Patents

Literature

79results about How to "Reduce assembly time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

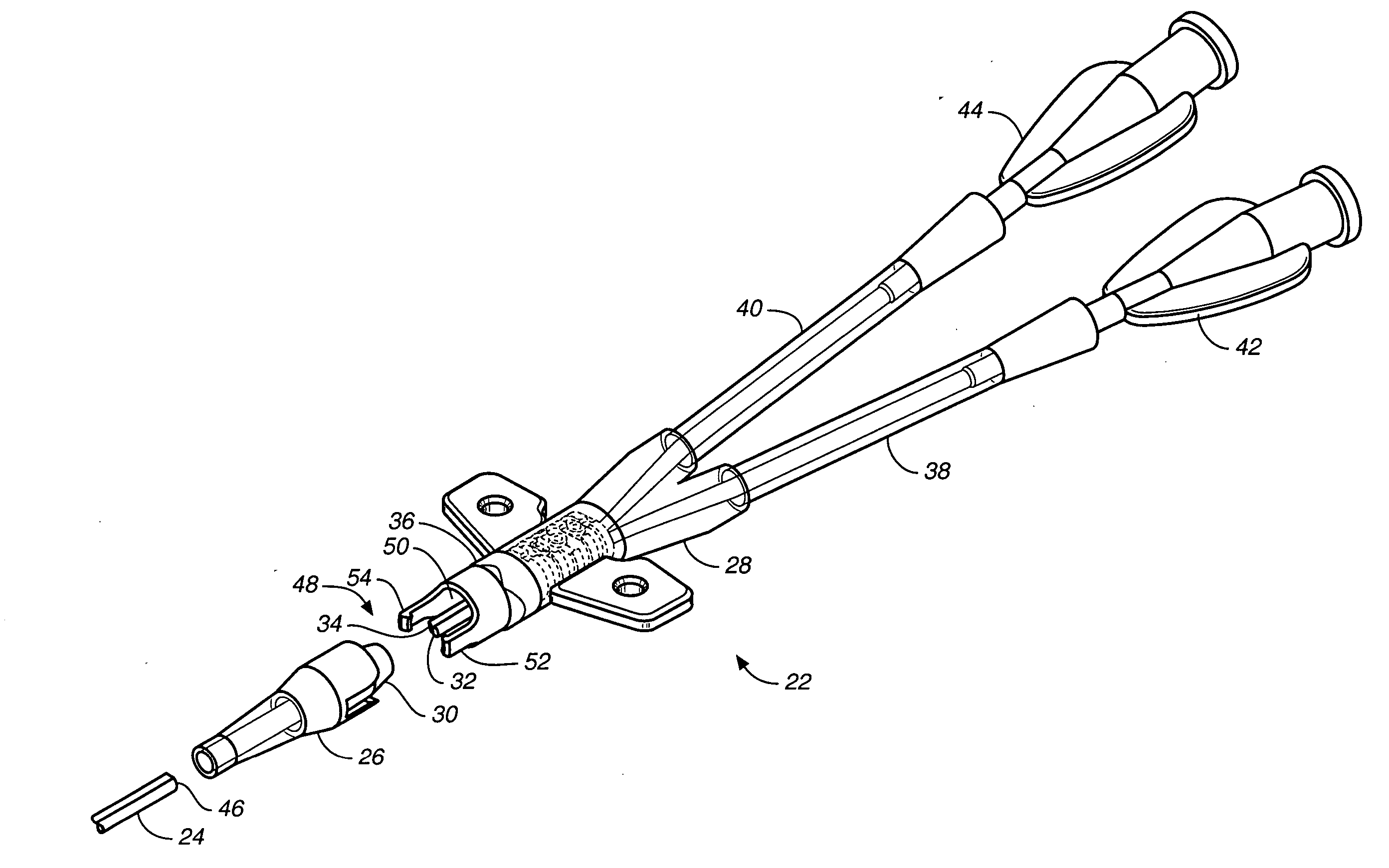

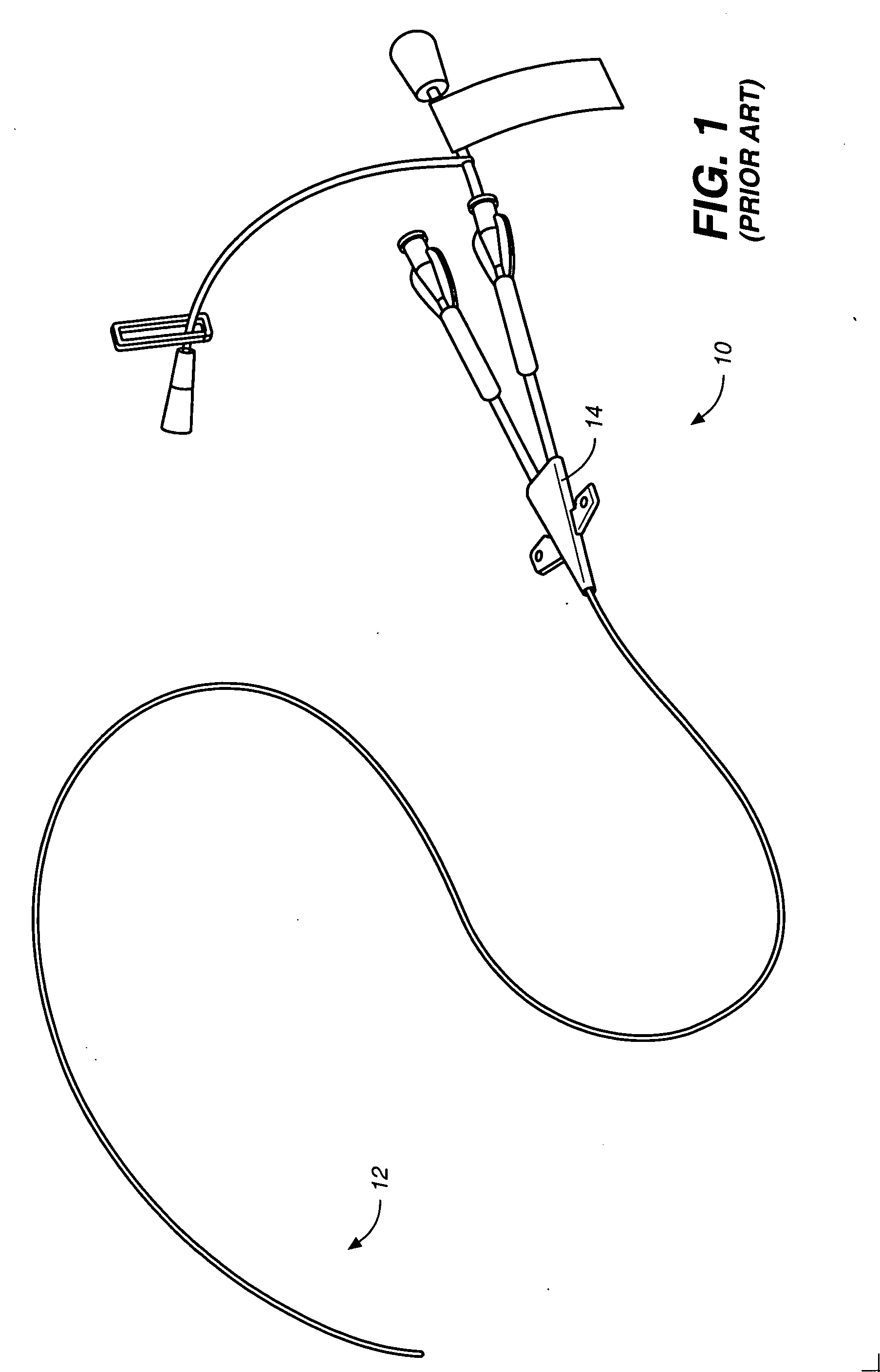

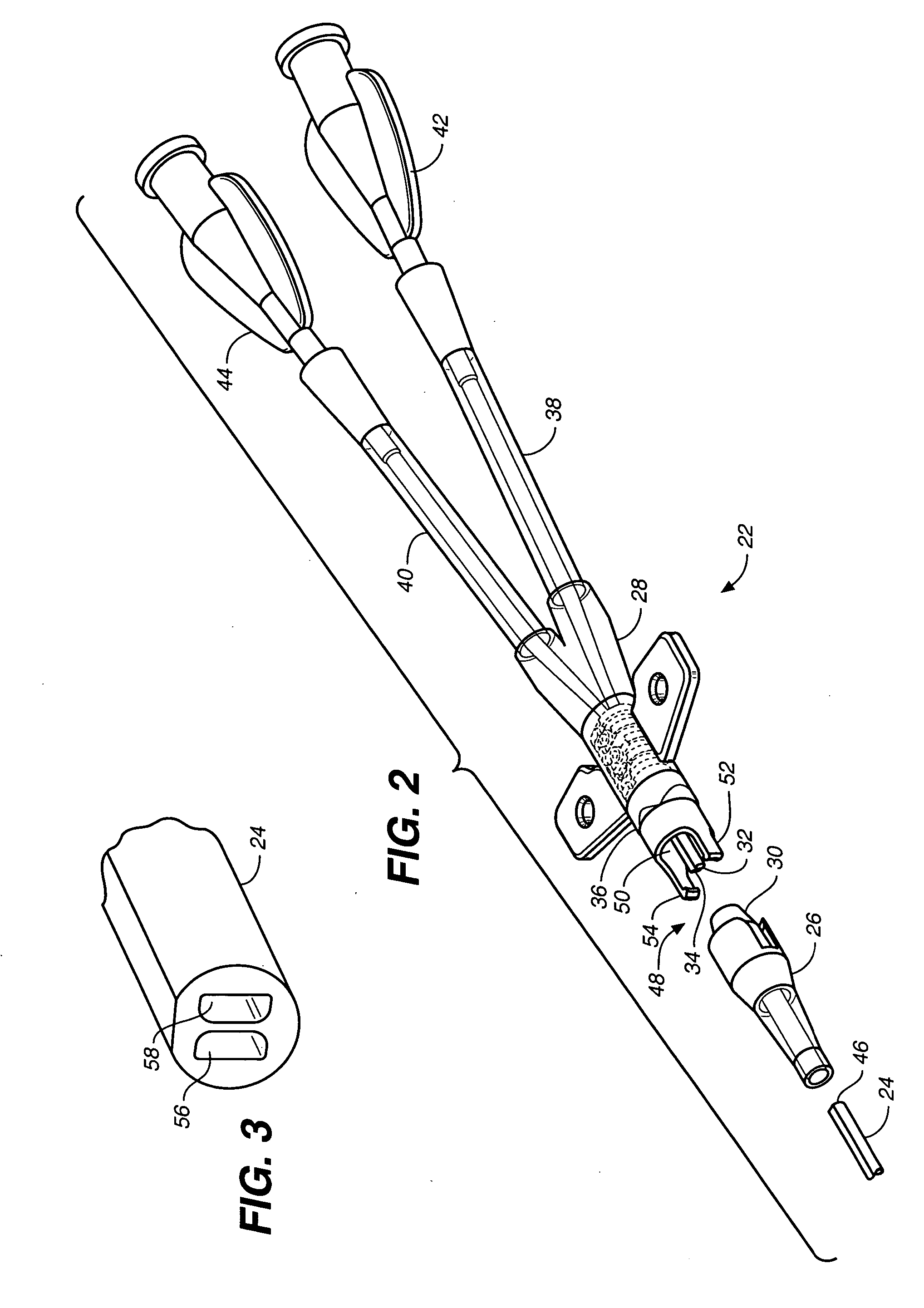

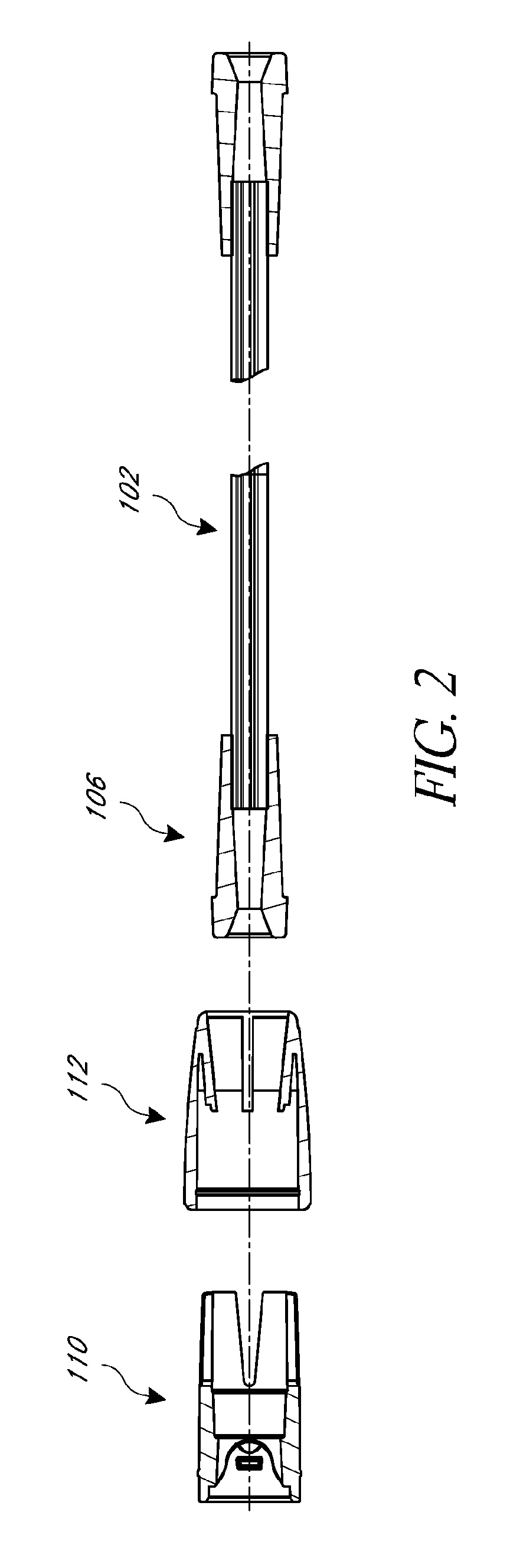

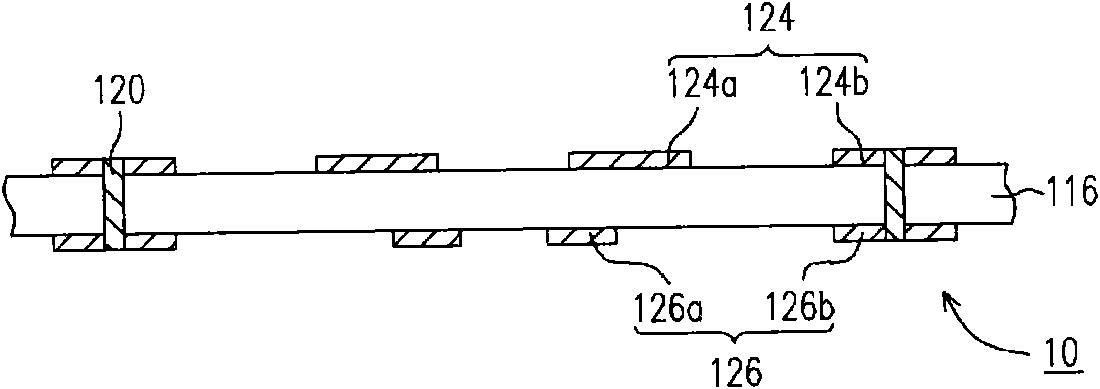

Catheter connector system

ActiveUS20060015086A1Safely and effectively connectsReduce assembly timeCatheterTube connectorsColletCatheter device

A catheter connector system that allows trimming of the proximal end of a catheter (single or multiple lumen) prior to the placement of a connector hub. In one variation, the catheter connector system comprises a catheter, a connector sheath including a soft collet, and a connector hub including a cannula for engaging the catheter and a connector hub interface for receiving the connector sheath.

Owner:CR BARD INC

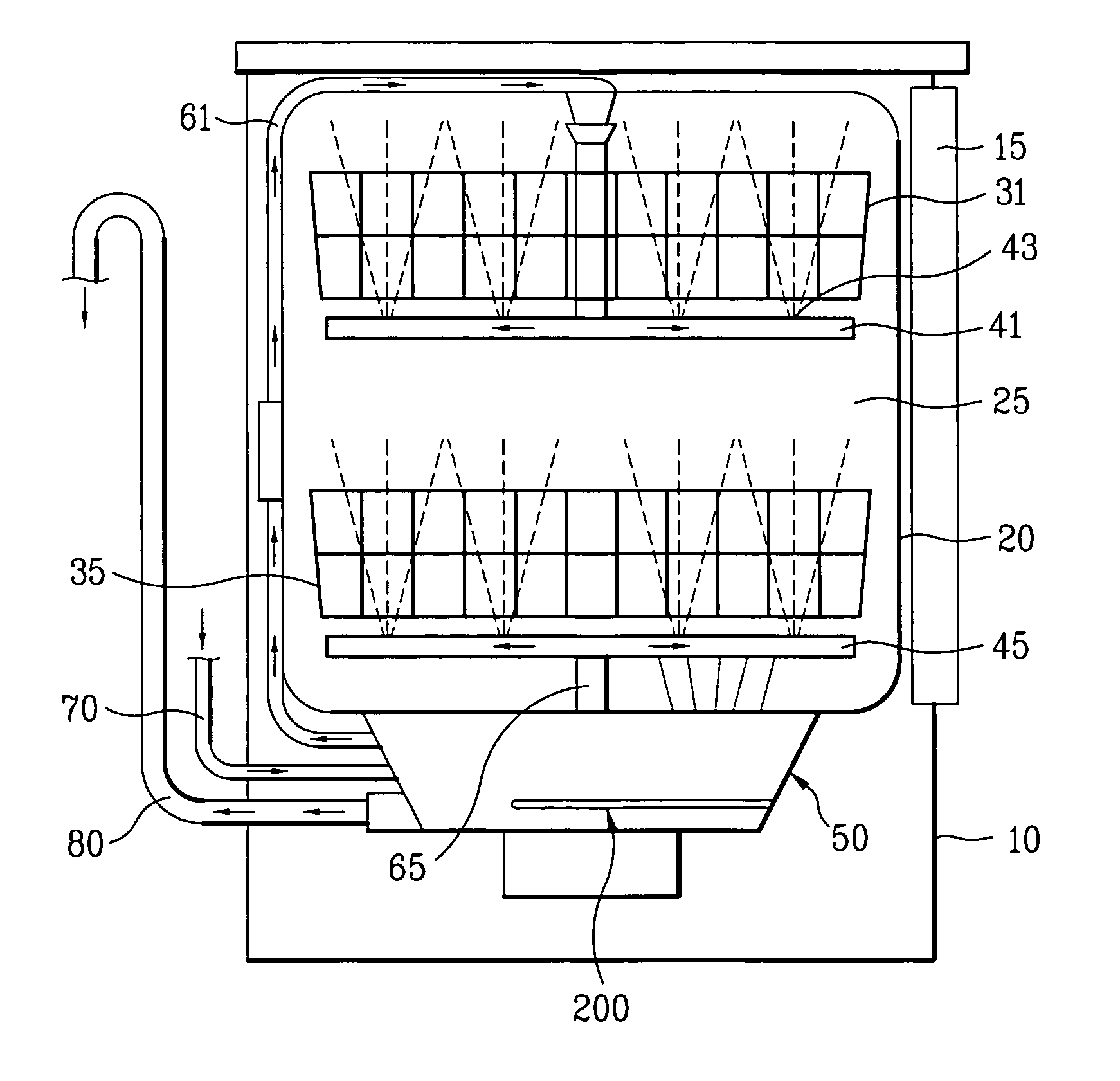

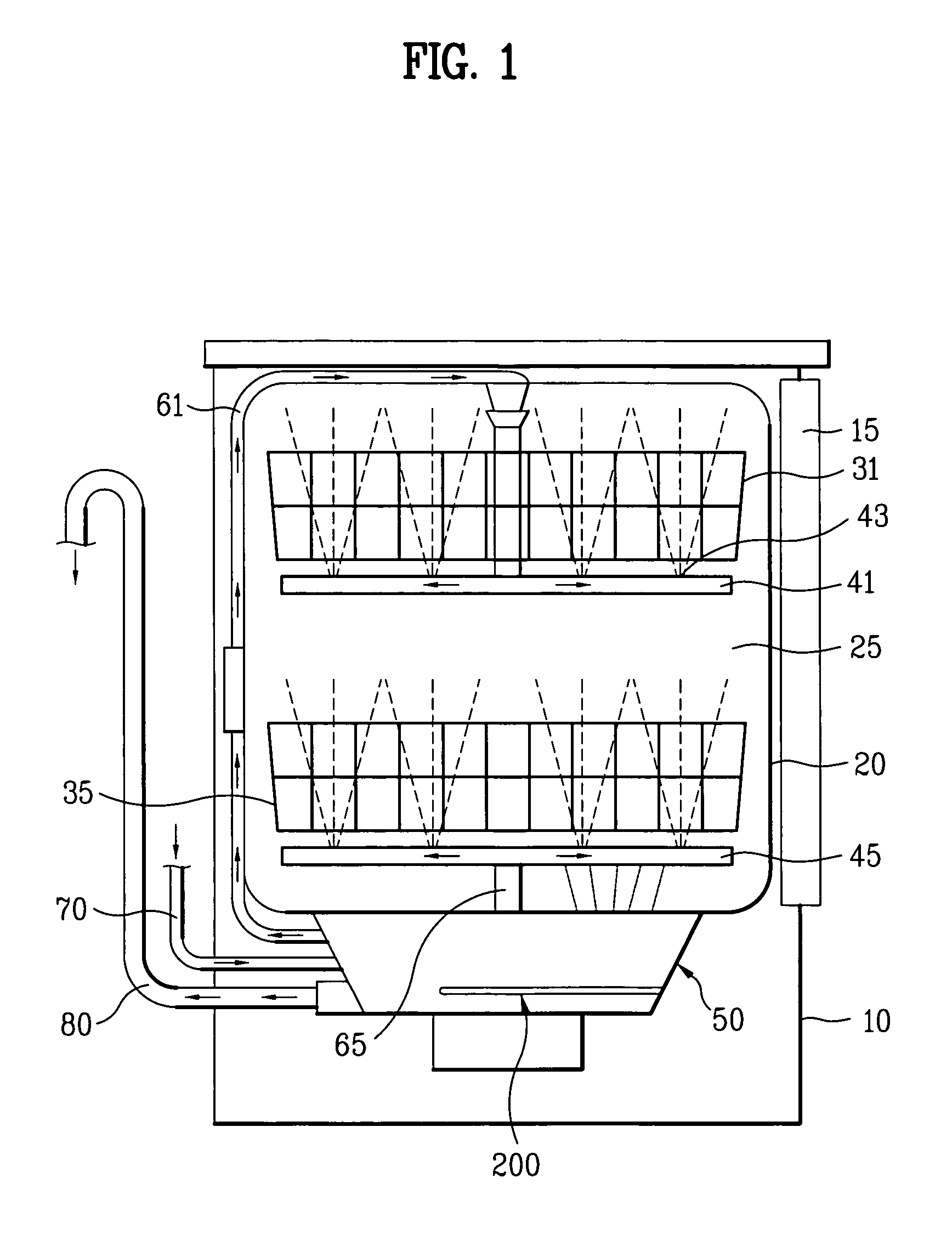

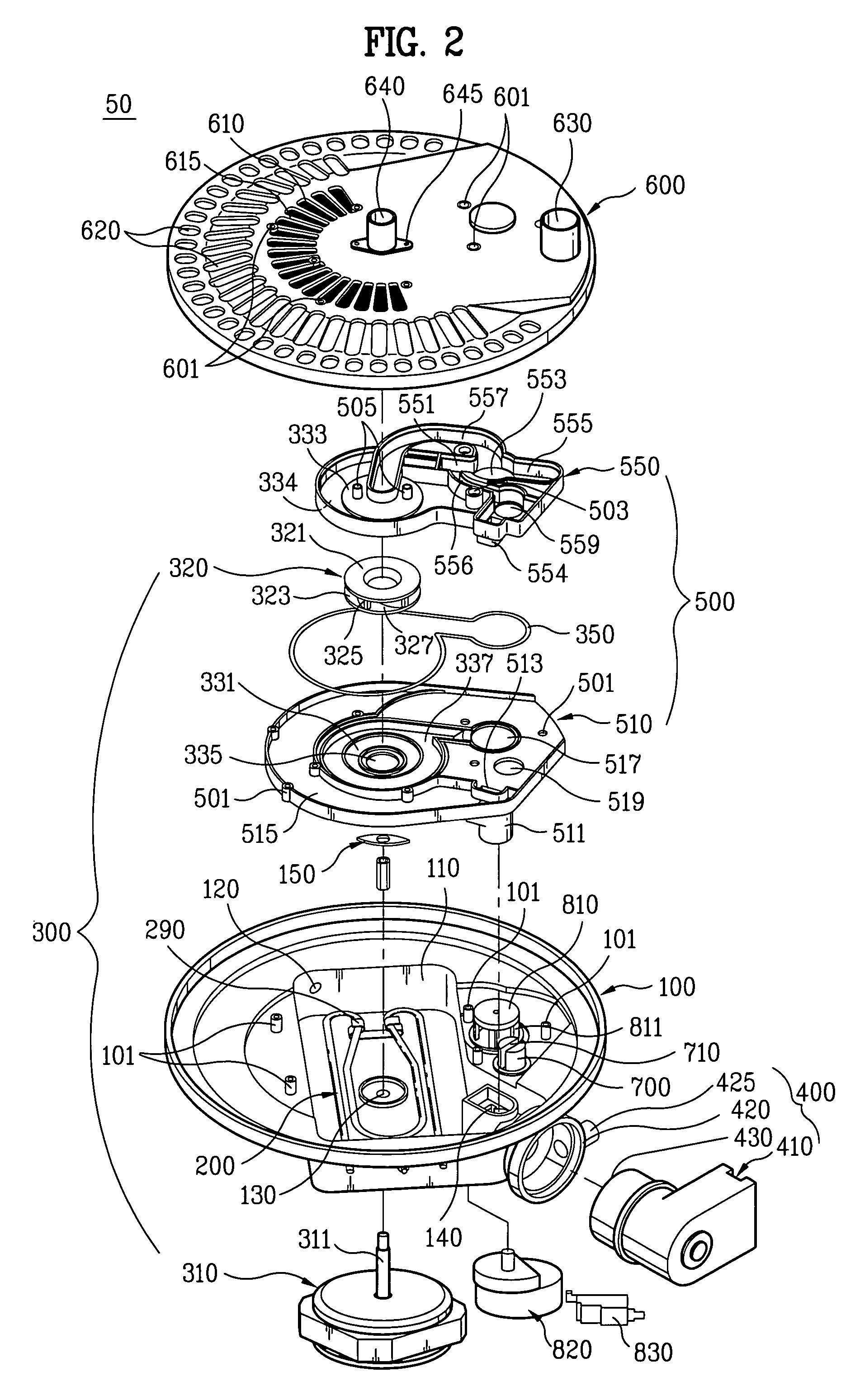

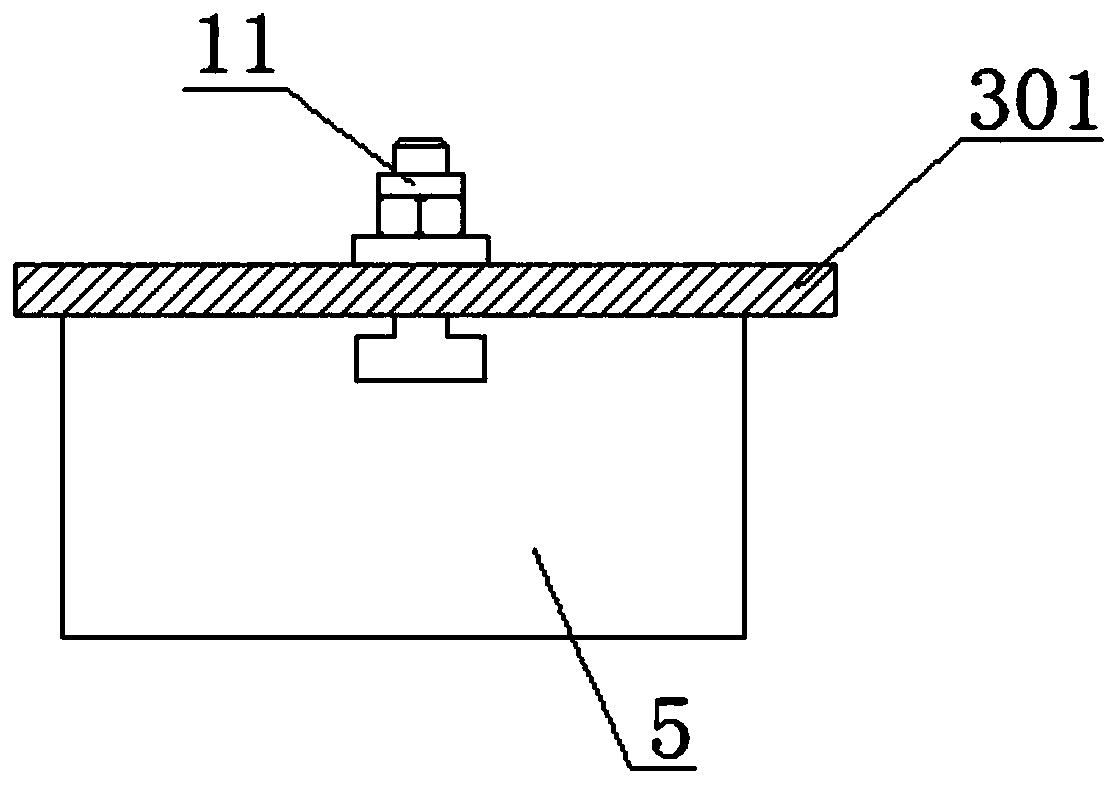

Sump assembly of dishwasher

InactiveUS20060060228A1Boost productivityReduce assembly timeTableware washing/rinsing machine detailsCleaning using liquidsNozzleSump

A sump assembly of a dishwasher stores water to be supplied to spray nozzles. The sump assembly includes a sump housing for storing water; a cover for covering the sump housing; and a water guide provided within the sump housing and disposed under the cover, the water guide being directly joined to the cover and having at least one guide passage for outputting water, wherein at least one of the water guide and the cover is partially fused to enable the joining without using a separate locking member.

