Device and method for assembling multi-stage drum type rotor of aero-engine

An aero-engine and rotor assembly technology, which is applied to engine components, machines/engines, safety devices, etc., can solve the problems of out-of-tolerance rotor components, narrow measurement range, low efficiency, etc., to achieve high coaxiality, universal Strong, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

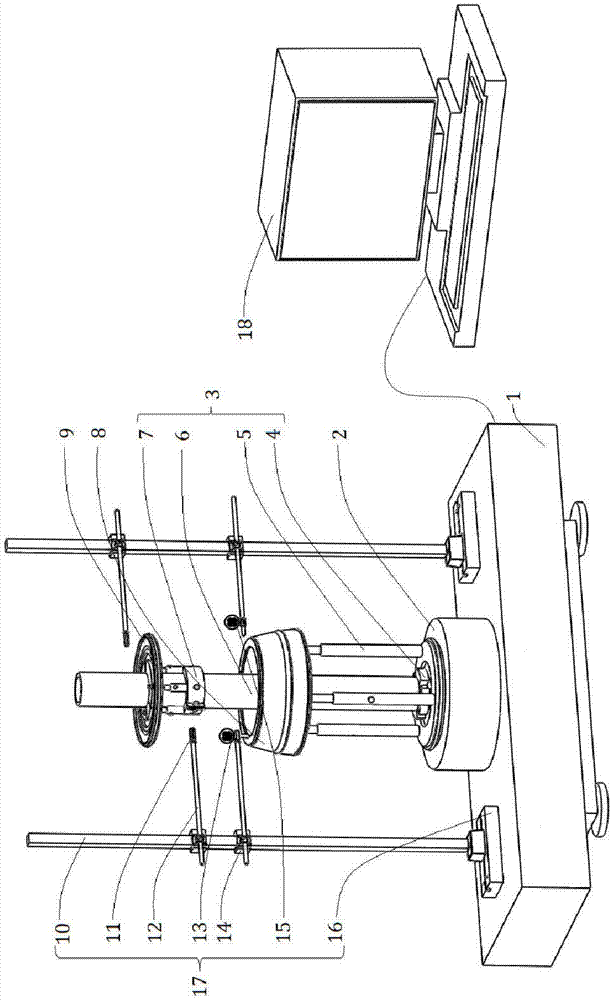

[0026] Such as figure 1 As shown, this embodiment relates to a multi-stage drum-disk rotor assembly device for an aero-engine, including: a base 1, an air-floating turntable 2, a fixture device 3, a measuring device 17 and a calculation control system 18, wherein: the air-floating turntable 3 Fixed on the center of the base 1, the fixture device 3 is installed on the air flotation turntable 2, and the measuring device 17 is installed on the base 1 and arranged on the left and right sides of the air flotation turntable 2;

[0027] The calculation and control system 18 is connected with the air bearing turntable 2 and transmits driving, centering and tilting information, and the calculation and control system 18 is connected with the measuring device 17 and collects the shape information of the assembled parts.

