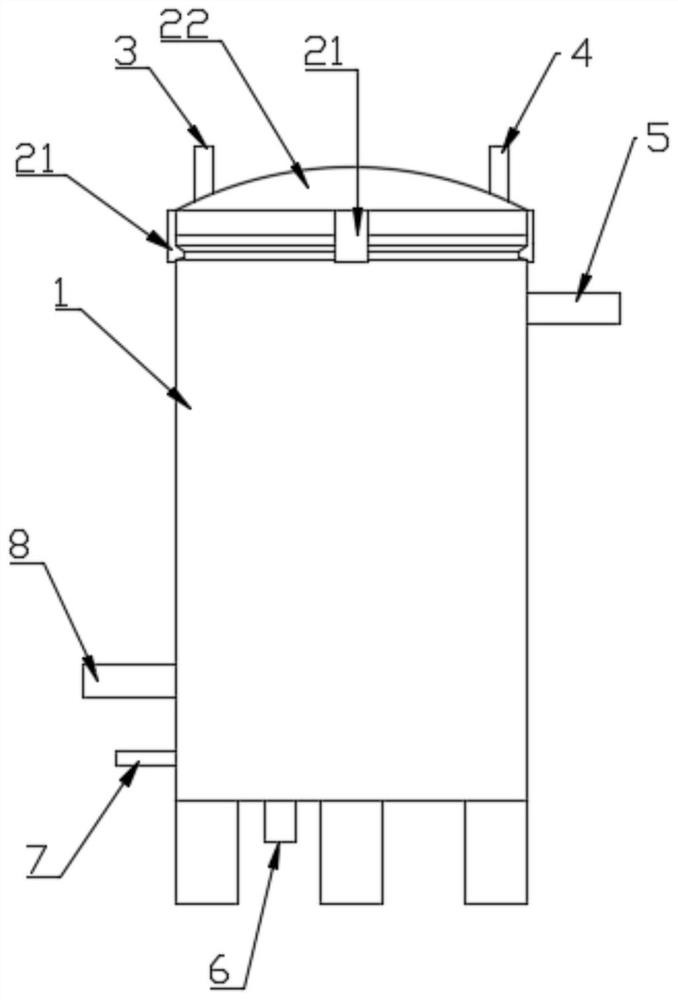

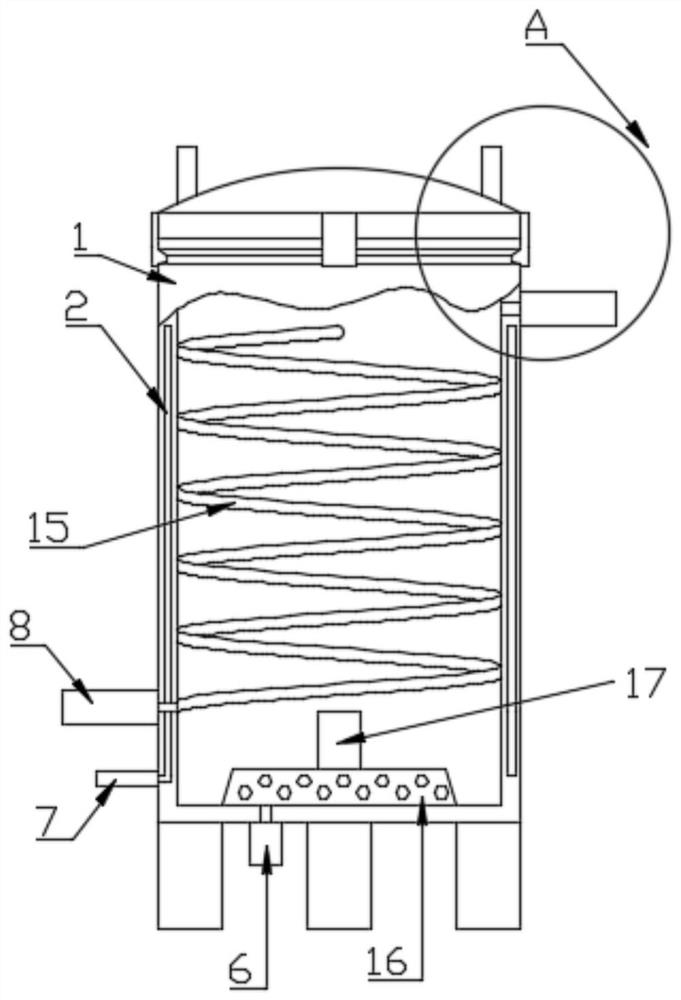

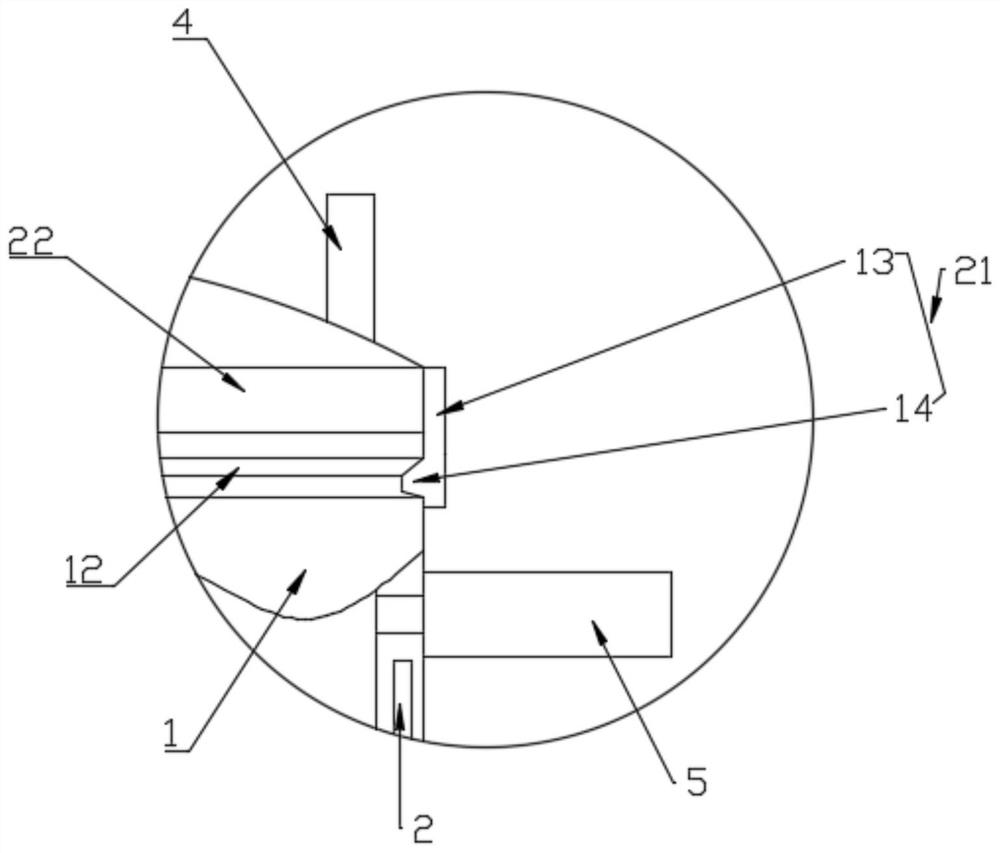

Evacuation pot capable of assisting citrus sinensis in peeling, and citrus sinensis peeling technology

ActiveCN111789268AAvoid burnsDecreased blanching temperatureFood shapingVegetable peelingMechanical engineeringBiotechnology

The invention provides an evacuation pot capable of assisting citrus sinensis in peeling. The evacuation pot comprises a pot body, wherein the pot body is provided with an interlayer; a sealing coveris buckled on the pot body and is provided with an exhaust pipe and a pressure pipe, which communicate with the inside of the pot body; the pot body is also provided with a liquid feeding pipe positioned on the upper end of the pot body, and a liquid discharging pipe arranged on the lower end of the pot body; the interlayer communicates with a gas inlet pipe and a liquid outlet pipe, which are arranged on the pot body; and the liquid feeding pipe and the liquid discharging pipe body both communicate with the inside of the pot body. The evacuation pot also comprises a hanging basket used for containing the citrus sinensis, wherein the upper end of the hanging basket is provided with an opening, and the opening is in threaded connection with a hole plate. The invention also provides a citrussinensis peeling technology which adopts the evacuation pot. According to the citrus sinensis peeling technology, a high temperature can be lowered, in addition, an operation is carried out in a sealed pot body, and employees can be prevented from being scalded. Meanwhile, under the assistance of enzyme treatment, the processed citrus sinensis has a high pulp separation degree, then, the citrus sinensi is added into a roller to be subjected to rolling processing, the pulp is separated, then, the citrus sinensi is introduced out to be subjected to manual separation, and a pulp damage rate is lowered to 5%.

