Patents

Literature

45results about How to "Continuous assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

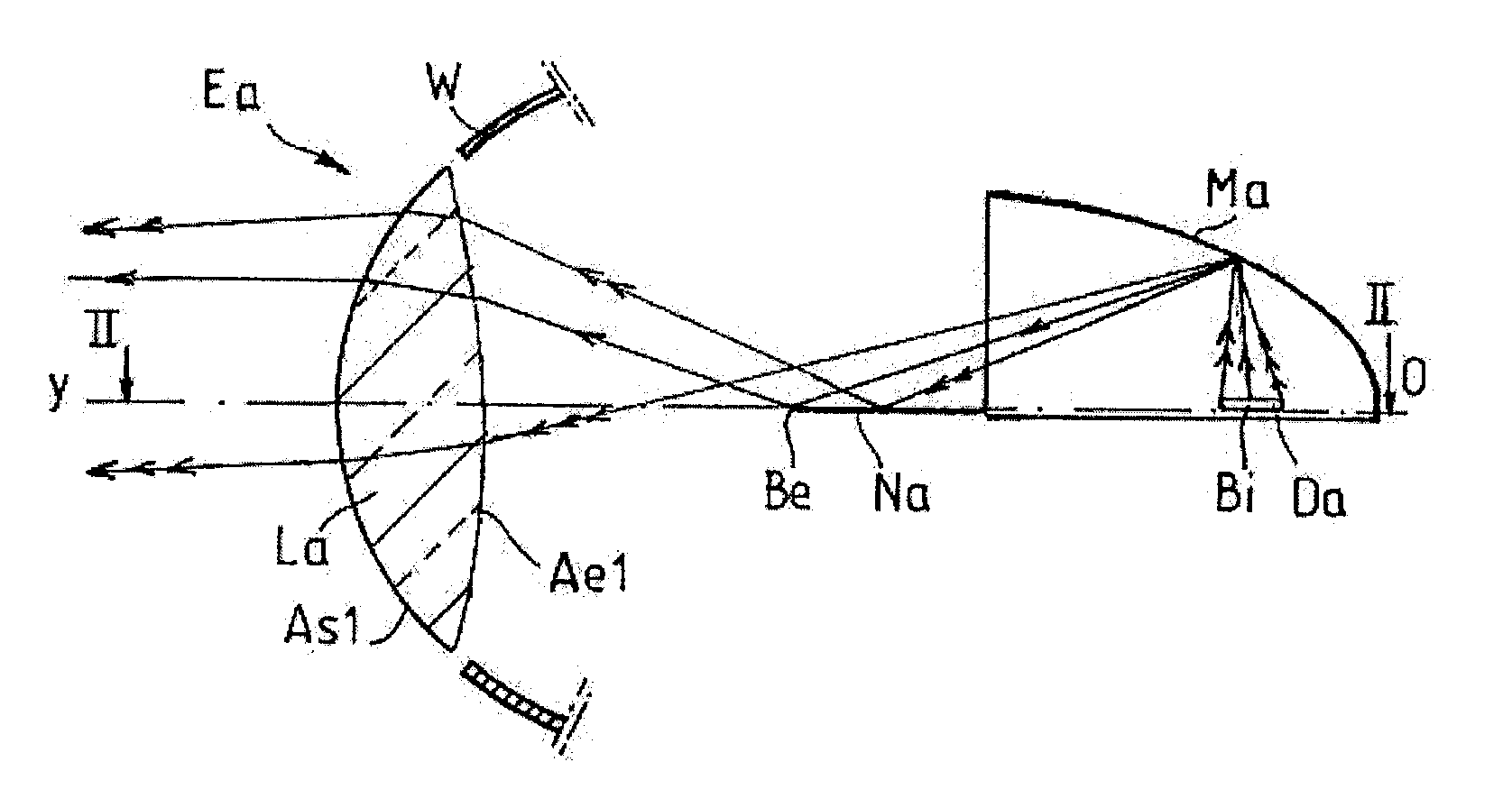

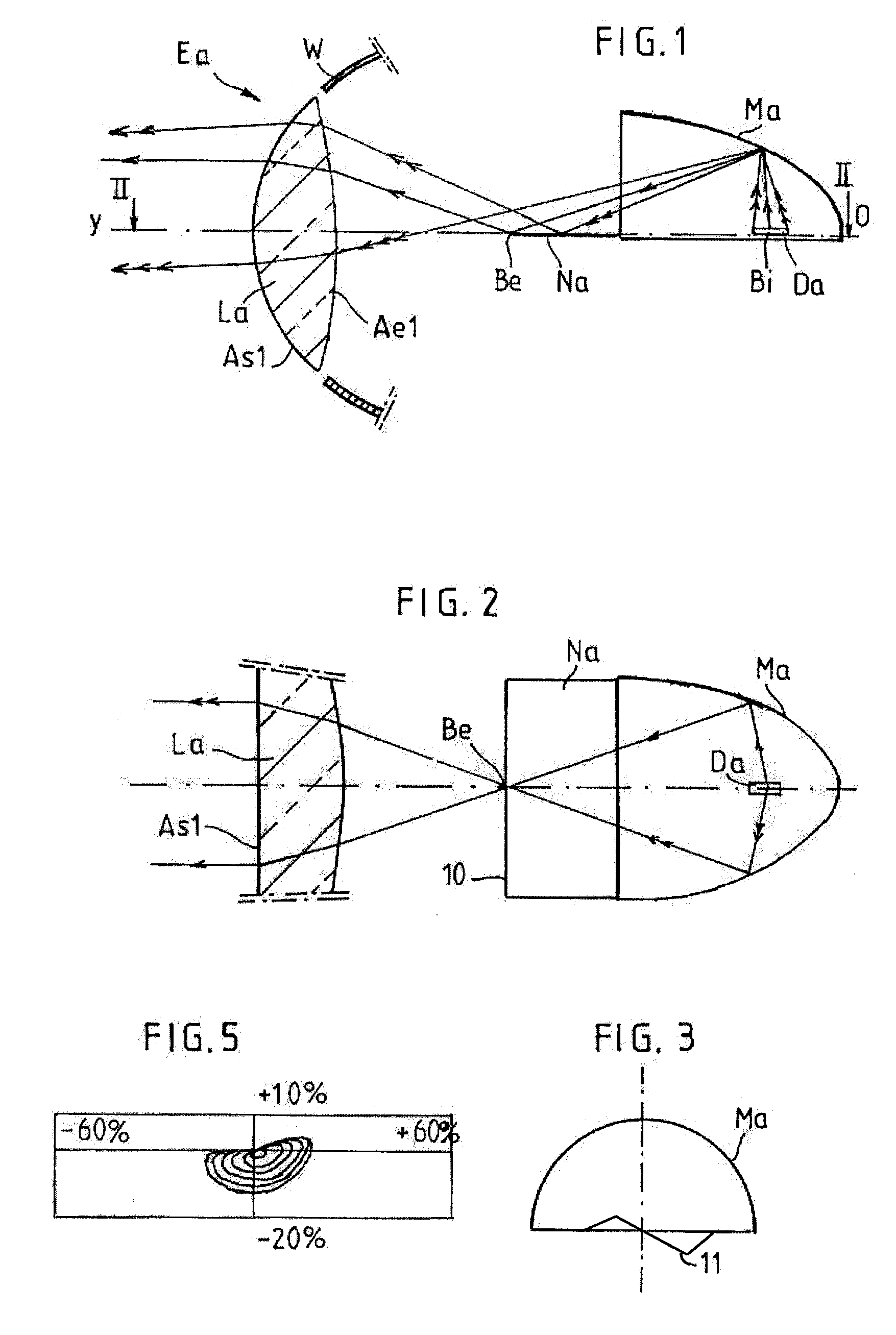

Method of constructing a headlight module for a motor vehicle, and the module and headlight

InactiveUS20070058386A1Continuous assemblyVehicle headlampsPoint-like light sourceLight beamExit surface

The invention concerns a method of constructing a headlight module giving a beam with cutoff, for a motor vehicle, comprising a lens and a light source disposed at the rear of the lens, from which it is separated by air, the light source being formed by at least one light emitting diode, according to which the exit surface of the lens is chosen so that it can possibly be connected on a smooth continuous surface with the exit surfaces of similar adjacent modules, and the entry surface of the lens is determined so as to obtain the cutoff of the light beam without using an occulting shield.

Owner:VALEO VISION SA

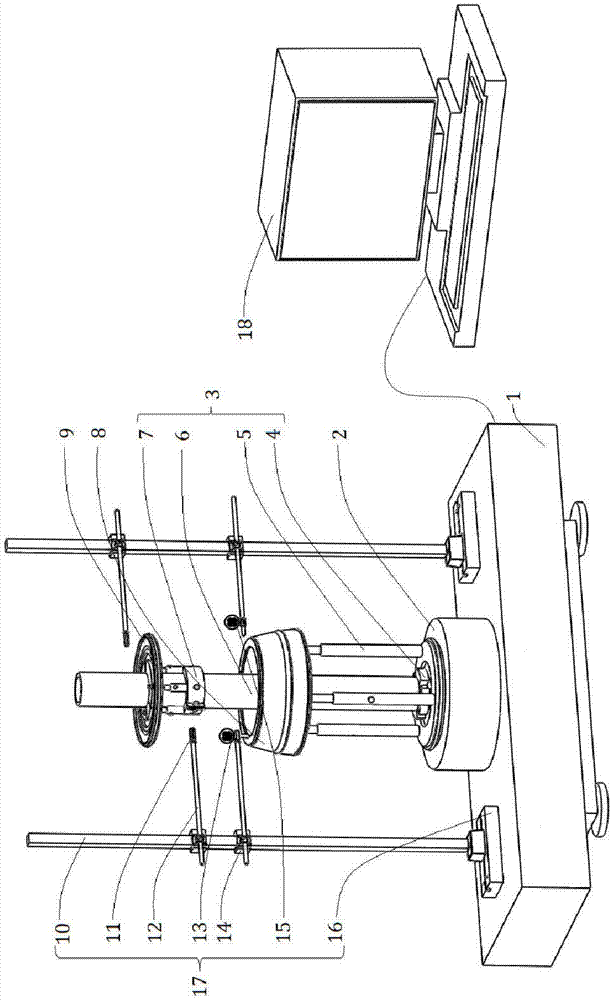

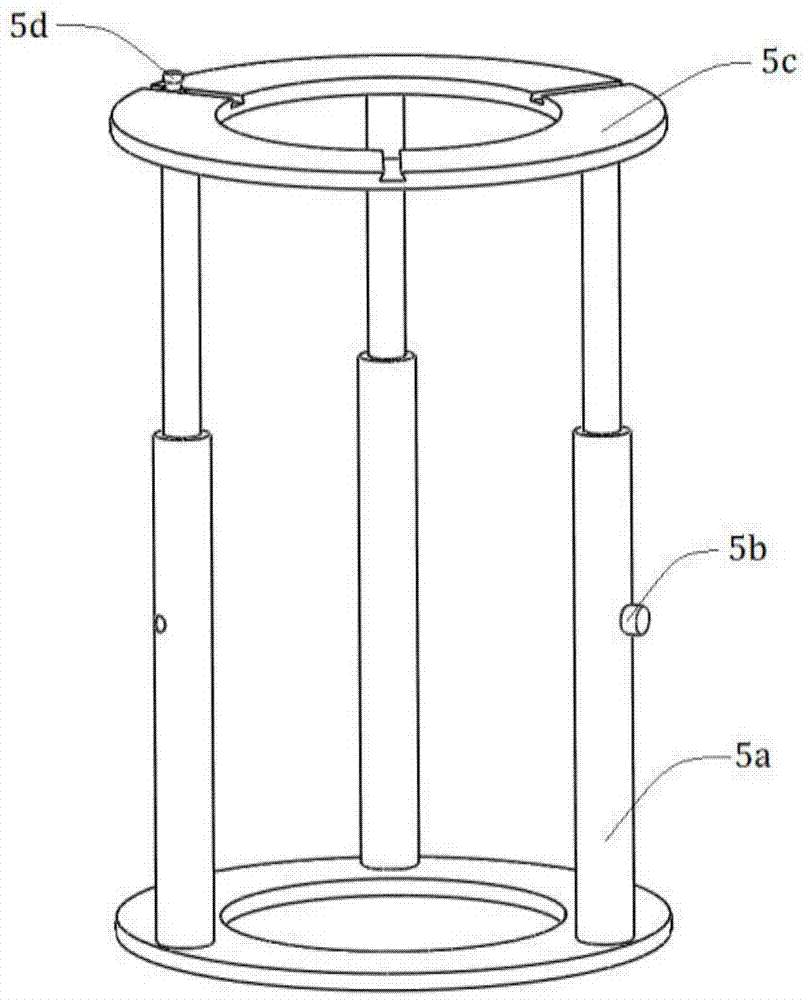

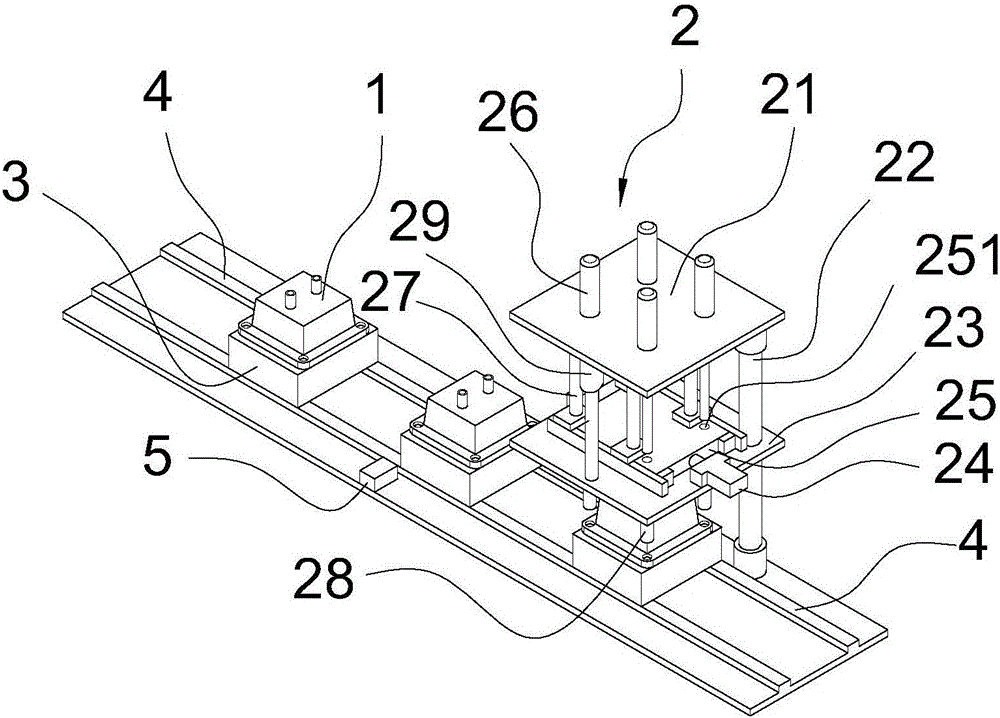

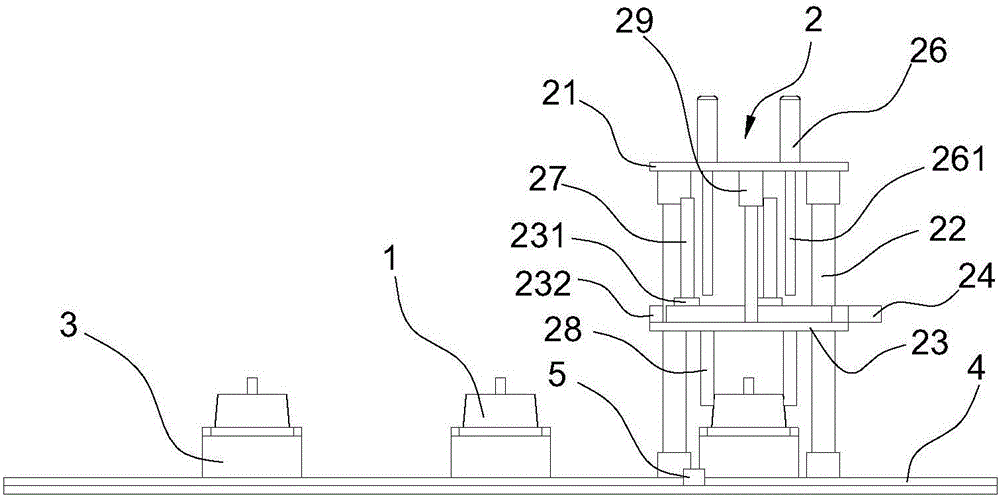

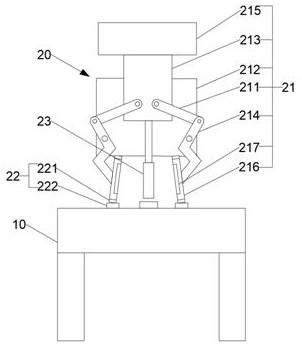

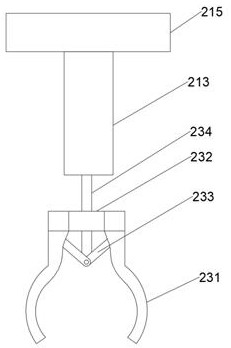

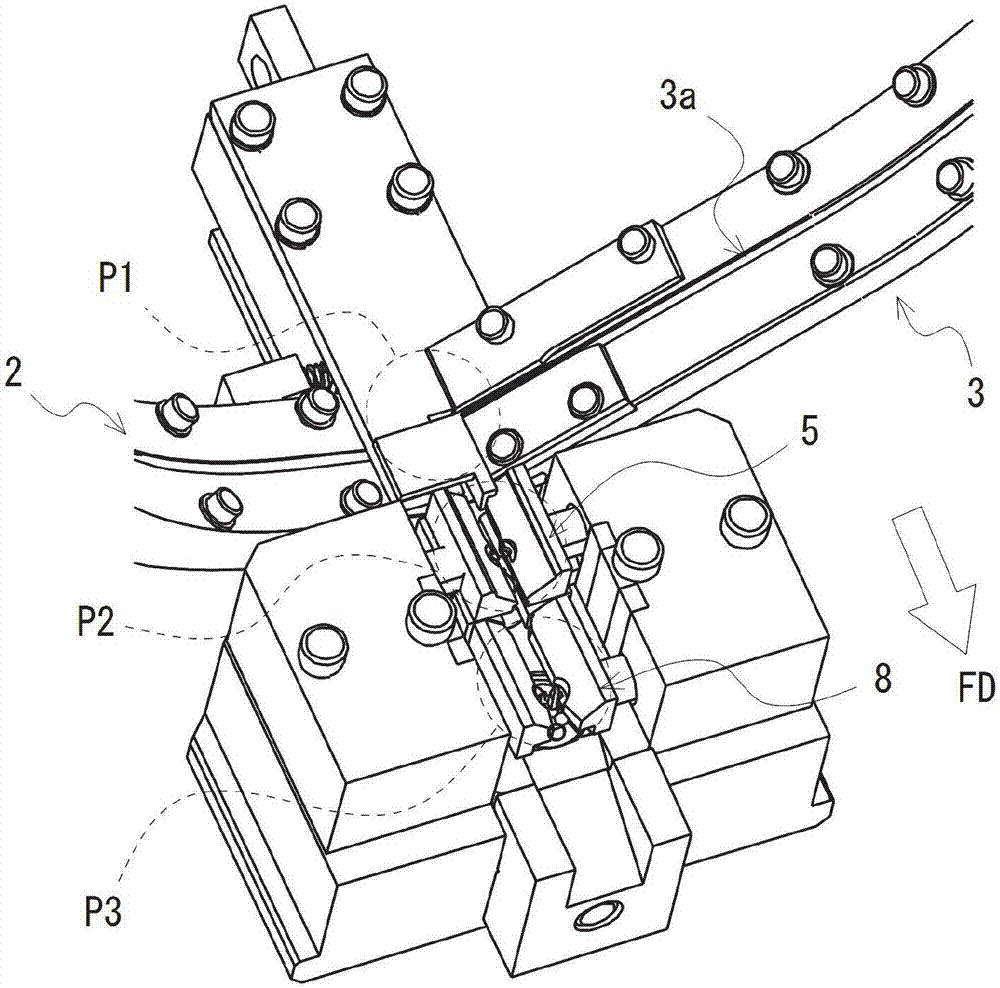

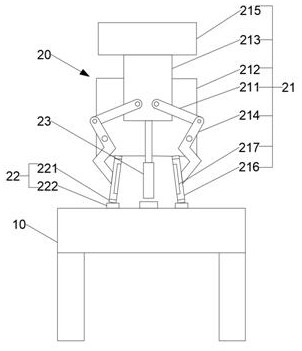

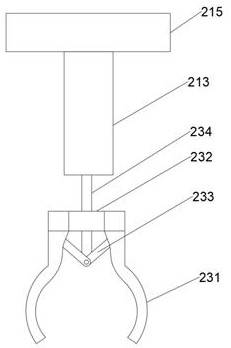

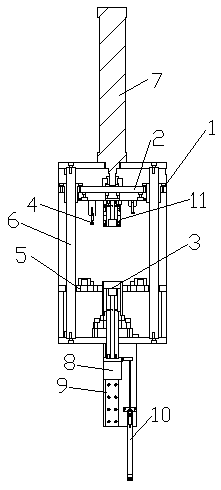

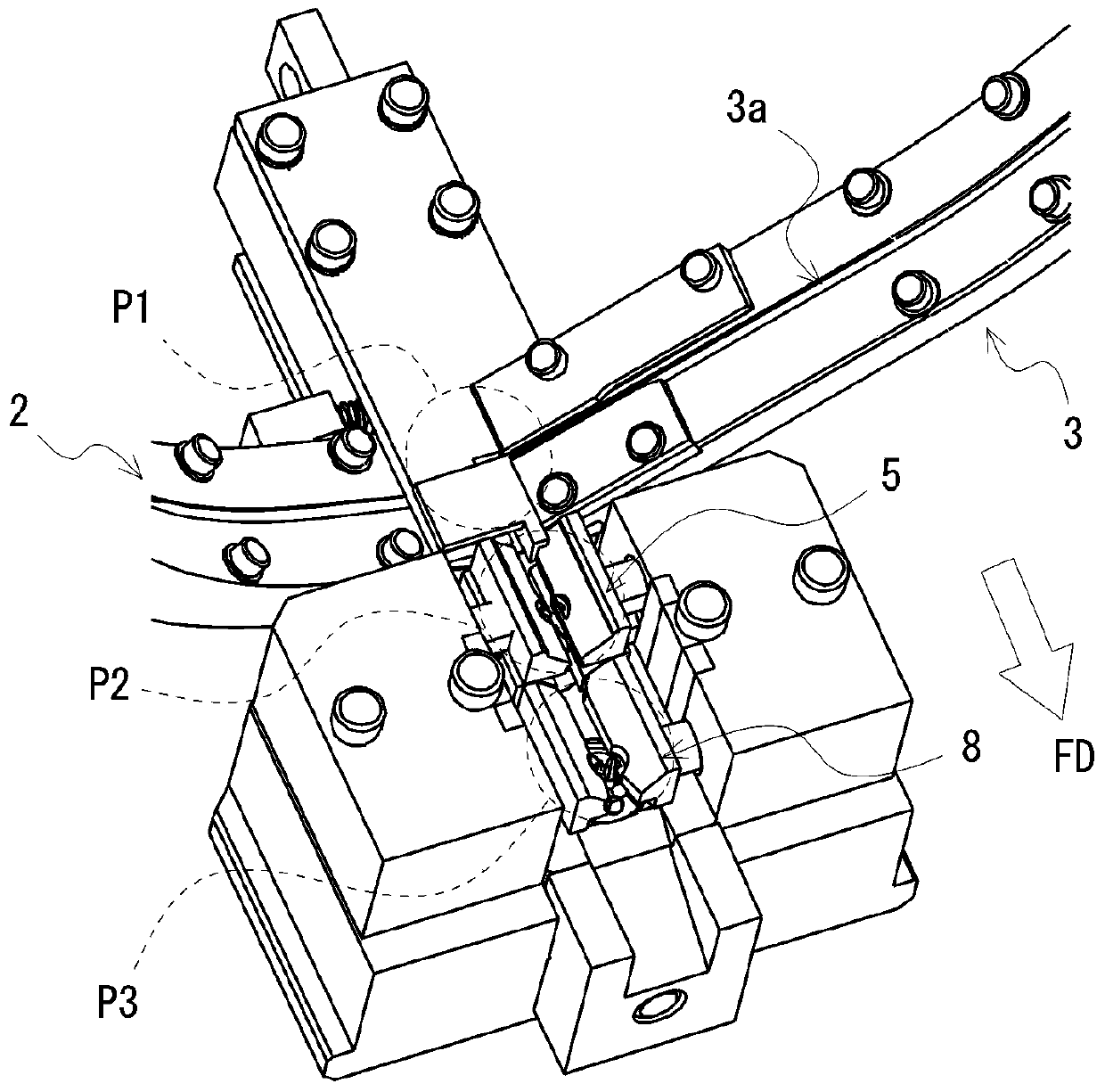

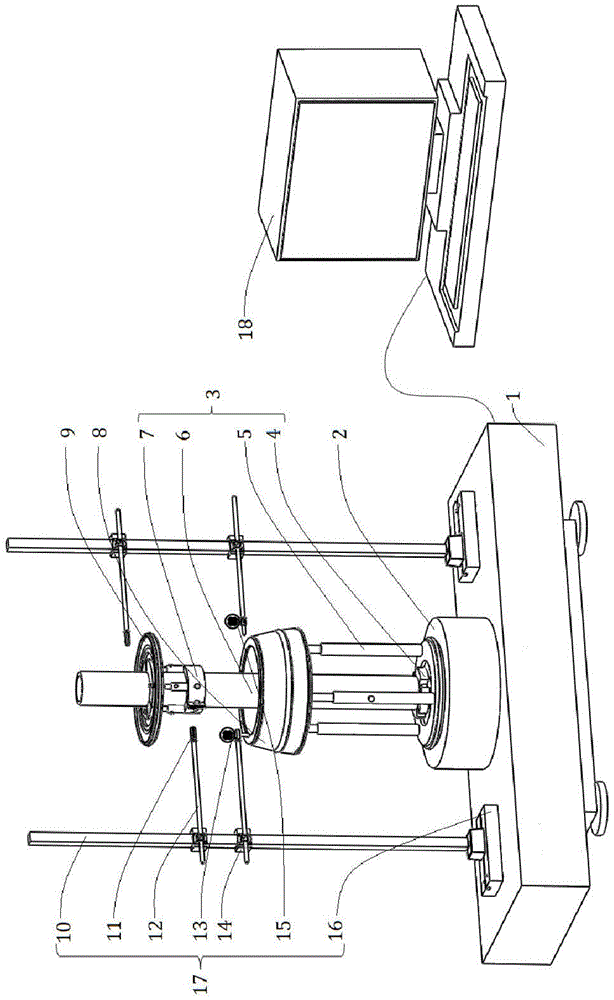

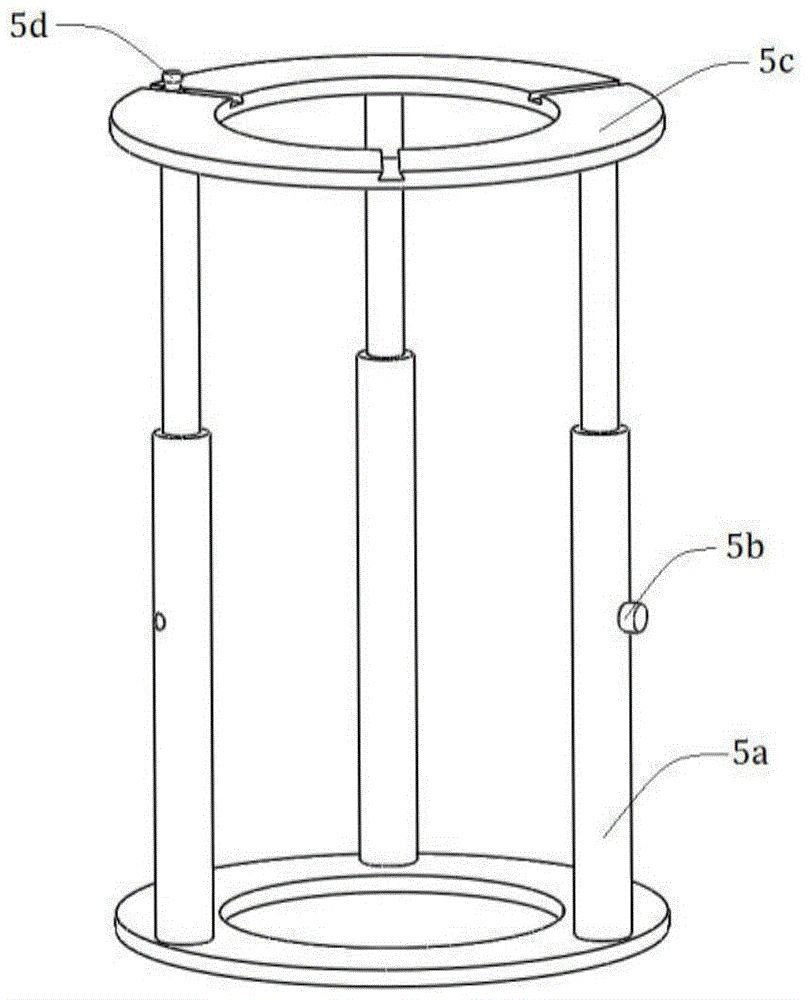

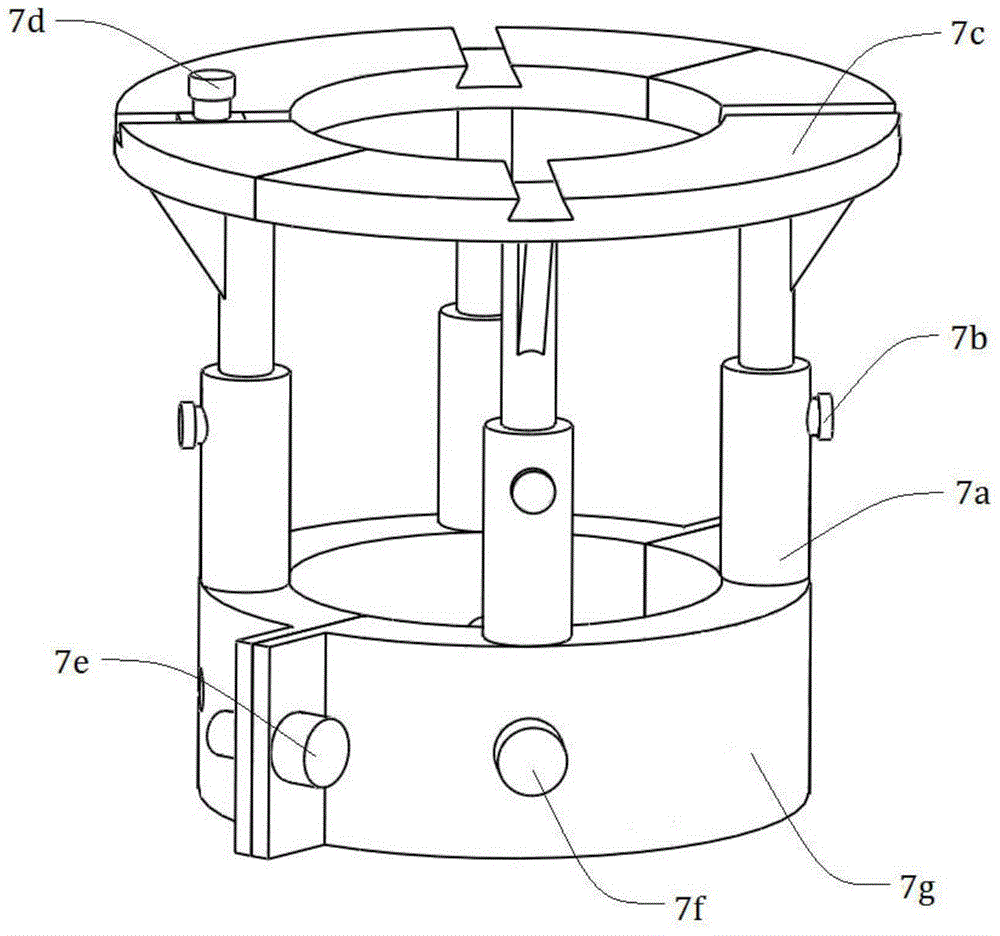

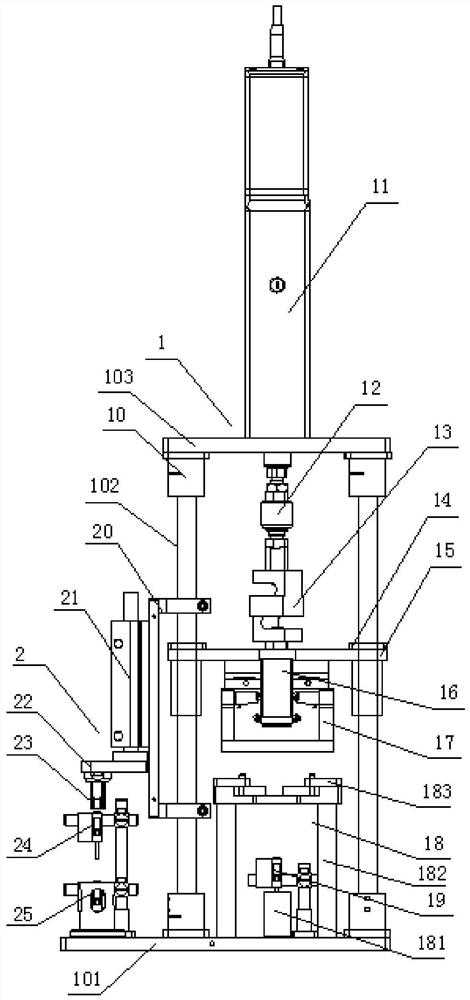

Device and method for assembling multi-stage drum type rotor of aero-engine

ActiveCN105443169AImprove coaxialityContinuous assemblyMachines/enginesSafety/regulatory devicesControl systemEngineering