Owner:LG ELECTRONICS INC

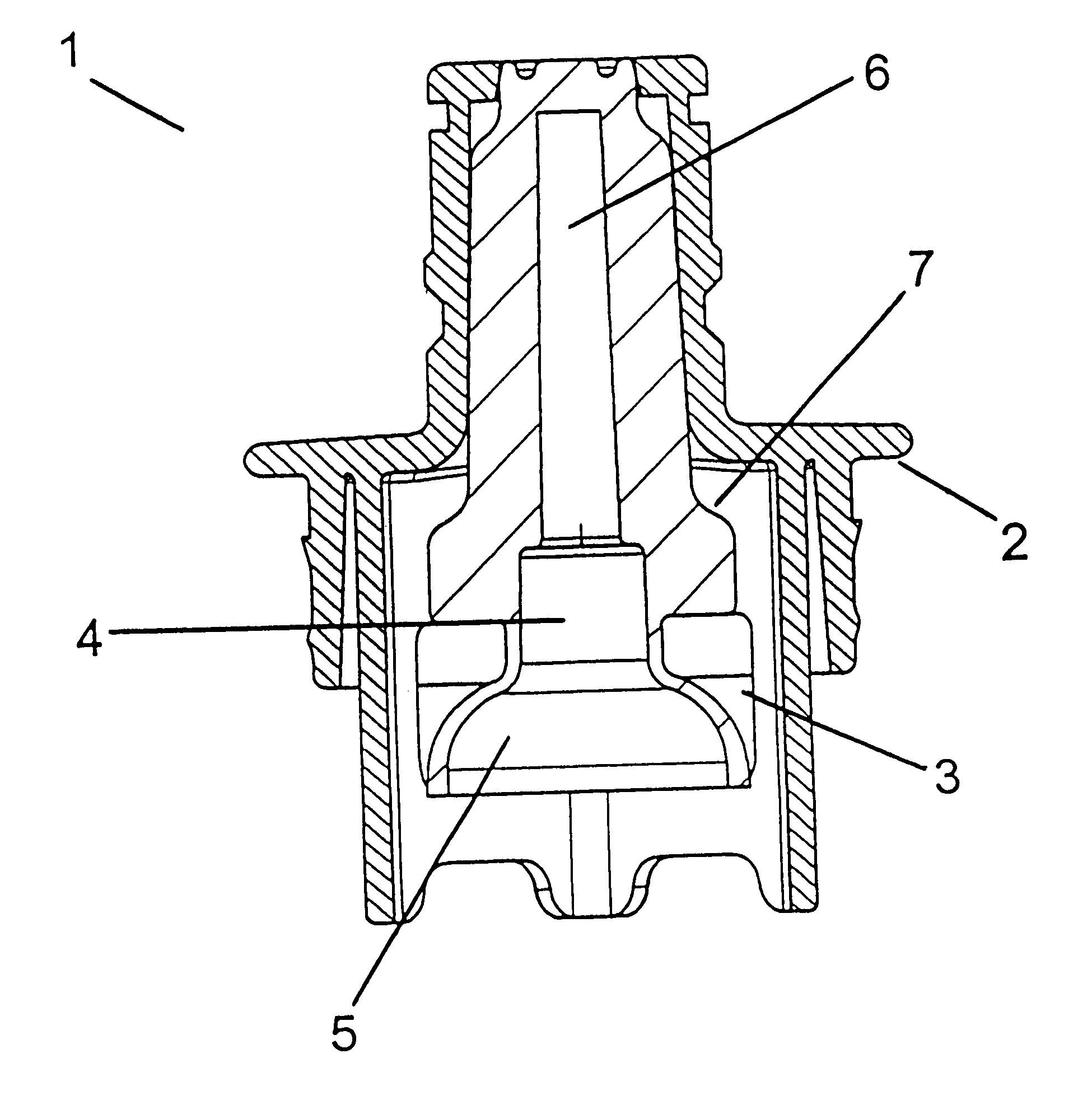

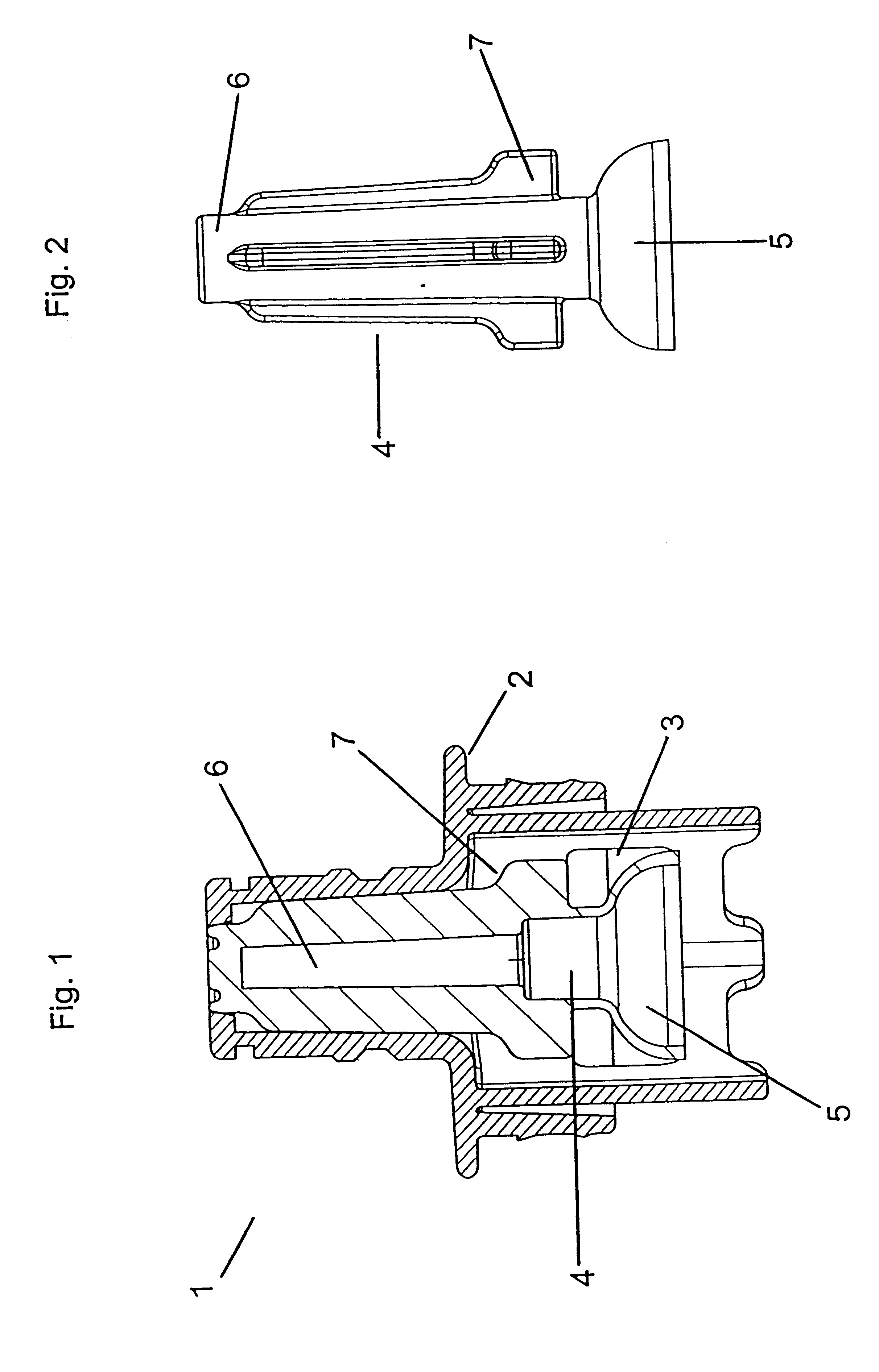

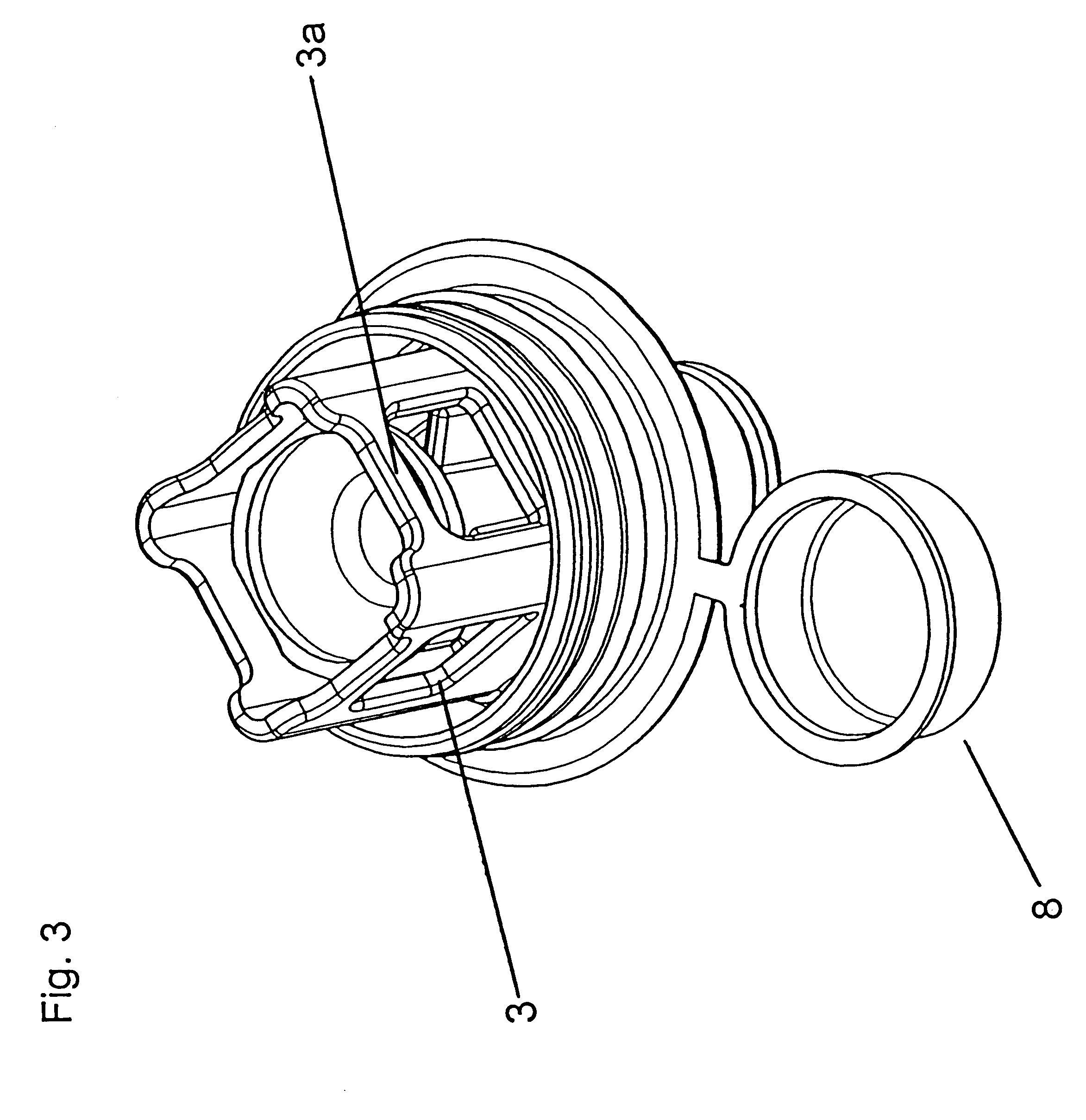

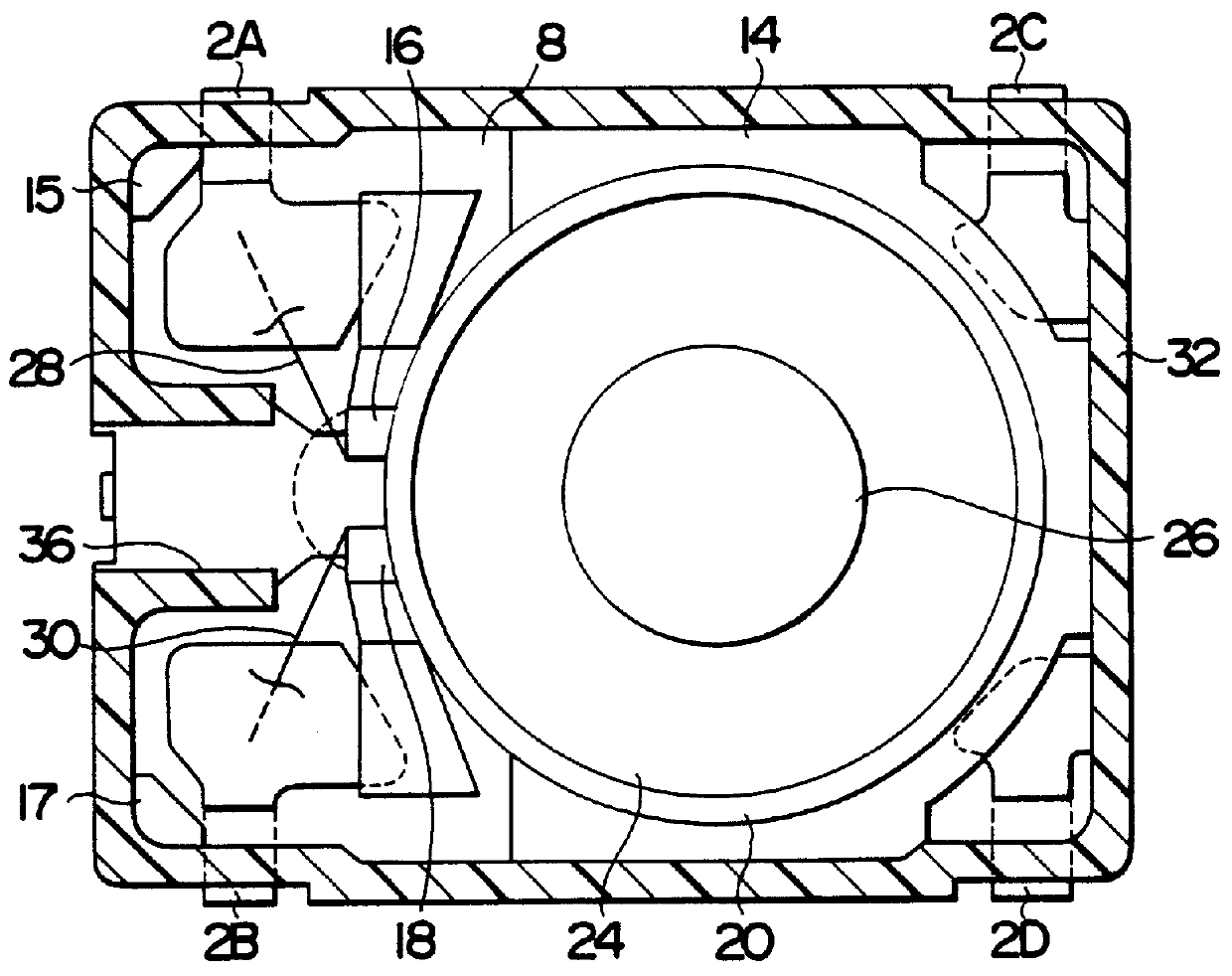

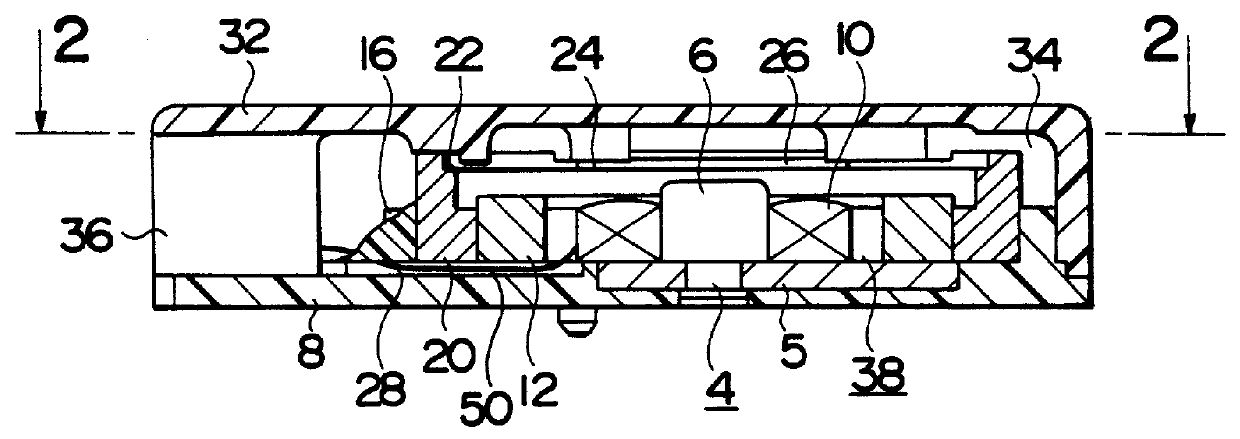

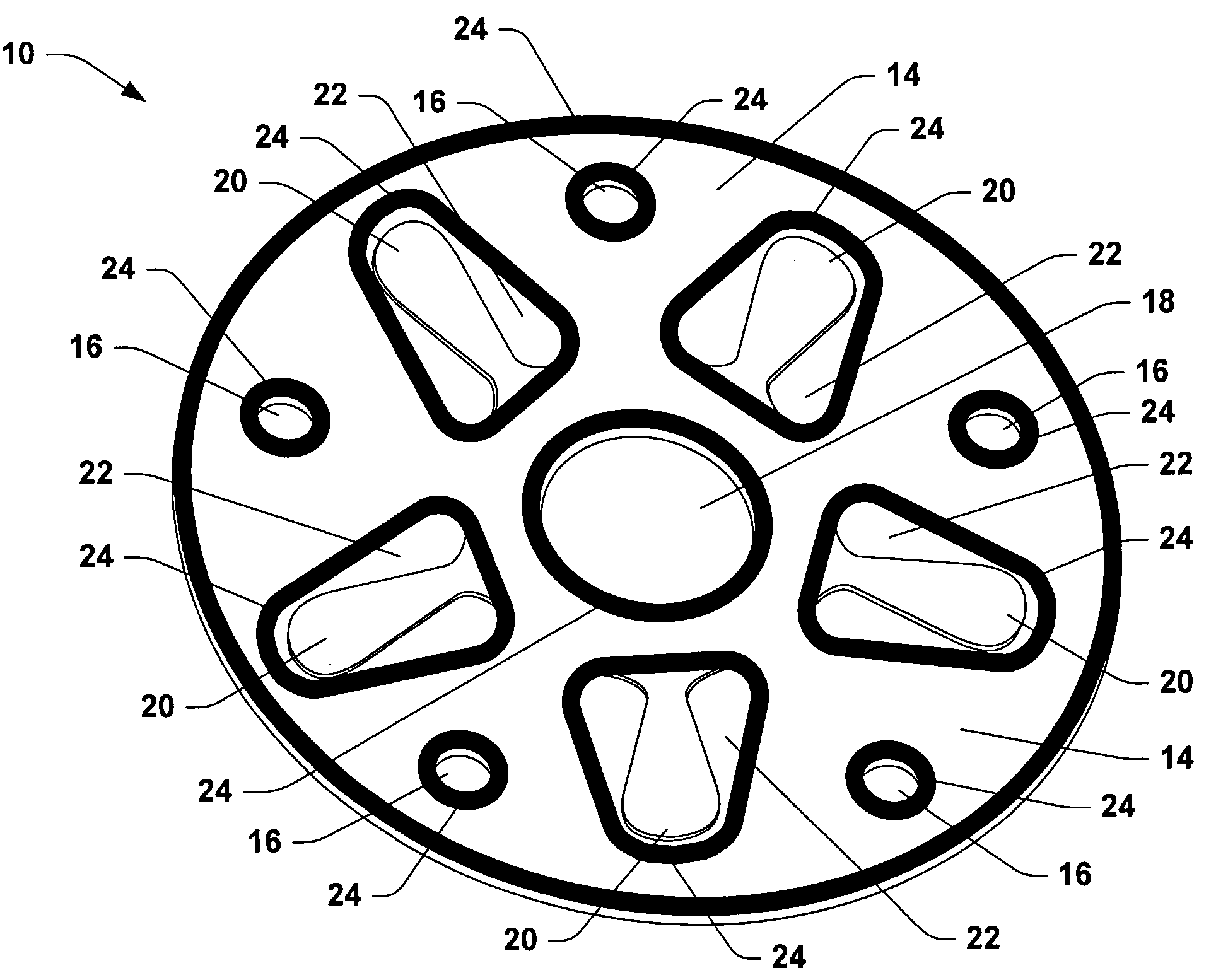

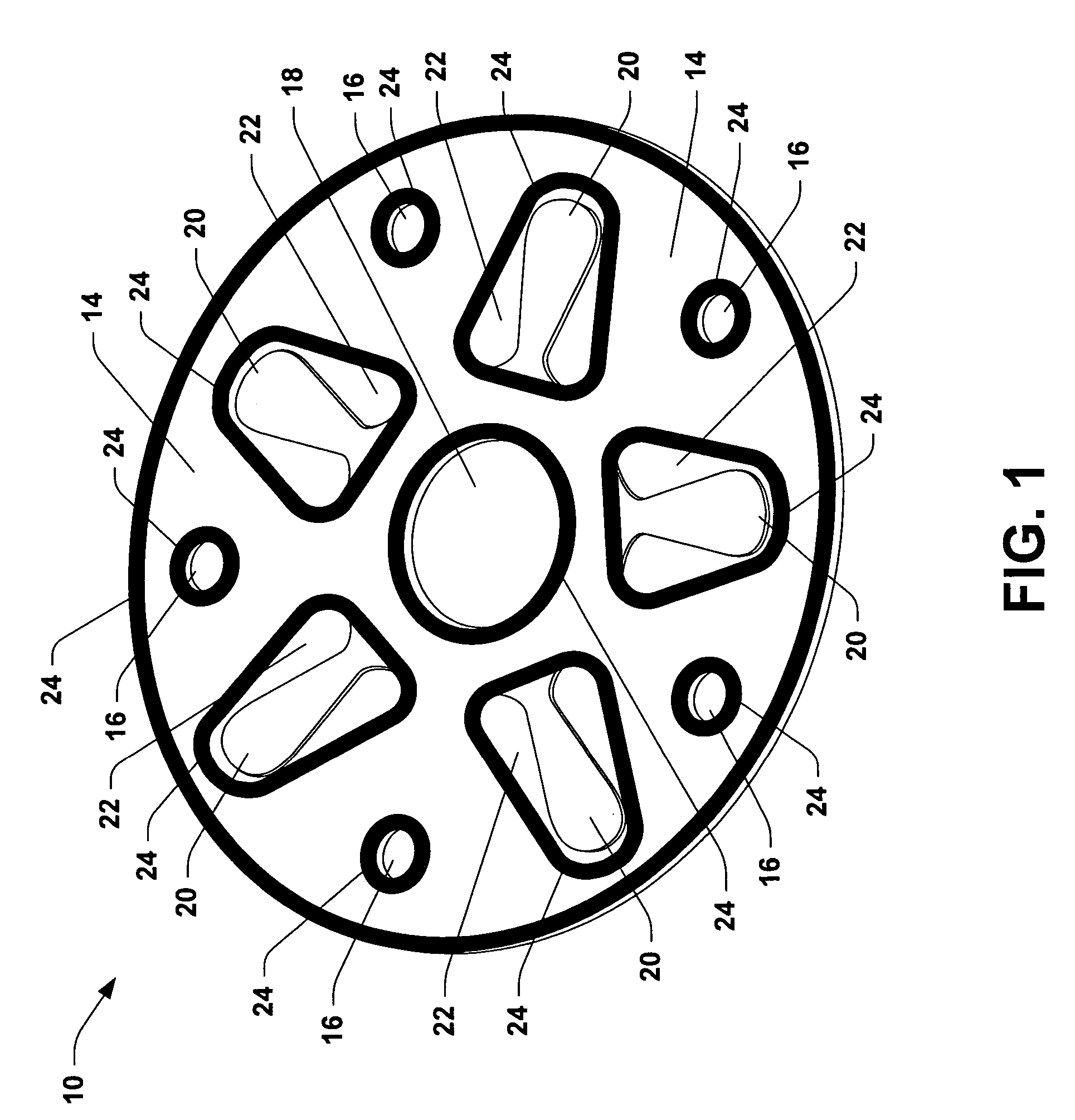

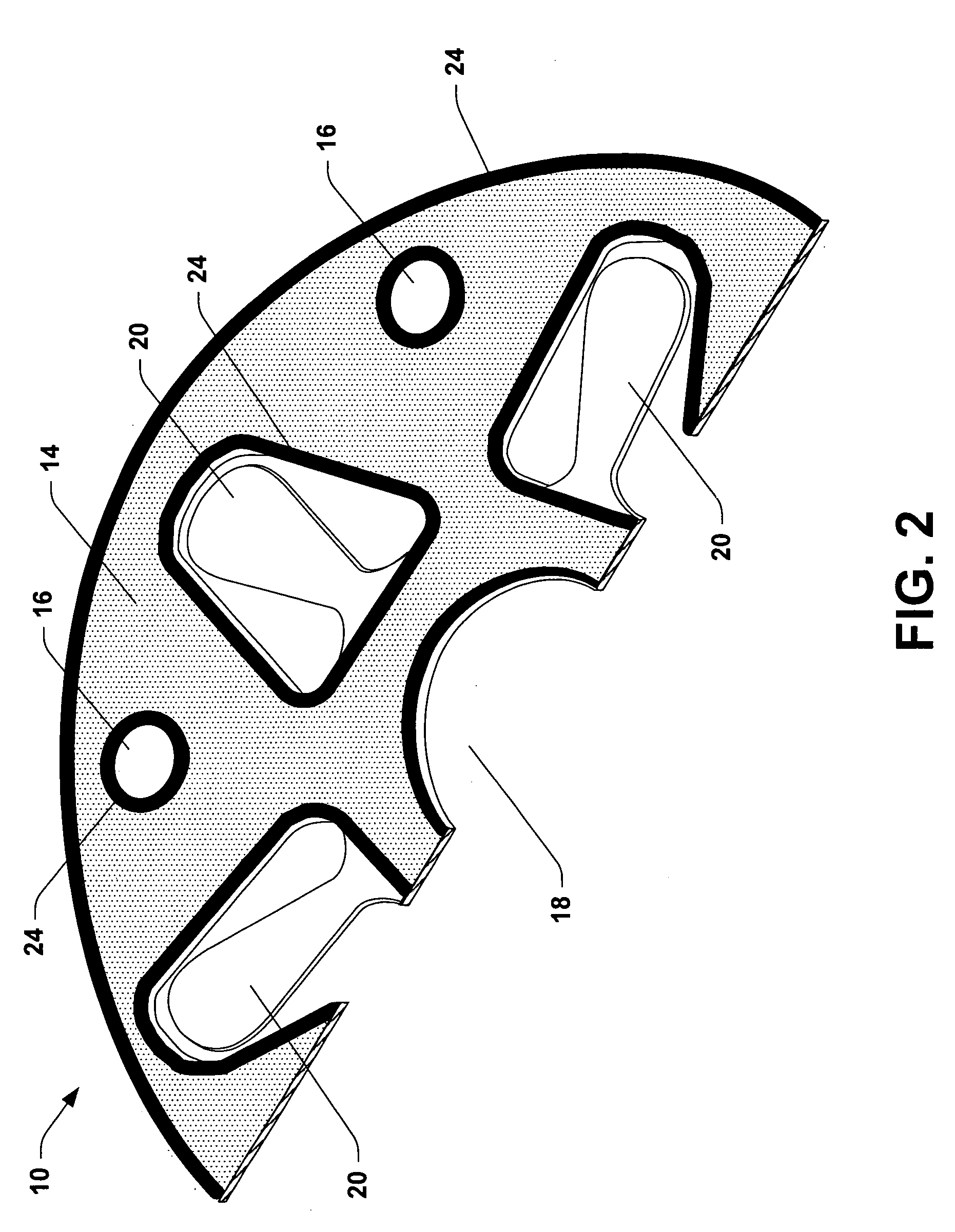

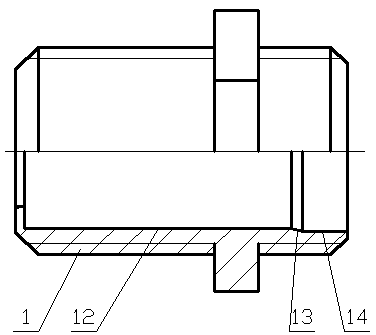

Valve

InactiveUS6293293B1Reduce manufacturing costReduce assembly timeOperating means/releasing devices for valvesPipeline systemsVALVE PORT

The present invention is capable of engagement with a fluid port and capable of being open to create a fluid path, where the valve assembly includes a valve head for closing a fluid path to a port associated with a valve assembly, and a housing, and at least one engagement element formed integrally with the housing, wherein the valve assembly is characterized in that to open the valve assembly the valve head is driven into an engagement element deforming the valve head and creating the fluid path through the valve assembly.

Owner:ITW NEW ZEALAND

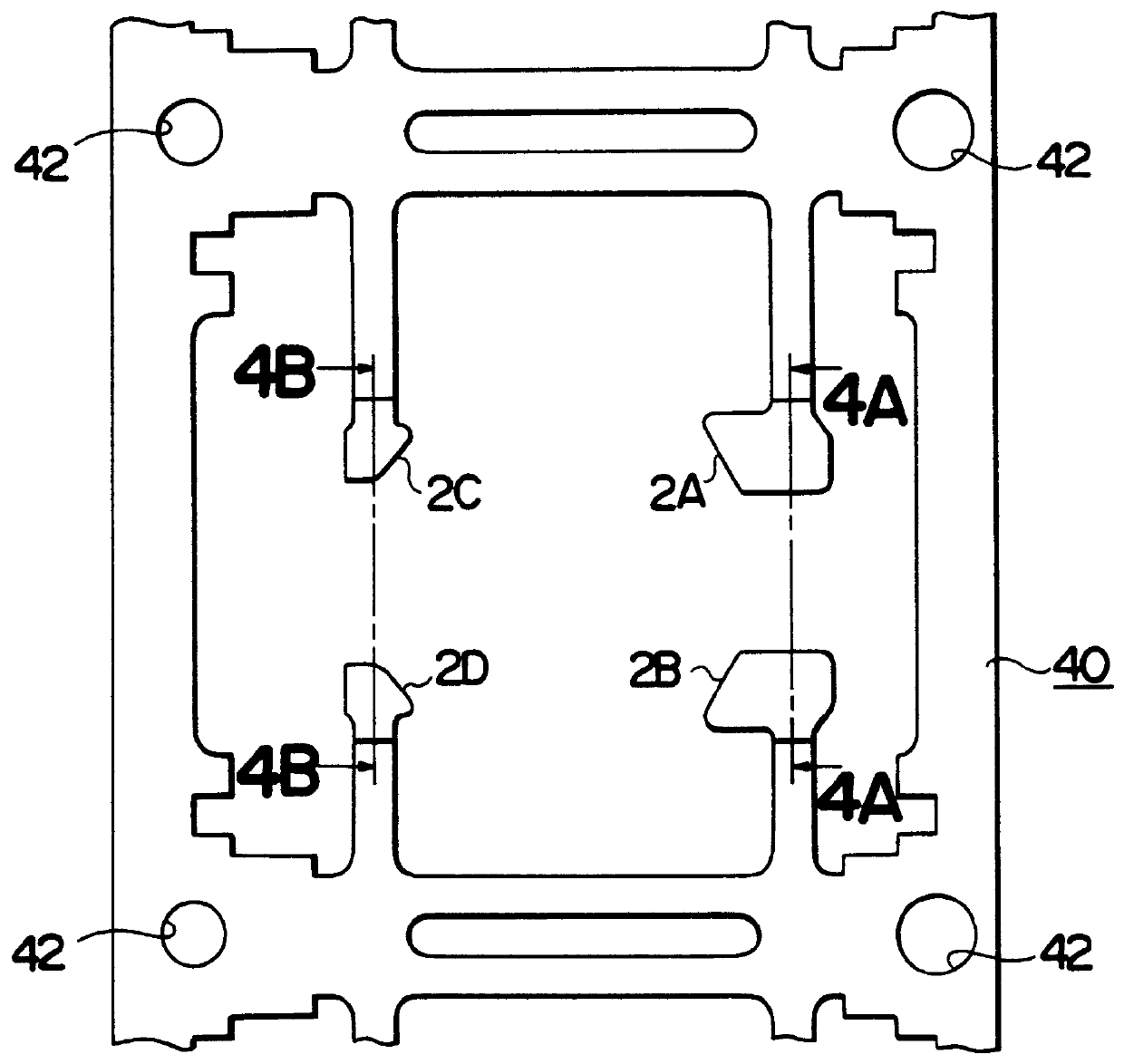

Method of fabricating an electroacoustic transducer

InactiveUSRE36512E1Reduce assembly timeContinuous operationTransducer detailsSound producing devicesEngineeringPole piece

The present invention provides a fabrication method of an electroacoustic transducer capable of simplifying an assembling process on a lead frame and realizing an automatic assembly. The method comprises steps of forming pole piece portions, forming a lead frame having a plurality of base forming areas thereon, each of the areas having lead terminals formed therein, forming bases of a synthetic resin on the lead frame by molding so that the pole piece portions are embedded in the bases, mounting a coil on the pole piece portions embedded in the bases, disposing a support ring and a magnet so as to surround the coil, and placing a diaphragm on the support ring to be held thereby, connecting opposite ends of the coil to the lead terminals, cutting off the lead terminals from the lead frame, putting cases on and fixedly joining the same to the bases, and subjecting the cut lead terminals to a forming process.

Owner:FOSTER ELECTRIC CO LTD

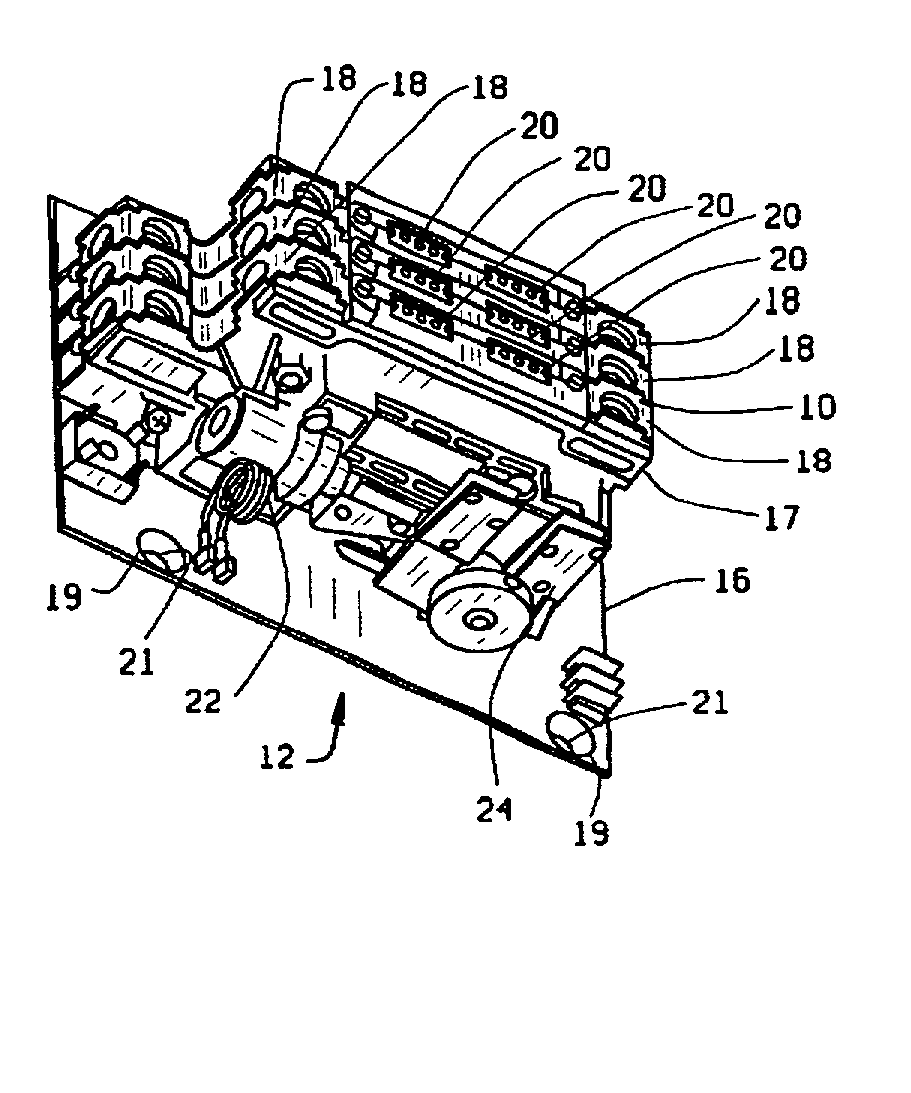

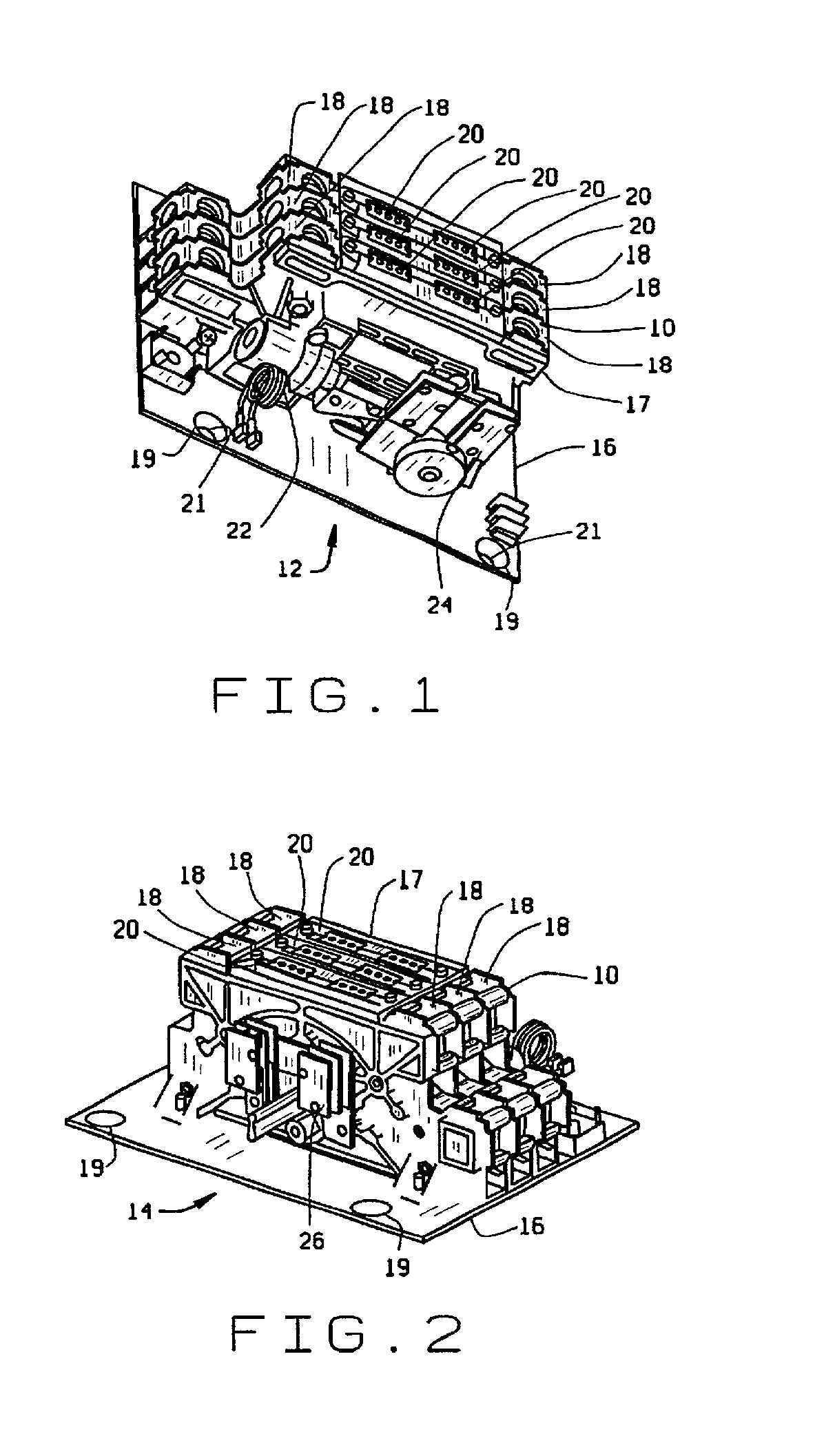

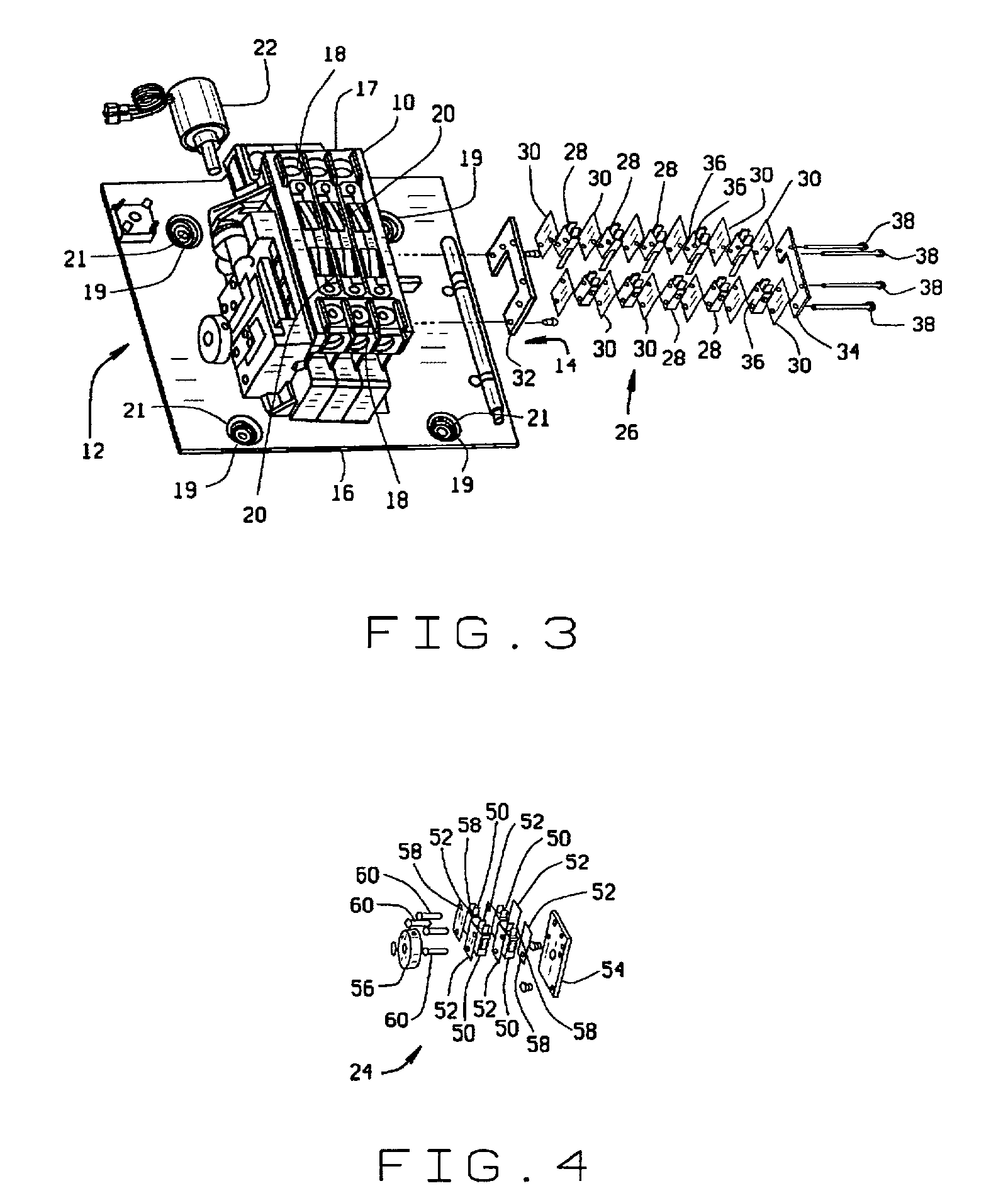

Methods and apparatus for automatically transferring electrical power

InactiveUS20020130023A1Reduce assembly timeReduce installation timeCircuit-breaking switches for excess currentsContact operating partsLimit switchTransfer switch

An automatic transfer switch includes a main body having a solenoid side and an auxiliary side. A solenoid side limit switch assembly is mounted to the solenoid side and an auxiliary side limit switch assembly is mounted on the auxiliary side. The solenoid side limit switch assembly includes a plurality of limit switches and a solenoid side mounting plate. The auxiliary side limit switch assembly includes a plurality of limit switches and an auxiliary side mounting plate.