Owner:YICHANG HAITONG FOOD

Method for safety communication between smart home and Bluetooth device

InactiveCN108966191AAvoid being connected by illegal terminalsAutomate the connectionConnection managementSecurity arrangementSecure communicationComputer terminal

The invention discloses a method for safety communication between a smart home and a Bluetooth device. The method comprises the following steps: (1) a Bluetooth function of a smart mobile terminal having the Bluetooth function is turned on, and an external Bluetooth device is scanned, wherein Bluetooth modules comprise a mobile Bluetooth acquisition module, a detection module and a transmission module, and through adoption of the infrared sensor technology, detection performed when accessing of a strange Bluetooth device in home is carried out can be achieved; and information is transmitted toa control use terminal through the transmission module. Through a safety connection method of the Bluetooth device provided by the invention, automatic connection between the Bluetooth device and anintelligent mobile terminal matching the same is achieved, and manual operation by a user is not need, and then user experience is improved.

Owner:WUHU XEROX INTELLIGENT TECH CO LTD

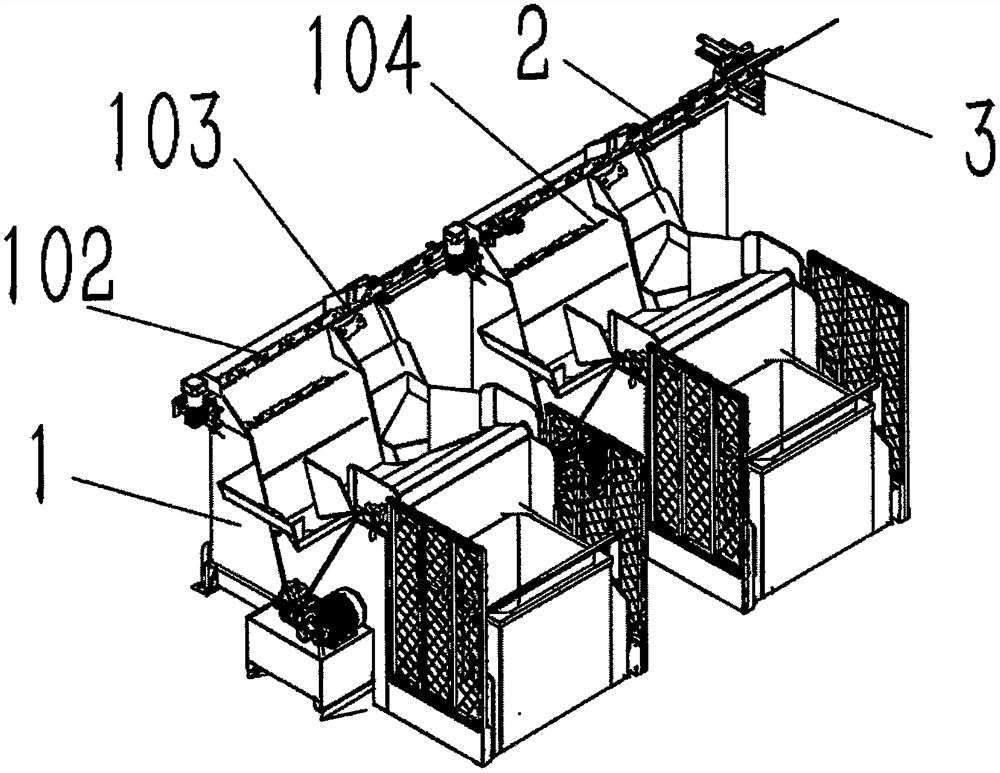

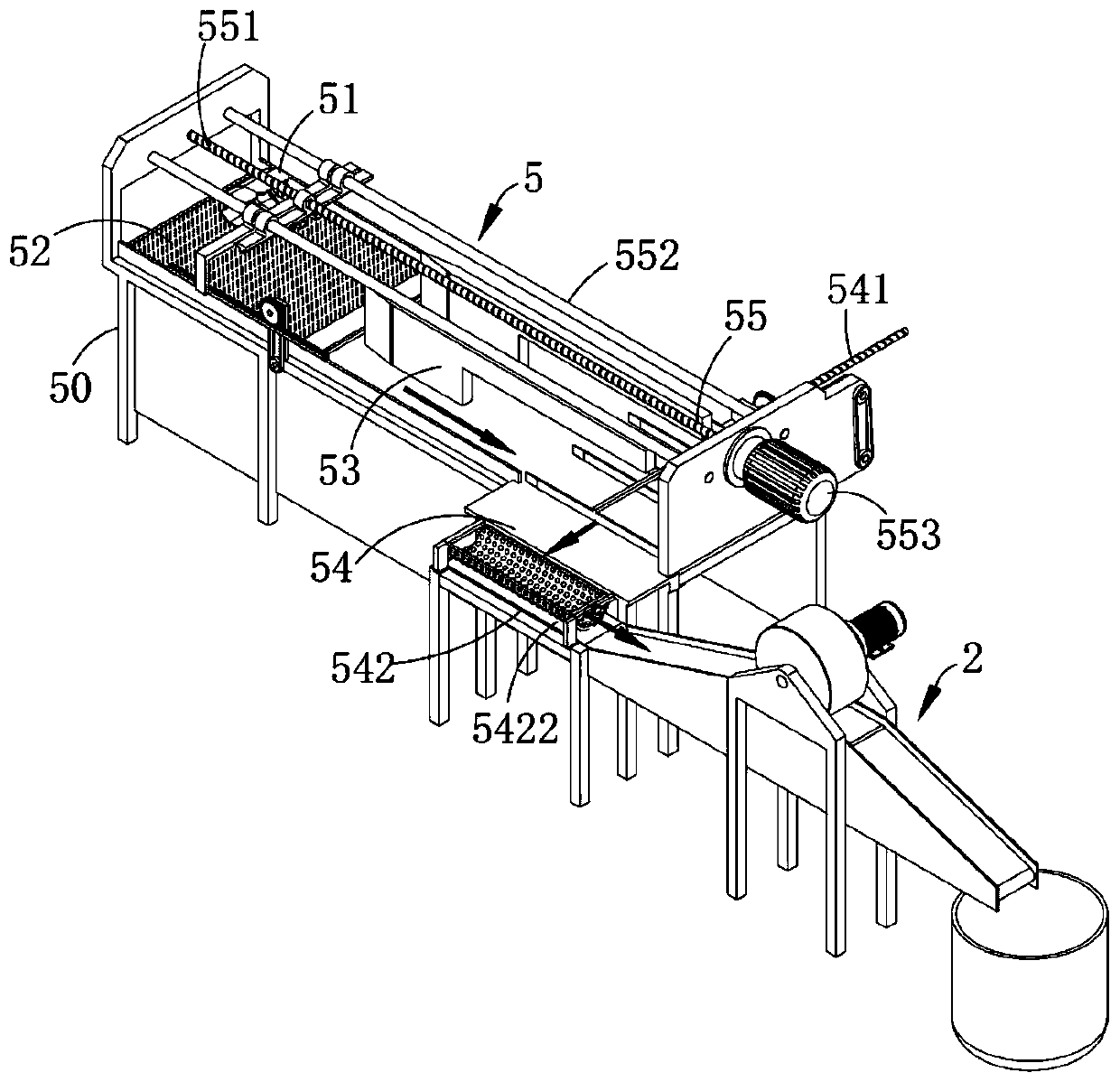

Automatic material increasing device for linen yarn production

The invention relates to the technical field of linen yarn production, in particular to an automatic material increasing device for linen yarn production. The automatic material increasing device comprises a rack, a traction mechanism, a bundle dividing mechanism, a material increasing mechanism and a transferring mechanism, wherein the traction mechanism comprises clamping assemblies and a propping assembly; the bundle dividing mechanism is used for dividing a long fiber into a plurality of fiber bundles; and the material increasing mechanism comprises a pushing assembly and an output assembly. Through the output assembly, the fiber bundles are mutually twined after being overlapped end to end; through the transferring mechanism and the output assembly, the fiber bundles are outputted; when the long fiber is directionally transferred through the traction mechanism, the removal of a short fiber from the long fiber and the division into the fiber bundles are performed through the cooperation with a carding mechanism and the bundle dividing mechanism correspondingly; by combination with the transmission connection properties of an overlapping mechanism and a driving mechanism, the fiber bundles are automatically twined when being overlapped end to end; the high-quality automatic production for linen bundle dividing and overlapping is achieved; and the technical problem that in the prior art, the yarn quality is unstable due to the non-uniform manual bundle dividing process is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

