Pneumatic Glasses Assembly Machine

A technology for assembly machines and glasses, applied in assembly machines, metal processing equipment, manufacturing tools, etc., to achieve the effects of fast printing speed, short production cycle, and good assembly line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

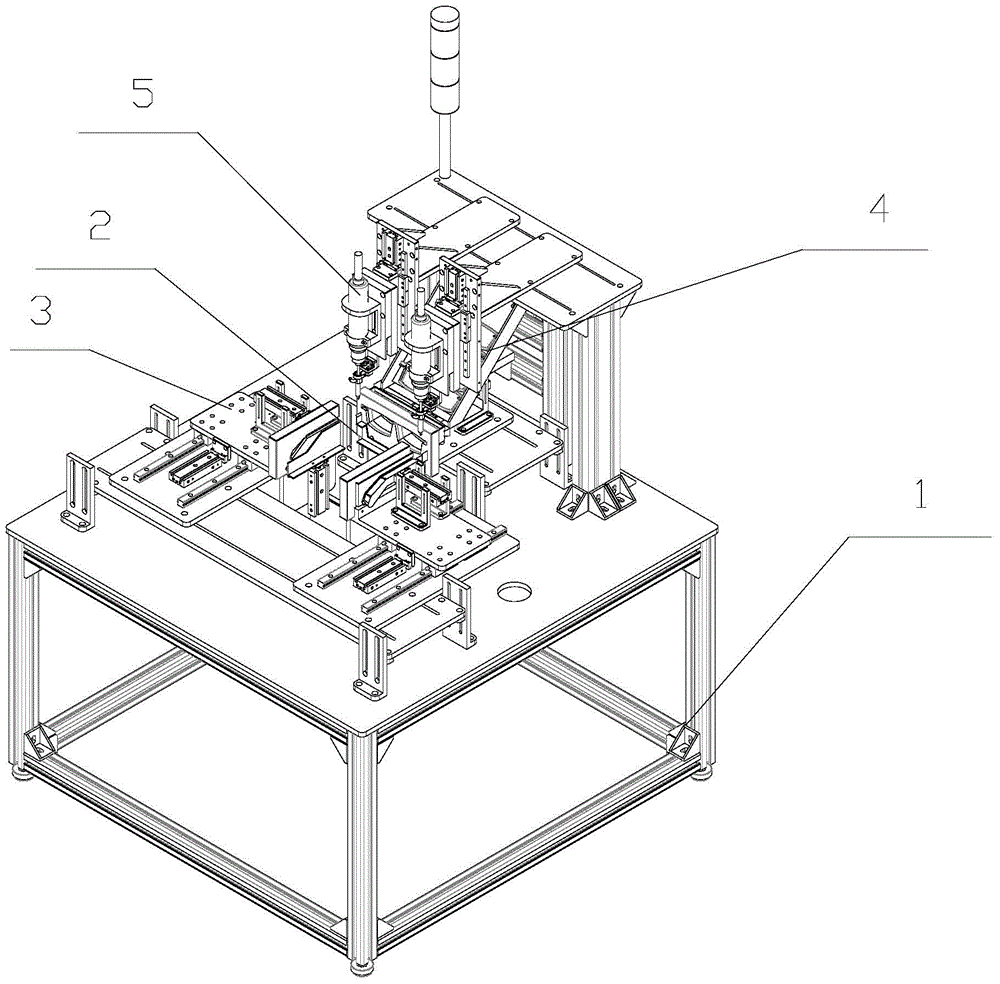

[0038] refer to Figure 1 to Figure 5b , pneumatic glasses assembly machine, including

[0039] A frame mechanism 2 for clamping the frame;

