A kind of preparation method of power socket and power socket

A socket and power supply technology, which is applied in the manufacture of contact box/base, contact manufacturing, base/housing, etc., can solve the problems of backward production technology, low efficiency of automatic assembly, simple structure, etc., and achieve high degree of automatic production, Effect of continuous plating and assembly, saving assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

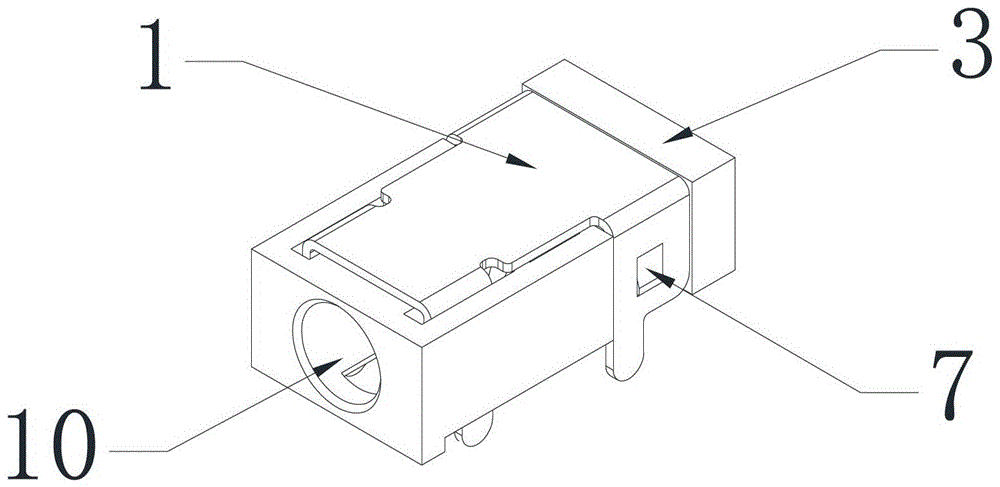

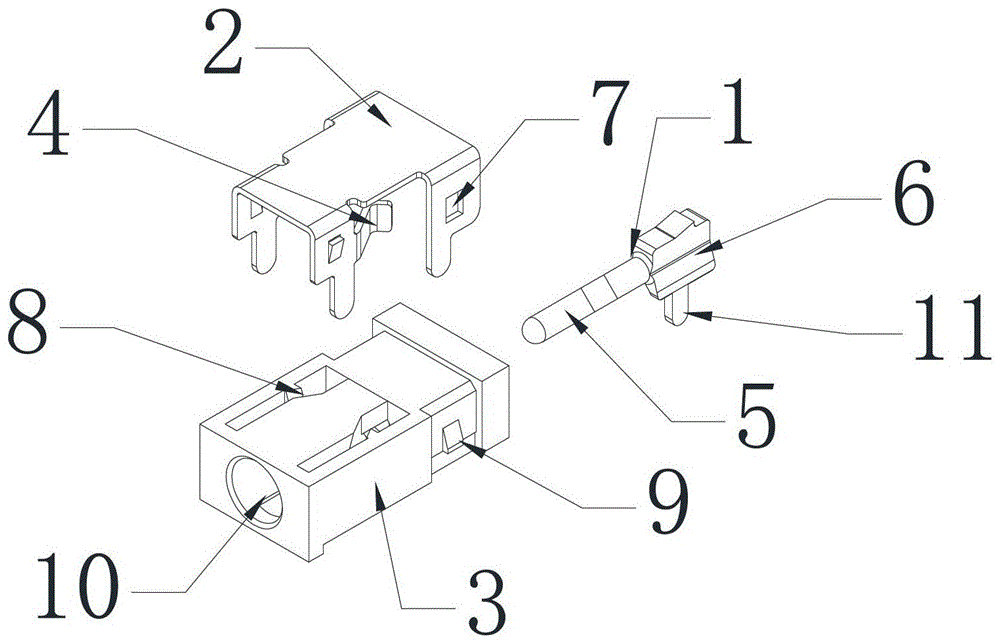

[0028] Example: see Figure 1 to Figure 4 , the preparation method of the power female socket provided by the present embodiment, it comprises the following steps:

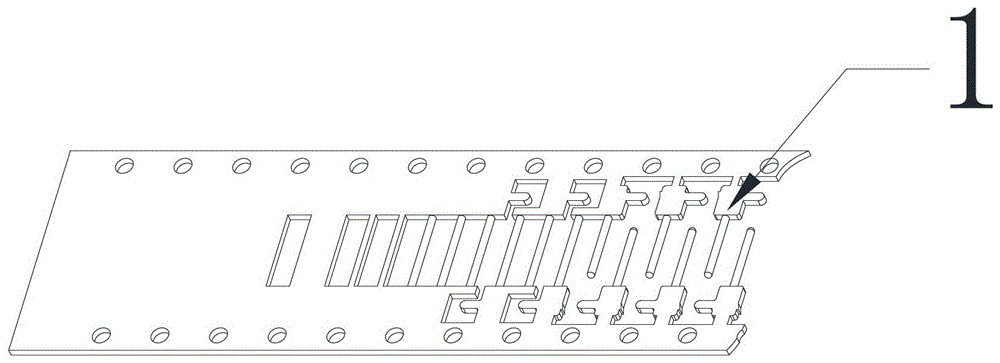

[0029] (1) Prepare the inner pole PIN pin 1: set a continuous stamping module, and the continuous stamping module performs punching, incision, shaping and blanking on the copper plate in turn to make an integrated copper inner pole PIN pin 1;

[0030] (2) Preparation of the outer pole casing 2: a continuous stamping module is set, and the continuous stamping module performs punching, incision, bending and blanking on the copper plate in sequence to form an integrated outer pole casing with the shrapnel 4 body 2;

[0031] (3) Preparing the rubber core 3: setting a continuous injection molding module, passing the plastic through the continuous injection molding module, injection molding, and making an integrated rubber core with a hollow interior;

[0032] (4) A PLC automatic control assembly machine is set, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com