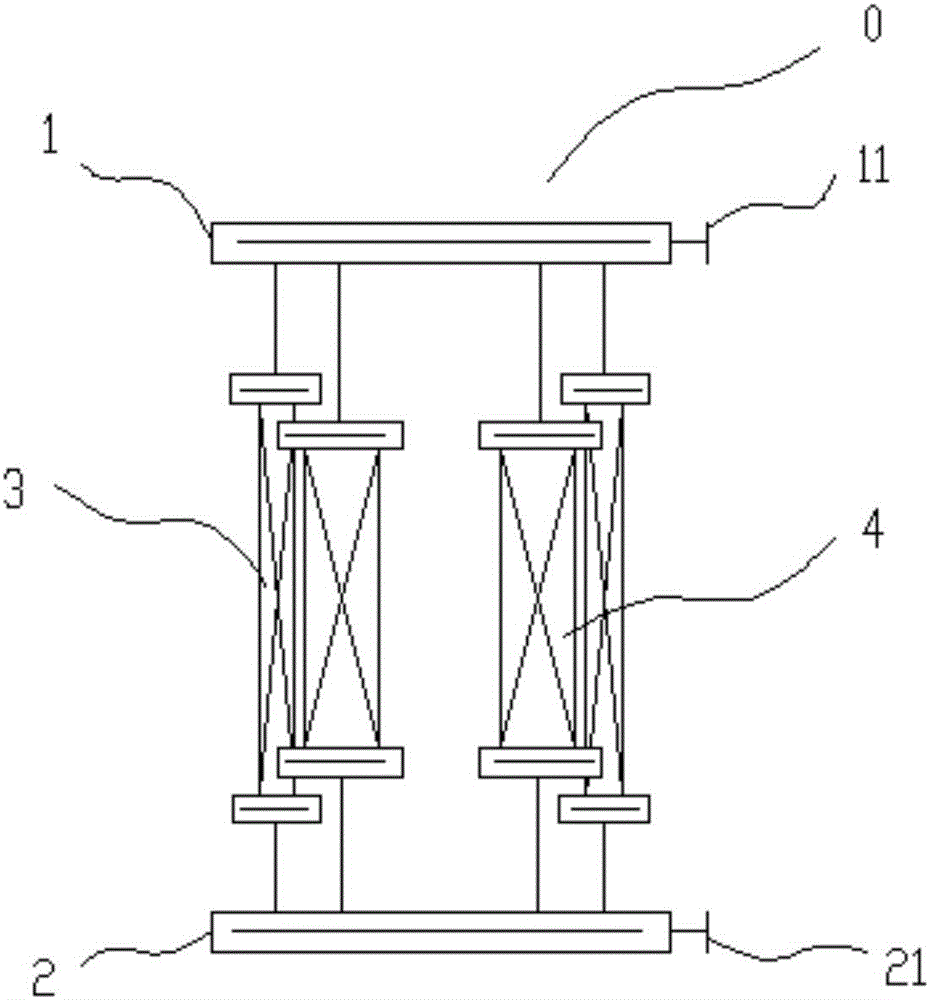

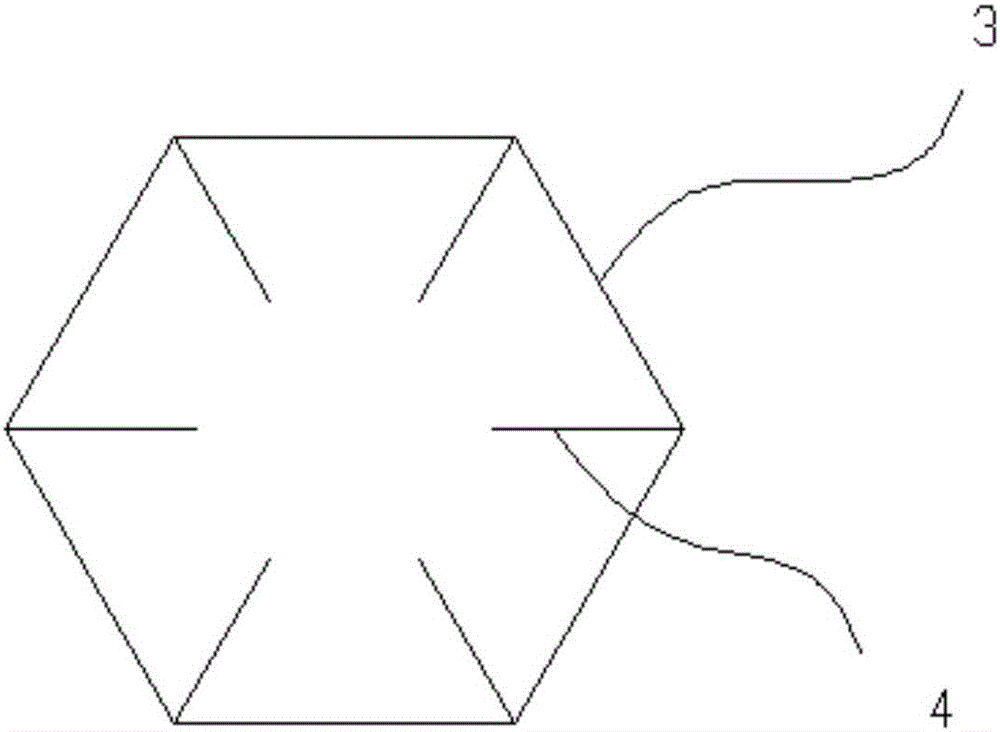

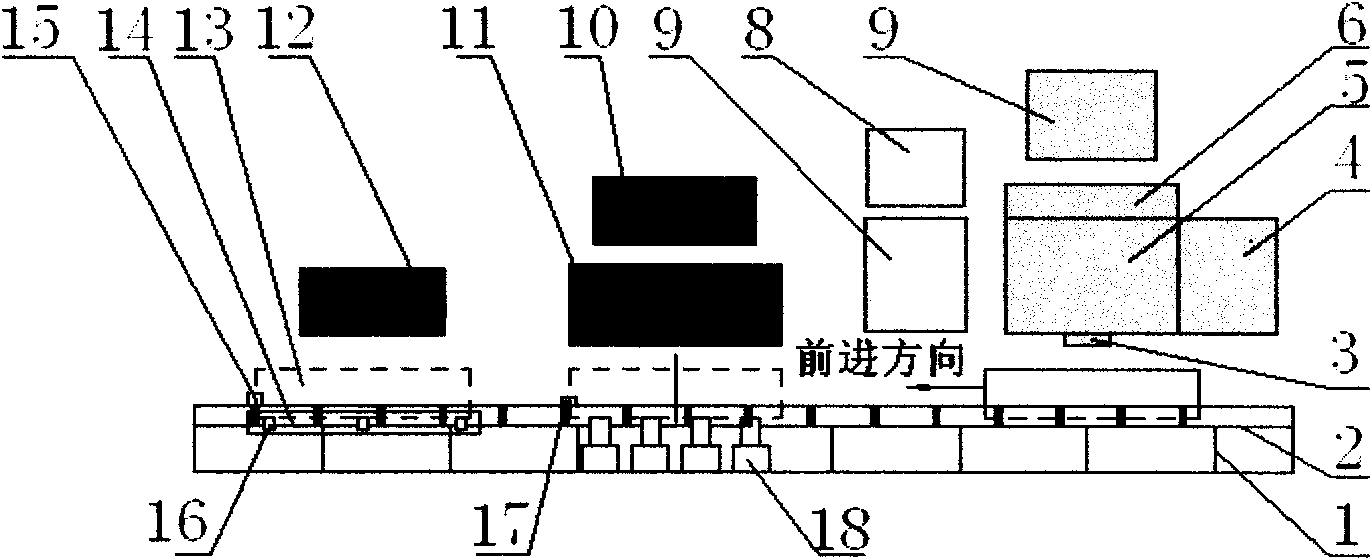

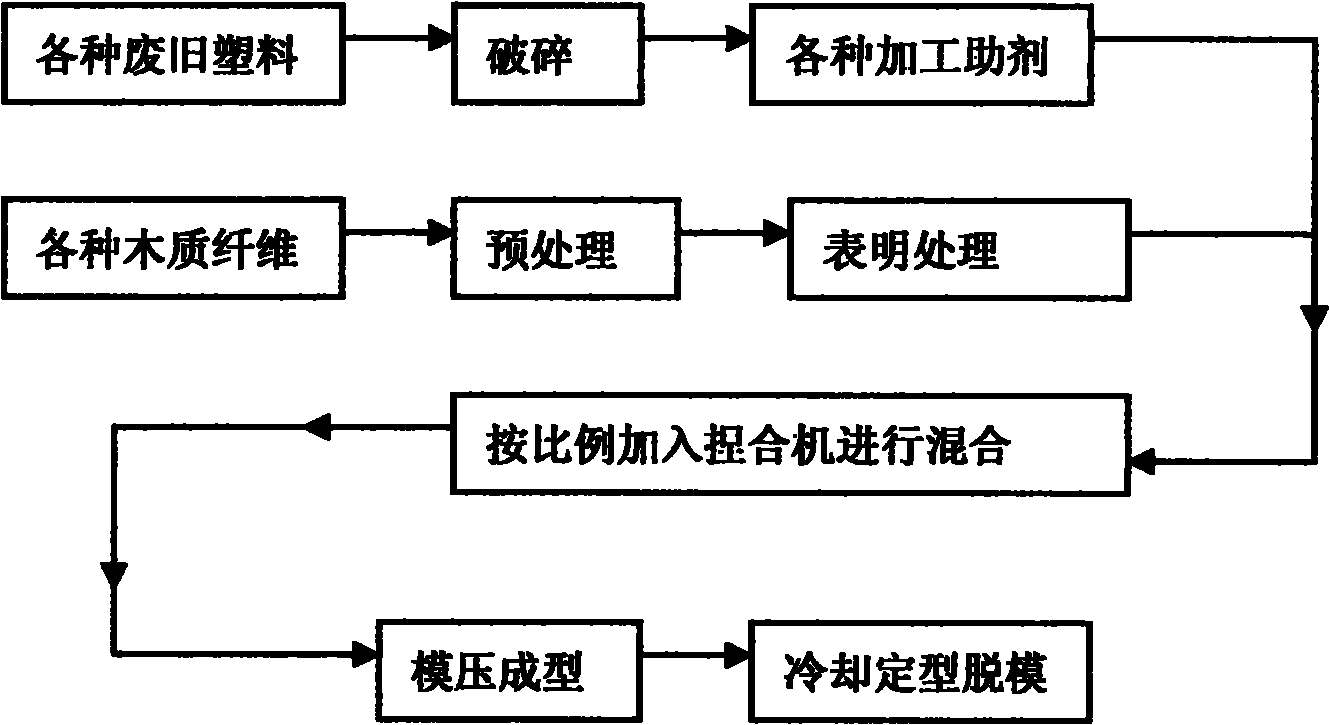

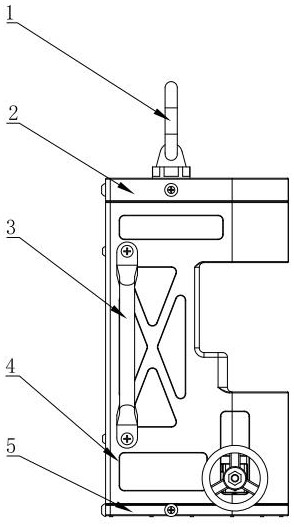

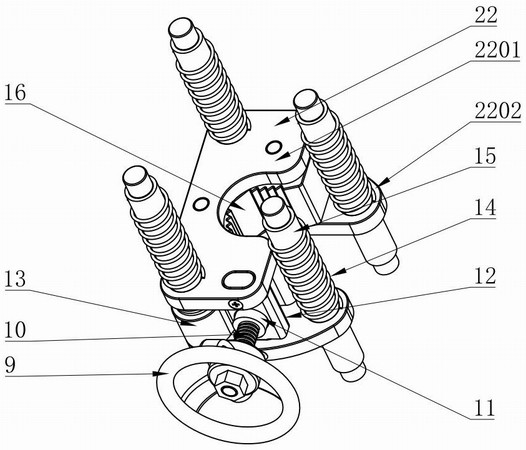

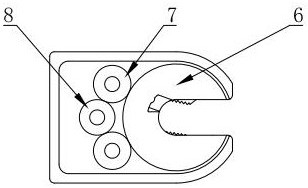

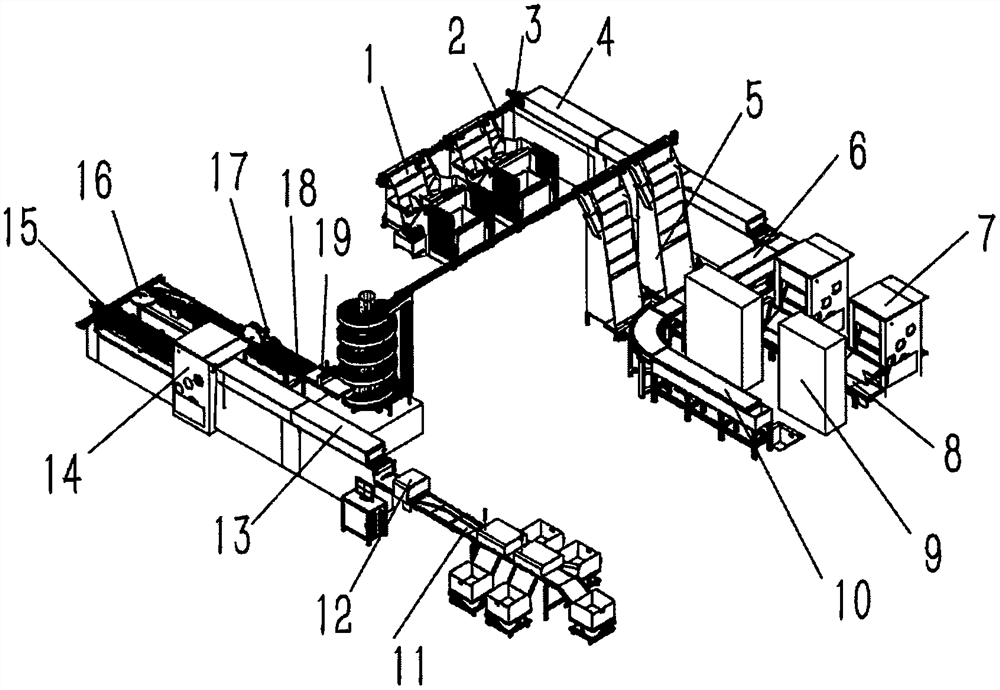

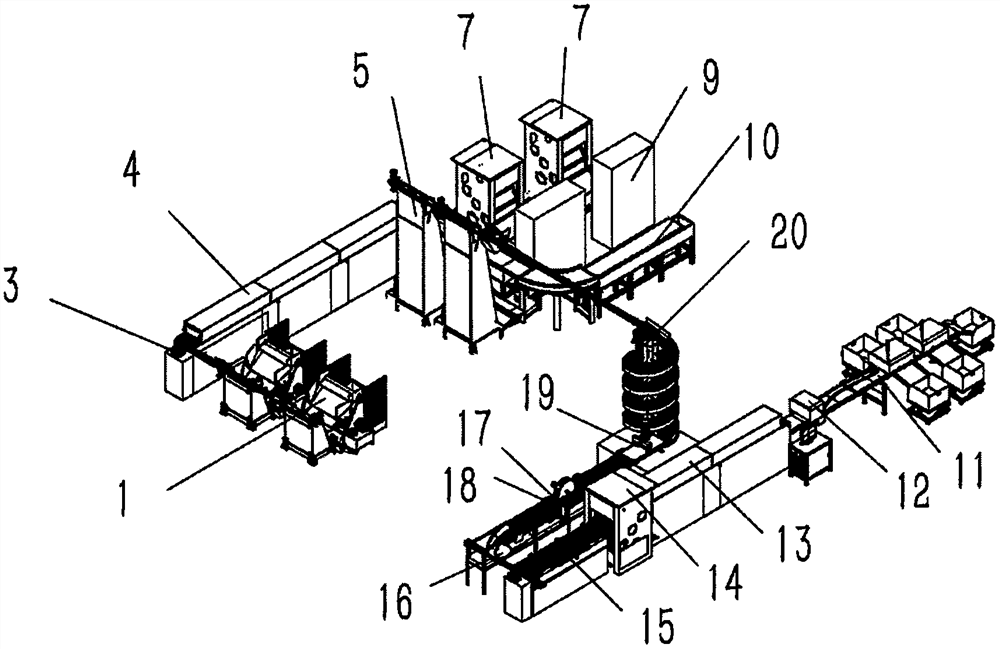

Laminated wood plate forming method

ActiveCN102248571BHigh strengthImprove local strengthWood working apparatusDomestic articlesFiberProduction line

The invention relates to laminated wood plate forming equipment and a laminated wood plate forming method, in particular to laminated wood material forming equipment and a laminated wood material forming method, which form a new composite material with high strength, high hardness and low cost by plasticizing mixed recovered waste plastics, kneading the plasticized mixed recovered waste plastics, a crushed wood fiber material and a processing assistant and die-pressing to form a common continuous phase structure. The production equipment comprises a kneading machine (5), a rail (3), a hydraulic press (11), a demolding mechanism (14) and a corresponding control panel.

Owner:BEIJING HENGTONG INNOVATION LUXWOOD TECH +1

Quick threaded connection equipment for threaded connection

