Quick threaded connection equipment for threaded connection

A threaded connection and equipment technology, which is applied in the field of connection equipment, can solve the problems of inability to adapt to large-scale and high-torque usage scenarios, insufficient torque of electric tools, and limited usage environments, etc., to achieve diverse job scenarios, low cost, and easy operation. simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

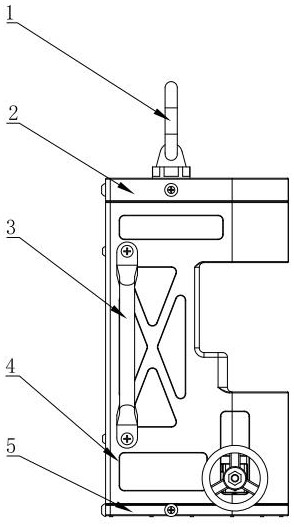

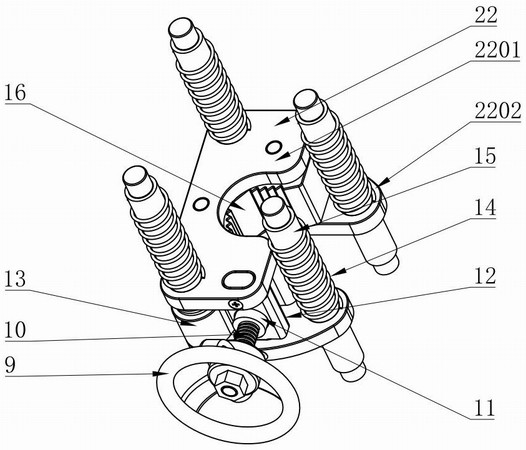

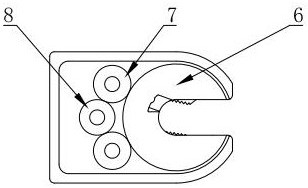

[0046] Figure 6 A schematic diagram of the actual use of the quick screw connection device provided for the example of the present invention when connecting vertical workpieces. When in use, connect the lifting ring through the hook, move the equipment to the vicinity of the working position, the operator holds the handle, and the auxiliary equipment enters the installation position to ensure that the manual clamping device is located at the fixed workpiece, the open gear is located at the workpiece to be installed, and the equipment is in place. Finally, the operator manually tightens the hand wheel to provide pre-tightening force for the clamping device. After confirming the clamping, press the switch and the equipment starts to work. When working, the servo motor first rotates at a high speed, and is transmitted to the driving wheel through the reduction gear of the planetary gear reducer, and the open gear is driven to rotate through the two idler gears, and the buckle-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com