The invention provides a device and method for assembling a multi-stage drum type rotor of an aero-engine. The device comprises a base, an air-floating rotary table, a clamp device, measuring devices and a computation control system, wherein the air-floating rotary table is fixed to the center of the base, the clamp device is mounted on the air-floating rotary table, and the measuring devices are mounted on the base and arranged on the two sides of the air-floating rotary table; the computation control system is connected with the air-floating rotary table and used for transmitting driving, center-regulating and tilt-regulating information, and the computation control system is connected with the measuring devices and used for collecting morphology information of assembled parts. By means of the device and method, coaxiality of all parts of the rotor can be guaranteed, continuous assembling can be carried out, and the situation that the parts are dismounted and then measured, marked and assembled one by one is avoided; universality is high, operation is easy, and assembling precision and assembling efficiency are high.

Owner:SHANGHAI JIAO TONG UNIV

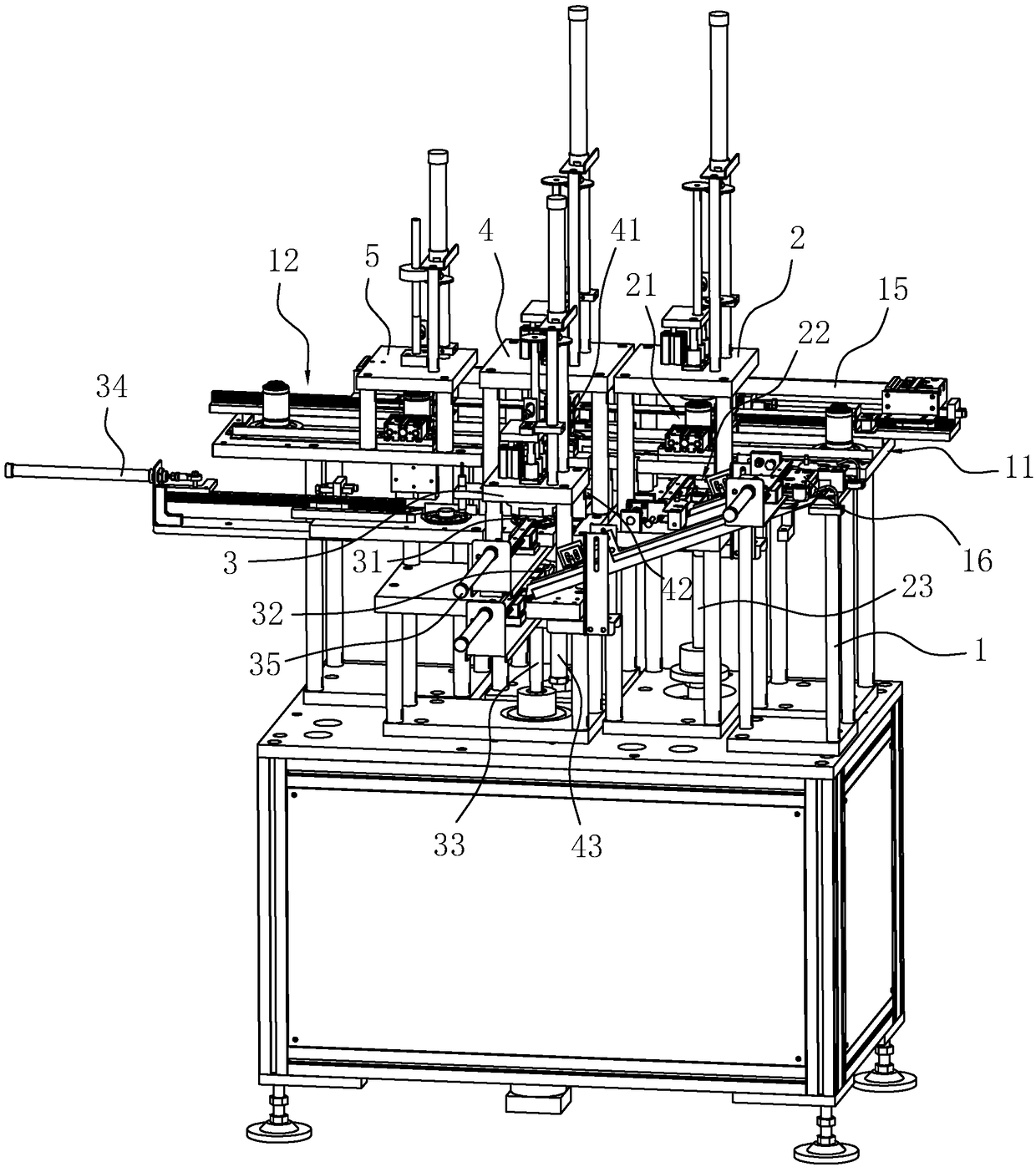

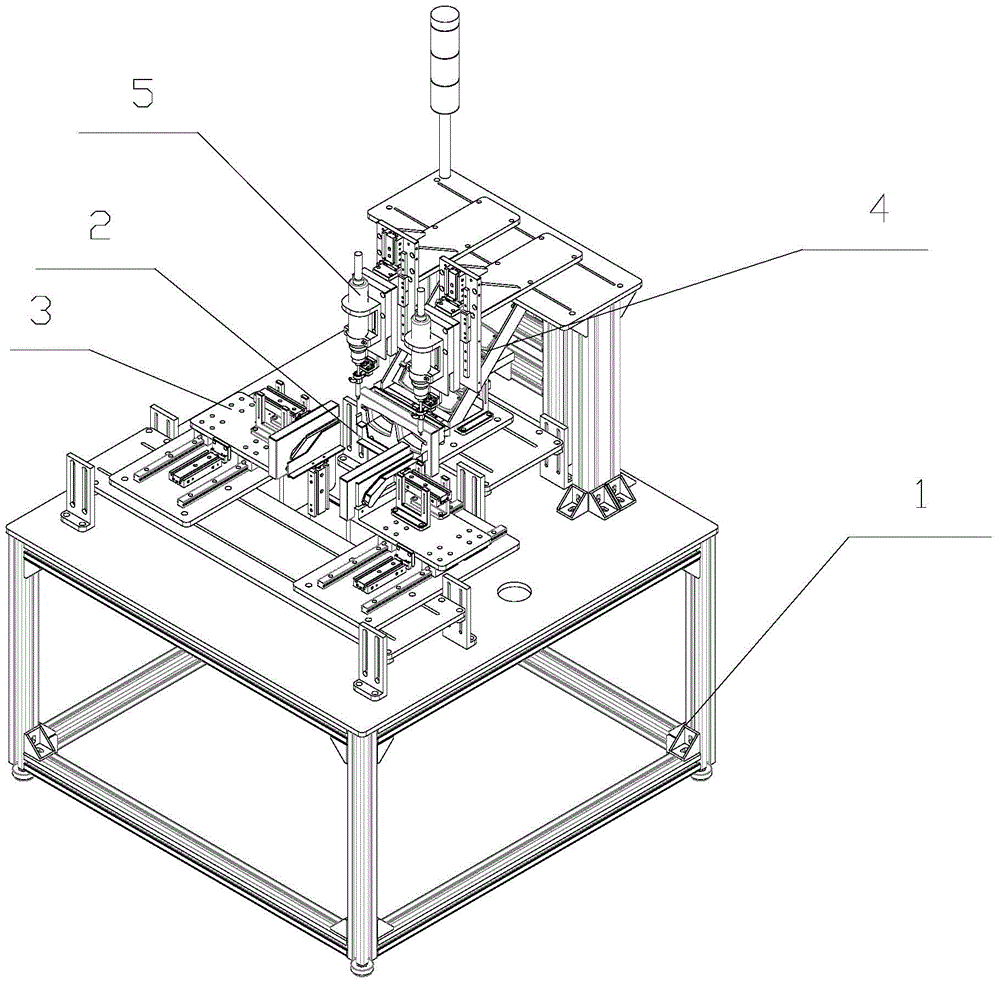

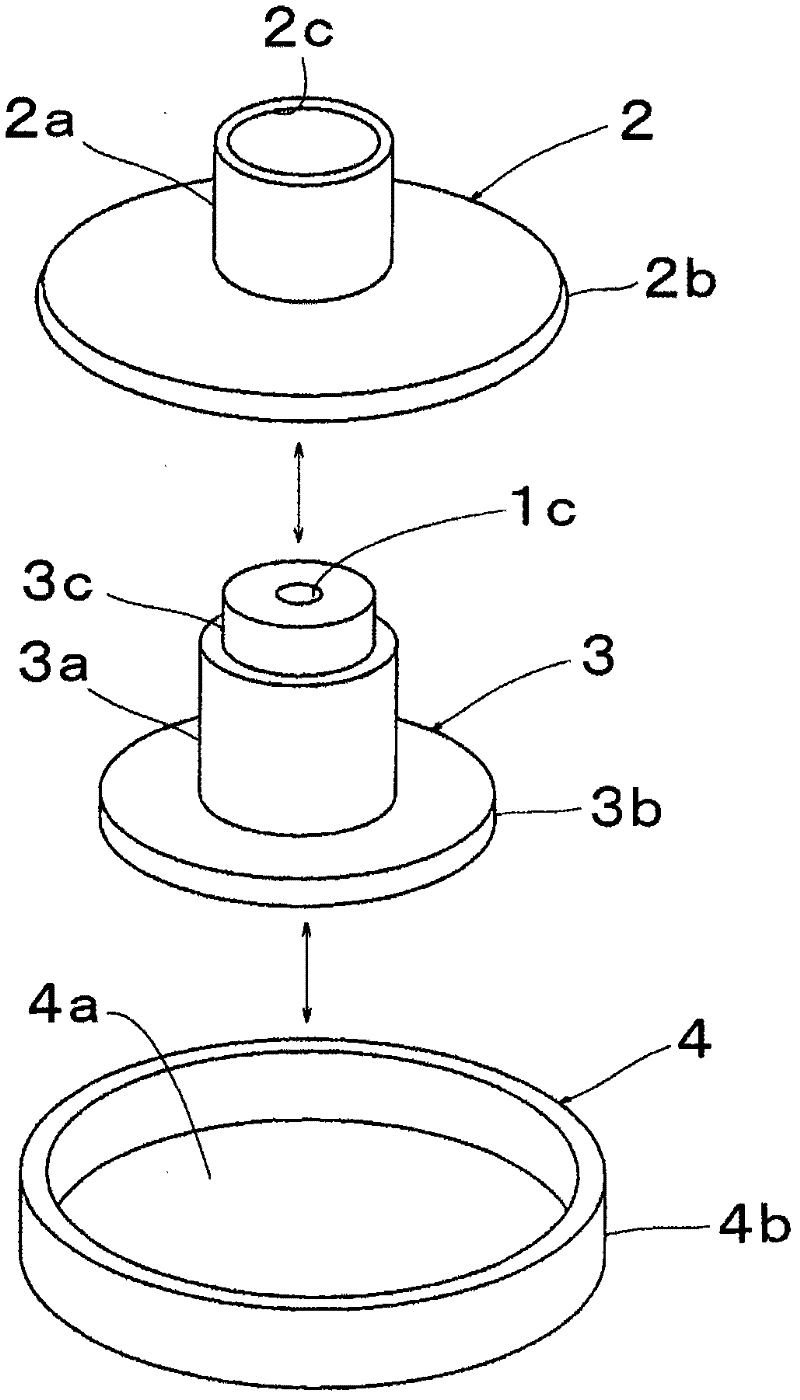

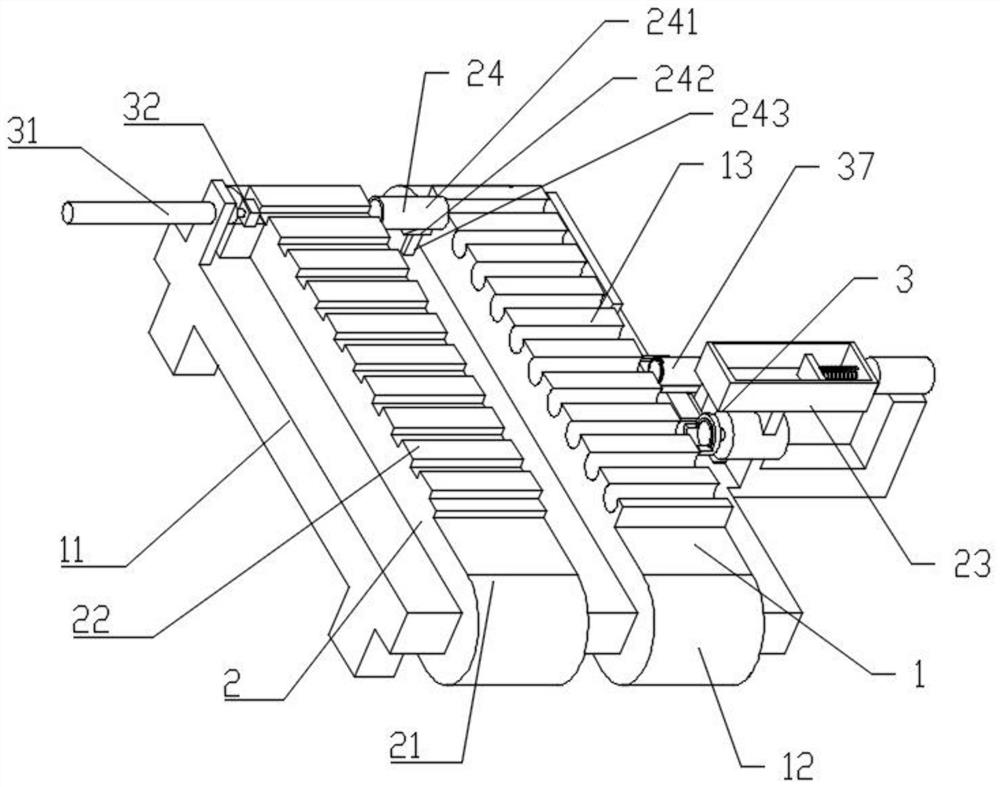

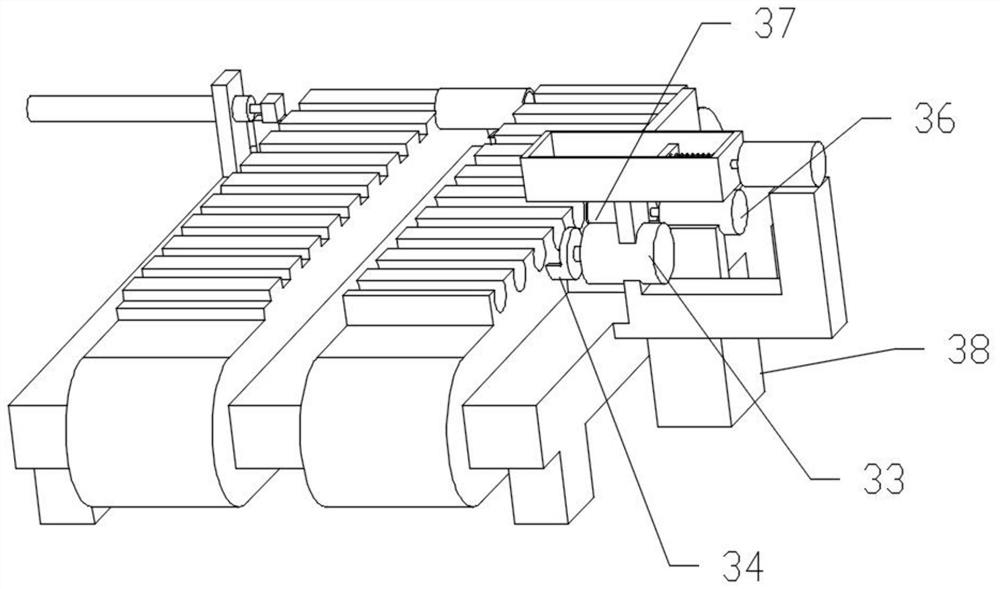

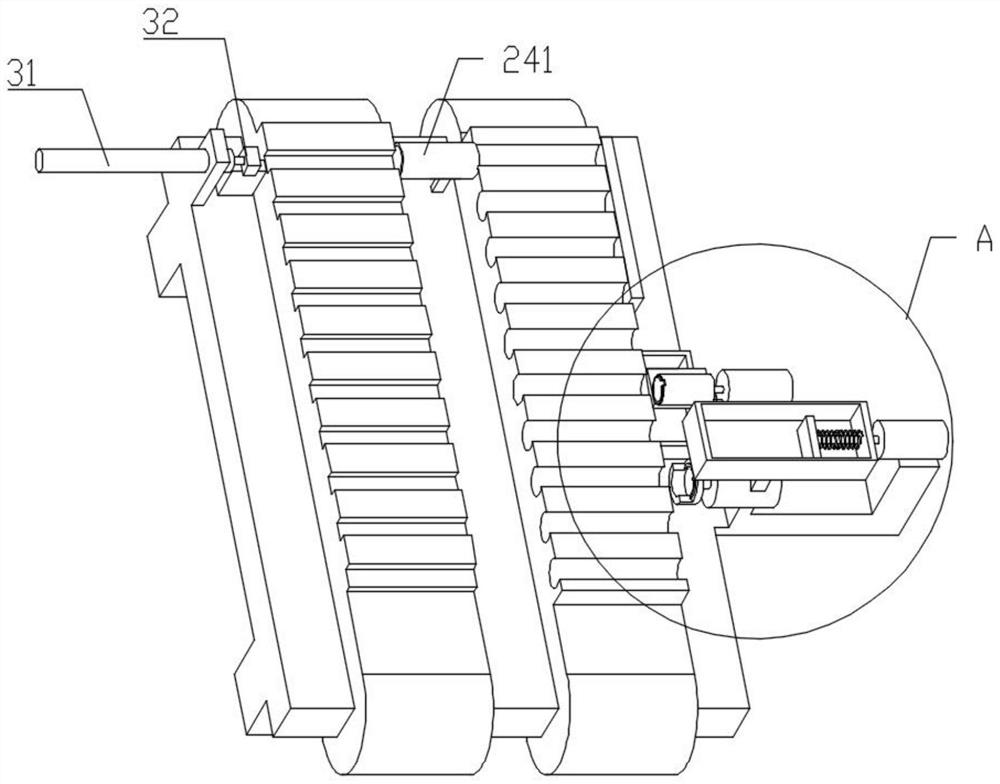

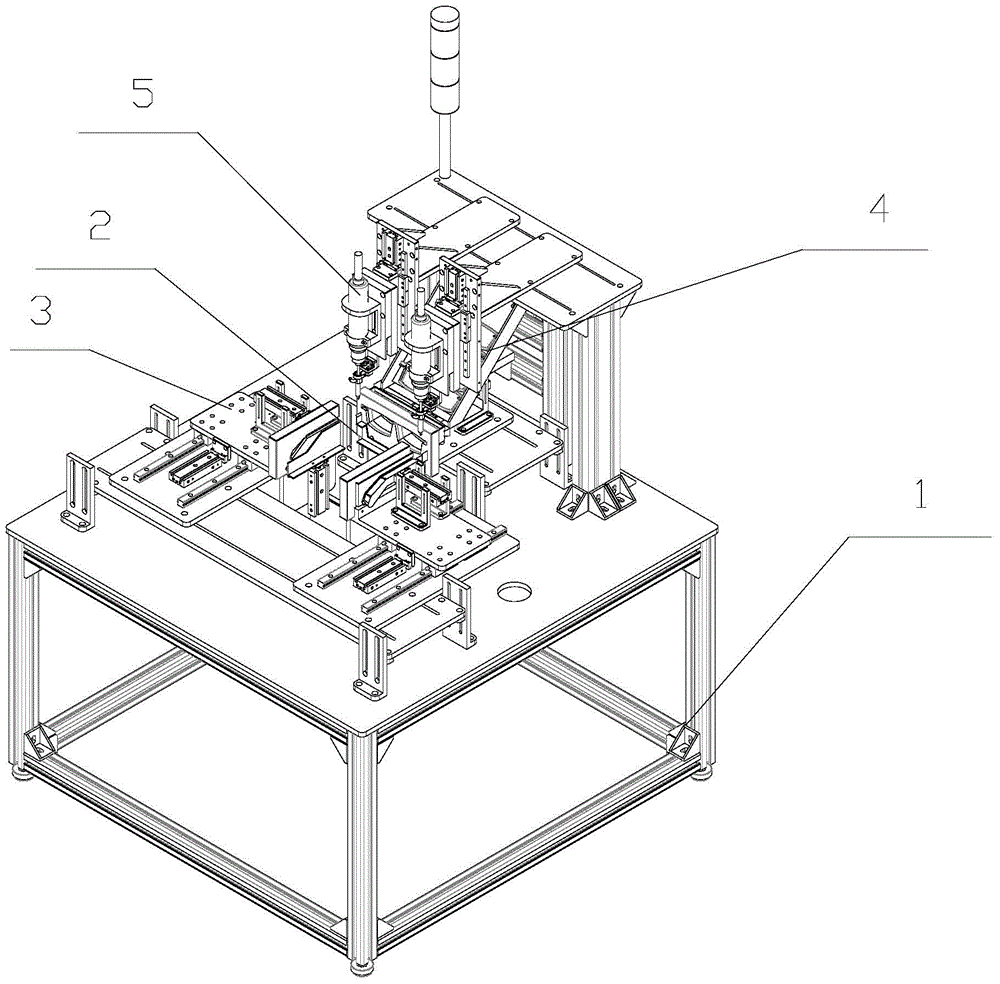

Shielding sleeve automatic assembly equipment

PendingCN108705306AHigh degree of automationLow input costAssembly machinesMetal working apparatusEngineeringAutomation

The invention discloses shielding sleeve automatic assembly equipment, and relates to the technical field of automation. According to the technical scheme, the shielding sleeve automatic assembly equipment is characterized in that a rack, a first station, a second station and a third station are included, the first station comprises a first upper installing position used for containing a sleeve body and a first lower installing position used for containing a ceramic ring, the second station comprises a second upper installing position used for containing a cover body and a second lower installing position used for containing the ceramic ring, and the third station comprises a third upper installing position and a third lower installing position; and the rack is provided with a pushing mechanism for moving the sleeve body in sequence, the second station further comprises a first cover feeding mechanism and a second cover feeding mechanism, the rack is provided with a ring feeding mechanism used for conveying the ceramic ring to the first lower installing position and the second lower installing position, and each station is internally provided with a press fitting cylinder. By meansof the assembly equipment, shielding sleeve automatic assembly can be completed, the automatic degree is high, and the labor input cost and the labor working quantity can be reduced; and the assemblyprocess is continuous, and the advantages of being high in reliability and high in production efficiency are achieved.

Owner:温岭市微米自动化设备有限公司

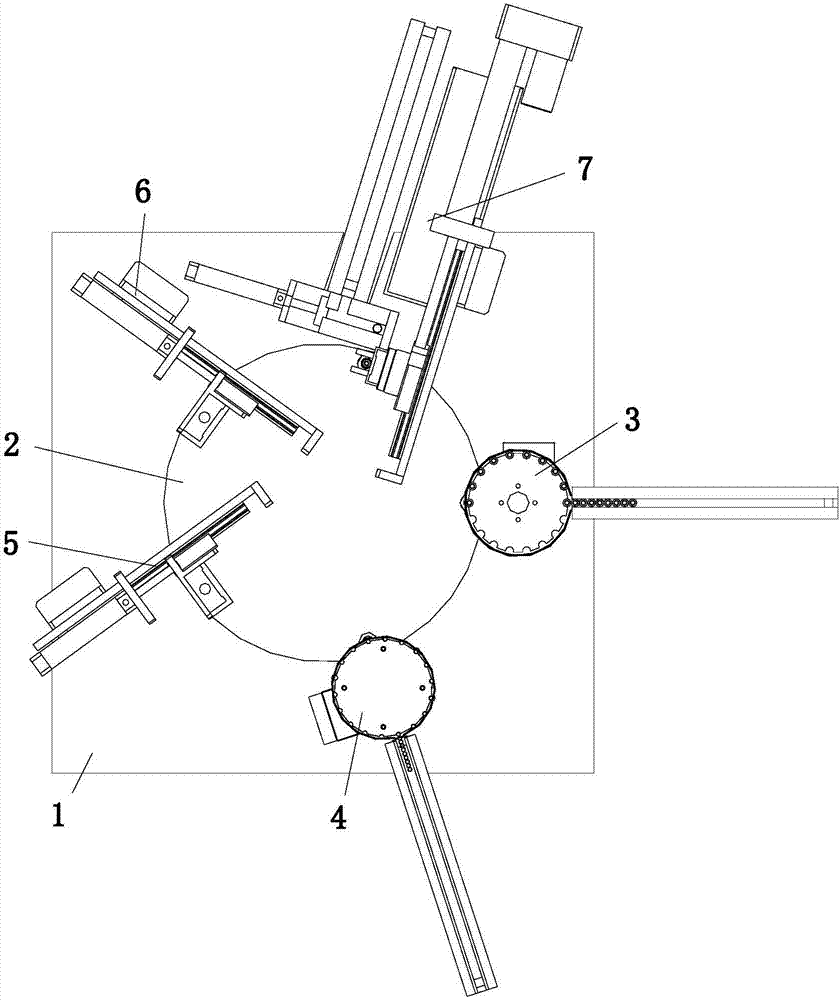

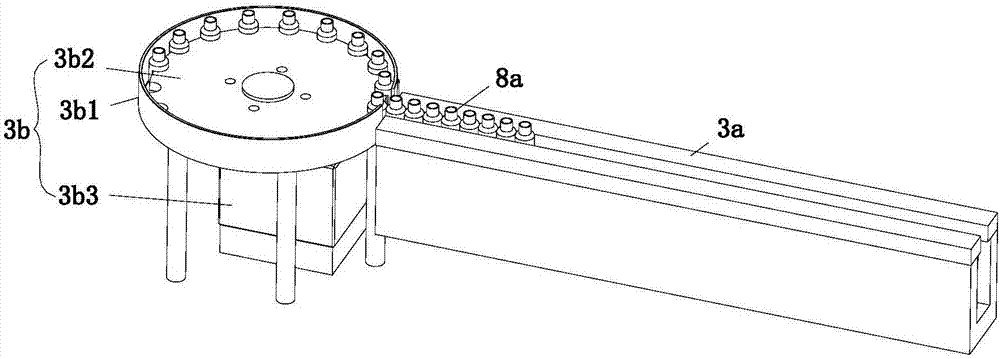

Needle assembly machine

ActiveCN107571016AContinuous assemblyReduce assembly timeAssembly machinesMotor driveElectric machinery

The invention relate to the technical field of medical instruments, in particular to a needle assembly machine. The machine comprises a machine frame, wherein a support plate is arranged at the top ofthe machine frame, a rotary table is arranged at the center of the support plate, and a first motor driving the rotary table to rotate stepwise is arranged in the machine frame; a pintle feeding device, a needle tip feeding device, a needle tip aligning device, a pressing device and a sheath sleeving device which are arranged in the rotating direction of the rotary table are arranged around the rotary table on the support plate; a plurality of fixtures are distributed uniformly circumferentially on the rotary table. The rotary table is used for driving the fixtures to pass through the pintlefeeding device, the needle tip feeding device, the needle tip aligning device, the press mounting device and the sheath sleeving device sequentially, automatic pintle positioning, needle tip placement, alignment, press mounting, sheath sleeving and blanking are realized, and accordingly, continuous needle assembly is realized, assembly time is shortened, investment of manpower and material resources is reduced, assembly cost is greatly reduced, and production efficiency is effectively improved.