InactiveCN112123228ASolve the problem of radial tightening workpieceVarious job scenariosPliersDrive wheelReduction drive

The invention provides quick threaded connection equipment for threaded connection. The quick threaded connection equipment is mainly composed of a motor, speed reducer and open gear mechanism, a manual clamping mechanism and a displacement compensation mechanism and further comprises a reset mechanism, a shell, a cover plate, accessories and other structural parts, wherein the motor, speed reducer and open gear mechanism is driven by a motor, power drives an open gear to rotate through a planetary gear reducer, a driving wheel and an idle wheel, and the connection action of a workpiece is completed; pre-tightening force can be applied to the manual clamping mechanism, and reliable clamping is guaranteed; the displacement compensation mechanism can compensate displacement caused by the workpiece being screwed into a screw thread, and the reset mechanism guarantees reverse rotation positioning of a gear; and the mechanisms are wrapped in the shell and matched with a lifting ring and a handle, so that quick threaded connection of the workpiece in different directions and in different scenes can be completed.

Owner:JIANGSU JINLING INST OF INTELLIGENT MFG CO LTD

A method for separating Gelcyne alkaloid monomers from Gelzia alkaloids by combining high-speed countercurrent chromatography with preparative liquid chromatography

ActiveCN111560024BLarge amount of preparationFlexibleOrganic chemistryCountercurrent chromatographyBiochemistry

The invention discloses a method for separating glyphosate alkaloid monomers from glyph alkaloids in combination with high-speed countercurrent chromatography and preparative liquid chromatography. After the individual components were separated, high-speed countercurrent chromatography was used for primary separation and preparative liquid chromatography for secondary separation, and the target Gelcyon alkaloid monomer components were collected respectively. The method uses a plurality of chromatographs in combination to separate glyphosate monomers, which has the advantages of large amount of preparation, short cycle time, high purity, etc., can simultaneously separate and obtain 8 glyph alkaloid monomers, has controllability and automatic productivity, and It has broad application prospects.

Owner:HUNAN AGRICULTURAL UNIV

Pump type scraper head matching device

ActiveCN103770457BPrecise Automatic Squeeze InjectionAutomatic Squeeze JetPrinting press partsEngineeringSolder paste

