A bonded gold ribbon and its preparation method

An alloy ribbon and gold ribbon technology, applied in circuits, electrical solid devices, semiconductor devices, etc., can solve the problems of inability to meet bonding requirements, low strength, poor solderability, etc., and achieve improved mechanical properties, high current resistance, and connection. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

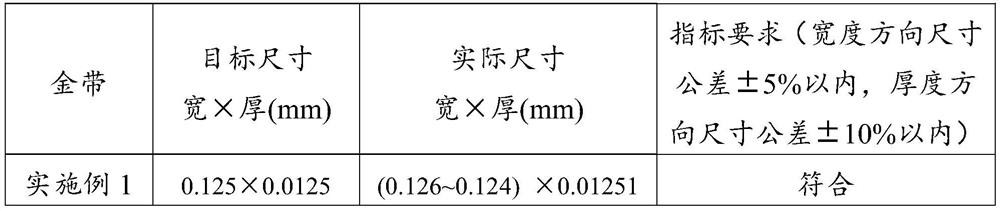

Embodiment 1

[0026] A bonding gold ribbon, its composition and content (percentage by weight) are as follows: Au 99.9984%, Be 0.0003%, Cu 0.0003%, Fe 0.0003%, Mg 0.0003%, Ag 0.0003% and other impurities 0.001%.

[0027] The preparation method of the bonding gold ribbon is as follows, the target size is: 0.125mm (width) × 0.0125mm (thickness):

[0028] (1) Put gold into the continuous casting furnace, then add trace elements Be, Cu, Fe, Mg and Ag, melt at 1200°C (1150-1250°C is acceptable), and cast gold rods.

[0029] (2) Use a wire drawing machine to draw the gold rod and process it into a gold wire of φ0.0453mm. The diameter tolerance of the gold wire is controlled to be ±0.0003mm; the elongation rate of the mold during the wire drawing process is 8% to 15%, and the wire drawing speed is 7 to 10m / s.

[0030] (3) Roll the gold wire with a special precision rolling mill for gold strips (gold strip calender KPS-Y4), and process it into a gold strip of the target size. The width tolerance ...

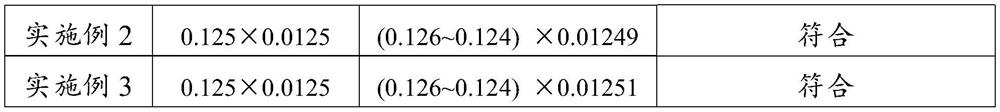

Embodiment 2

[0034] A bonding gold ribbon, its composition and content (percentage by weight) are as follows: Au 99.9979%, Be 0.0006%, Cu 0.0004%, Fe 0.0003%, Mg 0.0003%, Ag 0.0005% and other impurities 0.001%.

[0035] The preparation method of the bonding gold ribbon is the same as that of Example 1.

Embodiment 3

[0037] A bonding gold ribbon, its composition and content (percentage by weight) are as follows: Au 99.9971%, Be 0.0009%, Cu 0.0005%, Fe 0.0003%, Mg 0.0003%, Ag 0.0009% and other impurities 0.001%.

[0038] The preparation method of the bonding gold ribbon is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com