A thermocompression connection device for braided fiber-reinforced composite material plates

A technology for reinforcing composite materials and braided fibers, which is applied in the field of hot-pressing connecting devices for braided fiber-reinforced composite material sheets, can solve problems such as unfavorable industrialized mass application of composite material connections, reducing joint connection strength, and electrochemical corrosion of joints, etc. Electrochemical corrosion problem, realize automatic connection, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

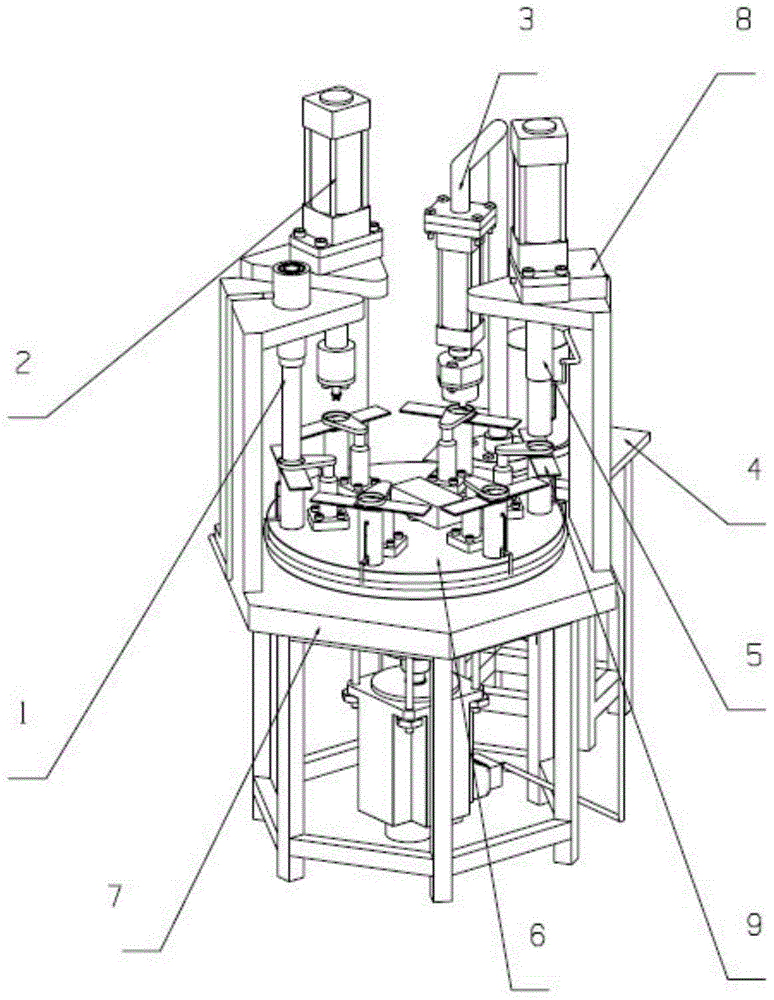

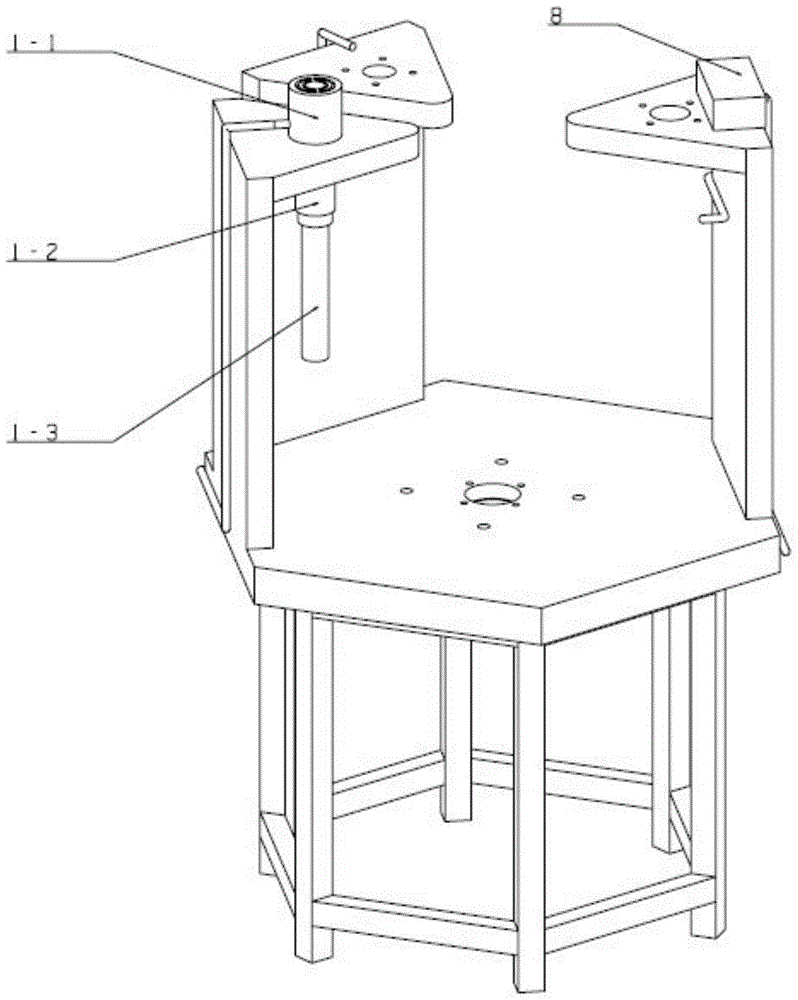

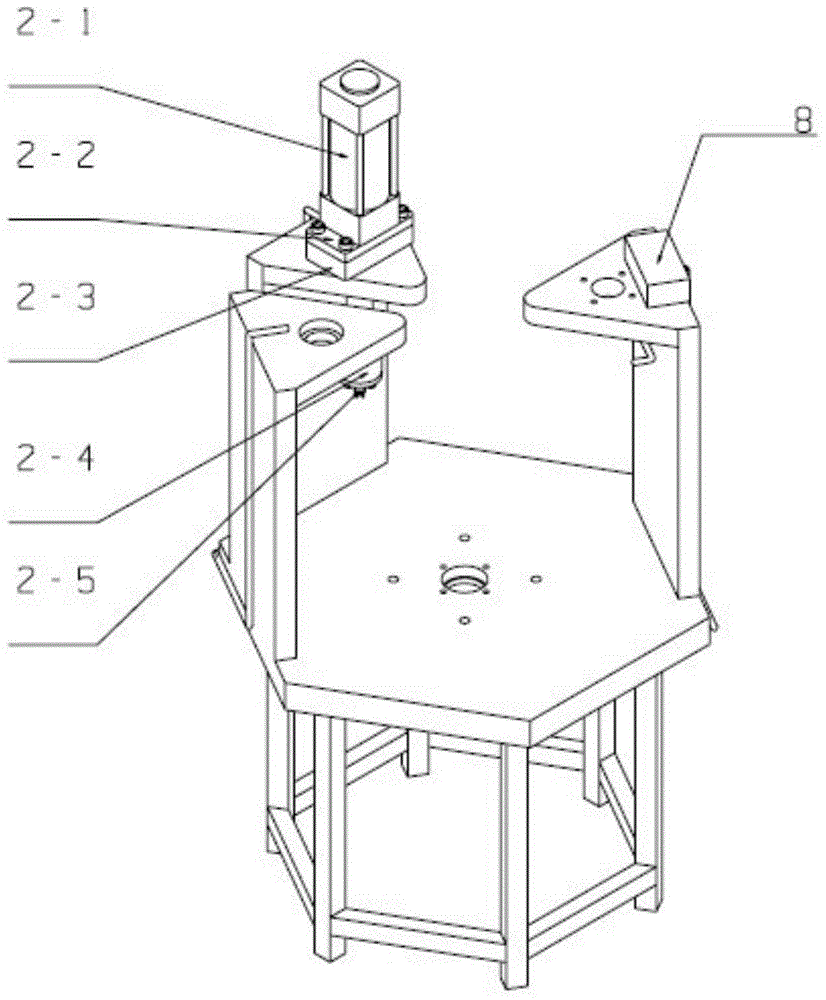

[0038] refer to figure 1 , a thermocompression connection device for braided fiber-reinforced composite material plates, including a bracket 7, a servo turntable system 6 is installed in the middle of the bracket 7, and a hot air heating system 1, a plate punching system 2, and rivets are installed in sequence around the bracket 7 Automatic installation system 3, riveting system 5, hot air heating system 1, plate punching system 2, rivet automatic installation system 3, riveting system 5 cooperate with corresponding stations of servo turntable system 6, rivet supply system 4 and rivet automatic installation system 3 Cooperate and connect to provide rivets for the rivet automatic installation system 3; the hot air heating system 1, the plate punching system 2, the rivet automatic installation system 3, the rivet supply system 4, the riveting system 5, and the servo tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com