Owner:HONGYI TECH AUTOMATION EQUIP HUIZHOU CO LTD

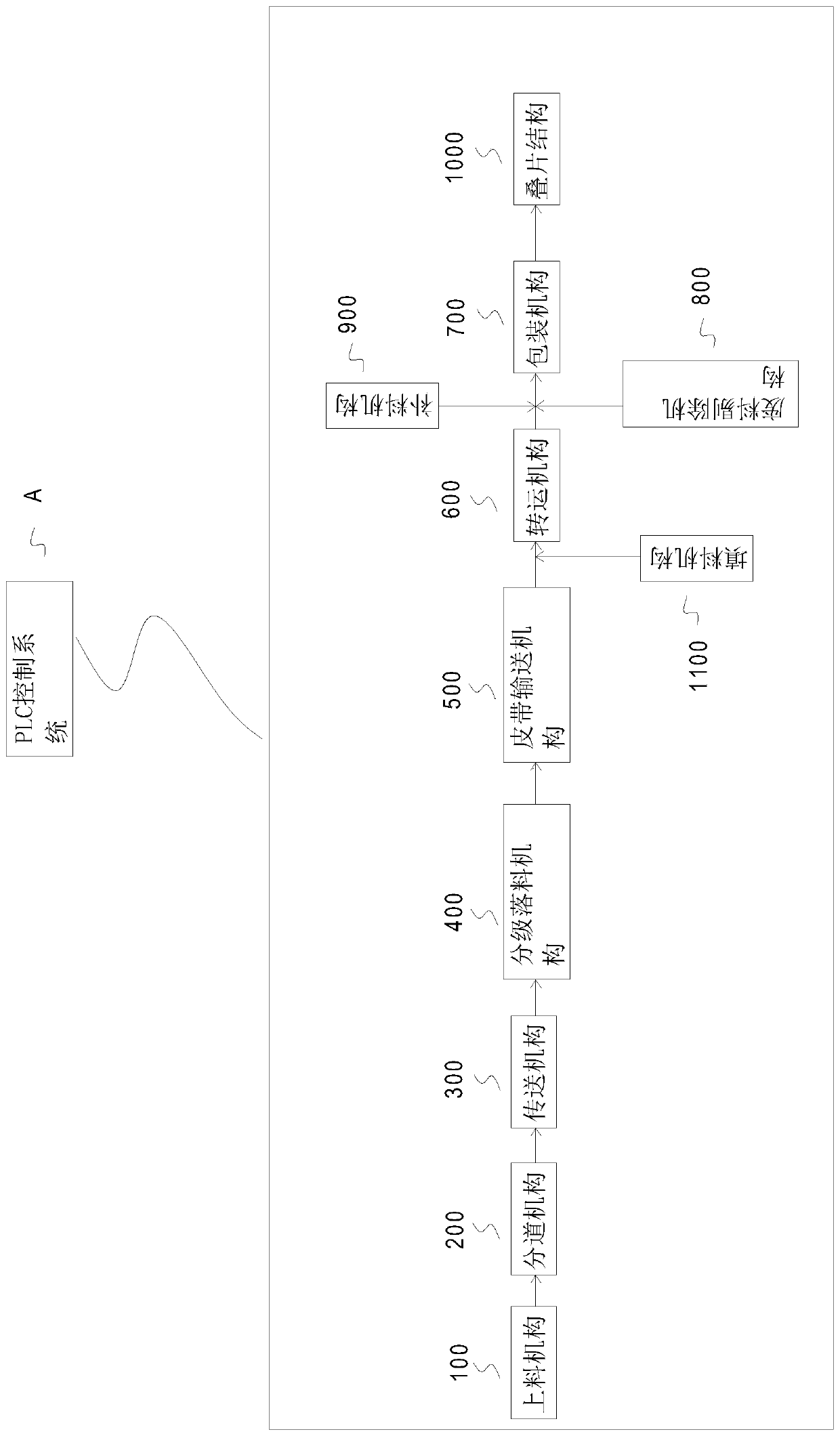

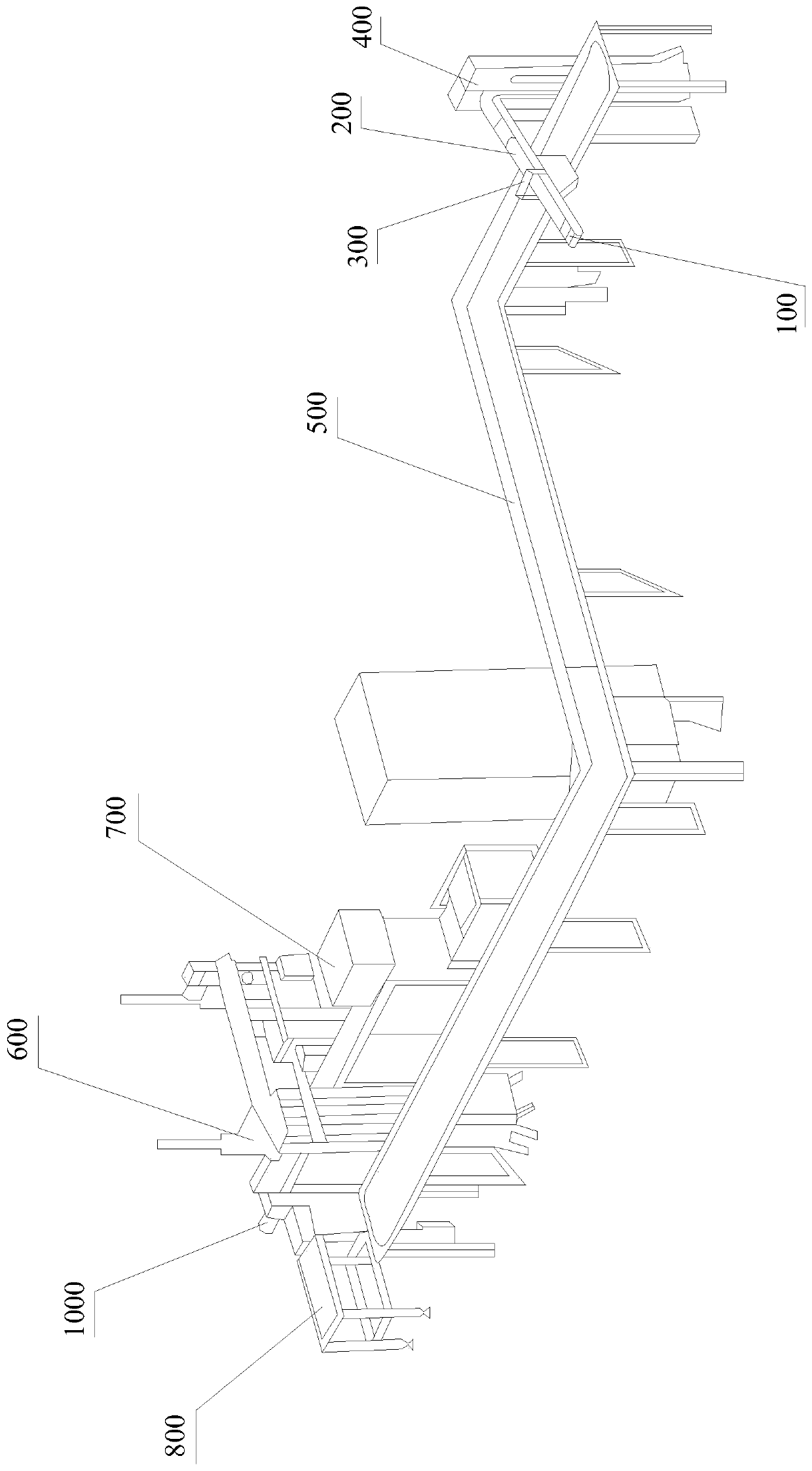

Automatic packaging production device and process for nursing pad

PendingCN110395435AAchieve the appearanceQuality improvementWrappingSortingControl systemEngineering

The invention provides an automatic packaging production device for a nursing pad. The automatic packaging production device comprises a feeding mechanism, a conveying mechanism, a branching mechanism, a grading falling mechanism, a belt conveying mechanism and a transferring device, wherein the feeding mechanism comprises a flow guide groove and a sensor, the sensor is in communication connectionwith a PLC control system, one end of the conveying mechanism is connected with the flow guide groove, the branching mechanism comprises a first driving device, a first driving pushing handle, a second driving device and a second driving pushing handle, the grading falling mechanism is arranged at the other end of the conveying mechanism and comprises a falling frame, a falling channel, a third driving device and a movable baffle are arranged on the falling frame, the belt conveying mechanism penetrates through the whole automatic packaging production device, a semi-finished tray is arrangedon the belt conveying mechanism, the transferring mechanism is arranged at the other end, far away from the feeding mechanism, the conveying mechanism, the branching mechanism and the grading fallingmechanism, of the belt conveying mechanism, and comprises a support, a fourth driving device and a mechanical claw.

Owner:北京雪莲生物科技有限公司

A thermocompression connection device for braided fiber-reinforced composite material plates

A hot-pressing connection device for braided fiber-reinforced composite material plates, including a rivet supply system, a rivet supply system and an automatic rivet installation system for joint connection, a hot air heating system, a plate punching system, an automatic rivet installation system, a riveting system, and a servo turntable system for installation On the bracket, the connected plates are installed on the servo turntable system through the pneumatic clamping device connected to the servo turntable system. With the rotation of the servo turntable system, the connected parts are heated by the hot air heating system in turn, and the plate punching system For the piercing holes of the connected parts, the rivet automatic installation system installs the rivets, and the riveting system performs hot-press riveting to form the connection joints. The invention reduces the damage to the fibers during the connection process of the braided fiber reinforced composite material plates, and realizes automatic production at the same time , reducing connection costs.

Owner:XI AN JIAOTONG UNIV +1

A continuous automatic production method of flax yarn

The invention relates to the linen yarn production technology field and especially relates to the continuous automatic production method of a linen yarn. A front processing portion, a heckling portion, a beam splitting portion, a twisting portion, a drawing portion and a blended yarn portion are included. After a linen raw material is split into a plurality of raw material bundles, a hackling machine carries out carding on the raw material bundles so as to obtain long fibers and short fibers. When the long fibers are transferred, the long fibers are split into bundles and the fiber bundles aresequentially pushed into an output component. Through the output component, the previous group of fiber bundles and the next group of fiber bundles in the output component are overlapped in an end-to-end mode, and during an output process, the fiber bundles are staggered and intertwined. A bundle splitting mechanism is used to split the long fibers in a directional transfer process through a guiding splitting mode, and then, the two adjacent groups of fiber bundles are directionally output in an end-to-end overlapping manner, and at the same time automatic winding is performed so as to realize the high-quality automatic production of linen splitting and lap joint. The technical problem of unstable yarn quality due to uneven artificial bundle splitting existing in the prior art is solved.