Owner:甘李药业山东有限公司

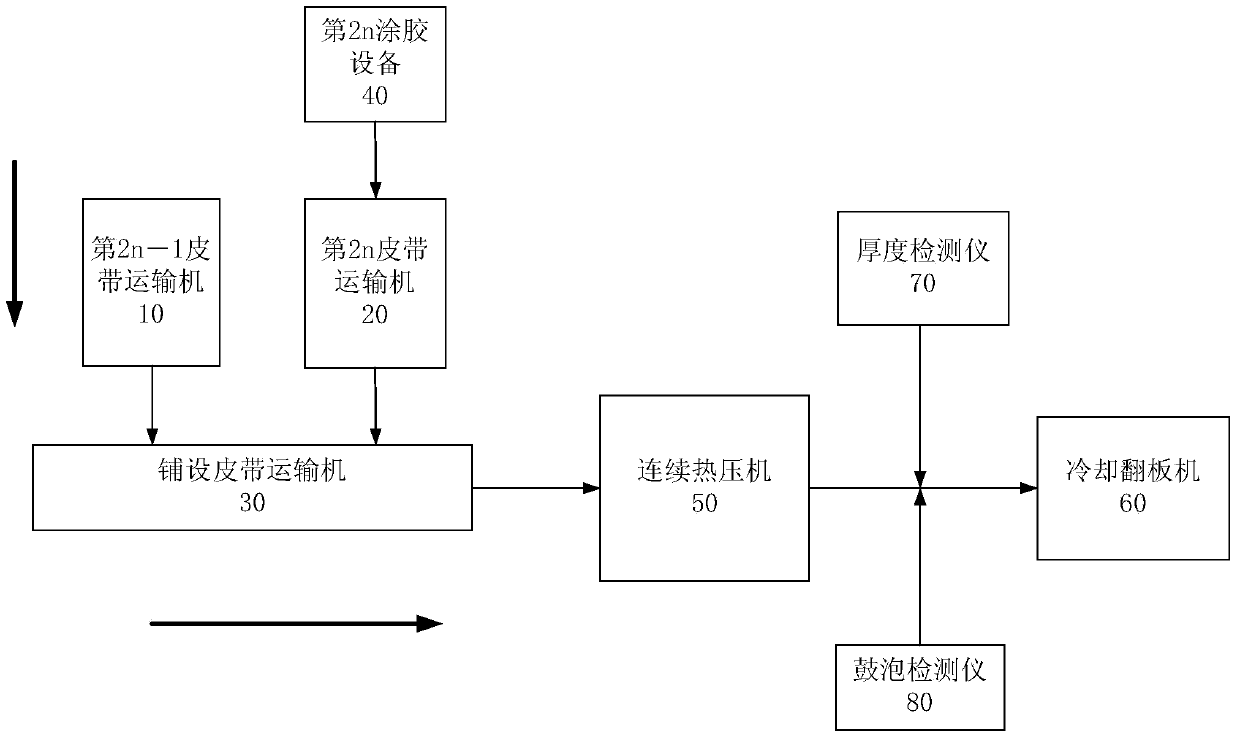

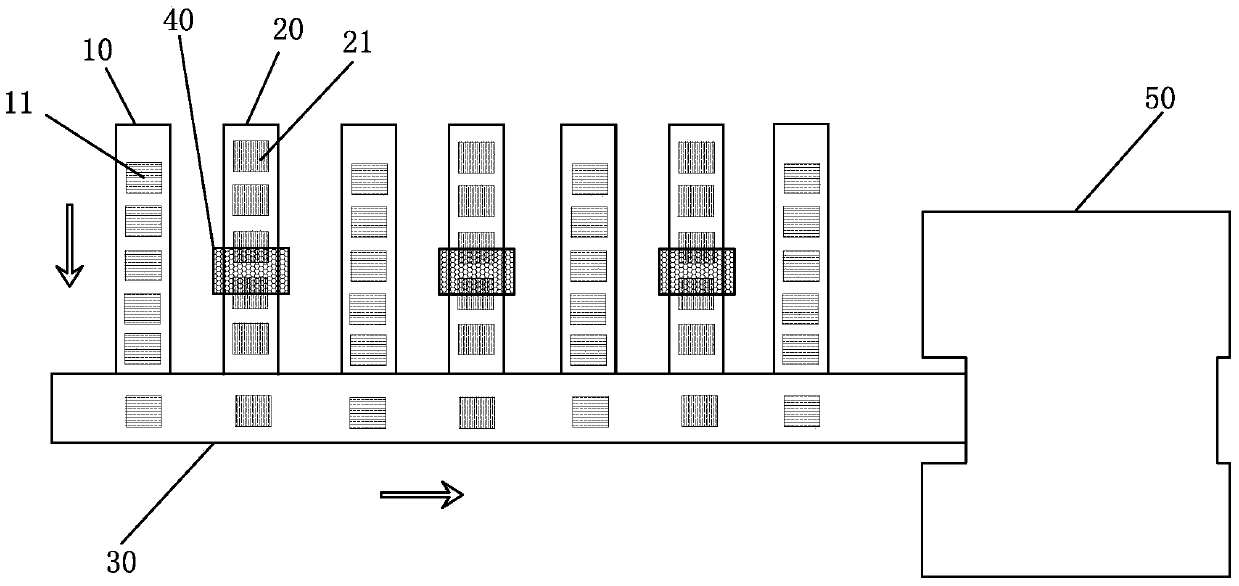

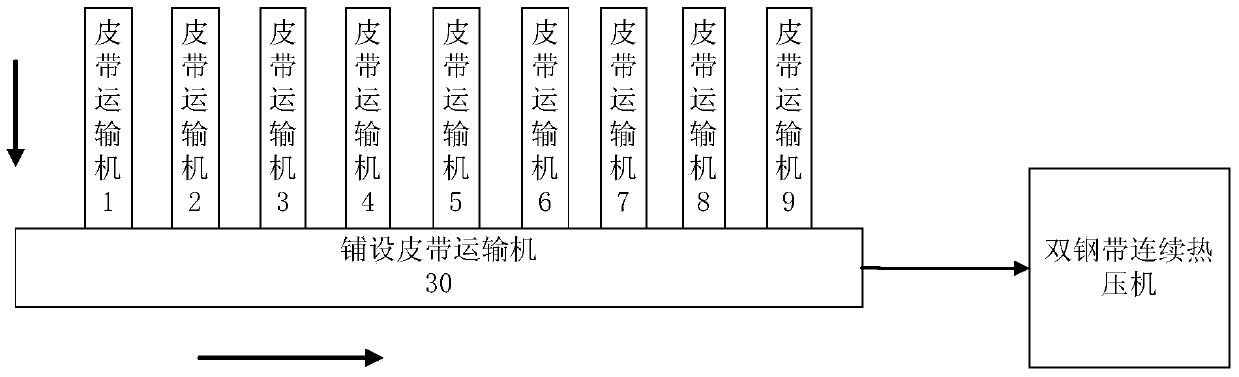

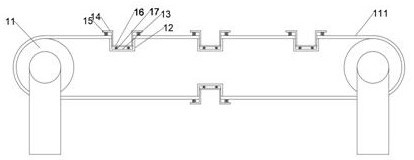

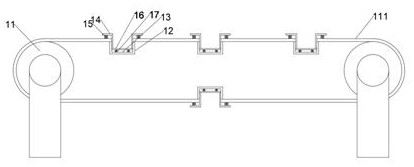

Plywood plate preparation system and method thereof

ActiveCN103737679AConstant performanceContinuous assemblyLaminationLamination apparatusMechanical engineeringHot pressing

The invention discloses a plywood plate preparation system and a method thereof. The plywood plate preparation system comprises belt conveyers, a constant thermo compressor and a belt conveyer group, wherein the belt conveyer group comprises a plurality of belt conveyers. A 2n-1th vacuum sucking disc is arranged on the upstream side of the 2n-1th belt conveyer and a 2nth vacuum sucking disc and a 2nth gumming device are arranged on the upstream side of the 2n belt conveyer. The 2nth belt conveyer and the 2n-1th belt conveyer are alternatively distributed on a same side of the belt conveyers along the conveyance direction of the belt conveyers, wherein n is a positive integer greater than 1. Composite board blanks conveyed by the belt conveyers are formed into plywood plates by the constant thermo compressor. The plywood plate preparation system can be used for constant assembly and thermo-compression formation of composite board blanks.

Owner:DIEFFENBACHER MACHINERY SERVICES BEIJING

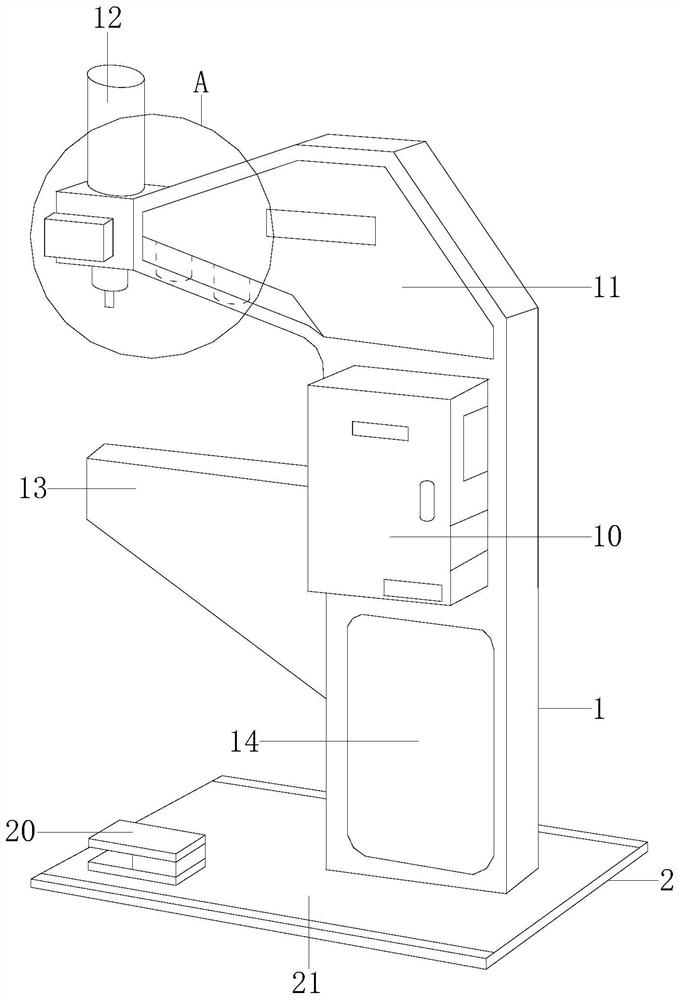

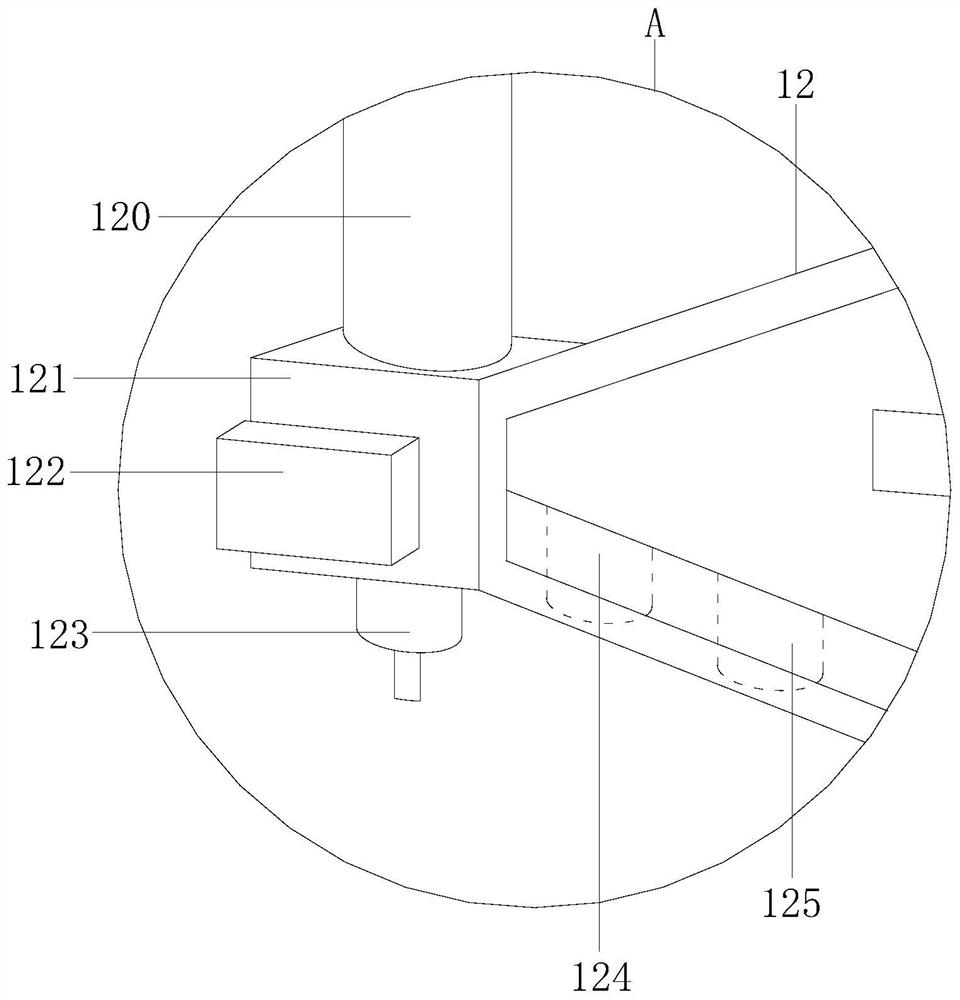

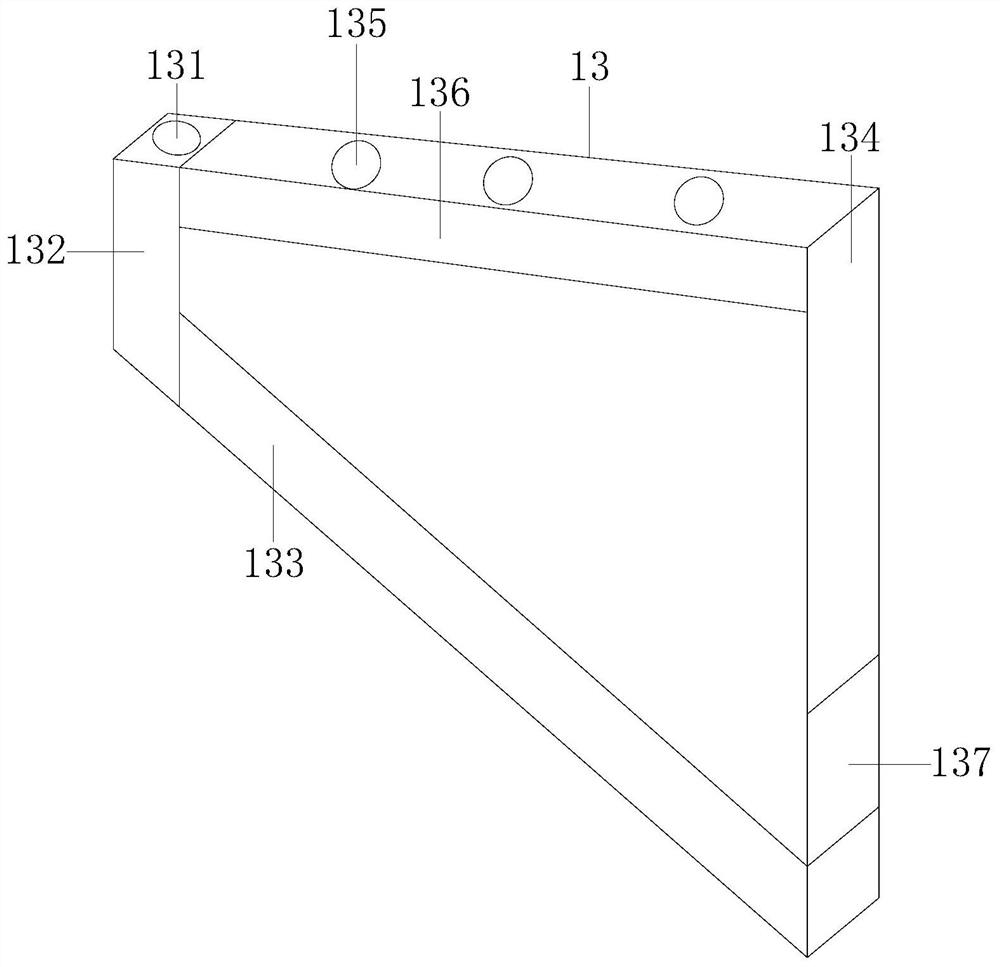

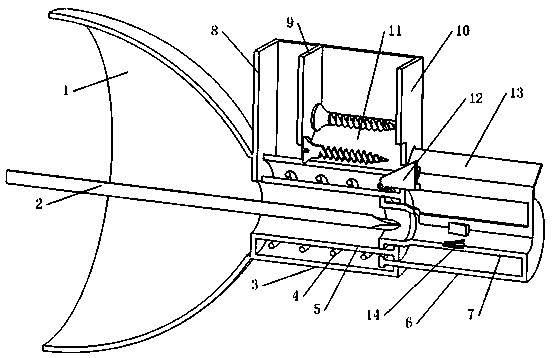

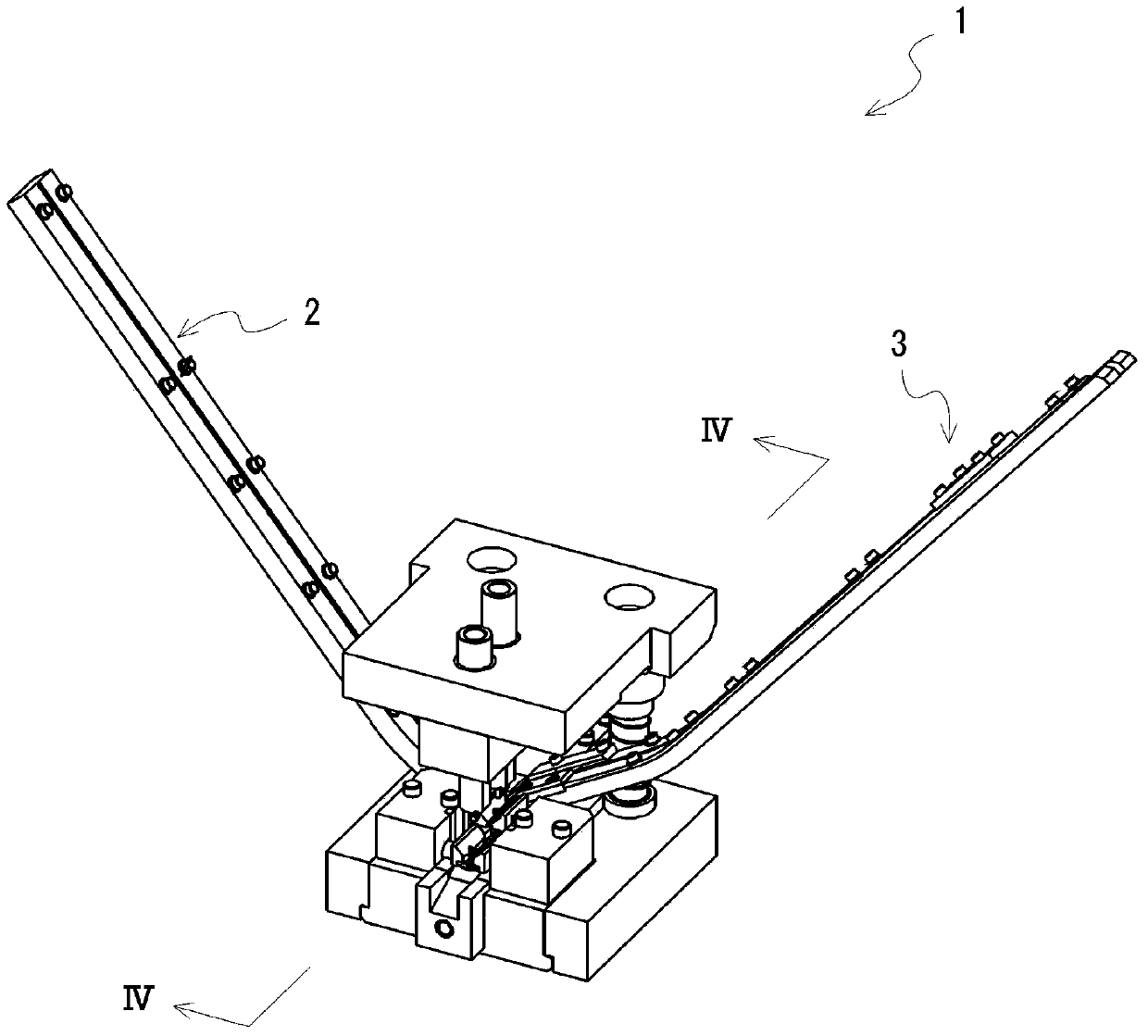

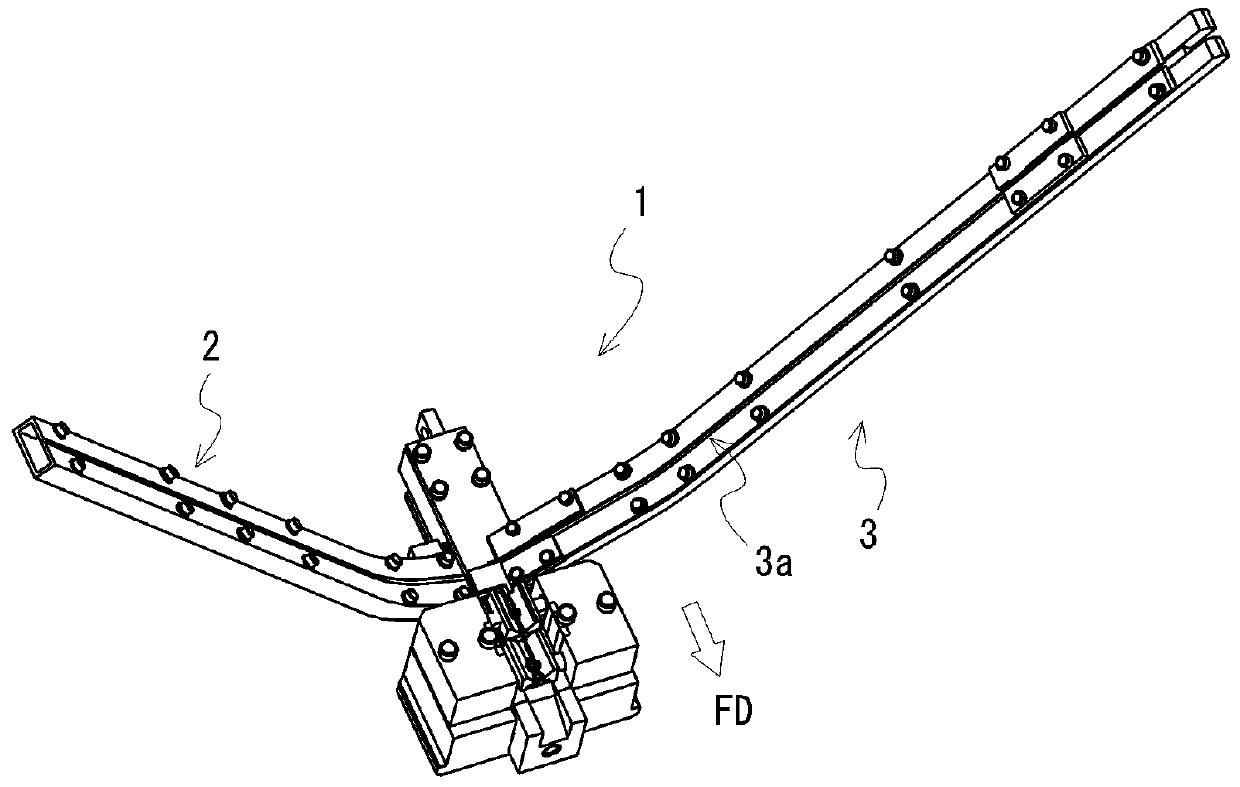

Pneumatic glasses assembling machine

The invention discloses a pneumatic glasses assembling machine. The pneumatic glasses assembling machine comprises a glasses frame mechanism used for clamping a glasses frame, glasses leg mechanisms used for clamping glasses legs and located on the two sides of the glasses frame mechanism, a feeding mechanism, a screw assembling mechanism and a control mechanism, wherein the glasses leg mechanisms can be moved to the work positions matched with the glasses frame mechanism to finish assembling of glasses components; the feeding mechanism is used for carrying out feeding for the glasses frame mechanism and the glasses leg mechanisms; the screw assembling mechanism is used for finishing assembling of the glasses components; the control mechanism is used for controlling action of the mechanisms. The feeding mechanism comprises a guide rail used for containing the glasses components, a limiting bar, a limiting piece, a limiting bar air cylinder and a limiting piece air cylinder. The limiting bar is connected with the limiting bar air cylinder. The limiting piece is connected with the limiting piece air cylinder. The guide rail is obliquely arranged on a rack. A discharging port in the lower end of the guide rail is aligned with a feeding port of a corresponding clamp. A limiting hole is formed in the guide rail and matched with the limiting bar to limit falling of the last glasses component. The discharging port in the lower end of the guide rail is provided with the limiting piece used for limiting feeding of the glasses components.