Owner:GENERAL ELECTRIC CO

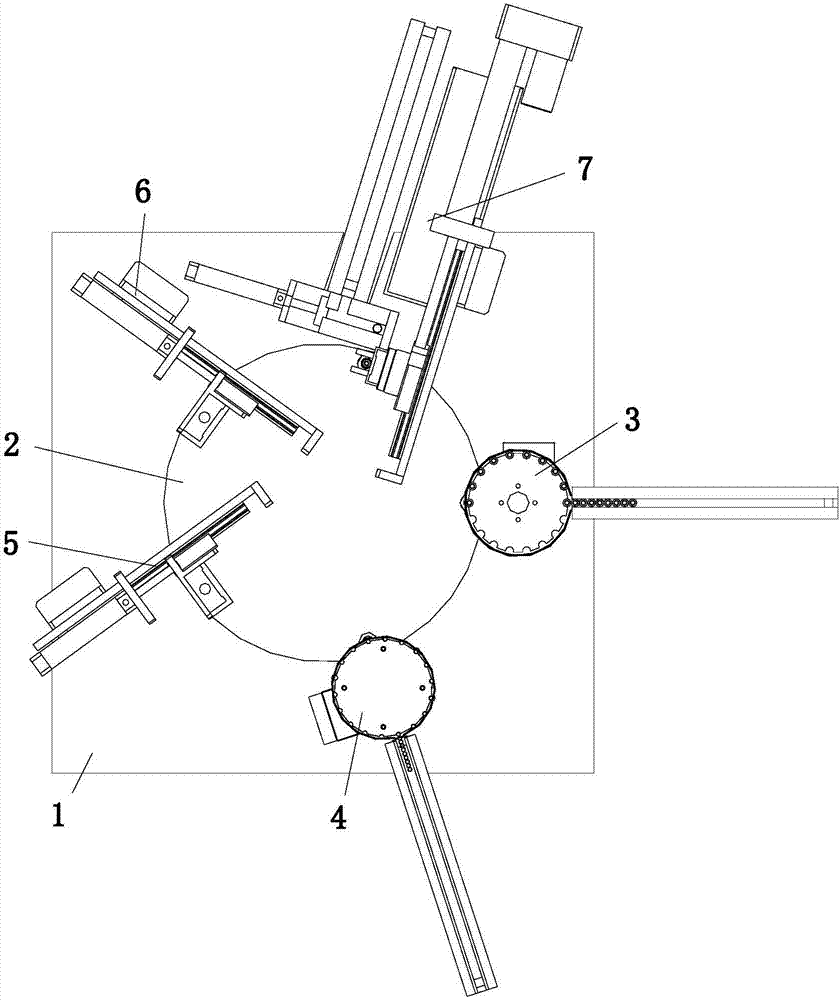

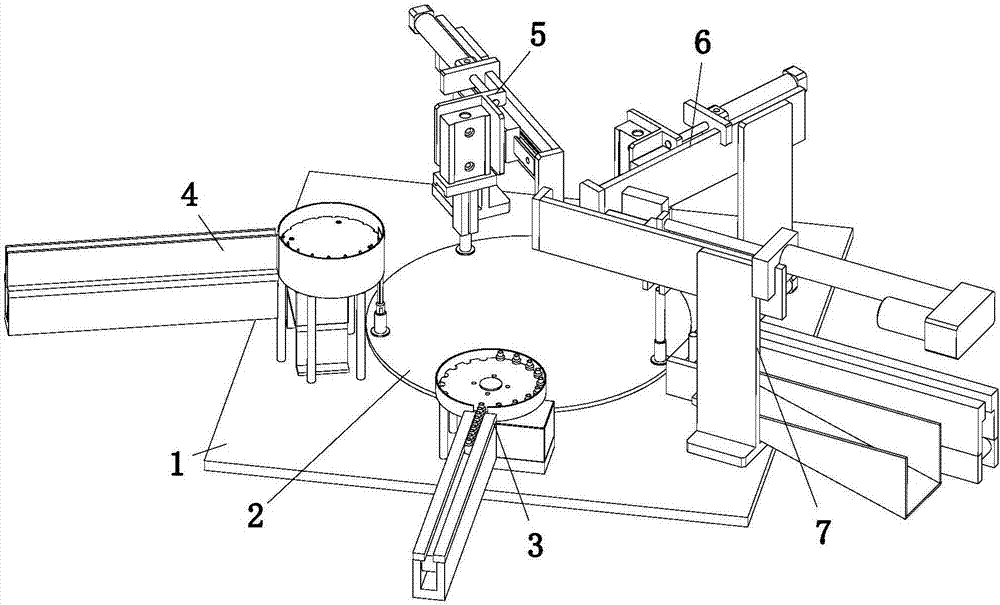

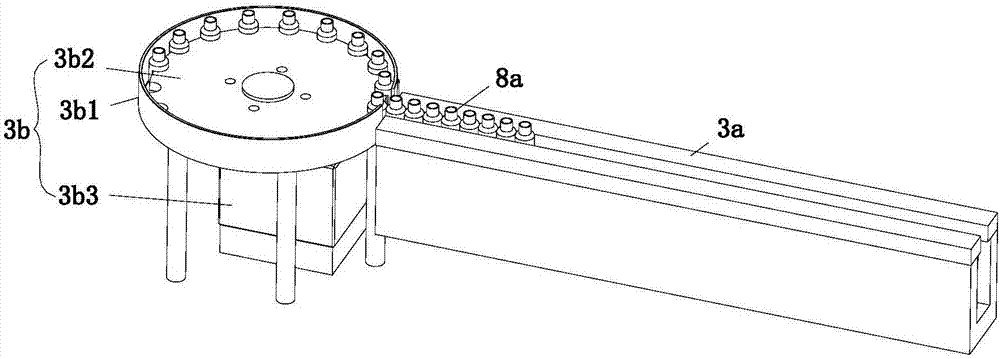

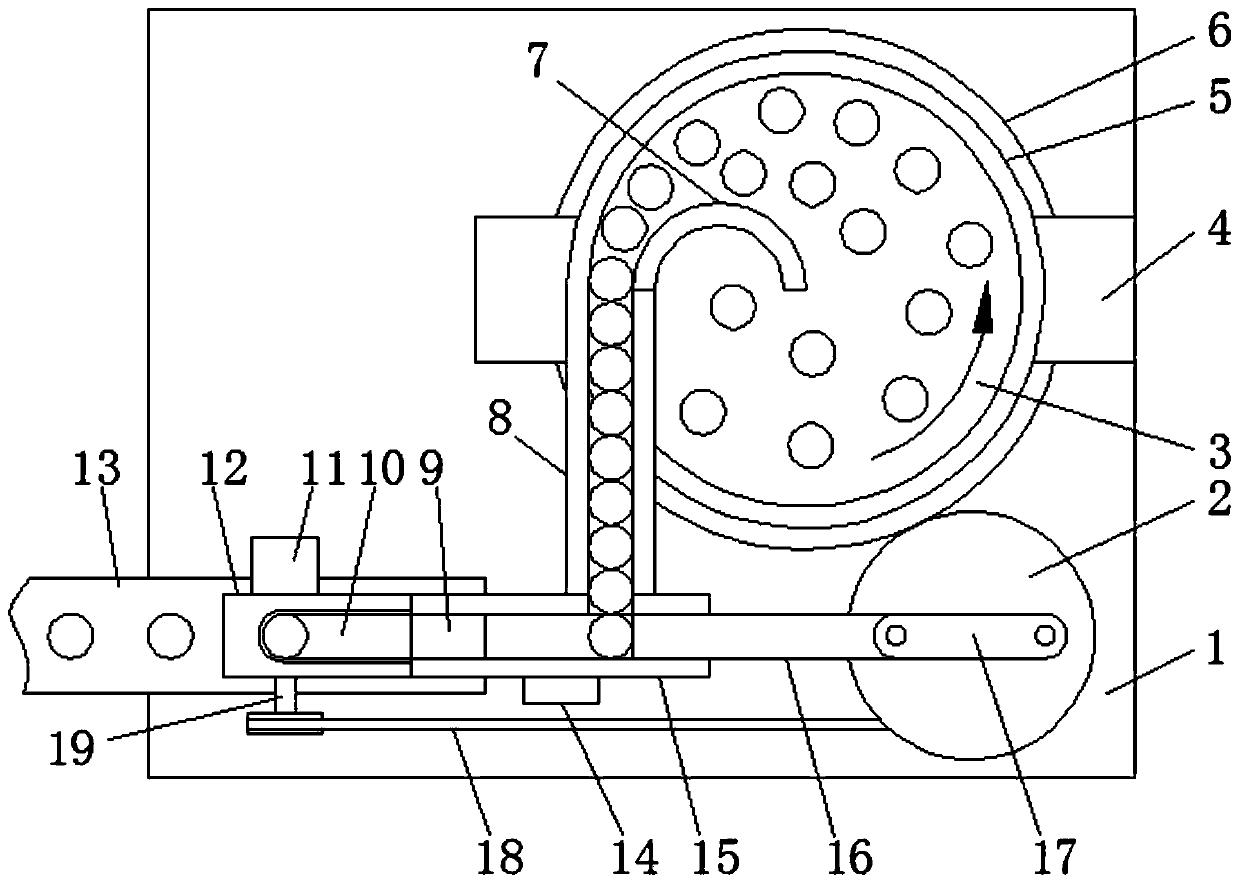

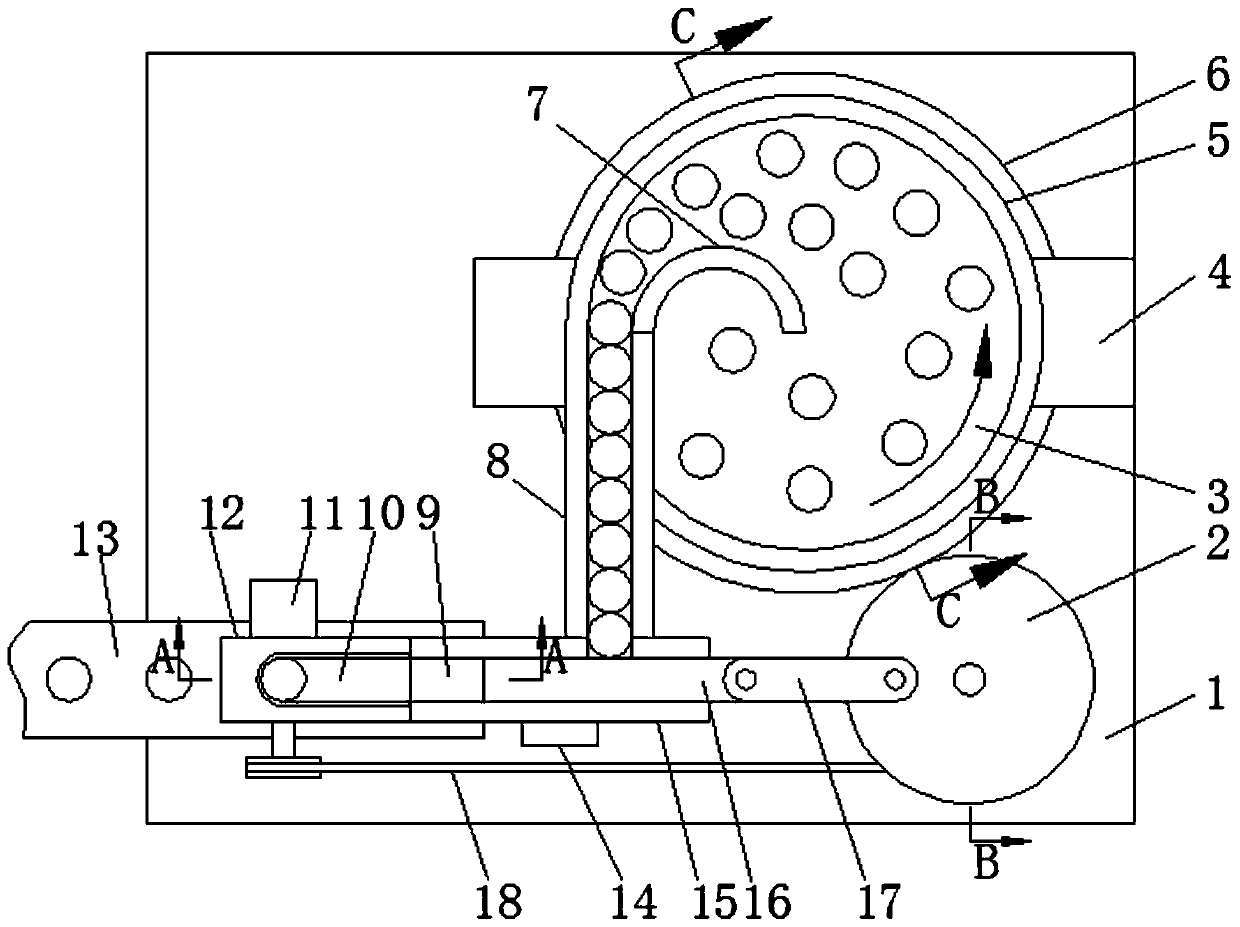

Needle assembly machine

ActiveCN107571016AContinuous assemblyReduce assembly timeAssembly machinesMotor driveElectric machinery

The invention relate to the technical field of medical instruments, in particular to a needle assembly machine. The machine comprises a machine frame, wherein a support plate is arranged at the top ofthe machine frame, a rotary table is arranged at the center of the support plate, and a first motor driving the rotary table to rotate stepwise is arranged in the machine frame; a pintle feeding device, a needle tip feeding device, a needle tip aligning device, a pressing device and a sheath sleeving device which are arranged in the rotating direction of the rotary table are arranged around the rotary table on the support plate; a plurality of fixtures are distributed uniformly circumferentially on the rotary table. The rotary table is used for driving the fixtures to pass through the pintlefeeding device, the needle tip feeding device, the needle tip aligning device, the press mounting device and the sheath sleeving device sequentially, automatic pintle positioning, needle tip placement, alignment, press mounting, sheath sleeving and blanking are realized, and accordingly, continuous needle assembly is realized, assembly time is shortened, investment of manpower and material resources is reduced, assembly cost is greatly reduced, and production efficiency is effectively improved.

Owner:甘李药业山东有限公司

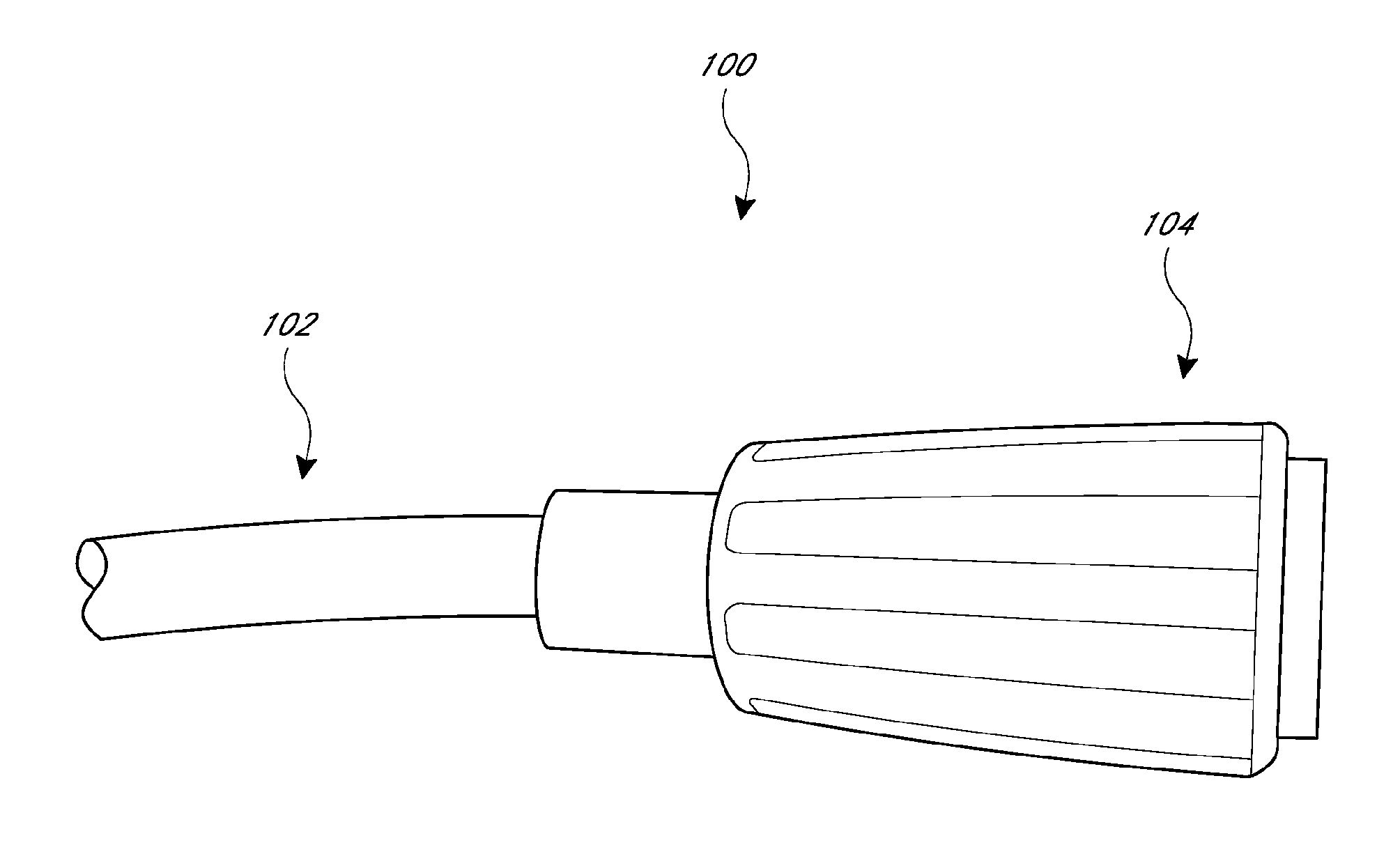

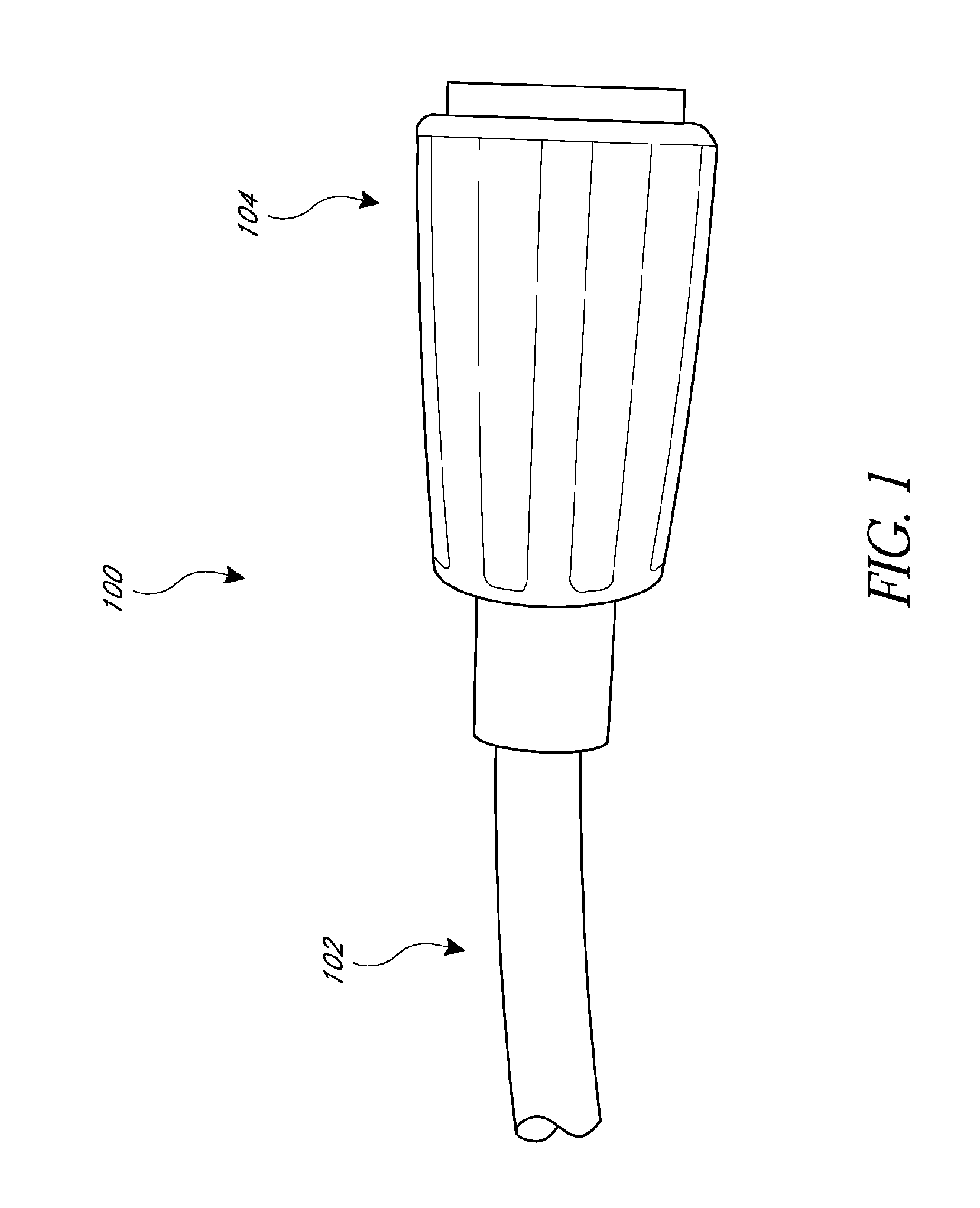

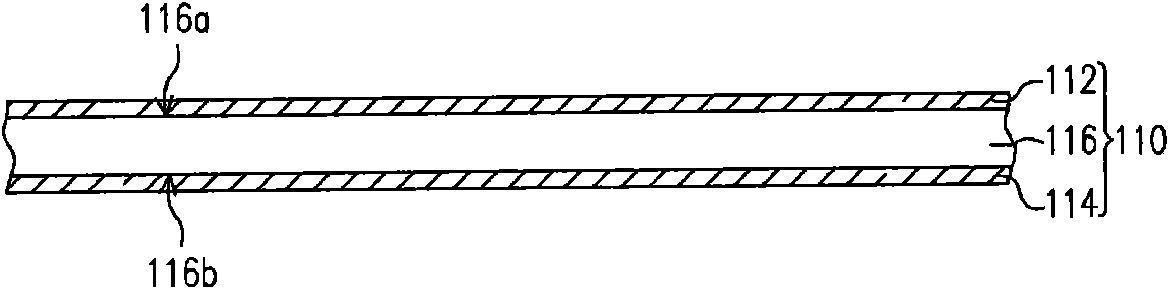

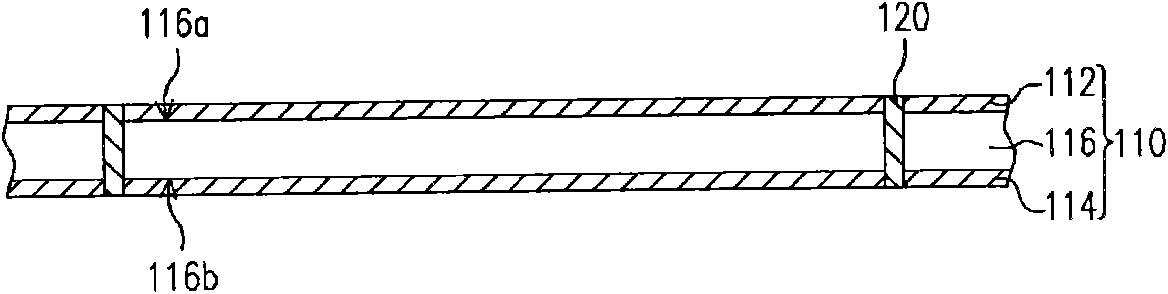

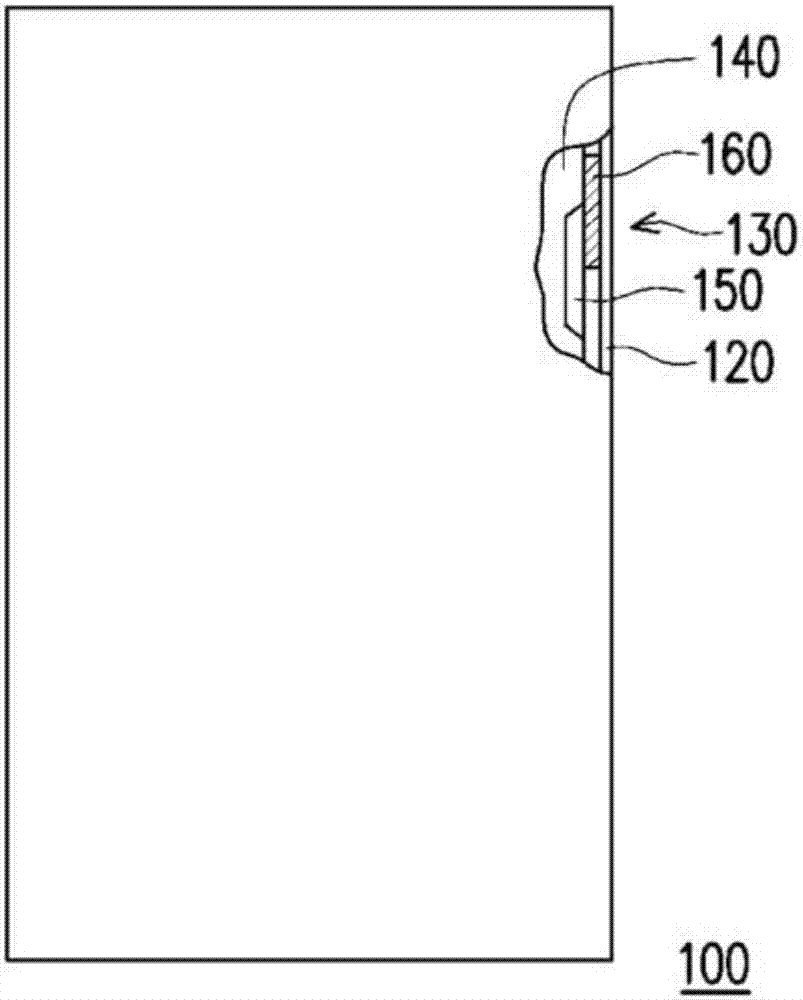

Apparatus and method for providing gases to a user

ActiveUS20160001031A1Improve throughputReduce assembly timeRespiratorsFlanged jointsBiomedical engineeringFlange

A connector and tubing combination includes a tubing segment with an end piece, such as a tubing flange. The tubing flange can be secured within the connector by an outer sleeve and an inner sleeve of the connector. Both of the inner sleeve and the outer sleeve are located outside of the tubing flange and the tubing segment. In addition, the inner sleeve, outer sleeve and the tubing flange are mechanically connected.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Valve or valve plate having an integrated gasket

InactiveUS20060016483A1EfficientReduce assembly timePositive displacement pump componentsCheck valvesEngineeringVALVE PORT

Owner:BARNES GROUP

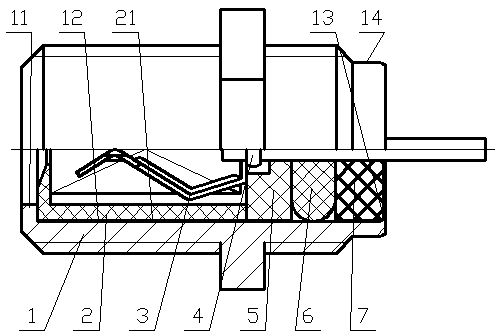

Energy-saving and noise-reducing vacuum pump

InactiveCN101526082AGuaranteed uptimeIncrease the counterweightPositive displacement pump componentsFlexible member pumpsPump chamberEngineering

The invention relates to an energy-saving and noise-reducing vacuum pump, which comprises a motor, a motor shell, a pump body and a pump cover, wherein both ends of a motor shaft are connected with a left pull rod and a right pull rod respectively; the head parts of the left pull rod and the right pull rod are fixedly connected with a film pressing piece and stretch into a left pump chamber and a right pump chamber; and a membrane is arranged between the head parts of the left pull rod and the right pull rod and the film pressing piece. The vacuum pump is characterized in that eccentric wheels are arranged between both ends of the motor shaft and the left pull rod and the right pull rod respectively. After the balance weight of the eccentric wheels is increased, the vacuum pump runs steadily during working, and the deflection phenomena can be avoided. The moving phase of the two pull rods is guaranteed to be 180 degrees so as to reduce various mechanical noises caused by gaps such as the gap between the motor shaft and a motor bearing, the gap between the motor bearing and a motor end cover, the gap between the eccentric wheels and the bearing, the gap between the bearing and the pull rods, and the like, and the mechanical noise is controlled to be below 45 decibels so as to meet the requirements on the noise of household appliances.

