A vacuum suction cup device for insulating glass inflatable line

A vacuum suction cup and glass technology, applied in the directions of transportation and packaging, furnace, charge control, etc., can solve the problem of insufflation of insulating glass that cannot be produced online, achieve continuous inflatable flow operation, solve the inability to produce online, and meet the needs of modern automated production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

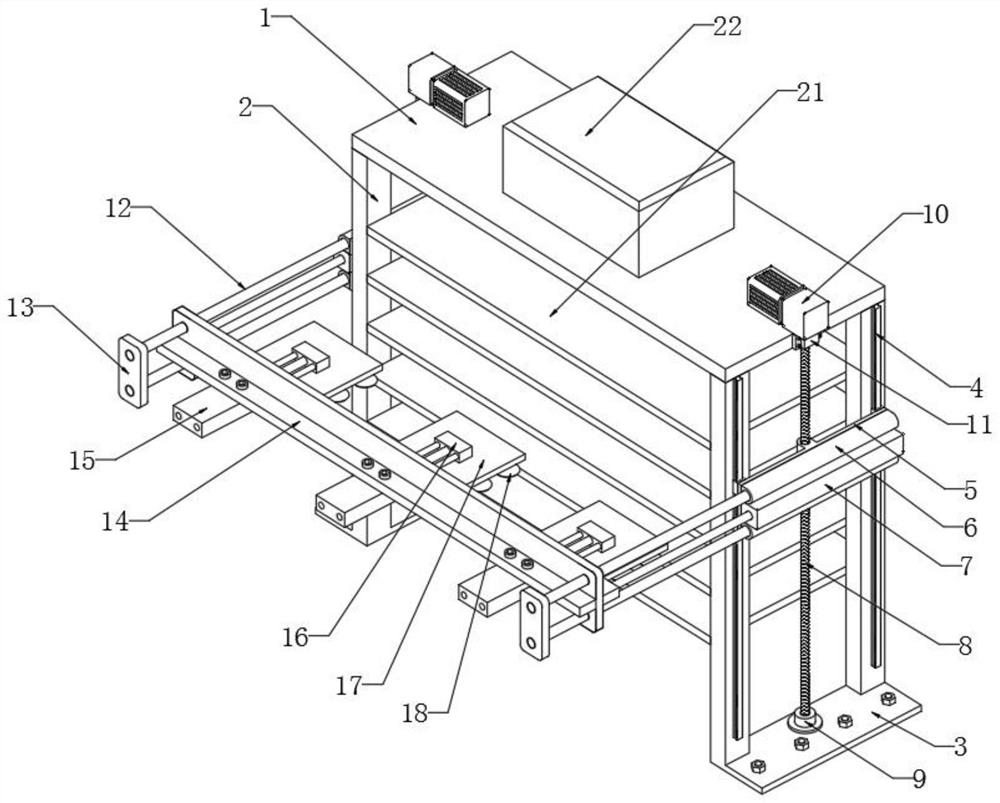

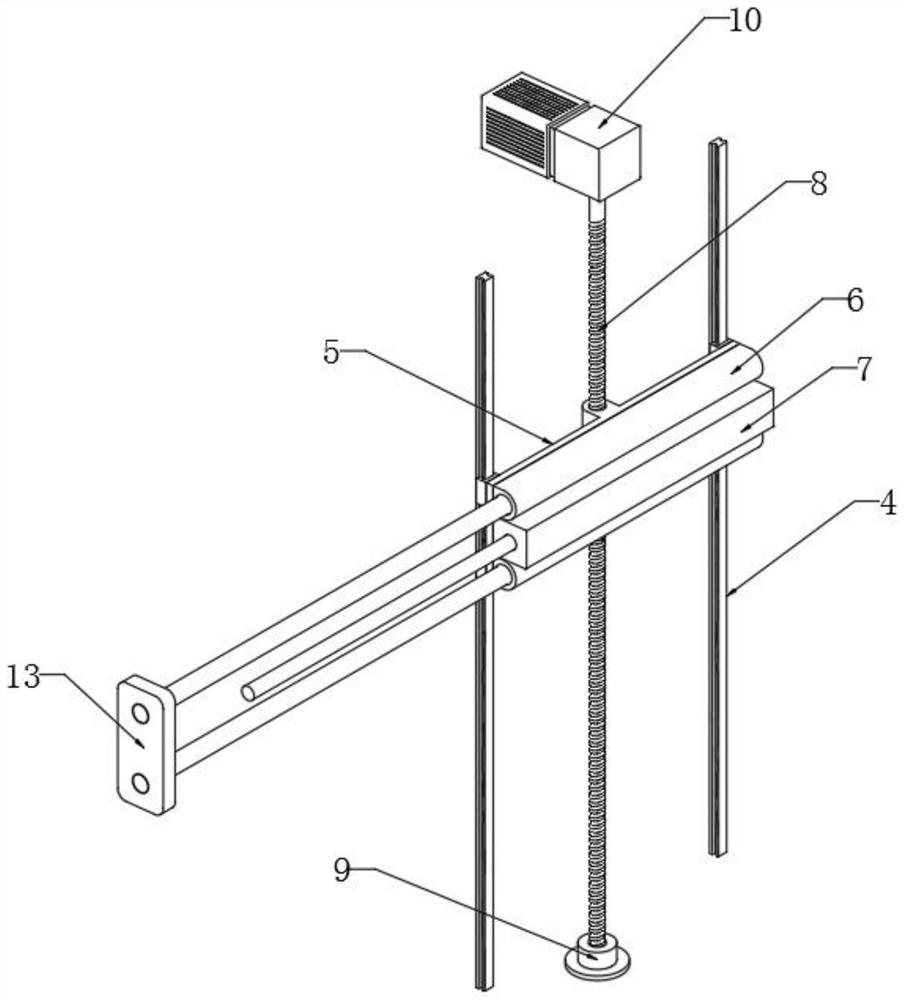

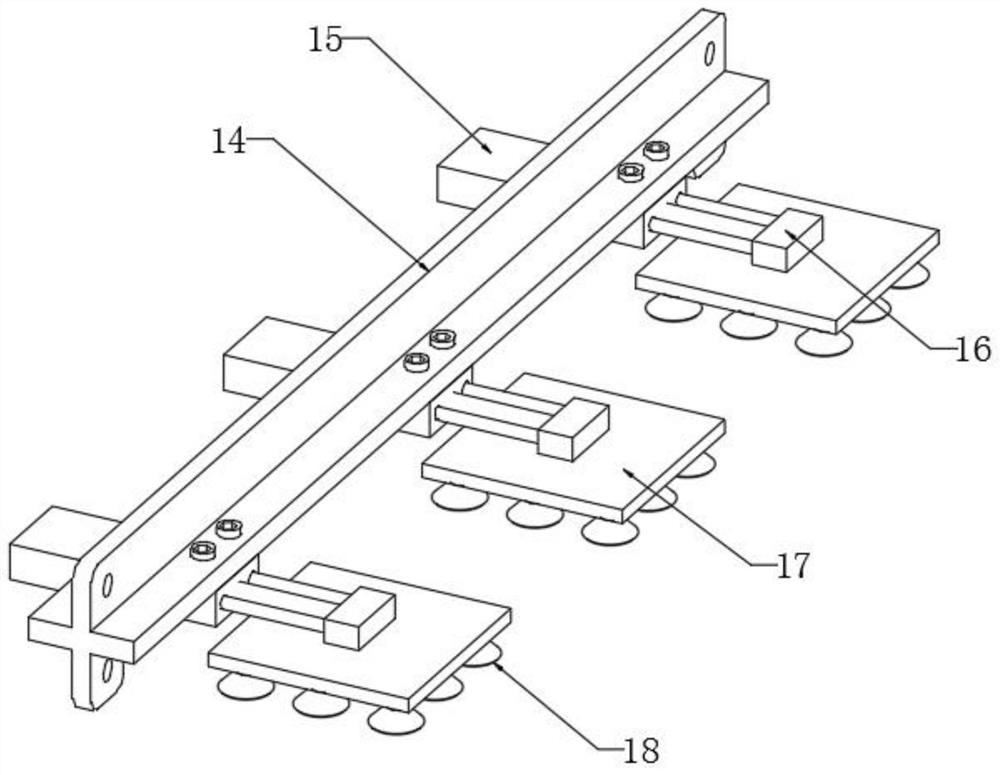

[0036]Example: The working process of the device is as follows: the insulating glass to be inflated passes through the bottom of the grasping structure of the device and stops for a short time, and the screw 8 is driven by the forward rotation of the motor 10 in the threaded hole 20 on the first sliding table 5. Rotate, control the first sliding table 5 to drive the first cylinder 7, the outer cylinder 6, the optical axis 12 and the grabbing structure to descend until the suction cup 18 is in contact with the insulating glass, and the suction cup 18 is switched to the vacuum air source through the control box 22, so that The suction cup 18 and the insulating glass are adsorbed together, and then the motor 10 is reversed, so that the grasping structure rises with the first sliding table 5 between the adjacent two sets of horizontal plates 21, and the piston rod of the first air cylinder 7 shrinks to remove The grabbing structure is pulled along the optical axis 12 to the frame d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com