Owner:ZHEJIANG UNIV OF TECH

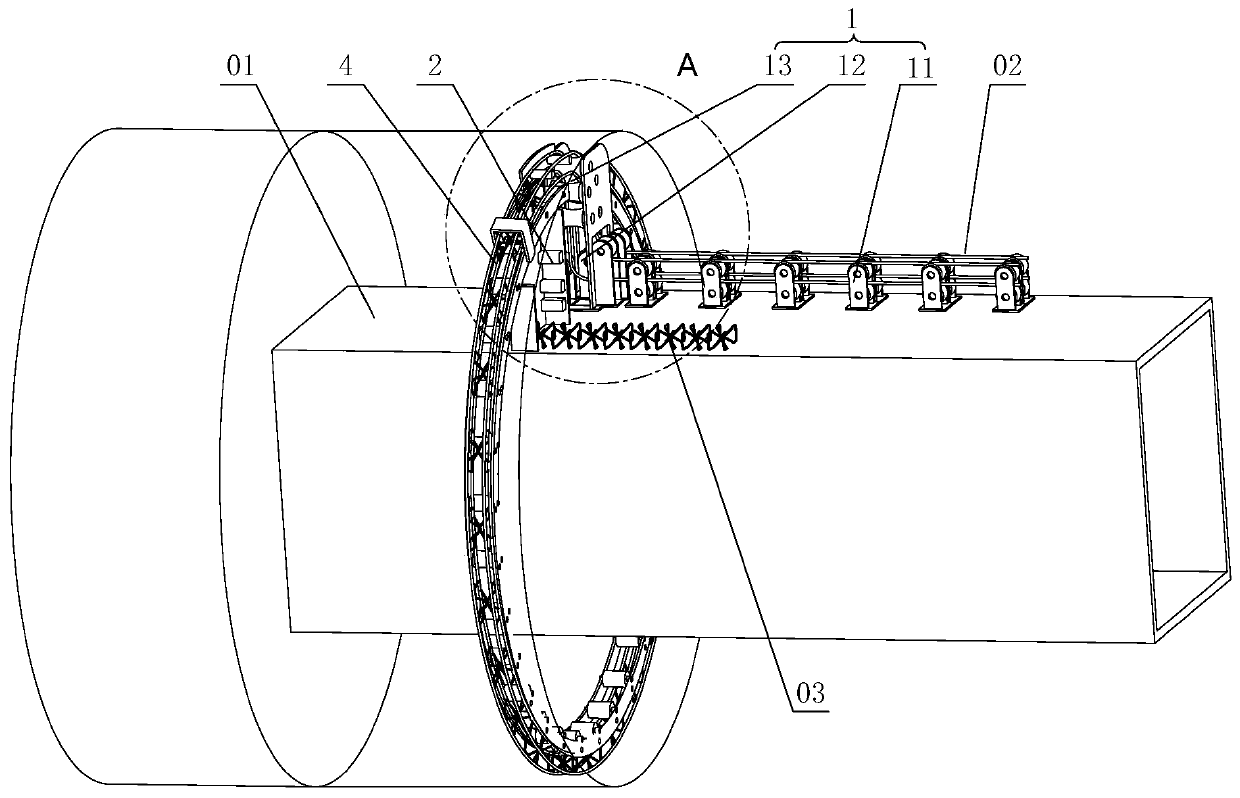

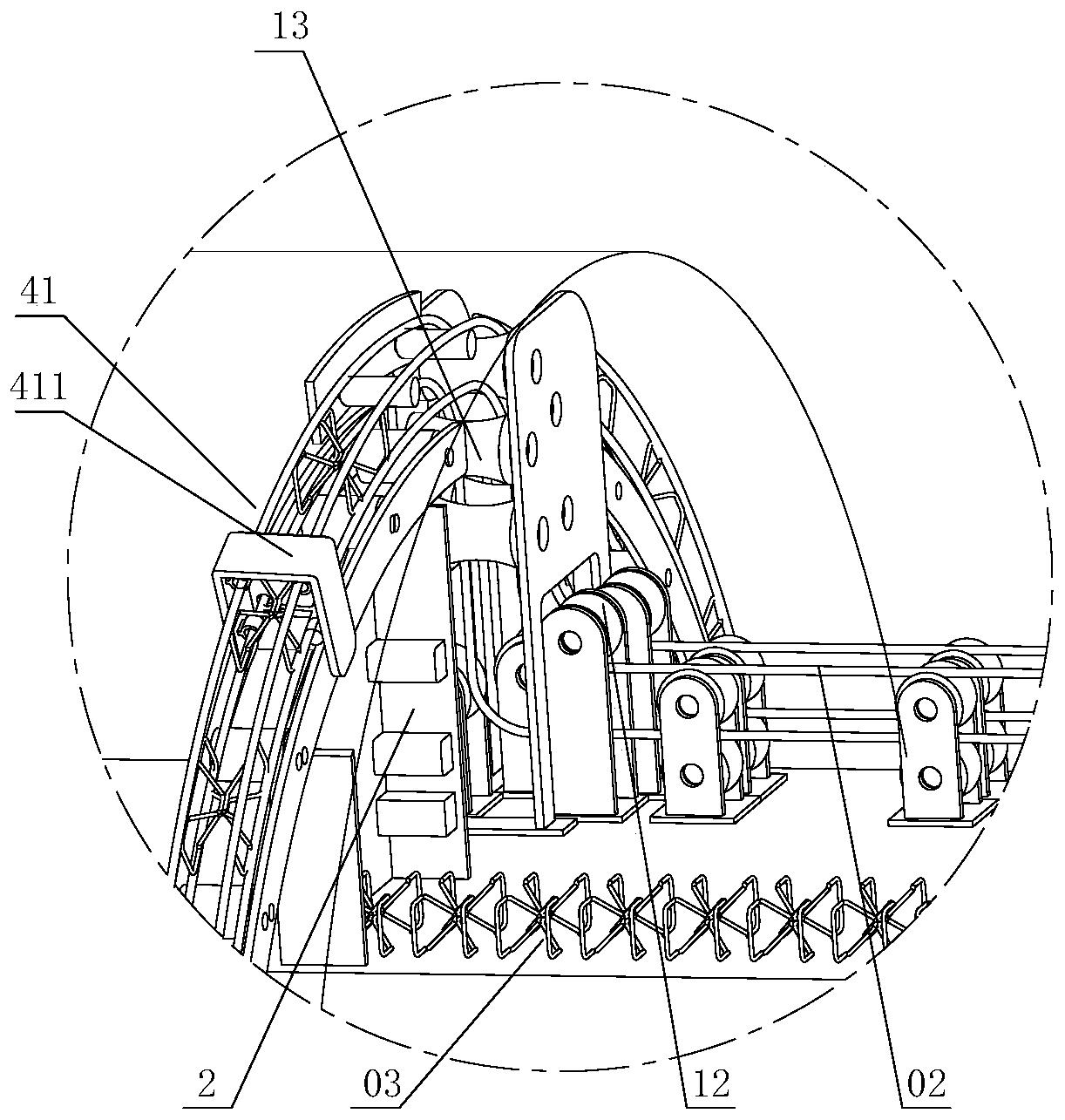

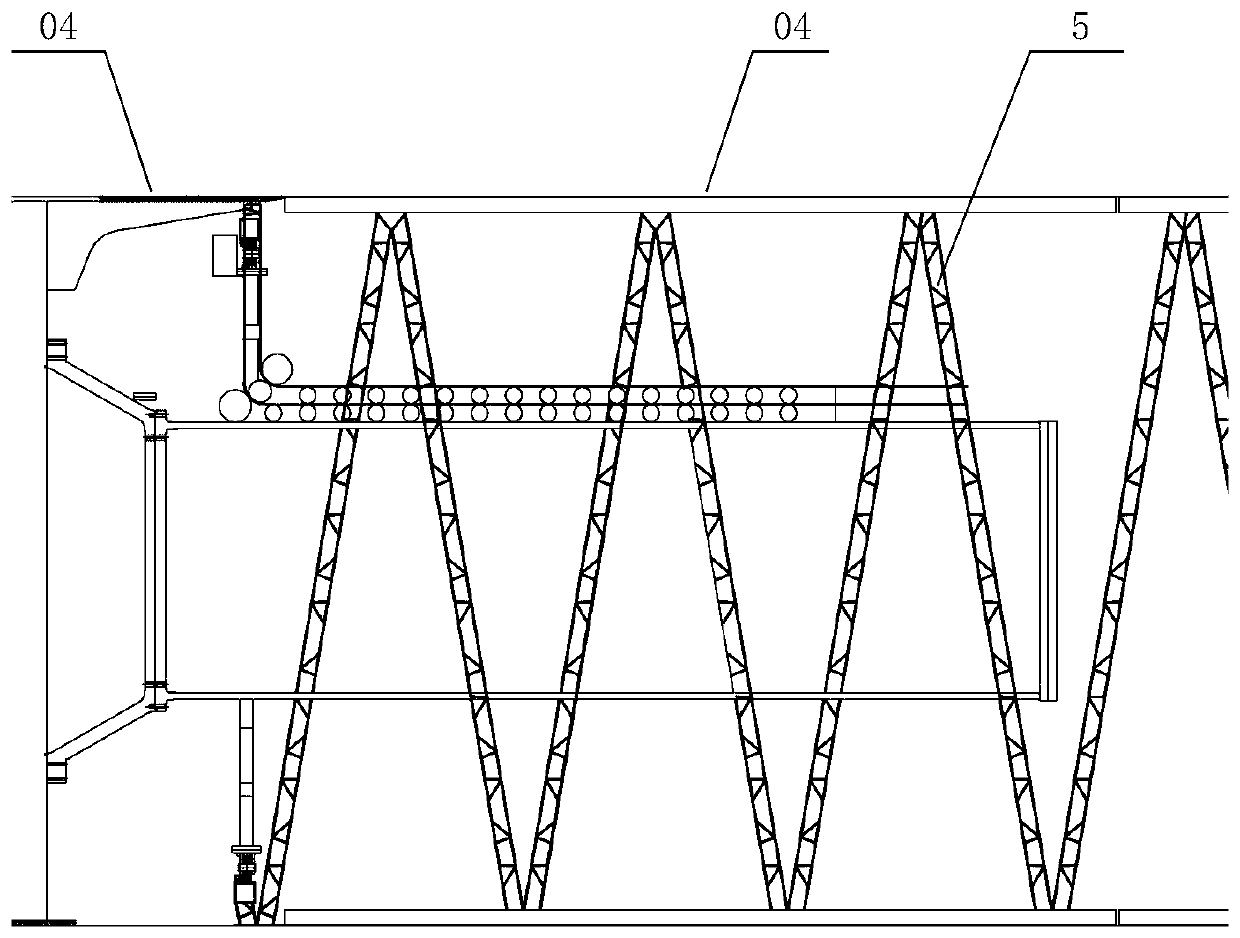

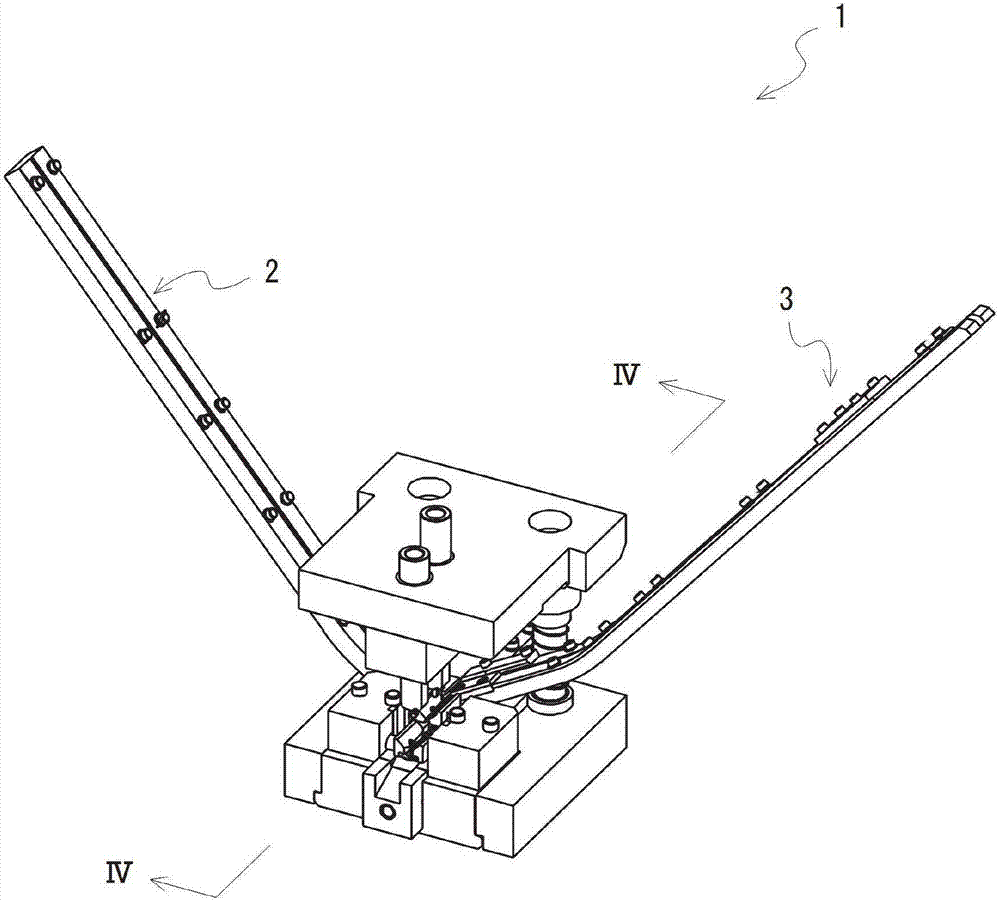

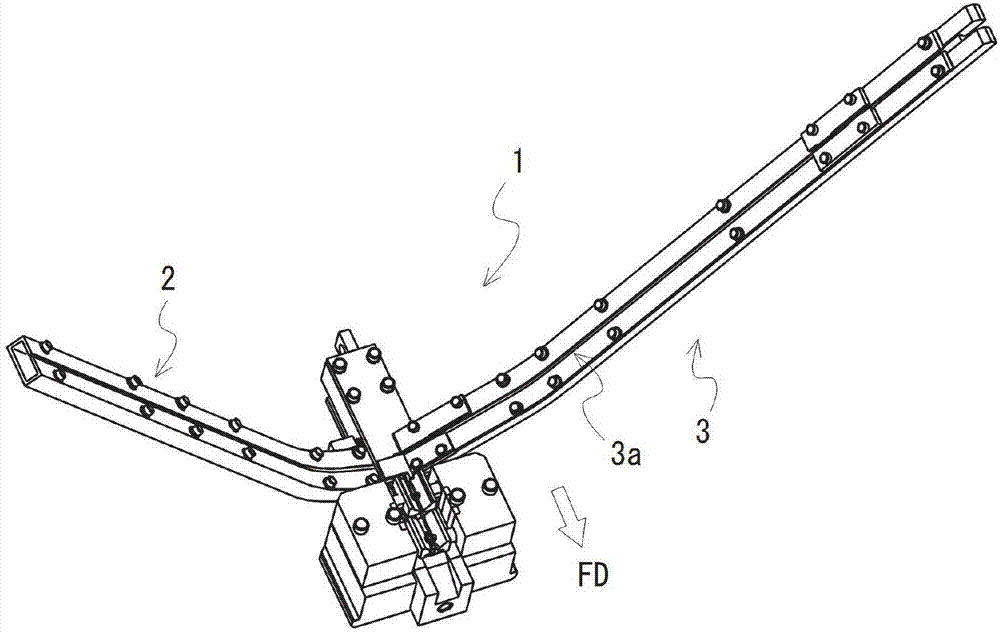

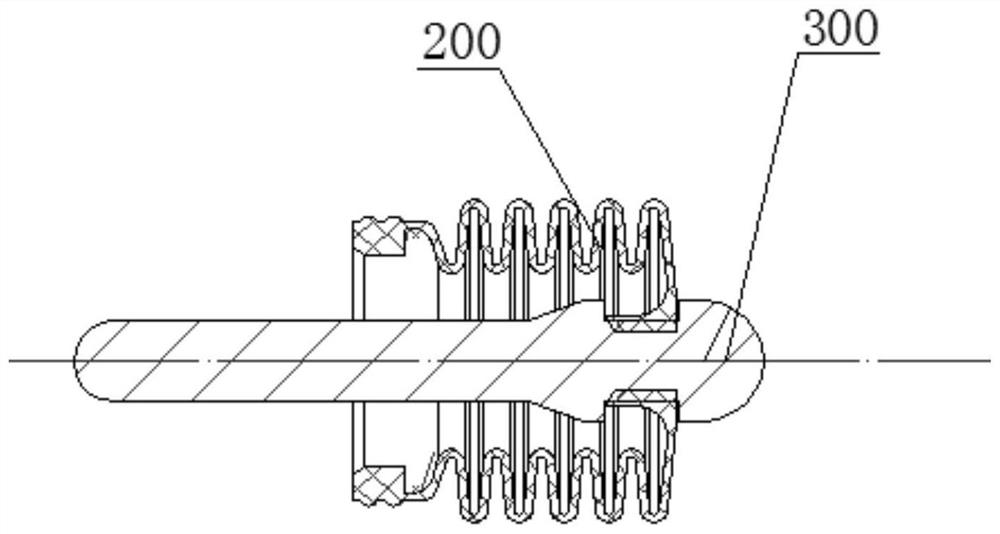

Tunnel supporting arch frame manufacturing system and manufacturing method

ActiveCN109915176ANo human intervention requiredHigh degree of automationUnderground chambersTunnel liningMiddlewareManufacturing systems

The invention discloses a tunnel supporting arch frame manufacturing system. The tunnel supporting arch frame manufacturing system comprises a main reinforcement conveying and bending mechanism, a middleware conveying mechanism, a fixed connecting mechanism, a rotary guiding mechanism and a control mechanism. Firstly, the main reinforcement conveying and bending mechanism is controlled to convey and bend a main reinforcement, and the main reinforcement is bent in the circumferential direction of a tunnel; the middleware conveying mechanism is controlled to convey a formed middle connecting piece to a preset position of the bent main reinforcement; then, the fixed connecting mechanism is controlled to fix the middle connecting piece located at the preset position to the bent main reinforcement, the main reinforcement and the middle connecting piece are fixedly connected into a whole, and the main reinforcement and the middle connecting piece are assembled in stages; and finally, the rotary guide mechanism is controlled to guide the main reinforcement fixedly connected with the middle connecting piece to be tightly attached to the inner wall of the tunnel, so that the main reinforcement and the middle connecting piece are spliced to form an arch frame main body. The tunnel supporting arch frame can be automatically spliced through the control mechanism, the automation degree is high, the splicing efficiency is high, and therefore efficient and continuous splicing can be achieved. The invention further discloses a tunnel supporting arch frame manufacturing method.

Owner:CHINA RAILWAY CONSTR HEAVY IND

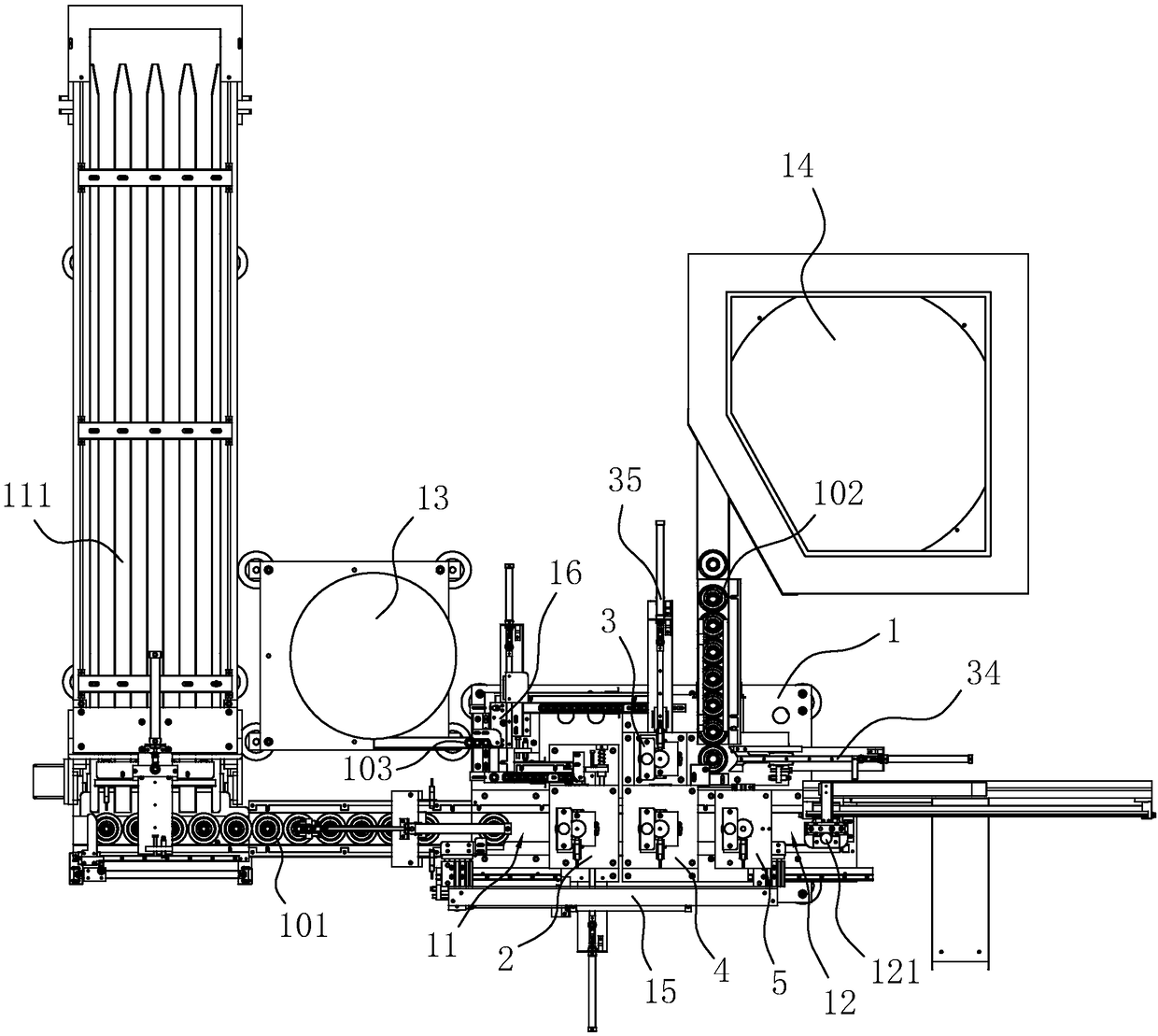

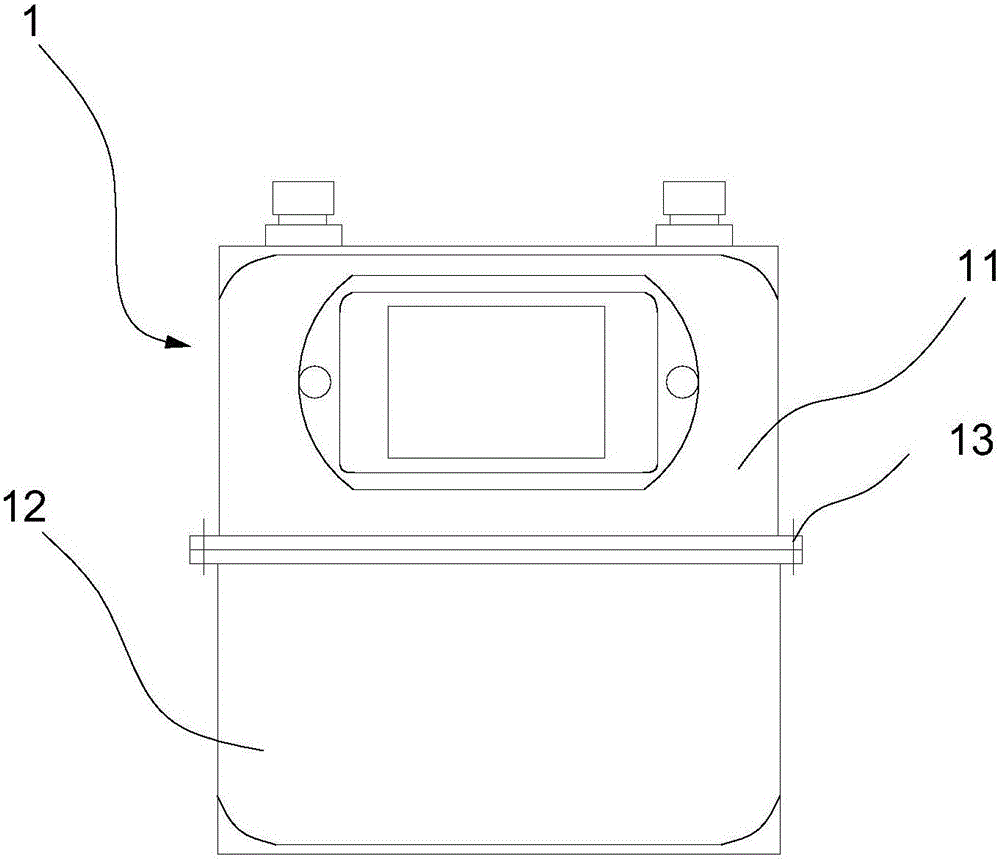

Automatic lock screw feeding assembly line for diaphragm gas meter

ActiveCN105855861AContinuous assemblyReduce workloadMetal working apparatusScrew placementEngineering

The invention discloses an automatic lock screw feeding assembly line for a diaphragm gas meter. The structure is simple, and screws can be completely placed at a time. The automatic lock screw feeding assembly line for the diaphragm gas meter comprises a feeding device, guide rails and conveying trolleys. The feeding device comprises a top plate, guide posts, a sliding plate, a horizontal sliding driving device, a sliding block, telescopic devices, a screw charging barrel, a screw guiding barrel and an installing seat. By means of the automatic lock screw feeding assembly line for the diaphragm gas meter, the workload of workers can be reduced, the screw placement efficiency is improved, and the assembly cost is reduced.

Owner:滁州市中诺设备模具制造有限公司

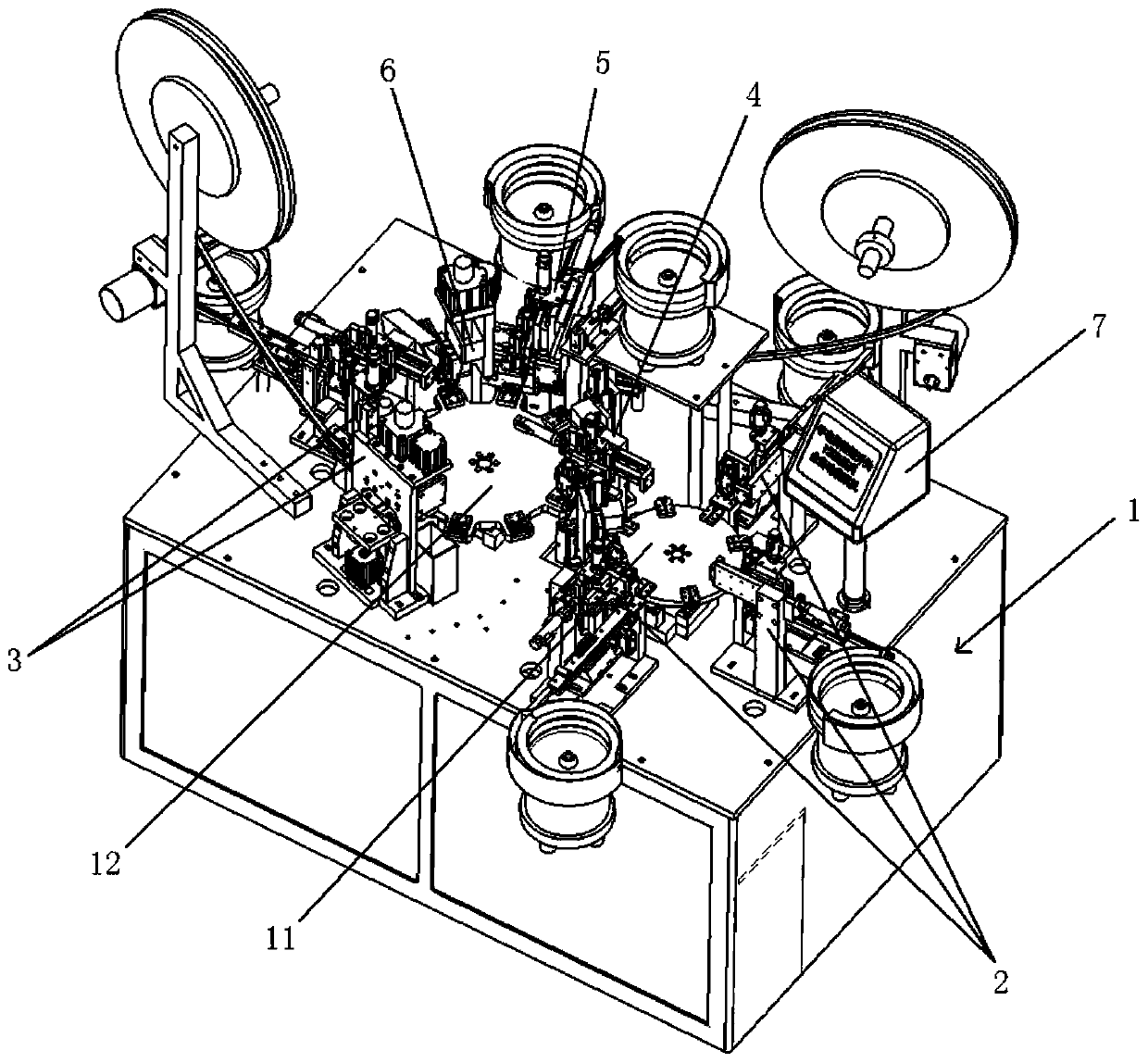

Laser transmitter assembling equipment of laser level meter

ActiveCN114535969AContinuous assemblyFinal product manufactureActive open surveying meansLaser transmitterMaterials science

The invention discloses laser transmitter assembling equipment of a laser level meter, which comprises a laser transmitter supply device for conveying a to-be-assembled laser transmitter of the laser level meter; the active pairing device is arranged above the laser transmitter supply device, and the active pairing device is used for driving a support frame of a laser level meter to be sequentially paired and mounted with a plurality of laser transmitters on the laser transmitter supply device; the press-down coordination mechanism is connected with the rotation switching mechanism, and the press-down pairing mechanism is used for driving the support frame to move downwards so as to enable the laser transmitter on the laser transmitter conveying device to be matched in the support frame; the active pairing device is used for driving the support frame of the laser gradienter to be sequentially paired and installed with the multiple laser emitters, and the mode is different from the mode that a mechanical arm is directly used for grabbing the laser emitters and the support frame for installation, so that the whole device is not limited by the specific shapes of the laser emitters.

Owner:南通亨德利电动工具有限公司

Automatic assembling equipment

PendingCN110033968AImprove assembly timeReduce waiting timeElectric switchesIndustrial engineeringWaiting time

The invention discloses automatic assembling equipment, which is used for assembling a button switch. The automatic assembling equipment comprises a rack, and a first rotary table, a second rotary table, a bottom part assembling component, a middle part assembling component, an upper part assembling component and a middle assembling device arranged on the rack; the middle assembling device is usedfor assembling a finished bottom part of the bottom part assembling component and a finished middle part of the middle part assembling component into a semi-finished part; and according to the condition that the assembling tail end of the middle assembling device is positioned on the first rotary table or the second rotary table, the first rotary table or the second rotary table continues to rotate for enabling the semi-finished part and the finished bottom part of the bottom part assembling component to finish finished product assembling. By adopting the technical scheme, the waiting time ofeach assembling process can be greatly shortened, so that the total assembling time is shortened, the overall assembling progress is accelerated, the assembling time of the button switch is shorter,the assembling efficiency is improved, the automatic assembling operation is realized, the product assembling quality is guaranteed, and the labor cost is reduced.