Owner:周纪昌

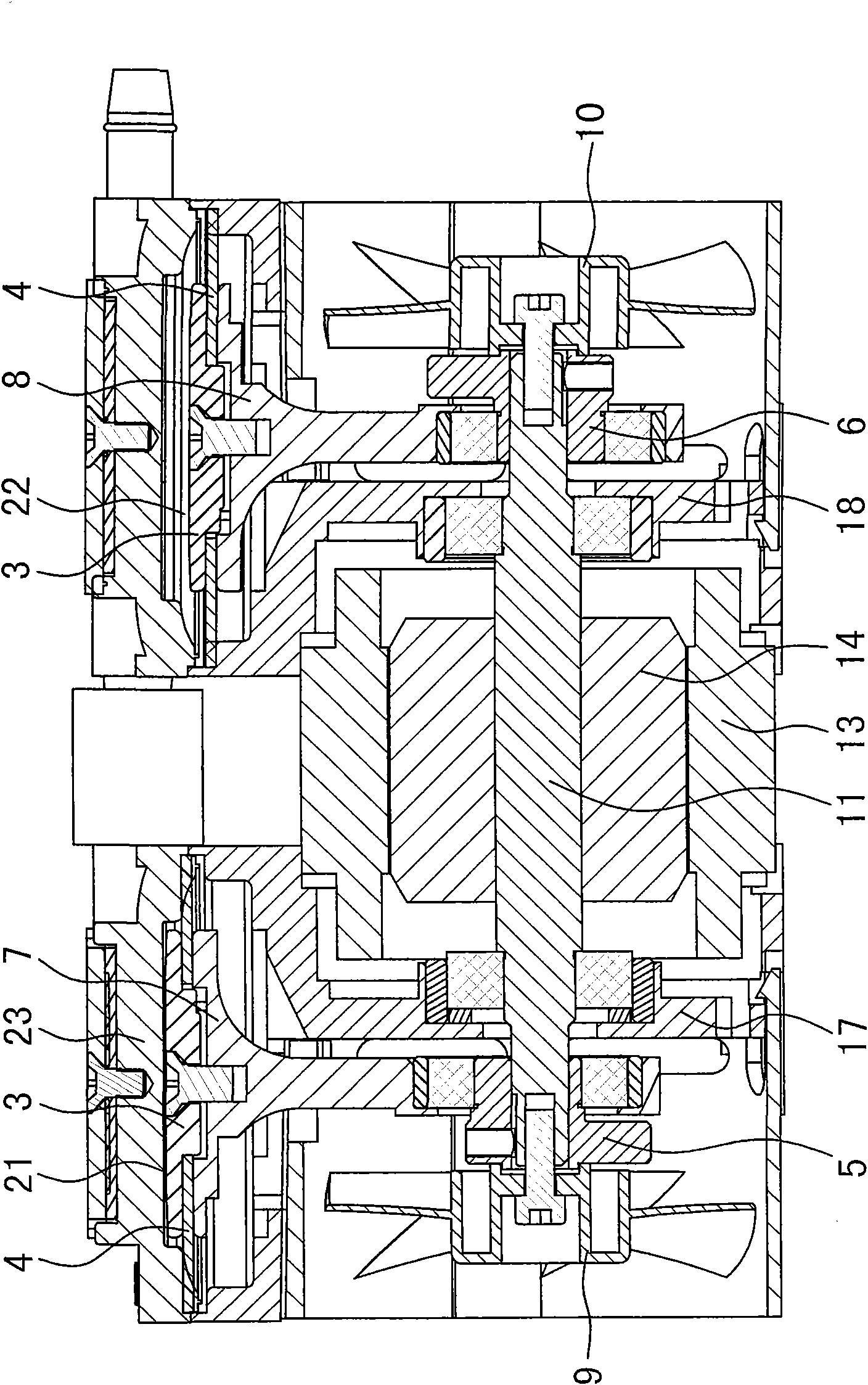

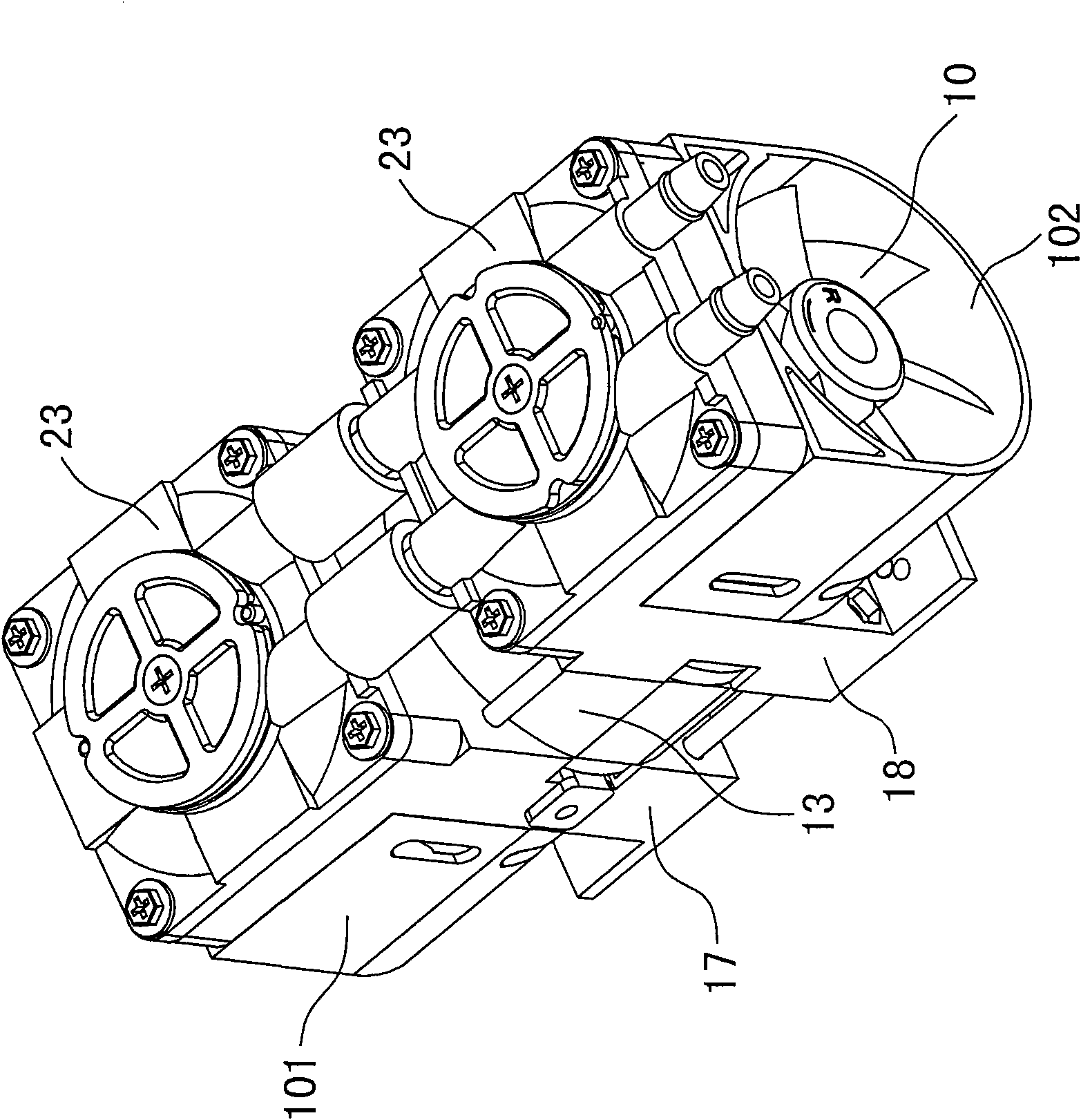

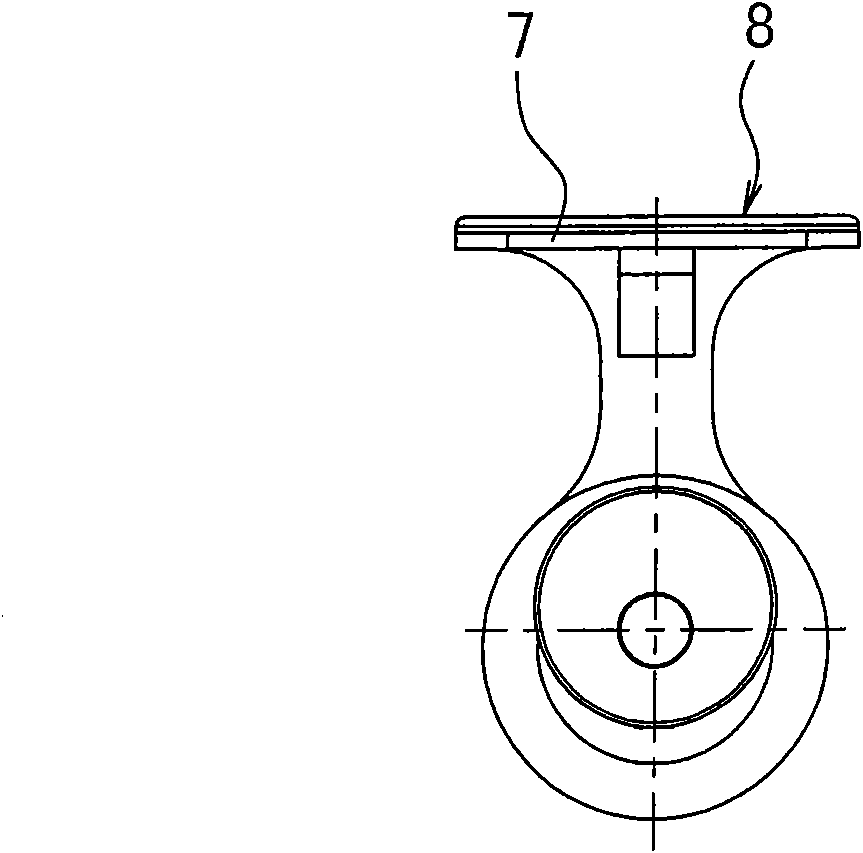

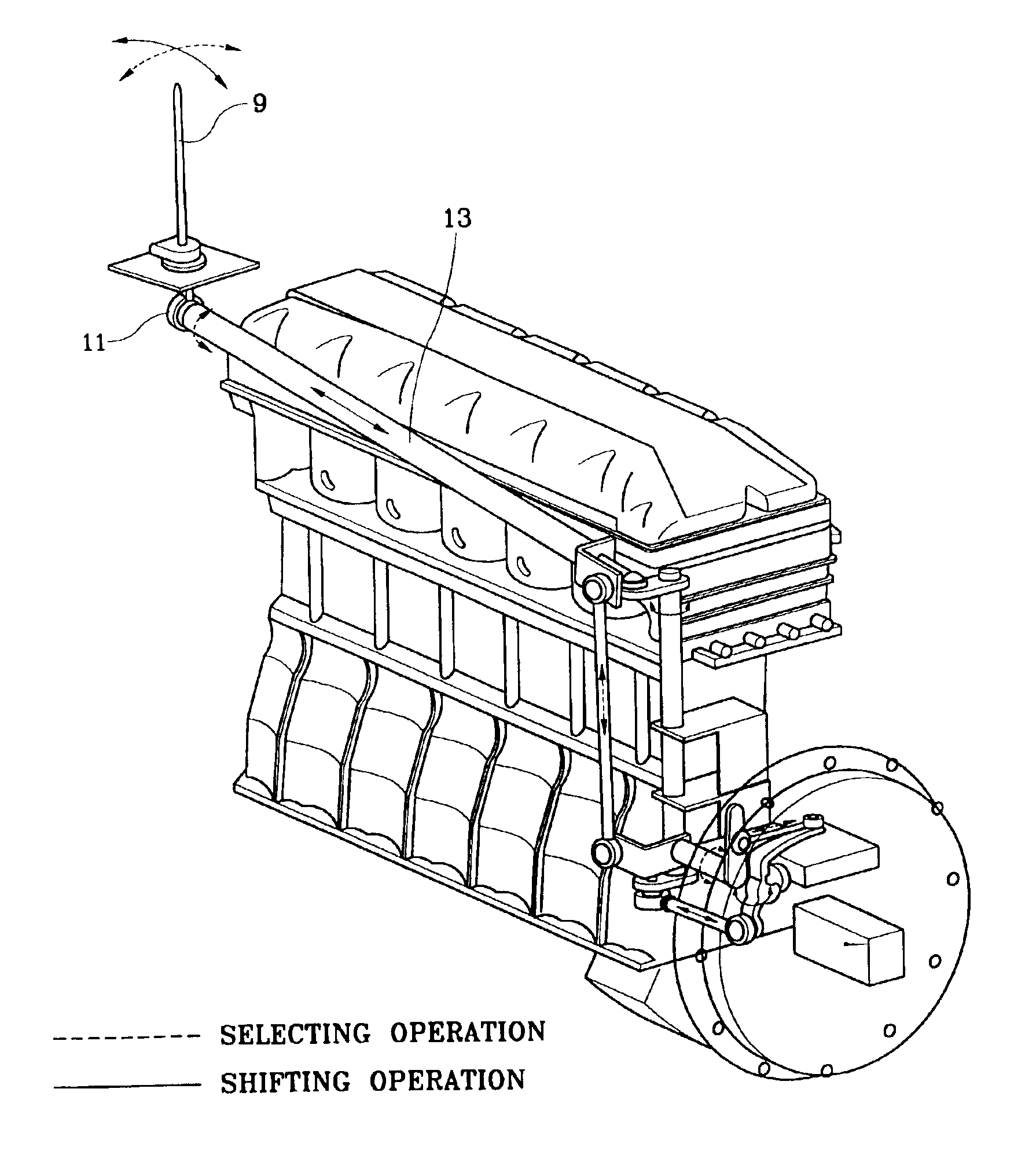

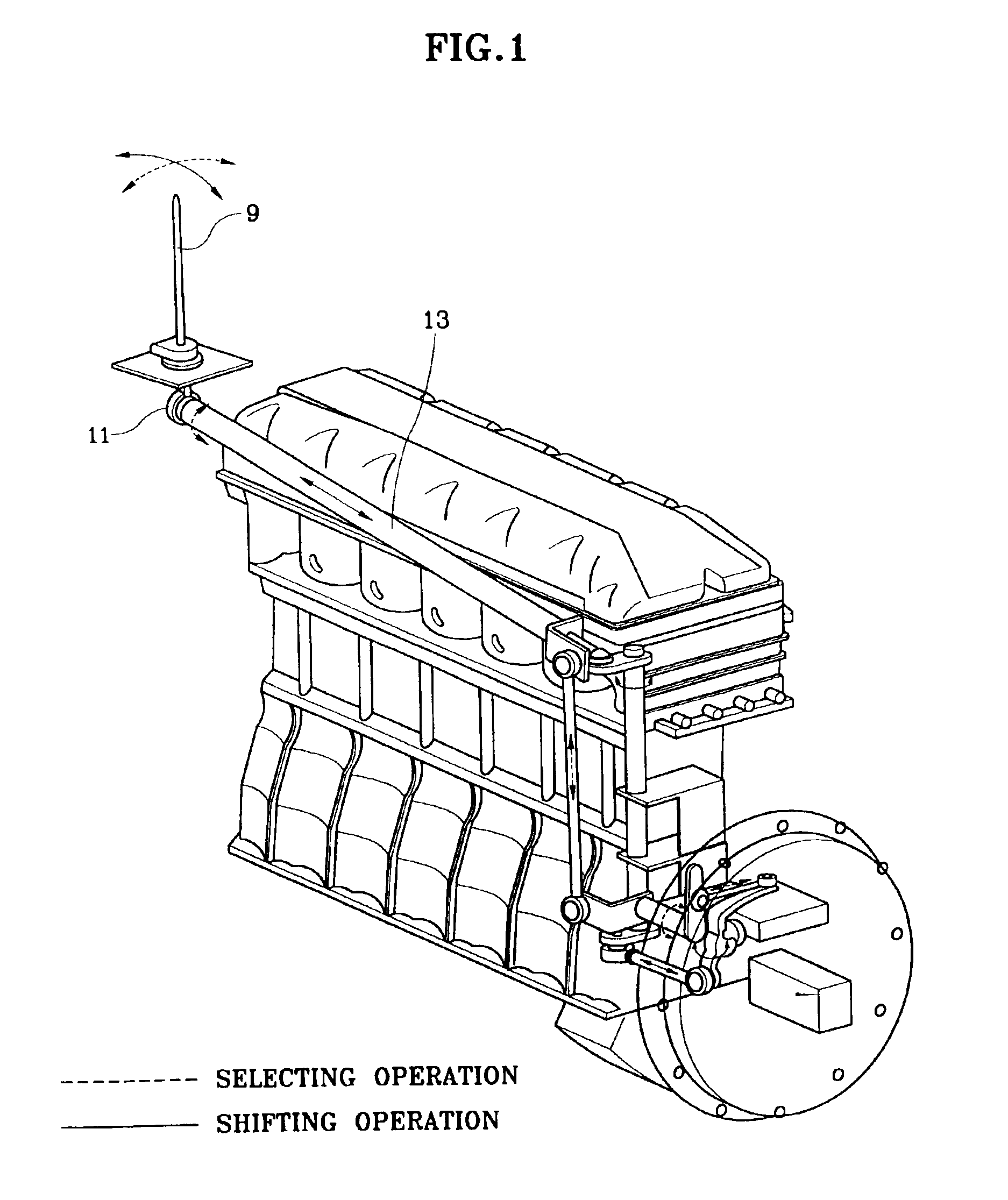

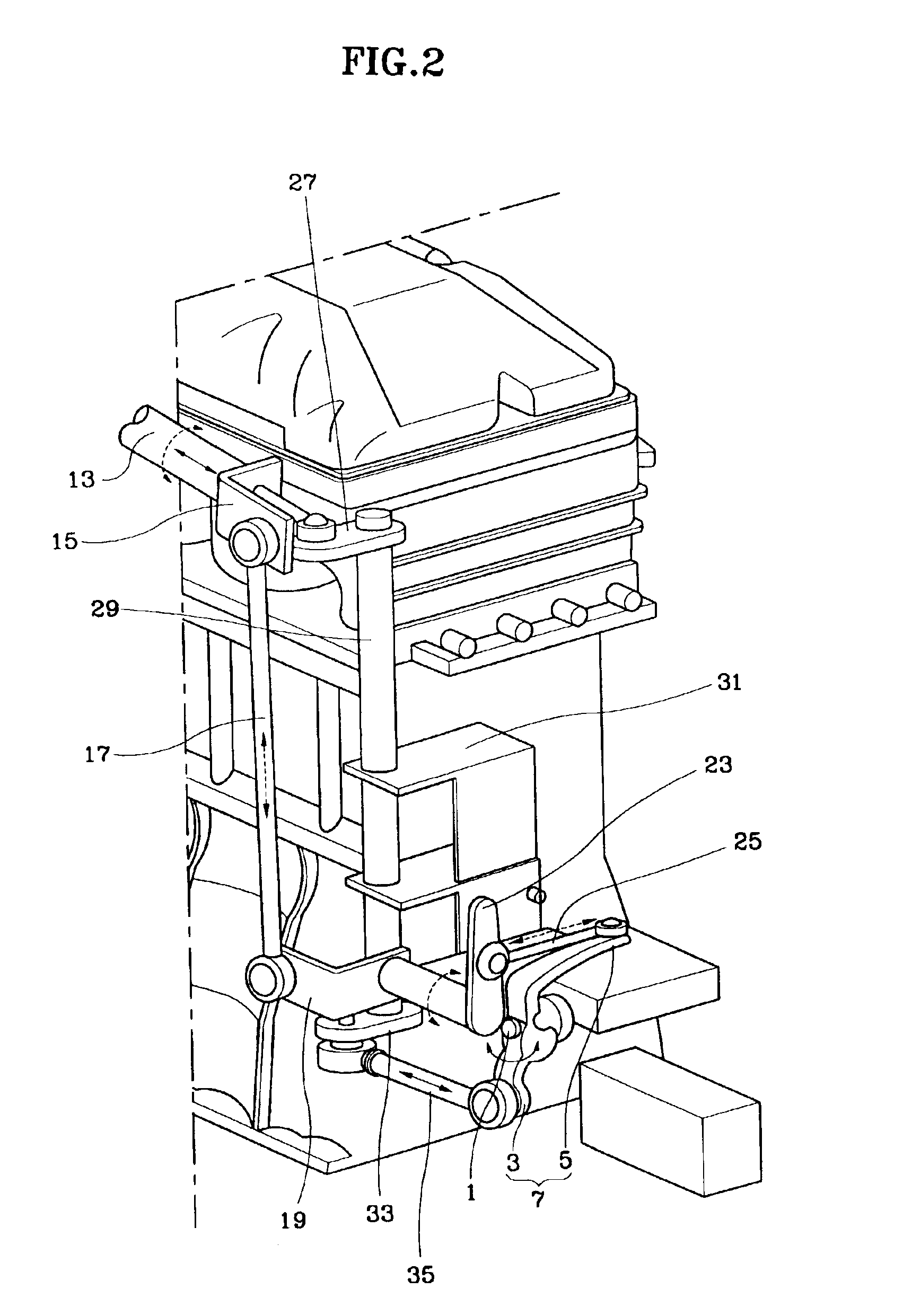

Manual transmission shifting device

InactiveUS6951151B2Smooth transferReduce assembly timeManual control with multiple controlled membersGearing controlManual transmissionVariator

A manual transmission shifting device in which a shifting force is transmitted only by a first rod from a shift lever to a transmission and the shifting force transmitted to the first rod is supplied to the transmission via a simple mechanical link system, such that the number of components is reduced, thereby improving the efficiency of transmitting the shifting force to a transmission.

Owner:HYUNDAI MOTOR CO LTD

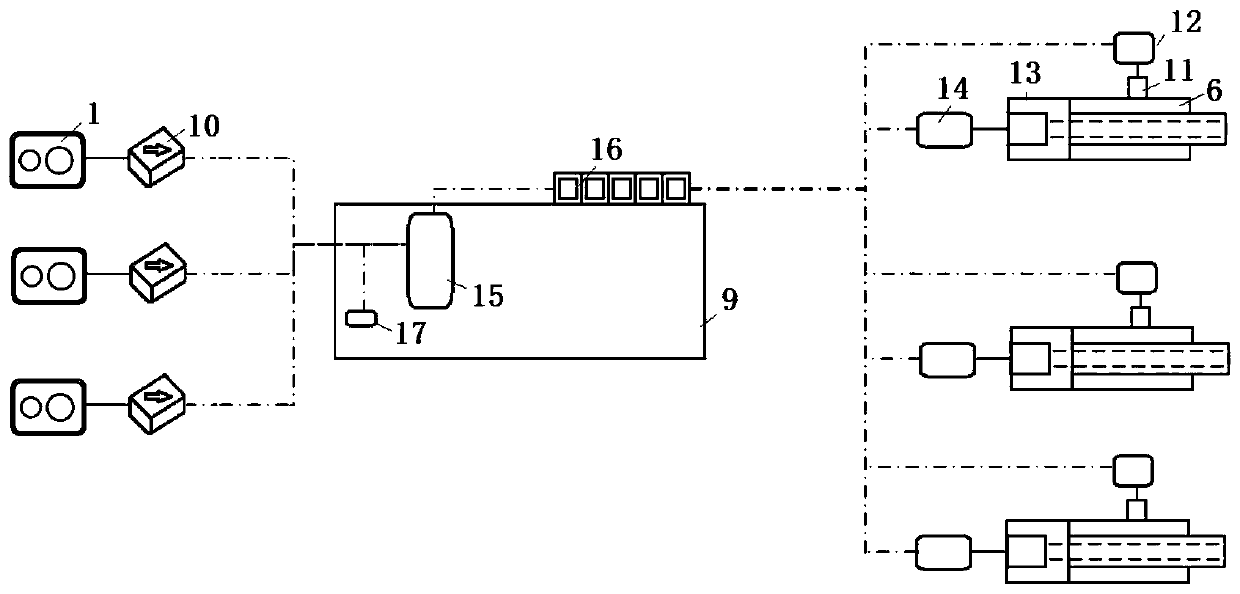

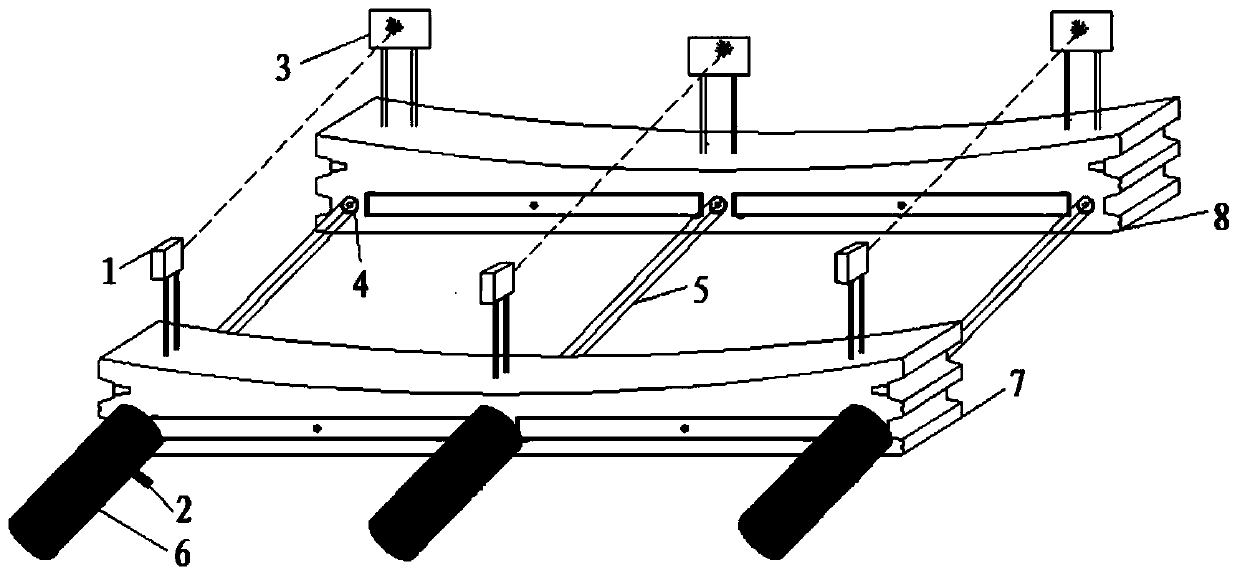

Prefabricated assembled structure automatic splicing control device system and method

ActiveCN110894727AAssembly precisionSolve the problem of inability to cast-in-place construction workArtificial islandsLifting devicesJackscrewCentroid algorithm

The invention discloses a prefabricated assembled structure multi-point cooperative splicing system and method. The prefabricated assembled structure multi-point cooperative splicing system comprisesprefabricated assembled underground structure splicing center control equipment, a plurality of hydraulic jacks on splicing pieces, a plurality of laser distance measuring instruments arranged on thesplicing pieces and a plurality of laser reflecting plates arranged on a target piece. By utilization of a component rubber pad counter-force centroid algorithm, a tensioning method based on centroidtracking and slit width control, an assembled component splicing frictional resistance calculating method, a multi-point cooperative communication and multi-mode protection method, a multi-point cooperative loading control method and other methods and algorithms, simultaneous different-amount accurate output control over the tensioning force and the tensioning speed when the different jacks are tensioned is achieved, accordingly, the prefabricated assembled component splicing control effect is effectively improved, smooth and safe proceeding of splicing is guaranteed, accurate output control is achieved, the assembling quality is improved, structure damage is avoided, and the prefabricated assembled component splicing control effect can be effectively improved.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO

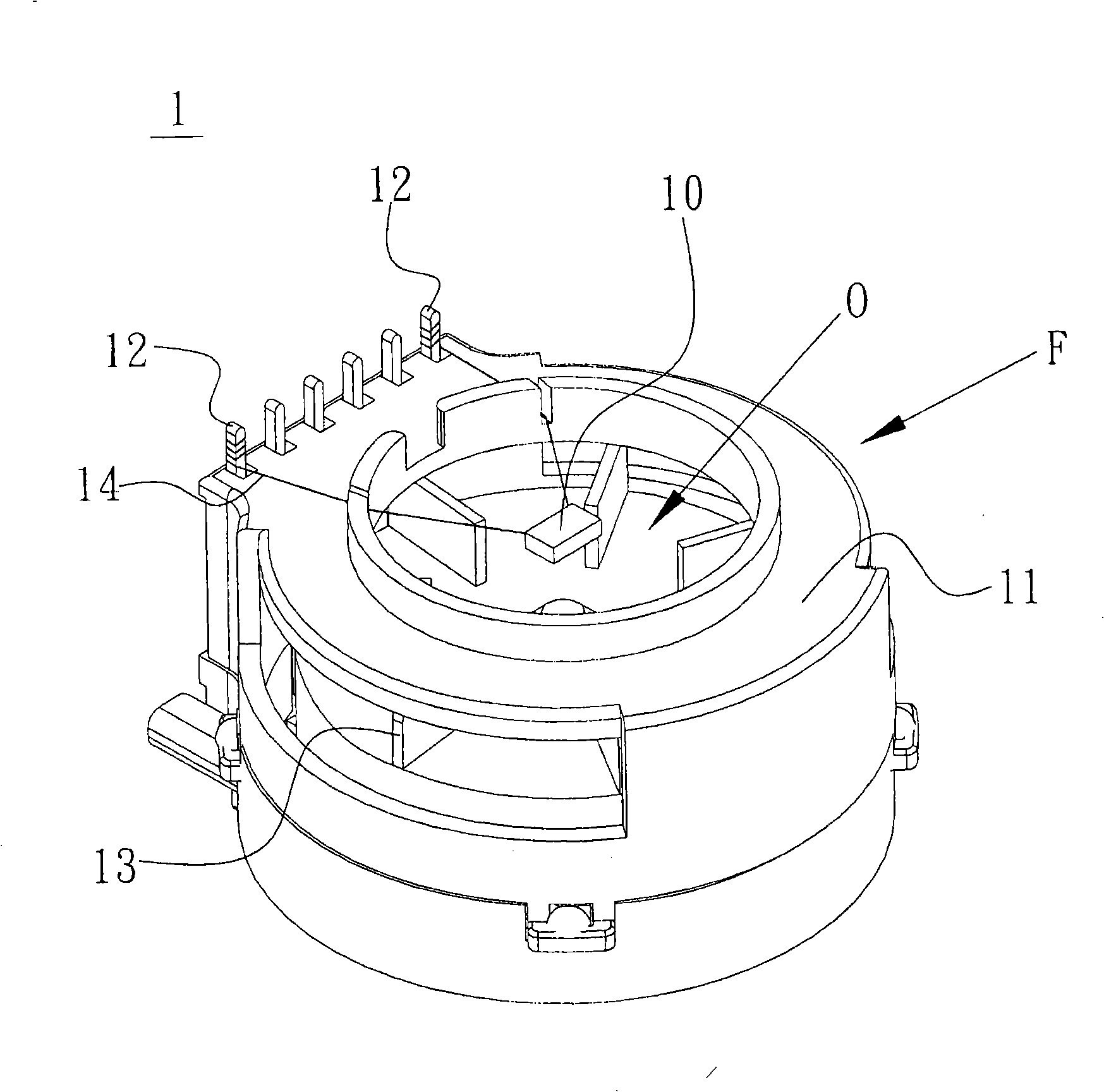

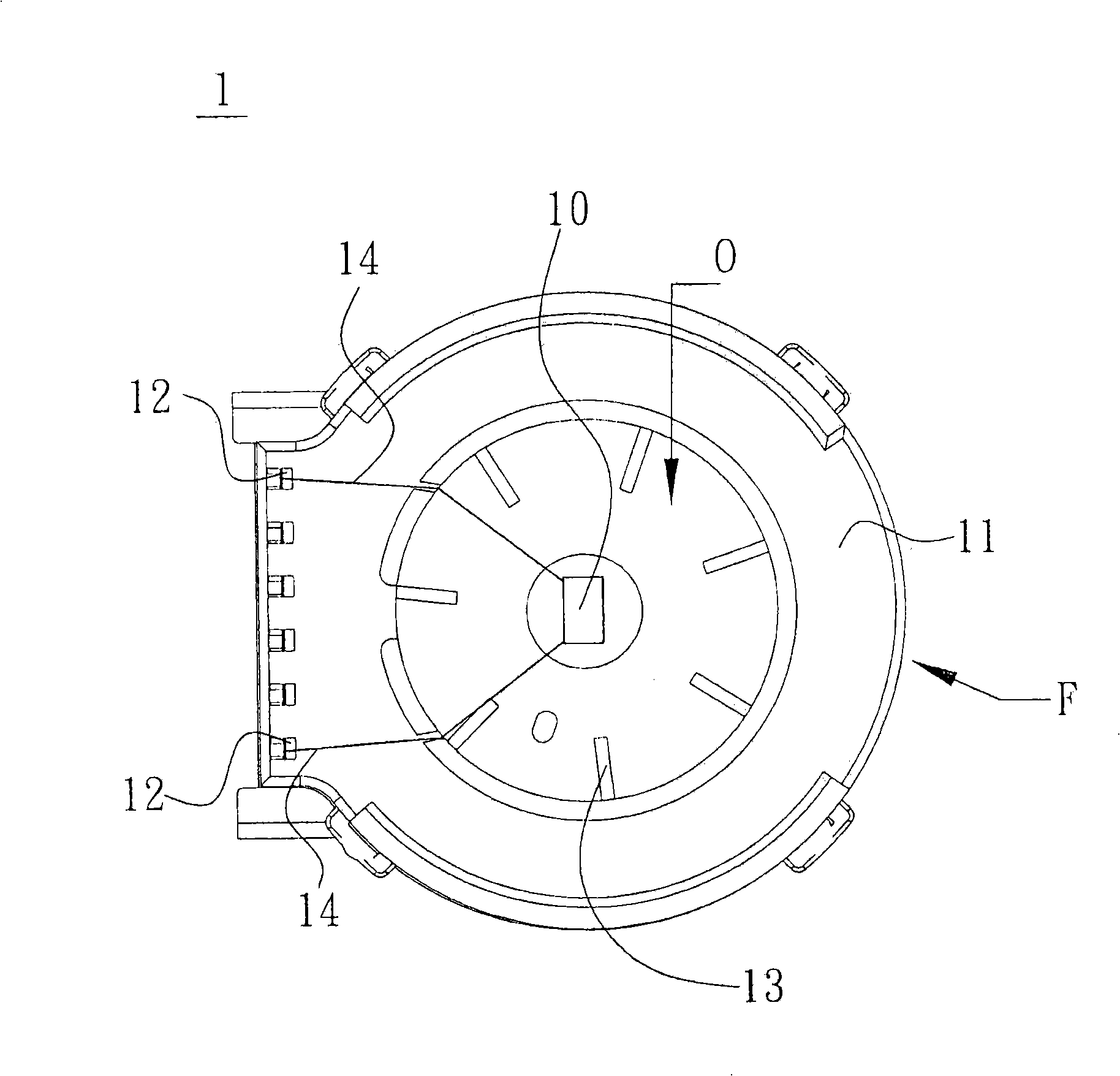

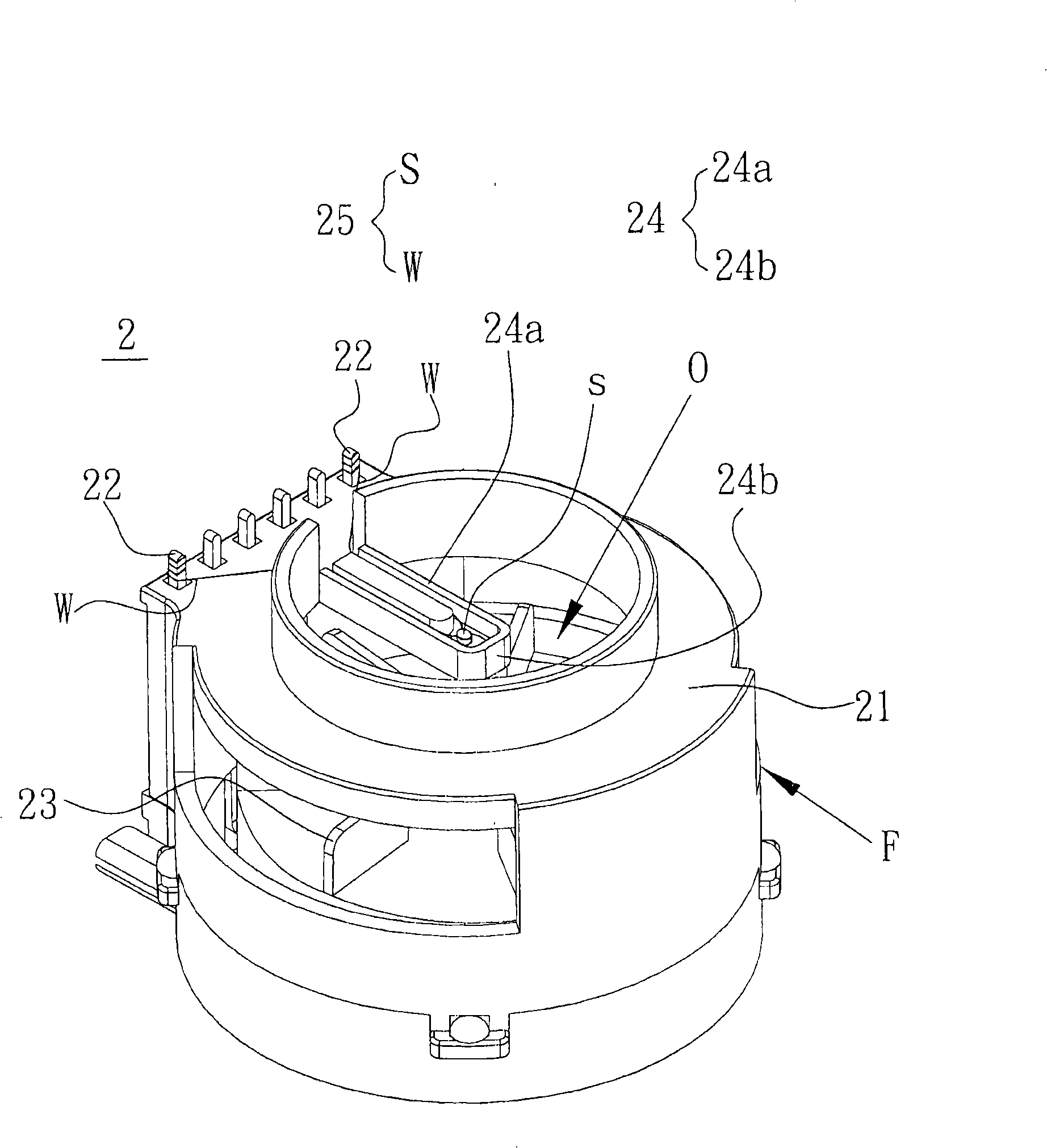

Fan with sensing element bearing structure and fan frame thereof

The invention discloses a fan with a sensing element bearing structure and a fan frame of the fan, which comprises a fan frame, a stator and a rotor with fan leaves. The fan frame comprises a body and a sensing element bearing structure, and the sensing element bearing structure extends to a wind inlet from the body. The stator and the rotor are arranged inside the fan frame, and the sensing element bearing structure is used to bear sensing elements.

