Shielded motor rotor shaft sleeve shrinkage fit process

A technology of shrink-fit technology and shielded motor, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of unfavorable influence and oxidation of the shaft sleeve and shaft section, and achieve the effect of convenient assembly method, high heating efficiency, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

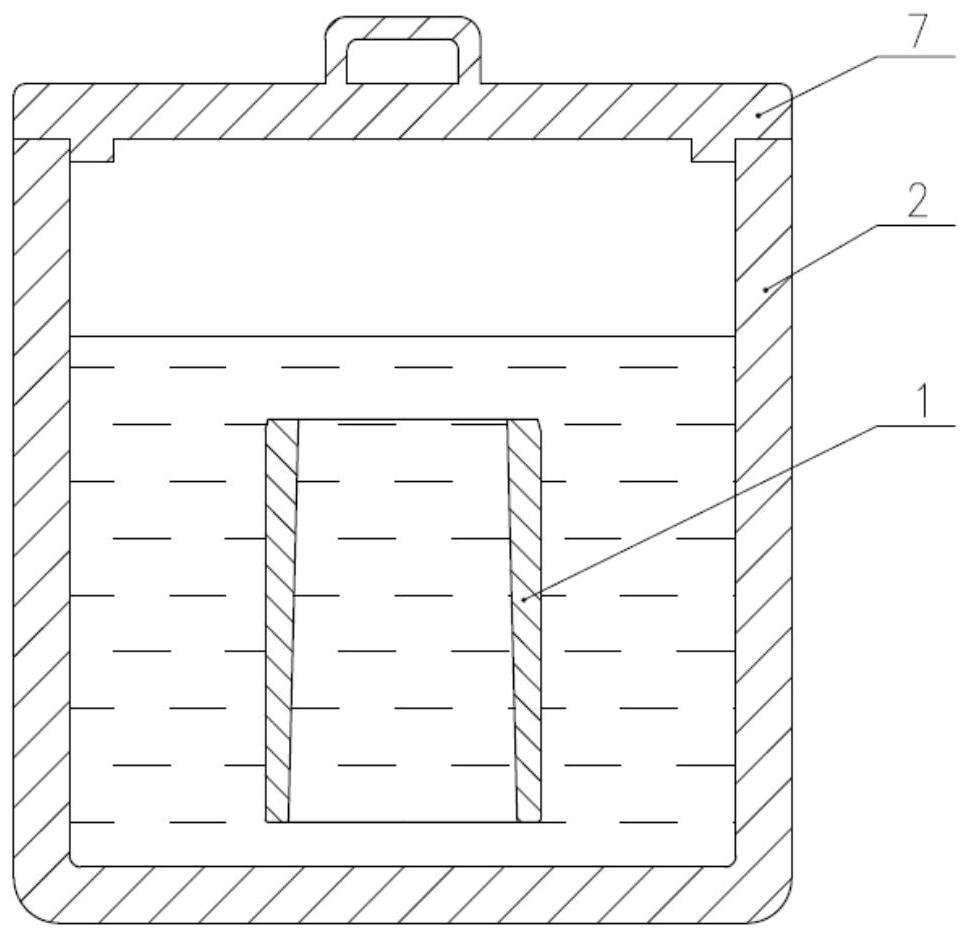

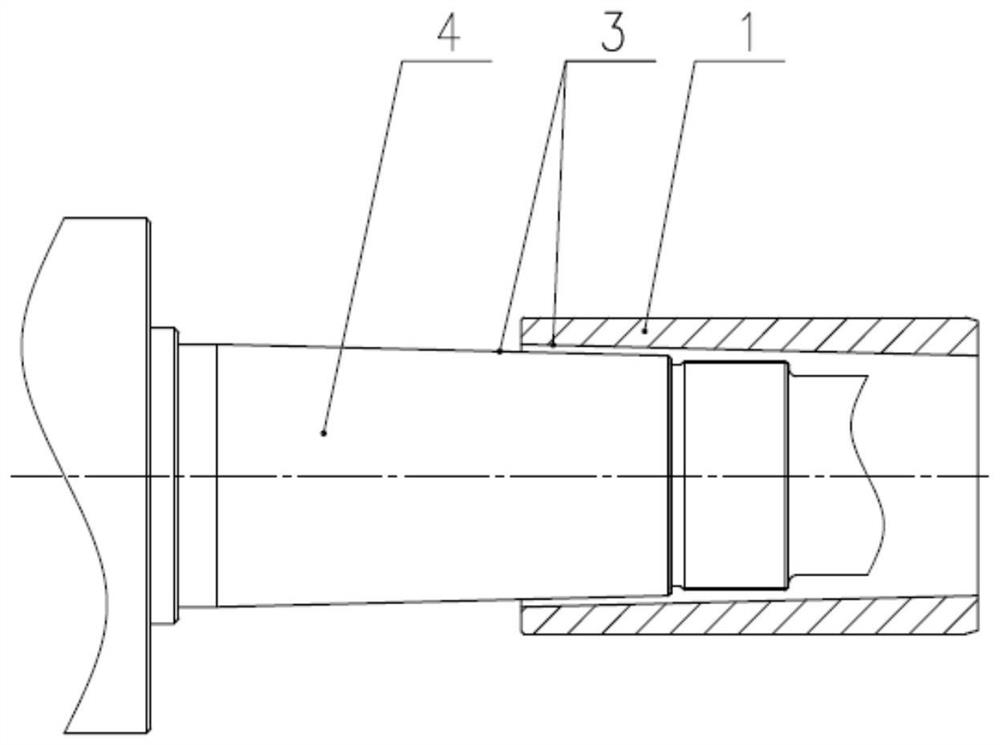

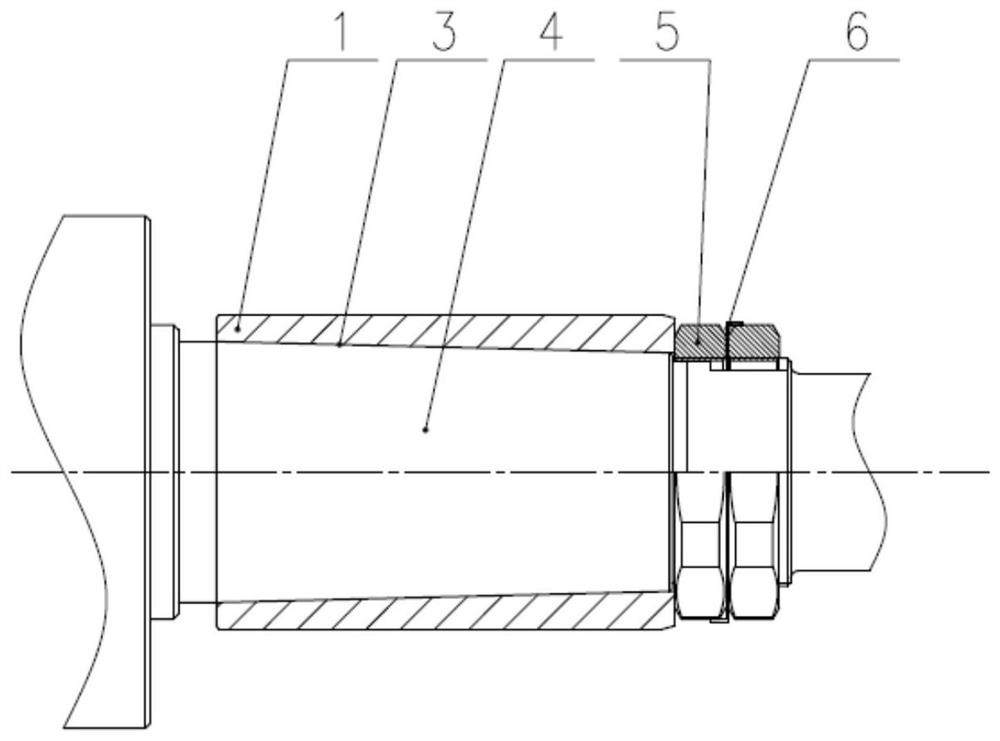

[0014] Such as figure 1 As shown, a shielded motor rotor bushing shrink fit process, the rotor bushing 1 and the rotor shaft 4 adopt the interference fit of the tapered surface 3, the rotor bushing 1 is completely immersed in the water bath environment of the water tank 2, and the heating temperature of the water tank 2 is controlled at Within the range of 95°C±5°C, after sufficient heat preservation, take the rotor sleeve 1 out of the water tank 2 and quickly install it on the rotor shaft 4; after the assembly of the rotor sleeve 1 and the rotor shaft 4 is completed, use the lock nut 5 and The sheet 6 fixes the rotor sleeve 1 on the rotor shaft 4 .

[0015] The specific operation steps are as follows:

[0016] Such as figure 1 As shown, the rotor bushing 1 is placed upright in the water tank 2, the water level is submerged over the rotor bushing 1, the heating temperature of the water bath is set within the range of 95±5°C, after sufficient heat preservation, the water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com