Owner:YUEQING BOFENG ELECTRONICS CO LTD

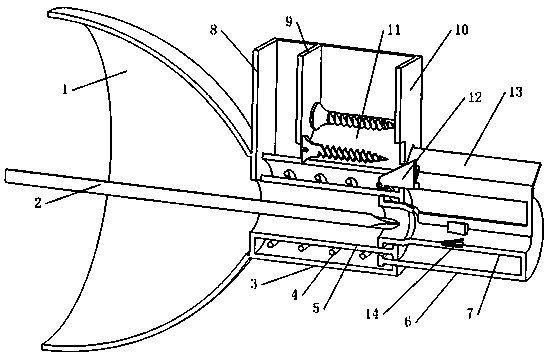

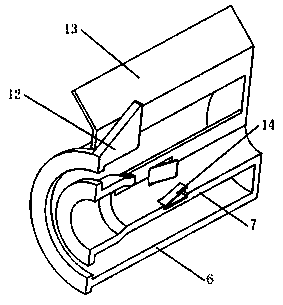

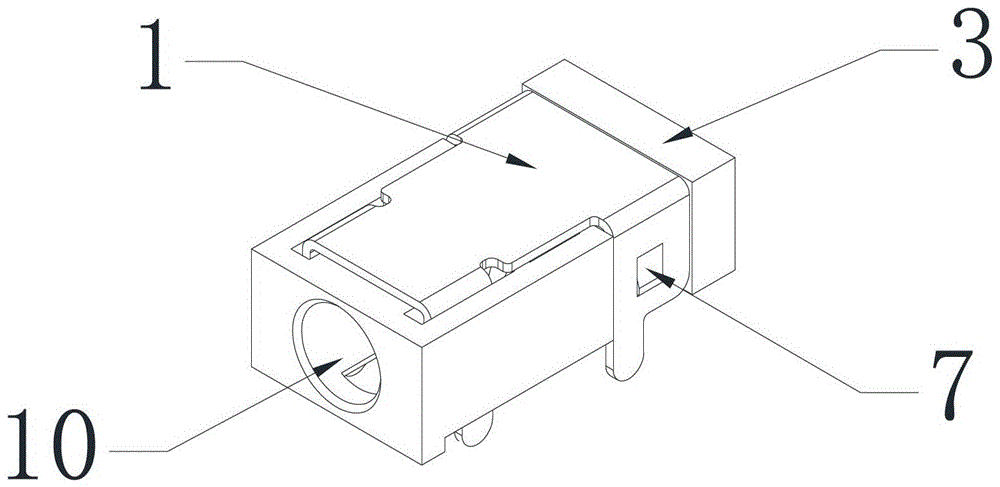

Electric screwdriver device

The invention discloses an electric screwdriver device. The electric screwdriver device comprises an electric screwdriver body, a motor is arranged in the electric screwdriver body, and the motor is in driving connection with a screwdriver head stretching out of the front end of the electric screwdriver body. The electric screwdriver device further comprises a storage device, a positioning device,a feeding device and a guide structure which are arranged at the front end of the electric screwdriver body. The storage device is located on the upper side of the front end of the electric screwdriver body and used for achieving storage of screws. The positioning device is located below the storage device and used for achieving the positioning effect that the screws right face the front side ofthe screwdriver head. The feeding device is connected between the storage device and the positioning device and used for sending the screw located on the bottommost portion of the storage device to the positioning device. The guide structure is arranged between the positioning device and the electric screwdriver body and used for achieving backward sliding of the positioning device and enabling the screwdriver head to penetrate into the positioning device and push out the screws in the positioning device to complete screw rotating connection during sliding. The storage device, the positioningdevice, the feeding device and the guide structure are matched for use to achieve continuous assembling of the screws.