Owner:DELTA ELECTRONICS INC

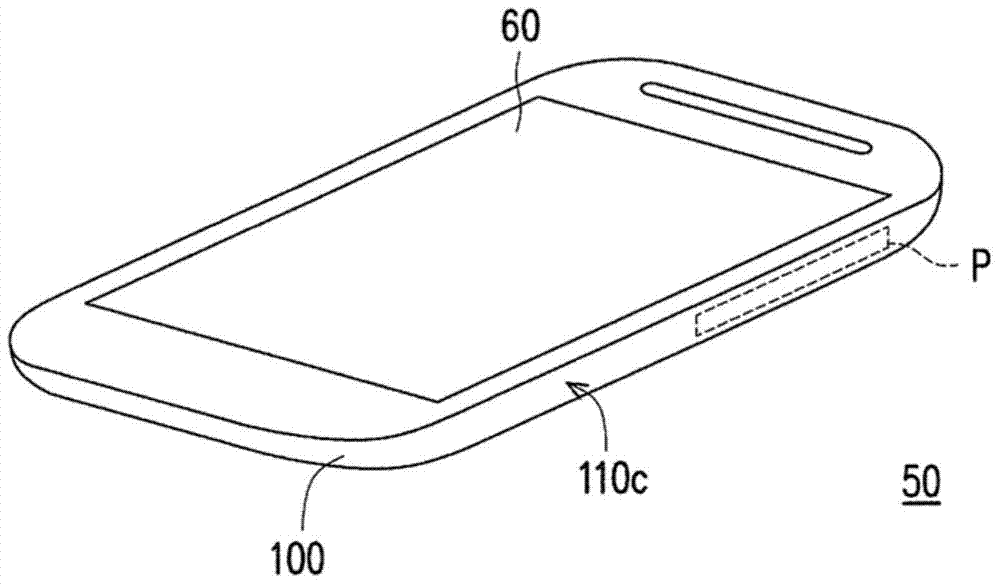

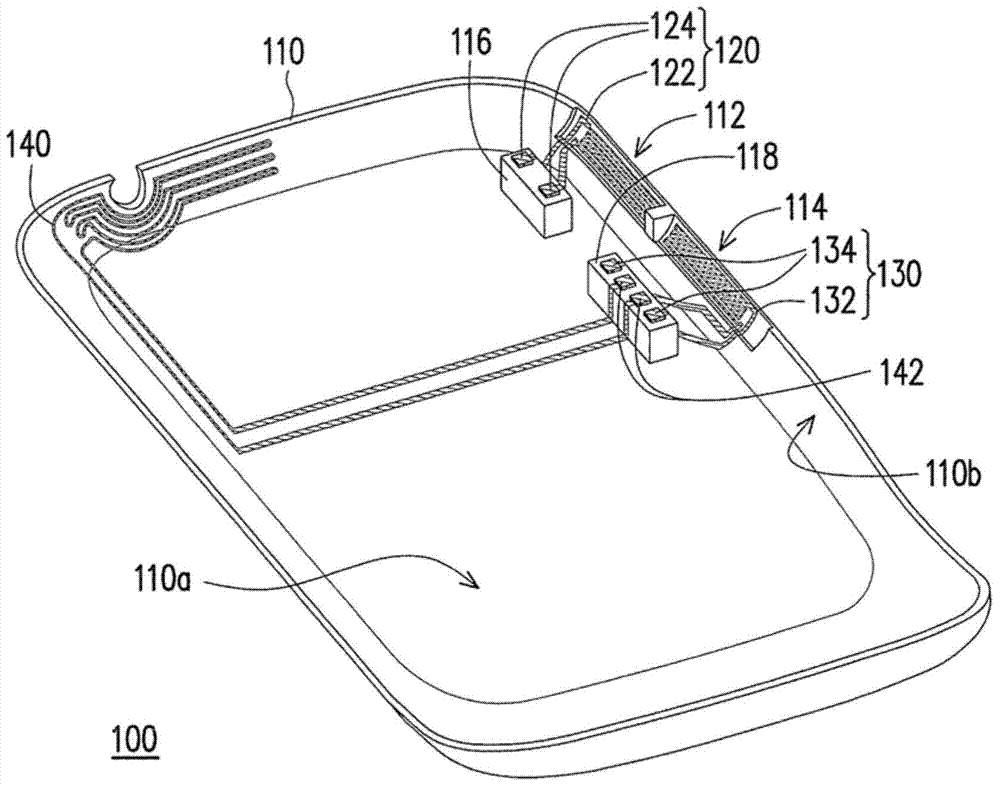

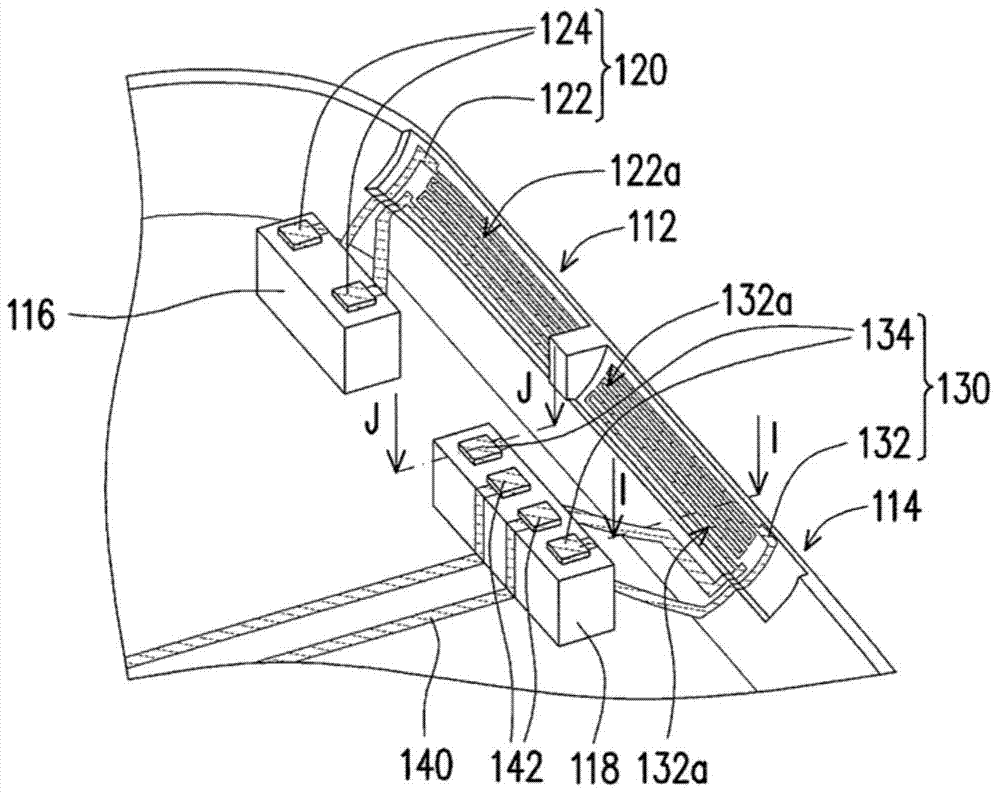

Electronic device and housing thereof

InactiveCN104780728AIntegrity guaranteedPrevent intrusionCasings/cabinets/drawers detailsElectronic switchingKey pressingElectrical resistance and conductance

The invention discloses an electronic device and a housing thereof. The housing comprises a housing body and an induction component, wherein the housing body is provided with a key part; the induction component comprises a first lead and two first contacts; the first lead is arranged on the internal surface of the housing body, and forms a strain induction pattern at the key part; and the first contacts are arranged on the internal surface of the housing body, and connected with the two ends of the first lead respectively. The strain induction pattern is suitable for allowing a resistance value to change along with deformation of the key part to generate an electrical signal.

Owner:HTC CORP

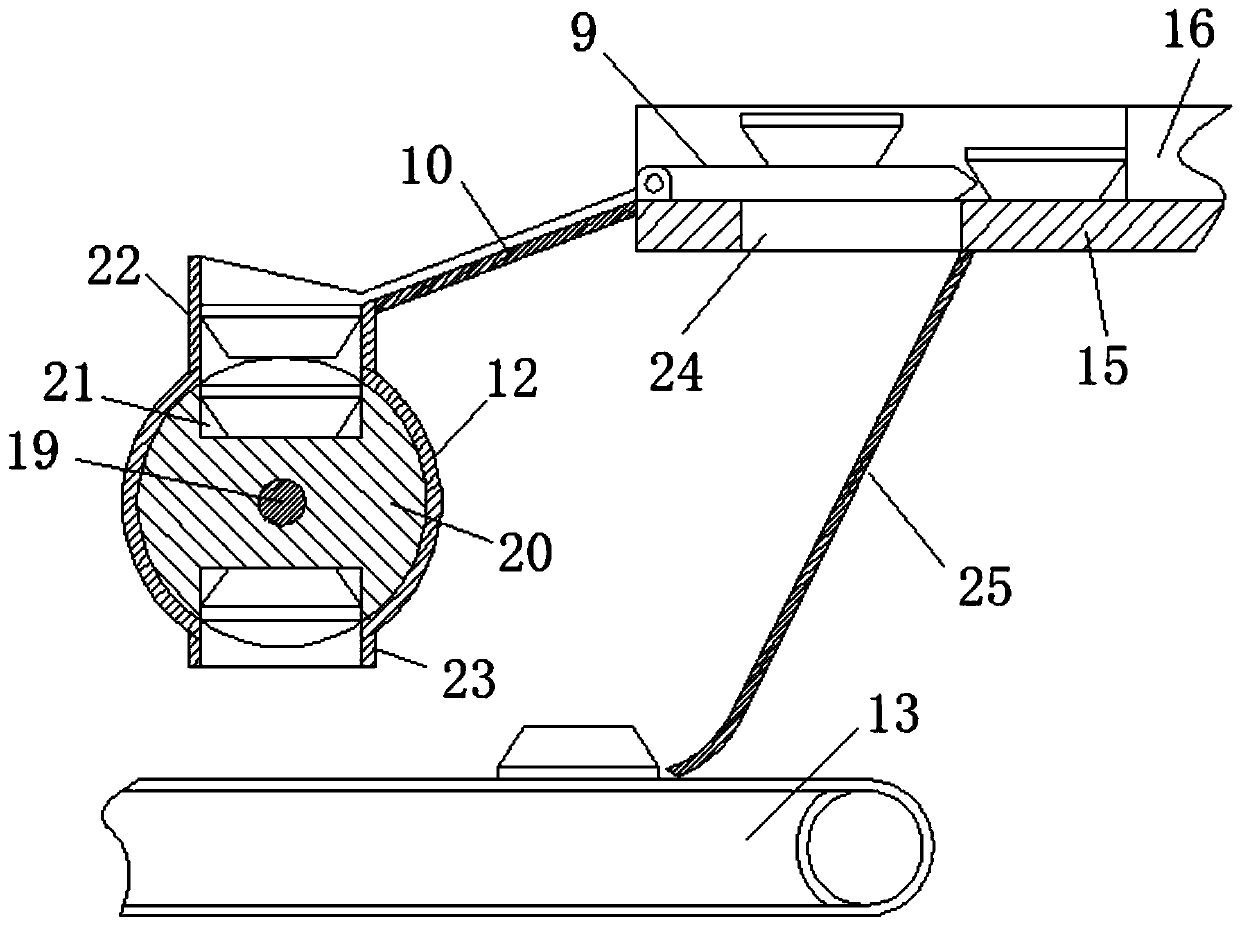

Conveyor for alarm workpiece production and using method thereof

InactiveCN111377215AOrderly rowsReduce labor intensityConveyor partsTransmission beltMaterial distribution

The invention relates to the field of alarm production equipment, in particular to a conveyor for alarm workpiece production and a using method thereof. The conveyor comprises a base, wherein a material arranging mechanism and a material pushing mechanism are arranged on the base, and the material pushing mechanism is in transmission connection with the material arranging mechanism; and a materialoverturning mechanism is arranged on the base, wherein the material overturning mechanism is located on the left side of the material pushing mechanism, and the pushing mechanism is in transmission connection with the overturning mechanism. According to the conveyor for alarm workpiece production and the using method thereof, top covers are orderly arranged through the material arranging mechanism, output is sequentially and orderly conducted through the material pushing mechanism, and materials in different directions are automatically distributed, so that the top covers in the needed directions are directly output, manual material distribution is not needed, time and labor are saved, the production efficiency is improved, the whole process does not need manpower interference, and the automatic production degree can be improved; and meanwhile, the material pushing mechanism drives the material overturning mechanism to overturn the materials in the opposite directions, the directionsof the top covers output by a conveying belt are consistent, manual overturning is not needed, and the production efficiency is further improved.

Owner:叶子路

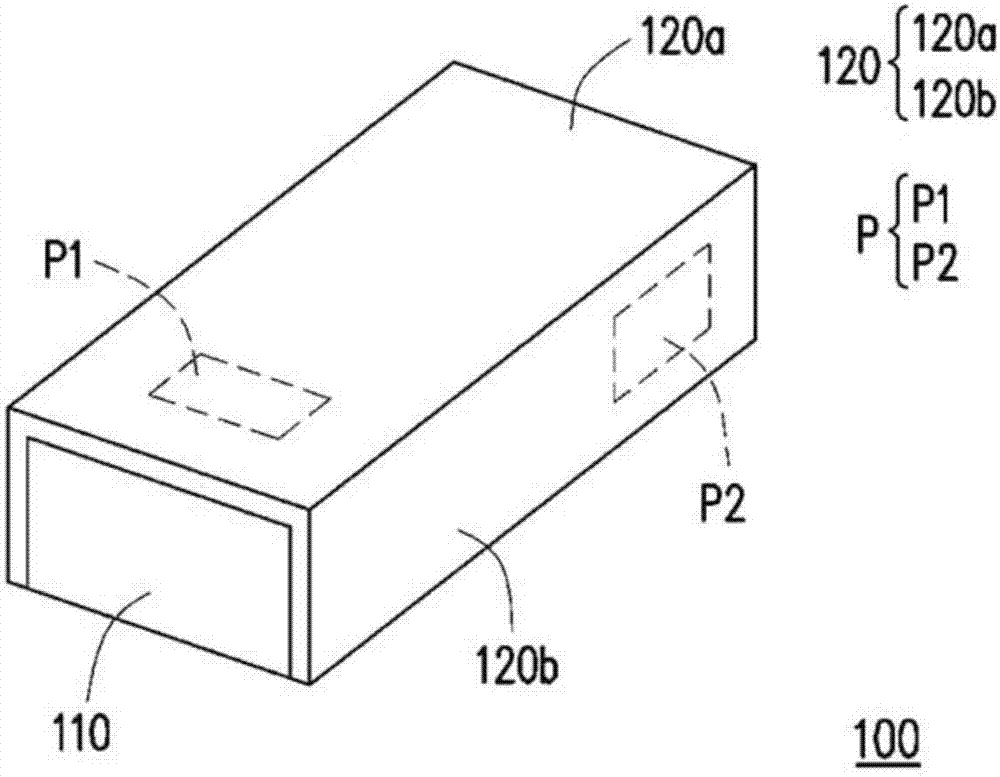

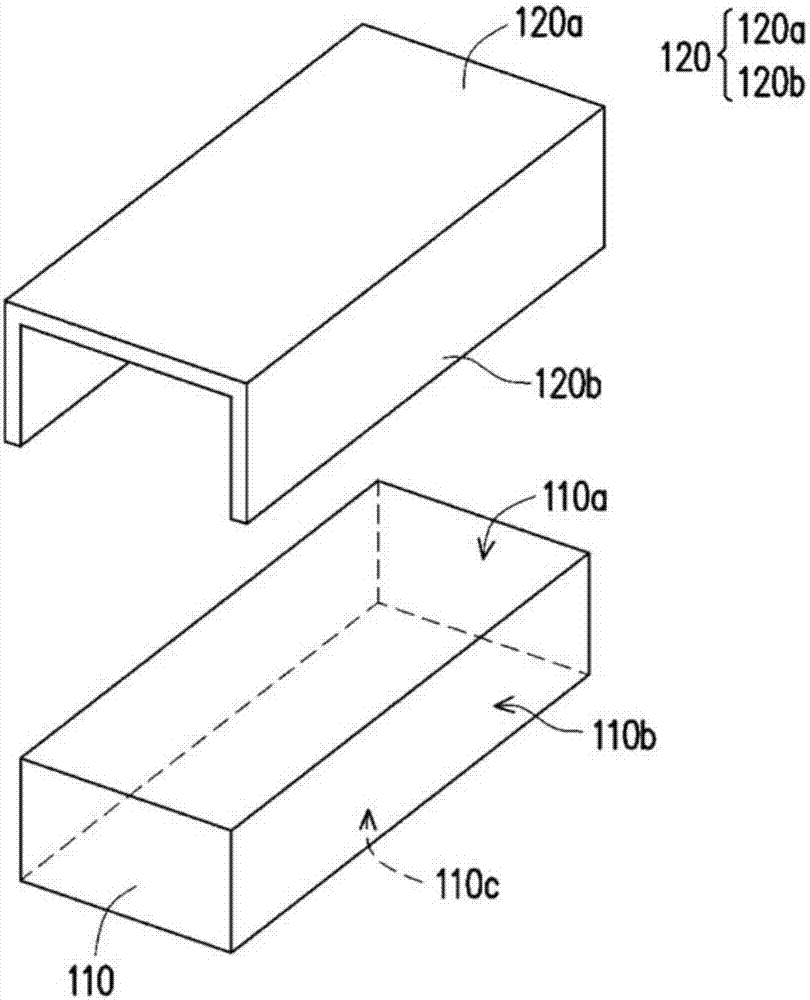

Semiconductor packaging structure and packaging technology thereof

ActiveCN101937899ASimple packaging processReduce assembly timeSemiconductor/solid-state device detailsSolid-state devicesComputer moduleSemiconductor package

The present invention discloses a semiconductor packaging structure with built-in electronic elements and packaging technology thereof. By means of more than two structural modules formed in advance, the electric elements can be assembled on the structural modules after conjoining so as to obtain the semiconductor packaging structure. By means of the structural modules formed in advance, it is possible to simplify the packaging technology of the semiconductor packaging structure and provide a great technology flexibility. Thereby, it is possible to shorten assembling time interval of the semiconductor packaging structure and improve finished product yield.

Owner:ADVANCED SEMICON ENG INC

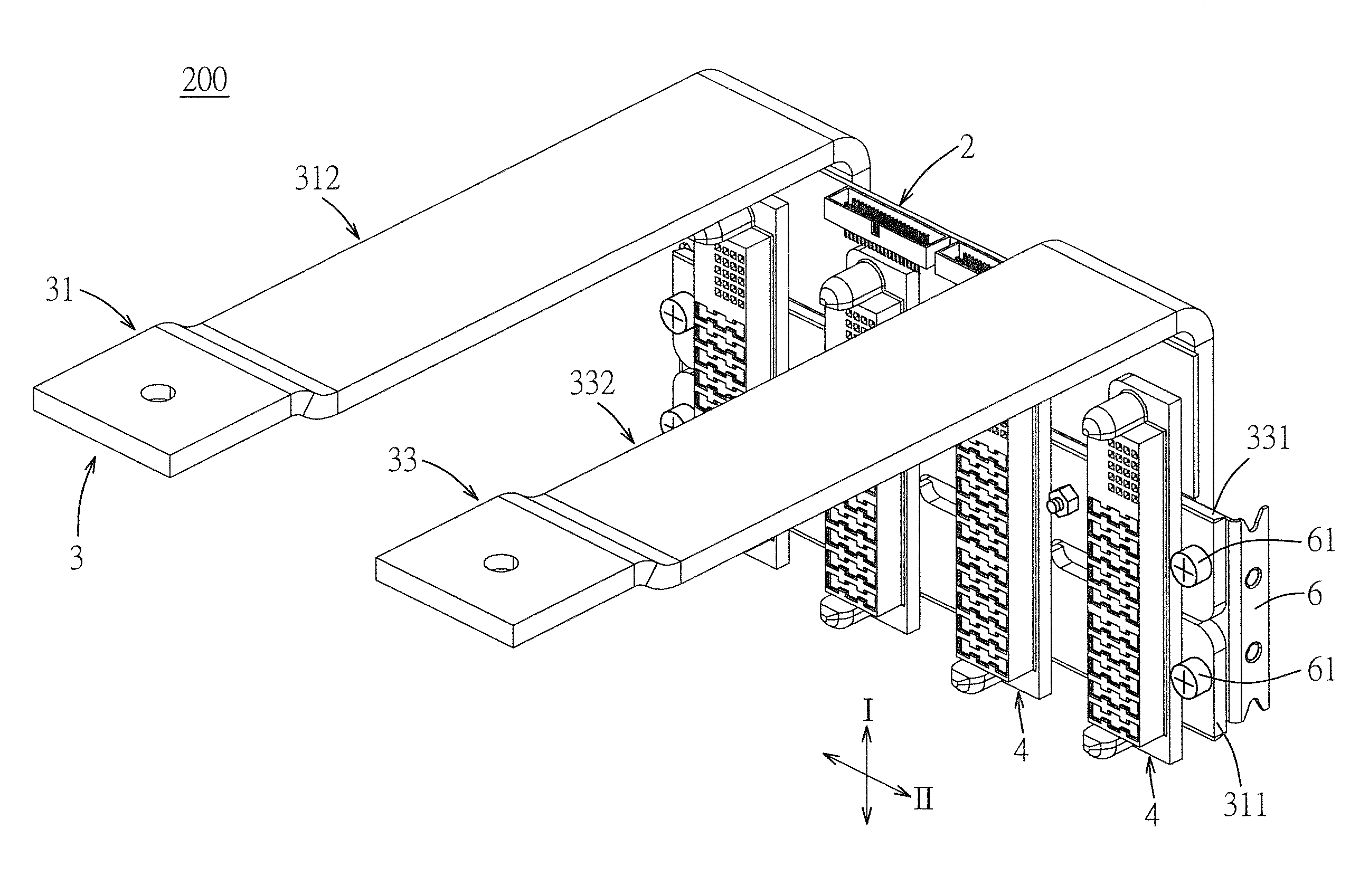

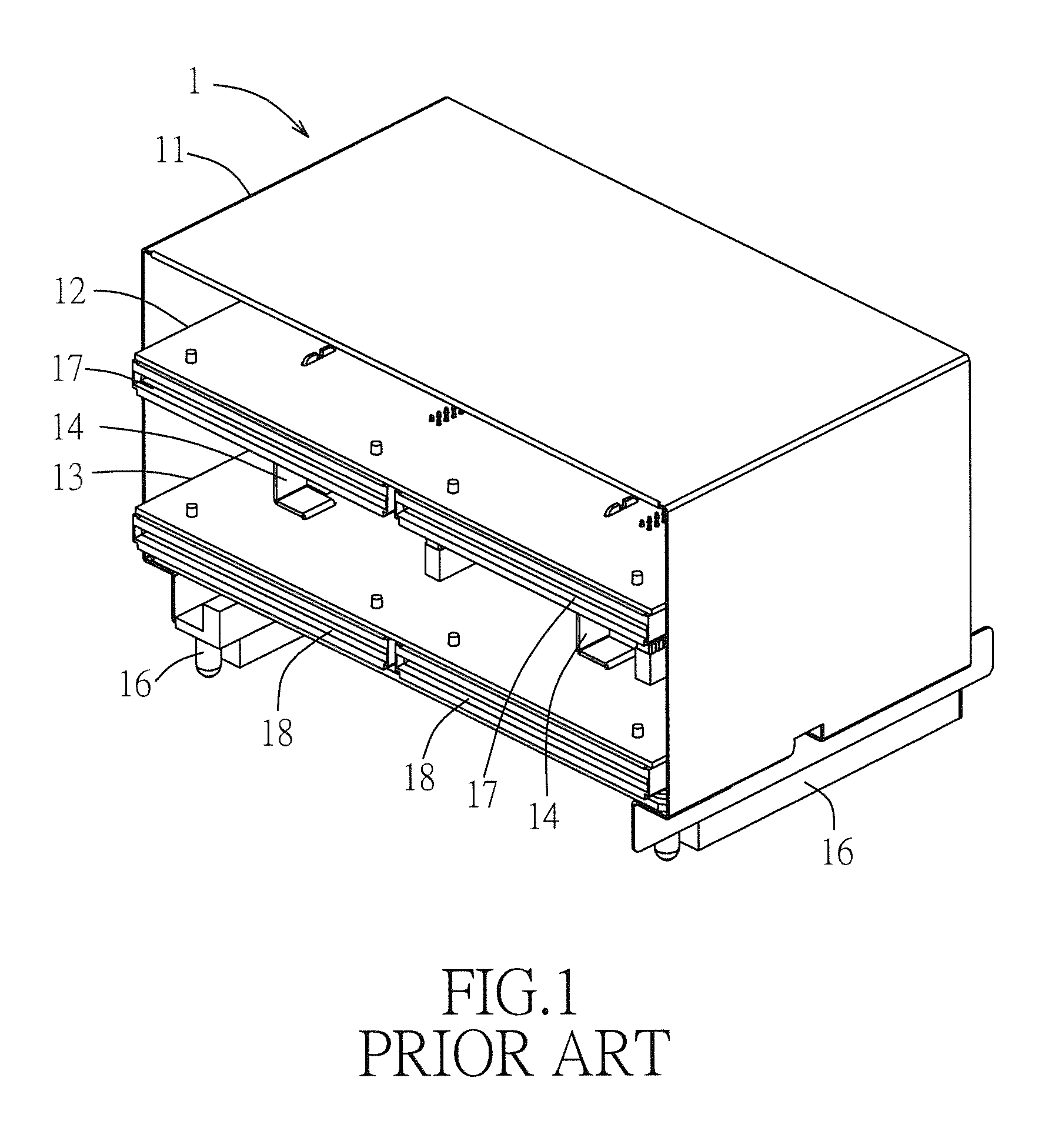

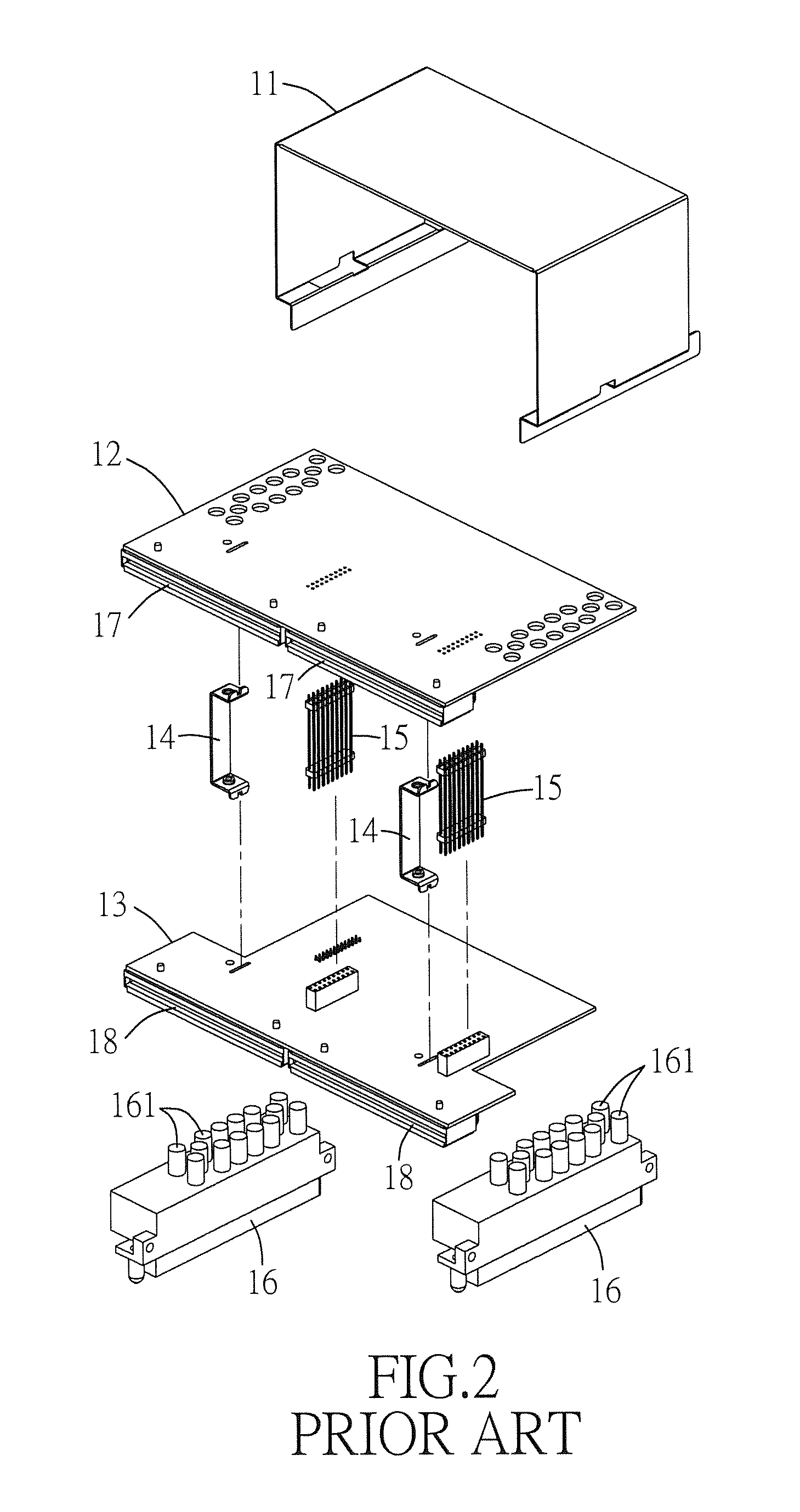

Power distribution device and assembling method thereof

ActiveUS9538685B2Shorten the transmission pathReduce lossesServersSubstation/switching arrangement casingsElectricityEngineering

A power distribution device for connection with a plurality of power supply units includes a signal control element, a transmission mechanism including a current transmission unit and a ground transmission unit, and a plurality of electrical connectors respectively adapted for insertion of and connection with the power supply units. Each electrical connector includes a first conductive terminals electrically connected to the signal control element for transmitting an electrical signal to the signal control element, and a plurality of second conductive terminals electrically connected to the current and ground transmission units for transmitting current to the current and ground transmission units.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

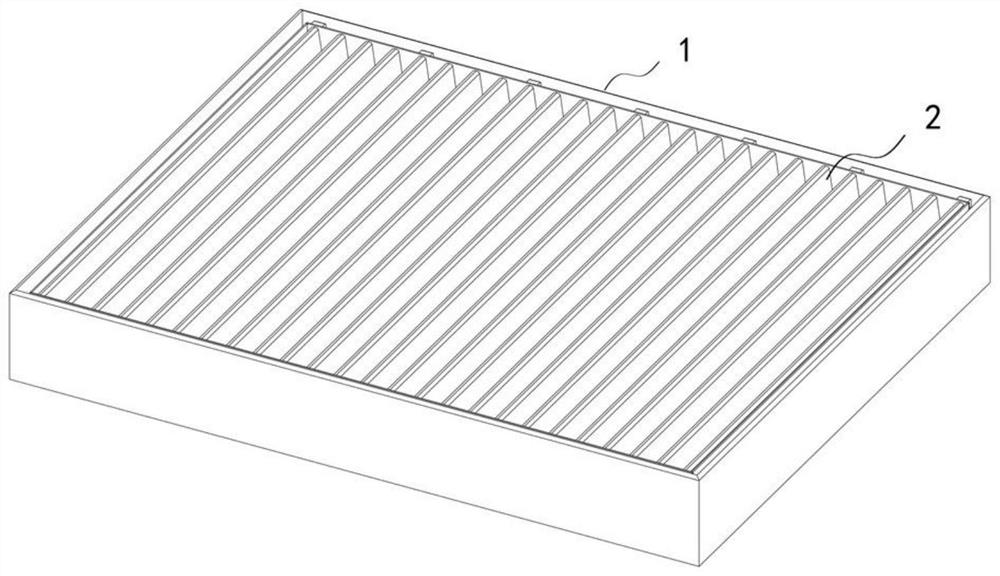

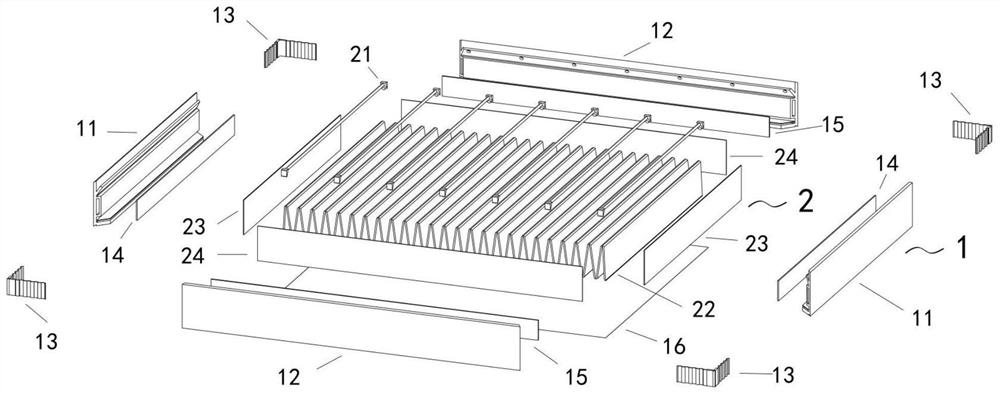

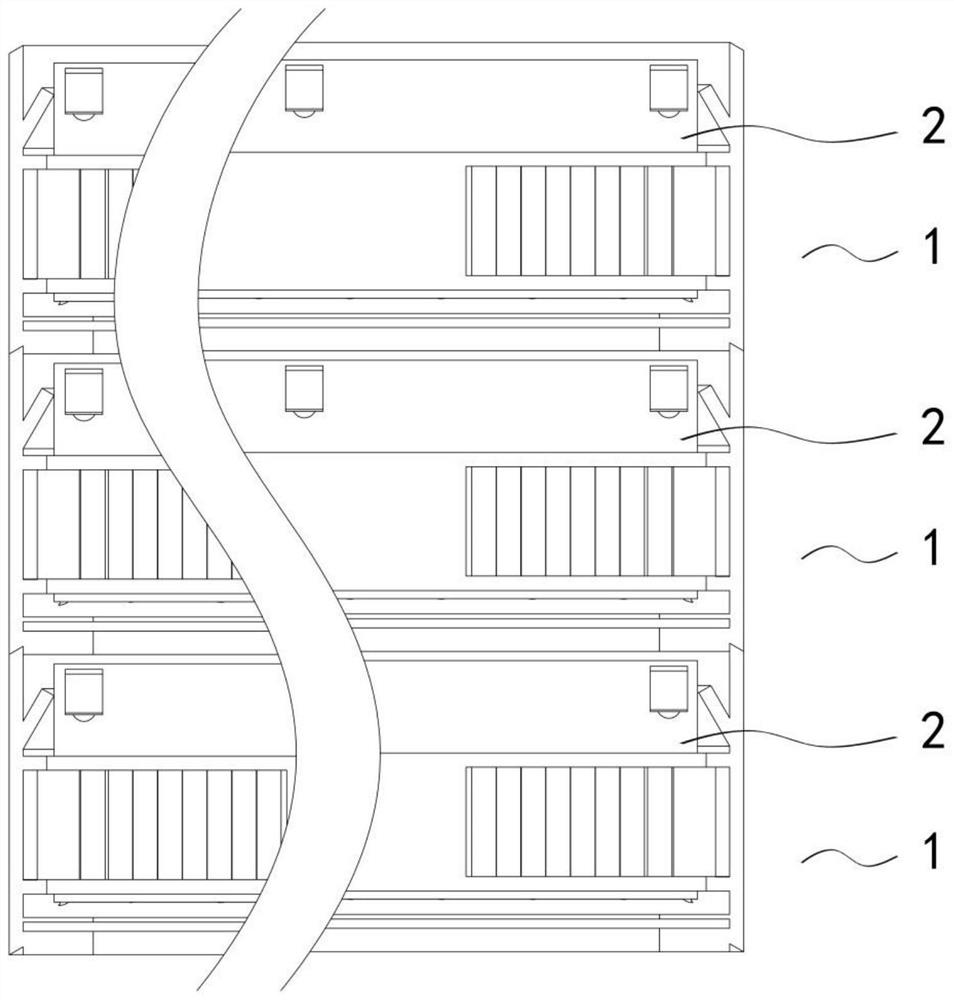

Telescopic filter element, and filter with replaceable filter element

ActiveCN113856367ASave manpower and material resourcesReduce hazardous wasteDispersed particle filtrationStructural engineeringControl theory

The invention discloses a telescopic filter element, and a filter with a replaceable filter element. The telescopic filter element comprises a wave-shaped filter part, first edge sealing strips and second edge sealing strips are arranged on the periphery of the wave-shaped filter part, the first edge sealing strips are arranged on the two sides of the folded edge of the filter part, the second edge sealing strips are arranged on the two sides of the multi-folded edge of the filter part, and fixing pieces are further arranged on the two sides of the multi-folded edge; and the filter with the replaceable filter element comprises the filter element and a frame, the frame is formed by splicing a first frame piece and a second frame piece, the whole frame piece is of an L-shaped structure, the upper edge of the top end of the long side of the frame piece is arranged to be an inclined face, an inclined protruding strip, a hollow reinforcing rib and a protective net baffle are sequentially arranged on the inner side of the long side from top to bottom, a surface protecting net is installed between the protective net baffle and the L-shaped short edge, and the filter element is installed in the upper space of the surface protecting net. The frame body and the filter element can be separated, the frame can be reused, the filter element can be replaced regularly, and energy conservation and consumption reduction are achieved; and the filter element is telescopic and is convenient to transport and store after being compressed.