Owner:湖北蜀峰线业发展有限公司

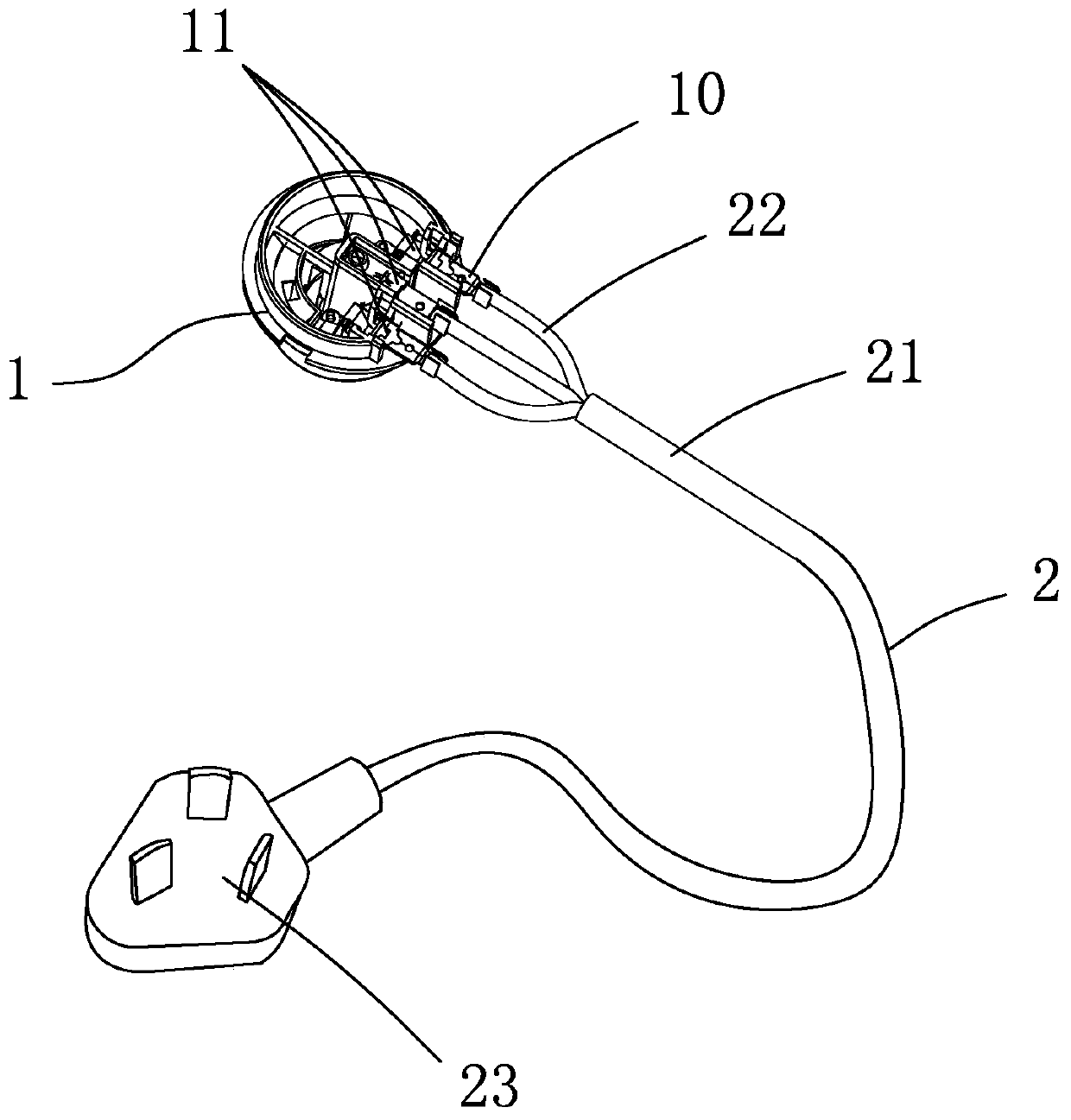

Automatic assembly line production system of coupler

PendingCN110091182AAutomate the connectionIncrease productivityOther manufacturing equipments/toolsEngineeringAssembly line

The invention discloses an automatic assembly line production system of a coupler. The automatic assembly line production system comprises a carrier doing circular motion, a line cutting and peeling device, a transferring device, a riveting device, a welding device, a heat shrink tube sleeving device and a heat shrink tube heating device. The line cutting and peeling device, the transferring device, the riveting device, the welding device, the heat shrink tube sleeving device and the heat shrink tube heating device are sequentially arranged in the motion direction of the carrier. The carrier comprises a first locating part for supporting and locating one end of a power line and a second locating part for supporting and locating the joint between a conducting plate and the other end of thepower line. The first locating part and the line cutting and peeling device cooperate to carry out line cutting and peeling on a branch line at one end of the power line. The second locating part cooperate with the riveting device, the welding device, the heat shrink tube sleeving device and the heat shrink tube heating device to carry out riveting, welding, heat shrink tube sleeving and heat shrink tube heating on the position between the conducting plate and the power line. The transferring device can clamp and transfer one end of the power line from the first locating part to the second locating part. The automatic assembly line production system is simple in structure and can achieve automatic production of the coupler, and the production efficiency is improved.

Owner:ZHEJIANG DAWEI ELECTRONICS +1

An automatic production line for steel back surface treatment

ActiveCN113086543BImplement sortingImplement automatic classificationLiquid surface applicatorsControl devices for conveyorsProduction lineAbrasive blasting