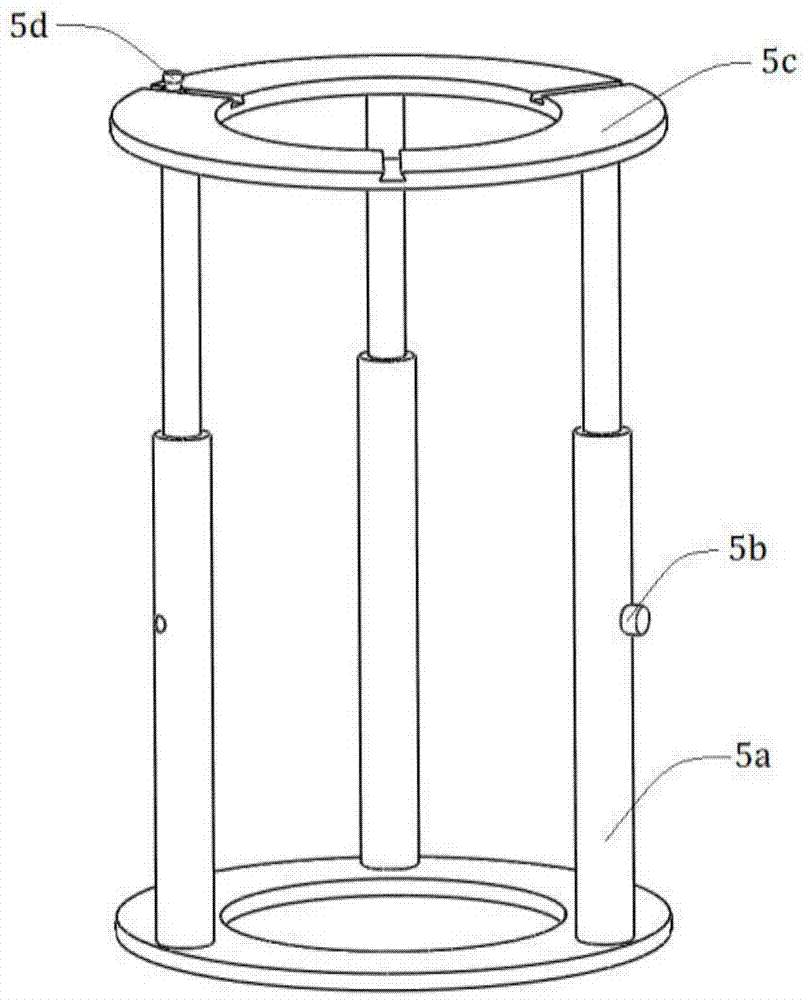

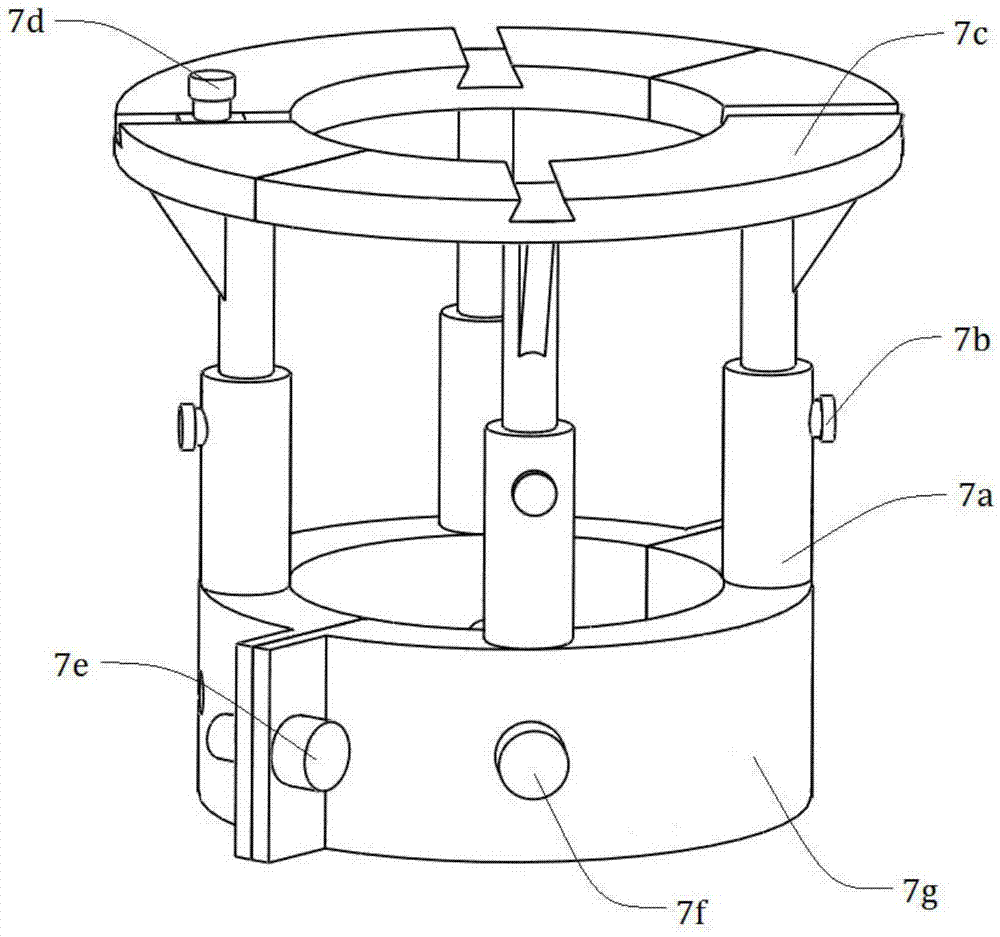

[0028] The clamp device 3 includes: a hydraulic chuck 4, a primary support 5, a standard center cylinder 6 and a secondary support 7, wherein: the hydraulic chuck 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com