Electric screwdriver device

An electric screwdriver and positioning device technology, applied in screwdrivers, power tools, wrenches, etc., can solve problems such as hidden safety hazards, uncontinuous assembly of screw connections, damage to parts or parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

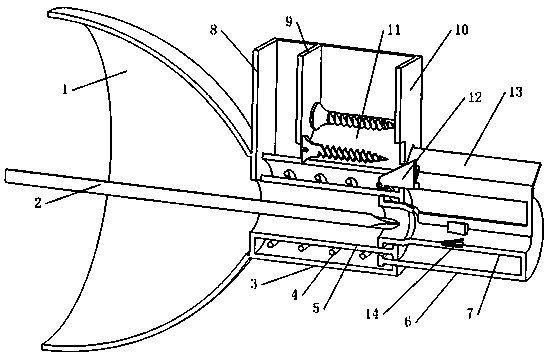

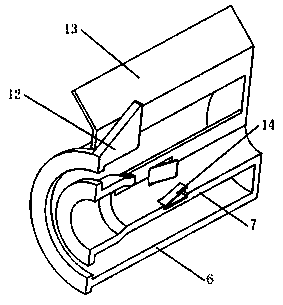

[0030] The invention discloses an electric screwdriver device, which comprises an electric screwdriver body, a motor is arranged inside the electric screwdriver body, and the motor is driven and connected to a bit 2 protruding from the front end of the electric screwdriver body. The storage device, positioning device, feeding device and guide structure at the front end of the screwdriver body, the storage device is located above the front end of the electric screwdriver body and is used to store the screws to be used, and the positioning device is located below the storage device And it is used to realize the positioning of the screw to be used facing the front of the batch head 2. The feeding device is connected between the storage device and the positioning device and is used to send the screw located at the bottom of the storage device into the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com