Owner:YANGTZE NORMAL UNIVERSITY

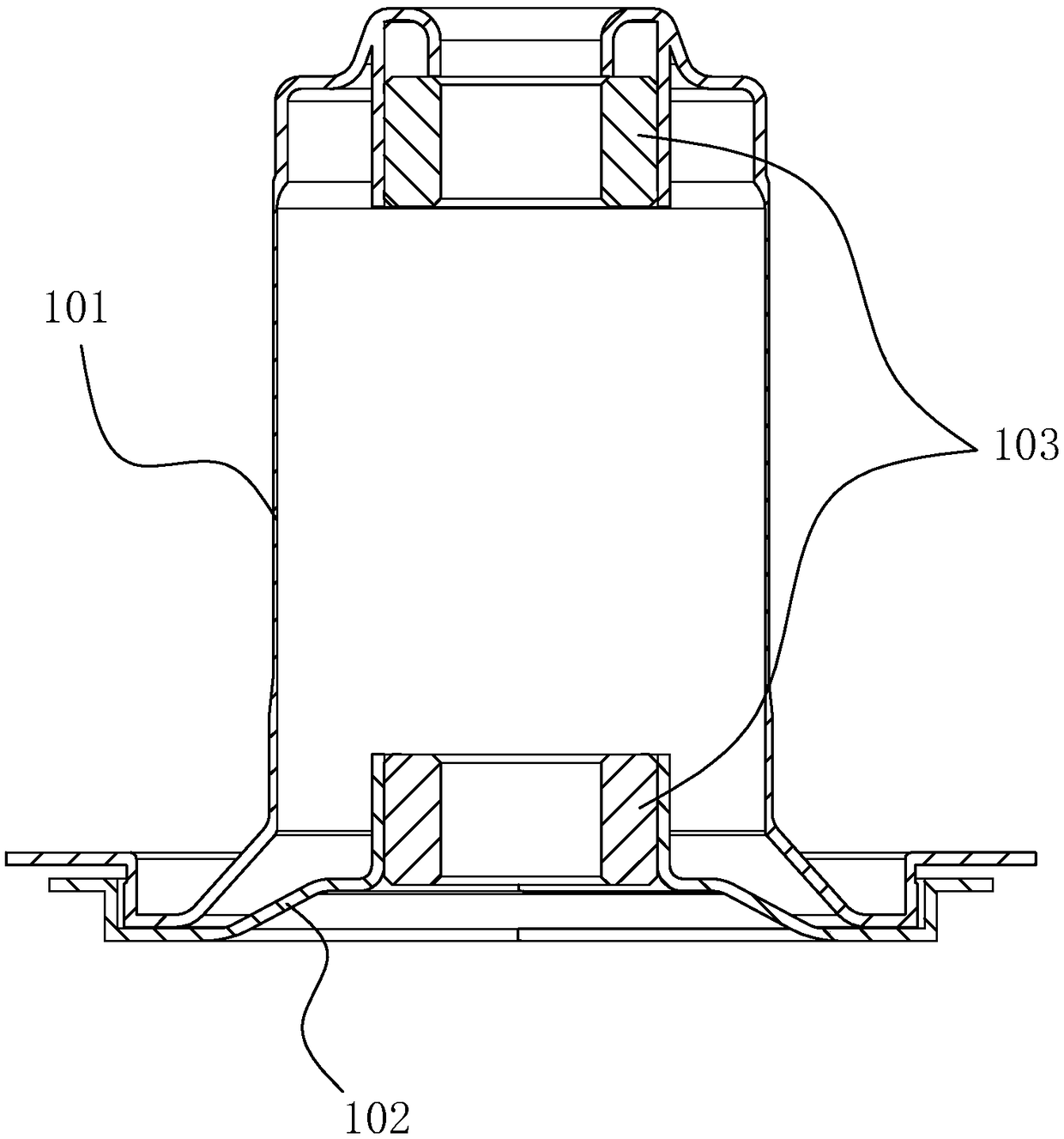

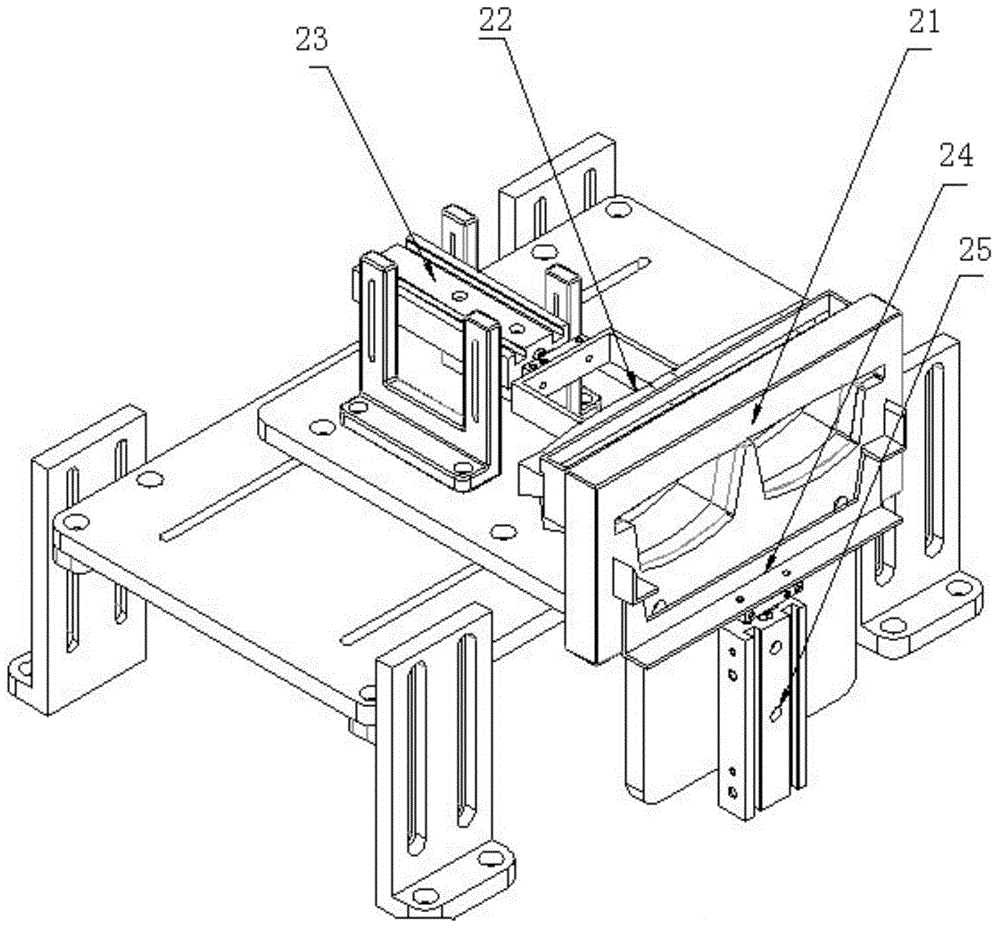

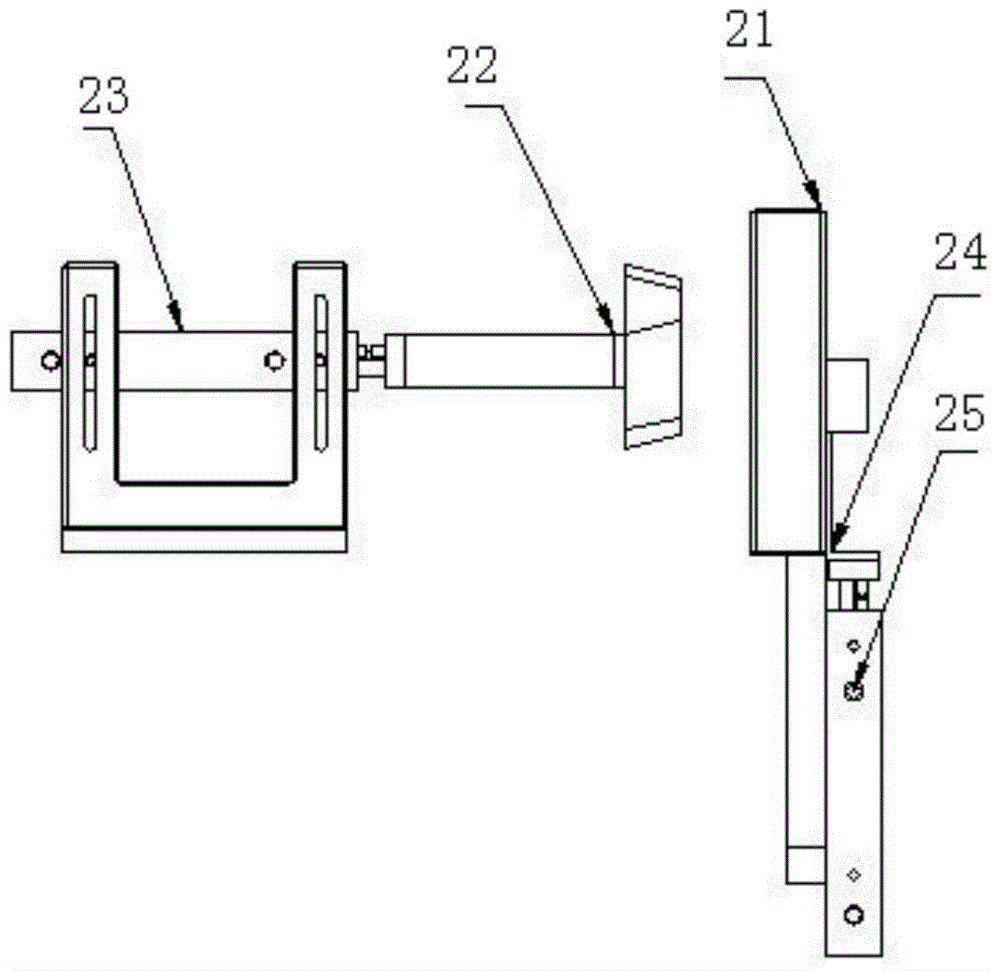

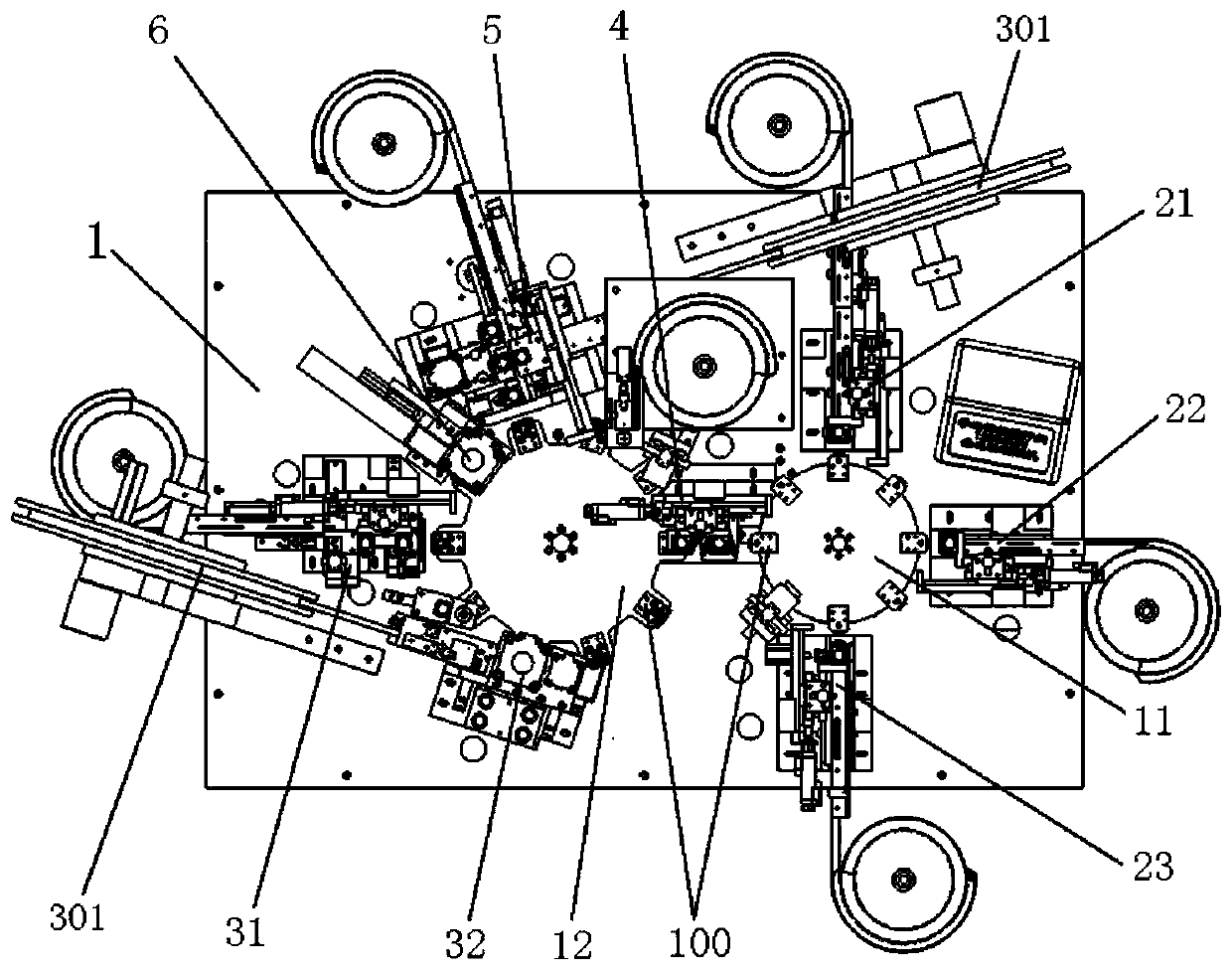

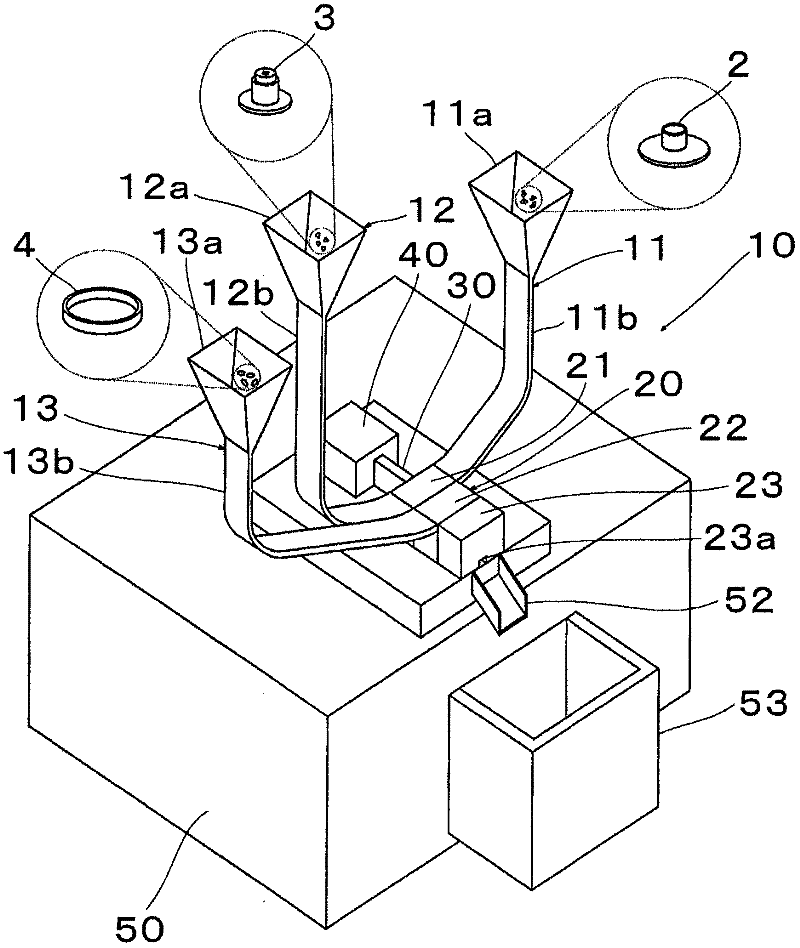

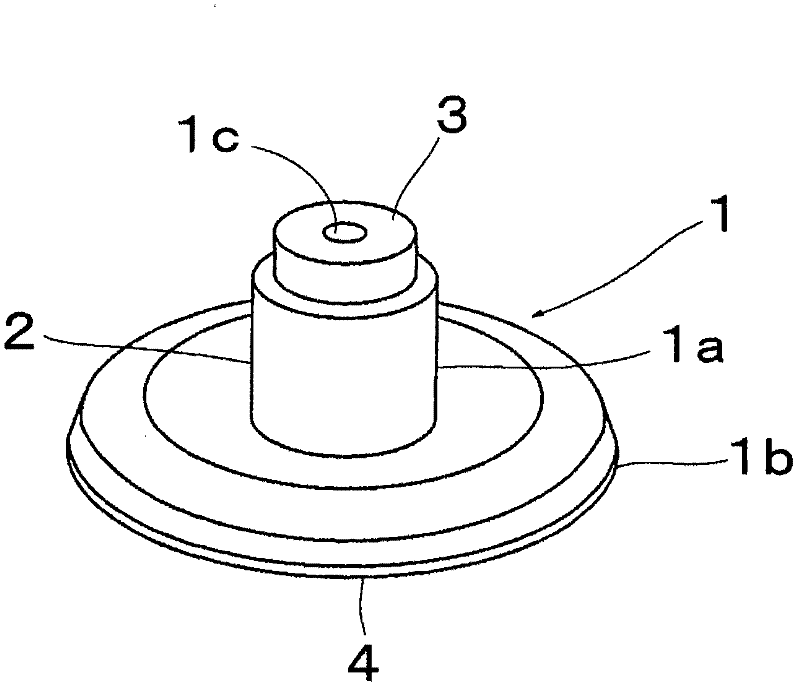

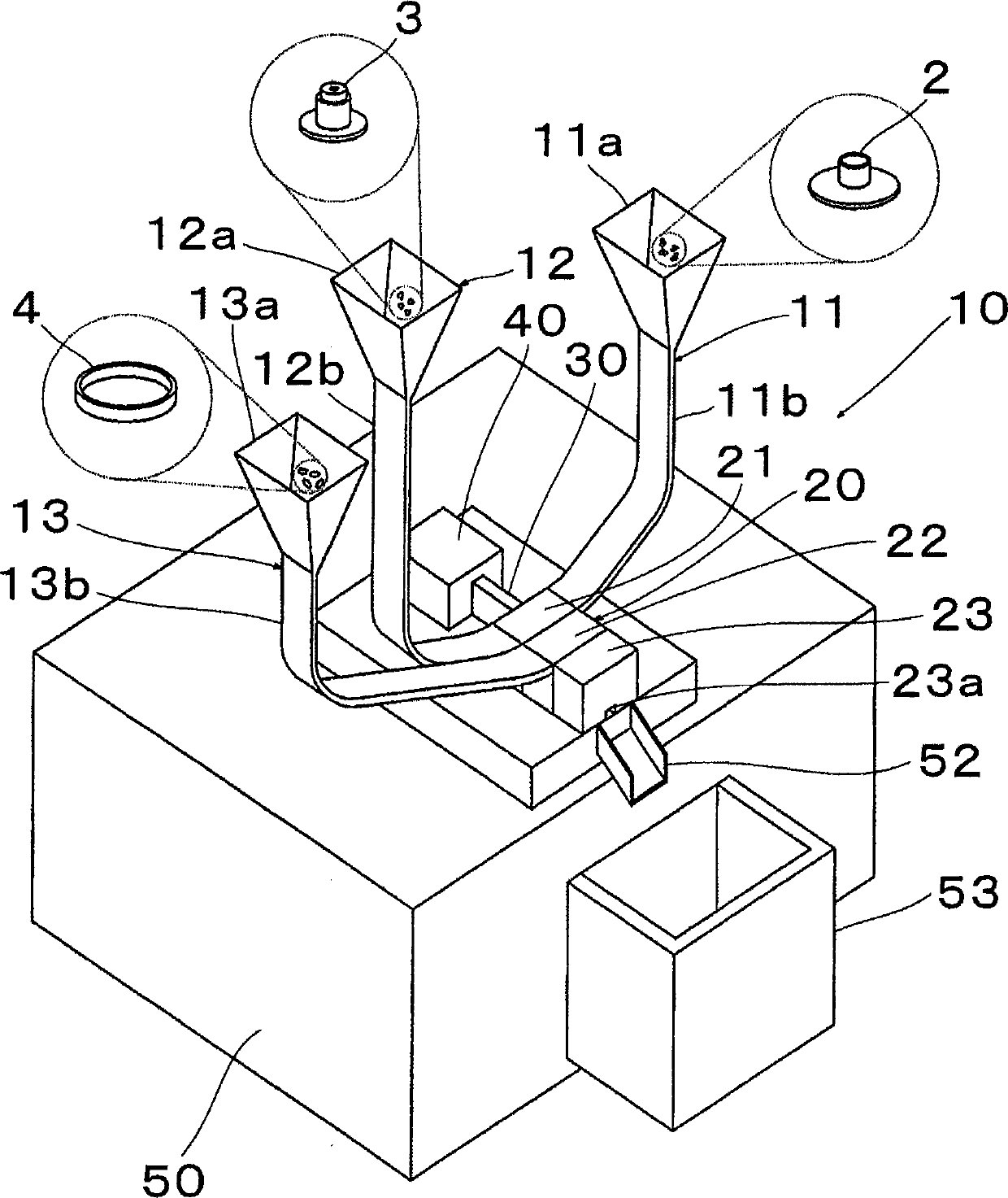

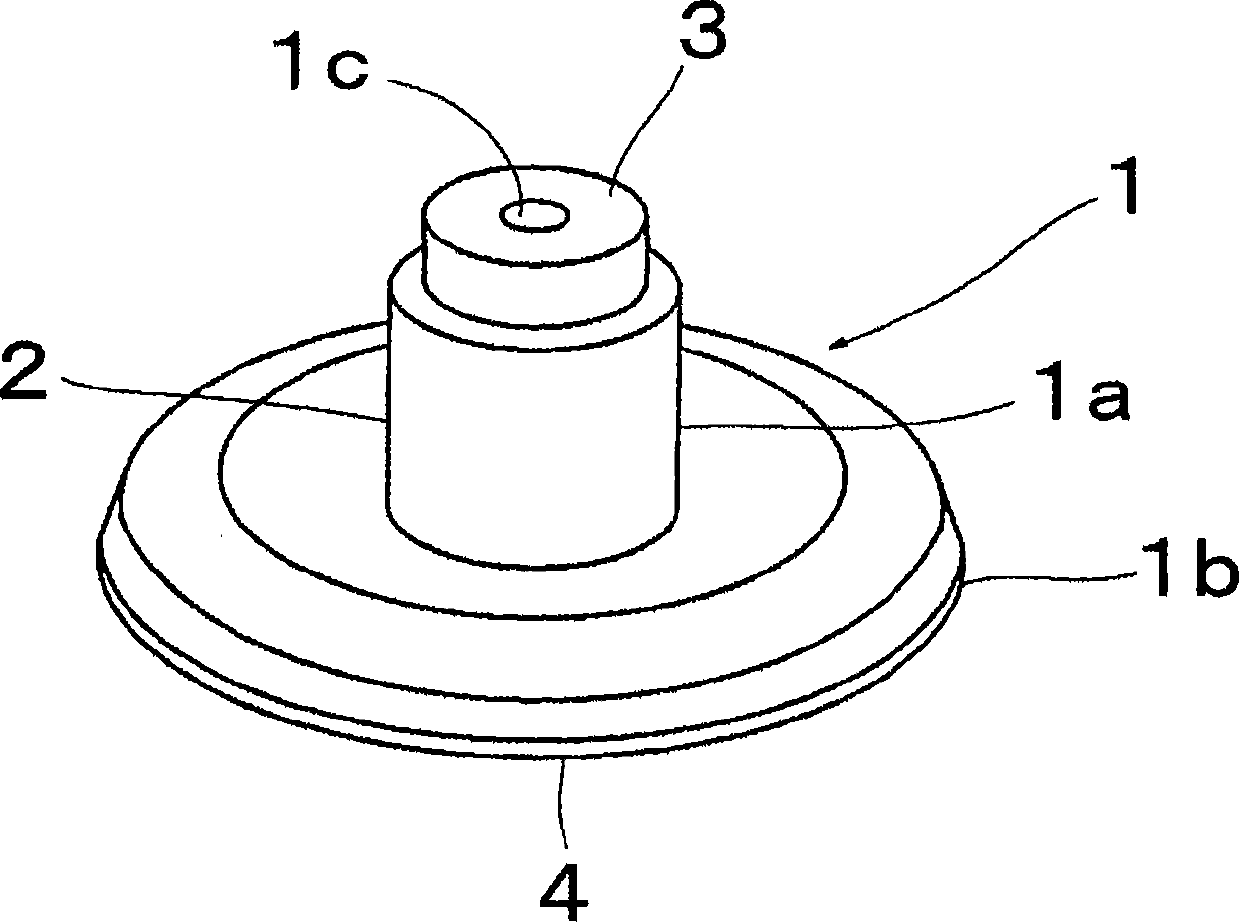

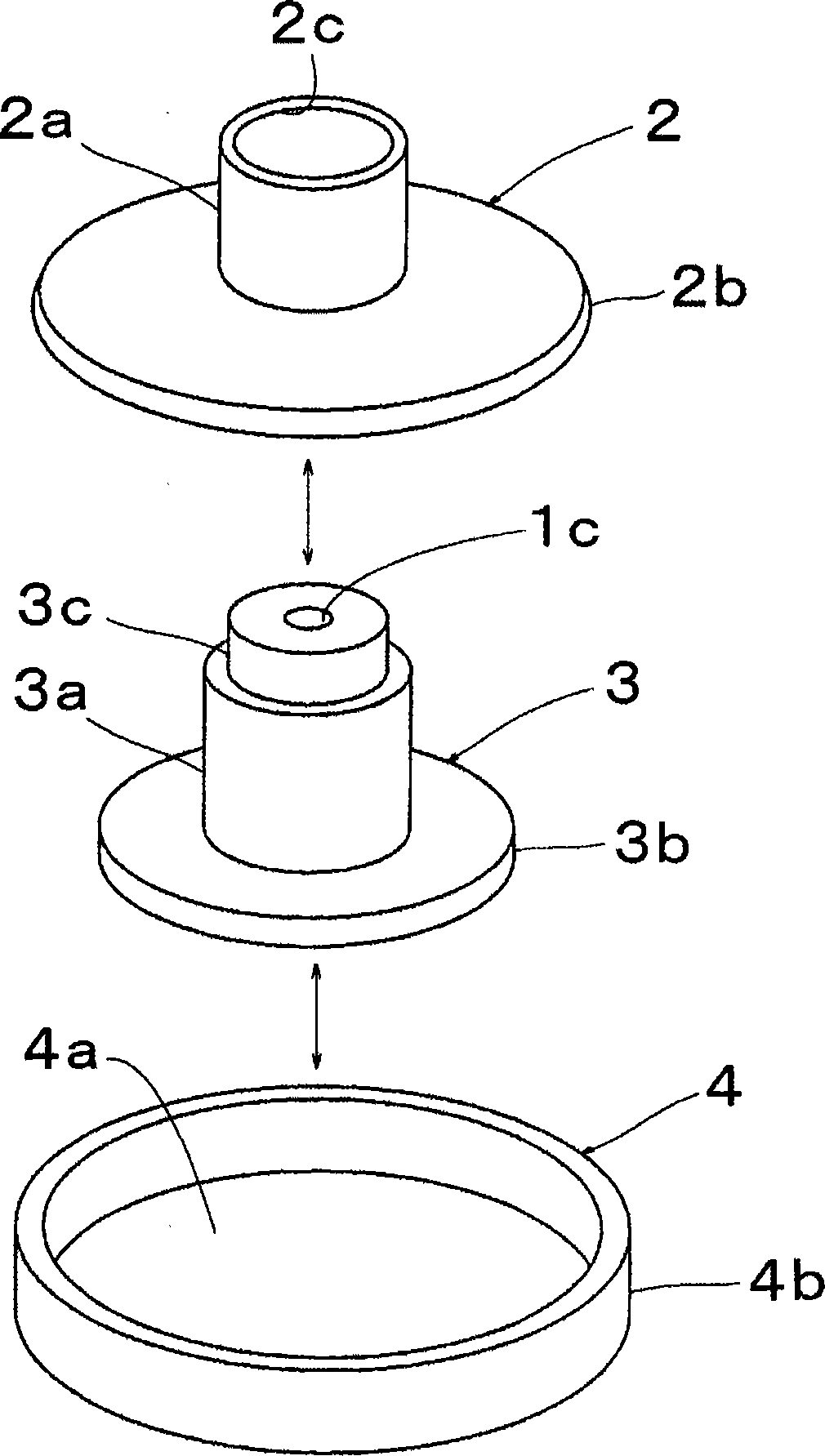

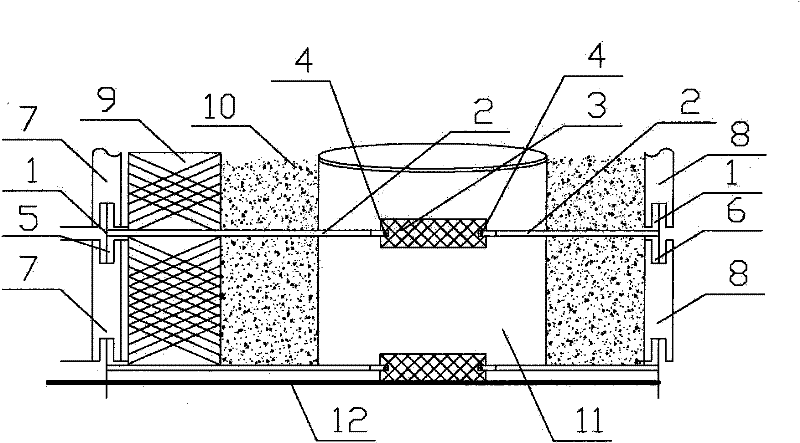

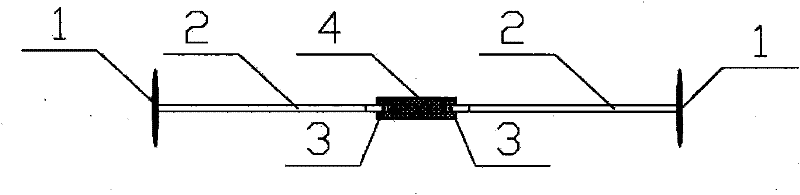

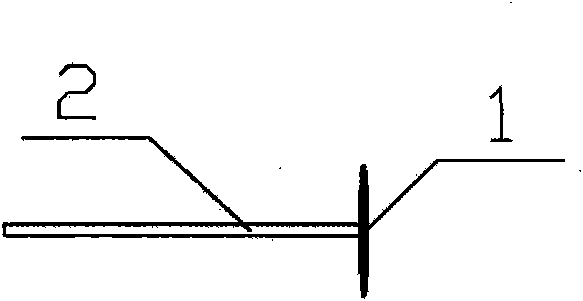

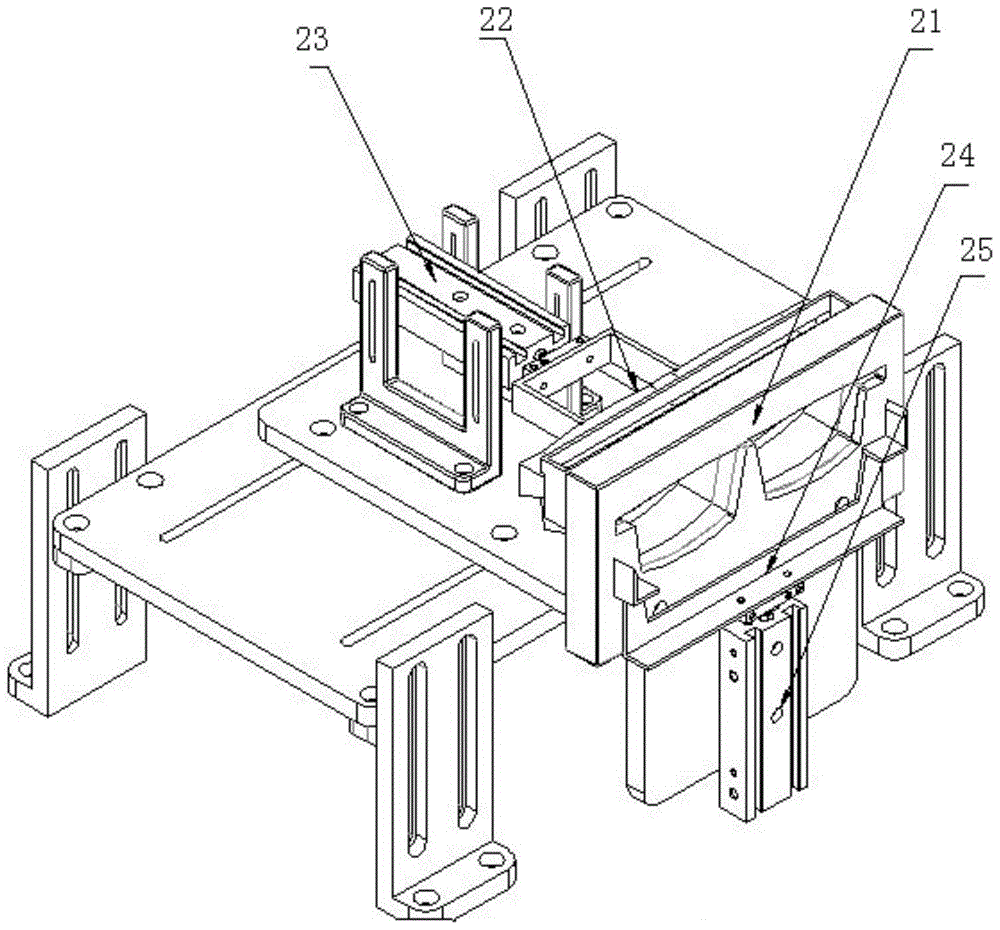

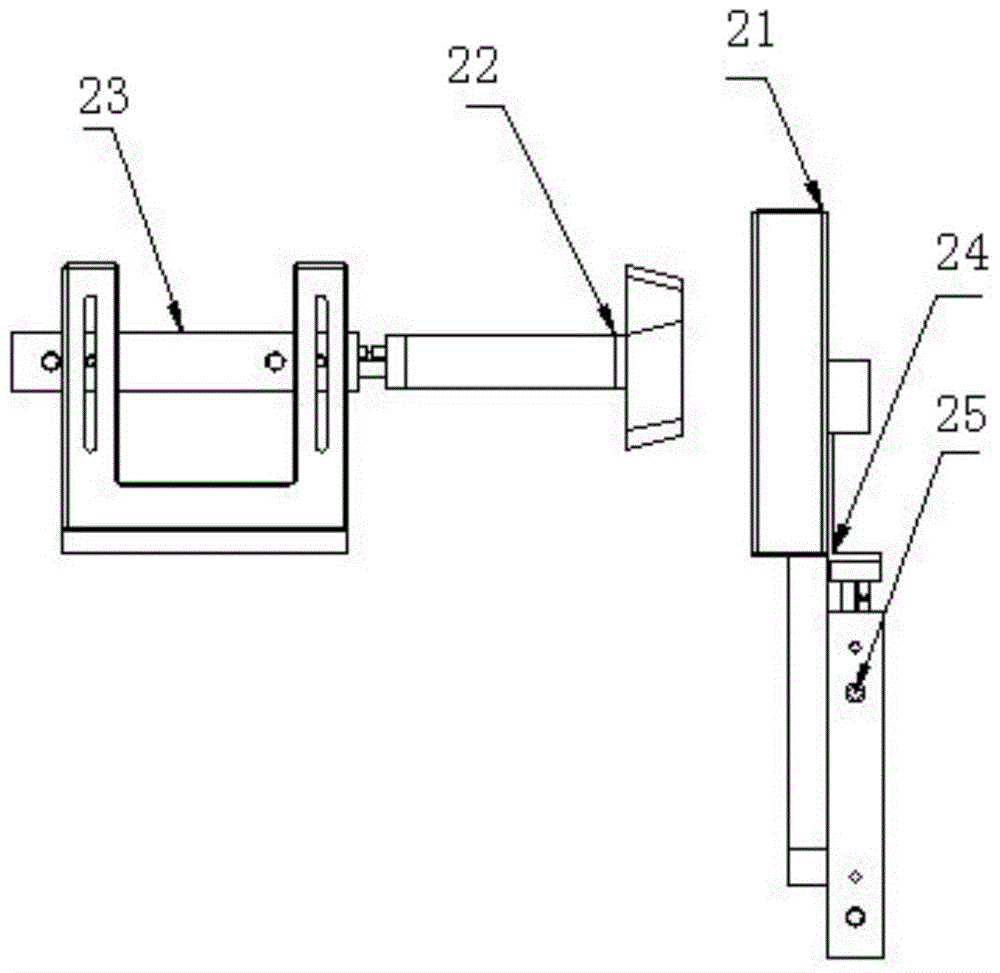

Button assembling device and button assembling method

ActiveCN102450782AContinuous assemblyClothes buttonsClothes making applicancesBiomedical engineeringStructural engineering

The present invention provides a button assembling device and a button assembling method. The buttons can be continuously assembled, wherein each button is composed of a body component, an insertion component and a housing component. The button assembling device (10) comprises the following components: a first unit (21) which is supplied to the body component (2) and the insertion component (3); a second unit (22) which combines the body component (2) and the insertion component (3) for obtaining an intermediate assembling member (1d), and furthermore the second unit (22) is supplied to the housing component (4); a third unit (23) which rivets the housing component (4) on the intermediate assembling member (1d) for obtaining the button (1); and a pushing member (30) which continuously reciprocates between a leading-in position and a projection position. Through the movement of the pushing member (30) from the leading-in position to the projection position, the intermediate assembling member (1d) and the housing component (4) in the second unit (22) are moved to the third unit (23), and furthermore the button (1) in the third unit (23) is discharged to outside.

