A flexible flat cable with a center distance of 0.3mm and its manufacturing method

A flexible flat cable and a manufacturing method technology, applied in the field of cables, can solve the problems of weak current resistance, environmental hazards, high production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

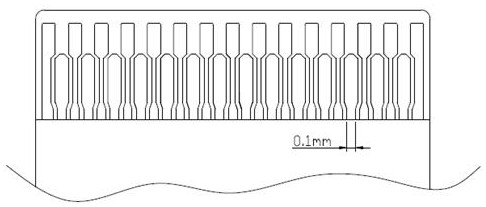

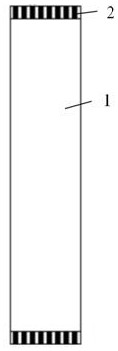

[0039] see Figure 2-4 As shown, the embodiment of the present invention discloses a flexible flat cable with a center distance of 0.3 mm, including a flexible flat cable body 2 and a reinforcing plate 3 with a plurality of conductors 1 evenly arranged inside. The center distance between them is 0.3 mm, the width of the conductor 1 is 0.15-0.20 mm, and the thickness of the conductor 1 is 0.025-0.050 mm. Wherein, the conductor 1 is a gold-plated copper conductor 1 and is a flat conductor 1 . Preferably, the width of the conductor 1 is 0.15mm, and the thickness of the conductor 1 is 0.025mm; preferably, the width of the conductor 1 is 0.19mm, and the thickness of the conductor 1 is 0.035mm; preferably, the width of the conductor 1 is 0.20mm, and the conductor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com