Owner:MAYAIR TECH (CHINA) CO LTD

Sensing element and electronic device with sensing element

InactiveCN107453746APrevent intrusionSimple manufacturing process stepsDigital data processing detailsForce measurementEngineeringStrain gauge

The invention discloses a sensing element and an electronic device with the sensing element. The sensing element includes a first support layer, the second supporting layer and the strain gauge first supporting layer are provided with a first supporting surface; the second supporting layer is provided with a second supporting surface; the second supporting layer is connected with the first supporting layer; the young coefficient of the first supporting layer is larger than that of the second supporting layer. The strain gauge has a sensing region sensing region covering at least a portion of the first support surface and at least a portion of the second support surface.

Owner:AU OPTRONICS CORP

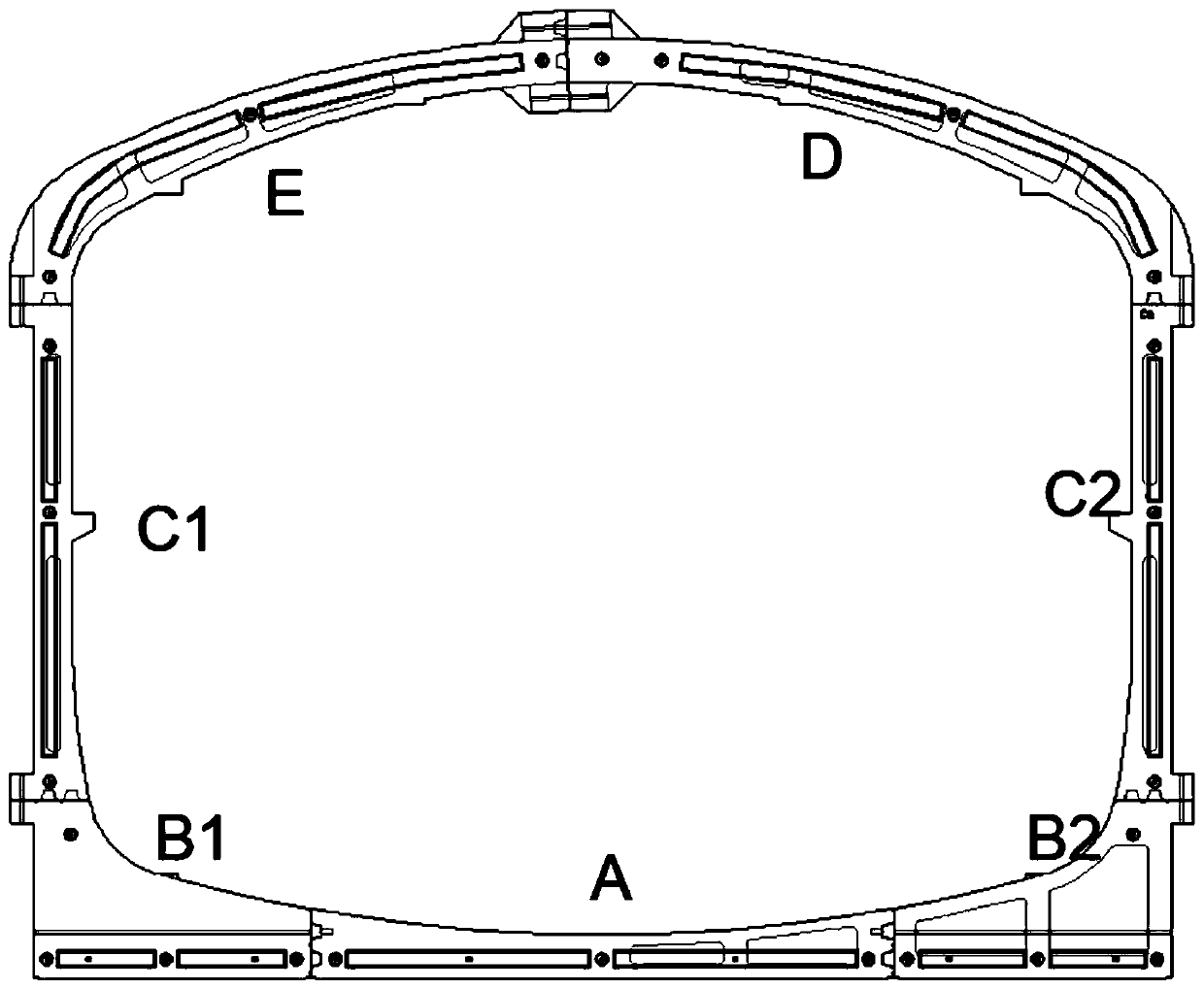

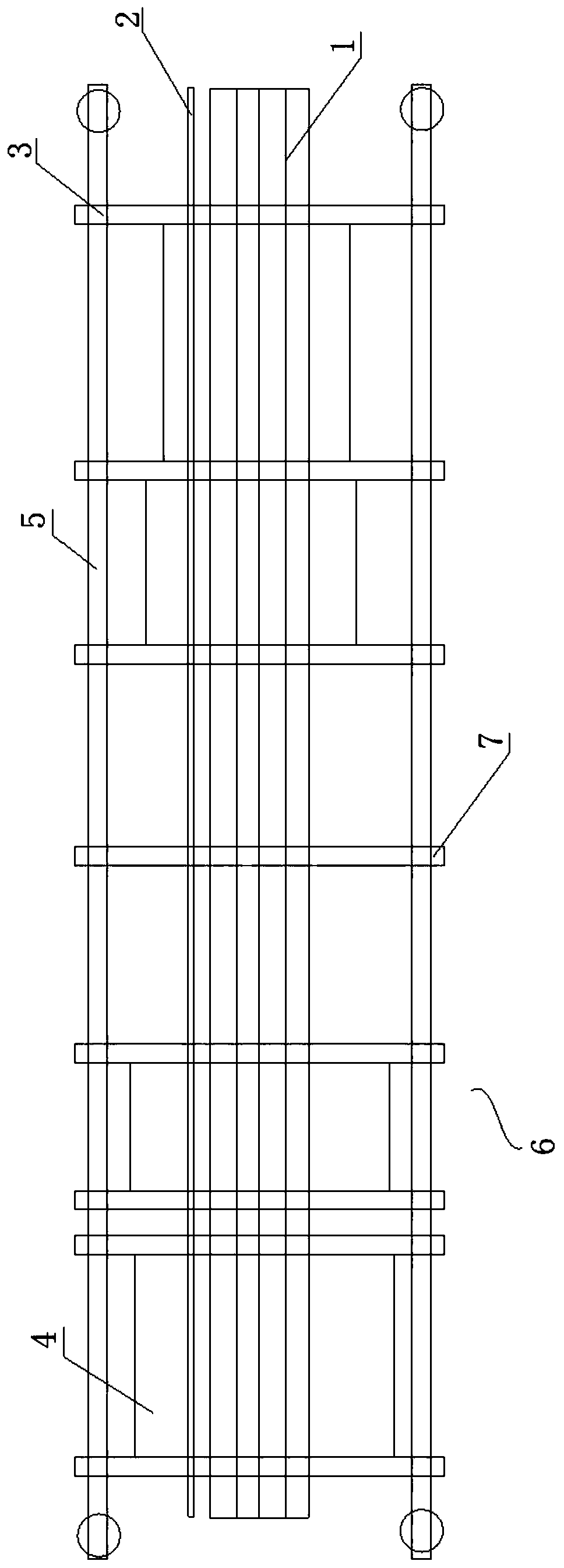

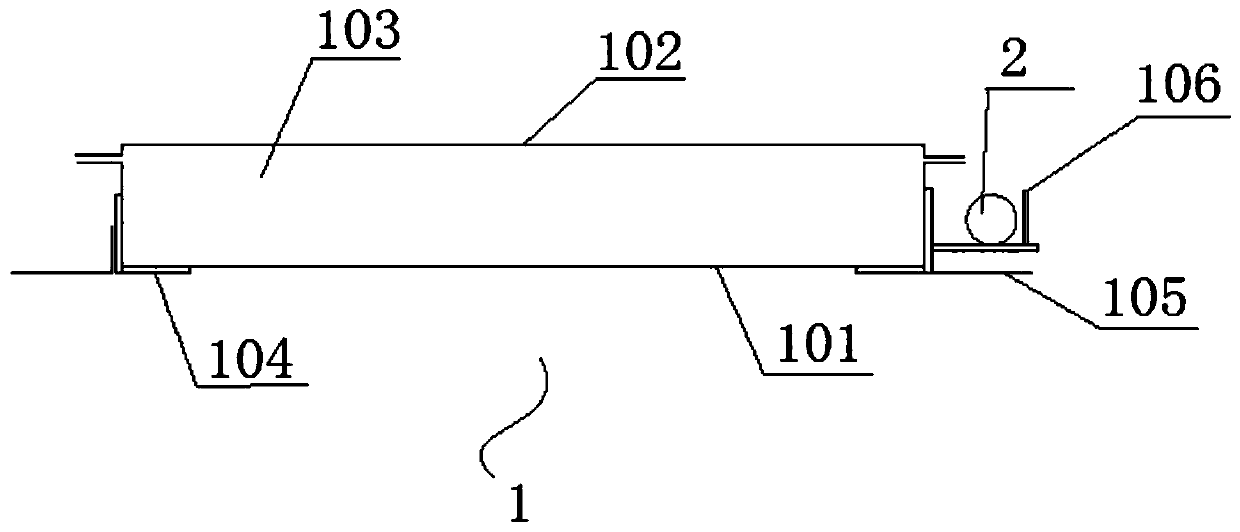

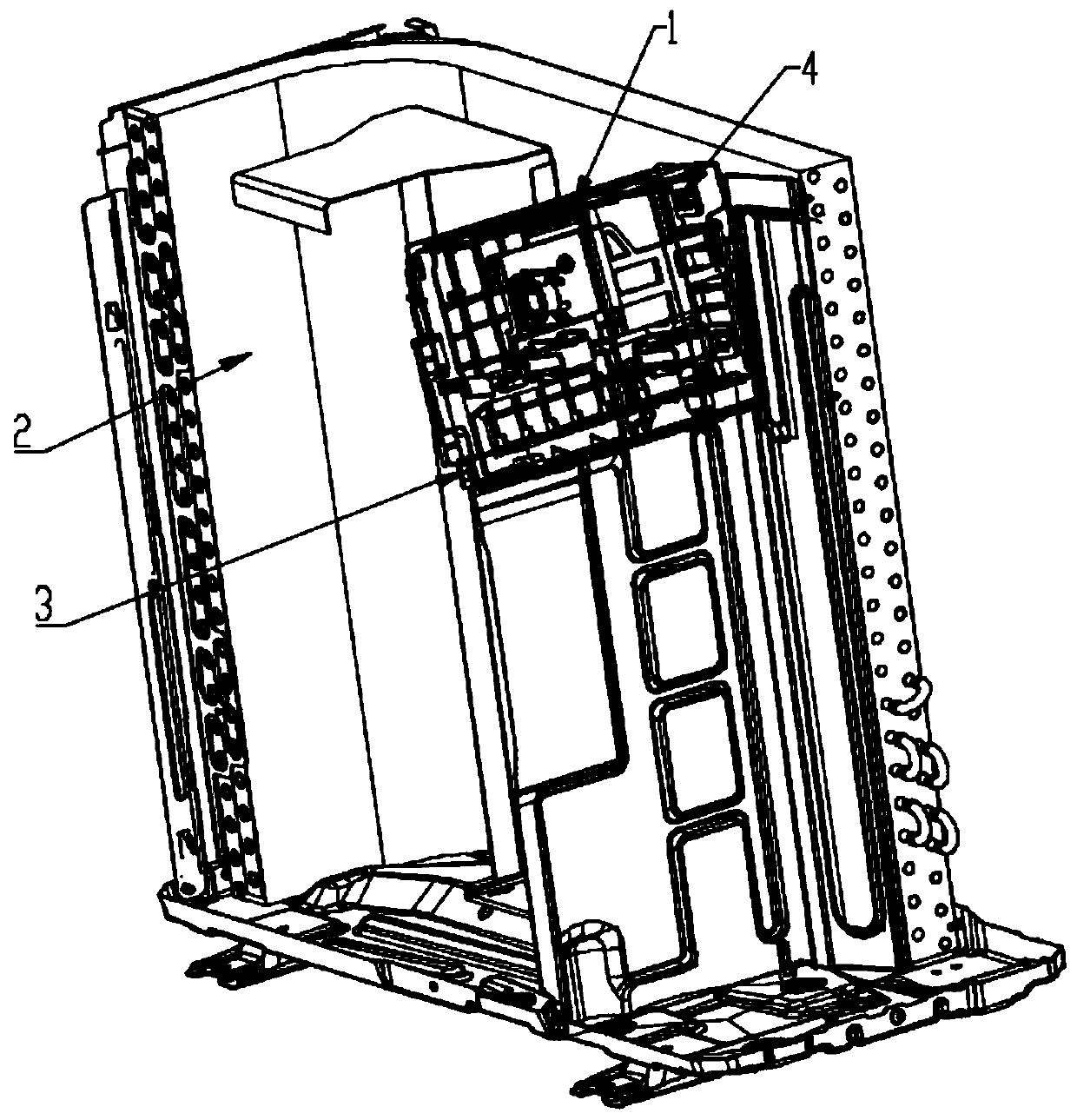

Railway vehicle underframe area arranging method and underframe area module

InactiveCN110155096AImprove turnover rateReduce assembly timeUnderframesEngineeringBuilding construction

The invention discloses a railway vehicle underframe area arranging method and an underframe area module. The underframe area arranging method comprises the following steps: A, mounting wiring ducts and pipelines on hanging cross beams, and arranging wires in the wiring ducts; B, hanging devices on the hanging cross beams; and connecting the wires; C, detachably mounting one end of each hanging cross beam to one longitudinal bearing beam, and detachably mounting the other end of each hanging cross beam to another longitudinal bearing beam so as to form a complete underframe module; D, arranging the complete underframe module to the bottom of a vehicle; and mounting two ends of each hanging cross beam on side beams of the bottom of the vehicle; and E, dismounting the longitudinal bearing beams. According to the method, an underframe area is structured into the complete module, thus the independent construction of a vehicle body and the underframe area is realized, and multi-work and multi-station synchronous construction can be carried out; the transferring rate of platforms of a workshop is increased; the complete underframe module is formed, so that the time of assembling to the vehicle body is decreased, and as a result, the production efficiency of production platforms can be improved; the traditional environment that the construction is carried out at the bottom part of thevehicle body is changed; the production cost is decreased; and the production efficiency is improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Assembly jig and assembly method of Halbach array magnets

PendingCN110977843AEasy and fast accessEasy to operateWork holdersMetal-working hand toolsMagnetic polesEngineering

The invention relates to an assembly jig and an assembly method of Halbach array magnets. The assembly jig comprises a mounting part and multiple auxiliary magnets. The mounting part is a non-magneticpart and is provided with a mounting surface. The multiple auxiliary magnets are mounted on the side, away from the mounting surface, of the mounting part at intervals, the magnetizing directions ofthe multiple auxiliary magnets are all vertical to the mounting surface, and the directions of magnetic poles of every two adjacent auxiliary magnets are opposite, so that multiple spaced attraction positions capable of attracting first magnets are formed on the mounting surface, a gap capable of containing each second magnet is formed between every two adjacent attraction positions, the first magnets are fixed to the other side of the mounting part in an attraction manner, the second magnets can be relatively easily embedded between the first magnets, the assembly process of the Halbach arraymagnets is easier to operate, assembly inconvenience can be reduced, the assembly time can be shortened, and the assembly efficiency can be improved; and by means of the assembly method, the Halbacharray magnets can be more easily and rapidly obtained, and the assembly efficiency is high.

Owner:SHENZHEN CORE MEDICAL TECH CO LTD

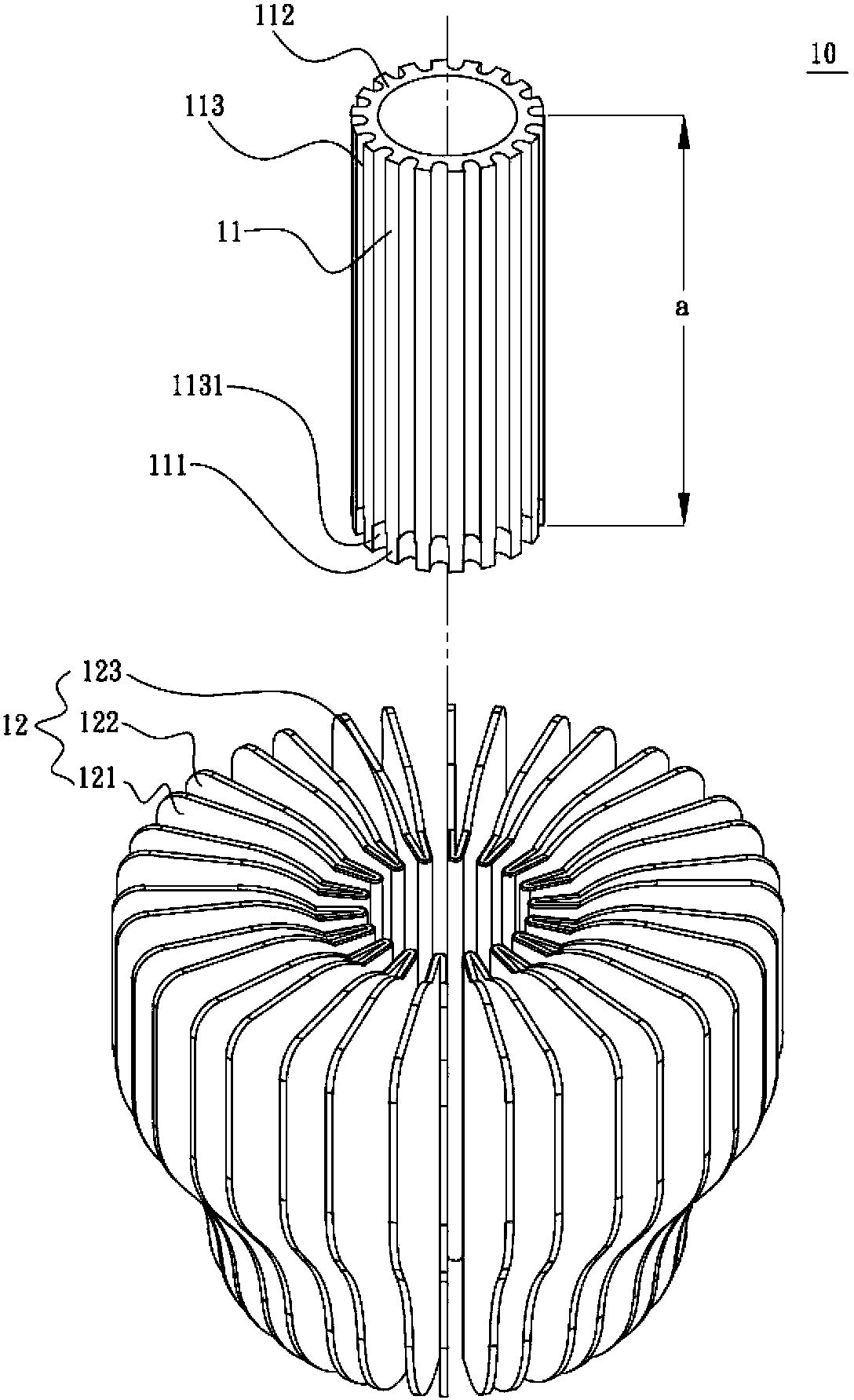

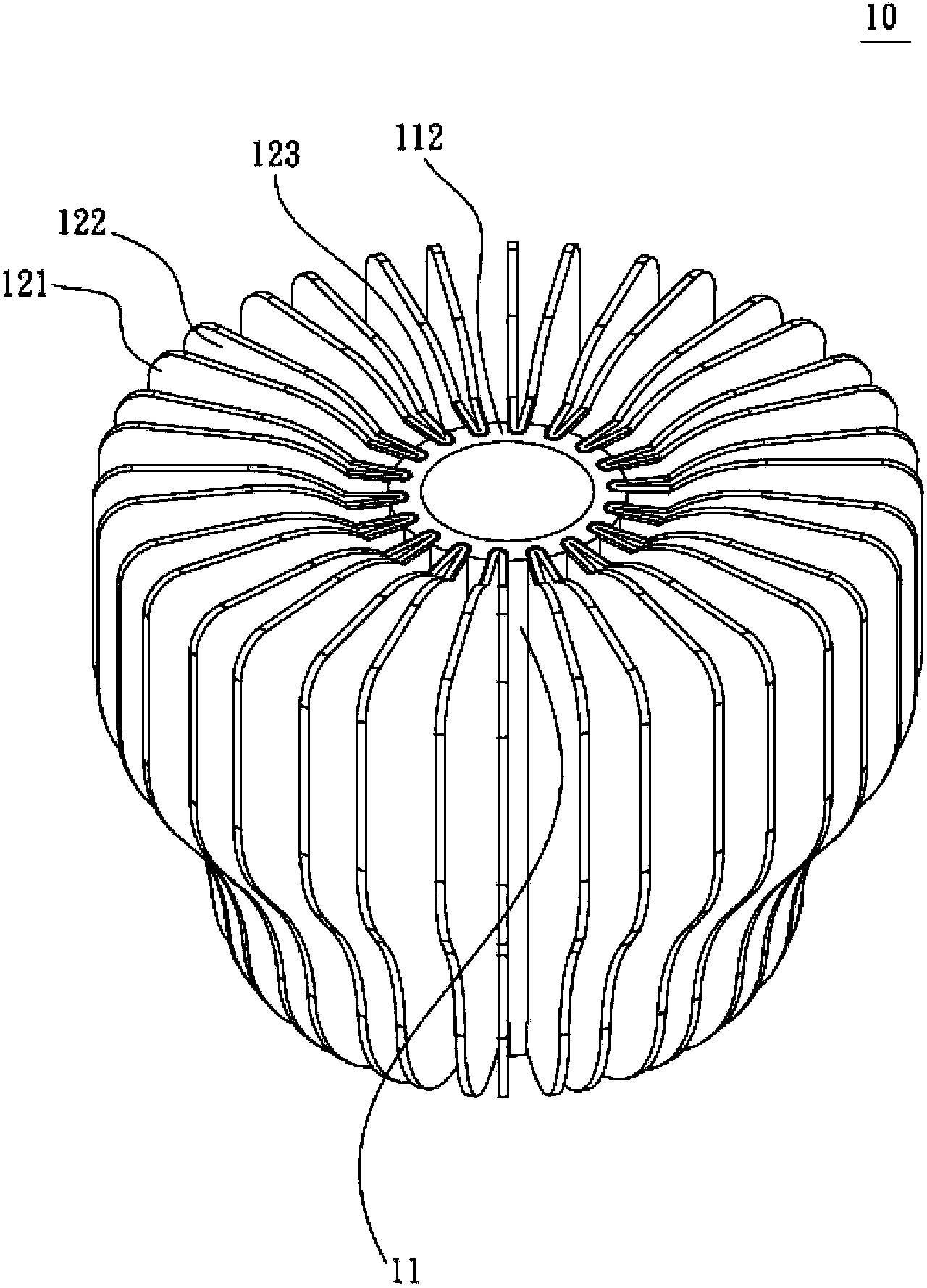

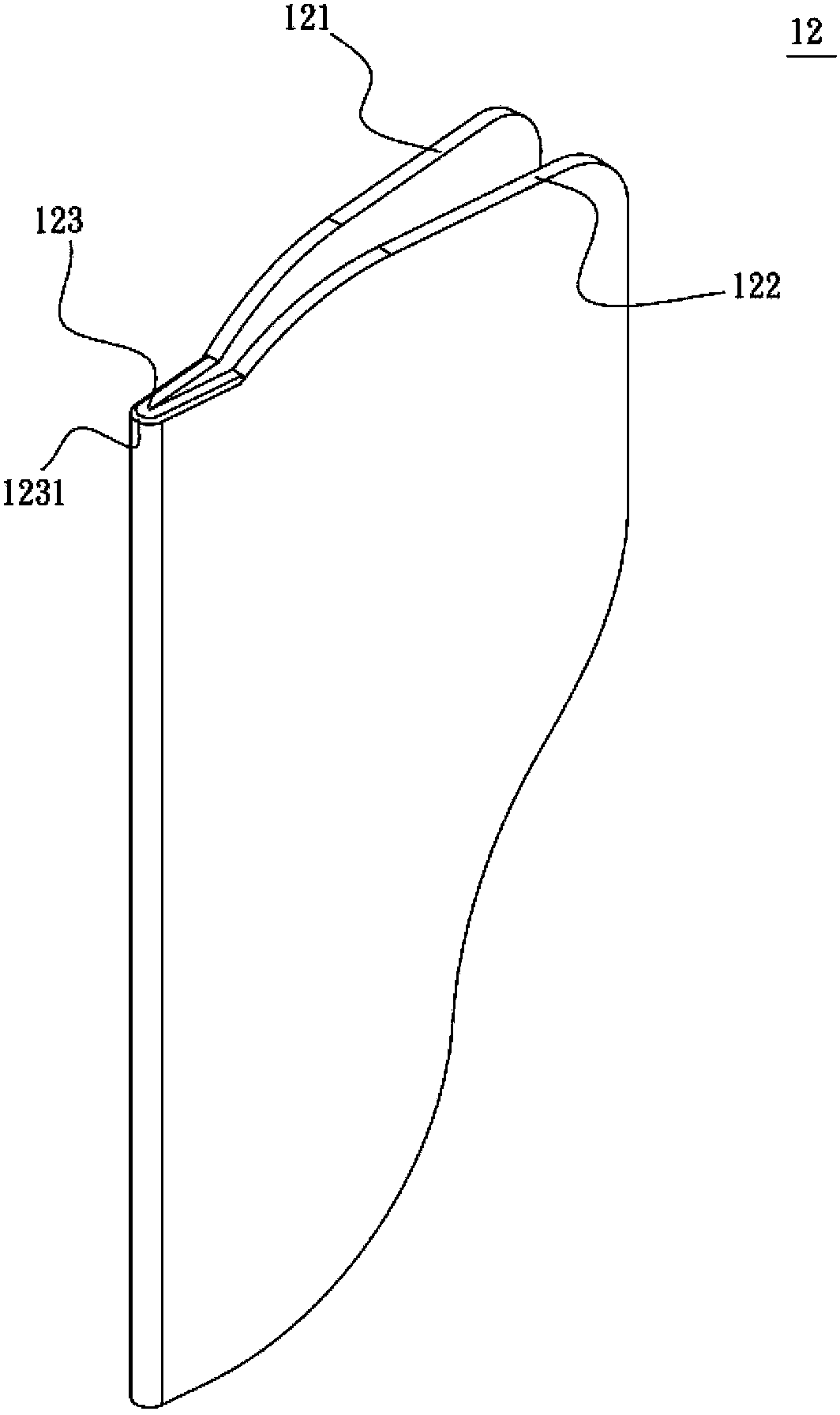

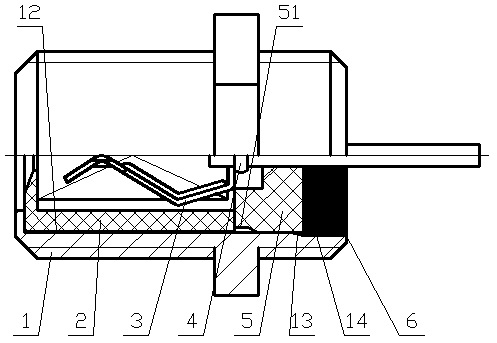

Radiator structure and production method thereof

ActiveCN103575150AStrengthen tight knotQuick assemblyShaping toolsHeat exchange apparatusEngineeringMachining

Disclosed are a radiator structure and a production method thereof. A radiator comprises a body and a plurality of radiating fins. The body is provided with a first end and a second end with the lengthwise direction defined therebetween. The radiating fins are arranged in a forming die, the body is enabled to be pushed into the forming die at a high speed in a machining mode, and bending sections of the radiating fins in the forming die facing toward the body are forced into combined slots from the first end and move along the lengthwise direction to the second end to be combined on the surface of the body.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Coaxial radio frequency connector

PendingCN107799977AReliable electrical connectionLess signal attenuationSecuring/insulating coupling contact membersAntenna connectorsElectrical conductorElectrical connection

The present invention provides a coaxial radio frequency connector. A front insulation piece and a rear insulation piece are respectively arranged at two sides of a center conductor of the internal portion of a housing, the front insulation piece and the rear insulation piece are nested in two ends of the center conductor in tandem and then is embedded in the housing; and the outer end of the rearinsulation piece is sealed by employing a sealant. The coaxial radio frequency connector is good in electrical connection performance and little in signal attenuation, reduces the production and manufacturing cost and reduces the resource consumption.