Owner:YKK CORP

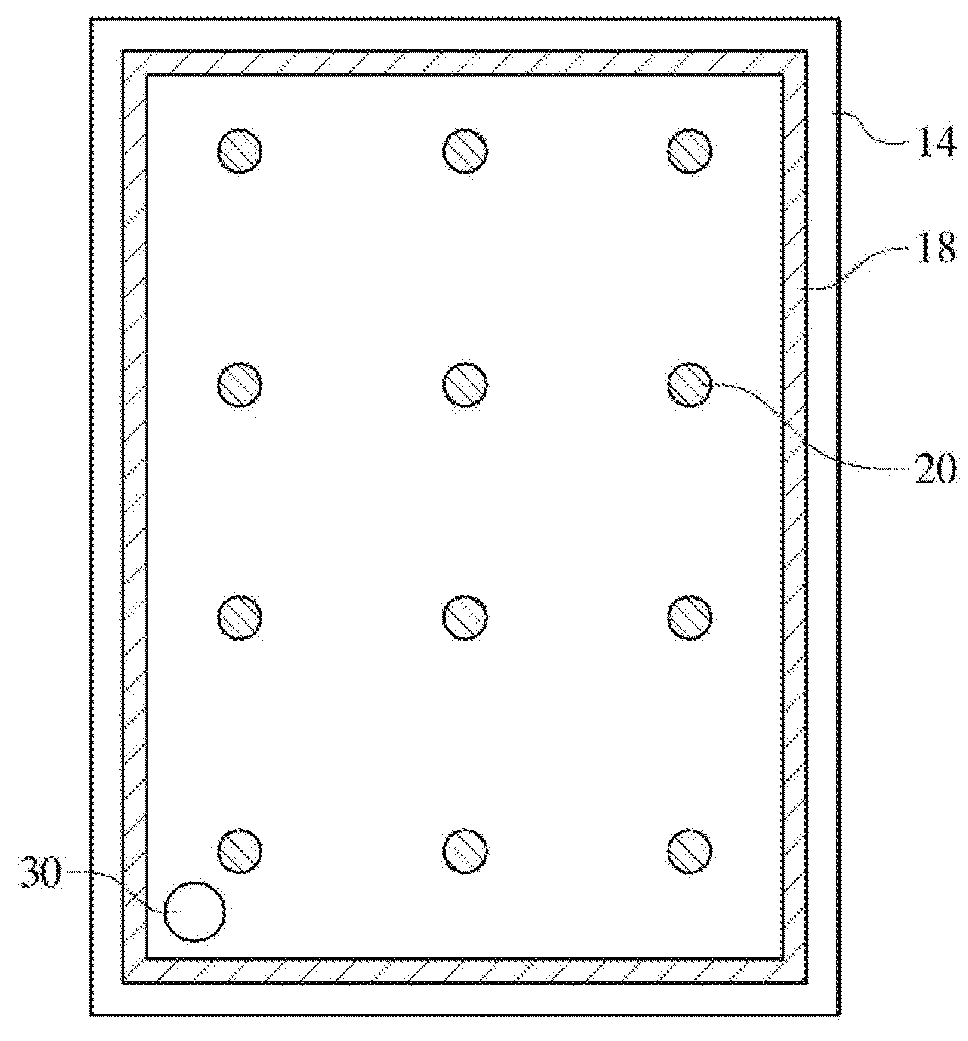

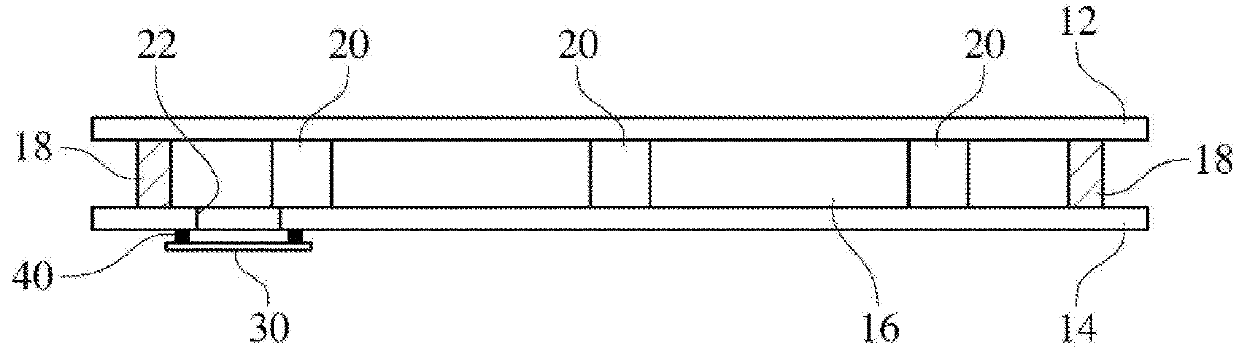

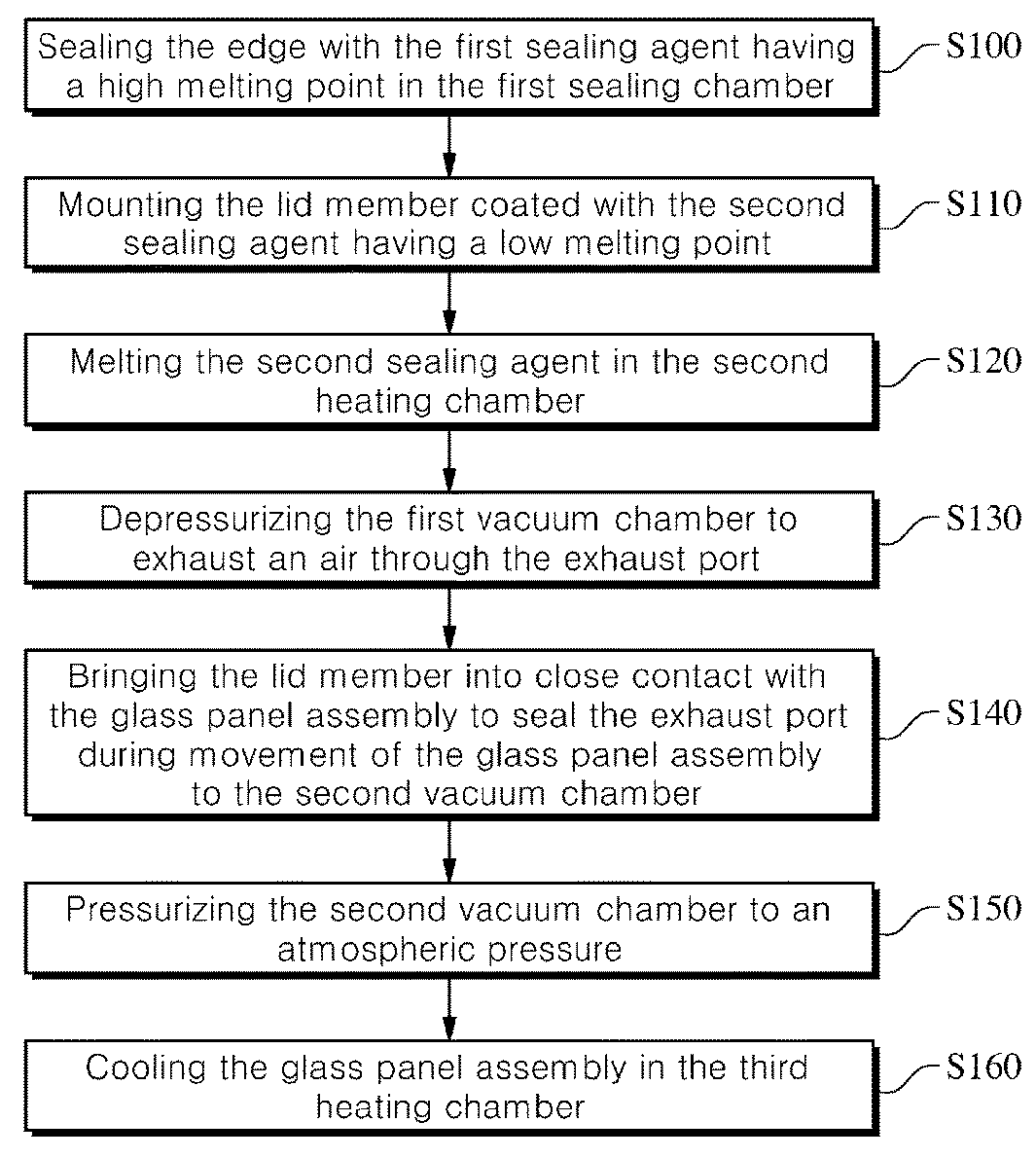

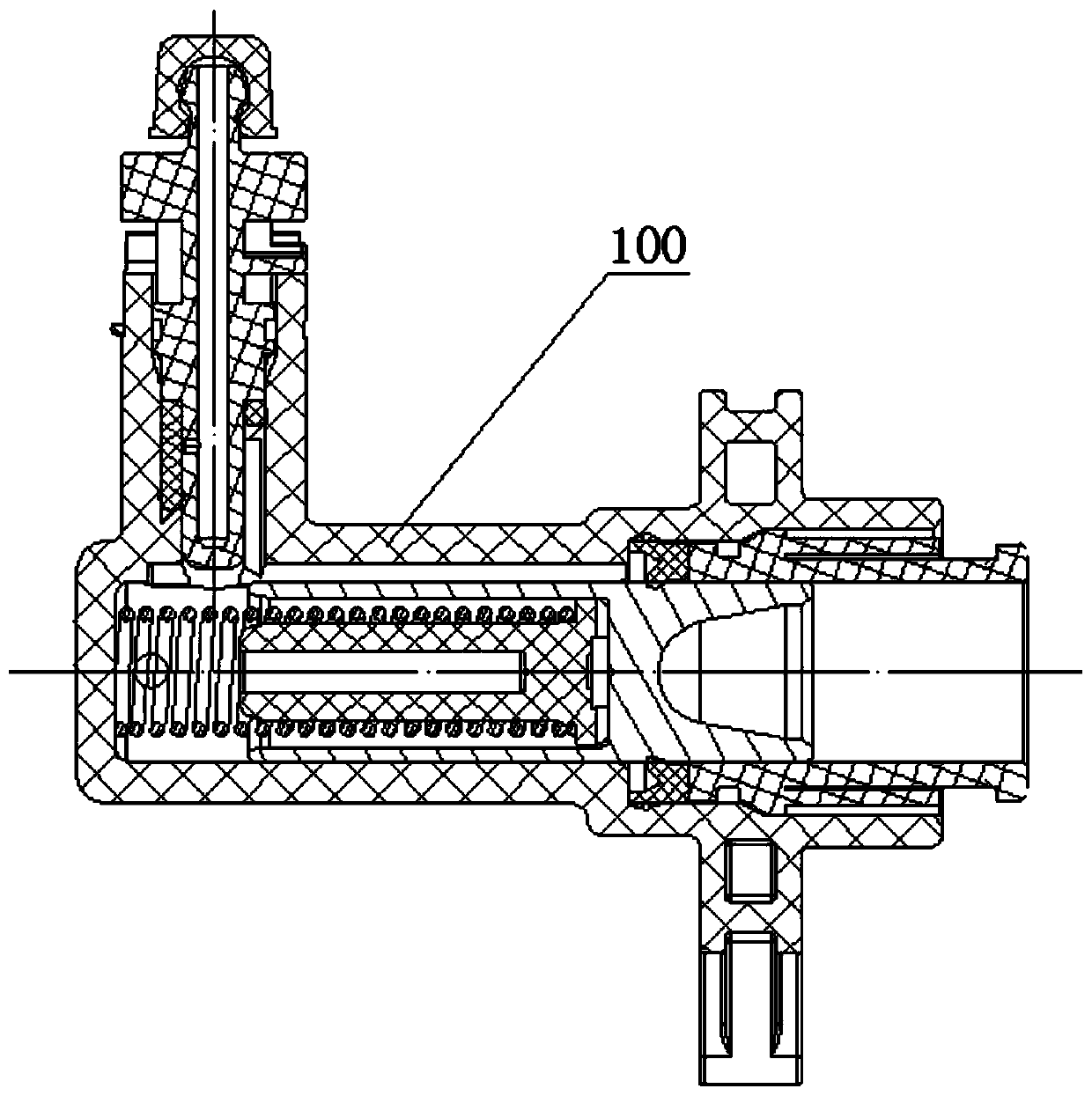

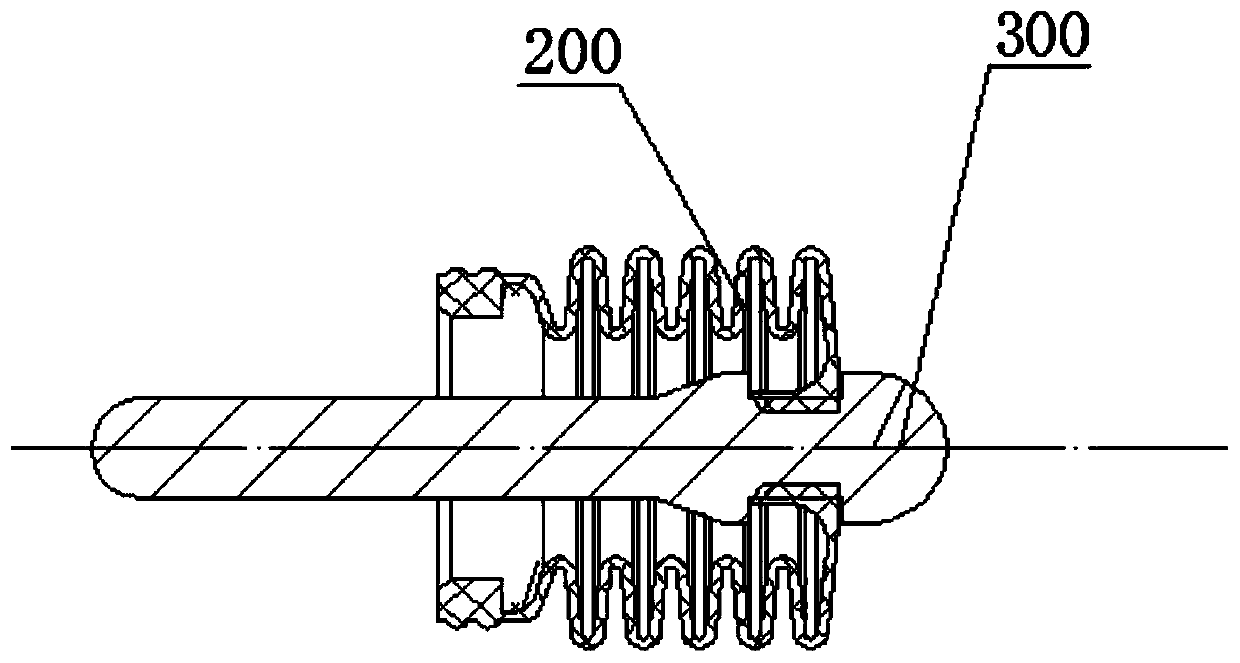

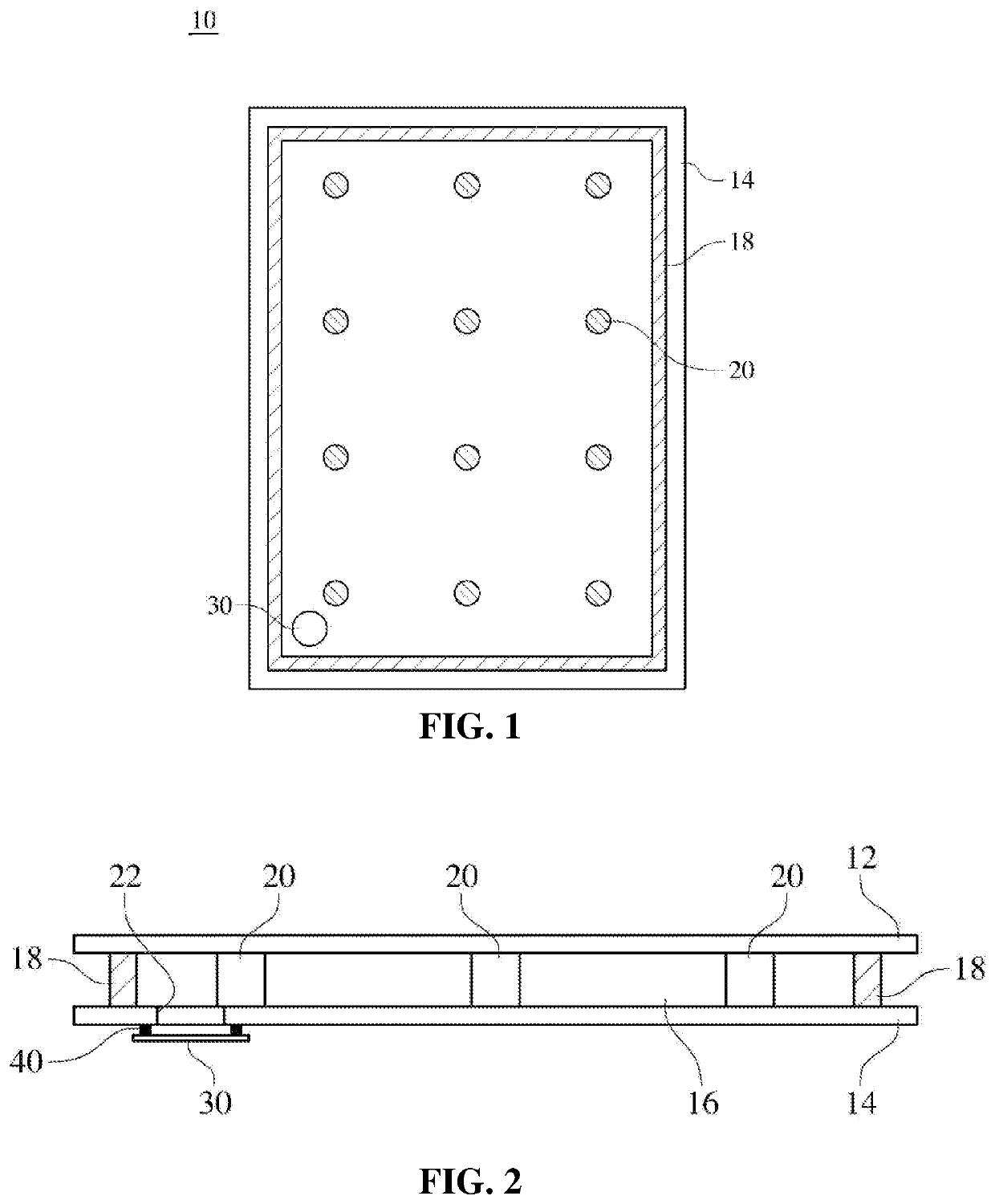

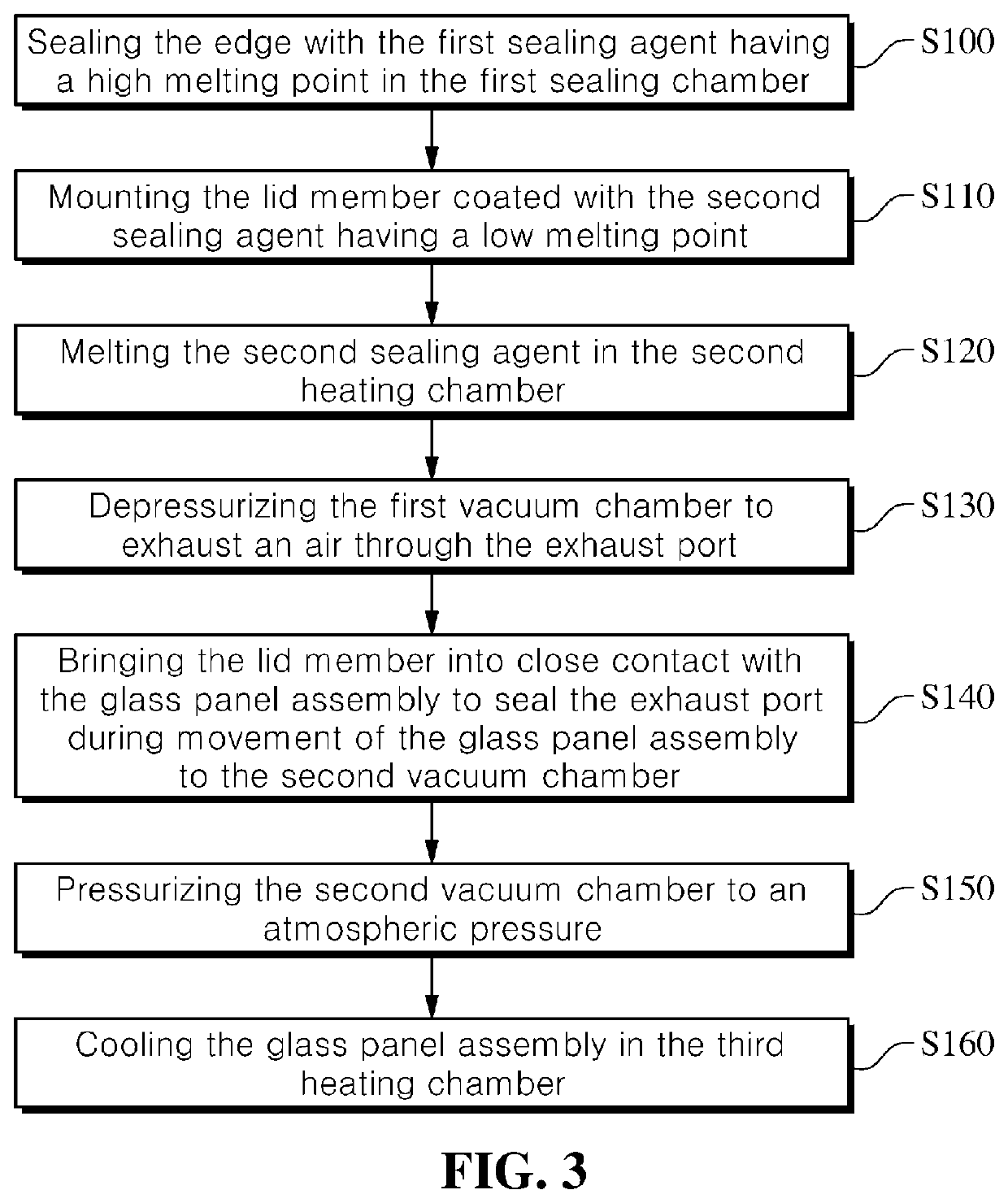

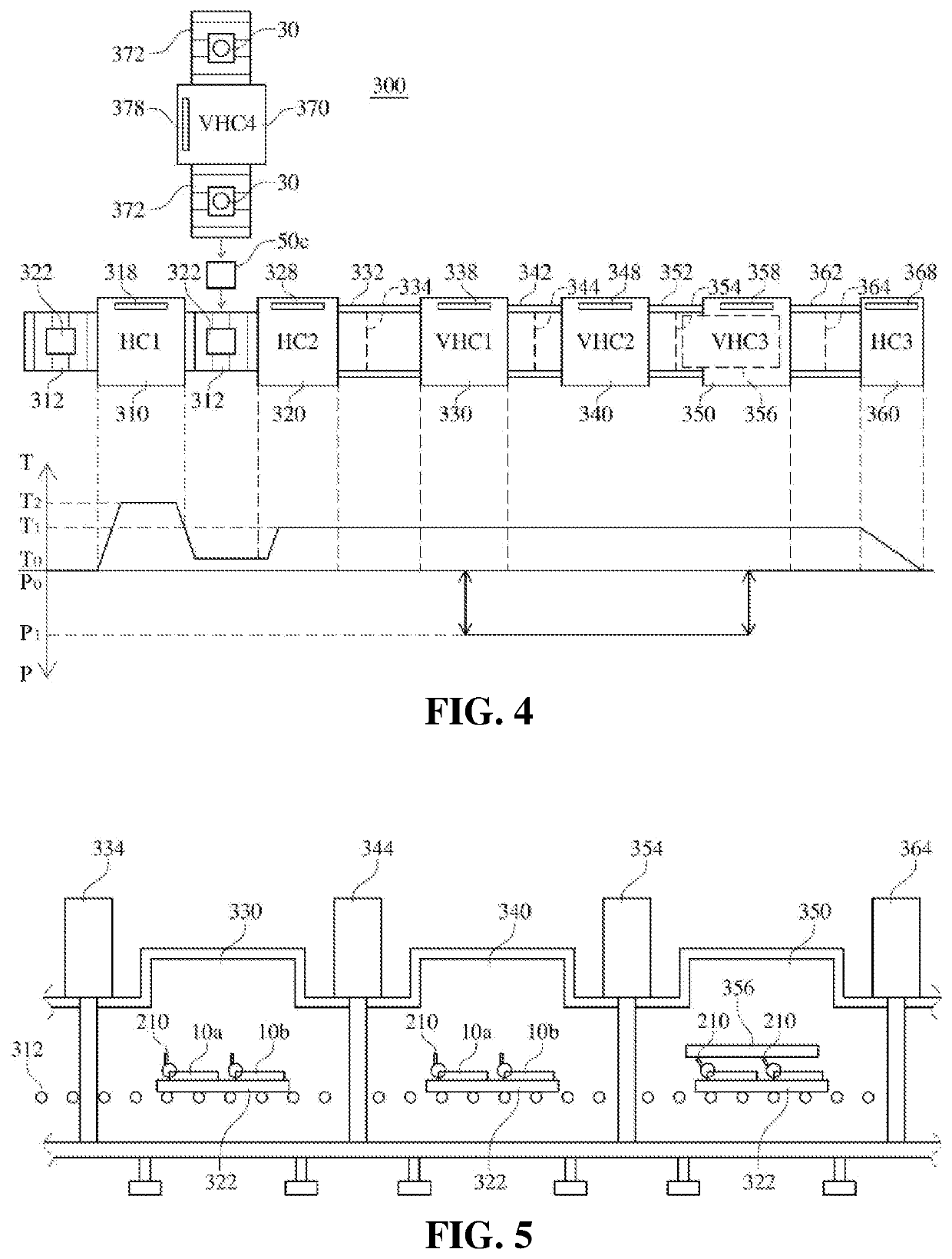

Vacuum insulation glass panel assembly manufacturing method and apparatus

ActiveUS20190210917A1Continuous assemblyLow costThermal insulationDoors/windowsEngineeringLow melting point

Provided is a vacuum insulation glass panel assembly manufacturing method and apparatus. The vacuum insulation glass panel assembly manufacturing method includes an edge sealing step of sealing an edge of a glass panel assembly of glass panels spaced apart at a predetermined interval, and an exhaust port sealing step of causing a lid member to seal an exhaust port of the glass panel assembly formed so as to communicate with a space between the glass panels whose edges are sealed. A glass solder having a high melting point is used in the edge sealing step, and a glass solder having a low melting point is used in the exhaust port sealing step. A specially designed lid member closing device is used for exhaust port sealing.

Owner:PARK JE IL

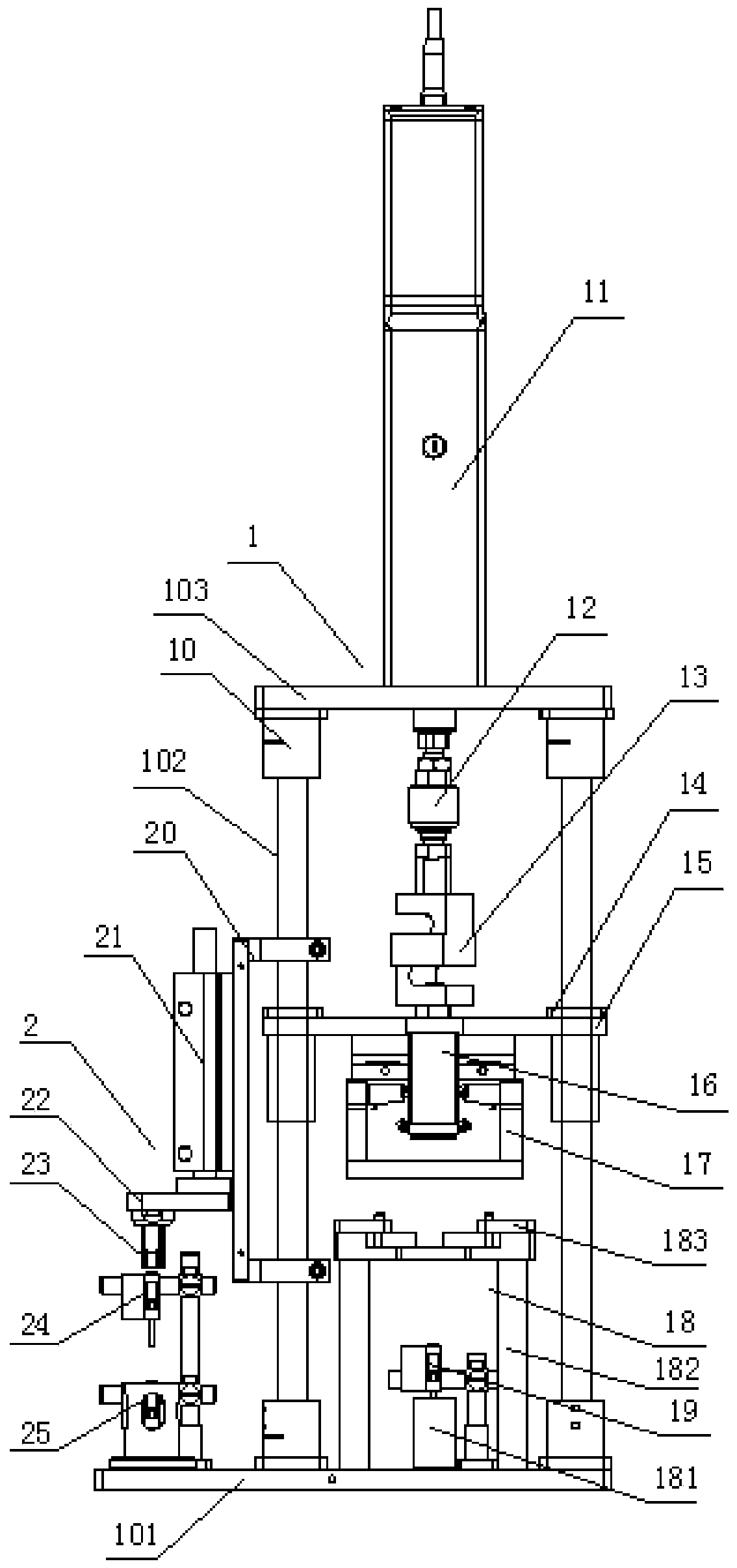

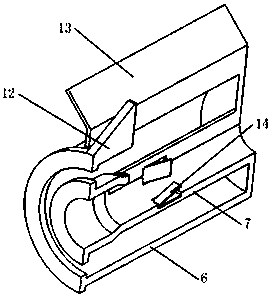

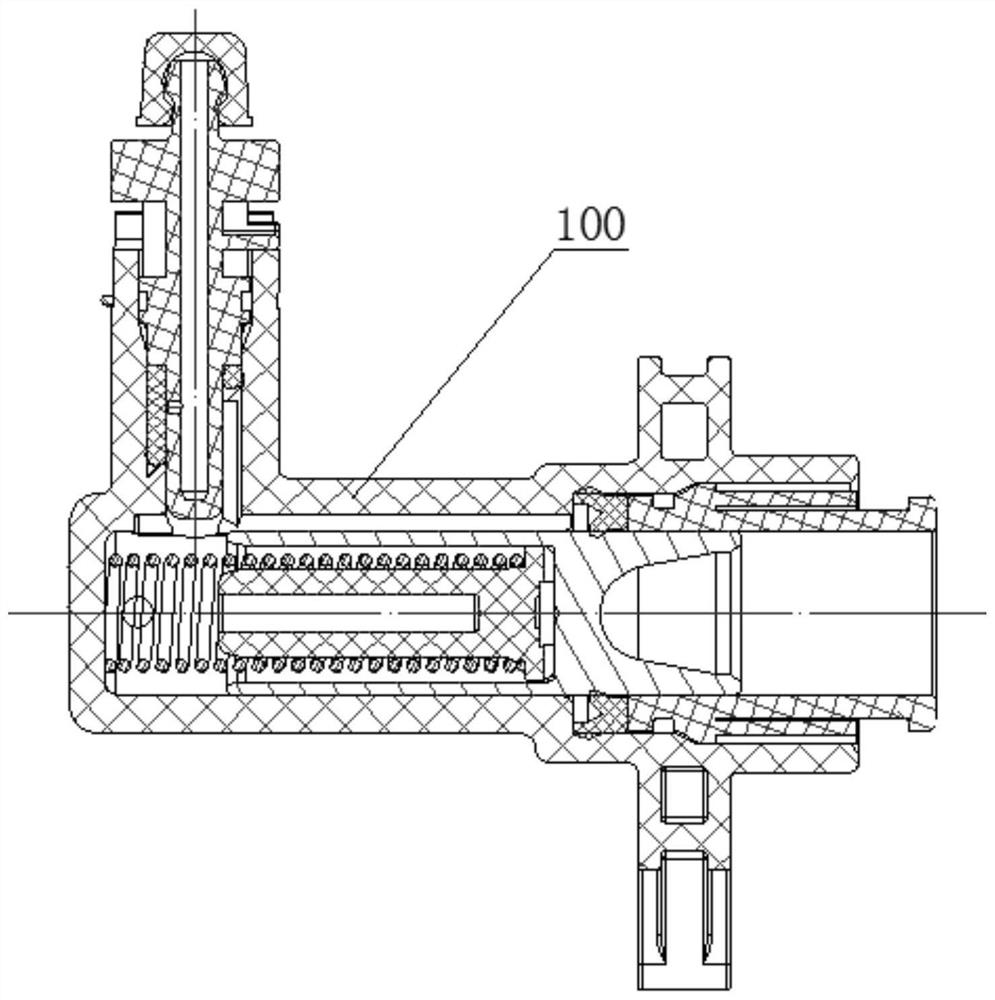

Clutch working cylinder shield and cylinder block assembly press fitting and detection device

ActiveCN110561082AContinuous assemblyContinuous pull-off testMachine part testingMetal working apparatusSlide plateEngineering

The invention discloses a clutch working cylinder shield and a cylinder block assembly press fitting and detection device. The clutch working cylinder shield and the cylinder block assembly press-fitting and detection device comprises a machine frame, a cylinder block assembly positioning structure, a shield and push rod assembly positioning structure, a press fitting and pull-off driver and a pressure sensor; the machine frame comprises a bottom plate, a top plate and stand columns, wherein the stand columns are fixed between the bottom plate and the top plate, and the cylinder block assemblypositioning structure is arranged on the bottom plate and is used for positioning the cylinder block assembly; the shield and push rod assembly positioning structure is arranged on a sliding plate which can slide up and down in the stand columns and is used for positioning the shield and push rod assembly; the press fitting and pull-off driver is arranged on the top plate and is used for drivingthe sliding plate to ascend and descend; when the press fitting and pull-off driver drives the sliding plate to descend, and the shield and push rod assembly and the cylinder assembly are pressed together; the pressure sensor is connected between the press fitting and pull-off driver and the sliding plate, and is used for detecting the pull-off force between the shield and push rod assembly and the cylinder assembly when the press fitting and pull-off driver drives the sliding plate to ascend. According to the clutch working cylinder shield and the cylinder block assembly press fitting and detection device, the shield and push rod assembly and the cylinder assembly are pressed together, and after press fitting is completed, and the shield pull-off test is automatically entered, so that theassembly and detection efficiency is improved.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

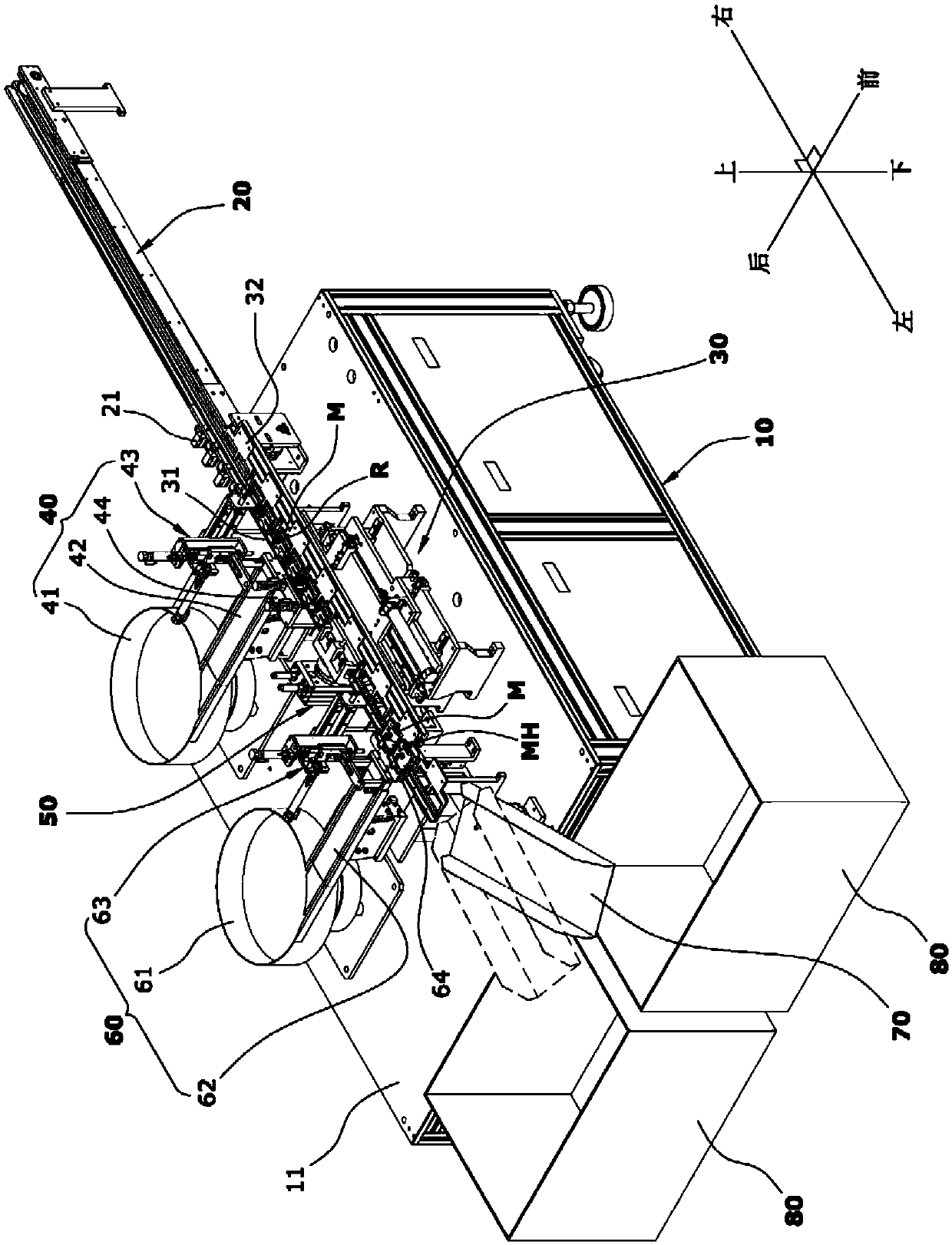

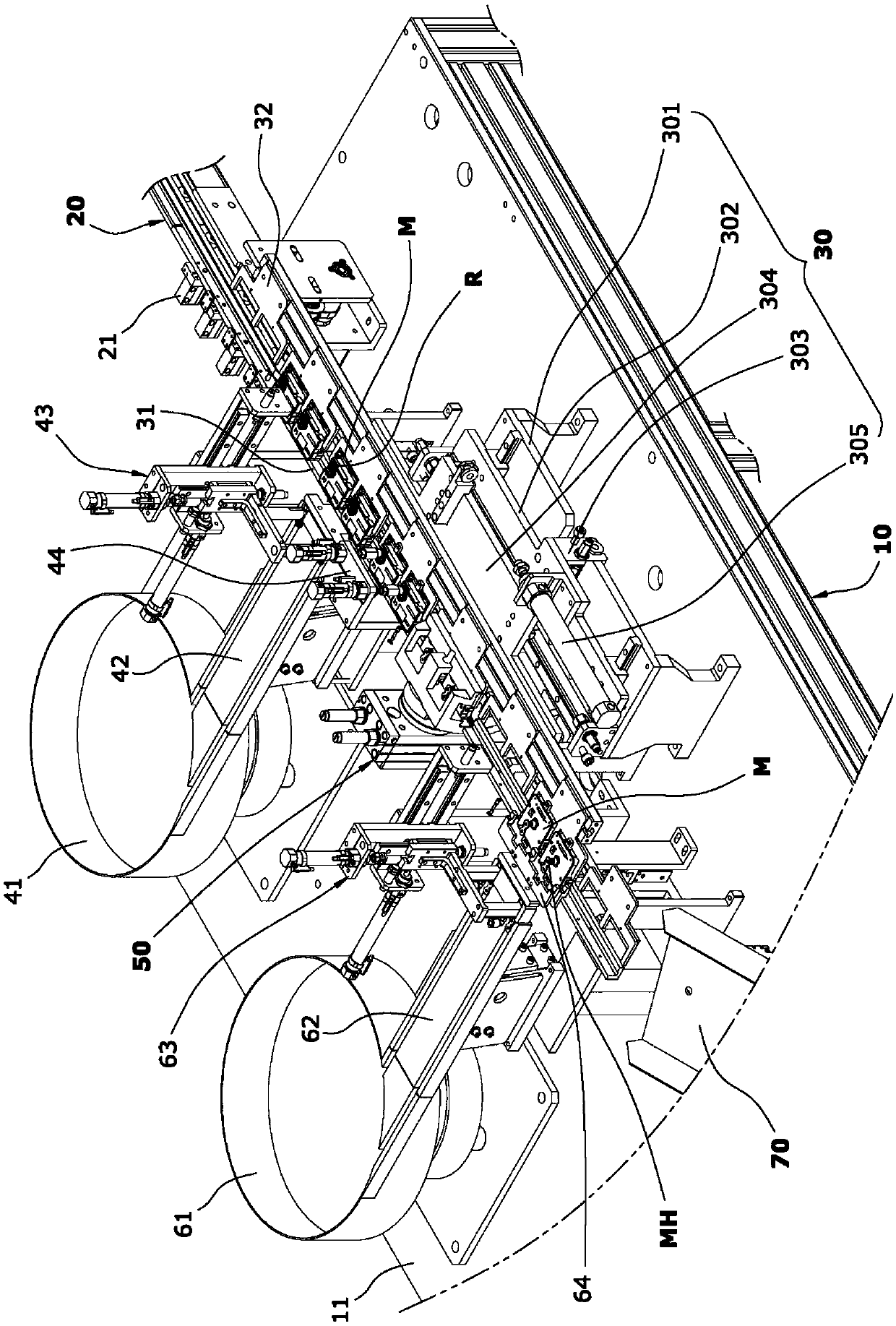

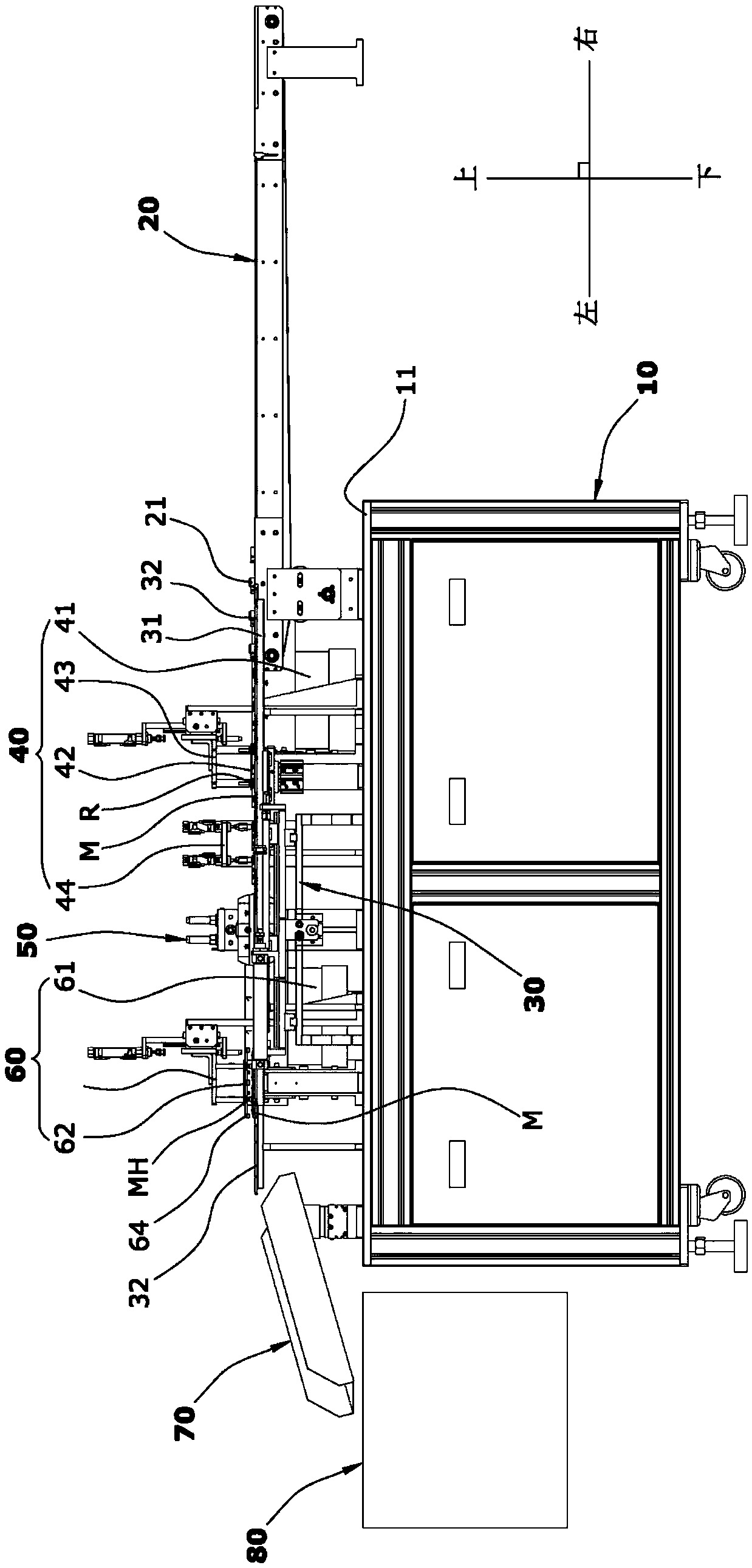

Automatic setting knob and minute hand assembling machine for clock

The invention discloses an automatic setting knob and minute hand assembling machine for a clock. The automatic setting knob and minute hand assembling machine comprises a rack with a table face, a movement conveying belt mechanism for conveying to-be-assembled movements is mounted on the right side of the table face, a sliding groove used for outputting finished movements is formed in the left side of the table face, and a movement carrying device used for shifting the movements from the movement conveying belt mechanism into the sliding groove in a stepping mode is mounted in the front of the table face; and a setting knob pressing-in machine, a movement overturning machine and a minute hand pressing-in machine which are used for conducting assembling operation on the movements shifted by the movement carrying device are sequentially mounted on the table behind the movement carrying device from right to left. According to the automatic setting knob and minute hand assembling machine,the setting knob pressing-in machine, the movement overturning machine and the minute hand pressing-in machine replace manual work to automatically, stably and continuously assemble and crimp settingknobs and minute hands onto the movements to be assembled, the production efficiency is high, the yield is high, and the production cost of clock movement assembling by manufacturers can be greatly lowered.

Owner:XIAMEN UNIV OF TECH +1

Explosion-proof type electric heating pipe processing device and technology

ActiveCN112621209AContinuous assemblySolve the problem of reduced heating efficiencyAssembly machinesMetal working apparatusEngineeringPipe

The invention discloses an explosion-proof type electric heating pipe processing device and technology. The explosion-proof type electric heating pipe processing device comprises a first conveying assembly, a second conveying assembly and mounting assemblies, wherein a first conveying line of the first conveying assembly is connected with a base; a pipe seat is arranged on the first conveying line and the first conveying line is used for transporting an explosion-proof pipe; the second conveying assembly is used for conveying electric heating wire head; the mounting assemblies are arranged on one side of the first conveying line and one side of the second conveying line and are driven through a first air cylinder; a cover plate chuck and a powder feeding pipe are arranged on one side of the first conveying line and are separately driven through a second air cylinder and a third air cylinder; and an annular welding head is arranged on the cover plate chuck. The electric heating wire head is pushed into the explosion-proof pipe through the heating head, the powder feeding pipe is moved and magnesium oxide powder is led into the powder feeding pipe, and the cover plate is fallen into the cover plate chuck from a cover plate rack and is pushed by the third air cylinder, so that the cover plate can seal the explosion-proof pipe, and the explosion-proof pipe can be welded and sealed by using the annular welding head, and thus, the explosion-proof type electric heating pipe can be quickly and continuously assembled, and the working efficiency is improved.

Owner:江苏驰迅科技有限公司

Button assembling device and button assembling method

ActiveCN102450782BContinuous assemblyClothes buttonsClothes making applicancesEngineeringStructural engineering

The present invention provides a button assembling device and a button assembling method. The buttons can be continuously assembled, wherein each button is composed of a body component, an insertion component and a housing component. The button assembling device (10) comprises the following components: a first unit (21) which is supplied to the body component (2) and the insertion component (3); a second unit (22) which combines the body component (2) and the insertion component (3) for obtaining an intermediate assembling member (1d), and furthermore the second unit (22) is supplied to the housing component (4); a third unit (23) which rivets the housing component (4) on the intermediate assembling member (1d) for obtaining the button (1); and a pushing member (30) which continuously reciprocates between a leading-in position and a projection position. Through the movement of the pushing member (30) from the leading-in position to the projection position, the intermediate assembling member (1d) and the housing component (4) in the second unit (22) are moved to the third unit (23), and furthermore the button (1) in the third unit (23) is discharged to outside.

