Screw positioning recharging device

A screw positioning and screw technology, applied in the direction of screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of continuous assembly, damage, screws or thread slippage in the screw connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

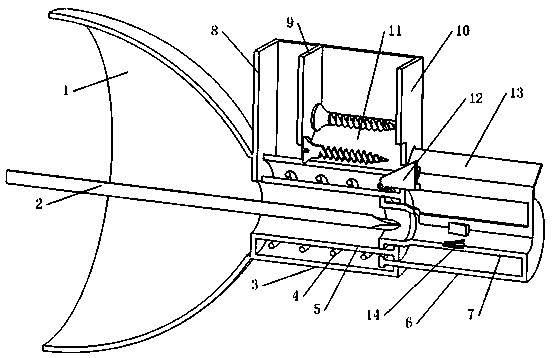

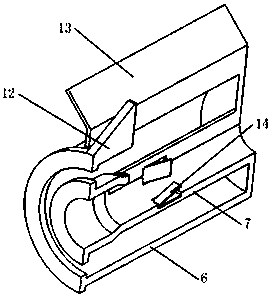

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The invention discloses a screw positioning and replenishing device, which comprises a casing, the rear end of the casing is provided with a socket structure 1 for socketing with the taper surface of the front end of the electric screwdriver body, and the front end of the casing is provided with a horizontally arranged first positioning tube 7, The inner diameter of the first positioning tube 7 is between one external diameter and two external diameters of the big end of the screw used by the electric screwdriver and is arranged directly in front of the bit 2. The first positioning tube 7 can be slid backwards by means of a guide structure and set and When the first positioning tube 7 slides backward, the bit 2 can penetrate into the first positioning tube 7 and push out the screw inside to complete the screw connection.

[0029] In this way, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com