Owner:RIZHAO POLYTECHNIC

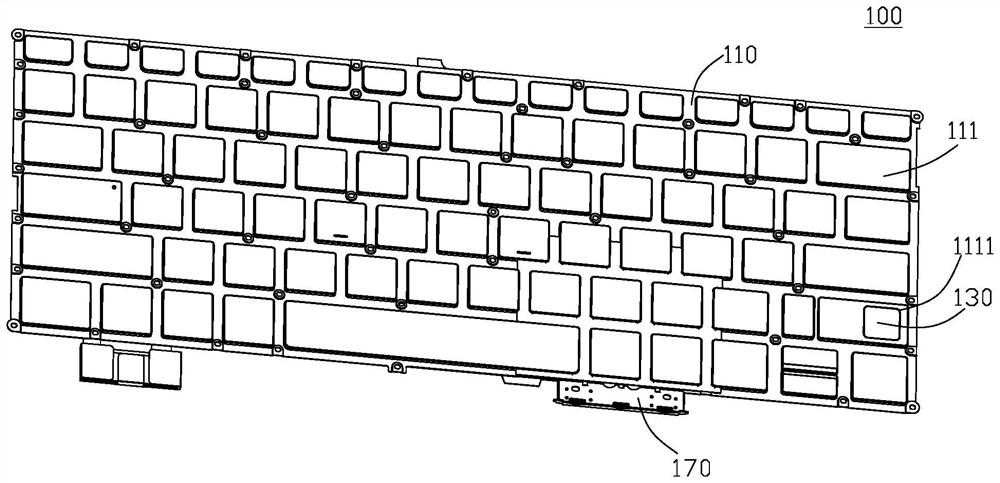

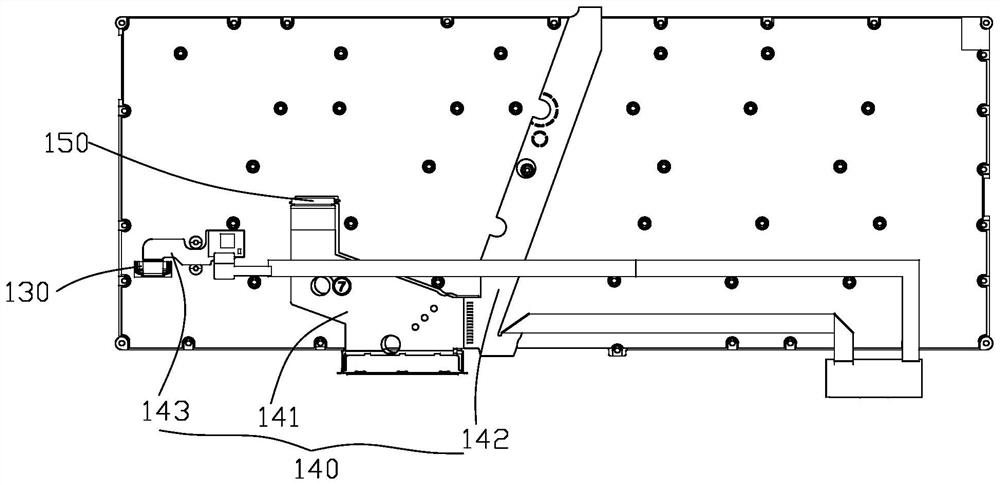

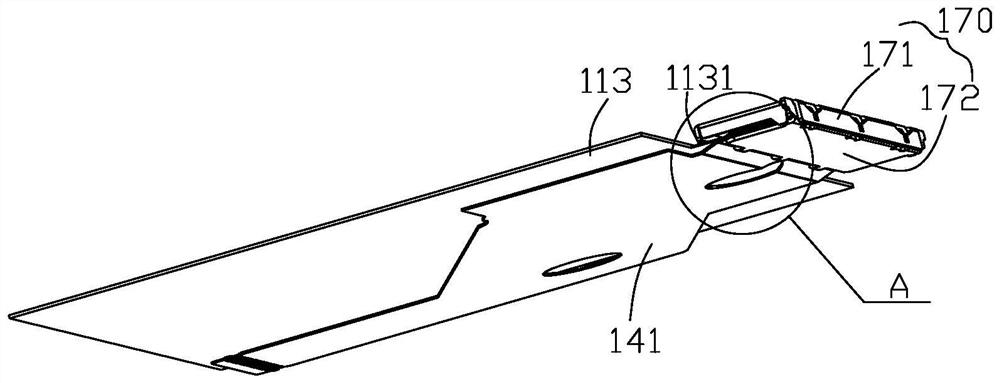

Keyboard and electronic device

PendingCN113760045AAutomate the connectionReduce assembly timeDigital data processing detailsCharacter and pattern recognitionComputer hardwareFlexible circuits

The invention provides a keyboard and an electronic device. The keyboard comprises a keyboard body, a backlight module and a fingerprint recognition module; the keyboard body is provided with a front face and a back face, a plurality of keys are arranged on the front face of the keyboard body, the keyboard body is connected with a first flexible circuit board, and the backlight module is arranged on the back face of the keyboard body and connected with a second flexible circuit board; the fingerprint identification module is connected with a third flexible circuit board, the fingerprint identification module is arranged corresponding to one key, the third flexible circuit board, the second flexible circuit board and the first flexible circuit board are connected to form a flexible circuit board assembly, and the flexible circuit board assembly is provided with a board-to-board connector used for being connected with the outside. The fingerprint recognition function is integrated on the keyboard, the assembling frequency can be reduced, automatic connection can be achieved, and the labor cost is reduced.

Owner:LCFC HEFEI ELECTRONICS TECH

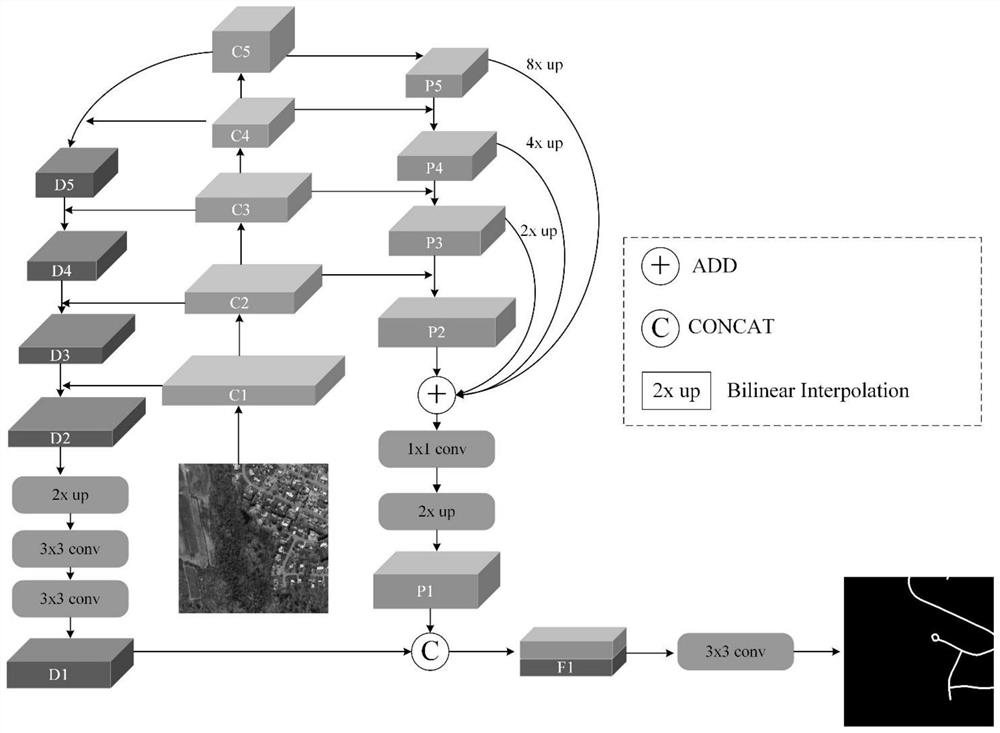

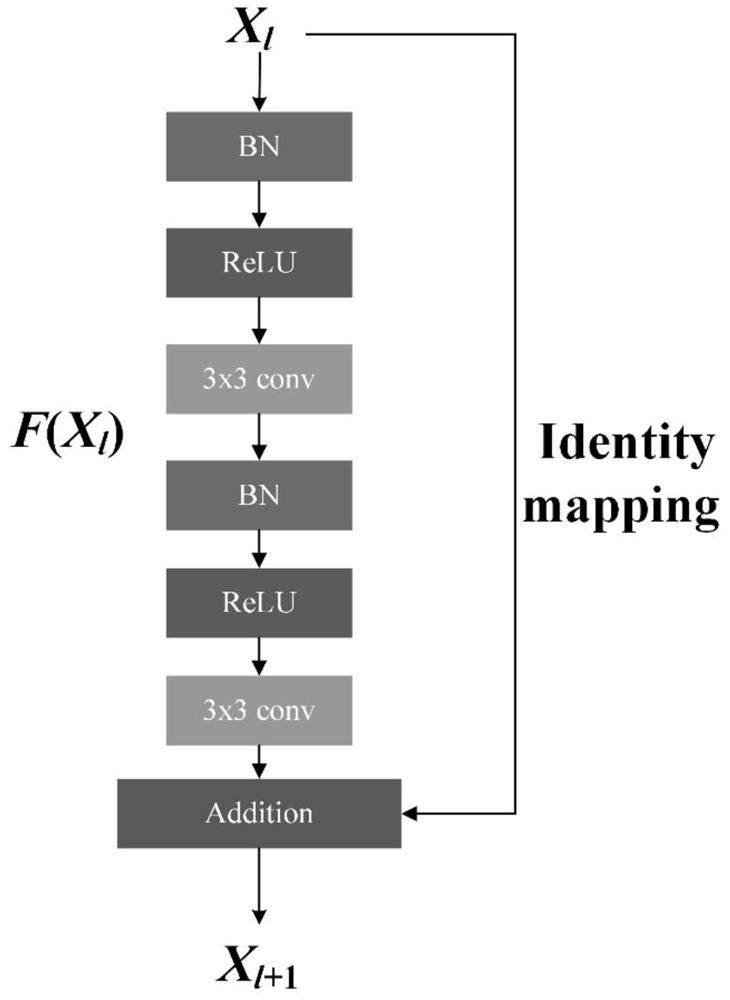

A Road Extraction Method Based on Multi-branch Pyramid Neural Network for Remote Sensing Image

ActiveCN112287807BIntegrity guaranteedEnhance reasoning abilityInternal combustion piston enginesScene recognitionStructure analysisSatellite image

The invention discloses a method for extracting complete road information on remote sensing images by using a convolutional neural network. A multi-branch pyramidal neural network is constructed. Through two parallel feature recovery structures and post-processing technology based on geometric structure analysis and feature point extraction, the low-level position information and high-level semantic information are fully mined to solve the problem of road extraction on satellite images. The problem of road sparsity and road breakage caused by vegetation and buildings are faced. This method comprehensively considers the sparsity of road distribution and the imbalance of samples through sparsity testing and designing a new loss function, so that the network pays more attention to sparse and difficult-to-classify road pixels. At the same time, in view of the situation where the road is covered by vegetation and buildings, this method performs automatic fracture detection and fracture connection based on geometric feature point analysis, which improves the accuracy of road extraction, and has an important role in computer vision and remote sensing road extraction scenarios. practical application value.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com