Owner:YKK CORP

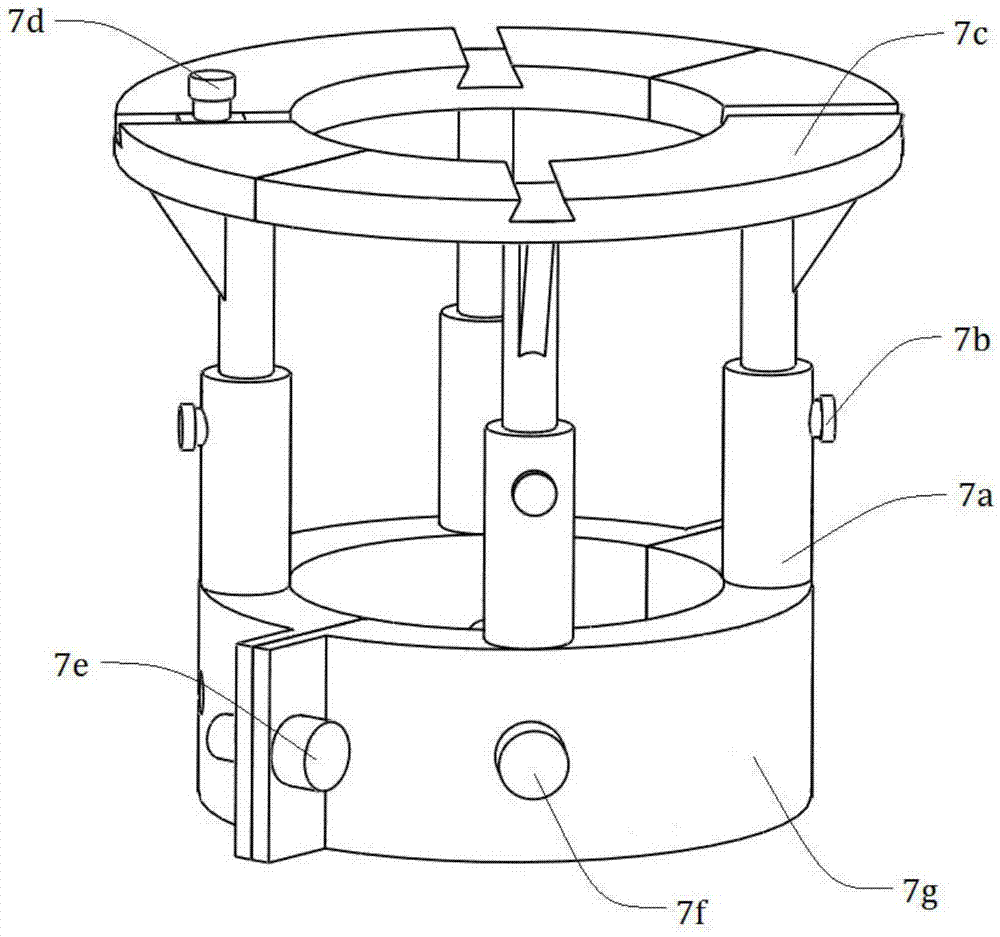

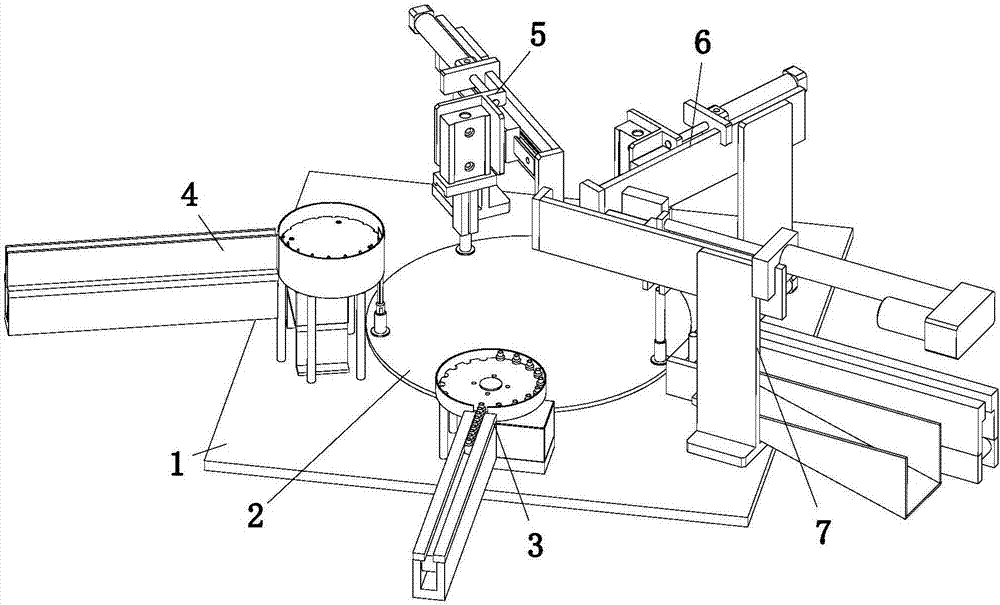

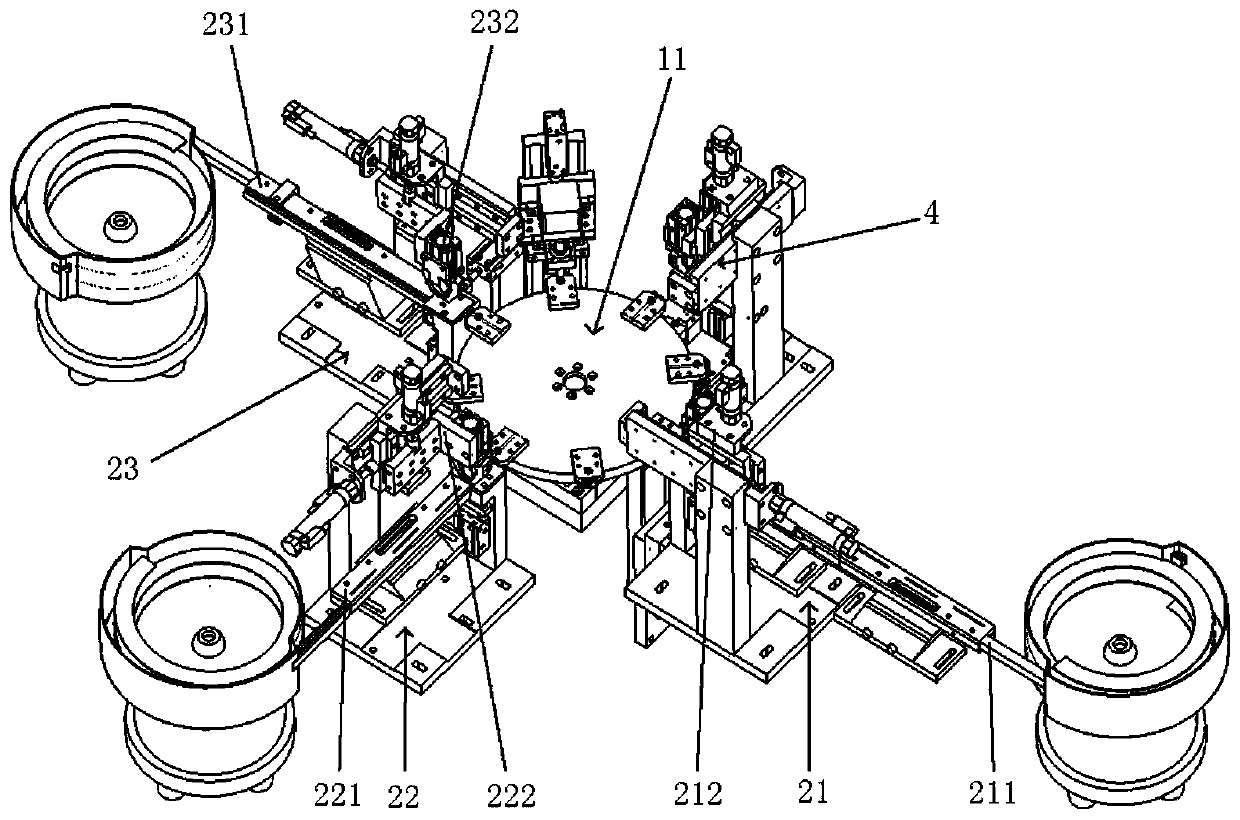

Assembling device for button fixing members

ActiveCN107568843AContinuous assemblyDoes not dent the bottomClothes buttonsWork in processWaste management

The invention provides an assembling device for button fixing members which can continuously assemble button fixing members having good appearances and high quality. When the assembling device (1) uses a claw (102) for allowing a pair of pins (102b) to protrude out of a base (102a), and a part of a housing (103) having a side wall portion (103b) arranged along the outer periphery of a bottom (103a) to assemble a finished product (101) of a button fixing member, the base having the claw (102) arranged on an inner side of the side wall portion of the housing can allow the side wall portion of the housing to deform inward so as to fix the housing on the claw (102). The assembling device (1) includes a part feeding portions (2, 3), a separated product pushing rod (4), a pair of part supportingcomponents (5), a first processing portion (6), a semi-finished product pushing rod (7), a pair of semi-finished product supporting components (8), and a second processing portion (9).

Owner:YKK CORP

Mold pipe building construction technology

InactiveCN101858143BSimple methodContinuous assemblyRoof covering using slabs/sheetsRoof covering using tiles/slatesArchitectural engineeringSolar water heating system

The invention provides a mold pipe building construction technology, which is a construction technology used in 1-6 floors of a frame structure cast-in-place concrete building, and belongs to the building field. The invention provides nine series of templates and nine series of mold pipes, replaces the production mode with many working procedures, long construction period, low speed and rough effect in the existing technology, can construct in an manner of one-by-one continuous fabrication, builds a six-storeyed building in about ten days, has the characteristics of decorated inner and outer wall surfaces, heat-insulted outer wall outer layer and perfect combination of a solar energy water heating system and a historic building roof, firmness, energy conservation, economy, beauty and obvious comprehensive benefits, and is a novel method capable of being widely in various building constructions.

Owner:徐学文

An automatic riveting machine used for lamp head assembly rivet conveying and correction

Owner:芜湖邦为诺能源科技有限公司

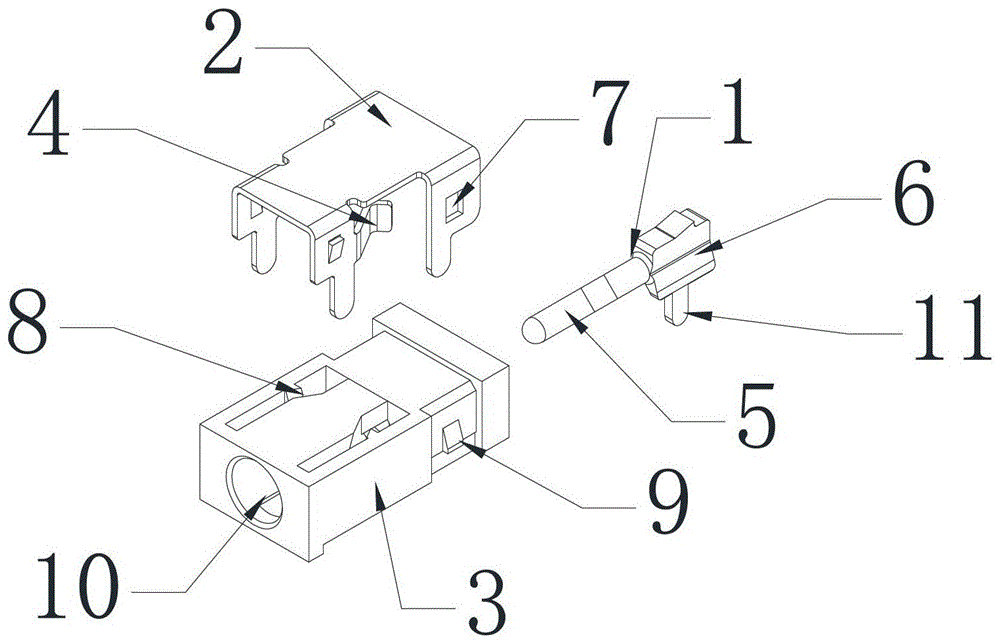

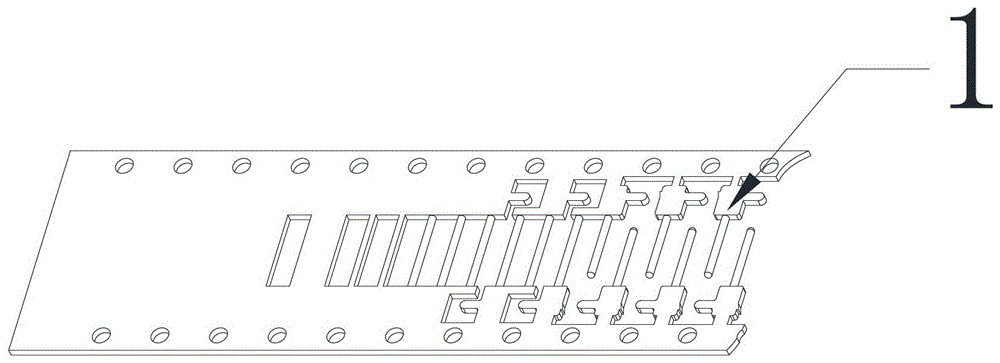

A kind of preparation method of power socket and power socket

ActiveCN103066477BHigh current resistanceIncrease productivityContact member manufacturingContact member cases/bases manufacturePunchingAutomatic control

The invention discloses a preparation method of a power supply female socket. The preparation method of the power supply female socket is characterized by comprising the following steps: (1) a continuous punching die group is arranged, and the continuous punching die group successively conducts punching, opening cutting , reforming and blanking to form an integrated-typed copper inner pole PIN; (2) a continuous punching die group is arranged, and the continuous punching die group successively conducts punching, opening-cutting, reforming and dropping on a copper plate and an integrated-typed outer pole shell body is formed; (3) a continuous injection mould die group is arranged, plastic cement is injected and molded through the continuous injection mould die group and an integrated-type rubber core with a hollow interior is formed; (4) a programmable logic controller (PLC) automatic control assembling machine is arranged, the inner pole pin which is obtained in the step (1) and the outer pole shell body which is obtained in the step (2) are respectively inserted into the rubber core which is obtained in the step (3) and compacted tightly and form the power supply female socket. The invention further discloses a power supply female socket which is prepared according to the method.

Owner:SHENMING ELECTRONICS DONGGUAN

A laser transmitter assembly equipment for a laser level

ActiveCN114535969BContinuous assemblyFinal product manufactureActive open surveying meansLaser transmitterRobot hand

The invention discloses a laser transmitter assembling equipment for a laser level, comprising: a laser transmitter supply device for conveying the laser transmitters to be assembled of the laser level; an active pairing device arranged above the laser transmitter supply device , the active pairing device is used to drive the support frame of the laser level to be paired and installed with a plurality of laser emitters on the laser emitter supply device in sequence; the pressing down matching mechanism is connected with the rotation switching mechanism , the press-down pairing mechanism is used to drive the support frame to move downward so that the laser transmitter on the laser transmitter conveying device is matched in the support frame; the present invention uses an active pairing device to drive the support of the laser level. The seat frame is paired with multiple laser transmitters in sequence, which is different from the way of directly using a robot to grab the laser transmitter and the support frame for installation, so that the entire device is not limited by the specific shape of the laser transmitter.

Owner:南通亨德利电动工具有限公司

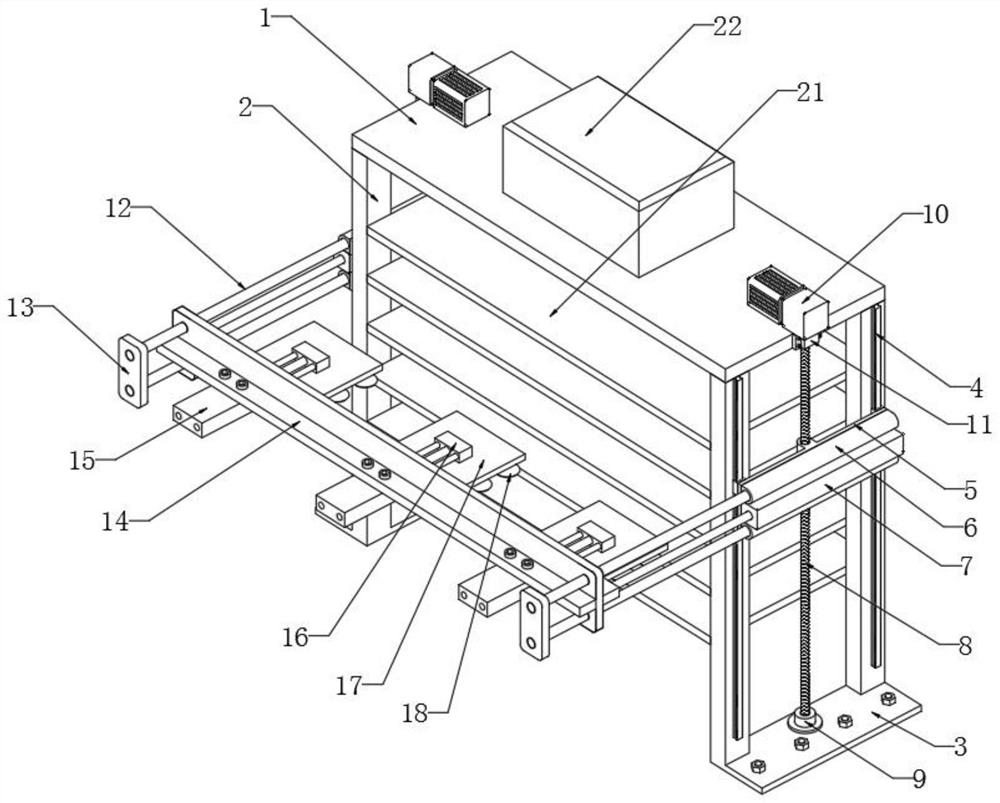

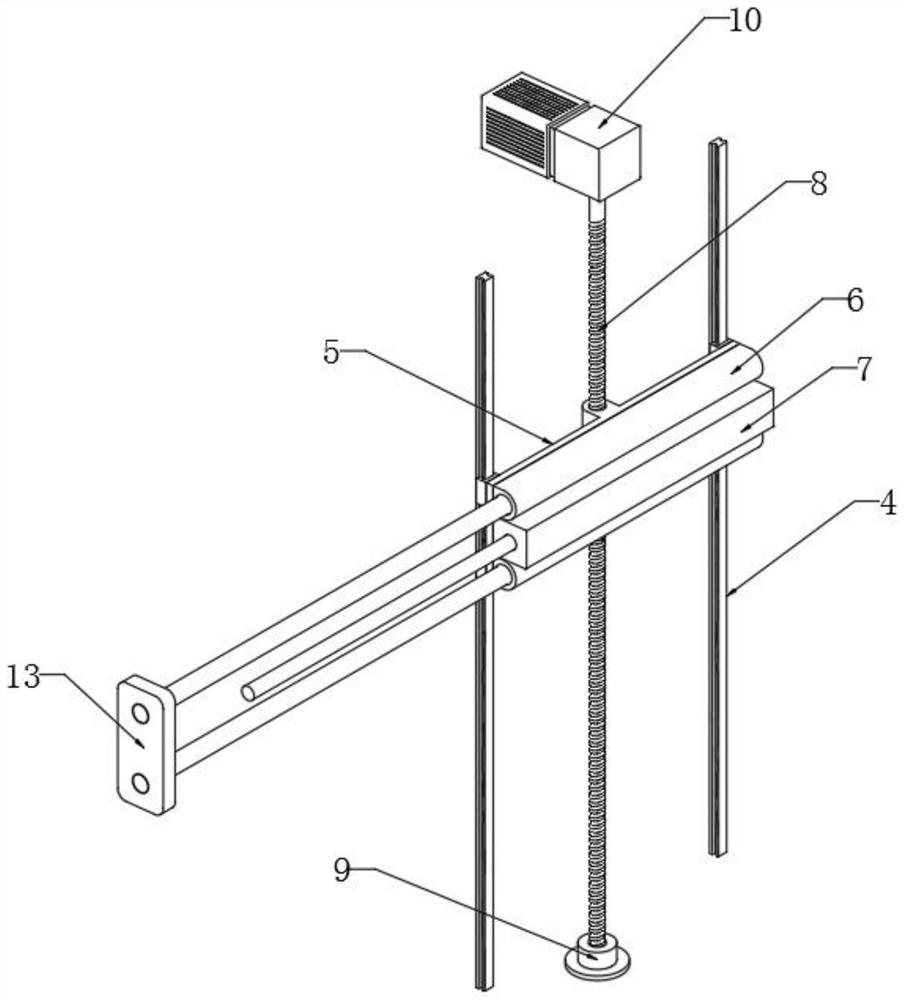

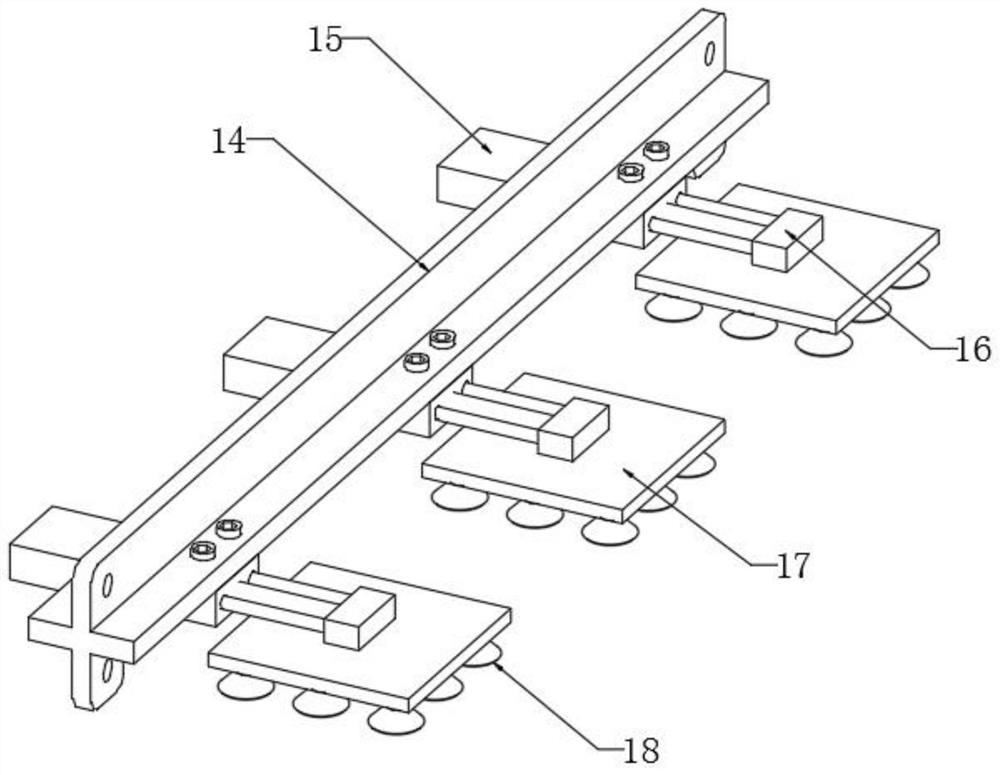

A vacuum suction cup device for insulating glass inflatable line

ActiveCN112607427BIncrease productivityContinuous assemblyCharge manipulationConveyor partsElectric machineryEngineering

Owner:山东阅航环保科技有限公司

A pressing device for magnet and spring sheet in stator

ActiveCN106067713BAutomate assemblyContinuous assemblyManufacturing stator/rotor bodiesEngineeringMagnet

Owner:SUZHOU GUOZHIFU AUTOMATION EQUIP

Screw positioning recharging device

InactiveCN108747944AImprove securityImprove installation qualitySpannersWrenchesScrew positionEngineering

The invention discloses a screw positioning recharging device. The screw positioning recharging device comprises a shell; and a sleeving connecting structure used for being connected with the front end of an electric screw batch body in a sleeved mode is arranged at the back end of the shell, a first positioning pipe which is horizontally arranged is arranged at the front end of the shell, the inner diameter of the first positioning pipe is between double and twice that of the big head end of the used screw in the electric screw batch body and arranged by directly facing the front of the batchhead, the first positioning pipe can slide backwards by relying on a guiding structure, and when the first positioning pipe slide backwards, the batch head can penetrate through the first positioningpipe and push the screw out of the first positioning pipe to complete screw screwed connecting. According to the screw positioning recharging device, individually customizing can be achieved, the sleeving connecting structure is connected with the electric screw batch in a sleeved mode, an inner cavity of the first positioning pipe can be used for storing the screw, the vertical wall is propped at the front end of the first positioning pipe during using, the electric screw batch is pushed frontwards, the first positioning pipe moves backwards, and the screw nailing-in and screwed connecting are achieved; and the damage to the hands or other parts of a human body of an operator caused by the exposure of the screw and the batch head is avoided.

Owner:YANGTZE NORMAL UNIVERSITY

Pneumatic Glasses Assembly Machine

The invention discloses a pneumatic glasses assembling machine. The pneumatic glasses assembling machine comprises a glasses frame mechanism used for clamping a glasses frame, glasses leg mechanisms used for clamping glasses legs and located on the two sides of the glasses frame mechanism, a feeding mechanism, a screw assembling mechanism and a control mechanism, wherein the glasses leg mechanisms can be moved to the work positions matched with the glasses frame mechanism to finish assembling of glasses components; the feeding mechanism is used for carrying out feeding for the glasses frame mechanism and the glasses leg mechanisms; the screw assembling mechanism is used for finishing assembling of the glasses components; the control mechanism is used for controlling action of the mechanisms. The feeding mechanism comprises a guide rail used for containing the glasses components, a limiting bar, a limiting piece, a limiting bar air cylinder and a limiting piece air cylinder. The limiting bar is connected with the limiting bar air cylinder. The limiting piece is connected with the limiting piece air cylinder. The guide rail is obliquely arranged on a rack. A discharging port in the lower end of the guide rail is aligned with a feeding port of a corresponding clamp. A limiting hole is formed in the guide rail and matched with the limiting bar to limit falling of the last glasses component. The discharging port in the lower end of the guide rail is provided with the limiting piece used for limiting feeding of the glasses components.

Owner:ZHEJIANG UNIV OF TECH

Assembly device for button fastening parts

ActiveCN107568843BContinuous assemblyDoes not dent the bottomClothes buttonsStructural engineeringMechanical engineering

The invention provides an assembling device for button fixing members which can continuously assemble button fixing members having good appearances and high quality. When the assembling device (1) uses a claw (102) for allowing a pair of pins (102b) to protrude out of a base (102a), and a part of a housing (103) having a side wall portion (103b) arranged along the outer periphery of a bottom (103a) to assemble a finished product (101) of a button fixing member, the base having the claw (102) arranged on an inner side of the side wall portion of the housing can allow the side wall portion of the housing to deform inward so as to fix the housing on the claw (102). The assembling device (1) includes a part feeding portions (2, 3), a separated product pushing rod (4), a pair of part supportingcomponents (5), a first processing portion (6), a semi-finished product pushing rod (7), a pair of semi-finished product supporting components (8), and a second processing portion (9).

Owner:YKK CORP

Vacuum insulation glass panel assembly manufacturing method and apparatus

ActiveUS11155497B2Continuous assemblyLow costThermal insulationClimate change adaptationInsulated glazingEngineering

Provided is a vacuum insulation glass panel assembly manufacturing method and apparatus. The vacuum insulation glass panel assembly manufacturing method includes an edge sealing step of sealing an edge of a glass panel assembly of glass panels spaced apart at a predetermined interval, and an exhaust port sealing step of causing a lid member to seal an exhaust port of the glass panel assembly formed so as to communicate with a space between the glass panels whose edges are sealed. A glass solder having a high melting point is used in the edge sealing step, and a glass solder having a low melting point is used in the exhaust port sealing step. A specially designed lid member closing device is used for exhaust port sealing.

Owner:PARK JE IL

Aeroengine multi-stage drum-disk rotor assembly device and assembly method

ActiveCN105443169BImprove coaxialityContinuous assemblyMachines/enginesSafety/regulatory devicesControl systemAero engine

The invention provides a device and method for assembling a multi-stage drum type rotor of an aero-engine. The device comprises a base, an air-floating rotary table, a clamp device, measuring devices and a computation control system, wherein the air-floating rotary table is fixed to the center of the base, the clamp device is mounted on the air-floating rotary table, and the measuring devices are mounted on the base and arranged on the two sides of the air-floating rotary table; the computation control system is connected with the air-floating rotary table and used for transmitting driving, center-regulating and tilt-regulating information, and the computation control system is connected with the measuring devices and used for collecting morphology information of assembled parts. By means of the device and method, coaxiality of all parts of the rotor can be guaranteed, continuous assembling can be carried out, and the situation that the parts are dismounted and then measured, marked and assembled one by one is avoided; universality is high, operation is easy, and assembling precision and assembling efficiency are high.

Owner:SHANGHAI JIAO TONG UNIV

Clutch working cylinder shield and cylinder block assembly press-fit and detection device

ActiveCN110561082BContinuous assemblyImprove assembly efficiencyMachine part testingMetal working apparatusEngineeringSlide plate

The invention discloses a press-fitting and detection device for a clutch working cylinder shield and a cylinder block assembly, comprising: a frame, including a bottom plate, a top plate, and a column fixed between the bottom plate and the top plate; On the bottom plate, it is used to position the cylinder block assembly; the positioning structure of the shield and push rod assembly is installed on a slide plate that can slide up and down along the column, and is used to position the shield and push rod assembly; press fit and pull off The driver, installed on the top plate, is used to drive the slide plate up and down. When the slide plate is driven down, the shield, the push rod assembly and the cylinder block assembly are press-fitted together; the pressure sensor is connected between the press-fit and pull-off drive and the slide plate When the press-fit and pull-off driver drives the slide plate up, it is used to detect the pull-off force between the shield, the push rod assembly and the cylinder assembly. The invention press-fits the guard cover, the push rod assembly and the cylinder body assembly together, and after the press-fitting is completed, it automatically enters the guard pull-off test to improve the assembly and detection efficiency.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com