High-strength environment-friendly polyurethane flame-retardant and waterproof paint and preparation method thereof

A waterproof coating and polyurethane technology, applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve the problems of reducing flame retardant effect, volatile, group dechaining, etc., to ensure flame retardant performance and thermal stability Excellent performance, enhance the effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the high-strength environment-friendly polyurethane flame-retardant waterproof coating of the present invention comprises the following steps:

[0046] 1. Preparation of A component

[0047] a1: Weigh the corresponding raw materials according to the above ratio for use;

[0048] b1: Add the flame retardant polyether polyol into the closed reaction kettle with agitator and vacuum pump at normal temperature and pressure, raise the temperature in the reaction kettle to 80-90℃ while stirring, start the vacuum pump, and make the negative pressure in the reaction kettle be -0.07 to -0.05MPa;

[0049] c1: Continue to raise the temperature in the reactor to 100-110°C, and dehydrate at this temperature for 1-3 hours;

[0050] d1: After step c1 is completed, reduce the temperature of the reactor to 55-65°C, add liquefied diphenylmethane diisocyanate while stirring, then raise the temperature of the reactor to 75-85°C, and the reaction time is 1.5-3 hou...

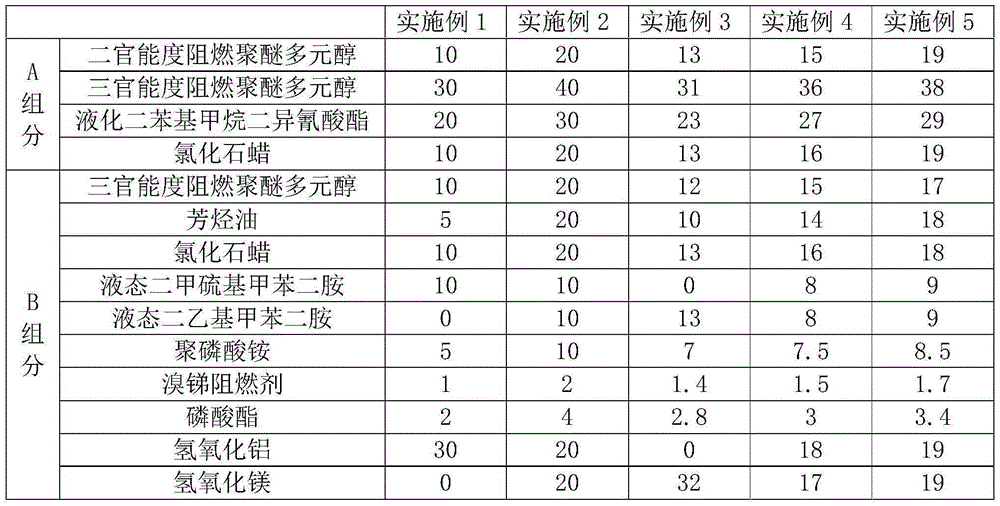

Embodiment 1

[0065] The high-strength environment-friendly polyurethane flame-retardant waterproof coating of the present invention comprises A component and B component,

[0066] Component A includes difunctional flame retardant polyether polyol, trifunctional flame retardant polyether polyol, liquefied diphenylmethane diisocyanate, and chlorinated paraffin. 10 parts of high flame retardant polyether polyol, 30 parts of trifunctional flame retardant polyether polyol, 20 parts of liquefied diphenylmethane diisocyanate, 10 parts of chlorinated paraffin;

[0067] Component B includes trifunctional flame retardant polyether polyol, aromatic oil, chlorinated paraffin, liquid dimethylthiotoluenediamine, ammonium polyphosphate, bromine antimony flame retardant, phosphate ester, aluminum hydroxide, the above components The contents are calculated in parts by mass: 10 parts of trifunctional flame-retardant polyether polyol, 5 parts of aromatic oil, 10 parts of chlorinated paraffin, 10 parts of liq...

Embodiment 2

[0087] The high-strength environment-friendly polyurethane flame-retardant waterproof coating of the present invention comprises A component and B component,

[0088] Component A includes difunctional flame retardant polyether polyol, trifunctional flame retardant polyether polyol, liquefied diphenylmethane diisocyanate, and chlorinated paraffin. 20 parts of high flame retardant polyether polyol, 40 parts of trifunctional flame retardant polyether polyol, 30 parts of liquefied diphenylmethane diisocyanate, 20 parts of chlorinated paraffin;

[0089] Component B includes trifunctional flame retardant polyether polyol, aromatic oil, chlorinated paraffin, liquid dimethylthiotoluenediamine, liquid diethyltoluenediamine, ammonium polyphosphate, bromide antimony flame retardant, phosphate ester , aluminum hydroxide, magnesium hydroxide, the contents of the above components are calculated in parts by mass: 20 parts of trifunctional flame retardant polyether polyol, 20 parts of aromati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com