Owner:JIANGSU MINGLIAN ELECTRONICS TECH

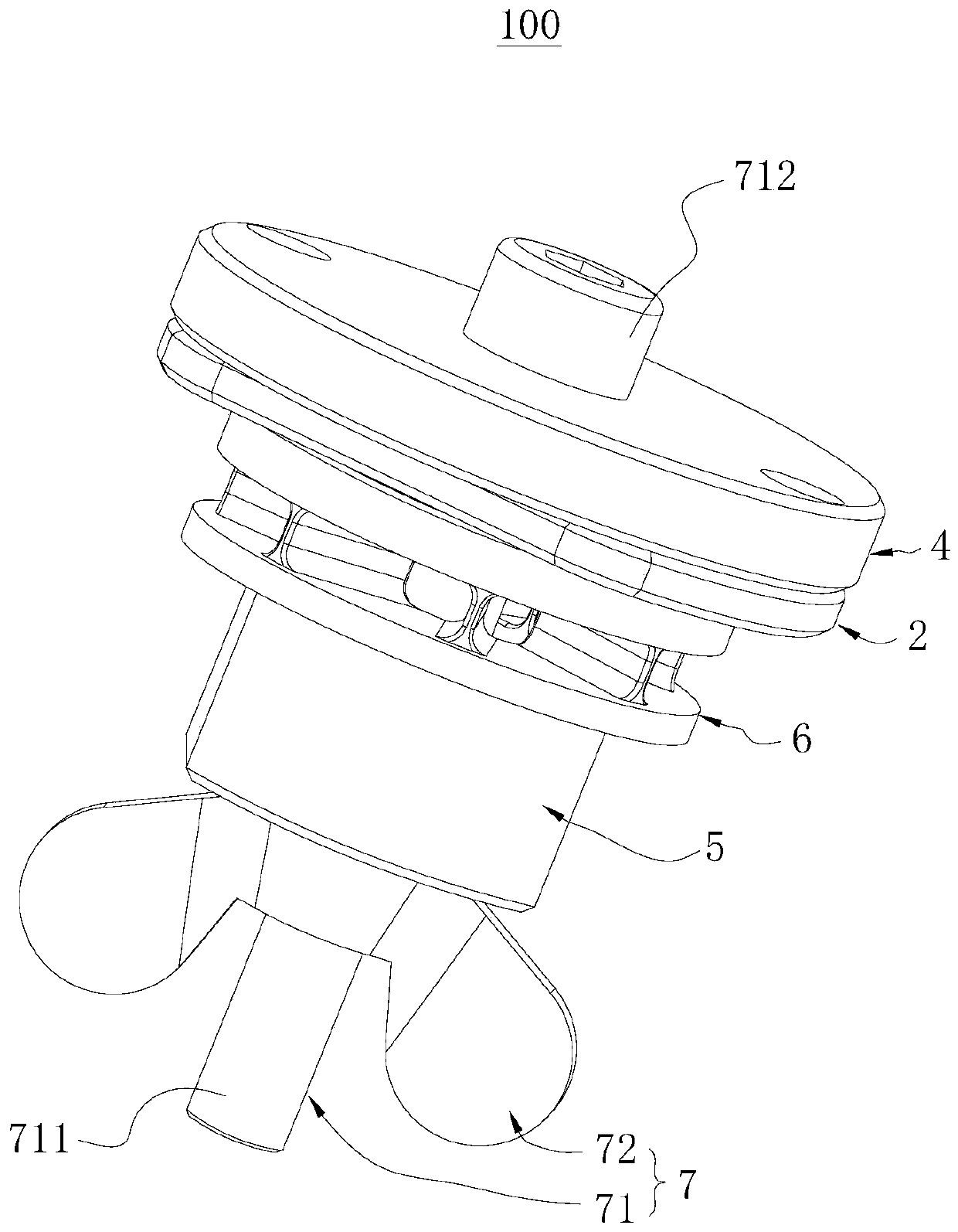

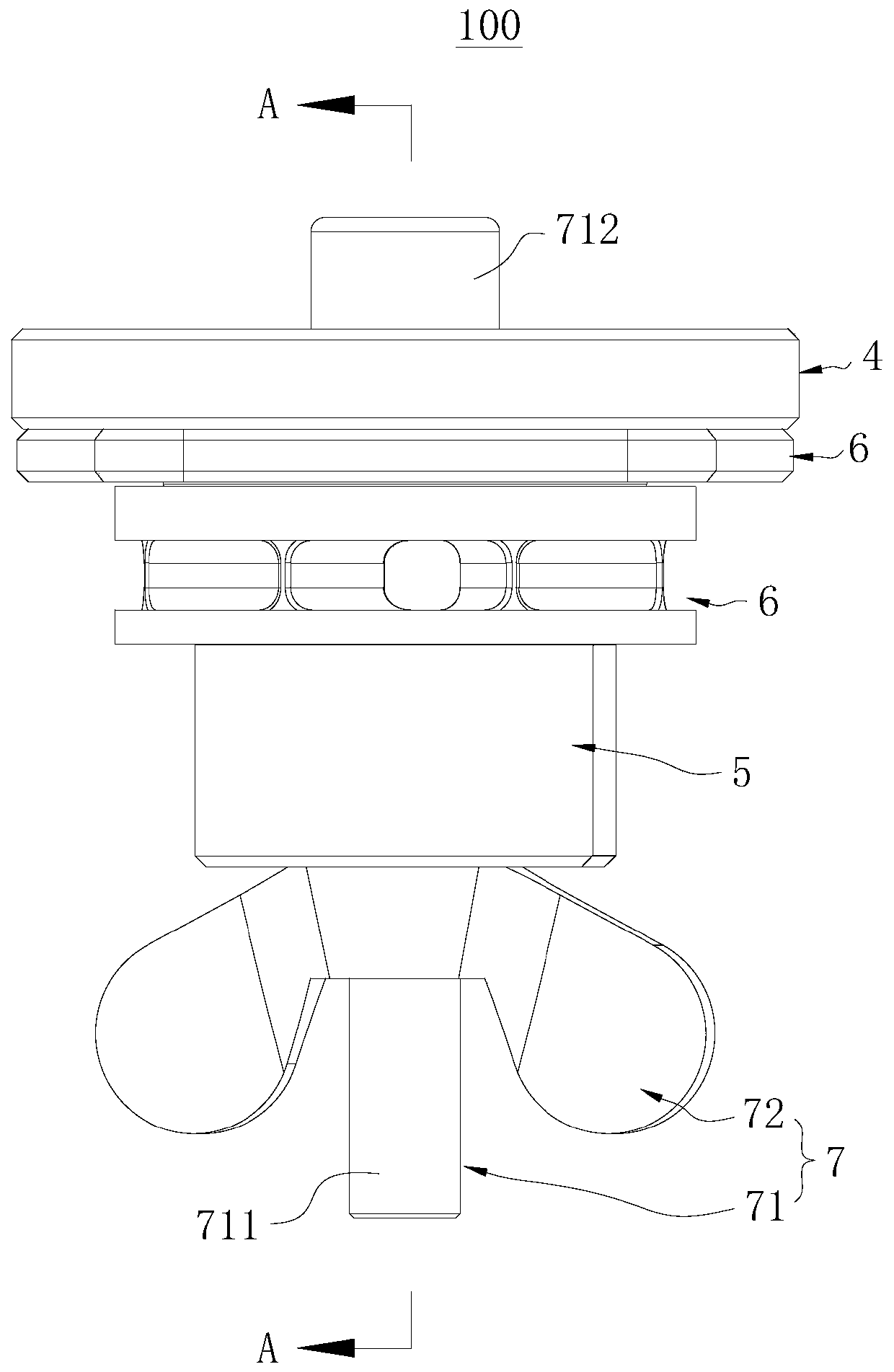

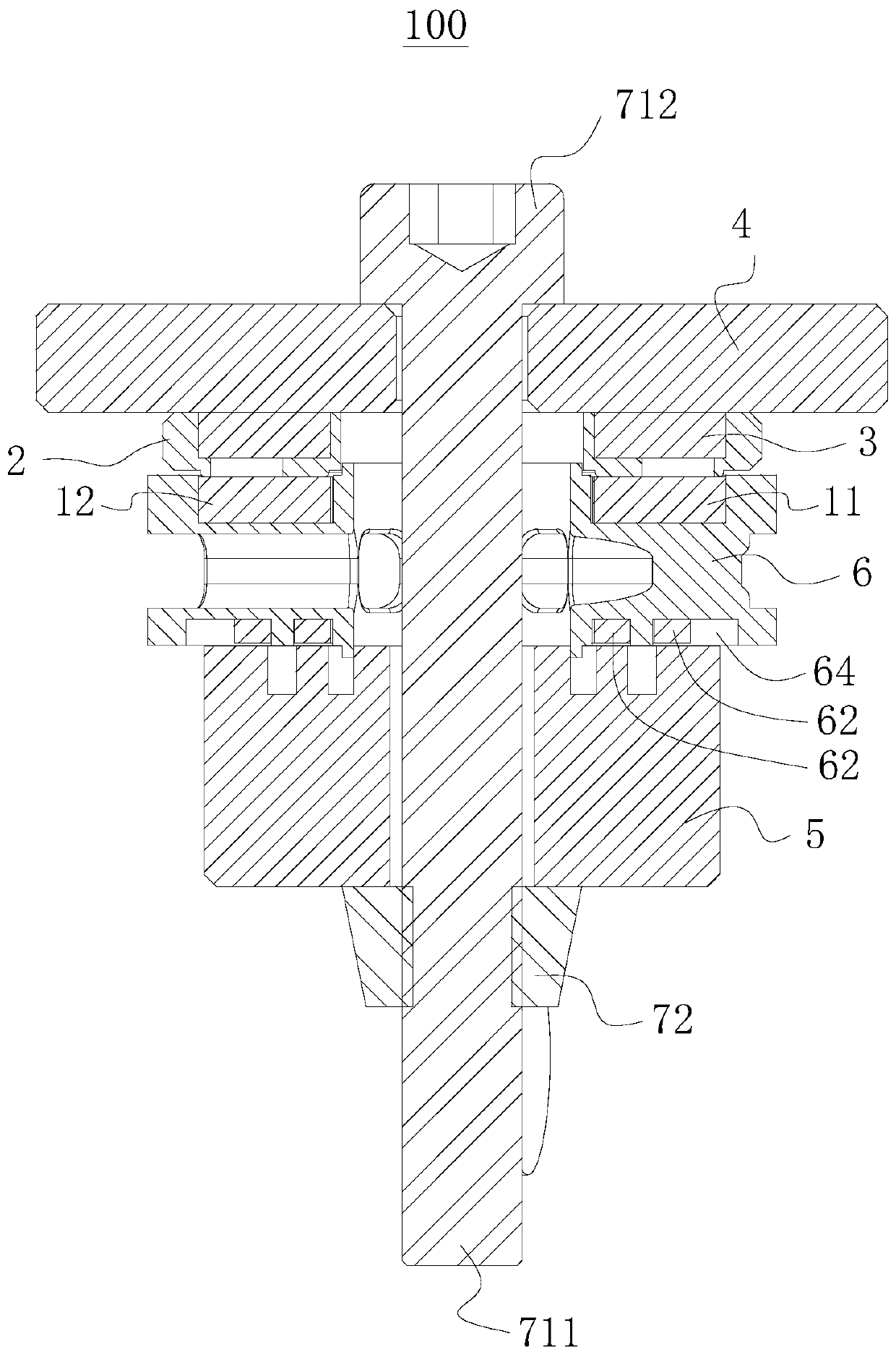

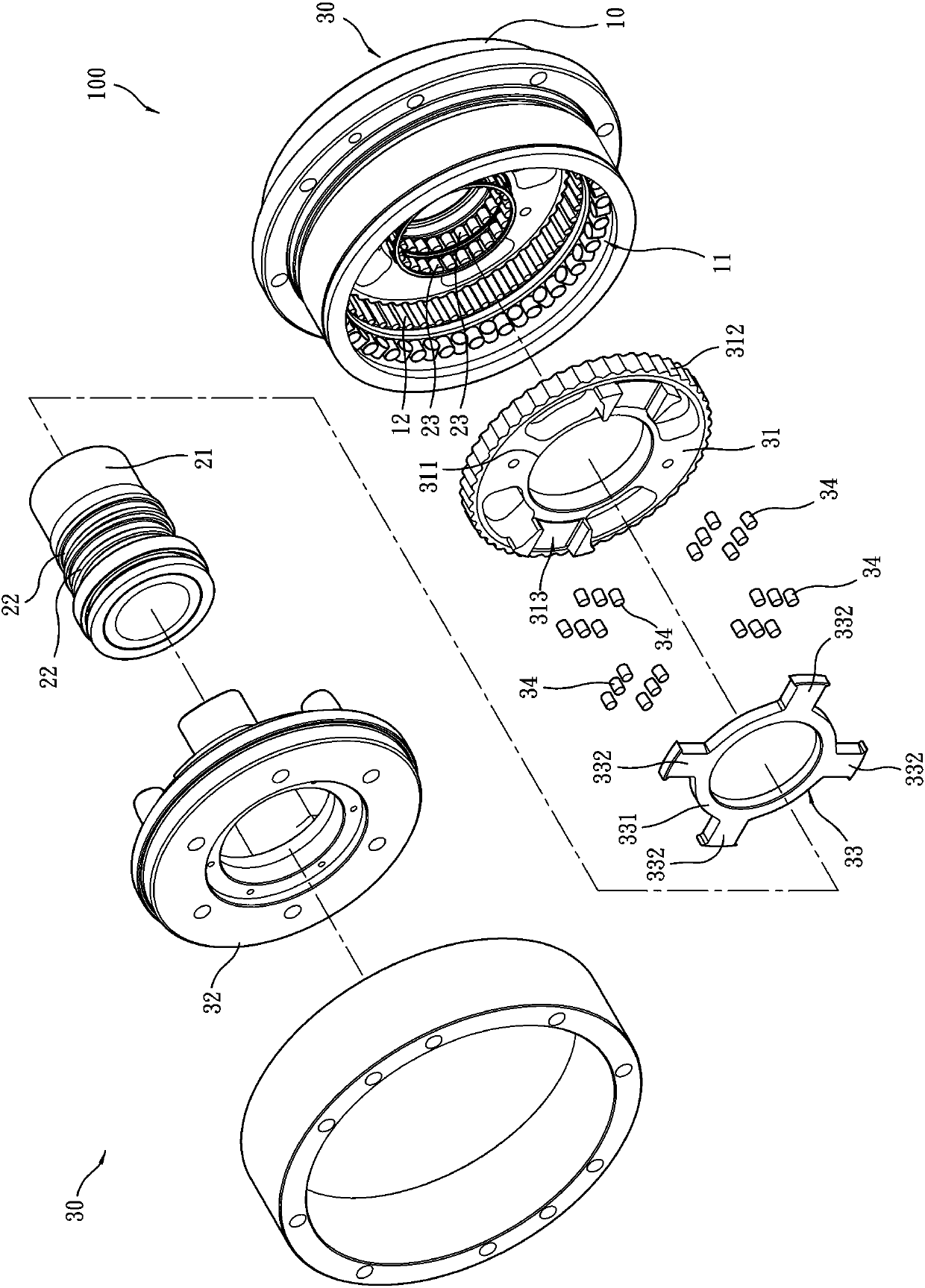

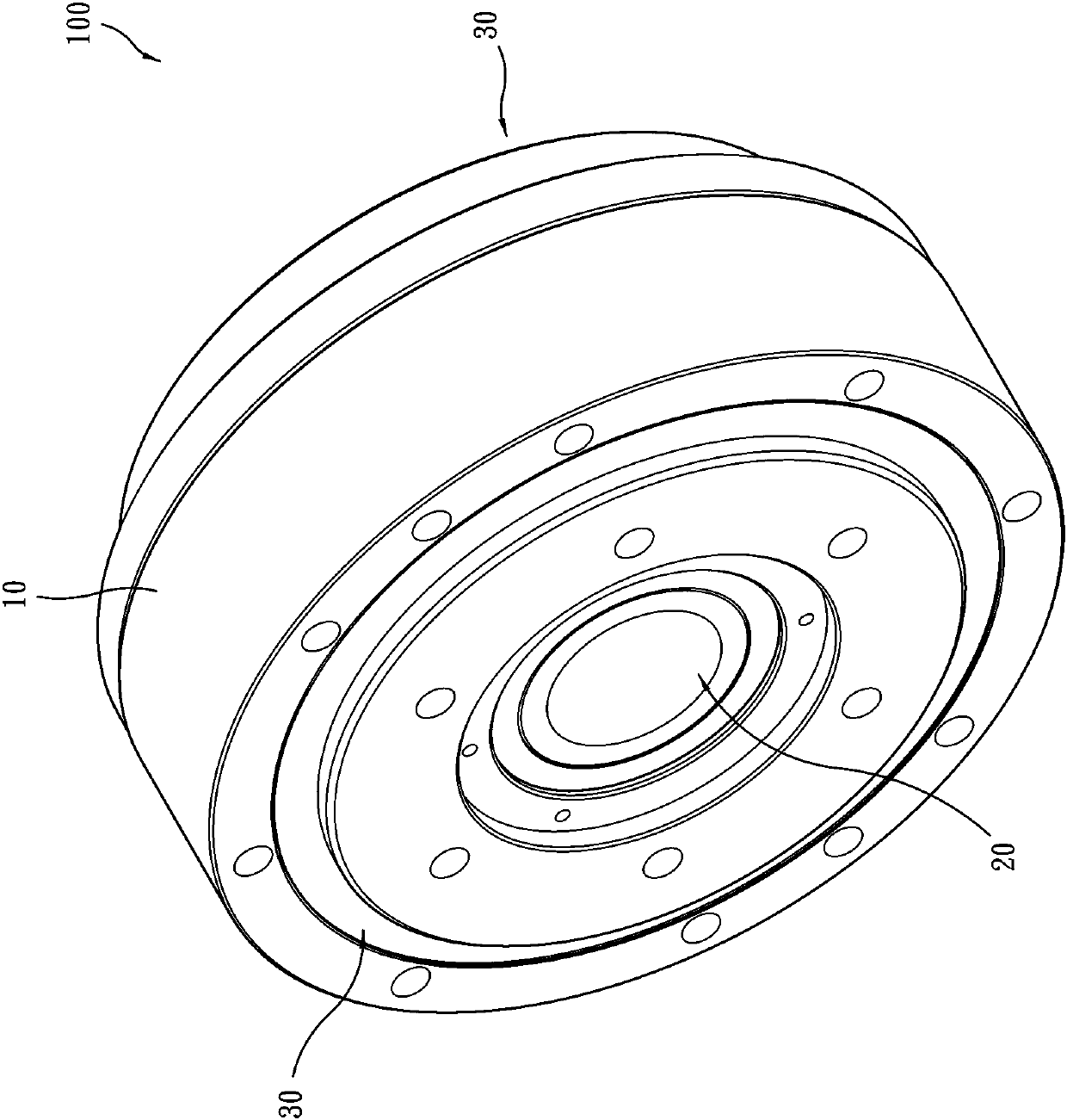

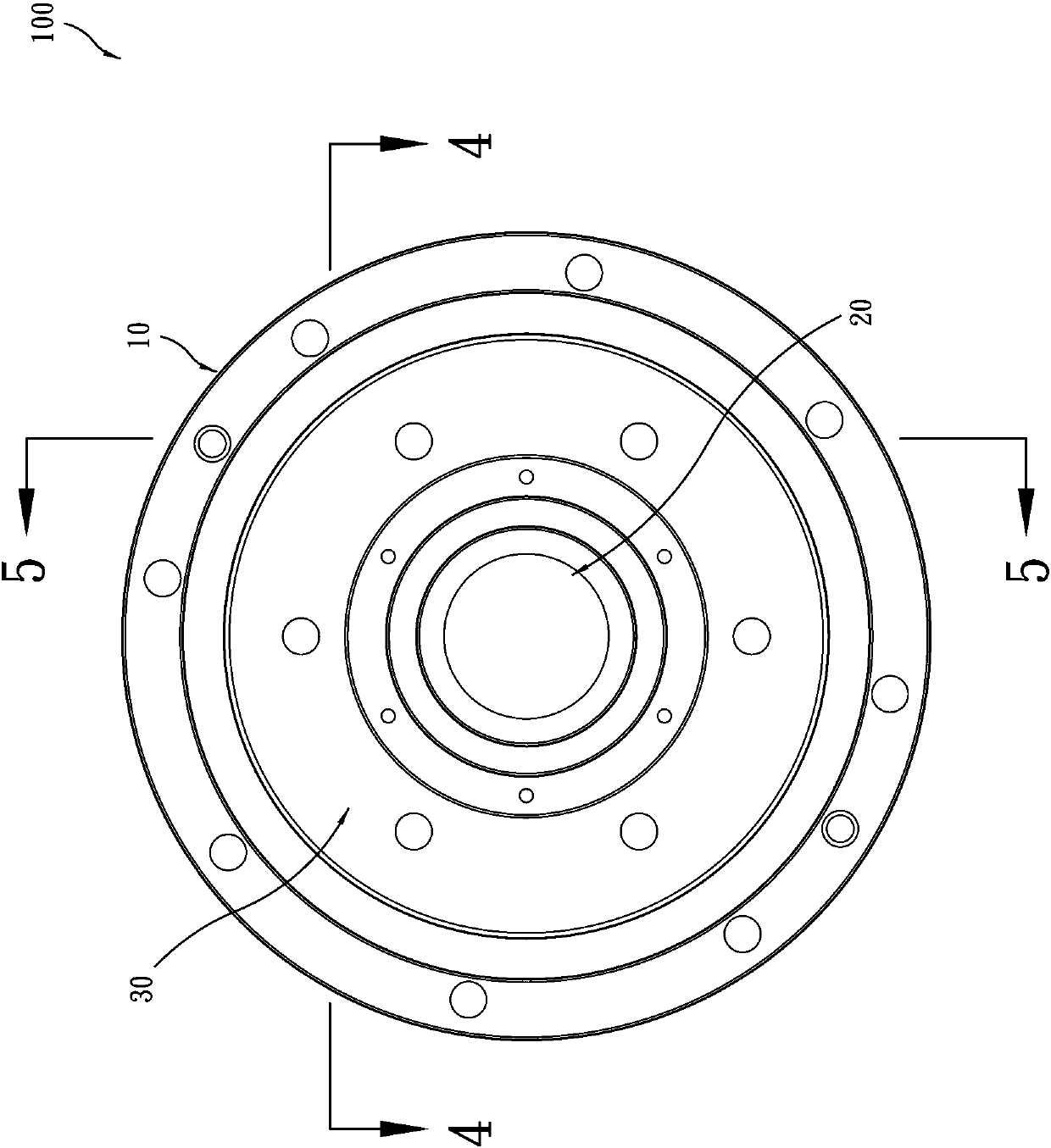

Cycloid type reducer

The invention relates to a cycloid type reducer. The cycloid type reducer comprises a main body, an input shaft sleeve and two deceleration output units. Each deceleration output unit is separately provided with a cycloid wheel, an output element, a cross oldham and a plurality of rolling elements, and the cycloid wheels sleeve the input shaft sleeve. The cycloid wheels are provided with a plurality of cycloid wheel grooves, and a side groove wall of each the cycloid wheel groove is an oblique surface. A plurality of output element grooves are formed in one end surface of the output elements,the cross oldhams are provided with central ring parts and four binding parts bulging in a cross shape, and one side wall of each output element is an oblique surface. The two binding parts of the cross oldhams are placed in the cycloid wheel grooves of the cycloid wheels, the other two binding parts are placed in the output element grooves of the output elements, the rolling elements are separately placed between the oblique surfaces of the cycloid wheels and the oblique surfaces of the cross oldhams, and between the groove walls of the output element grooves and the side walls of the bindingparts of the cross oldhams. The effects that the assembly efficiency is good, transmission back gaps are reduced, an idle running phenomenon is avoided, the positioning accuracy is good, and collision noise is reduced are realized.

Owner:HIWIN TECH

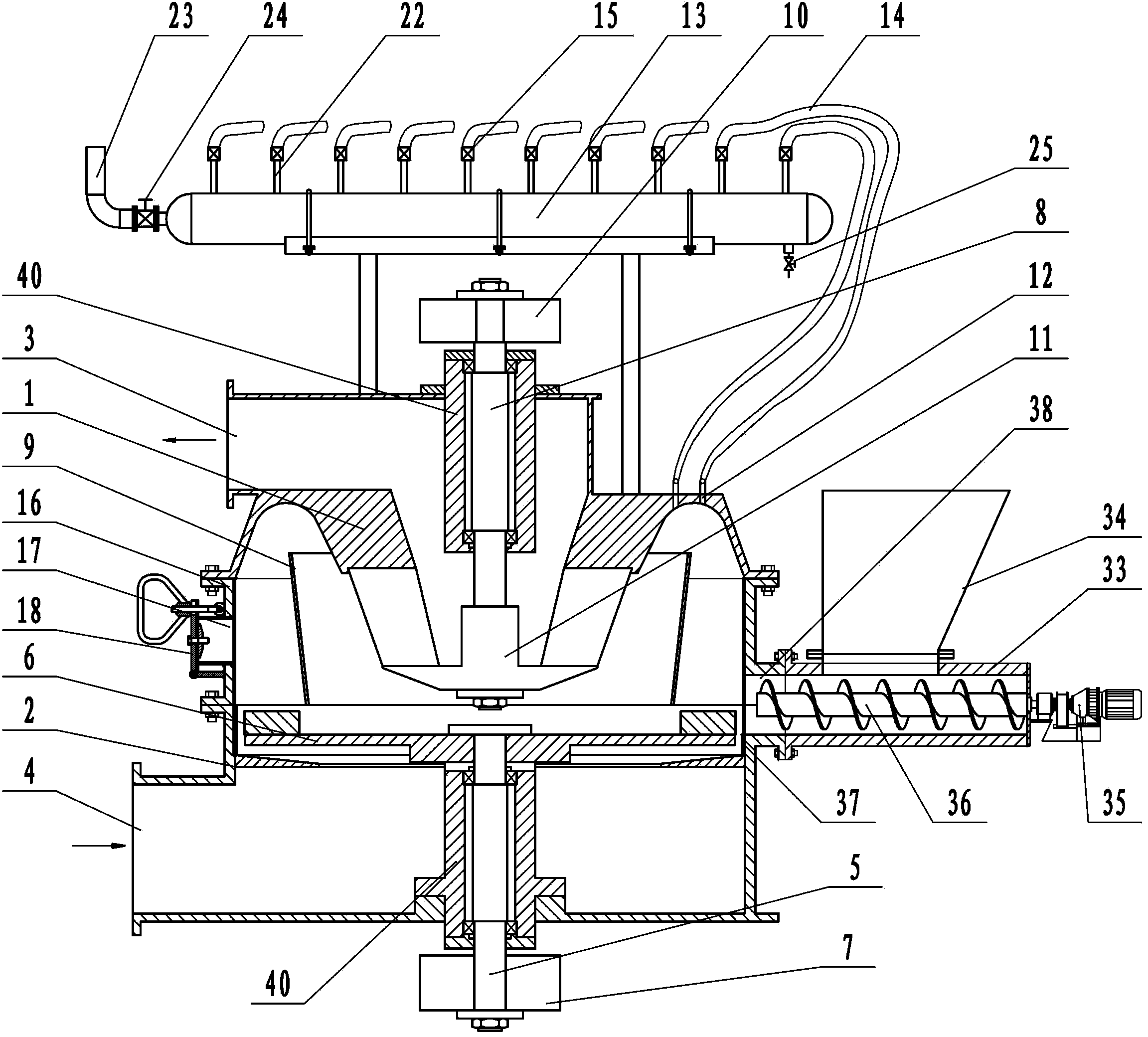

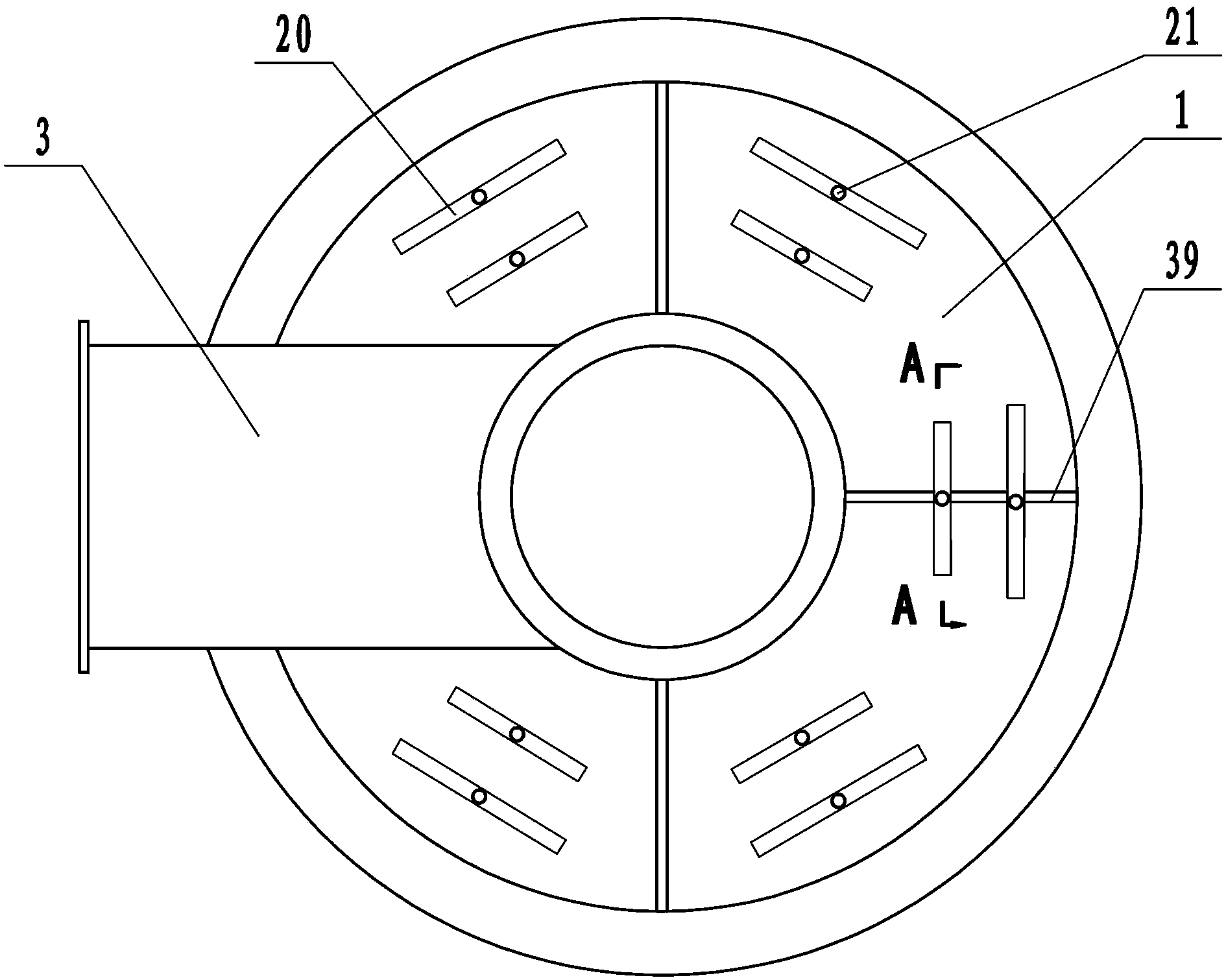

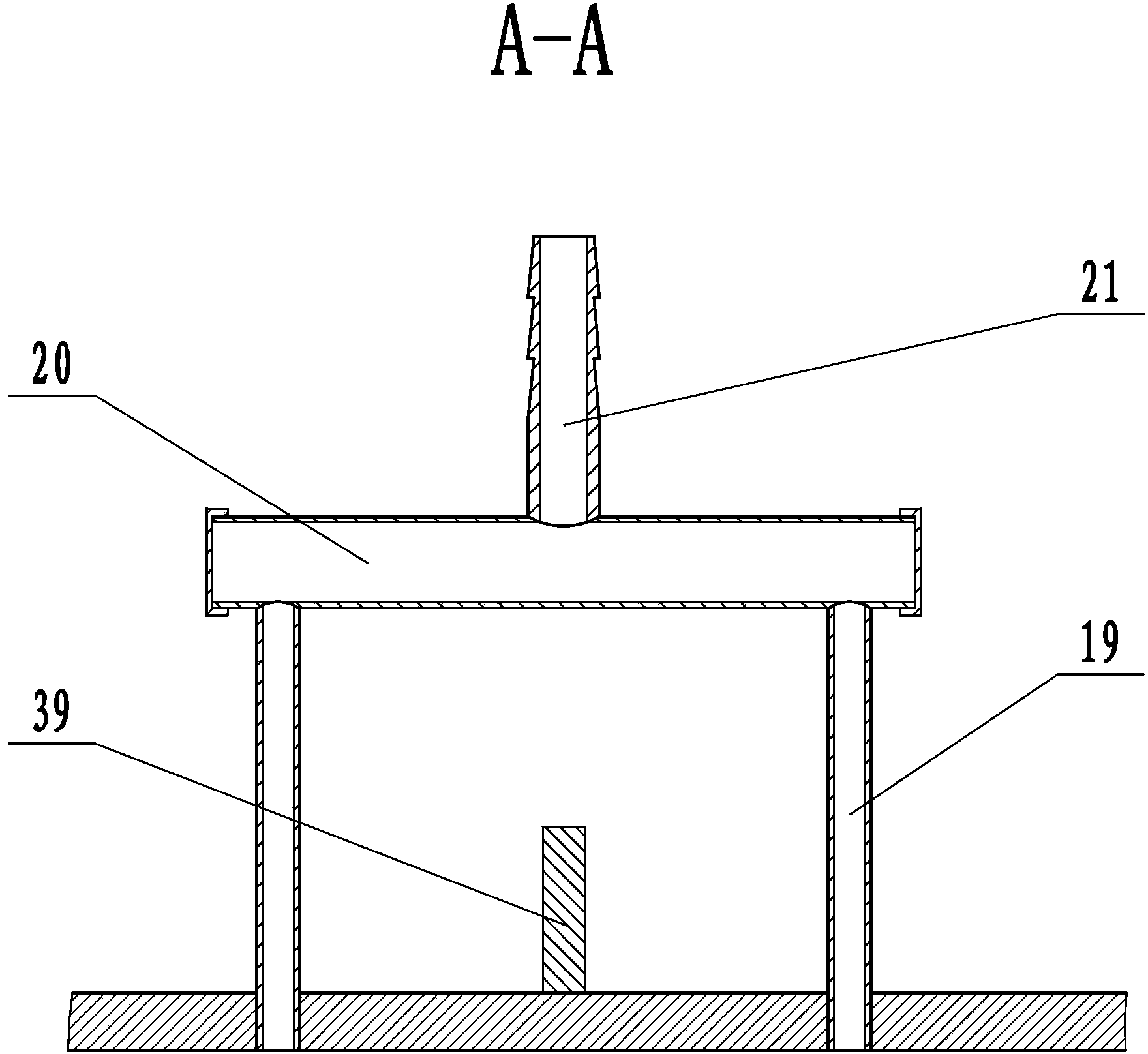

Ultramicro pulverizer

ActiveCN102784708BEasy to controlNot easy to clog with powderGrain treatmentsAgricultural engineeringControl valves

Owner:浙江天石纳米科技股份有限公司

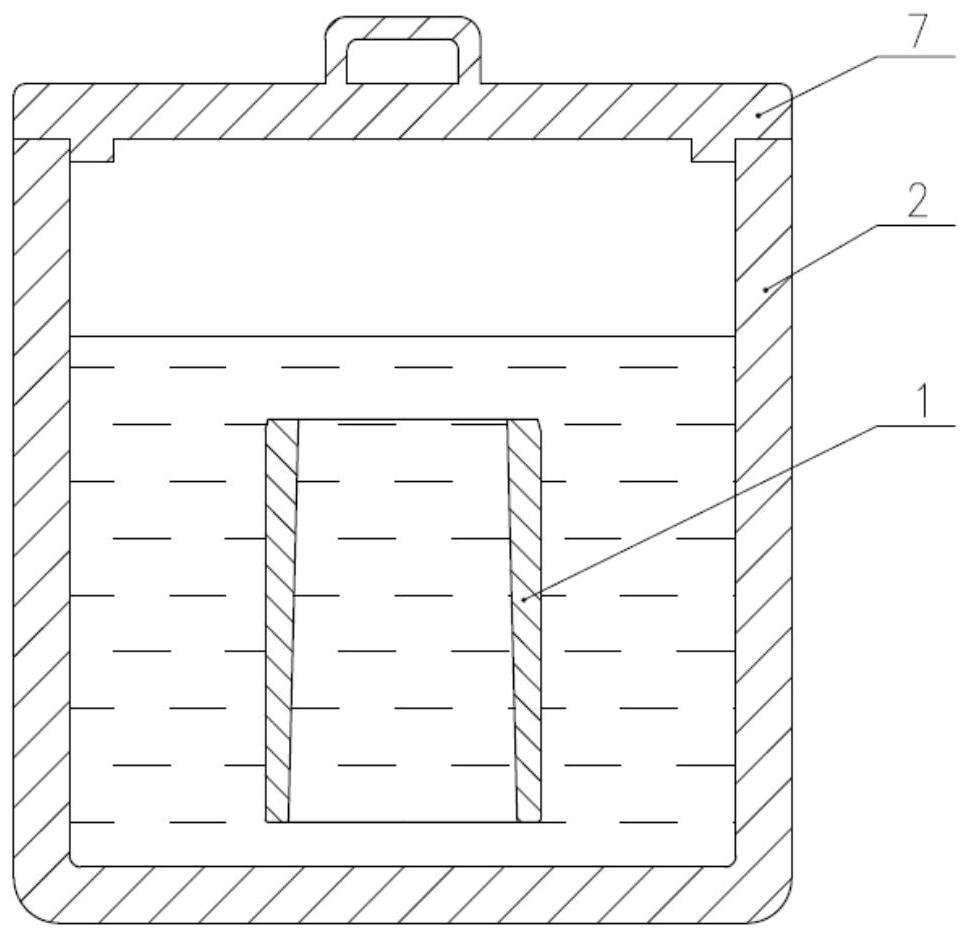

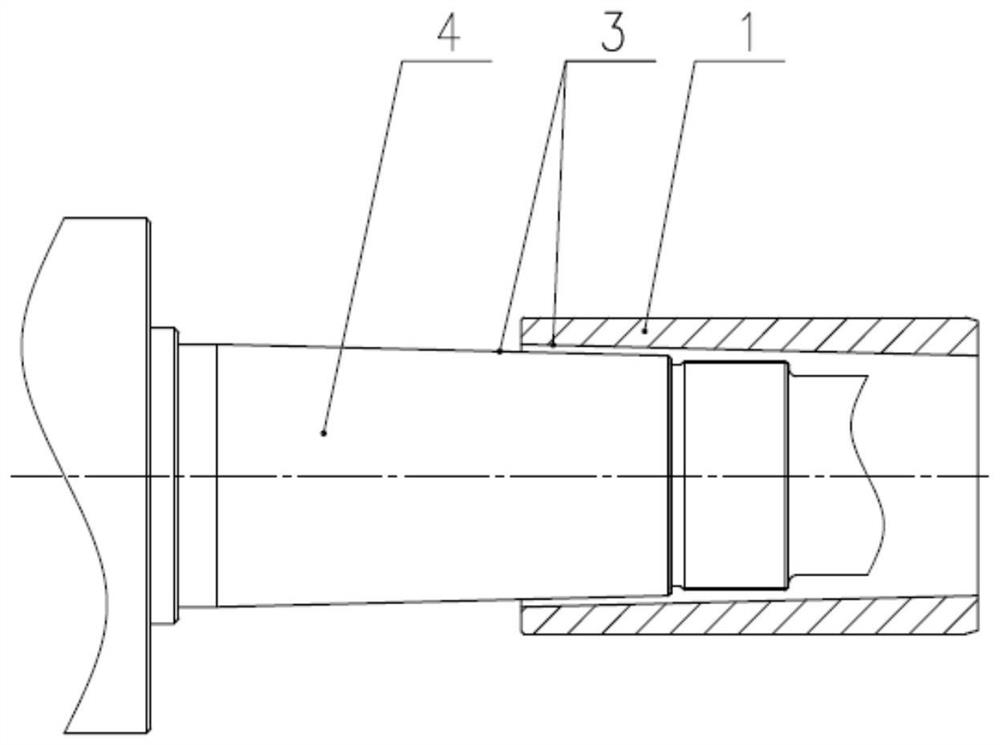

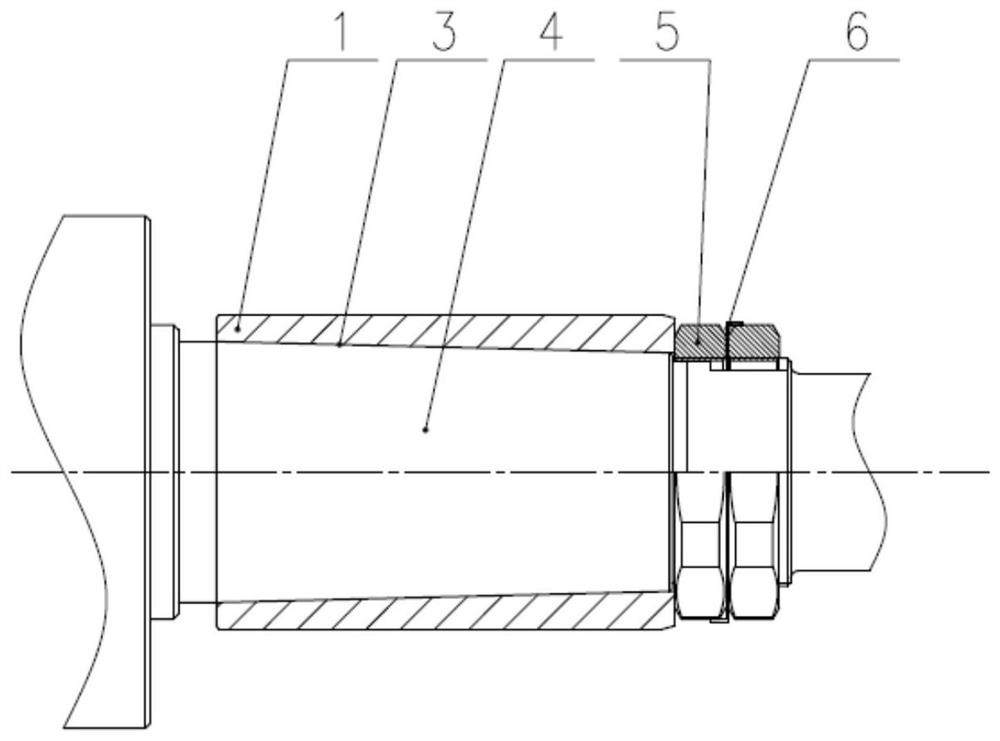

Shielded motor rotor shaft sleeve shrinkage fit process

InactiveCN112600369ALow costImprove heating efficiencyManufacturing stator/rotor bodiesInterference fitTemperature control

The invention relates to a shielded motor rotor shaft sleeve shrinkage fit process. A rotor shaft sleeve (1) and a rotor shaft (4) are in interference fit through a conical surface (3), the rotor shaft sleeve (1) is completely immersed in a water bath environment of a water tank (2), the heating temperature of the water tank (2) is controlled within the range of 95+ / -5 DEG C, and after sufficientheat preservation, the rotor shaft sleeve (1) is taken out of the water tank (2) and rapidly installed on the rotor shaft (4); and after the rotor shaft sleeve (1) and the rotor shaft (4) are assembled, the rotor shaft sleeve (1) is fixed on the rotor shaft (4) by adopting the locking nut (5) and the locking plate (6). The water tank water bath is adopted for heating the shaft sleeve, equipment issimple, cost is lower, higher heating efficiency can be achieved, and the beneficial effects of saving energy and reducing consumption are achieved; the assembling process of the rotor shaft sleeve is simpler, more convenient and faster without depending on a high-precision tool; the possibility that the rotor shaft sleeve and the shaft neck are not installed in place due to lapping-in in the installation process is avoided to a large extent, and stability, safety and reliability of shaft sleeve operation can be effectively guaranteed.