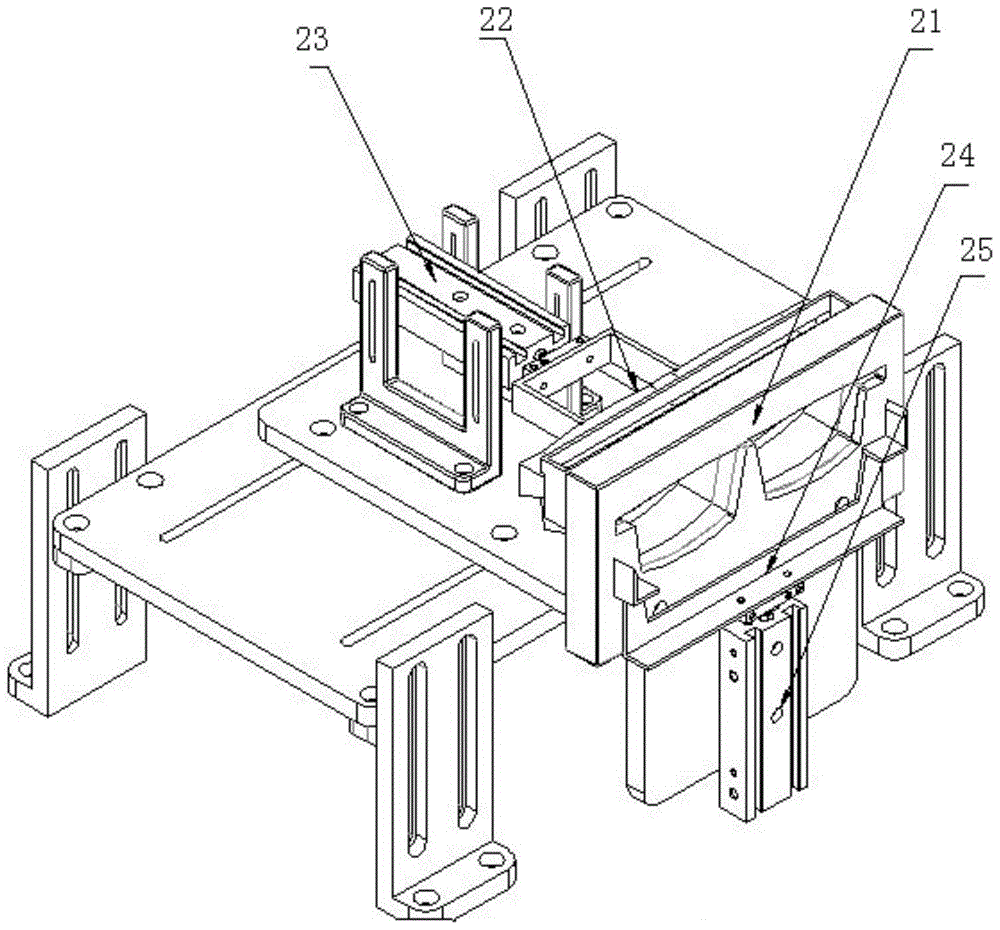

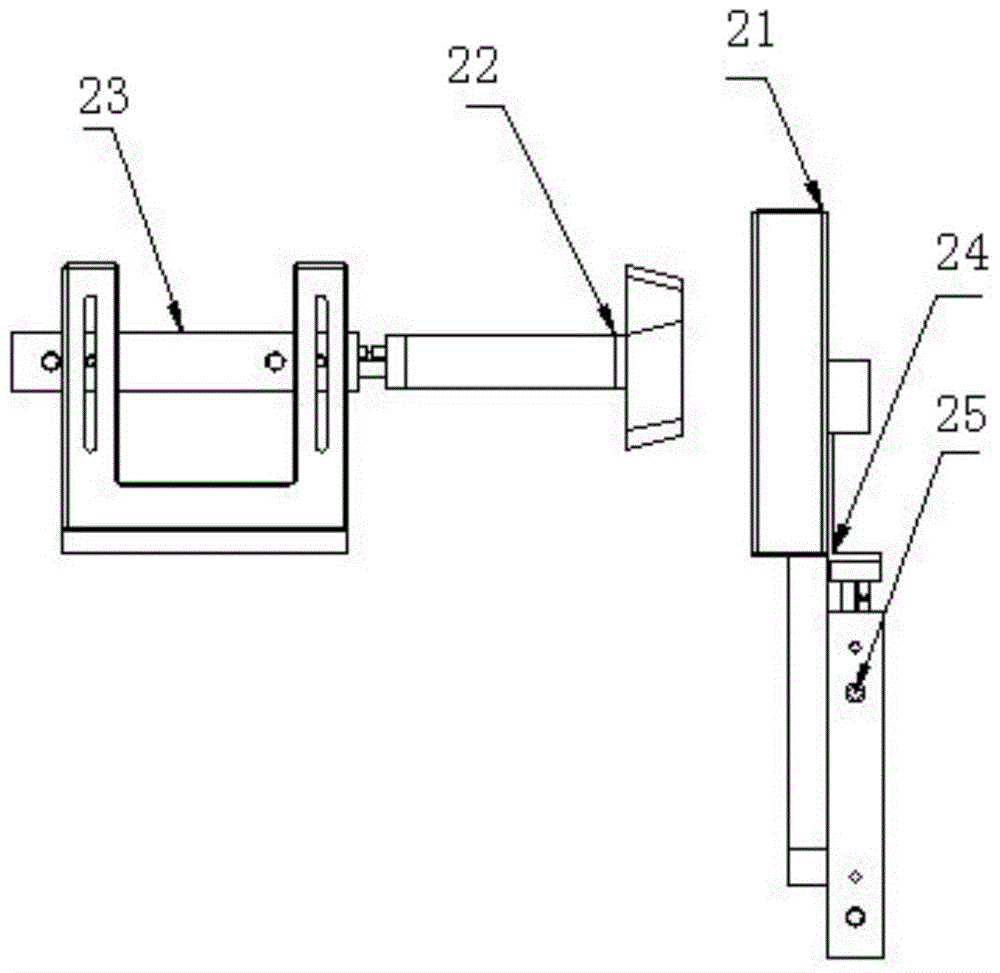

[0040] The temple mechanism 3 used to clamp the temple and located on both sides of the frame mechanism, the temple mechanism 3 can be moved to the working position matched with the frame mechanism 2 to complete the assembly of the spectacle parts;

[0041] A feeding mechanism 4 for feeding the above-mentioned mirror frame mechanism 2 and temple mechanism 3 respectively;

[0042] A screw assembly mechanism 5 for completing the assembly of eyeglass components; and

[0043] The control mechanism that controls the actions of the above-mentioned mechanisms;

[0044]Described feeding mechanism 4 comprises the guide rail 41 that is used to place spectacle parts, stop bar 42, stop sheet 44, stop bar cylinder 43 and stop sheet cylinder 45, described stop bar 42 and stop bar Cylinder 43 is connected, and described limit sheet 44 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com