Owner:HARBIN ELECTRIC POWER EQUIP

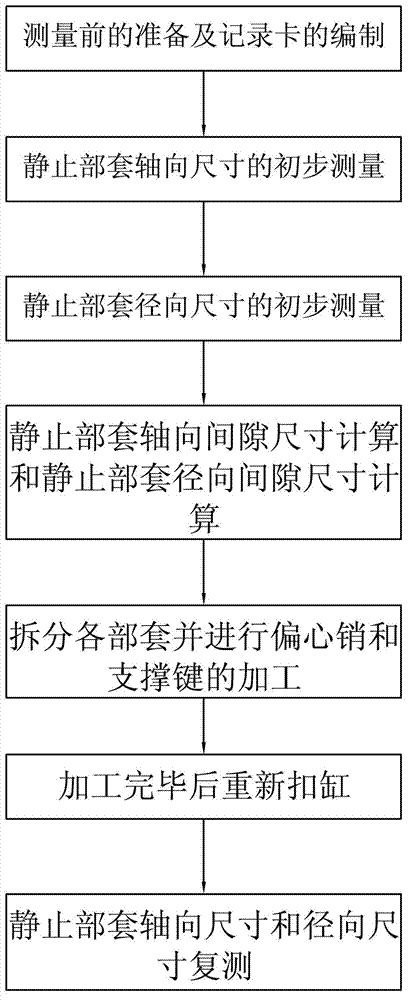

A Method for Measuring Through Flow of Steam Turbine Without Rotor

ActiveCN102944182BShorten delivery timeShorten assembly cycleUsing optical meansUltimate tensile strengthMachining

The invention discloses a rotor-free through-flow measurement method for a steam turbine, and relates to a through-flow measurement method, in particular to a rotor-free through-flow measurement method for a steam turbine. The invention solves the problems in the prior art, such as complicated operation, low safety and high labor intensity. Specifically, the method comprises the following steps: doing preparation before measurement and making record cards, performing primary measurement of the axial dimension of a static part sleeve, performing primary measurement of the radial dimension of the static part sleeve, calculating the axial clearance of the static part sleeve and the radial clearance of the static part sleeve, dismounting each part sleeve and machining an eccentric pin and a support key, re-mounting a cylinder after completing the machining, and measuring the axial dimension and radial dimension of the static part sleeve again. The rotor-free through-flow measurement method is used for measuring the through-flow clearance of the static part sleeve of the steam turbine.

Owner:HARBIN TURBINE +1

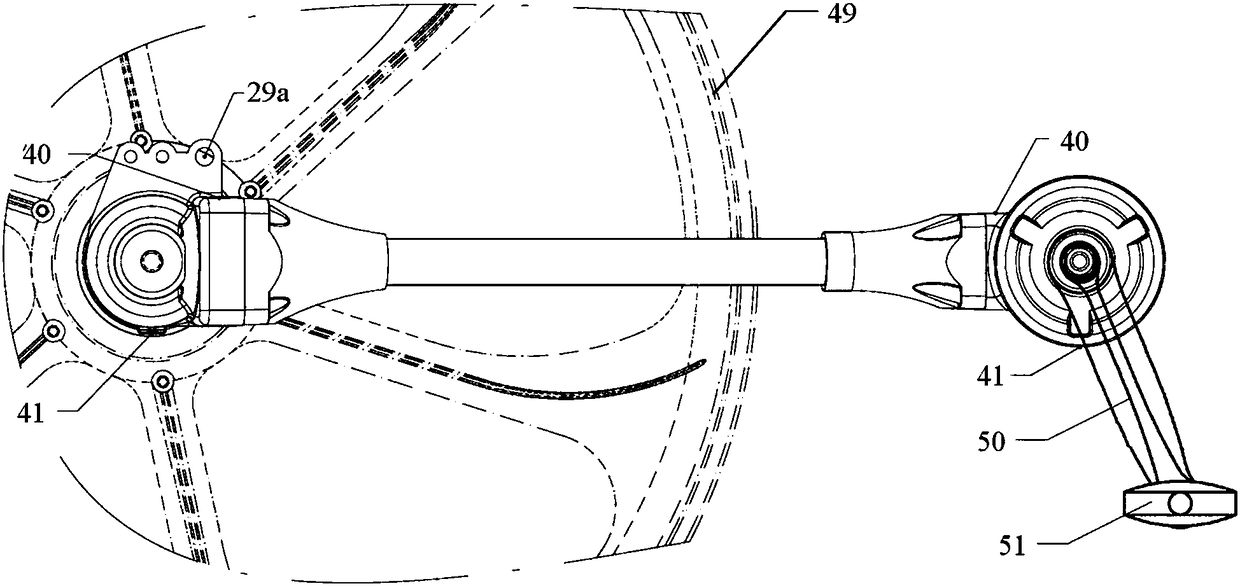

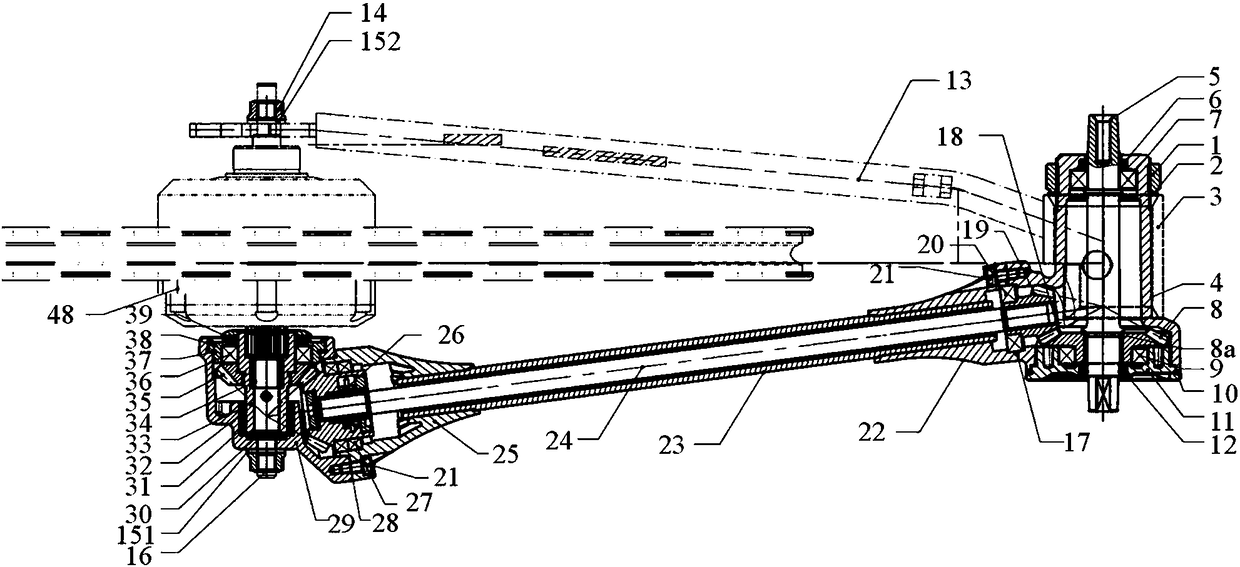

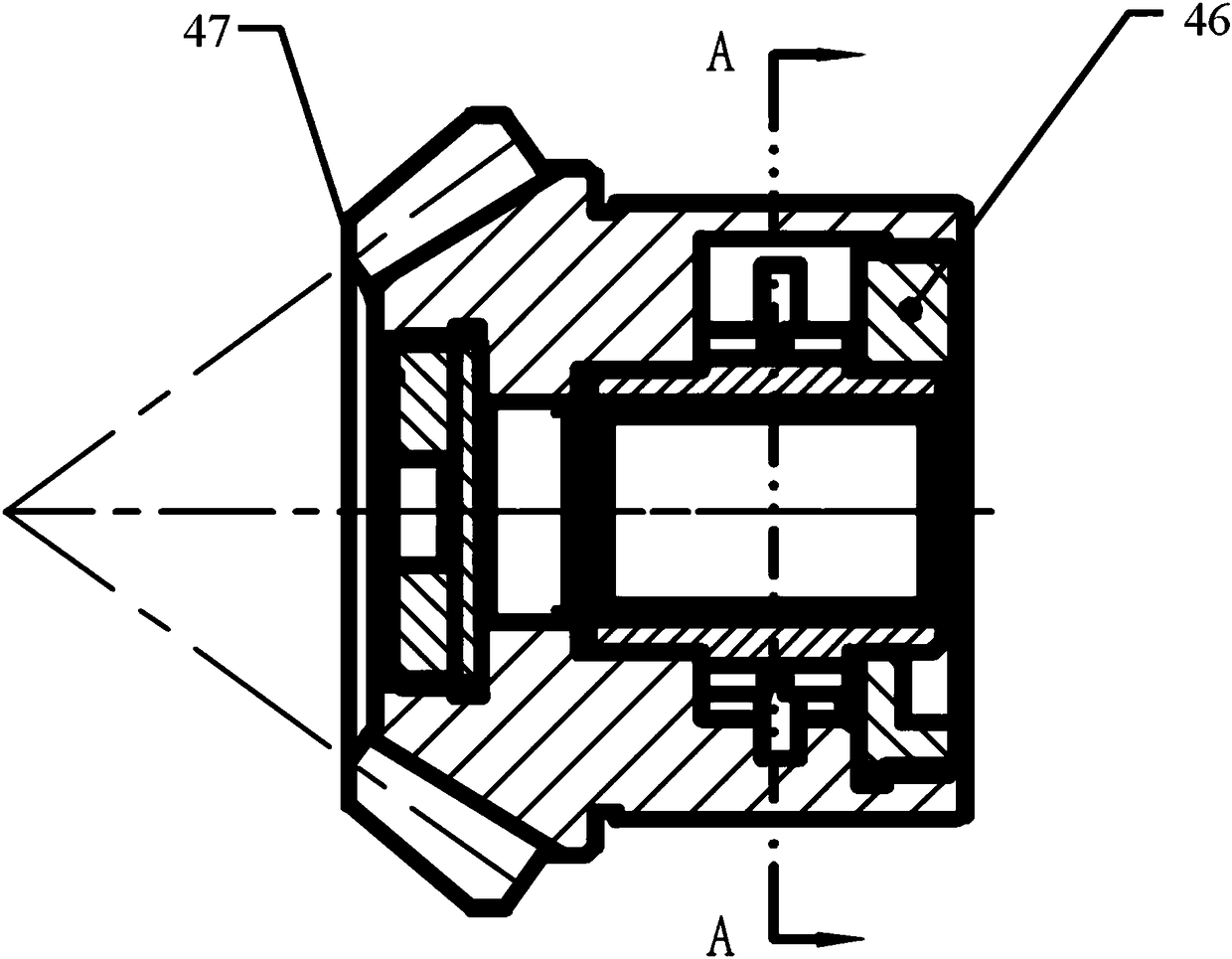

A rear wheel drive mechanism of a bicycle or an electric bicycle

PendingCN108974241AReduced precision requirementsReduce consumptionWheel based transmissionCycle equipmentsGear wheelElectric machinery

A rear wheel transmission mechanism of a bicycle or an electric bicycle includes a rear driving gear assembly including a rear driving gear having a ratchet cavity for setting ratchets therein; and arear driving gear assembly having a ratchet cavity for setting ratchets therein. A pawl seat disposed in the ratchet cavity; A limiting assembly for fixing the pawl seat in the ratchet cavity; A pawlmember disposed within the pawl seat and configured to selectively enter or disengage the ratchet wheel such that the ratchet wheel selectively drives or does not drive the rear drive gear to rotate.As that scheme of the invention is reasonably design, the rear driven teeth are directly connected with the flower drum or the motor through the spline shaft, and the structure is simple, and the precision requirement of the flower drum is not high, so that the assembly time is reduce, and the processing cost is greatly reduced.

Owner:卢金堂 +1

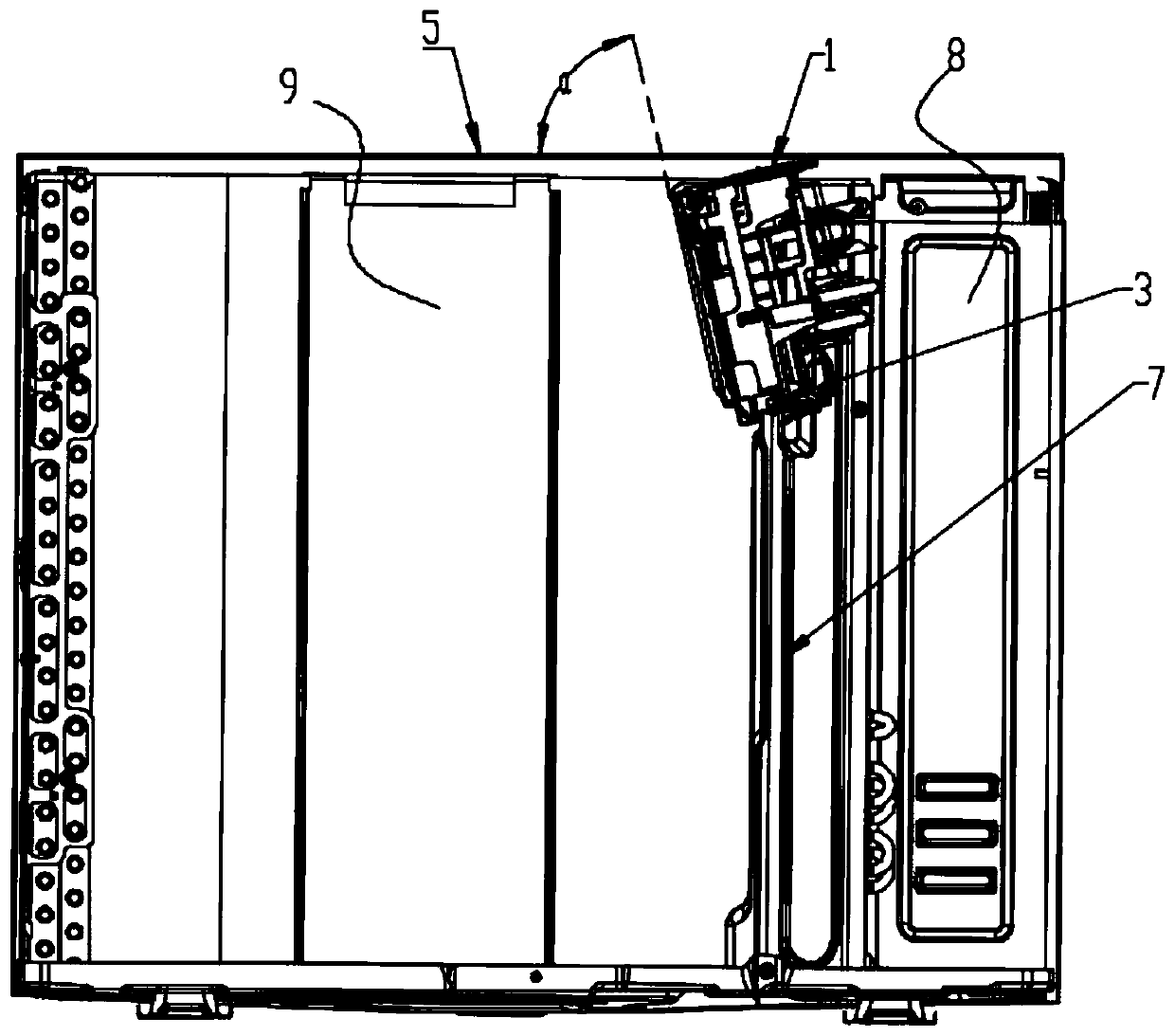

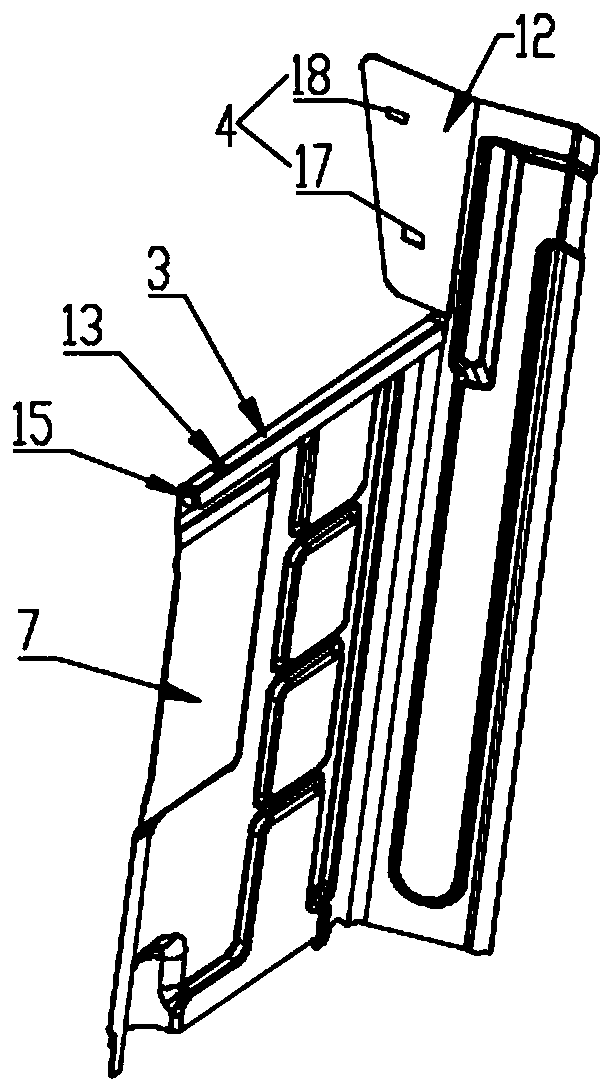

Electric appliance box installing structure, outdoor unit and air conditioner

InactiveCN111121177ASolve the problem of small and difficult to disassembleImprove assembly efficiencyLighting and heating apparatusAir conditioning systemsEngineeringTop cap

The invention provides an electric appliance box installing structure, an outdoor unit and an air conditioner. The electric appliance box installing structure comprises an electric appliance box installed in the outdoor unit of the air conditioner, a first supporting part and a second supporting part which are used for fixing two adjacent side edges of the electric appliance box, wherein the electric appliance box can be installed from the top of the outdoor unit and the side face of the air outlet direction of a fan of the outdoor unit and fixed through the first supporting part and the second supporting part, the included angle between the electric appliance box and a top cover of the outdoor unit is alpha, and the alpha is smaller than or equal to 90 degrees. According to the electric appliance box installing structure, the outdoor unit and the air conditioner, the electric appliance box of the electric appliance box installing structure is obliquely arranged and can be installed from the upper part and the side face, and therefore when the electric appliance box is installed from the upper part, assembling can be completed only needing a small height space, and the electric appliance box and a partition plate piece are stably and firmly connected, so that the matching of the electric appliance box and the partition plate is more stably without screws, the assembly efficiency of a product is improved, the assembly time is saved, and after-sales disassembly and maintenance are facilitated as well.

Owner:GREE ELECTRIC APPLIANCES INC

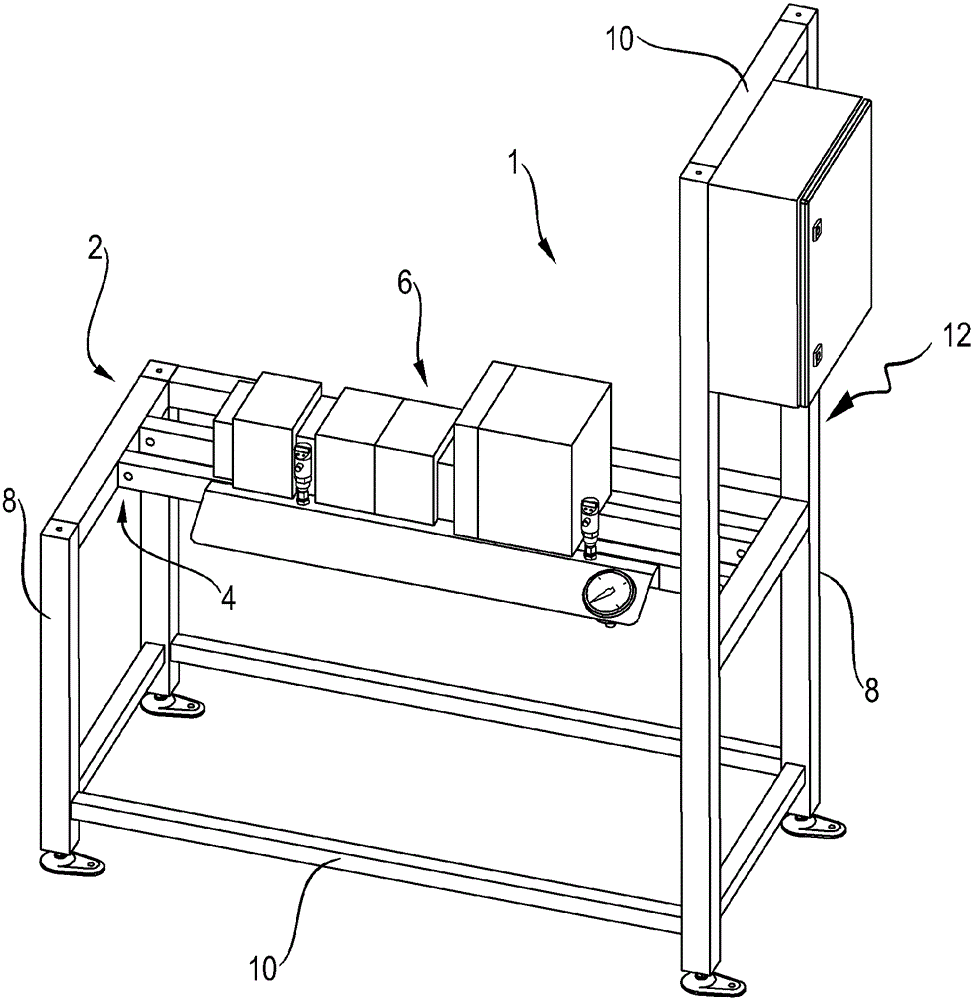

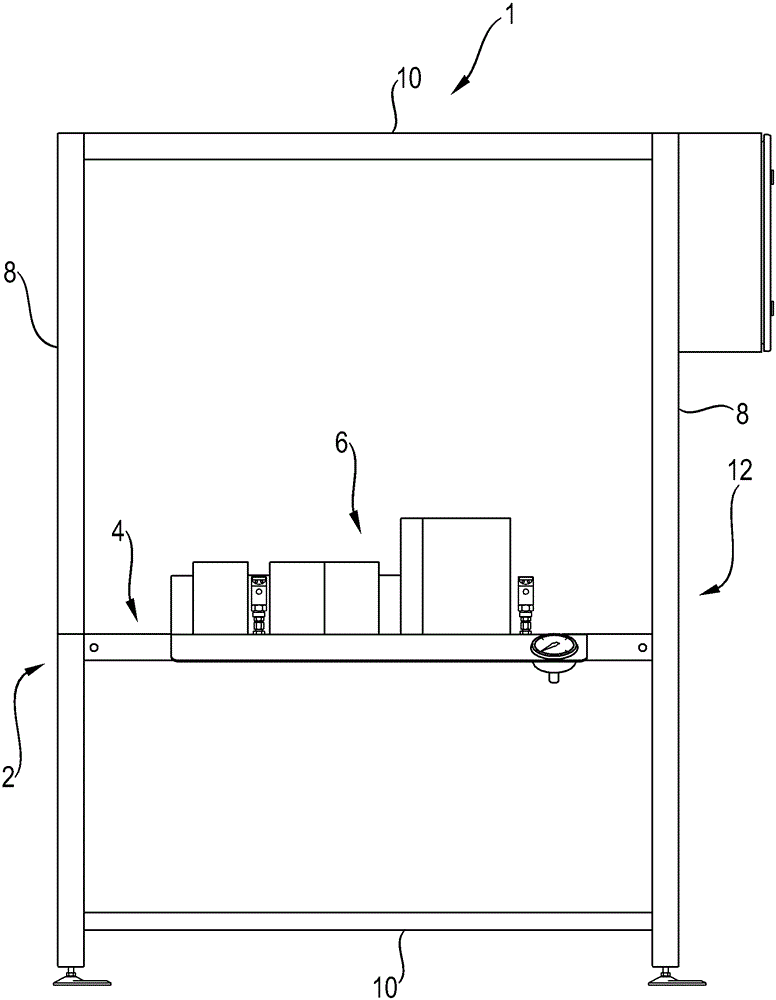

Valve station

ActiveCN105215954AShorten production timeShorten delivery timeWork benchesEngineeringMechanical engineering

Disclosed is a valve station with a frame and a platen is mounted. A hydraulic and / or pneumatic control component is disposed on the platen and / or the frame, and the hydraulic and / or pneumatic control component is connected with a control organ. The valve station is made from aluminium system profiles.

Owner:ROBERT BOSCH GMBH

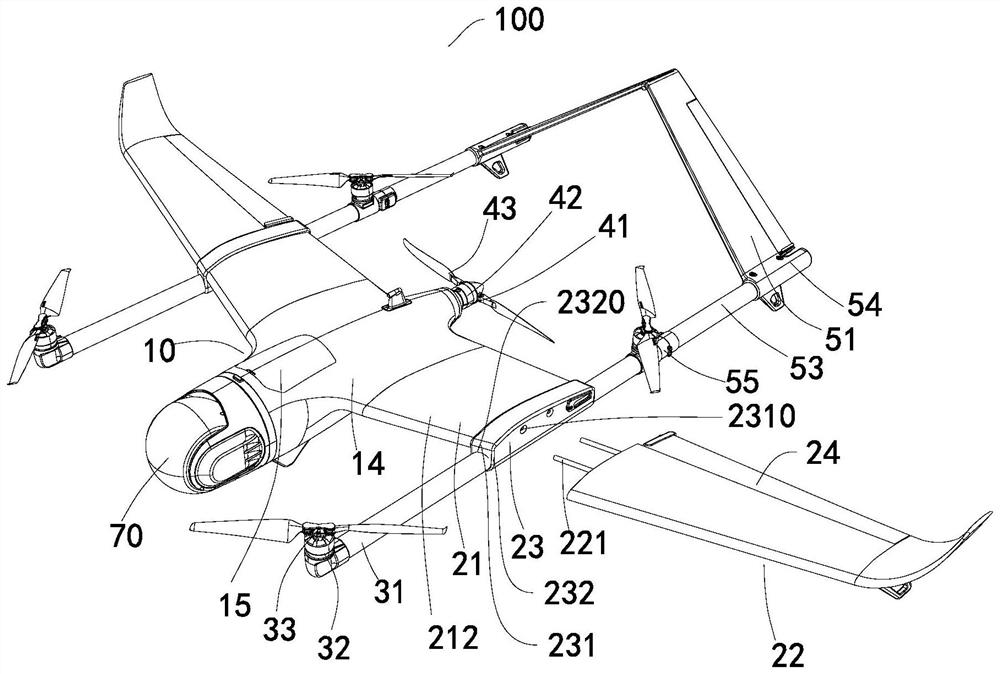

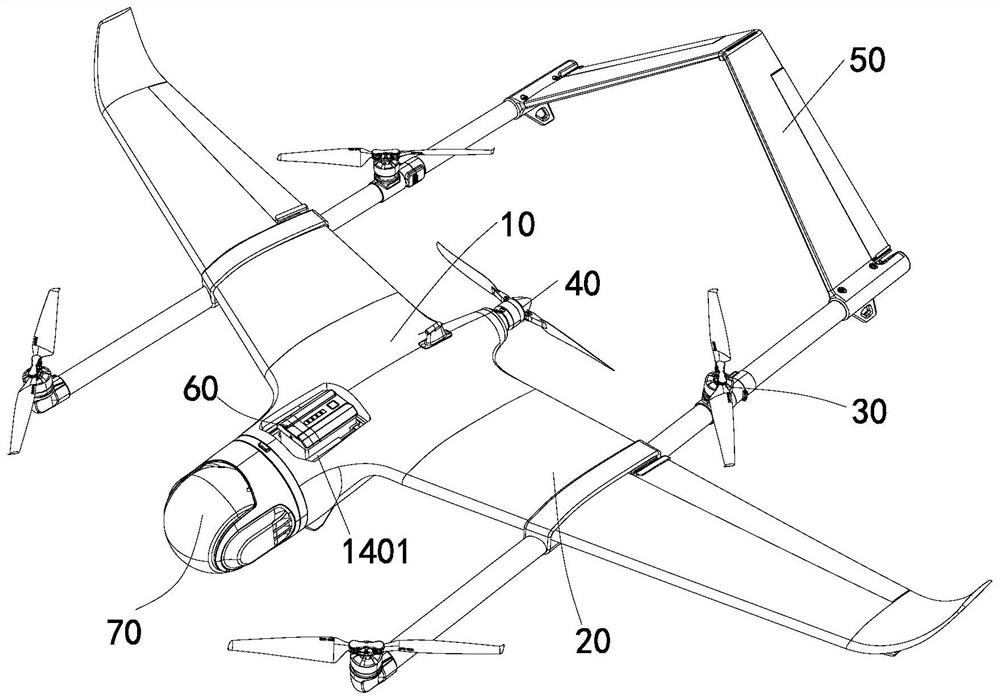

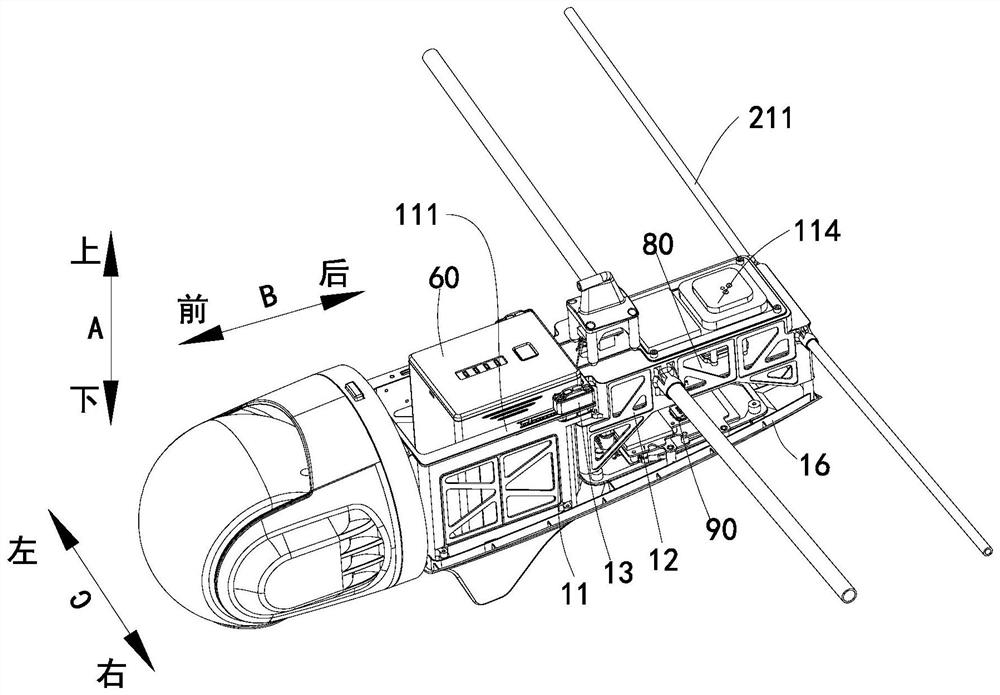

Fuselage of unmanned aerial vehicle and unmanned aerial vehicle with fuselage

PendingCN112278228AImprove assembly efficiencyReduce assembly timeFuselage framesFlight vehicleStructural engineering

The invention discloses a fuselage of an unmanned aerial vehicle and the unmanned aerial vehicle with the fuselage. The fuselage of the unmanned aerial vehicle comprises a fuselage frame comprising afirst fixing frame and a second fixing frame, a first storage cavity is formed in the first fixing frame, and a second storage cavity is formed in the second fixing frame; the first fixing frame and the second fixing frame are connected in parallel in the length direction of the fuselage; a lower cover is arranged on the bottom wall of the fuselage frame, and a wiring space is defined among the bottom wall of the second fixing frame, the side wall of the first fixing frame and the lower cover; a first electronic element is arranged at the top of the second fixing frame; a second electronic element is arranged in the second storage cavity and is positioned below the first electronic element; and a third electronic element is arranged on the lower cover and is positioned below the second electronic element. When in use, the electronic elements are convenient to install and arrange, the assembly efficiency of the fuselage is improved, and enough operation space and accommodating space areconvenient to reserve for connecting wire terminals among the electronic elements.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com